Patents

Literature

34results about How to "Accurately met" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

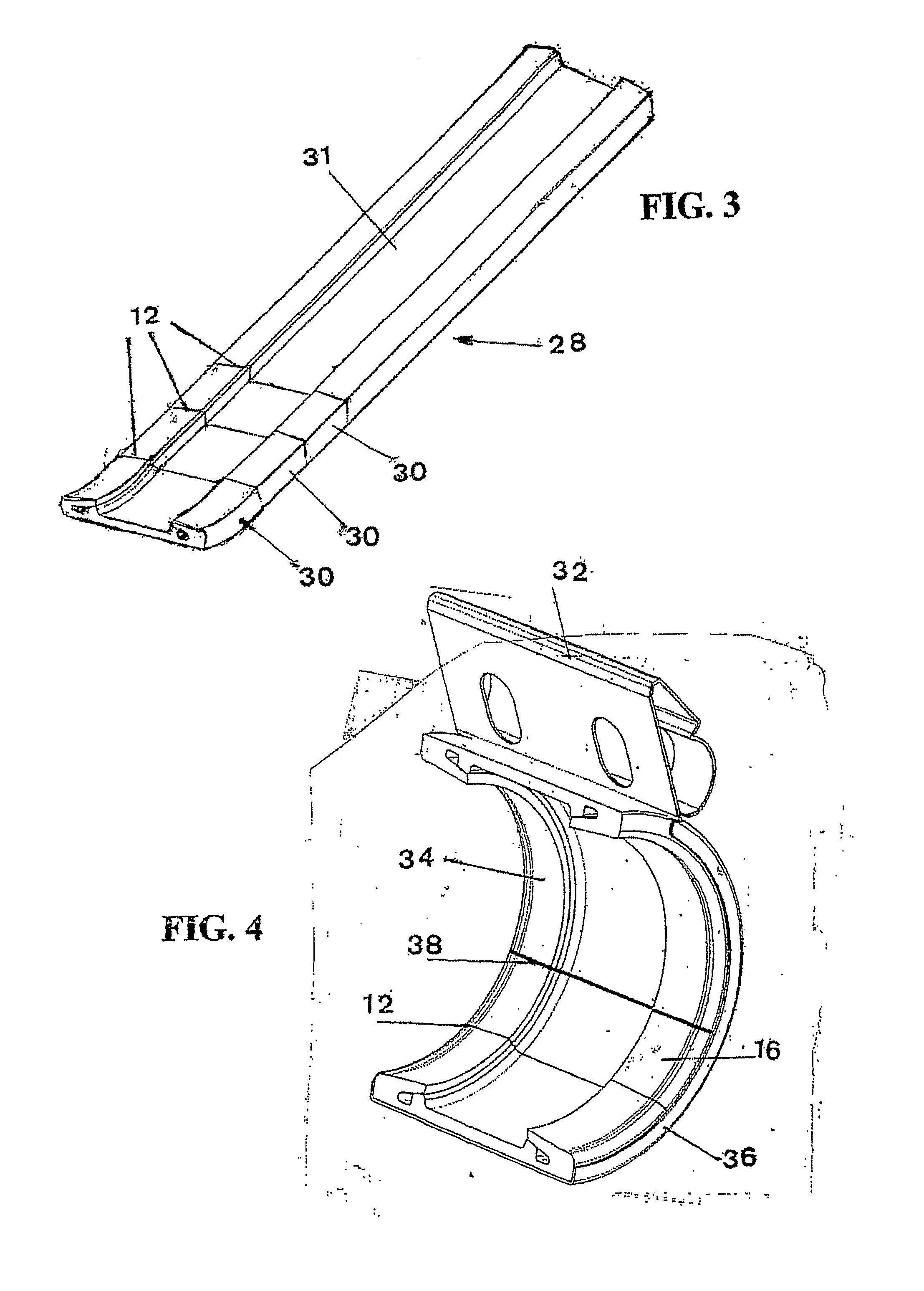

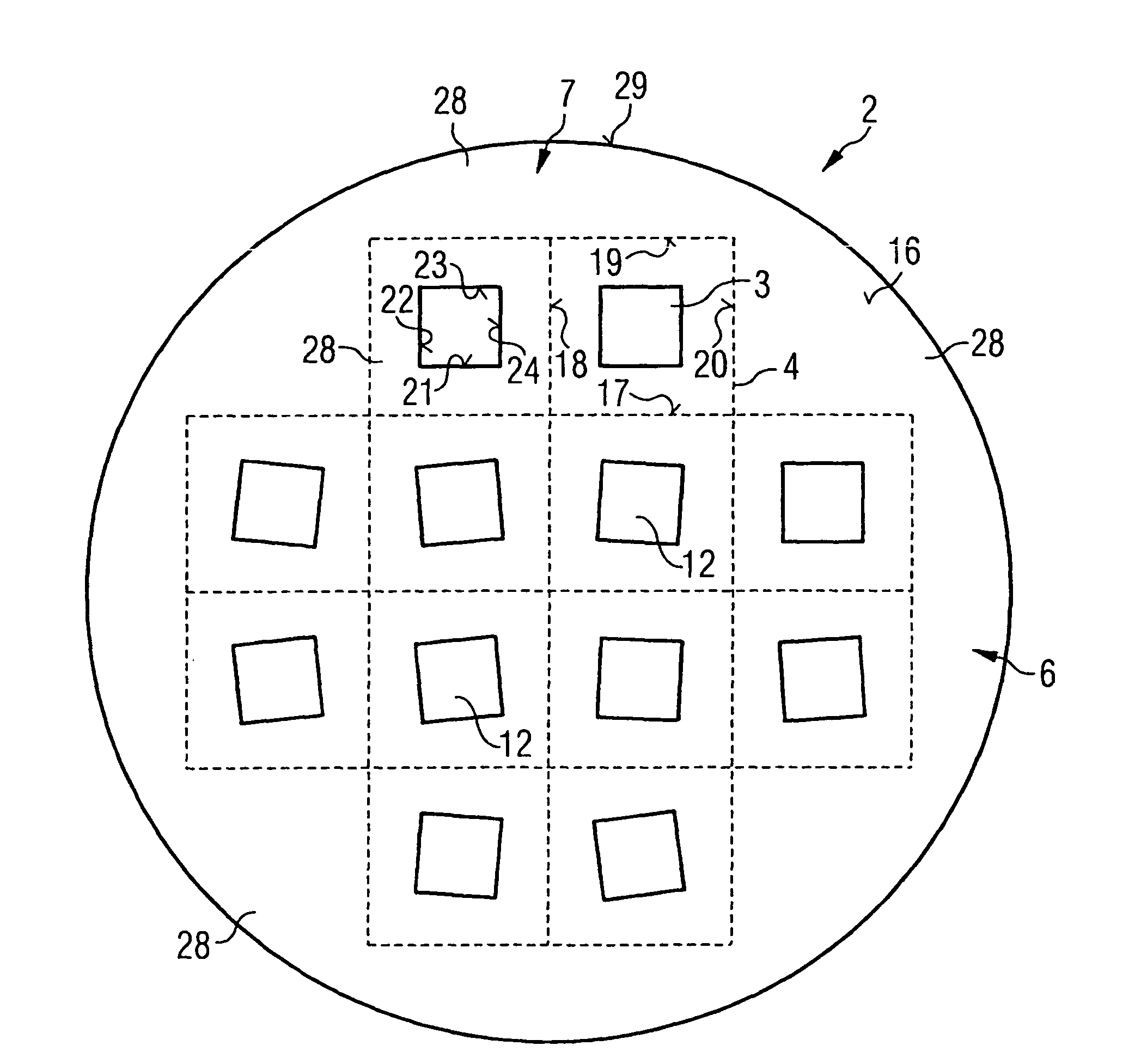

