Patents

Literature

46results about How to "Good inking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of lithographic printing plate, lithographic printing plate precursor and lithographic printing method

ActiveUS20060046199A1Reduction in development removabilityGeneration can be inhibitedPlaten pressesPhotosensitive materialsPolyvinyl alcoholImage recording

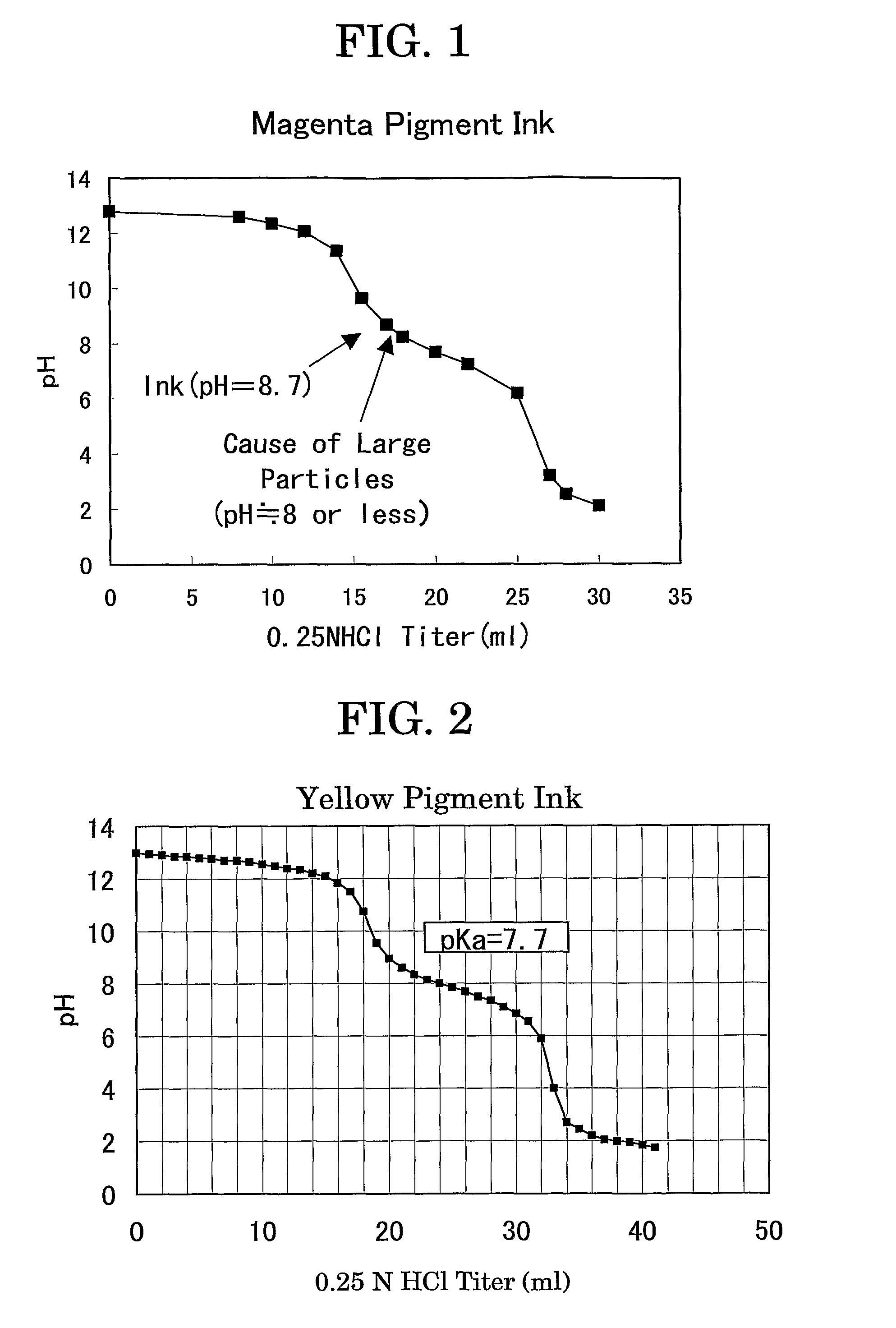

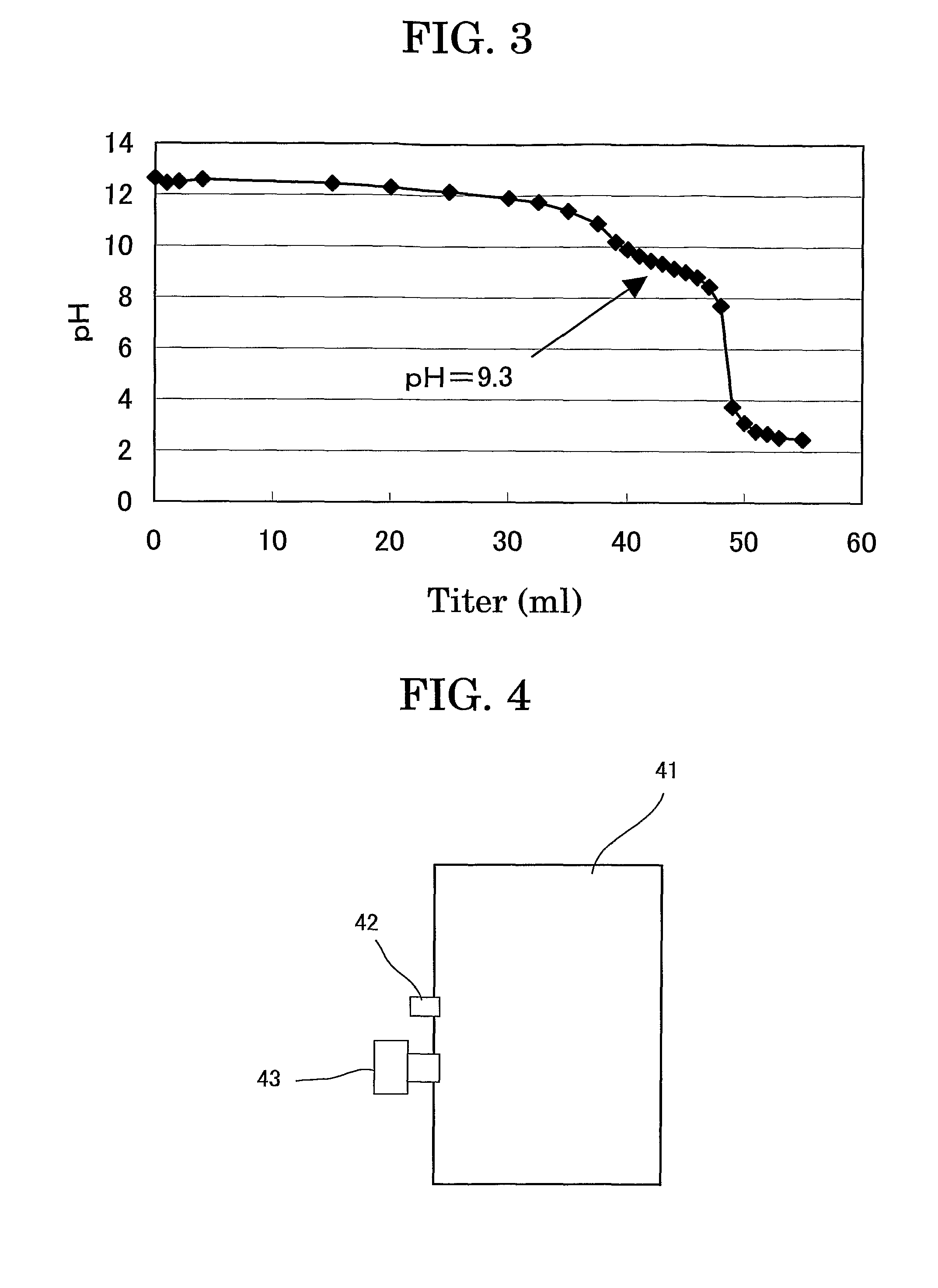

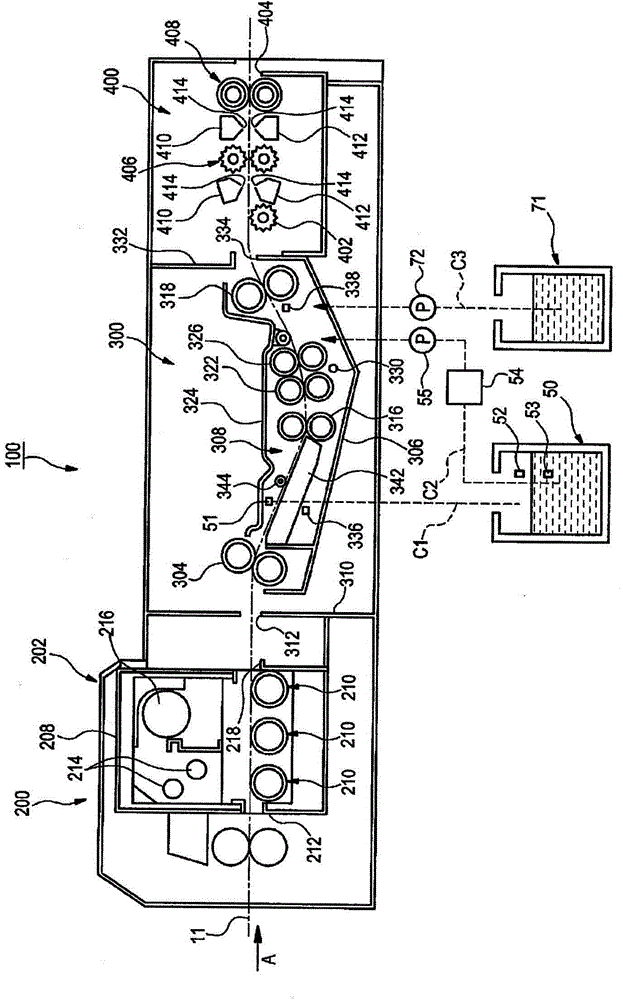

A method for producing a lithographic printing plate is provided, wherein, in the non-alkaline development of a lithographic printing plate precursor having a protective layer, even if the protective layer components are mingled into the developer, the reduction in development removability of the image recording layer and the generation of development scum can be inhibited; an on-press development type lithographic printing plate precursor with excellent inking property, high scratch resistance, satisfied on-press developability and good fine line reproducibility is provided; and a lithographic printing method is provided, each of which is a method for producing a lithographic printing plate, comprising: imagewise exposing a lithographic printing plate precursor comprising a support, an image recording layer and a protective layer, and rubbing the plate surface by a rubbing member of an automatic processor in the presence of a developer at a pH of 2 to 10 to remove the protective layer and the image recording layer in the unexposed area; a lithographic printing plate precursor comprising a support, an image recording layer removable with a printing ink and / or a fountain solution, and a protective layer containing a polyvinyl alcohol having a carboxyl group and / or a sulfonic acid group within the molecule; and a lithographic printing method comprising on-press development.

Owner:FUJIFILM CORP

Planographic printing plate precursor

InactiveUS20050064325A1Improve solubilityHighly lipophilicPhotosensitive material auxillary/base layersPhotosensitive materials for photomechanical apparatusImideRecording layer

The planographic printing plate precursor of the invention includes a recording layer capable of forming an image upon irradiation with infrared rays, wherein the recording layer comprises (A) an alkali-soluble resin having, in a main chain, a structural unit containing at least one type of bond selected from an amide bond, urea bond, urethane bond and ester bond and having at least one type of acid group selected from a phenolic hydroxyl group, sulfonamide group and active imide group, and (B) an infrared absorbing agent. The invention provides a positive-working planographic printing plate precursor excellent in printing durability and chemical resistance.

Owner:FUJIFILM CORP +1

Ink jetting ink set and cleaning method

ActiveUS20130213440A1Excellent ejection stabilityEasy to washHollow article cleaningInksViscosityPigment

An ink jetting ink set includes an ink composition for recording supplied to and used in an ink flow path and containing at least one of a glitter pigment and a metal oxide as a coloring material, and an auxiliary ink composition used in cleaning of the ink flow path, in which, in cases where a dynamic viscosity at 20° C. in the ink composition for recording is η1 (mm2 / s) and a surface tension at 20° C. is γ1 (mN / m), and the dynamic viscosity at 20° C. in the auxiliary ink composition is η2 (mm2 / s) and the surface tension at 20° C. is γ2 (mN / m), the following formula (1) and the following formula (2) are satisfied at the same time.η1≦η2 (1)γ1≧γ2 (2)

Owner:SEIKO EPSON CORP

Recording ink, ink cartridge, ink record, inkjet recording apparatus and inkjet recording process

InactiveUS7950793B2Good colorImprove stabilityInking apparatusMeasurement apparatus componentsEngineeringColor saturation

The object of the present invention is to provide a recording ink having excellent color developing properties and high delivery stability, by which not only the color saturation of the obtained image can be remarkably improved, but also the image having a high quality can be formed. For this object, the present invention provides a recording ink used for an inkjet recording using a dye ink and a pigment ink properly alternately through one inkjet head, wherein the dye ink and the pigment ink have respectively a viscosity at 25° C. of 5 mPa·s or more and the difference between the viscosity of the dye ink and the viscosity of the pigment ink is 3 mPa·s or less.

Owner:RICOH KK

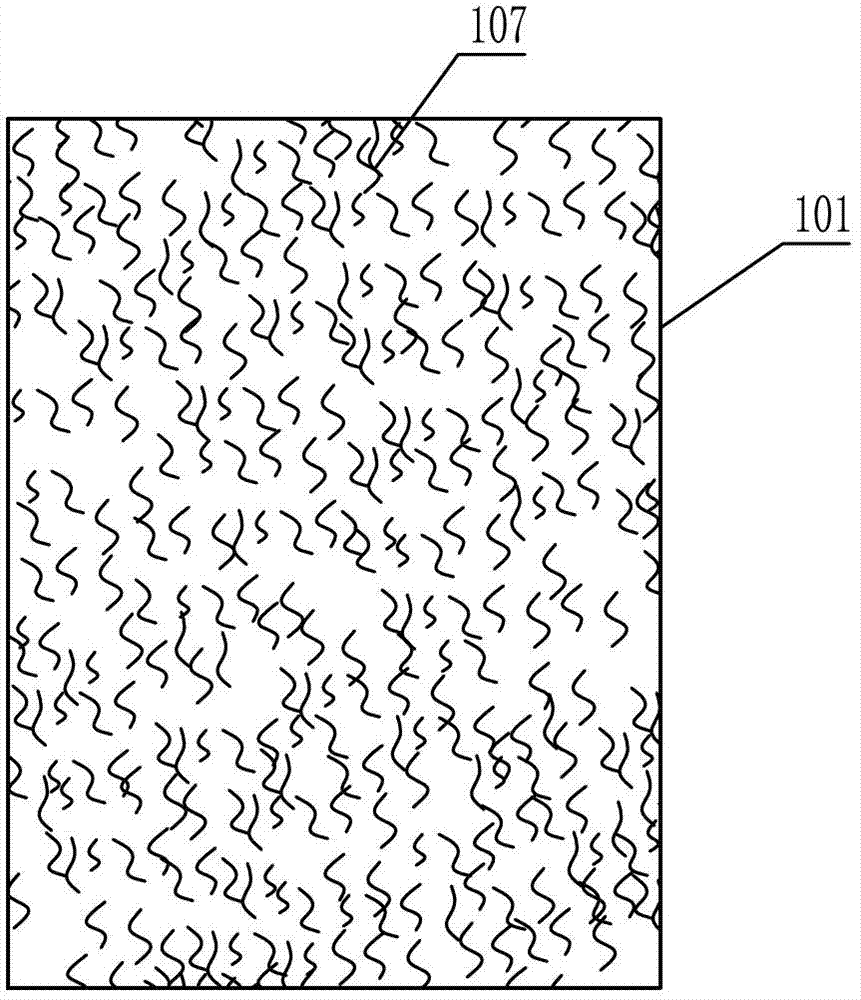

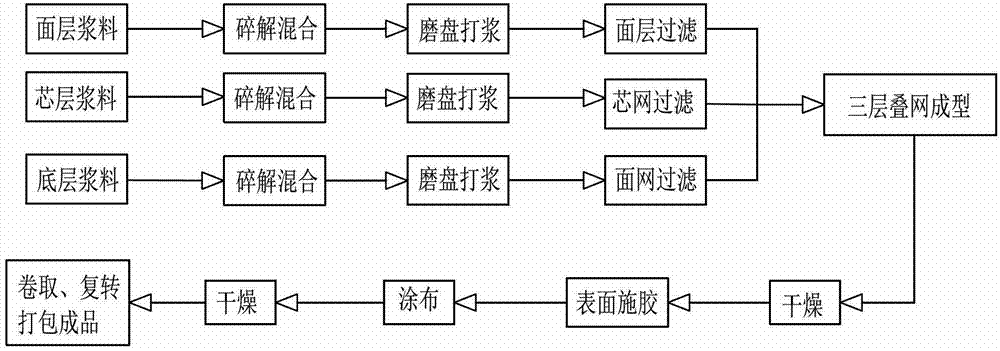

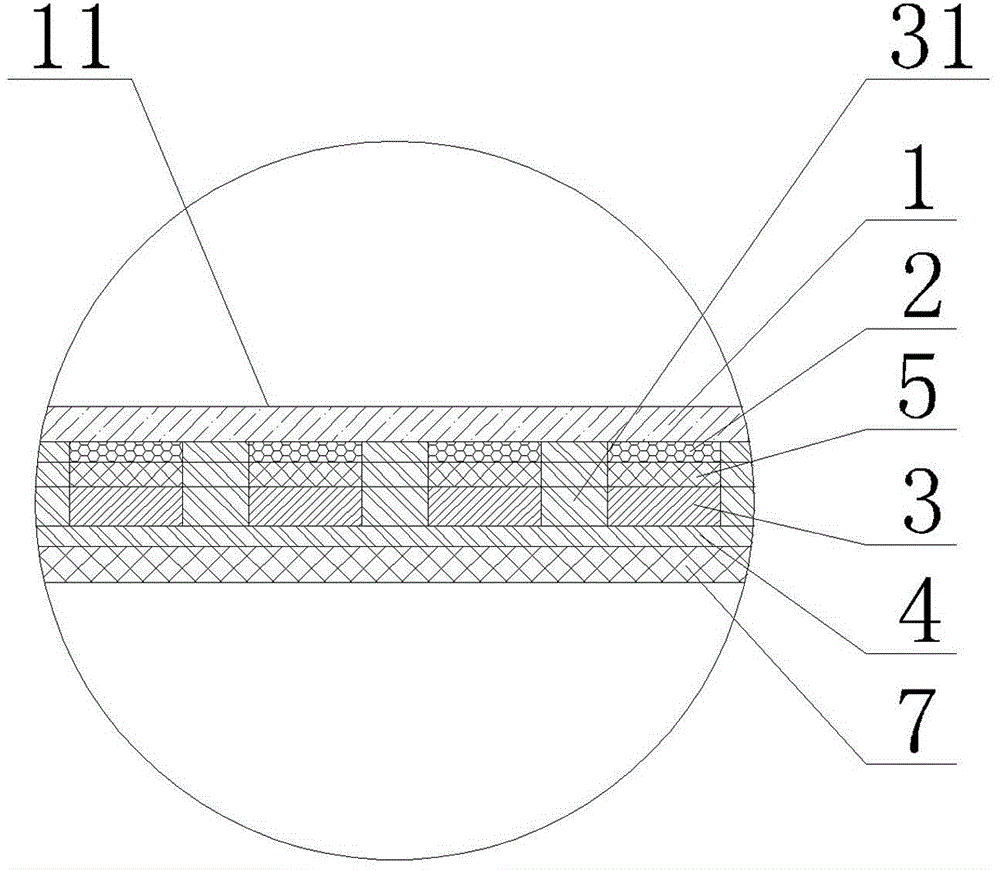

Coating white cardboard and production process thereof

ActiveCN103321096AEasy to identifyEmission reductionDefoamers additionCoatings with pigmentsCardboardSurface layer

The invention provides a coating white cardboard comprising a raw paper and a coating layer, wherein the raw paper comprises a surface layer, a core layer and a bottom layer which are orderly overlaid, the bottom layer is distributed with natural color fibers accounting for 5-10% by weight of the bottom layer, and the coating layer is coated on the surface layer. Because the natural color fibers which are distributed on the bottom layer form textures, the coating white cardboard is easy to be distinguished and recognized from conventional white cardboards. The natural color fibers do not need to be bleached through chemical processing, thereby influence of environment from bleaching chemicals is reduced, and COD emission load when in pulping is effectively reduced. The flexible performance and the bond strength of the coating white cardboard are increased by adopting a fiber structure, binding force between layers is increased, and therefore packaging strength is increased.

