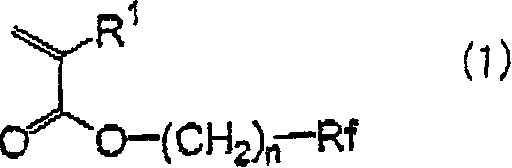

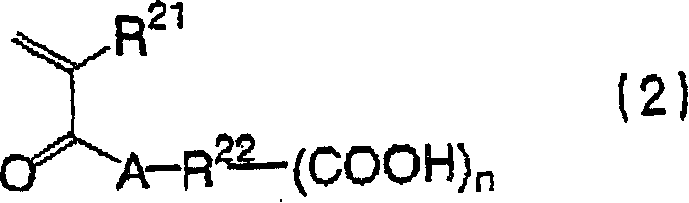

Planographic printing plate precursor

A technology of lithographic printing plate and original plate, which is applied in the field of positive-working photosensitive lithographic printing plate original plate, which can solve the problems of developing scum, poor inking performance, and reduced sensitivity, etc., and achieve the effect of excellent developing property and good image forming property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0219] [Preparation of lithographic printing plate precursor]

[0220] The method for preparing a planographic printing plate precursor includes dissolving the components of the coating solution of the desired layer, such as the components of the recording layer coating solution and the protective layer coating solution of the present invention, in a solvent, and coating the solution On a suitable carrier.

[0221] The recording layer may have a single-layer structure or a multilayer structure.

[0222] When the lithographic printing plate precursor recording layer of the present invention adopts a multilayer structure composed of a plurality of layers having different composition components, a configuration may be adopted in which, for example, the recording layer has a lower layer and an upper layer, and the lower layer contains an alkali-soluble resin The upper layer contains an alkali-soluble resin and a compound that interacts with the alkali-soluble resin to reduce the solub...

specific Embodiment approach

[0314] Hereinafter, the present invention will be explained by way of examples, but these examples do not limit the scope of the present invention.

[0315] (Preparation of carrier)

[0316] Using a JIS-A-1050 aluminum plate with a thickness of 0.3 mm, the aluminum plate is processed through a combination of the following steps to prepare carriers A, B, C, and D.

[0317] (a) Mechanical surface roughening treatment

[0318] While supplying a suspension containing a polishing agent (silica sand) with a specific gravity of 1.12 and water as a polishing slurry on the surface of each aluminum plate, mechanical surface roughening treatment was performed by a rotating roller-type nylon brush. The average particle size of the polishing agent is 8 μm, and the maximum particle size is 50 μm. The material of the nylon brush is 6-10 nylon, and the bristle length and bristle diameter are 45mm and 0.3mm respectively. Nylon brushes are manufactured by densely inserting nylon bristles into holes...

Embodiment 1~10

[0360] [Examples 1 to 10, Comparative Examples 1 to 6]

[0361] The first layer (lower layer) coating solution having the following composition was coated on the obtained support with a wire rod, and dried in a drying oven at 150°C for 60 seconds to adjust the coating amount to 0.85g / m 2 .

[0362] The second layer (upper layer) coating solution having the following composition was coated on the obtained support with the lower layer using a wire rod. After coating, dry in a drying oven at 145°C for 70 seconds to adjust the total coating amount to 1.15g / m 2 , The positive pattern lithographic printing plate precursors of Examples 1 to 10 and Comparative Examples 1 to 6 were prepared.

[0363]

[0364] ●Copolymer 1 (synthesized as described below) 2.133g

[0365] ●Cyanine dye A (lower structure) 0.098 g

[0366] ●2-Mercapto-5-methylthio-1,3,4-thiadiazole 0.030g

[0367] ●cis-Δ 4 -Tetrahydrophthalic anhydride 0.100g

[0368] ●4,4’-sulfonyl diphenol 0.090g

[0369] ●P-toluenesulfoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com