Printer

A printing machine, a new type of technology, applied in printing machines, rotary printing machines, printing, etc., can solve problems such as unstable watering, waste of printed matter quality, and insufficient watering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

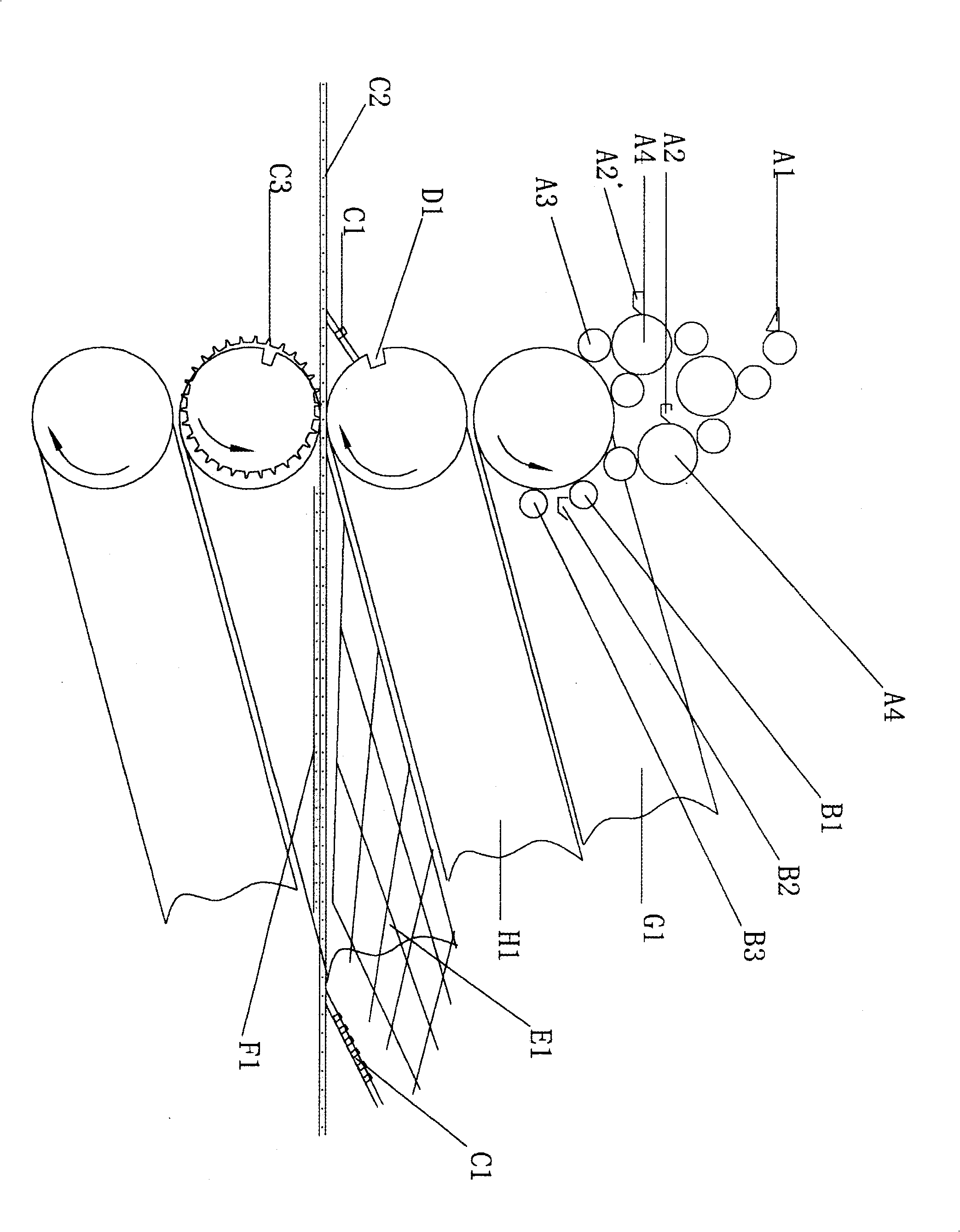

[0010] Comparing with the accompanying drawings in the manual, it can be seen that the new printing machine has three main differences with the current printing machine. The first is the addition of the ink collection control ink meter A2, the second is the addition of the water collection control water value device, and the third is a A new type of substrate printing method. There is a stainless steel plate at the angle of the ink volume control device for ink collection to facilitate the storage of the recovered ink (see picture). The sheet can be in the upper and lower 30°-50° position of the ink distribution roller), so that the ink distribution roller can reach the standard inking layer of the ink distribution roller to control the ink form roller under the regulation of the steel plate of the ink collection control ink meter, and the inside of the ink distribution roller Equipped with heating and adjustable electrical appliances, different dilutions are formed according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com