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER +1

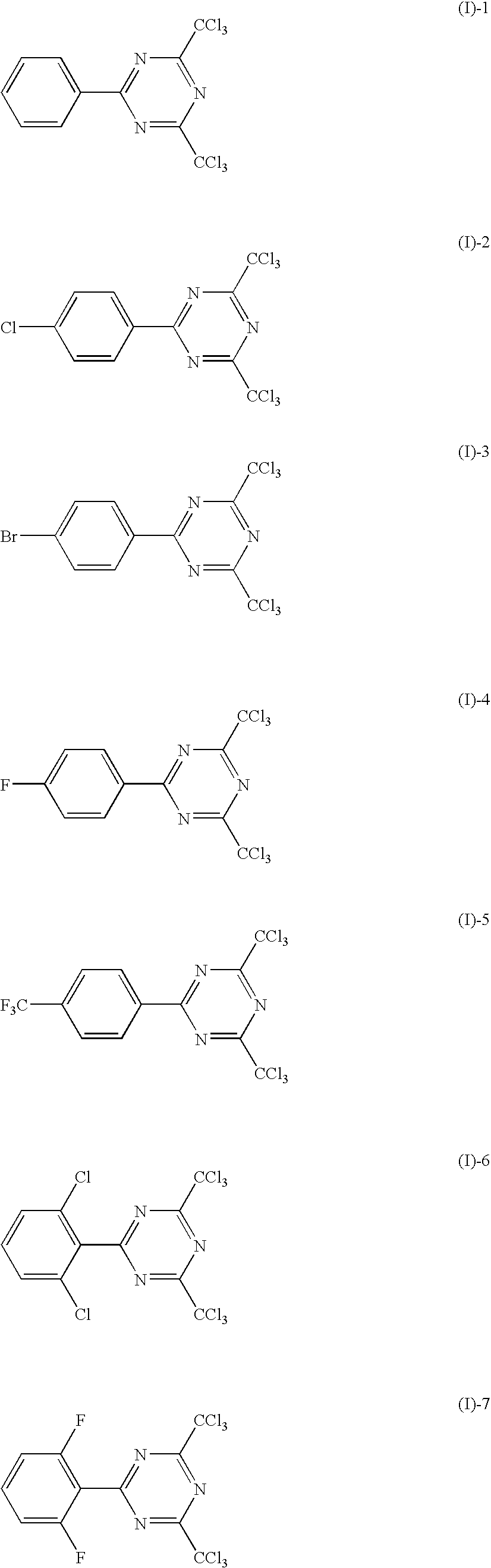

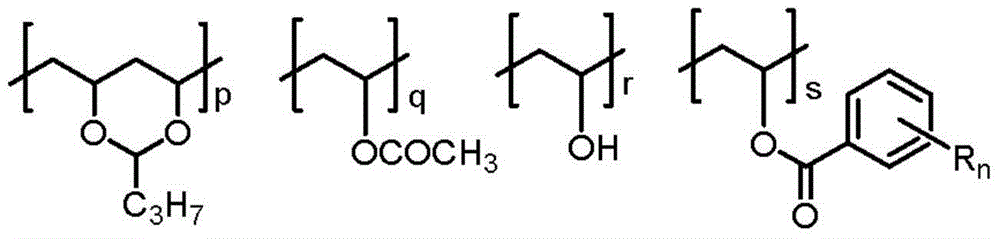

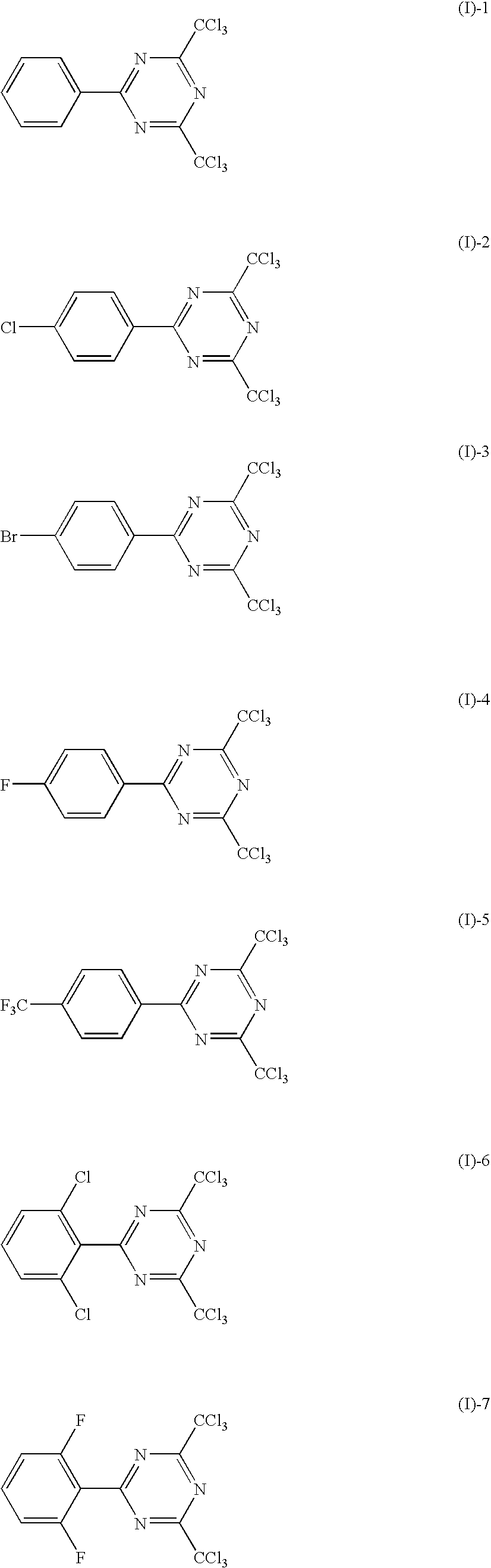

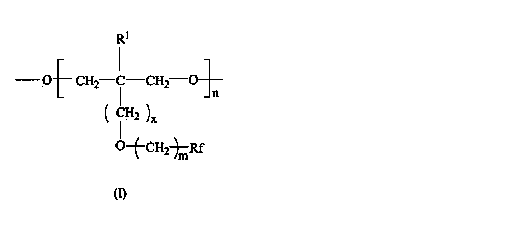

Photosensitive lithographic printing plate

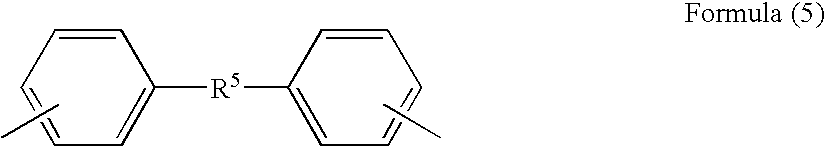

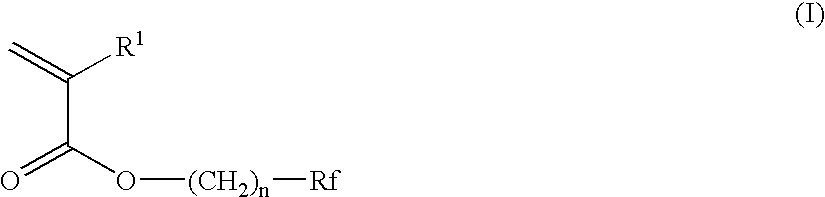

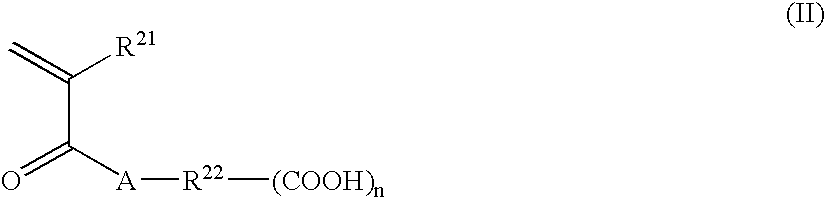

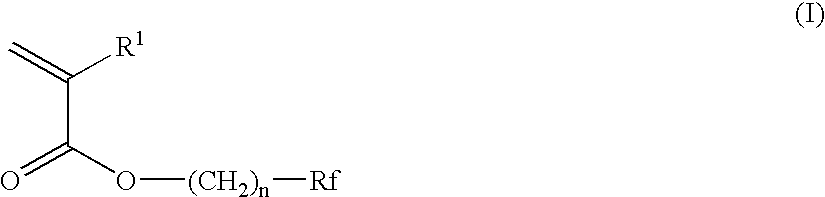

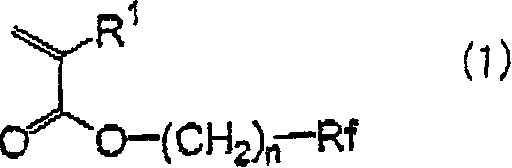

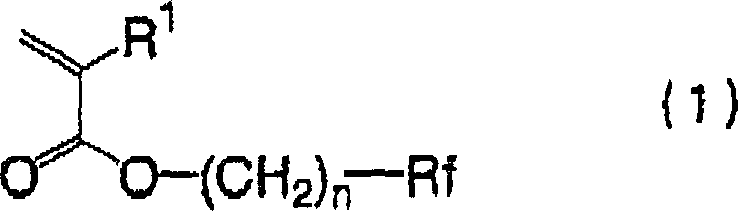

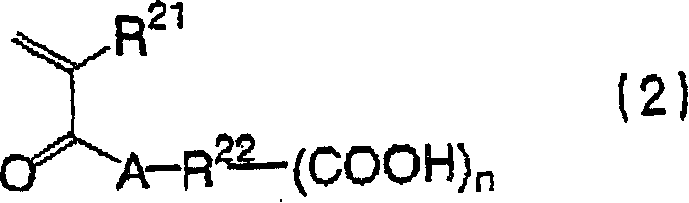

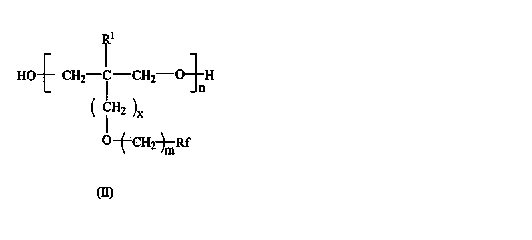

InactiveUS20060263720A1Improve bulkAvoid it happening againPhotosensitive materialsPhotomechanical apparatusCarbon numberPolymer science

A photosensitive lithographic printing plate comprising: a support; and a polymerizable photosensitive layer that comprises: an addition-polymerizable compound having an ethylenically unsaturated double bond; a polymerization initiator; and a polymer compound having (a) a monomer represented by formula (I) and (b) a monomer represented by formula (II) as copolymerization component: wherein Rf represents a substituent containing a fluoroalkyl or perfluoroalkyl group having 9 or more fluorine atoms; n represents 1 or 2; and R1 represents a hydrogen atom or a methyl group; wherein R21 represents a hydrogen atom or a methyl group; R22 represents a divalent hydrocarbon group having a carbon number of 3 to 30 and having an aliphatic cyclic structure; A represents an oxygen atom or —NR23—; and R23 represents a hydrogen atom or a monovalent hydrocarbon group having a carbon number of 1 to 10.

Owner:FUJIFILM HLDG CORP +1

Ink for ink-jet printing, printed cylindrical containers and method for producing the same

ActiveUS20150010722A1Dry quicklyExcellent drying propertyDuplicating/marking methodsSynthetic resin layered productsSolventWater soluble

An ink for ink-jet printing used for ink-jet printing images onto the ink non-absorptive surfaces of cylindrical containers, and comprising at least a water-soluble solvent, a coloring material, a surfactant, a thickener and / or a binder resin, the coloring material being contained in an amount of 5 to 20% by weight, the surfactant in an amount of 0.1 to 5% by weight, the thickener in an amount of not more than 10% by weight, and the binder resin being contained in an amount of not more than 30% by weight . Owing to its ink-jet printability, the ink for ink-jet printing of the invention can be favorably used for printing images on the non-absorptive cylindrical containers such as seamless cans that are used for containing beverages and foods.