Heart valve repair apparatus and methods

InactiveUS20060149368A1More reliable and permanentEasy to implementAnnuloplasty ringsHeart valve repairBiomedical engineering

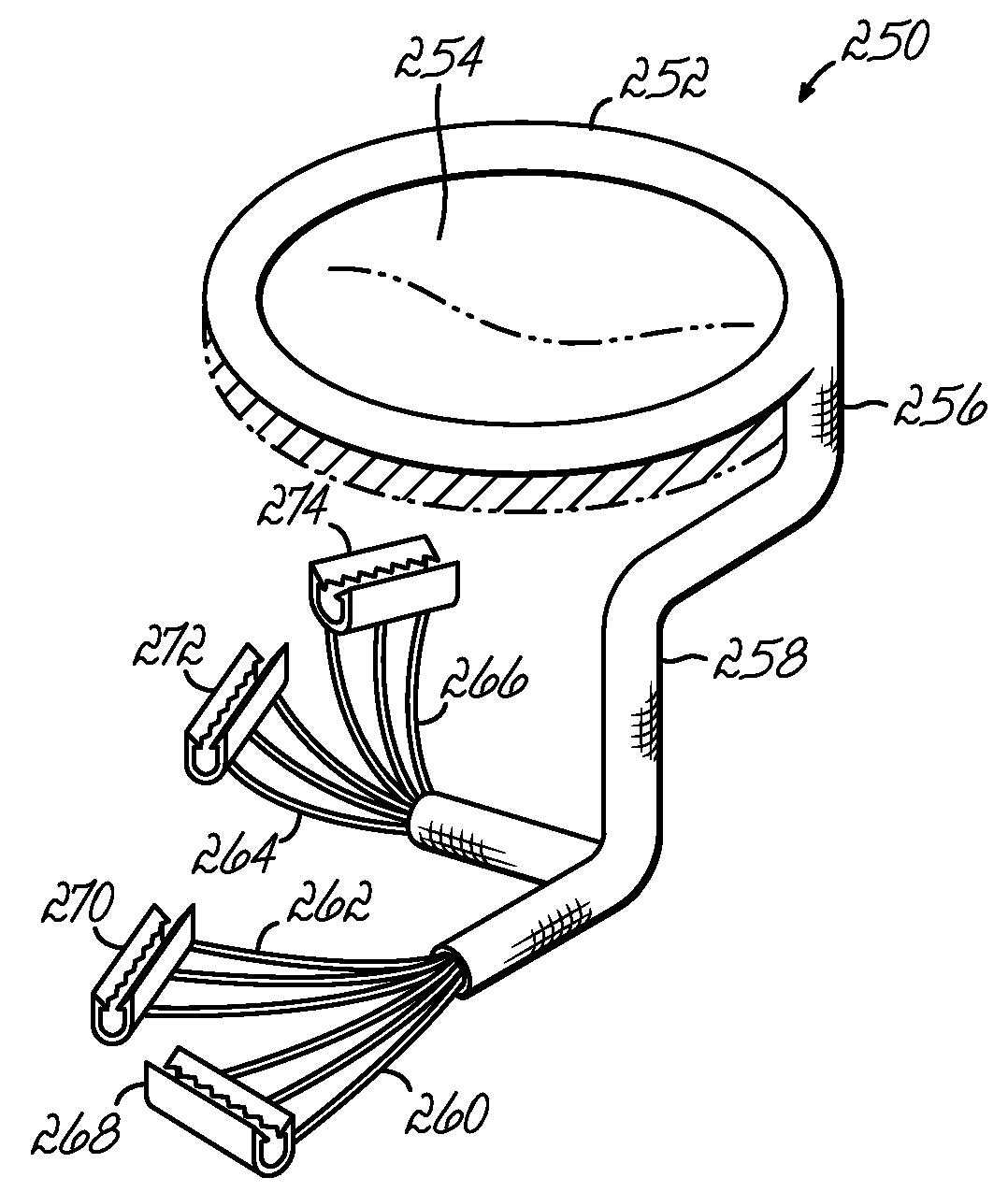

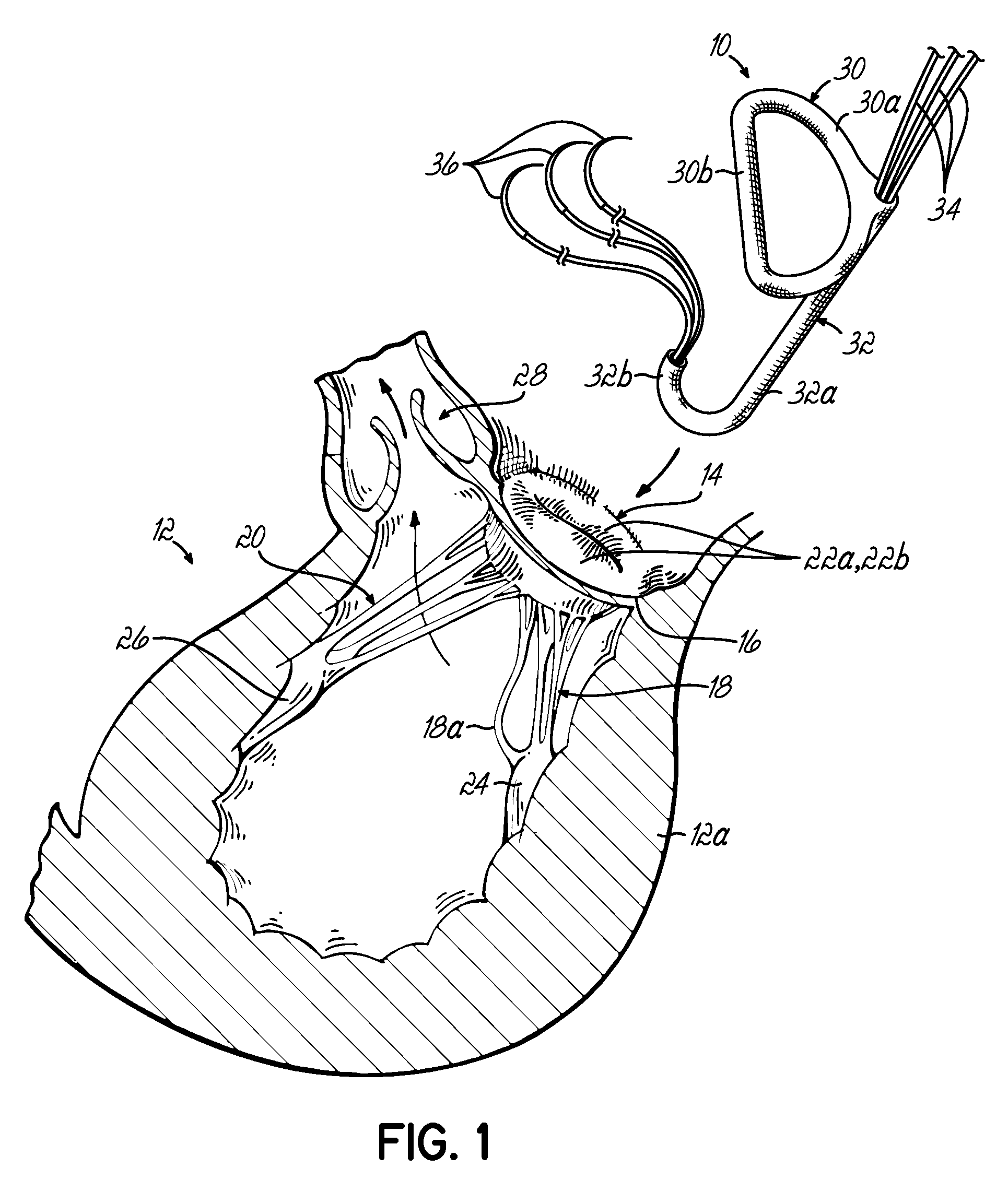

