Automatic power control circuit for driving optical communication laser

An automatic power control and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of complex design and negative feedback loop stability, etc. The effect of occupying a small chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in further detail below in conjunction with the accompanying drawings.

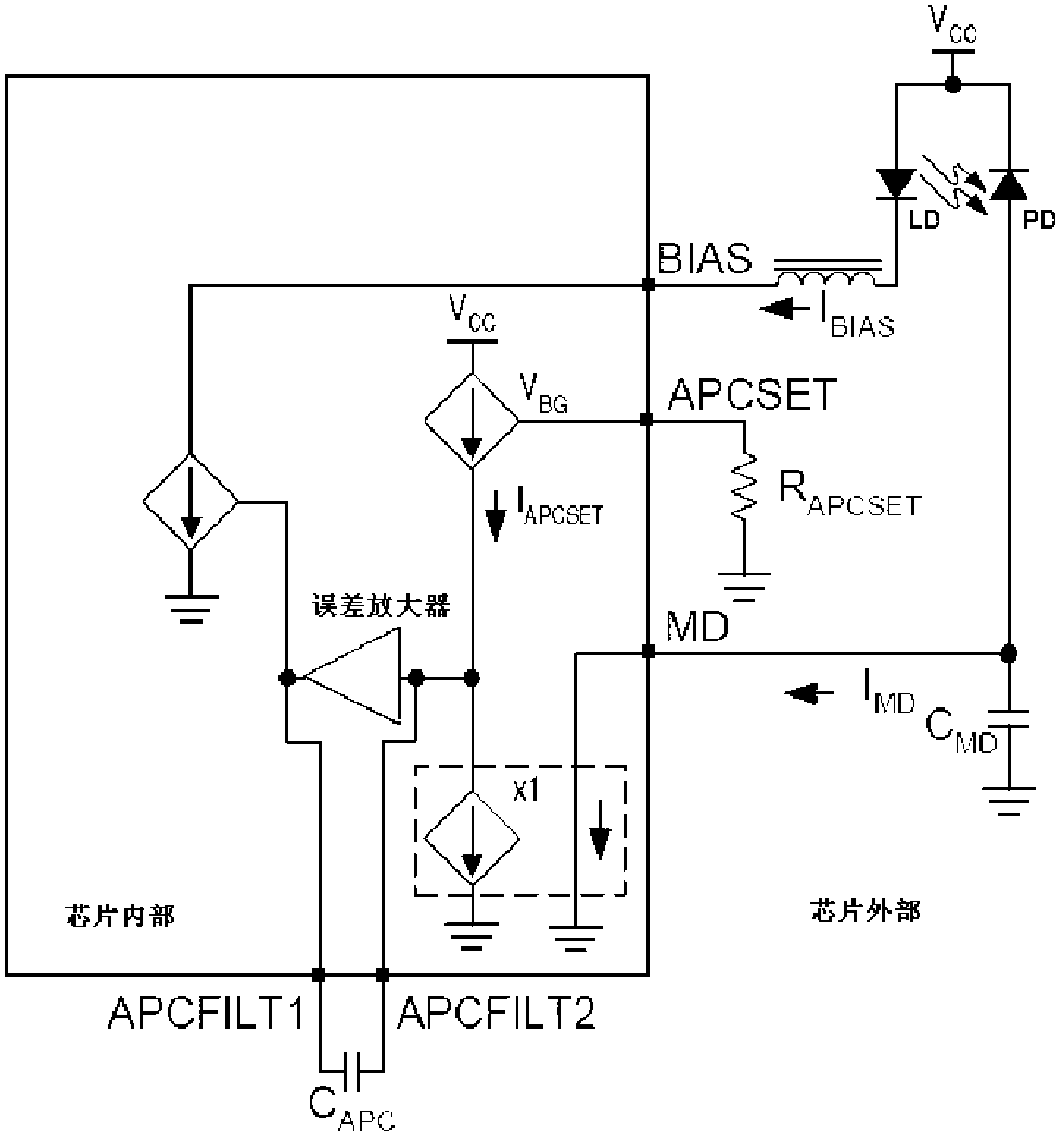

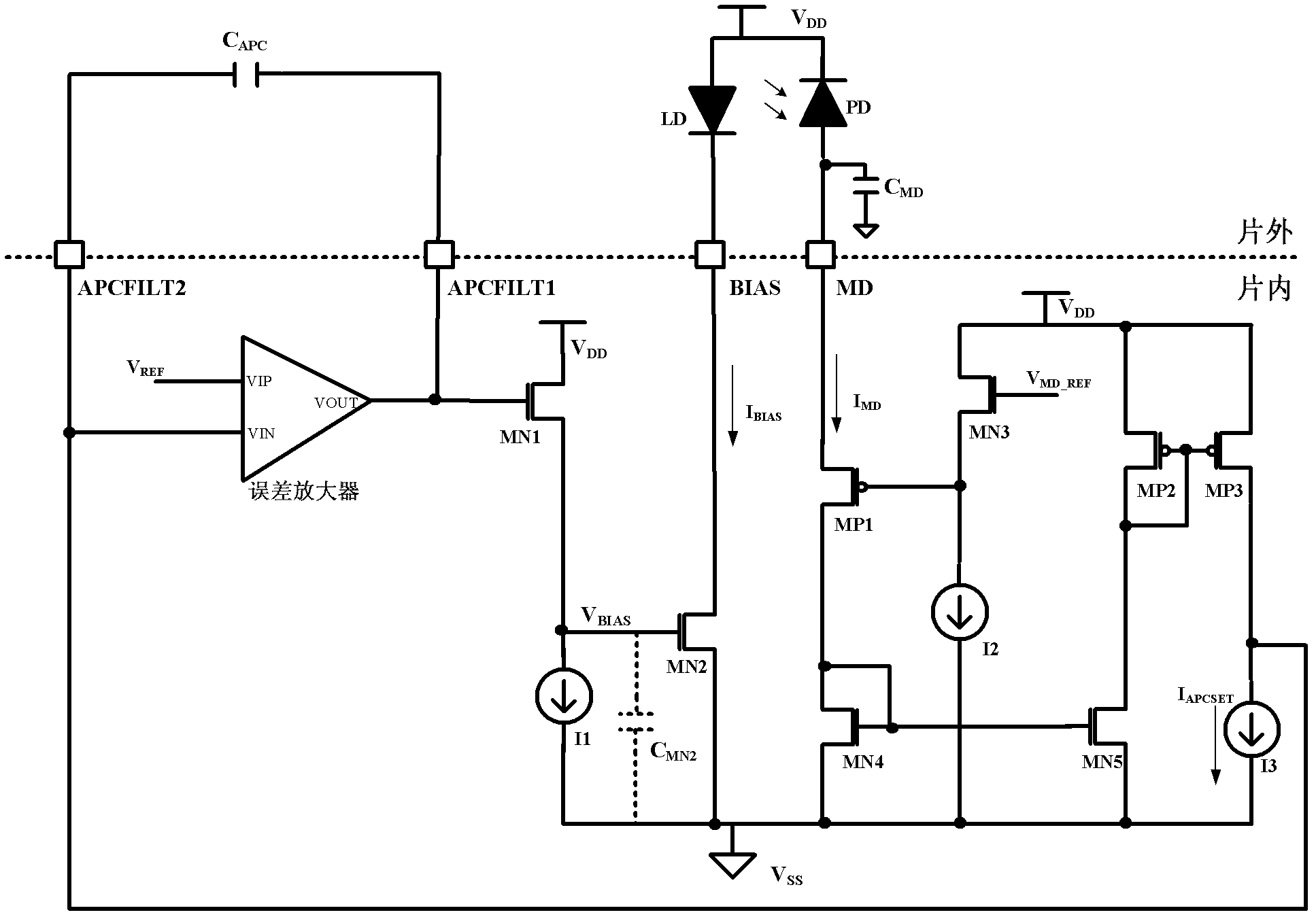

[0074] The automatic power control circuit for optical communication laser driver described in the present invention, such as image 3 shown ( image 3 The part above the dotted horizontal line indicates the external circuit and components of the chip), including: an error amplifier,

[0075] DC reference stable voltage V REF Connected to the positive input terminal VIP of the error amplifier,

[0076] Node APCFILT2 is connected to the negative input terminal VIN of the error amplifier,

[0077] The output VOUT of the error amplifier is connected to node APCFILT1,

[0078] Node APCFILT1 and node APCFILT2 are respectively connected to the capacitor C outside the chip APC both ends of

[0079] Node ACPFILT1 is also connected to the gate of NMOS transistor MN1,

[0080] The drain of transistor MN1 is connected to the power supply V DD , the source is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com