Owner:TOMATEC CO LTD +1

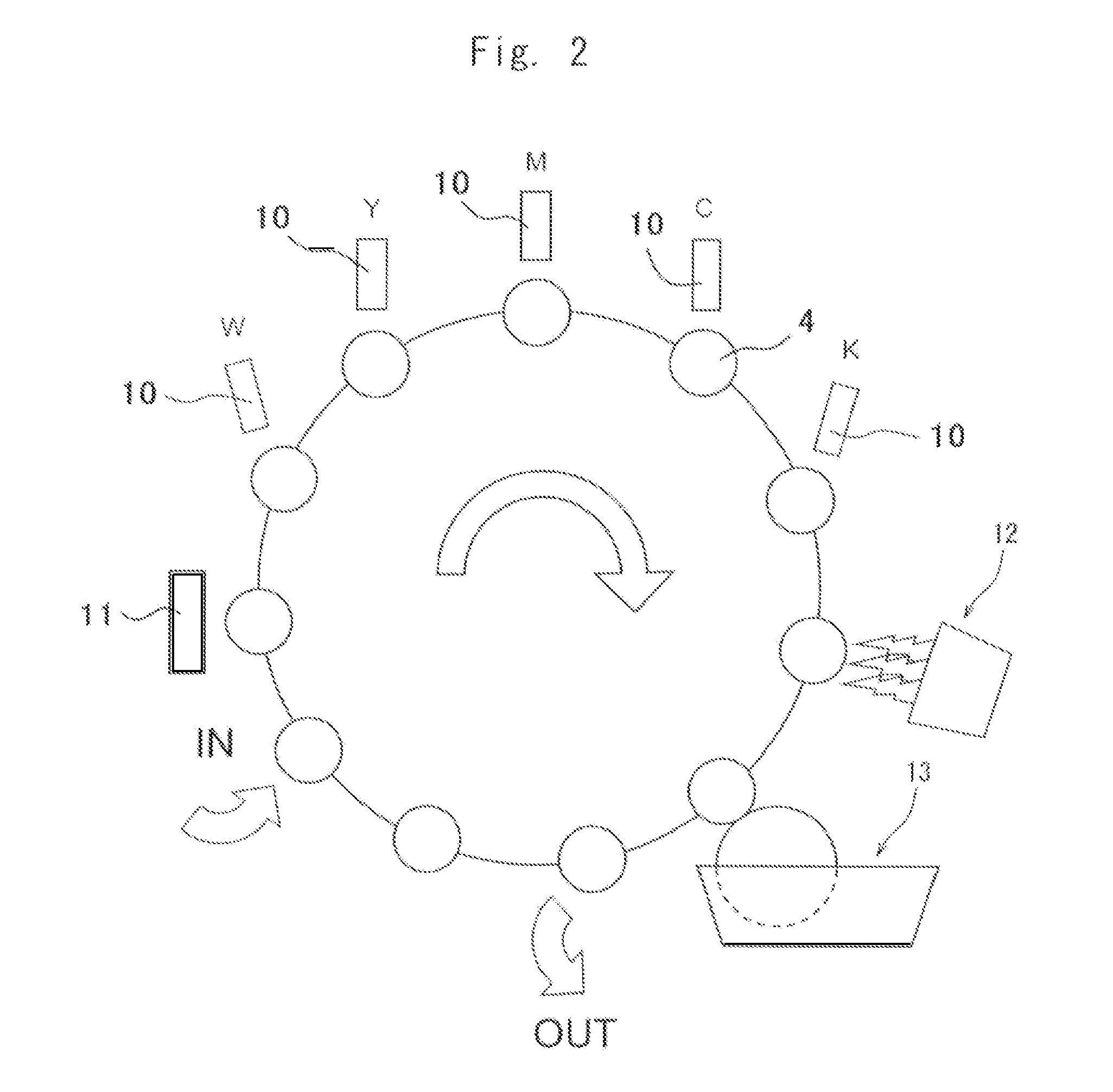

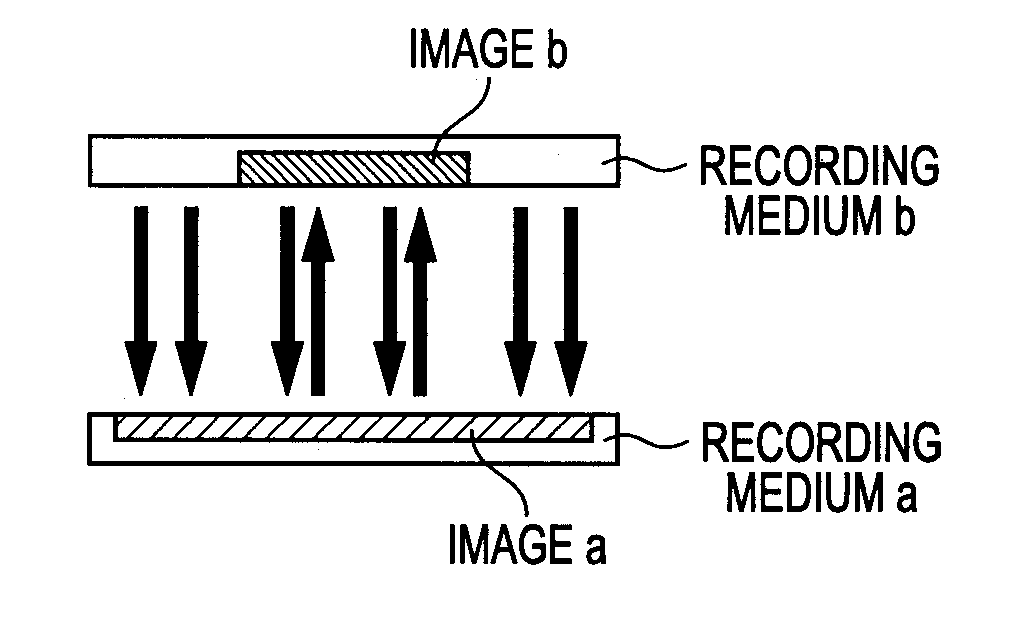

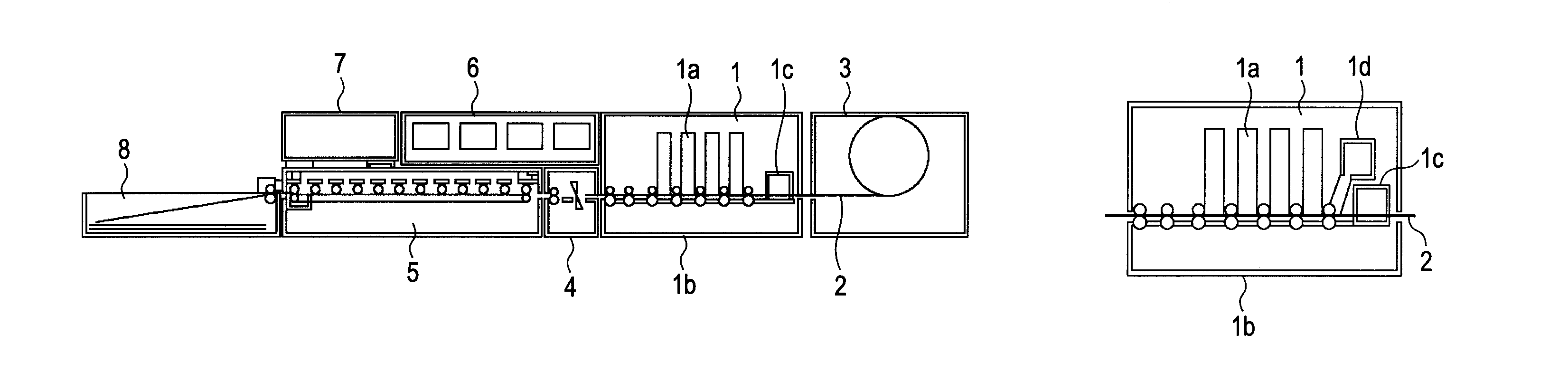

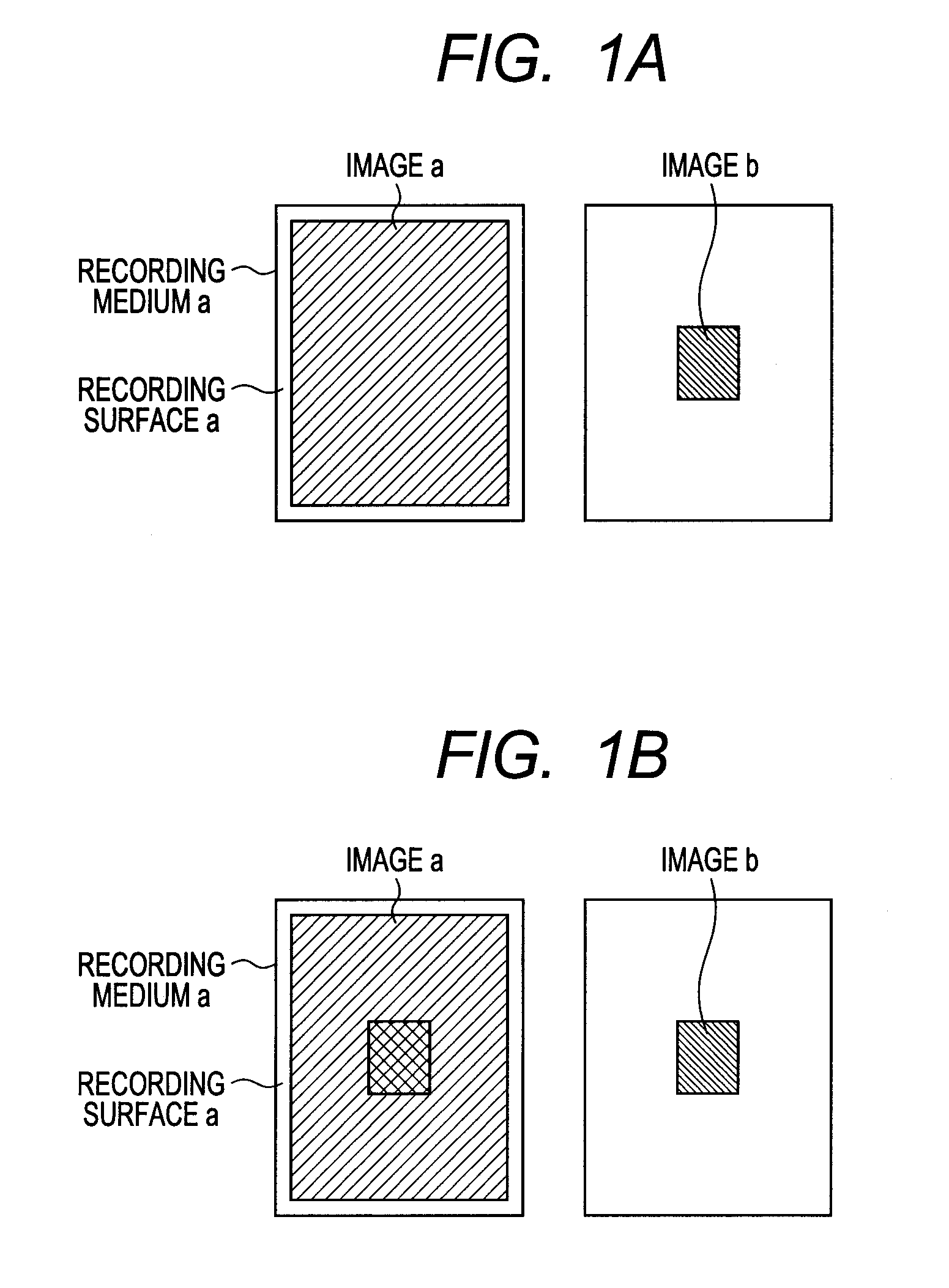

Ink jet recording method and ink jet recording apparatus

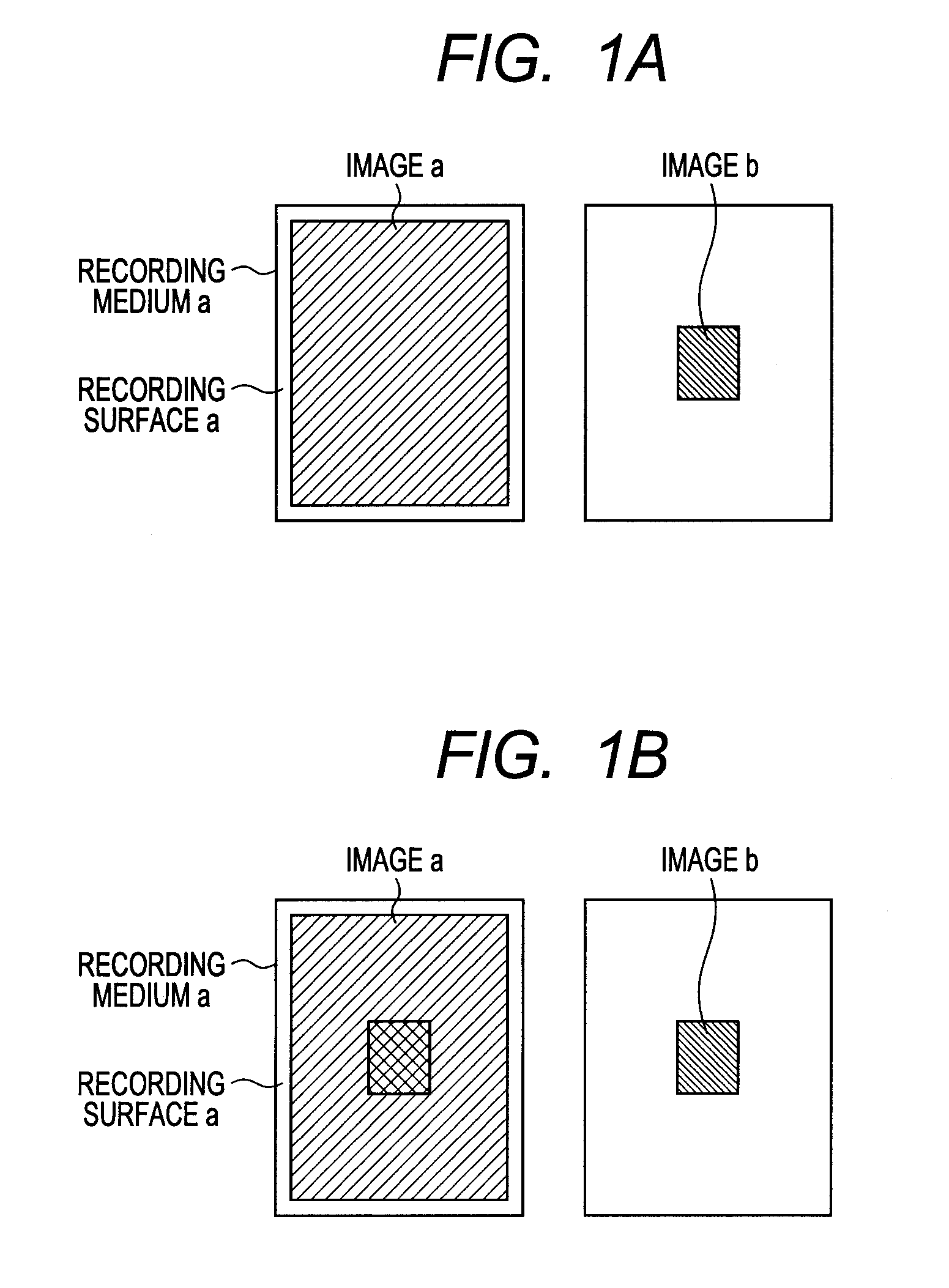

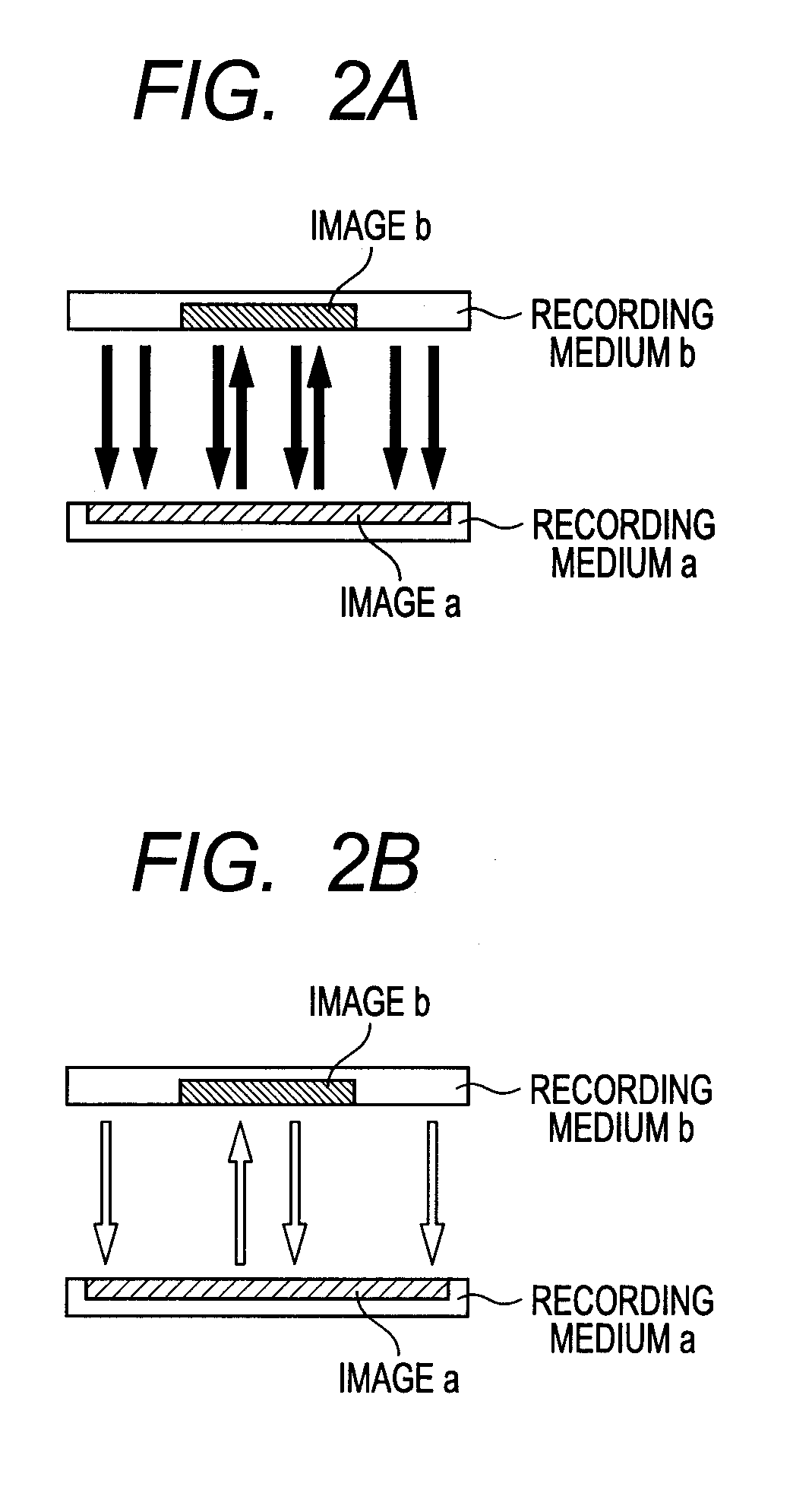

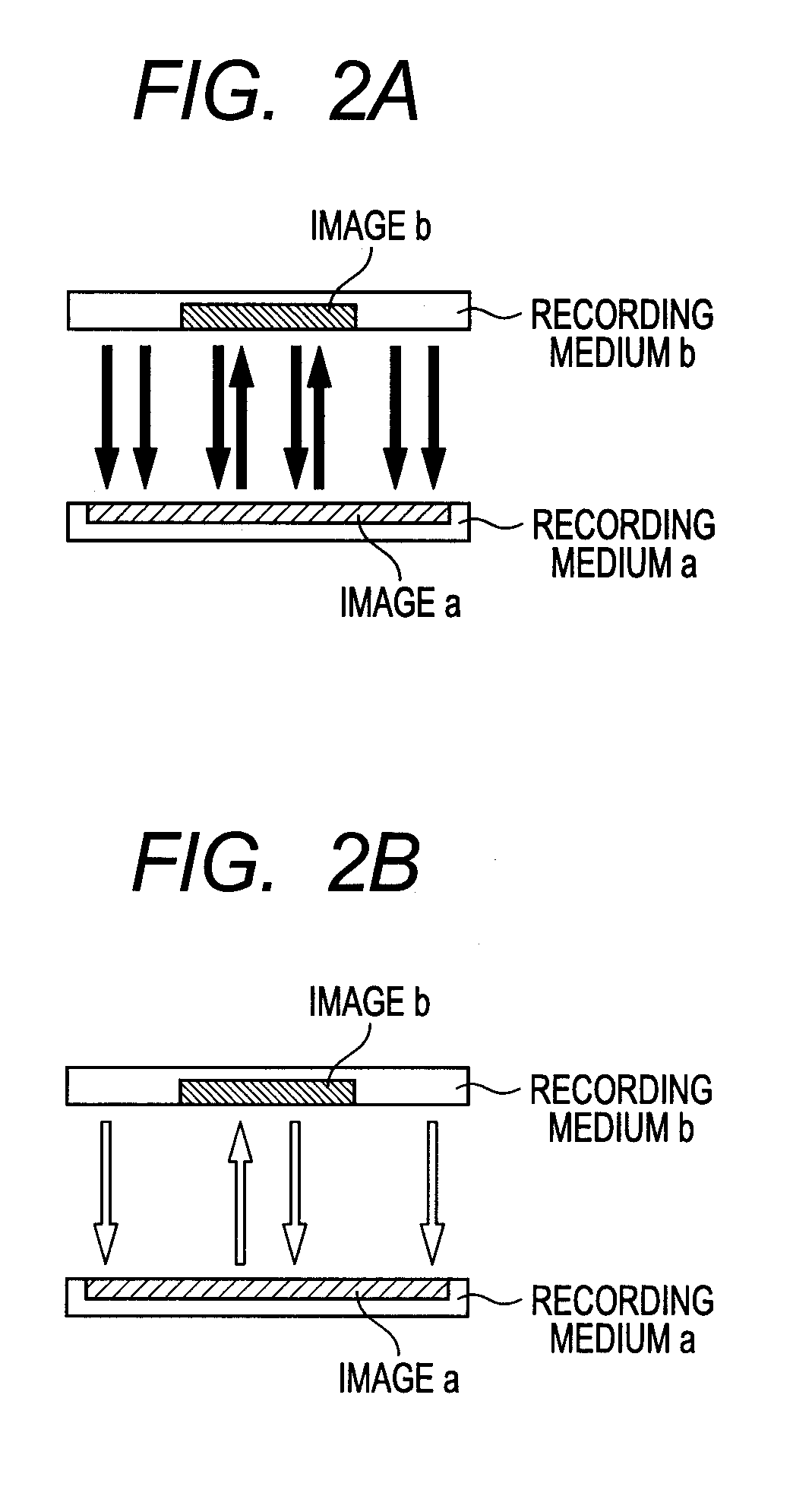

ActiveUS20110310162A1Increase opportunitiesOpportunities of forming the photograph bookDuplicating/marking methodsInksOrganic solventWater soluble

An object of the present invention is to provide an ink jet recording method which gives an ink excellent anti-sticking properties and can suppress the occurrence of undertrapping when recording surfaces of recording media which each have an ink-receiving layer are overlapped with each other, and to provide an ink jet recording apparatus. The ink jet recording method of forming an image on the recording medium having the ink-receiving layer by ejecting an ink from an ink jet recording head, the method including performing at least one of drying the recording medium which has the image formed thereon and humidifying a gap between the recording head and the recording medium, wherein the ink to be used for forming the image is an ink which contains water, a water-soluble organic solvent and a specific compound.

