Double-sided color electric aluminum hot stamping foil and production method thereof

A production method, anodized aluminum technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of easy scratches, inability to print pattern positioning and registration, etc., and achieve the effect of strong gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

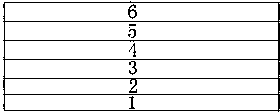

[0026] The double-sided color anodized aluminum hot stamping foil designed by the present invention comprises a biaxially stretched polyester film 1, a release layer 2, a color layer 3, an aluminum coating layer 4, a color layer 2 5, and an adhesive layer 6; it is prepared according to the following steps The double-sided color anodized aluminum hot stamping foil:

[0027] (1) Use a 210-mesh anilox roller to coat the wax emulsion with water as the dispersion solvent on the surface of the biaxially oriented polyester film, and use five temperature zones to dry, and the drying temperatures in the five temperature zones are 80°C-120°C-145 ℃-145℃-130℃, the frequency conversion of the fan in the five temperature zones is 40-45-50-50-50Hz respectively.

[0028] The release layer coating includes: 1.7% wax emulsion; 97.3% water; 0.5% defoamer; 0.5% wetting and leveling agent.

[0029] (2) Coat the surface of the release layer after the treatment in step (1) with a color layer coatin...

Embodiment 2

[0037] The double-sided color anodized aluminum hot stamping foil designed by the present invention comprises a biaxially stretched polyester film 1, a release layer 2, a color layer 3, an aluminum coating layer 4, a color layer 2 5, and an adhesive layer 6; it is prepared according to the following steps The double-sided color anodized aluminum hot stamping foil:

[0038] (1) Use a 210-mesh anilox roller to coat the wax emulsion with water as the dispersion solvent on the surface of the biaxially oriented polyester film, and use five temperature zones to dry, and the drying temperatures in the five temperature zones are 80°C-120°C-145 ℃-145℃-130℃, the frequency conversion of the fan in the five temperature zones is 40-45-50-50-50Hz respectively.

[0039] The release layer coating includes: 7.1% wax emulsion; 91.9% water; 0.5% defoamer; 0.5% wetting and leveling agent.

[0040] (2) Coat the surface of the release layer after the treatment in step (1) with a color layer coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com