Owner:CANON KK

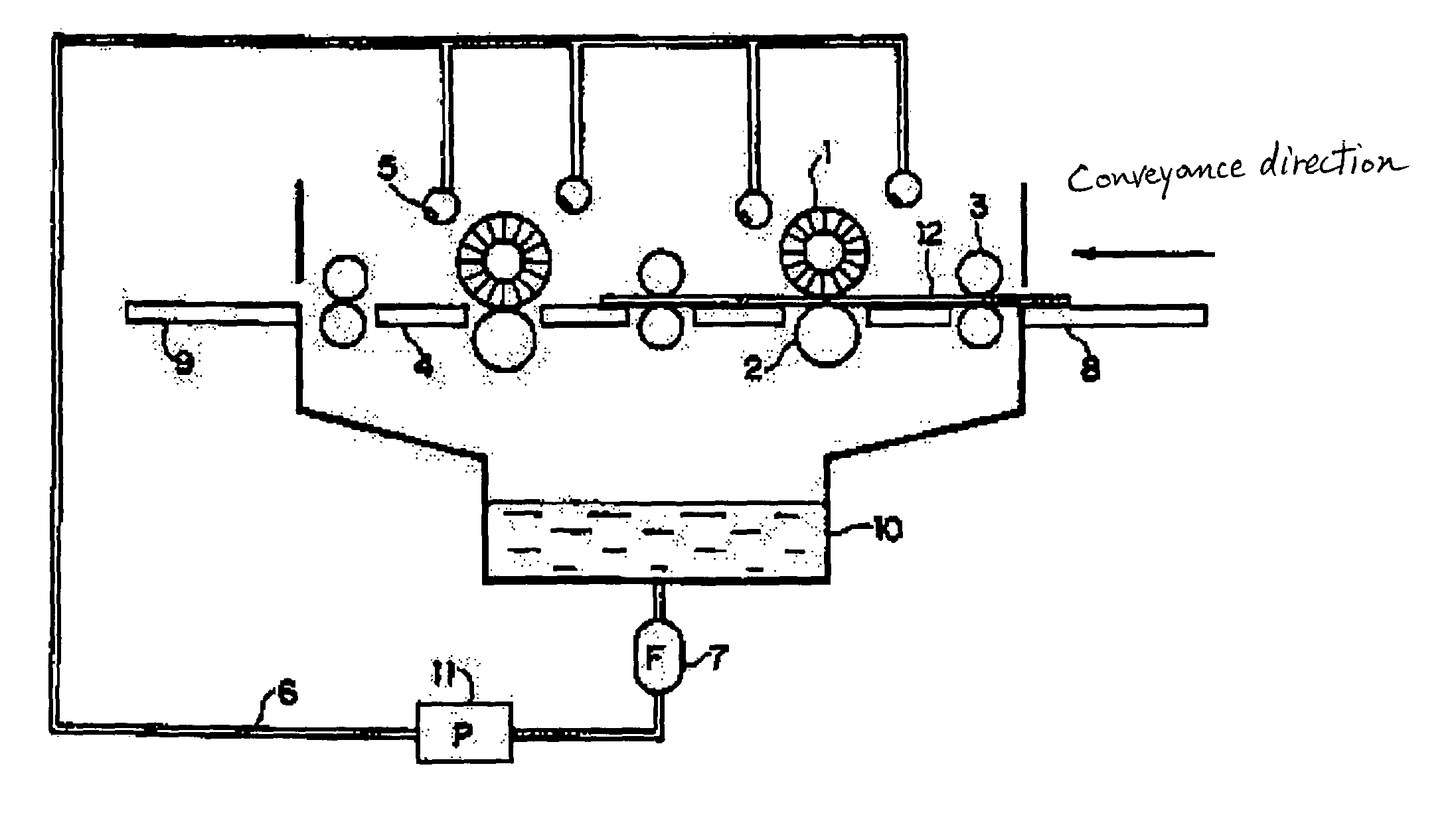

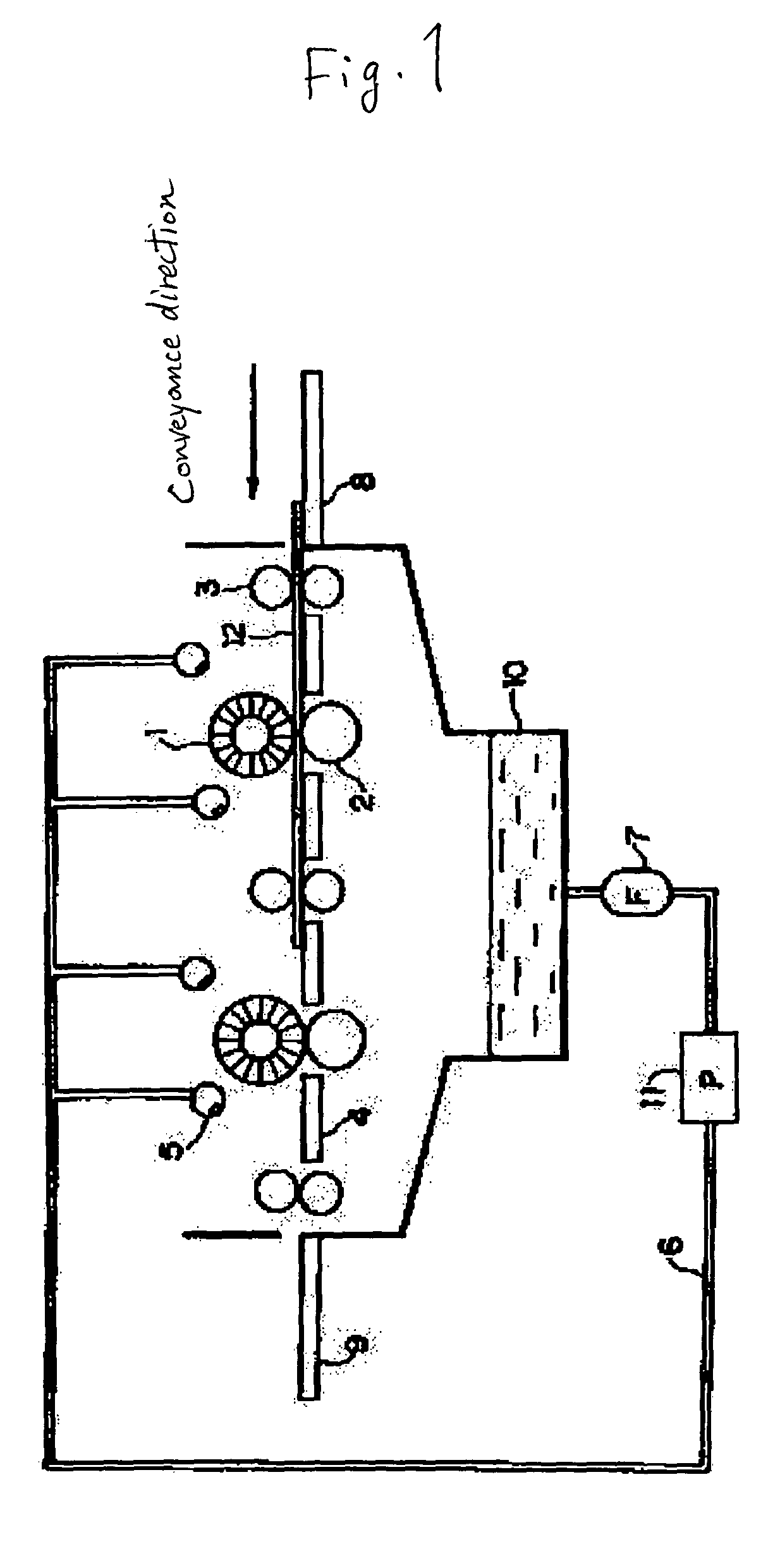

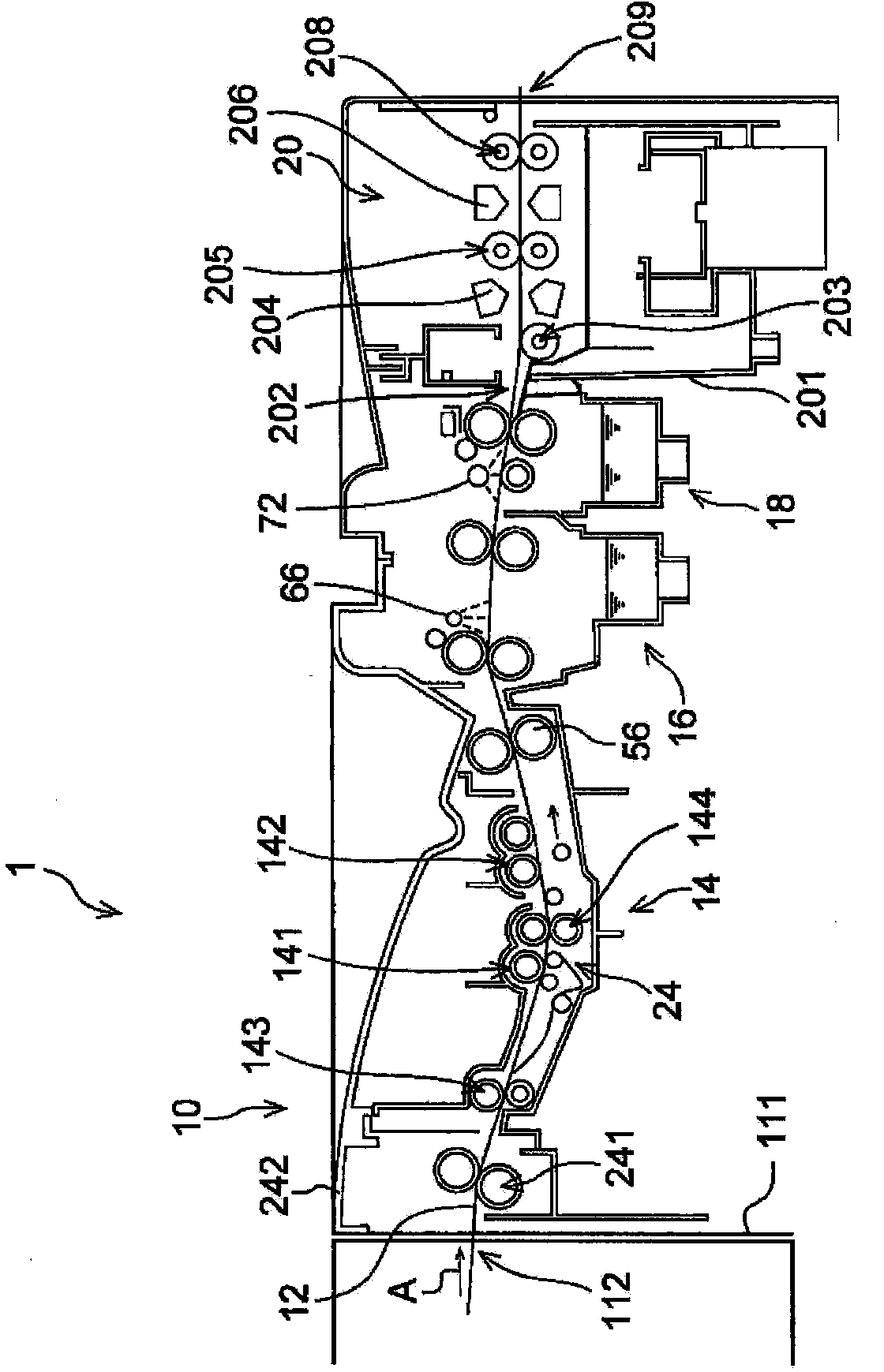

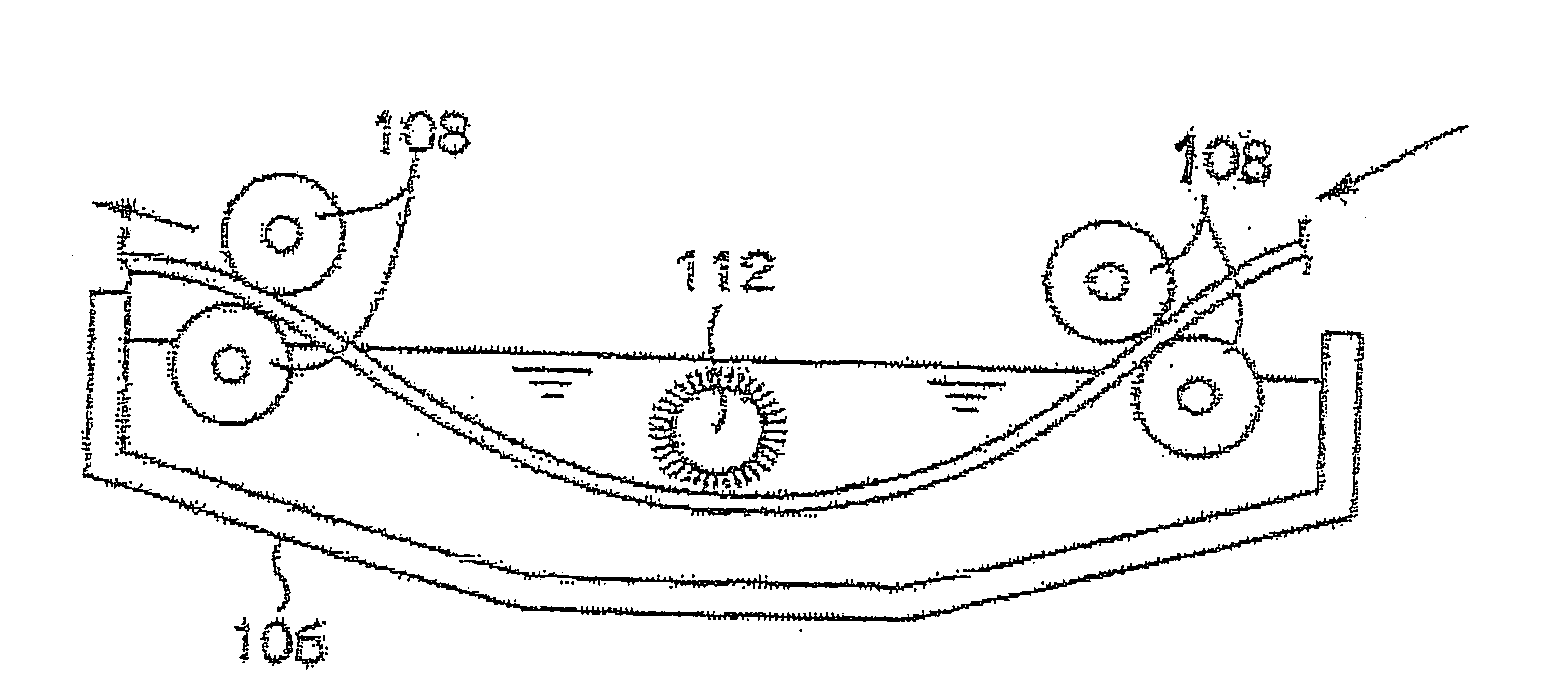

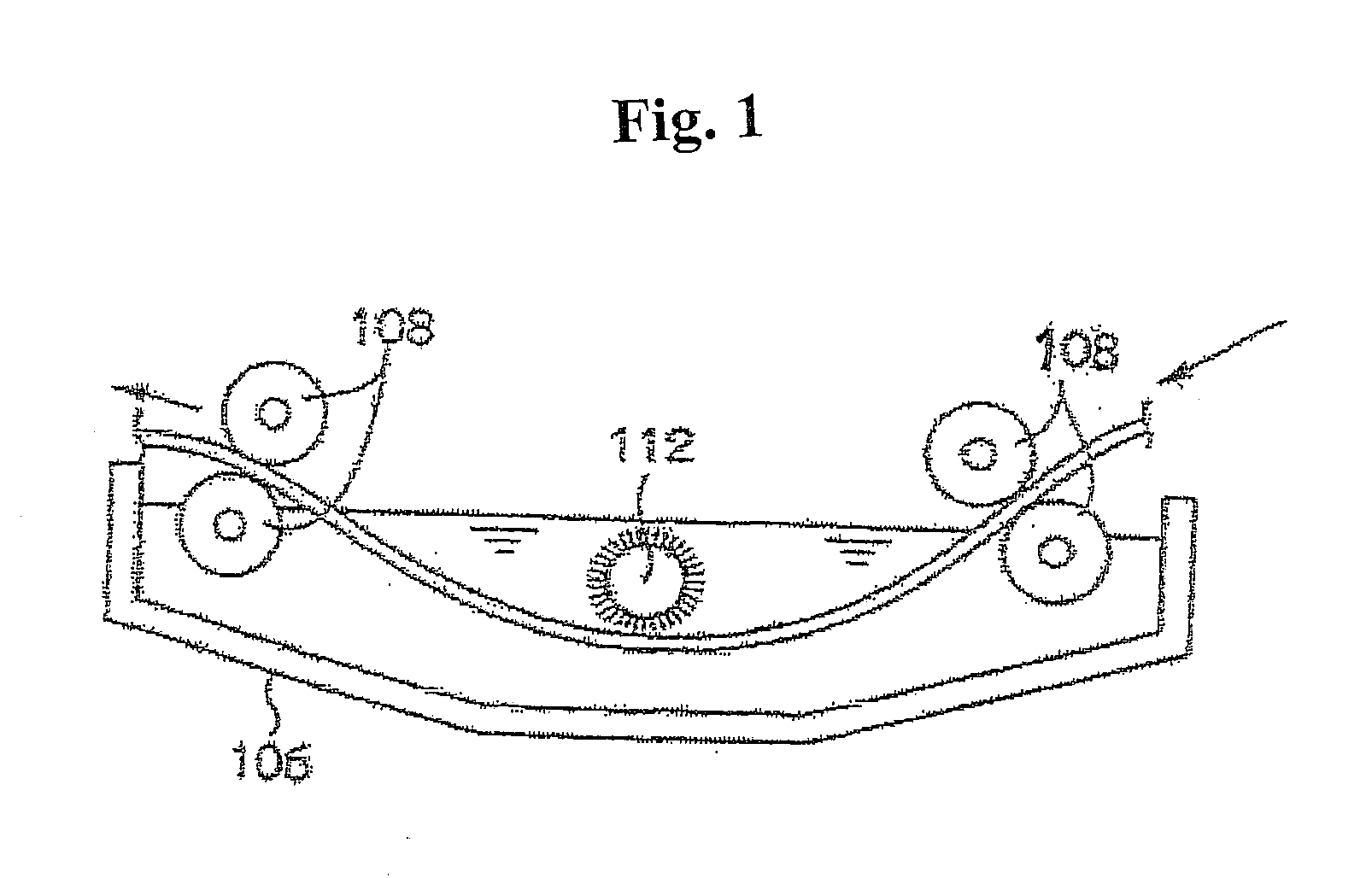

Plate-making method of lithographic printing plate precursor

InactiveUS20090246700A1Extended press lifeExcellent developabilitySemiconductor/solid-state device manufacturingPhotosensitive material processingCompound (substance)Water soluble

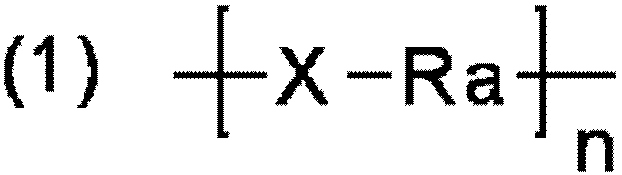

A plate-making method of a lithographic printing plate precursor including an image forming layer and a support, includes: (a) a step of preparing a lithographic printing plate precursor containing, in the image forming layer, an infrared absorber, a polymerization initiator, a polymerizable compound, a hydrophobic binder polymer and a compound represented by the formula (1) or (2) as defined herein; (b) a step of imagewise exposing the lithographic printing plate precursor; and (C) a step of developing the exposed lithographic printing plate precursor with an aqueous solution containing at least one water-soluble polymer selected from the group consisting of gum arabic and starch with an automatic processor equipped with a rubbing member.

Owner:FUJIFILM CORP

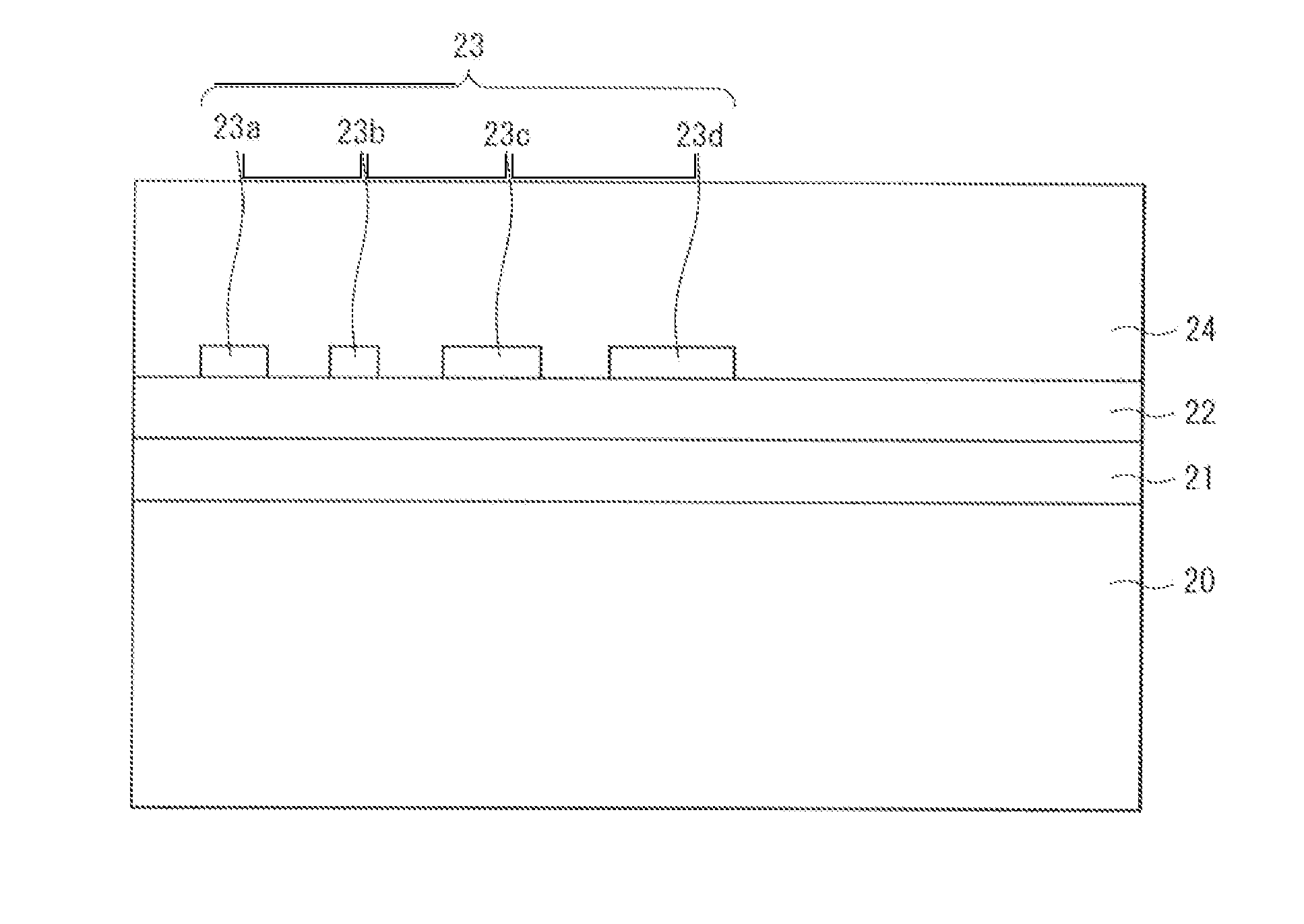

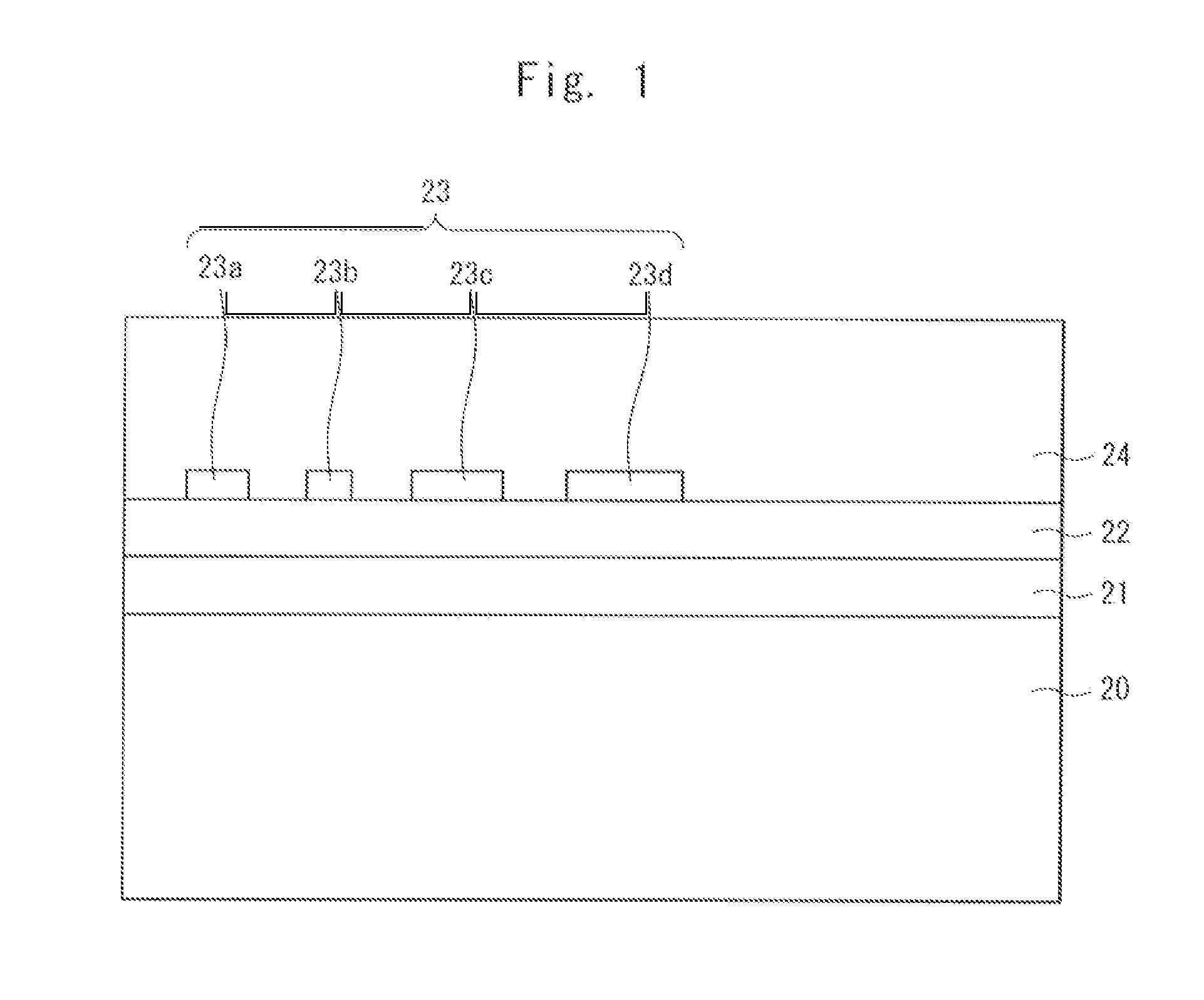

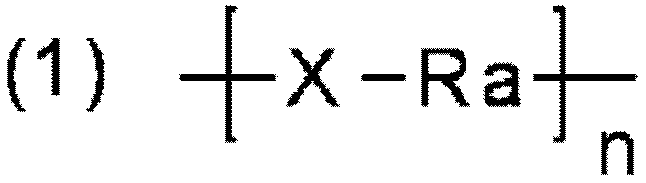

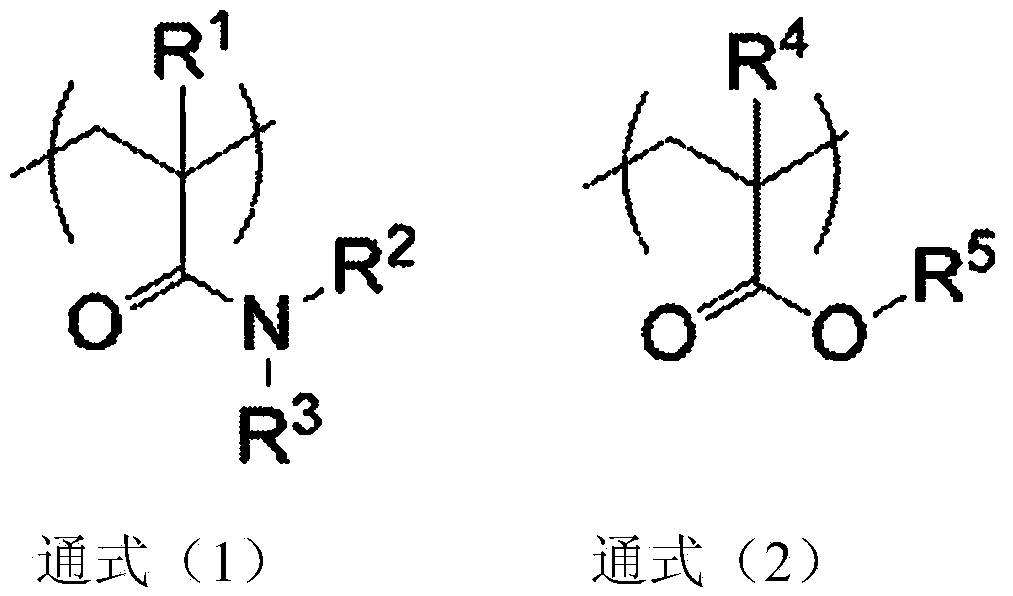

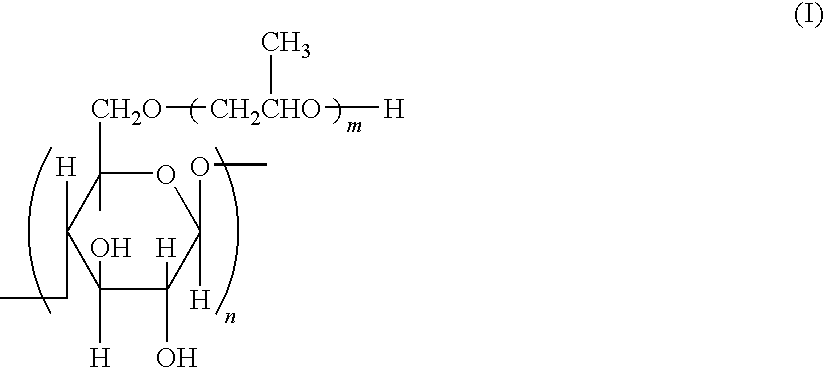

Planographic printing plate precursor

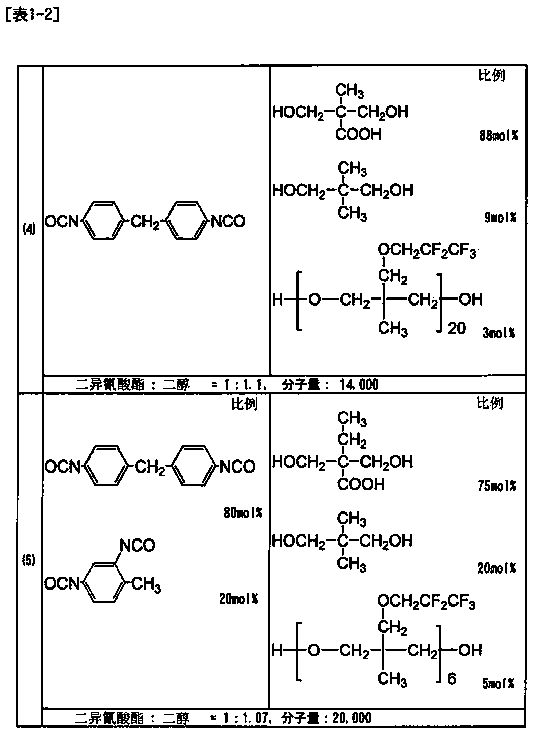

InactiveCN1737682AExcellent developabilityGood inking effectPhotosensitive materials for photomechanical apparatusHydrogenPositive type

The positive-type planographic printing plate precursor of the invention comprises a support and a recording layer provided on the support, wherein the recording layer contains: a polymer compound having (a) a monomer represented by the following formula (1), (b) a monomer having an alicyclic group having 7 or more carbon atoms and having a bridge bond, and (c) a monomer having an acid group as a copolymerization component; and an infrared-ray absorbing agent. The positive-type planographic printing plate precursor of the invention achieves both excellent developability and excellent inking property, as well as better image-forming property and a clear image. Wherein in the formula (1), Rf is a substituent containing a fluoroalkyl group or a perfluoroalkyl group having 9 or more fluorine atoms, n represents 1 or 2, and R1 represents hydrogen or a methyl group.

Owner:FUJIFILM CORP

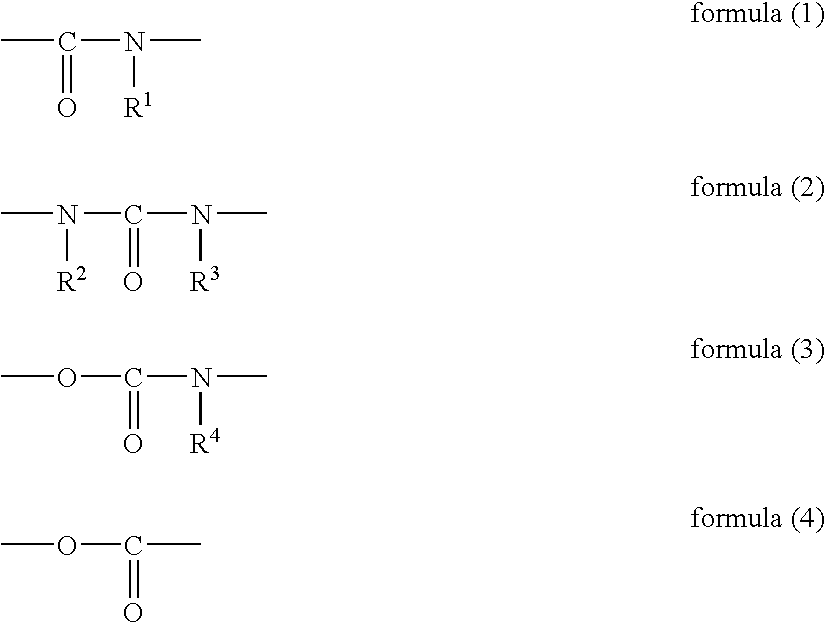

Lithographic printing original plate and plate making method

InactiveCN107921808AExcellent adhesion preventionGood inking effectPhotomechanical apparatusPlate printingRecording layerOxygen

Provided is a lithographic printing original plate which has an image recording layer on a supporting body, and wherein the image recording layer contains a polymer that has a sulfonamide group, an amide group, an imide group or a carbonate group in the main chain, while having a group represented by general formula (1). This lithographic printing original plate has excellent on-press developability, development scum adhesion preventing properties, receptibility and printing durability. Also provided is a plate making method. In formula (1), X represents a single bond or an oxygen atom; Ra represents an alkylene group having 6-40 carbon atoms in cases where X is a single bond, while representing an alkylene group having 2-20 carbon atoms in cases where X is an oxygen atom; and n representsa number of 1-45.

Owner:FUJIFILM CORP

Lithographic printing plate original and method for producing lithographic printing plate

InactiveCN104136996AGood inking effectExcellent brush resistancePlate printingPhotosensitive material processingPolymer scienceMeth-

Owner:FUJIFILM CORP

Ink jet recording method and ink jet recording apparatus

ActiveUS8764178B2Opportunities of forming the photograph bookIncrease opportunitiesMeasurement apparatus componentsDuplicating/marking methodsOrganic solventEngineering

An object of the present invention is to provide an ink jet recording method which gives an ink excellent anti-sticking properties and can suppress the occurrence of undertrapping when recording surfaces of recording media which each have an ink-receiving layer are overlapped with each other, and to provide an ink jet recording apparatus. The ink jet recording method of forming an image on the recording medium having the ink-receiving layer by ejecting an ink from an ink jet recording head, the method including performing at least one of drying the recording medium which has the image formed thereon and humidifying a gap between the recording head and the recording medium, wherein the ink to be used for forming the image is an ink which contains water, a water-soluble organic solvent and a specific compound.

Owner:CANON KK

Production method of lithographic printing plate, lithographic printing plate precursor and lithographic printing method

ActiveUS7745090B2Reduce developmentGeneration can be inhibitedPlaten pressesPhotosensitive materialsAlkali freePolyvinyl alcohol

A method for producing a lithographic printing plate is provided, wherein, in the non-alkaline development of a lithographic printing plate precursor having a protective layer, even if the protective layer components are mingled into the developer, the reduction in development removability of the image recording layer and the generation of development scum can be inhibited; an on-press development type lithographic printing plate precursor with excellent inking property, high scratch resistance, satisfied on-press developability and good fine line reproducibility is provided; and a lithographic printing method is provided, each of which is a method for producing a lithographic printing plate, comprising: imagewise exposing a lithographic printing plate precursor comprising a support, an image recording layer and a protective layer, and rubbing the plate surface by a rubbing member of an automatic processor in the presence of a developer at a pH of 2 to 10 to remove the protective layer and the image recording layer in the unexposed area; a lithographic printing plate precursor comprising a support, an image recording layer removable with a printing ink and / or a fountain solution, and a protective layer containing a polyvinyl alcohol having a carboxyl group and / or a sulfonic acid group within the molecule; and a lithographic printing method comprising on-press development.

Owner:FUJIFILM CORP

Method for concentrating processing waste liquid and method for recycling processing waste liquid

ActiveCN104395834AAvoid foamingInhibitionWater treatment parameter controlPaint waste treatmentLiquid wasteOrganic solvent

This method for concentrating processing waste liquid includes a step in which waste liquid produced by developing lithographic printing plates with a developer is obtained after exposure. The lithographic printing plate has, on a substrate, an image recording layer containing an infrared-absorbing dye, a polymerization initiator and a polymerizable compound on a substrate, and a protective layer. The developer: contains 1 mass% to 10 mass% of an anionic surfactant having a naphthalene skeleton and / or a nonionic surfactant having a naphthalene skeleton; contains 2 mass% or less of an organic solvent with a boiling point of 100 DEG C to 300 DEG C; and a pH of 6.0 to 9.5. This method for concentrating processing waste liquid further includes a step in which the waste liquid is concentrated through evaporation in such a manner that the ratio of the quantity of the processing waste liquid after concentration to the quantity of processing waste liquid before concentration is 1 / 2 to 1 / 10 on a volume basis.

Owner:FUJIFILM CORP

Coating liquid used for surface of environment-friendly rich mineral paper

ActiveCN102675989BGood surface feelImprove flatnessConjugated diene hydrocarbon coatingsUltimate tensile strengthButadiene-styrene rubber

The invention discloses a coating liquid used for the surface of environment-friendly rich mineral paper, which solves the problems of harsh surface handfeel, lack in gloss, low strength, poor bending performance and the like of the paper caused by the existing product. The coating liquid comprises the following components in percentage by weight: 14.8%-17.2% of butadiene styrene rubber latex, 31.0%-36.0% of inorganic mineral powder, 33.5%-42.7% of pure water, 0.4%-0.5% of glycol, 0.22%-0.25% of dispersing agent, 0.11%-0.13% of antifoaming agent, 0.18%-0.21% of thickening agent, 9.7%-11.3% of PVA (poli vinyl alcohol)-S and 0.8%-1.0% of lubricating agent. The invention also provides a preparation method of the coating liquid. The surface handfeel, the flatness, the flexibility and the printing performance of the environment-friendly paper can be observably improved, and the surface strength of the paper is improved.

Owner:孔令发

Water transfer printing construction method

InactiveCN109703226AGood inking performanceNo malleabilityPattern printingInk transfer from master sheetWater transferDuctility

The invention discloses a water transfer printing construction method. A PET film, polyvinyl alcohol fibers, an adhesive coating and an activating agent are needed. The water transfer printing construction method comprises the following steps that 1, image-text intaglio printing is conducted on the surface of the PET film, an image-text ink layer is generated on the surface of the PET film, and then the film surface, printed with the image-text ink layer, of the PET film is coated with the polyvinyl alcohol fibers in a shower coating mode; and 2, the PET film coated with the polyvinyl alcoholfibers is laid on the surface of a steel belt of shower coating equipment, temperature difference is formed through the difference between the cooled steel belt temperature and the PET film laying temperature, therefore, a film layer is instantly formed by polyvinyl alcohol fiber liquid, and the polyvinyl alcohol fibers are adhered to the image-text ink layer. According to the water transfer printing construction method, the PET film is good in inking performance and has no ductility, and therefore clear images and texts can be conveniently printed; and meanwhile, the cost of shower coating the polyvinyl alcohol fibers is reduced compared with the existing polyvinyl alcohol film printing cost, and the requirement for the environment in the manufacturing process is lowered.

Owner:东莞市鑫烨转印材料有限公司

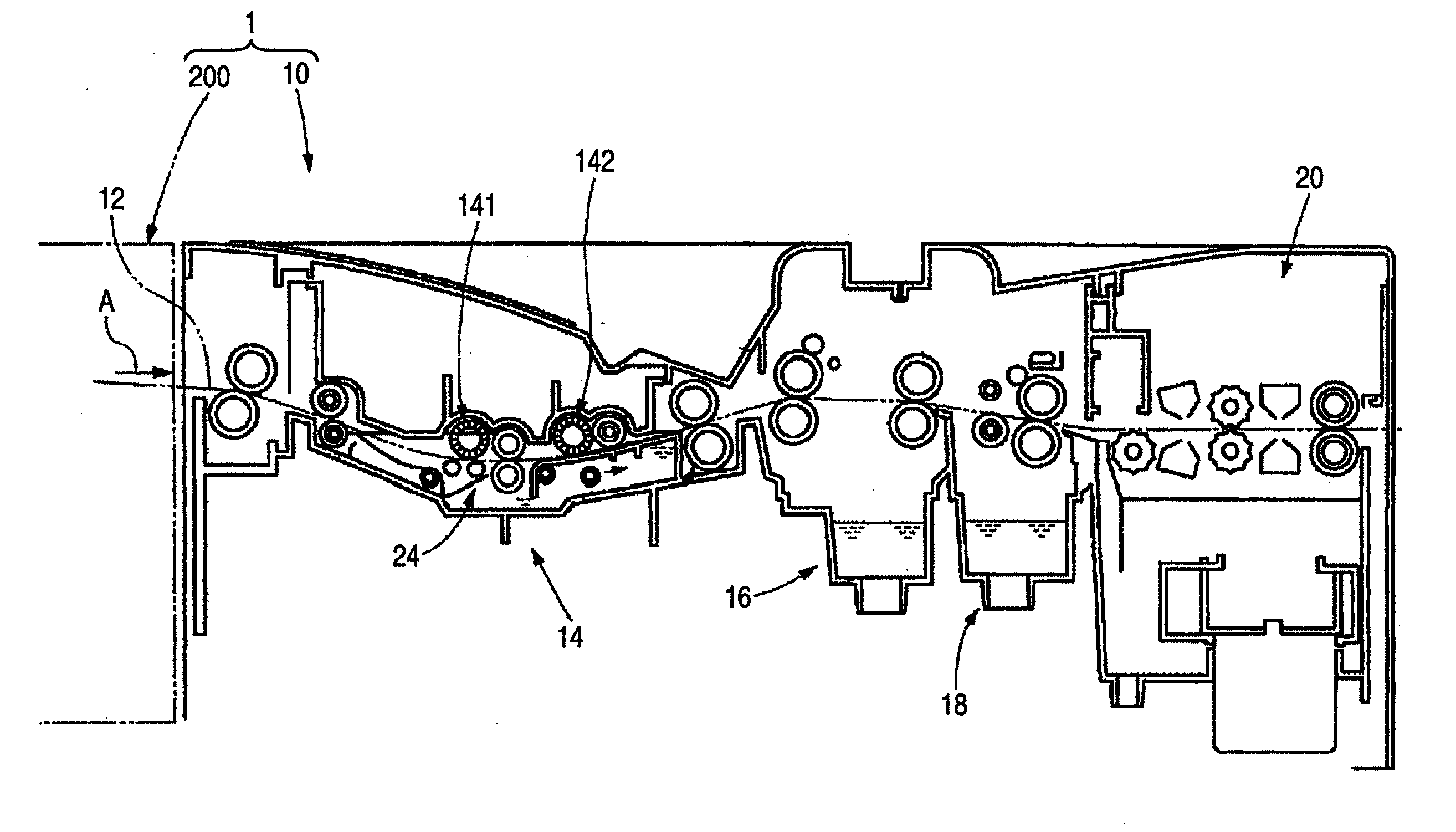

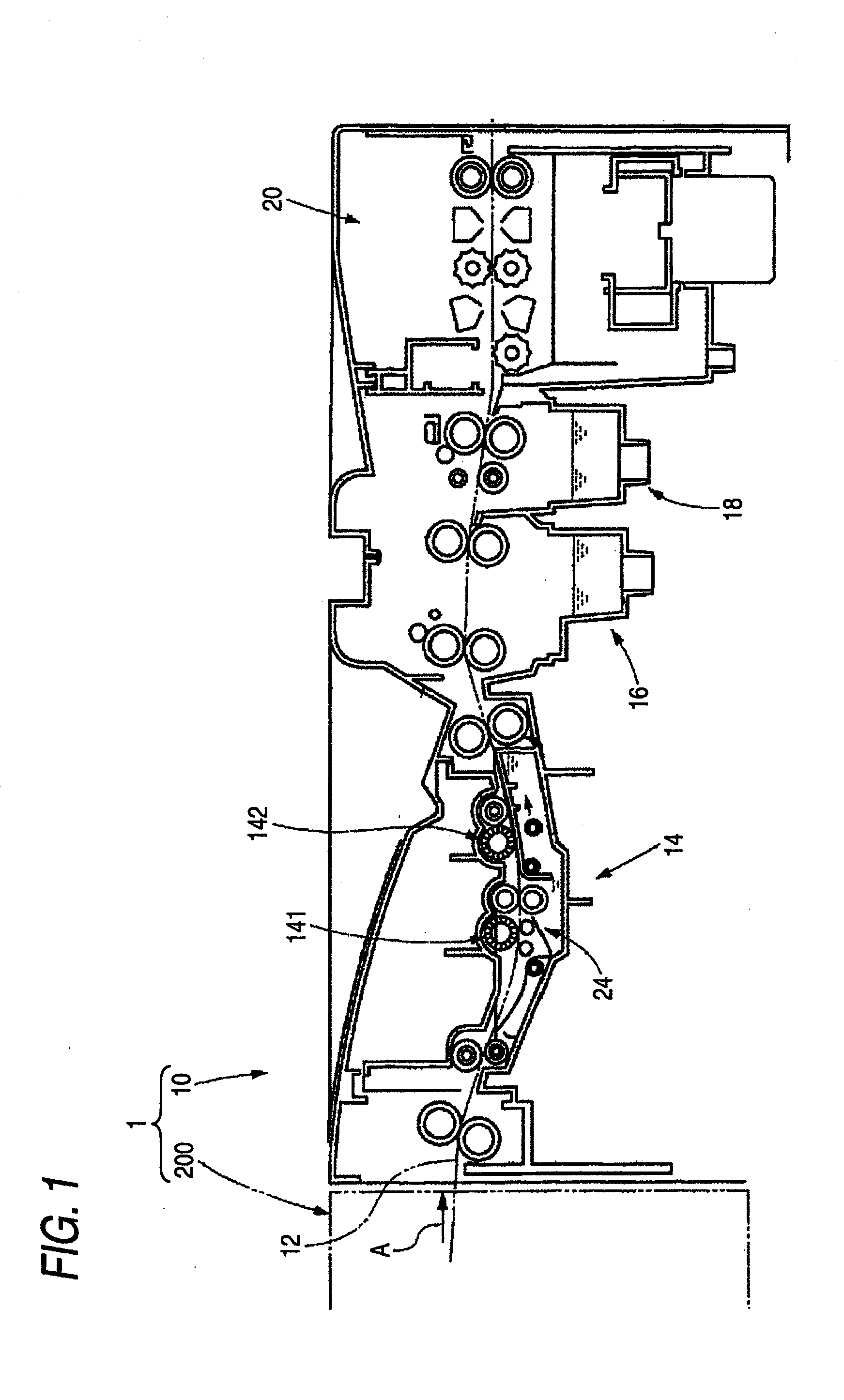

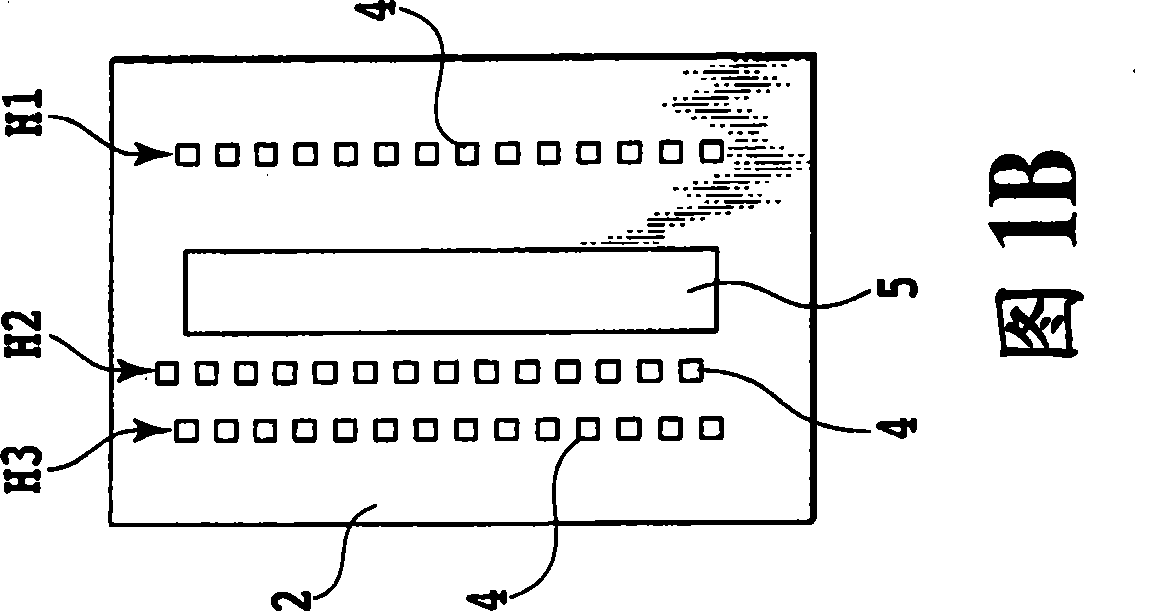

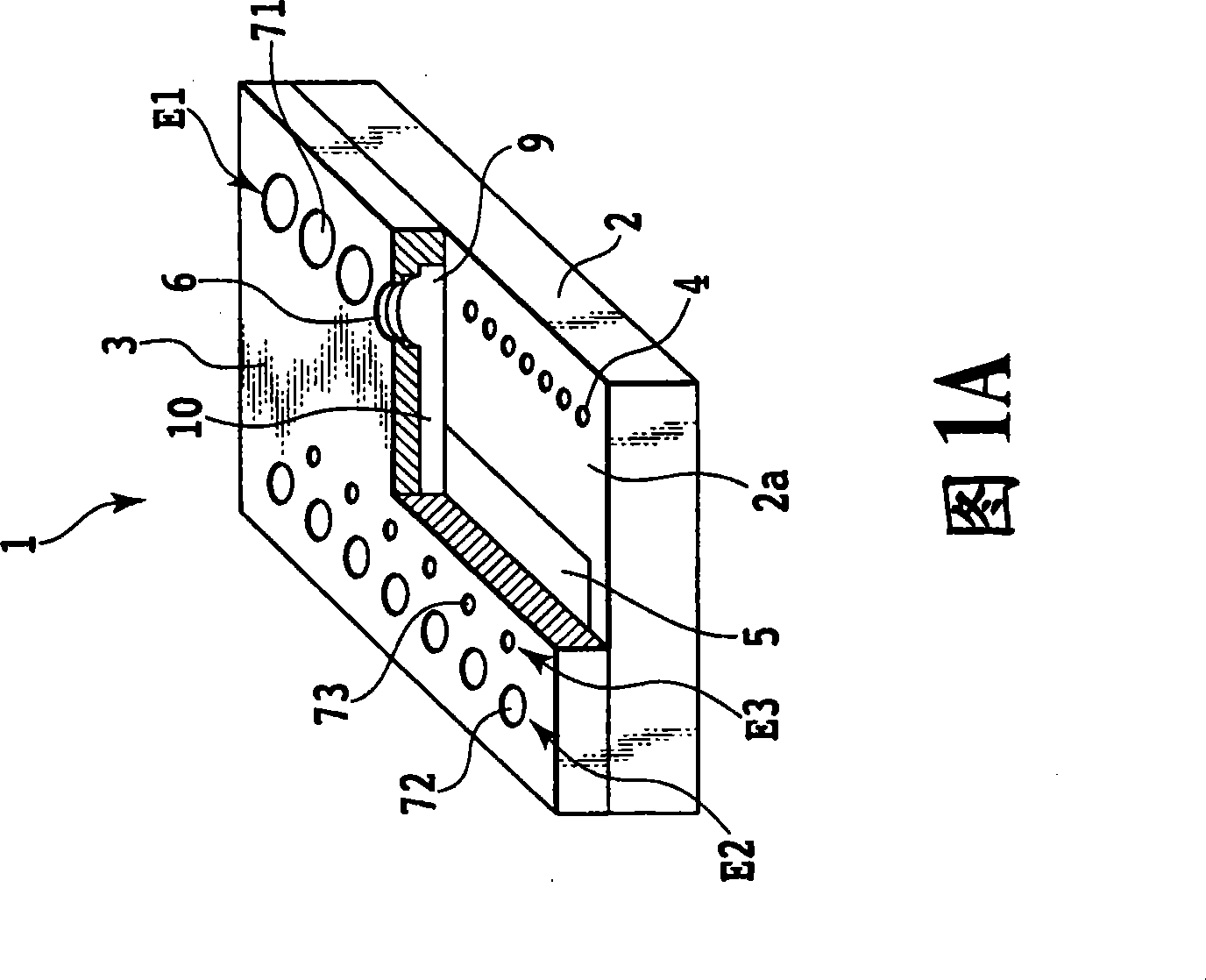

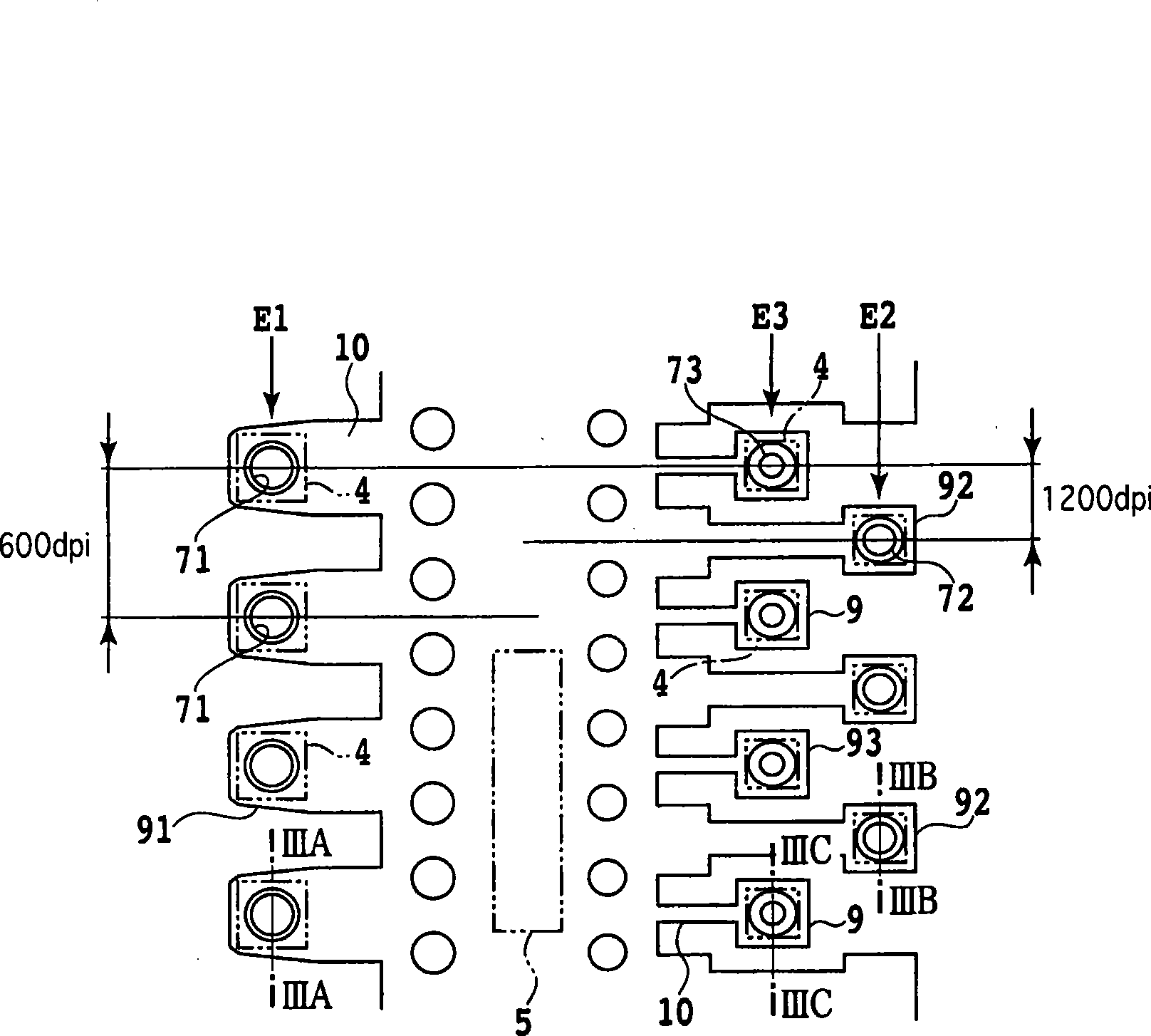

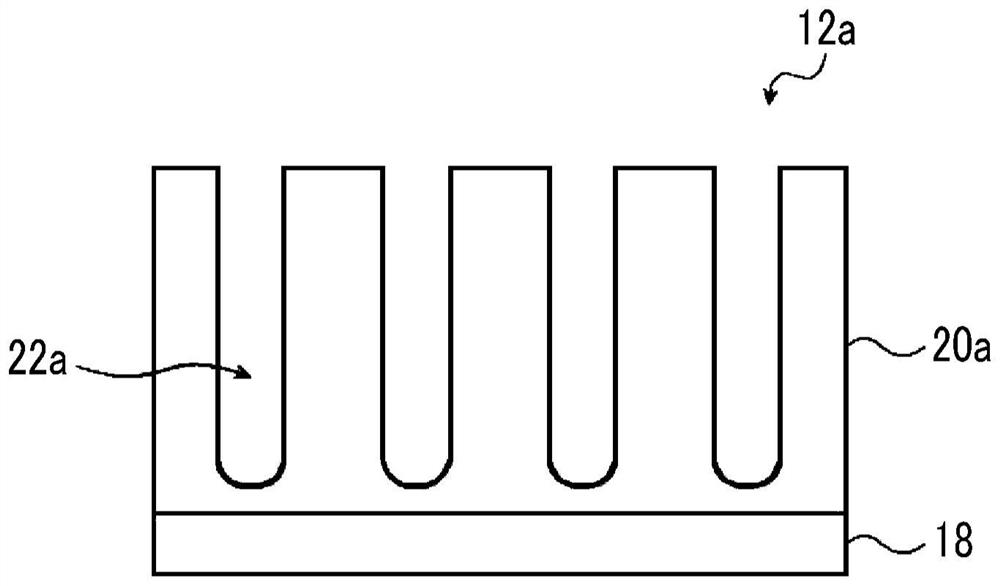

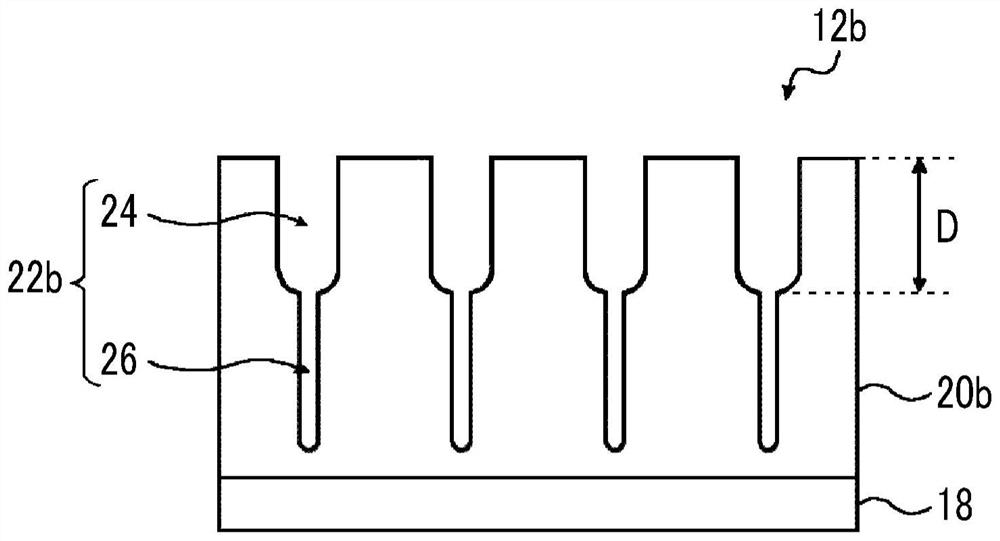

Ink jet print head

An object of the present invention is to provide an ink jet print head having plural types of nozzles arranged on the same substrate and through which ink droplets of different sizes are ejected, the ink jet print head exhibiting acceptable ejection performance regardless of the type of the nozzle. Thus, according to the present invention, each of the plural types of nozzles includes a bubbling chamber having an ejection energy generating element allowing an ink droplet to be ejected to a position located opposite an ejection port and an ejection port portion allowing the ejection port and the bubbling chamber to communicate with each other. Ratio of opening area of the ejection port portion at a position where the ejection port portion and the bubbling chamber communicate with each other, to the opening area of the ejection port is higher for the nozzle with a smaller ejection amount.

Owner:CANON KK

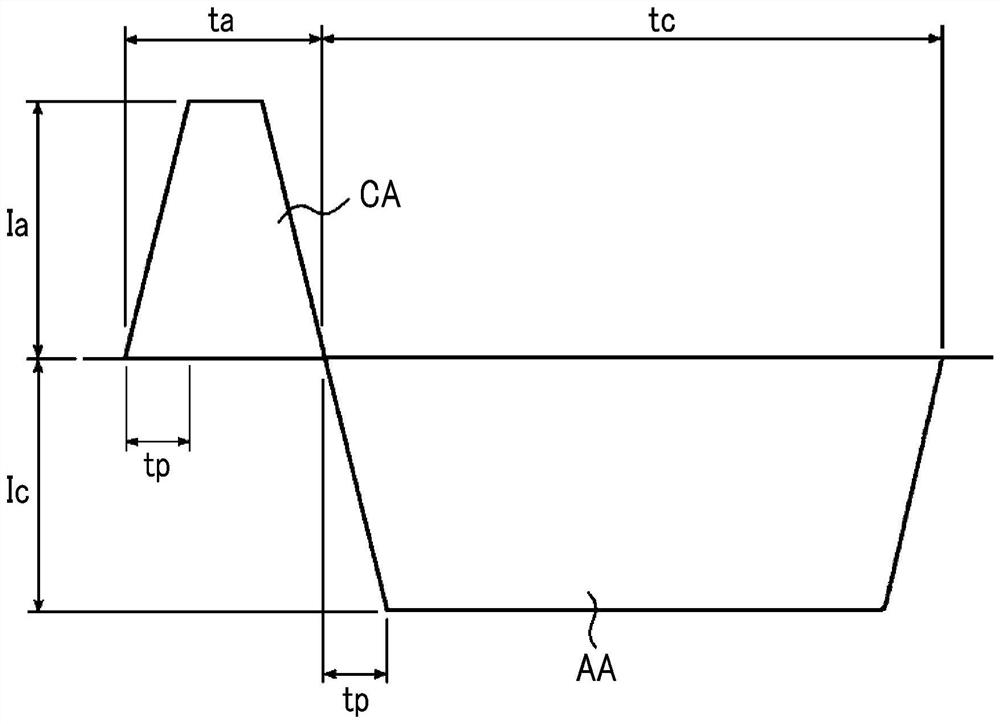

Non-alkali-developer violet laser photopolymerization type lithographic printing plate and developing method thereof

ActiveCN103879166AImprove the development effectGood inking effectPlate printingPhotosensitive material processingEngineeringPlanographic printing

A non-alkali-developer violet laser photopolymerization type lithographic printing plate comprises a support. A photopolymerization type photosensitive layer is arranged on the support, a waterborne protective layer is cling to the photopolymerization type photosensitive layer, and photosensitive ingredients include ethylene unsaturated group-containing compounds, single component or double-component or multi-component initiator systems, colouring agent and the like. Exposed areas of the violet laser photopolymerization type lithographic printing plate are cured, and unexposed areas are removed through non alkali developer in a developing manner. The PH value of the non-alkali developer ranges from 2 to 9.

Owner:LUCKY HUAGUANG GRAPHICS

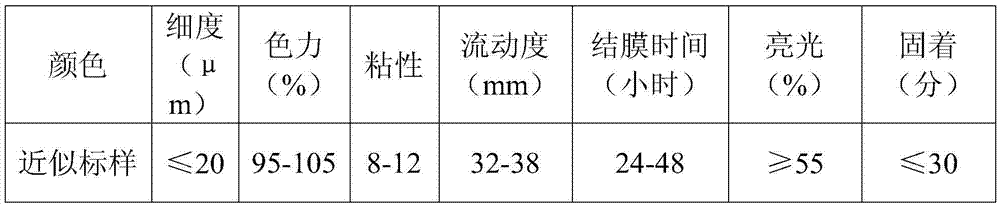

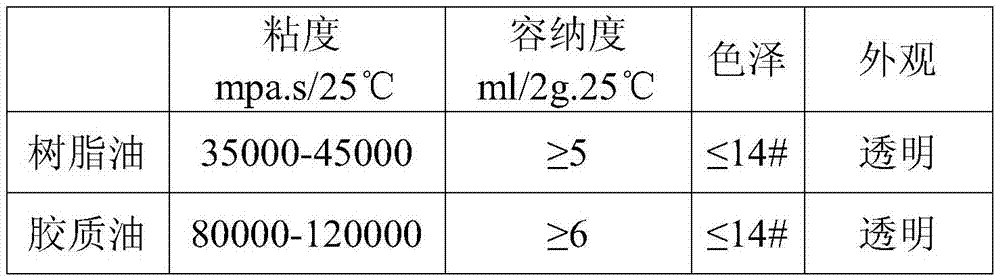

Environment-friendly black ink

The invention belongs to the technical field of ink printing and particularly relates to environment-friendly black ink which is characterized by comprising, by weight percentage, 30-34% of colloid oil, 25-39% of resin oil, 13-16% of soybean oil solvent, 22% of carbon black, 2% of Hualan pigment, 3% of reflex blue, 0.5-2% of auxiliaries and 0.8-2.5% of desiccant. The environment-friendly black ink has the advantages that the environment-friendly black ink is excellent in environmental friendliness, good in abrasion resistance and inking performance and free of toxicity, waste paper is deinked more easily, the printing amount is larger, and the environment-friendly black ink is deep, rich and bright in color and can be widely suitable for color printing.

Owner:吕建军

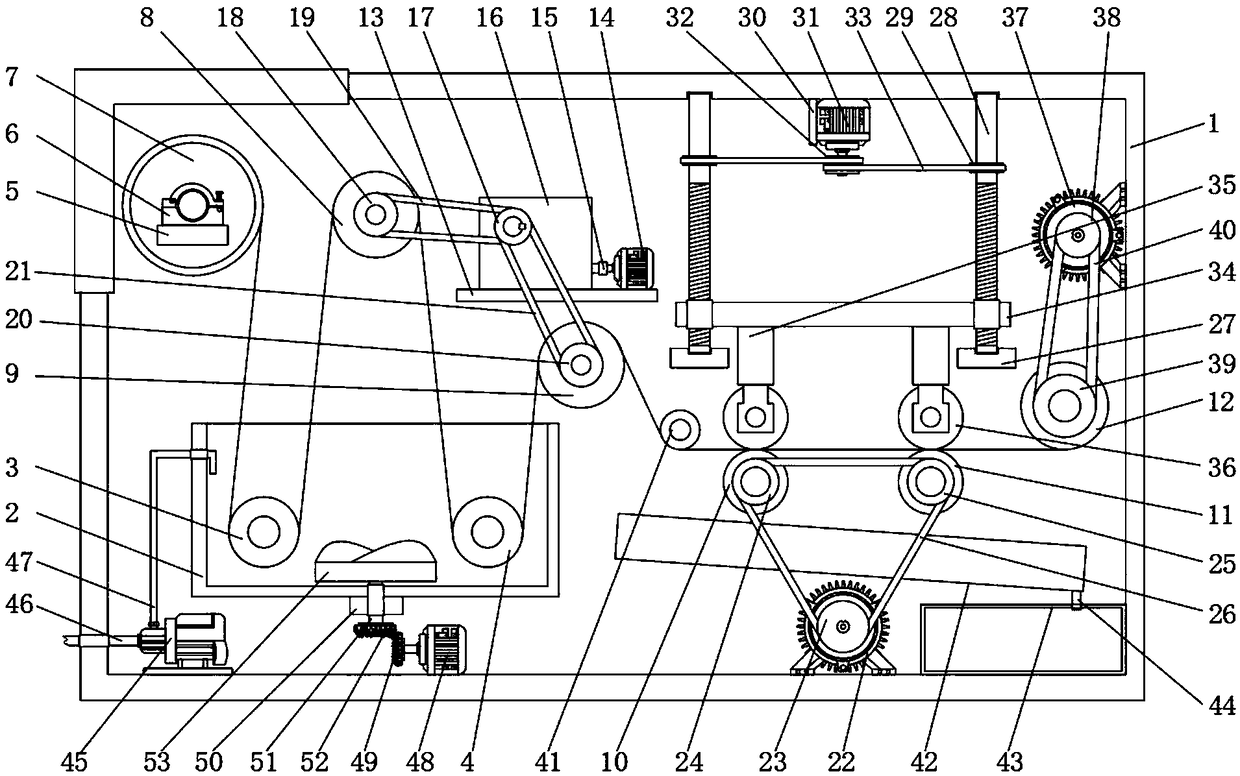

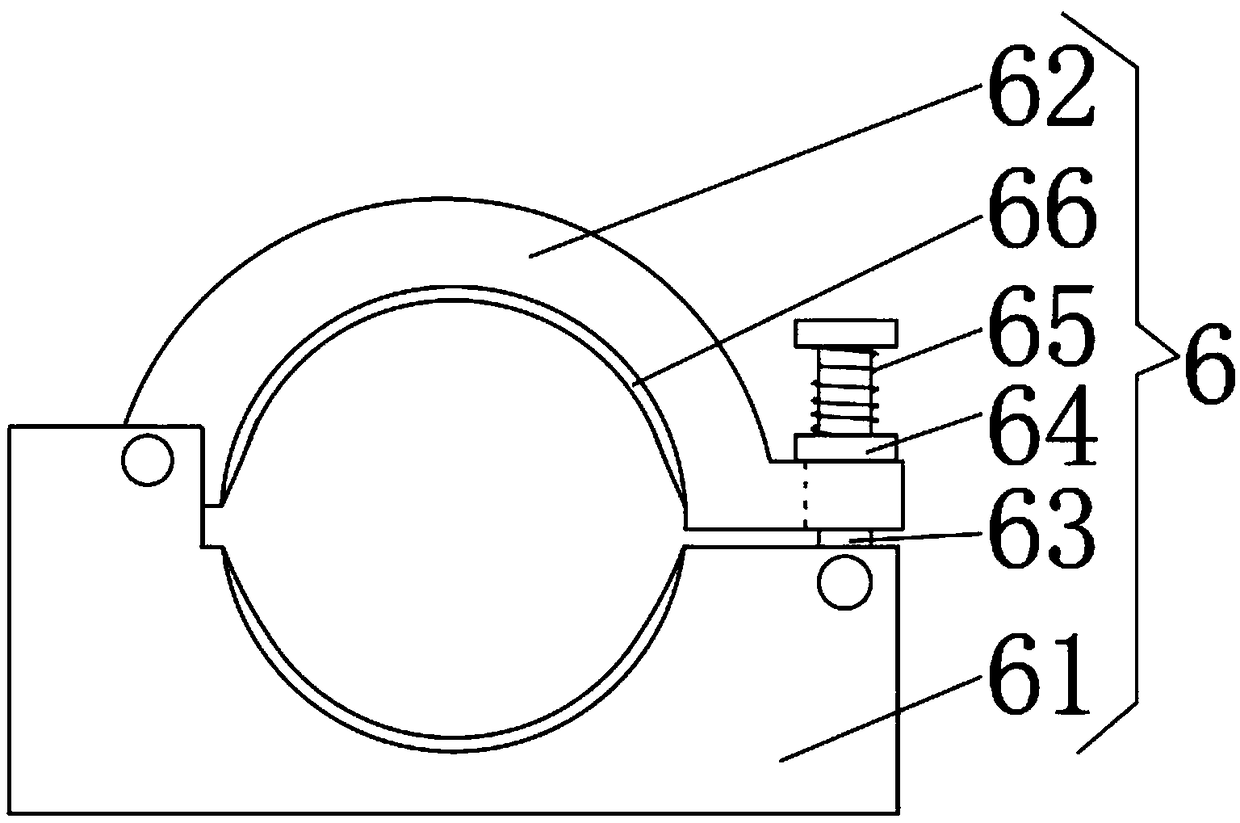

Inking device of colored tape

InactiveCN108569051AQuality improvementSolve the problem of not evenly invading the tape baseInk ribbonsEngineeringScrew thread

The invention discloses the inking device of a colored tape. The device comprises a box body. A dye box is fixedly connected between the two opposite sides of the inner wall of the box body. A first roller and a second roller are successively and rotatably connected between the two opposite sides of the inner wall of the dye box. A third roller, a fourth roller, a first active pressing roller, a second active pressing roller, and a colored tape material collecting roller are successively and rotatably connected between the two opposite sides of the inner wall of the box body. A rotation pedestal is fixedly connected between the two opposite sides of the inner wall of the box body. A screw rod is rotatably connected between the top of the rotation pedestal and the top of the inner wall of the box body. The surface of the screw rod is connected to a moving plate in a threaded connection mode. The bottom of the moving plate is rotatably connected to a driven pressing roller through a buffer device. A rotation roller is rotatably connected between the two opposite sides of the inner wall of the box body. The device relates to the colored tape technology field. By using the inking device of the colored tape, a problem that the ink can not invade a tape base uniformly during a colored tape inking process is solved, the uniform ink in the colored tape is guaranteed and the quality ofthe colored tape is increased.

Owner:湖州富丽华色带有限公司

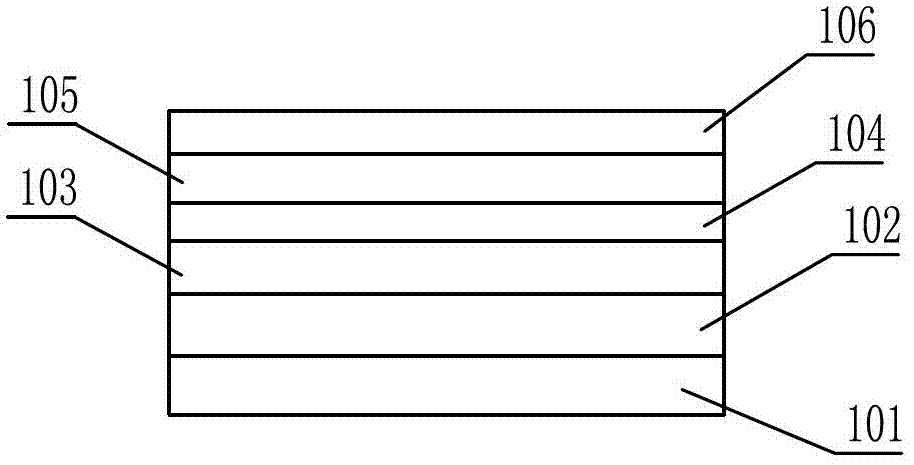

Flexographic printing original plate and water-developable laminate of photosensitive resin

InactiveUS20140216285A1Good inking effectImprovement factorPlate printingFoil printingLetterpress printingEngineering

The present invention provides a water-developable laminate of photosensitive resin for letterpress printing original plate by which finer pattern can be reproduced excellently upon making a plate and printing. The flexographic printing original plate being developable by water according to the present invention is characterized in that at least a support, a photosensitive resin layer containing 25% by mass or more of latex having gelation degree of 55% or more and an adhesion-preventing layer are successively laminated, and that the adhesion-preventing layer contains a cellulose derivative. The water-developable laminate of photosensitive resin according to the present invention is characterized in that at least a support, an adhesive layer, a photosensitive resin layer containing a water-soluble polymer compound and an adhesion-preventing layer are successively laminated, and that the adhesion-preventing layer contains a cellulose derivative.

Owner:TOYO TOYOBO CO LTD

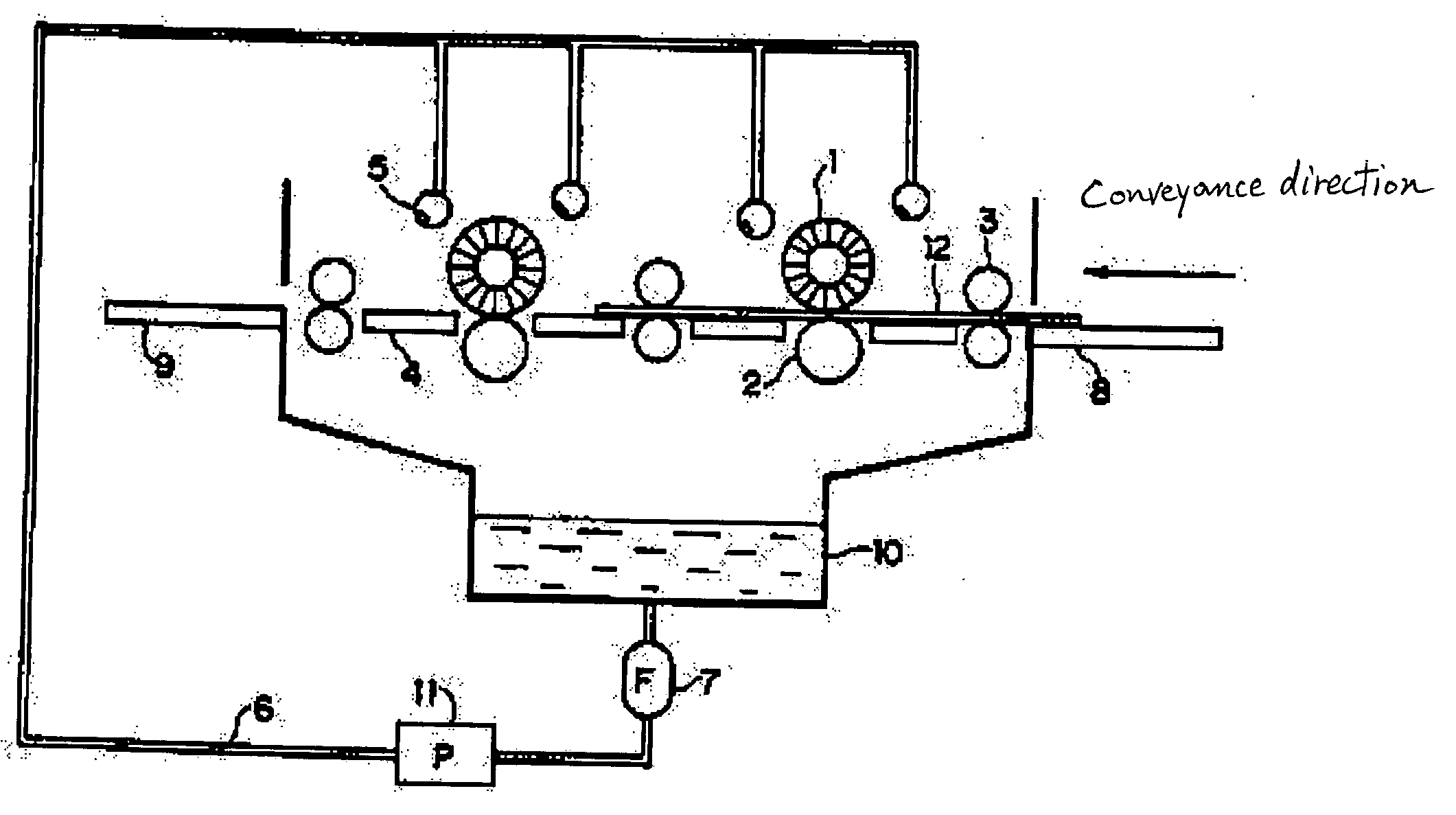

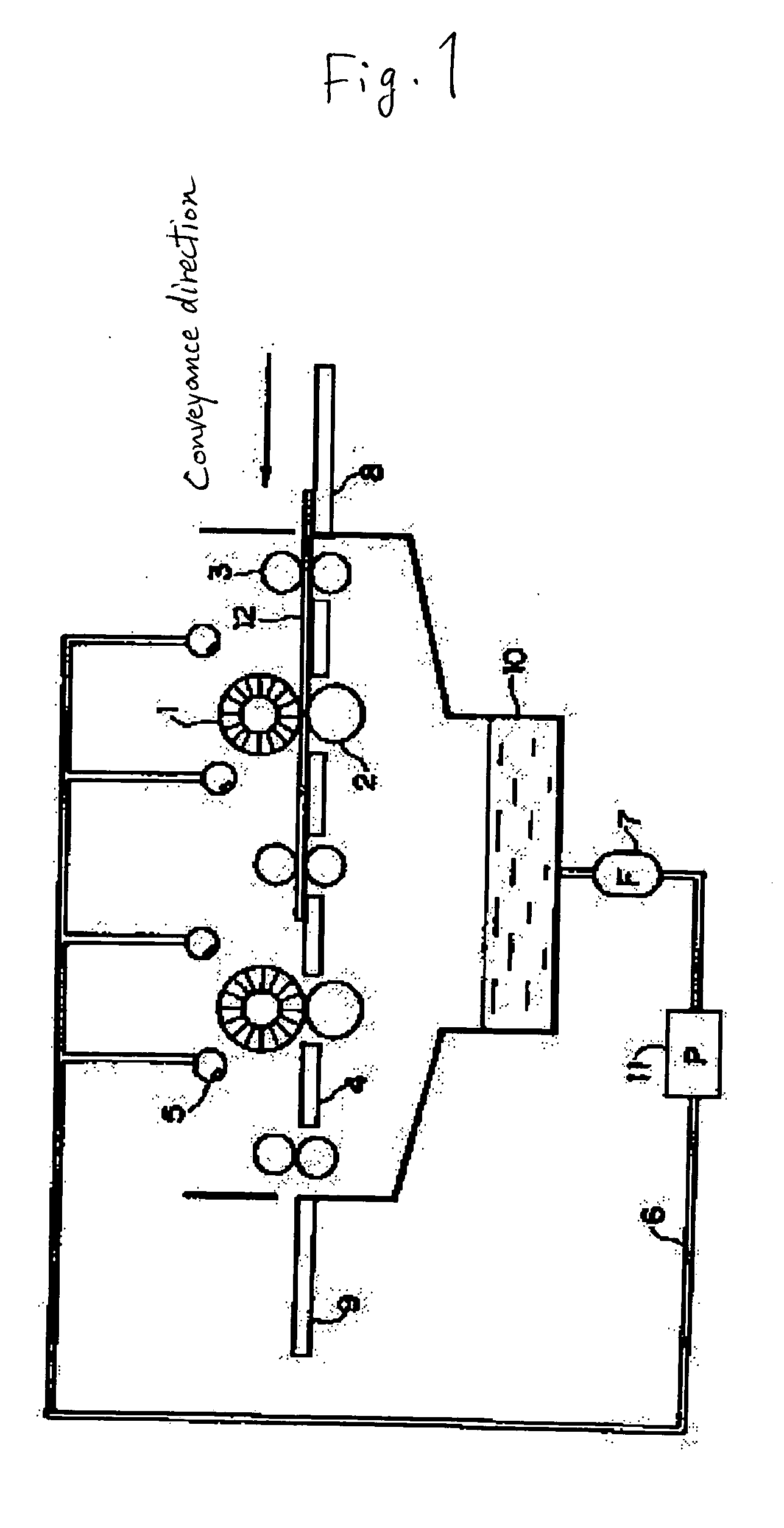

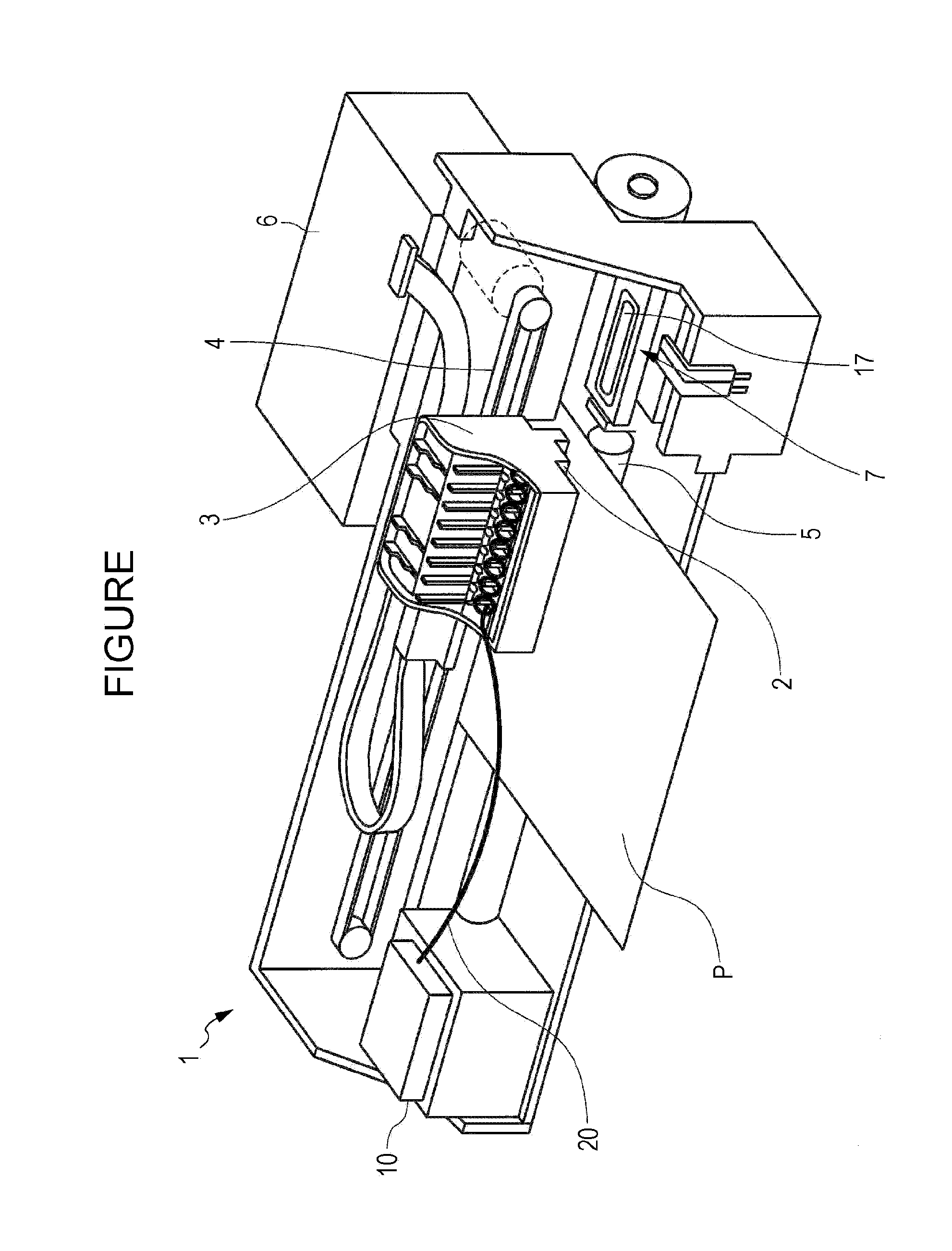

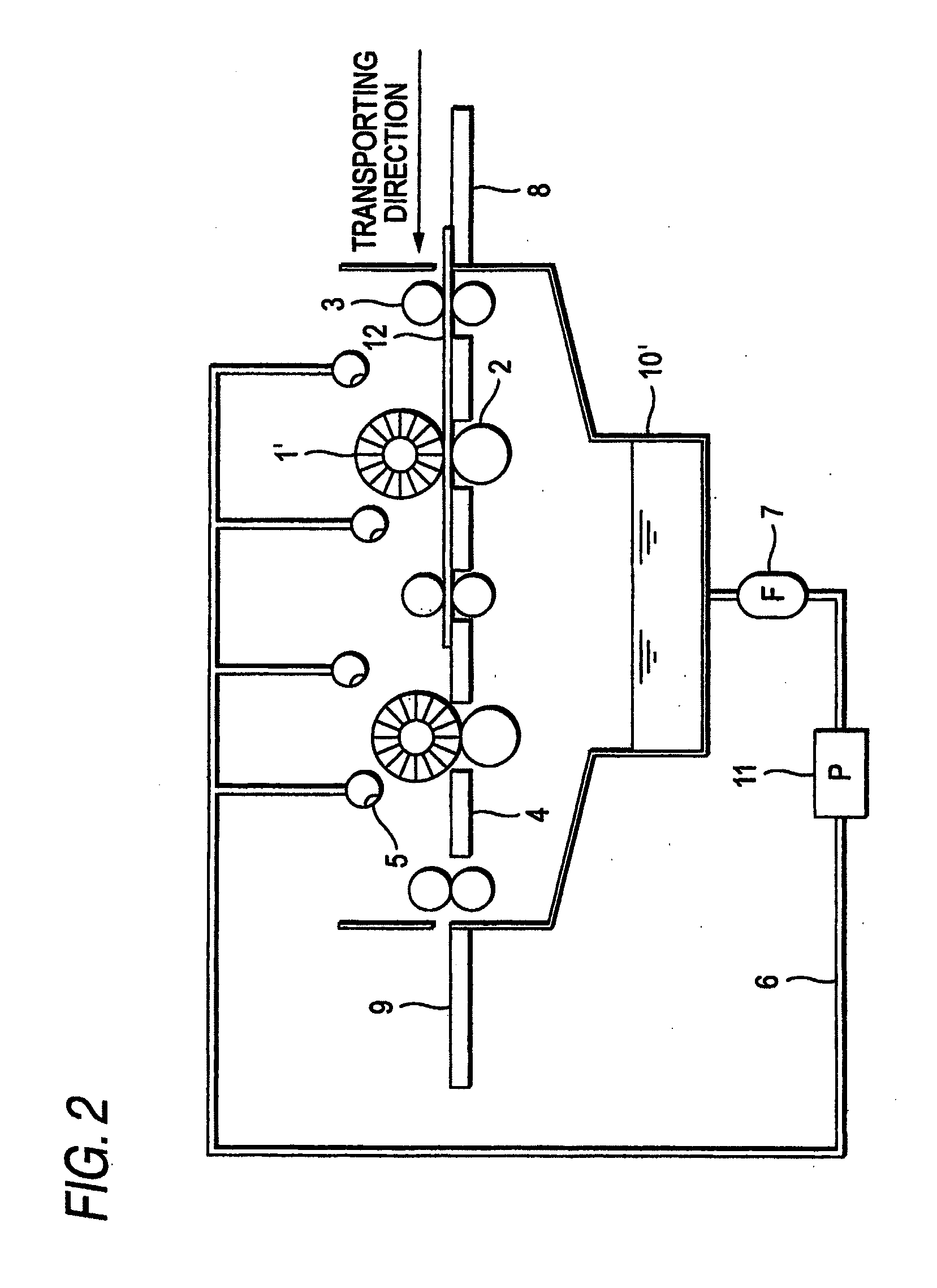

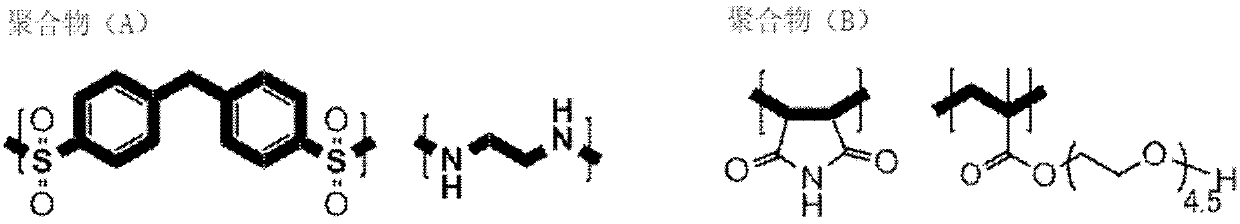

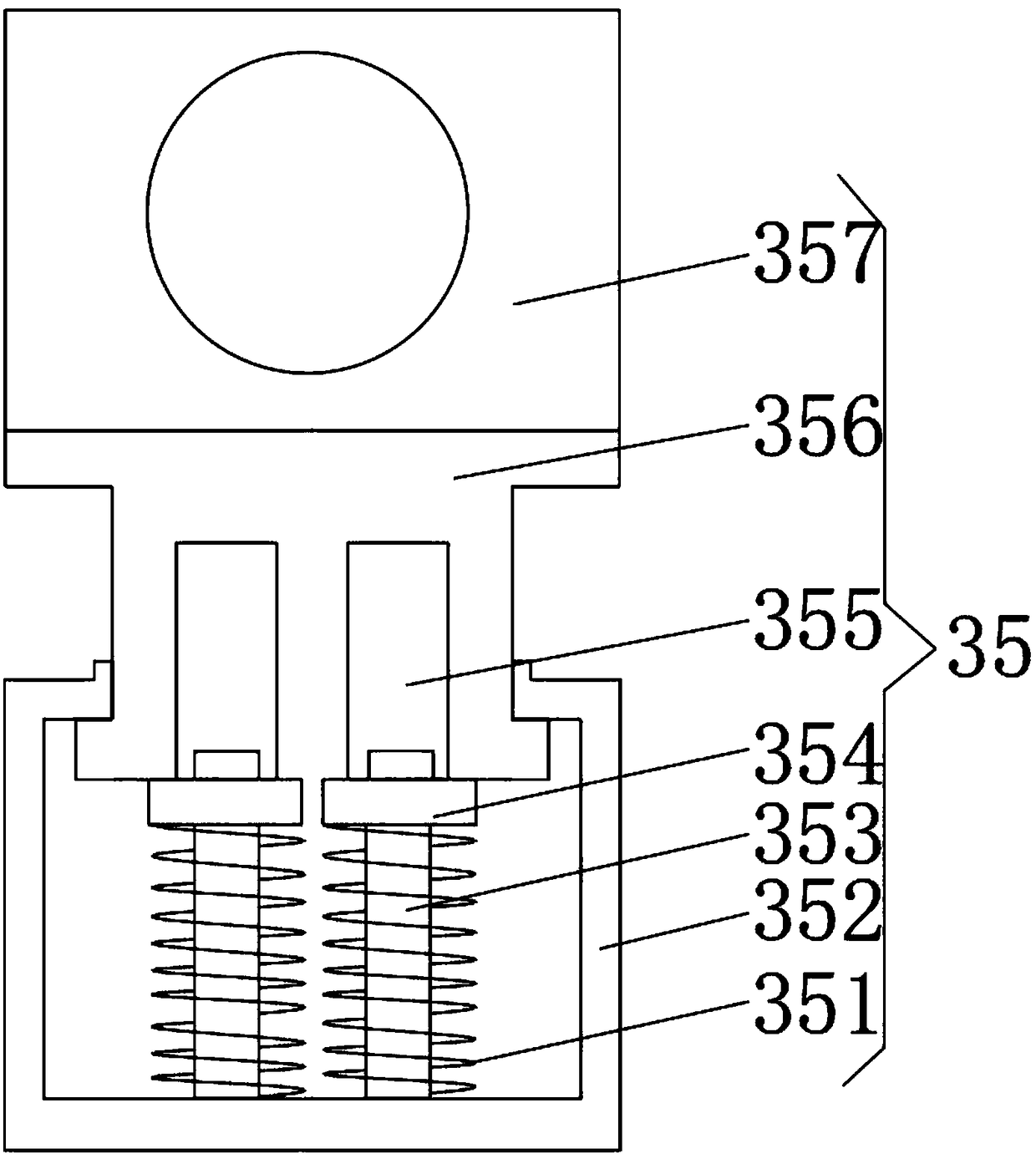

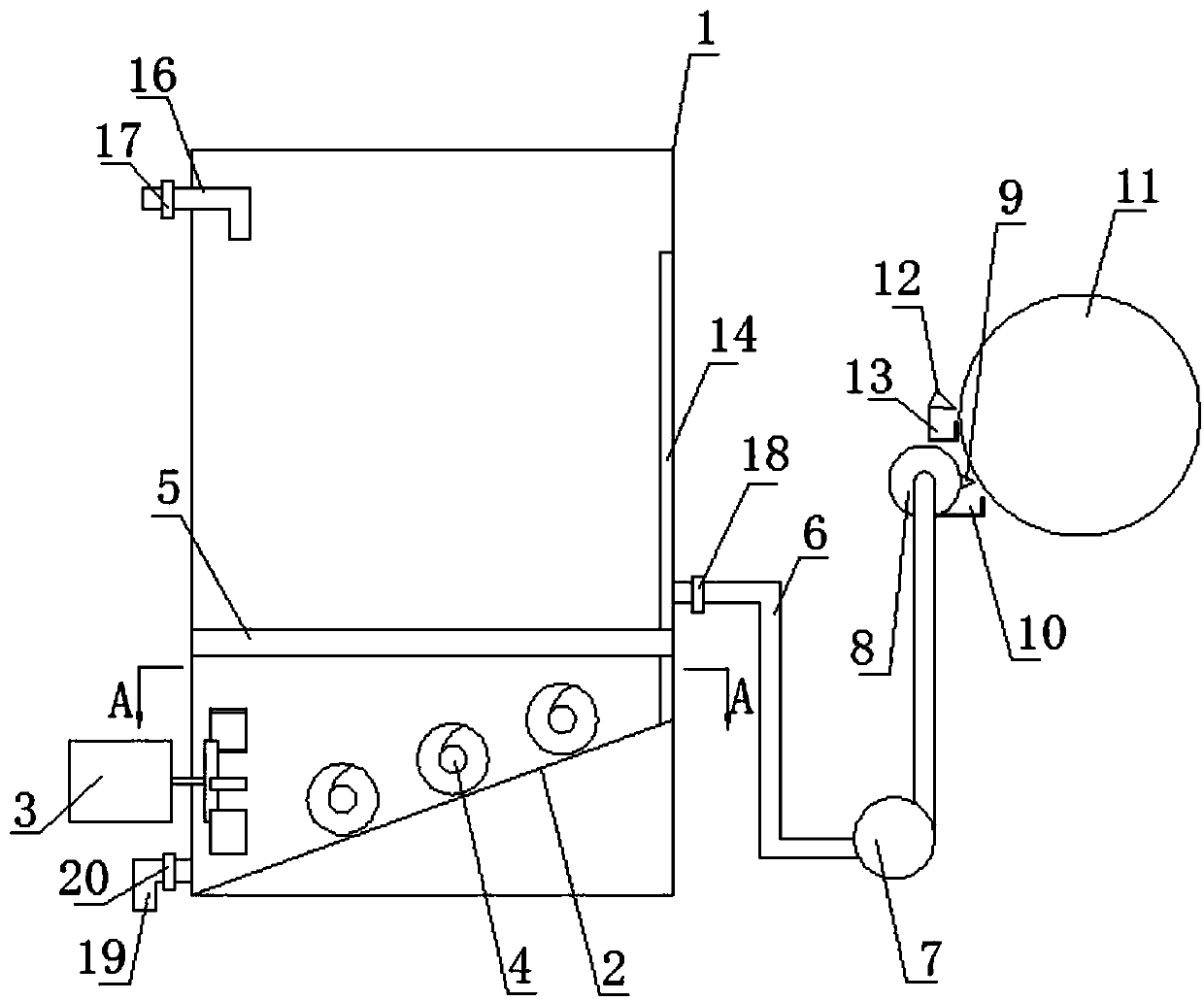

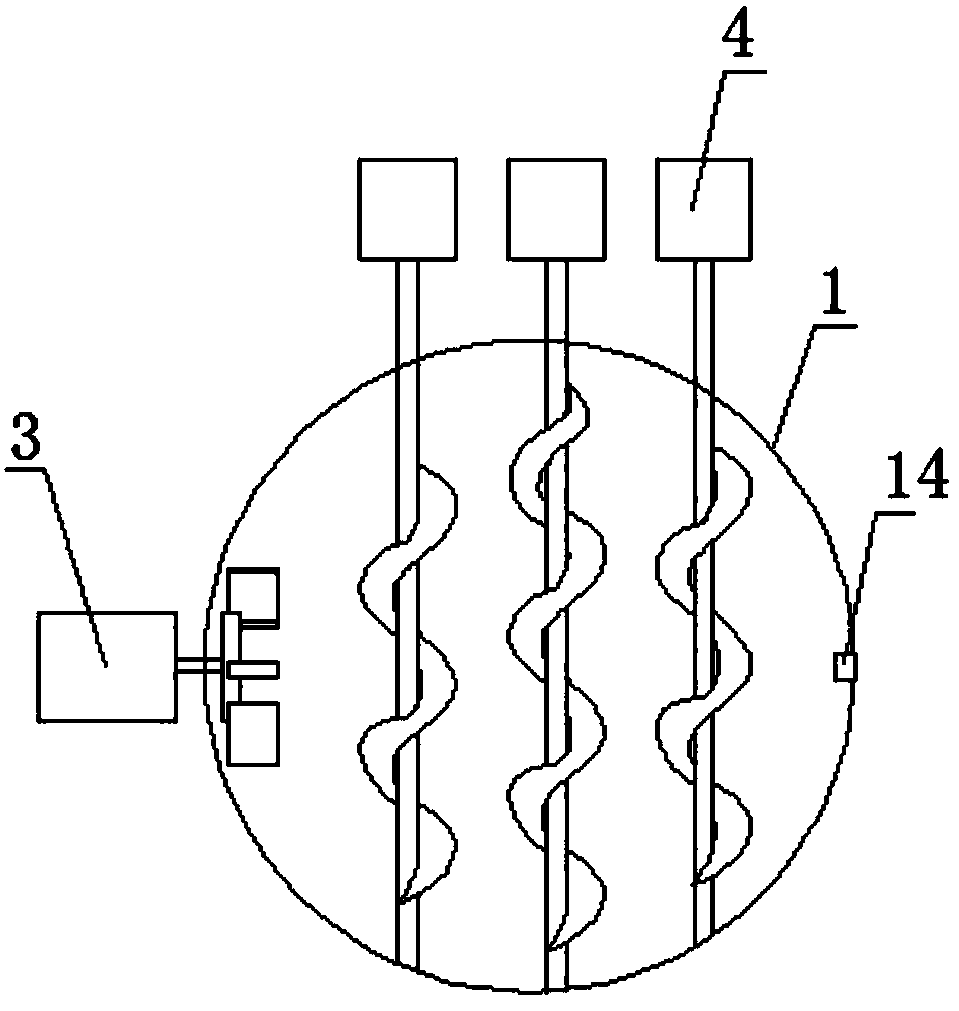

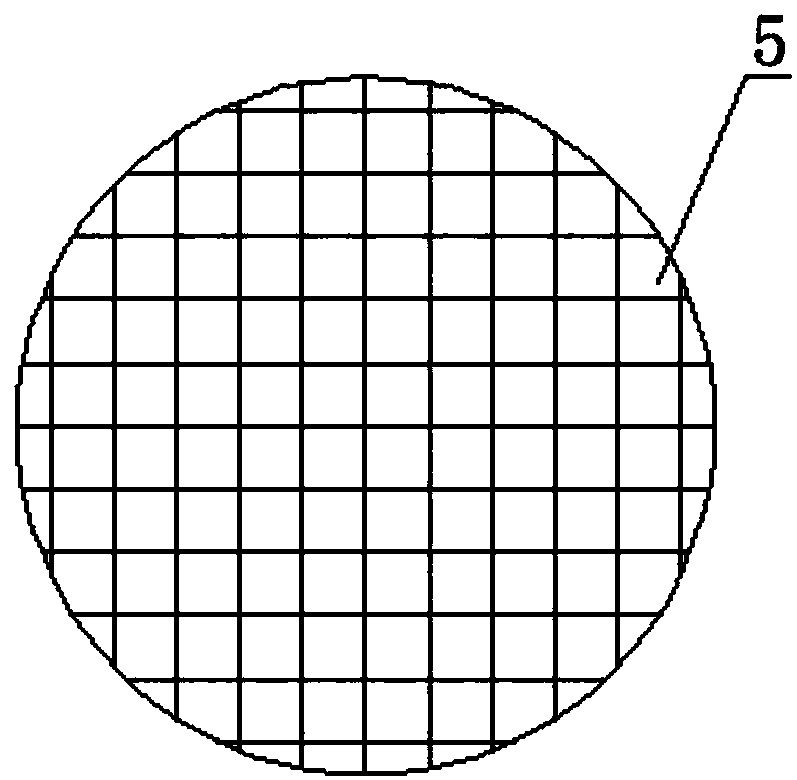

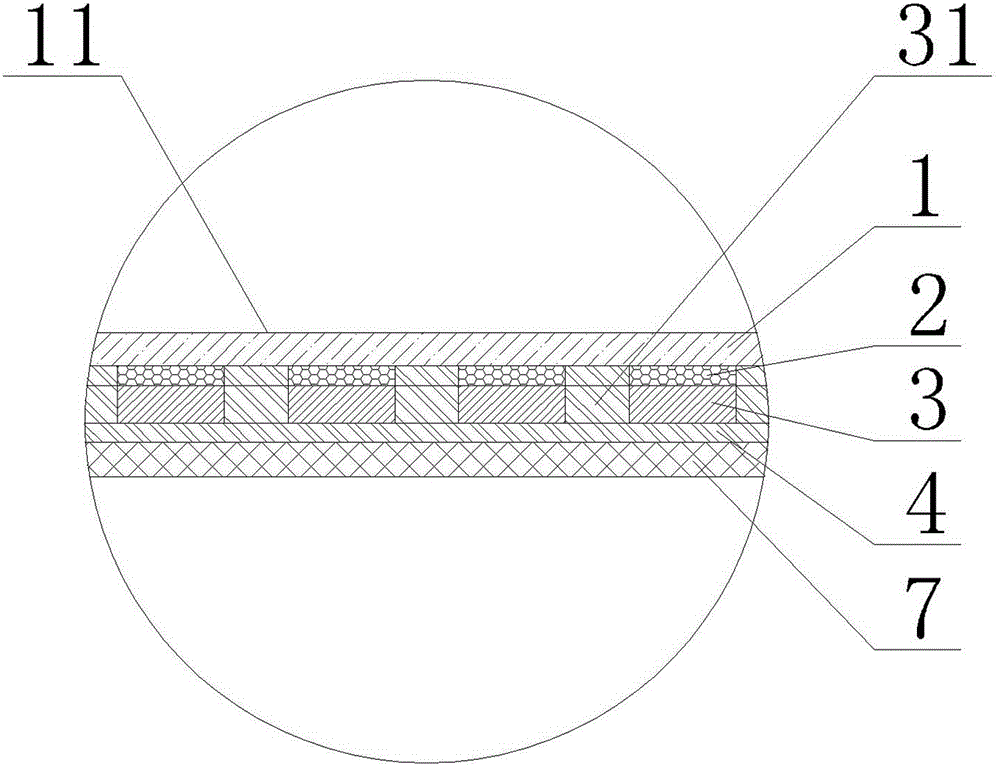

Inking uniform printing mechanism

InactiveCN107757116AGood mixing effectGood inking effectRotary stirring mixersPrinting press partsFeeding pumpsTurbine

The invention discloses a printing mechanism with uniform inking, which comprises an ink pool (1), a bottom end of the ink pool (1) is connected with an inclined partition plate (2); the bottom end of the ink pool (1) is connected with a turbine Type agitator (3), the turbine type agitator (3) is located on the inclined downward side of the partition plate (2); A grid plate (5) is arranged above the ribbon stirrer (4); a feeding pipe (6) is connected to one side of the ink pool (1), and the feeding pipe (6) is connected by a feeding pump (7). There is an inkjet tube (8); the inkjet tube (8) is provided with a plurality of inkjet heads (9), and a number of collection grooves (10) are arranged below the plurality of inkjet heads (9); One side of the head (9) is provided with an ink roller (11), and one side of the ink form roller (11) is provided with a scraper (12). The invention not only has good stirring effect, but also has the advantages of good inking effect and convenient maintenance.

Owner:HUZHOU JIANING PRINTING

Environment-friendly plant oil-based ink used for offset printing

The invention belongs to the technical field of ink printing and particularly relates to environment-friendly plant oil-based ink used for offset printing. The ink is characterized by comprising the following ingredients in parts by weight: 30-34 parts of gummy oil, 25-39 parts of resin oil, 13-16 parts of a soya-bean oil solvent, 13-27 parts of color pigments, 0.5-2 parts of an additive and 0.8-2.5 parts of a drying agent. The ink provided by the invention has the beneficial effects that the ink is excellent in environmental friendliness, better in abrasion resistance and good in inking property, and has no toxicity, so that waste-paper deinking is easier, the printed volume is large, and the color is deep, abundant and bright. Therefore, the ink can be widely applied to color printing.

Owner:TIANJIN ANGEL CHEM GRP

Environment-friendly paper and manufacturing process thereof

InactiveCN108277692ALow costPreparation process specificationNon-fibrous pulp additionCoatings with pigmentsPulp and paper industryChemical resistance

The invention provides environment-friendly paper and a manufacturing process thereof. The environment-friendly paper is prepared from a base paper layer, wherein the base paper layer is prepared fromthe following components: 68 to 75 parts by weight of colliery powder, 15 to 20 parts by weight of PE and 0.5 to 2 parts by weight of aids, wherein the PE is prepared from one or two of LDPE or MDPE.The environment-friendly paper and the manufacturing process thereof, disclosed by the invention, have the advantages of minimal and uniformly-distributed surface micro-pores, good inking performance, good printing effect, capability of reproducing the bright effect of a printing plate, as well as outstanding water resistance, oil resistance and chemical resistance.

Owner:ZHEJIANG NORMAL UNIVERSITY

A kind of manufacturing method of two-way see-through film

ActiveCN103481587BQuality improvementStrong metal feelingLamination ancillary operationsLaminationOptoelectronicsPrinting ink

The invention discloses a double-direction perspective film and a manufacturing method thereof. The double-direction perspective film successively comprises a transparent film, an adhesive layer, a metal layer and a pasting layer, wherein a photic zone is distributed on the metal layer, and the photic zone penetrates through the adhesive layer. The double-direction perspective film and the manufacturing method thereof provided by the invention have the advantages that a structure that the transparent film and the metal layer are mutually matched is adopted, the disadvantage of printing ink is fully made up through the strong covering power and color rendering of the metal layer, a problem of printing oil transfer after long-term storage is avoided as the metal layer has stable quality, and a picture has the strong metal feel due to the metal layer; meanwhile, the photic zone arranged on the metal layer can guarantee that the picture is distinctly showed, transmitting and perspective effects are met, an ink surface of the photic zone is also inked and colored, the picture printed on the front side is distinct, the picture of a mirror image is also seen from the reverse side, and the metal layer can realize a background layer with different colors on the two surfaces, which can not be realized by the printing ink; the double-direction perspective film and the manufacturing method thereof provided by the invention have the advantages that the structure is simple, the manufacture is convenient, and the pasting is convenient and firm.

Owner:广州市杰诚科技有限公司

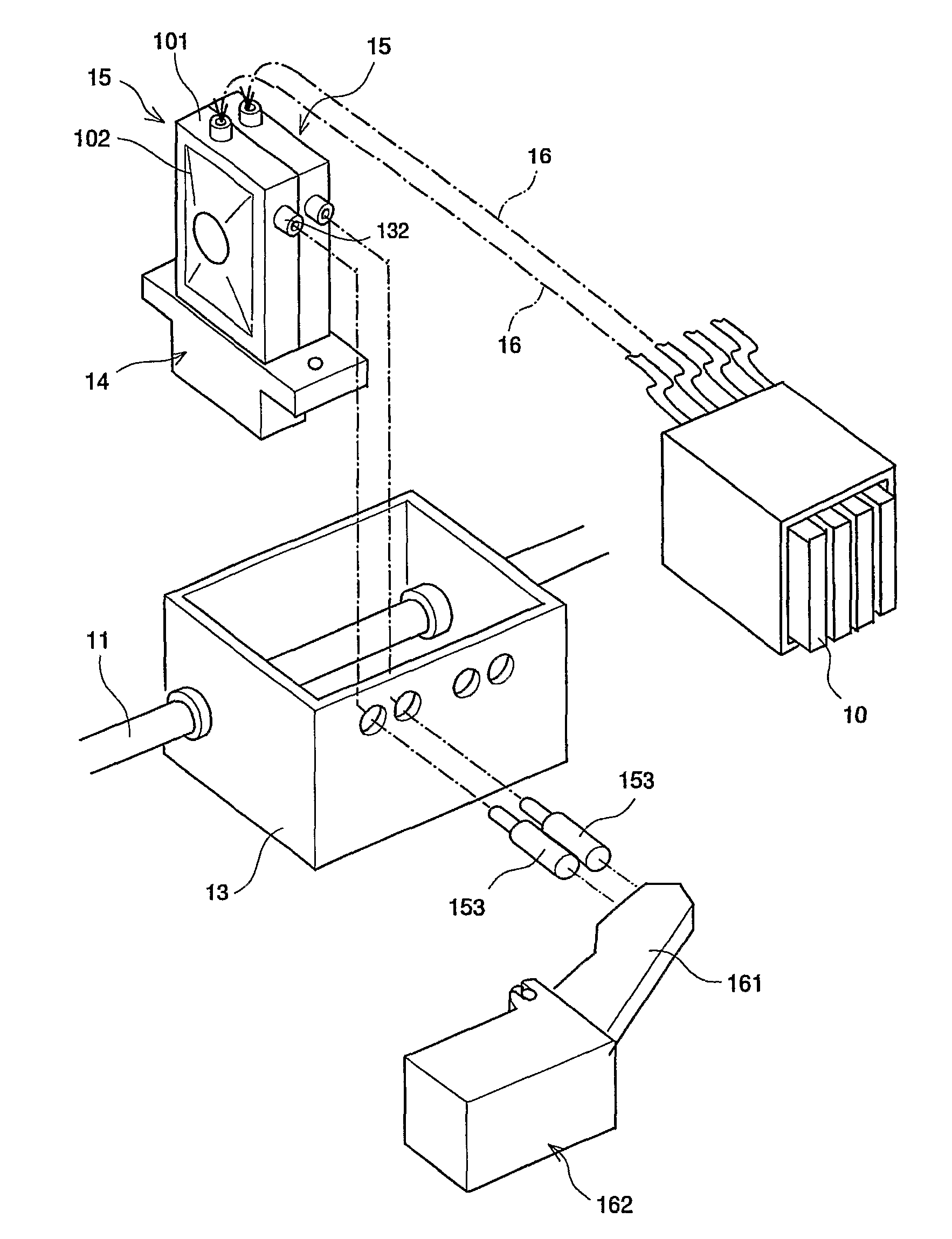

Original plate for lithographic printing plate, lithographic printing plate manufacturing method, and lithographic printing method

Provided is an original plate for a lithographic printing plate that has an aluminum support and an image recording layer on the aluminum support, wherein the image recording layer includes an infrared absorber, a polymerization initiator, a polymerizable compound, and an addition polymerization type resin having a dispersible group, and where the capacitance Cp of the original plate for a lithographic printing plate is set as Cp(t) / Cp(20 seconds) = 0.95, t < 12 seconds is satisfied, or the capacitance Cp of the original plate for a lithographic printing plate satisfies Cp(0 seconds) > 400 nF, and also provided are a method for producing a lithographic printing plate and a lithographic printing method using the original plate for a lithographic printing plate. The capacitance Cp of the original plate for a lithographic printing plate is measured by bringing at least the measurement portion of the image recording layer into contact with a 2% by mass sodium chloride aqueous solution at 25 DEG C.

Owner:FUJIFILM CORP

Platemaking method for lithographic printing plate precursor and planographic printing method

InactiveUS20090293748A1Excellent developabilityGood inking effectDuplicating/marking methodsPhotosensitive material processingWater insolubleImage recording

A platemaking method for a lithographic printing plate, comprises: imagewise exposing a lithographic printing plate precursor comprising: a hydrophilic substrate; and a negative image recording layer containing a water-insoluble polymer; and removing a non-exposed area of the image recording layer with an aqueous solution, wherein a temperature of the aqueous solution is higher than a glass transition temperature (Tg) of the water-insoluble polymer.

Owner:MITSUMOTO TOMOYOSHI +1

Non-alkaline developing violet laser photopolymerizable lithographic printing plate and its developing method

ActiveCN103879166BImprove the development effectGood inking effectPlate printingPhotosensitive material processingPhotopolymerEngineering

A non-alkali-developer violet laser photopolymerization type lithographic printing plate comprises a support. A photopolymerization type photosensitive layer is arranged on the support, a waterborne protective layer is cling to the photopolymerization type photosensitive layer, and photosensitive ingredients include ethylene unsaturated group-containing compounds, single component or double-component or multi-component initiator systems, colouring agent and the like. Exposed areas of the violet laser photopolymerization type lithographic printing plate are cured, and unexposed areas are removed through non alkali developer in a developing manner. The PH value of the non-alkali developer ranges from 2 to 9.

Owner:LUCKY HUAGUANG GRAPHICS

Lithographic printing plate precursor and process for producing lithographic printing plate

InactiveCN103917918AReduce generationHigh print resistancePhotosensitive material processingLithographyAlkaline waterHydrogen atom

Provided is a lithographic printing plate precursor which shows satisfactory developability by a developing solution having a pH of 12 or less and which comes to have high printing durability and satisfactory scratch resistance and have improved ink receptibility. The lithographic printing plate precursor is a positive type precursor that comprises a base and, formed on the base, an image-forming layer comprising a resin which is insoluble in water and is soluble or dispersible in alkaline aqueous solutions, and that is characterized in that the image-forming layer comprises a lower layer and an upper layer and the resin in the lower layer and / or in the upper layer comprises a polyurethane including a unit which contains a substituent having an acidic hydrogen atom and a unit represented by general formula (I). (In the formula, Rf is an alkyl or polyether group in which at least 50% of the hydrogen atoms have been fluorinated, R1 is a hydrogen atom or an (un)substituted alkyl group, m is 0 or is 1-10, n is 1-30, and x is 1-4.)

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com