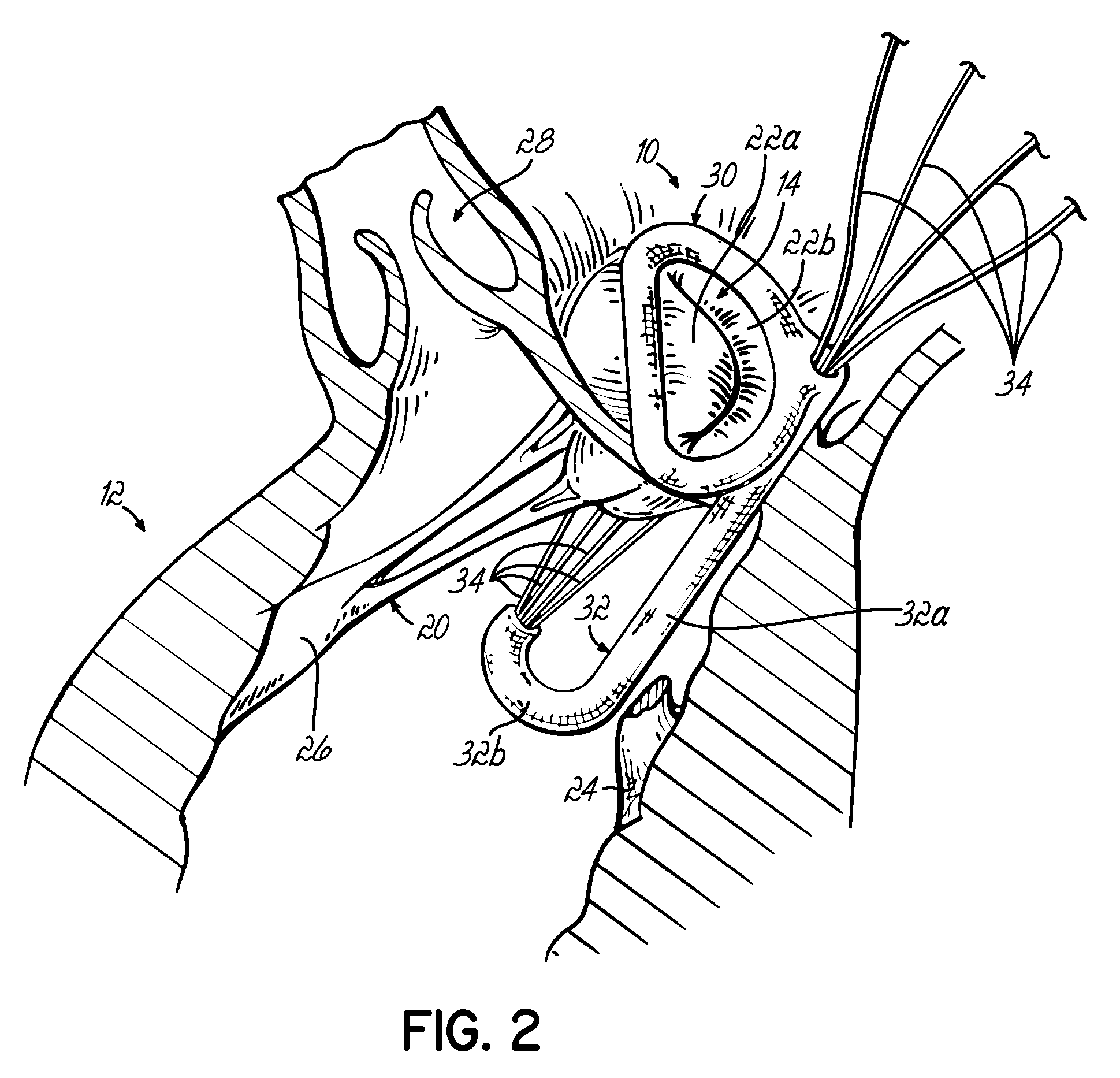

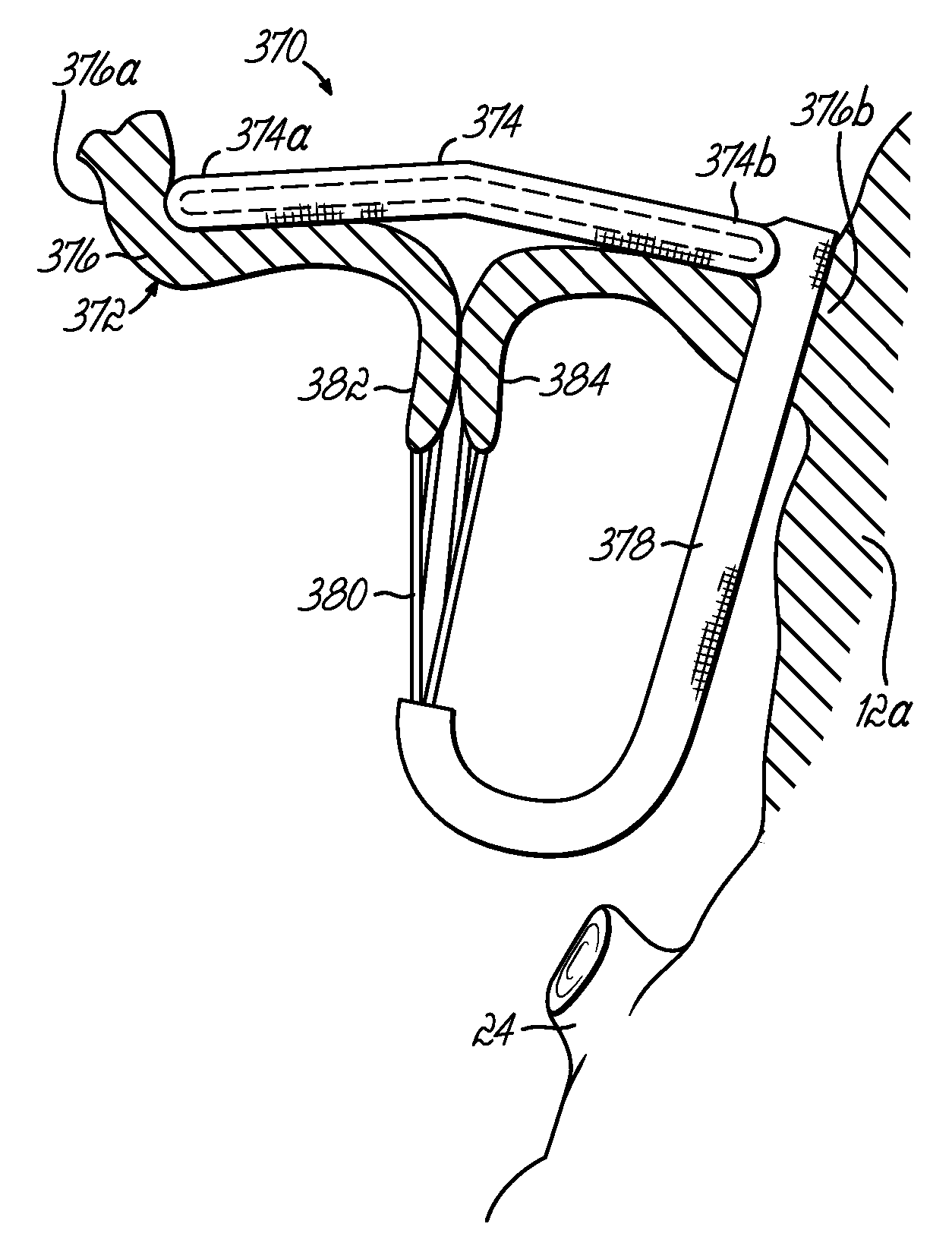

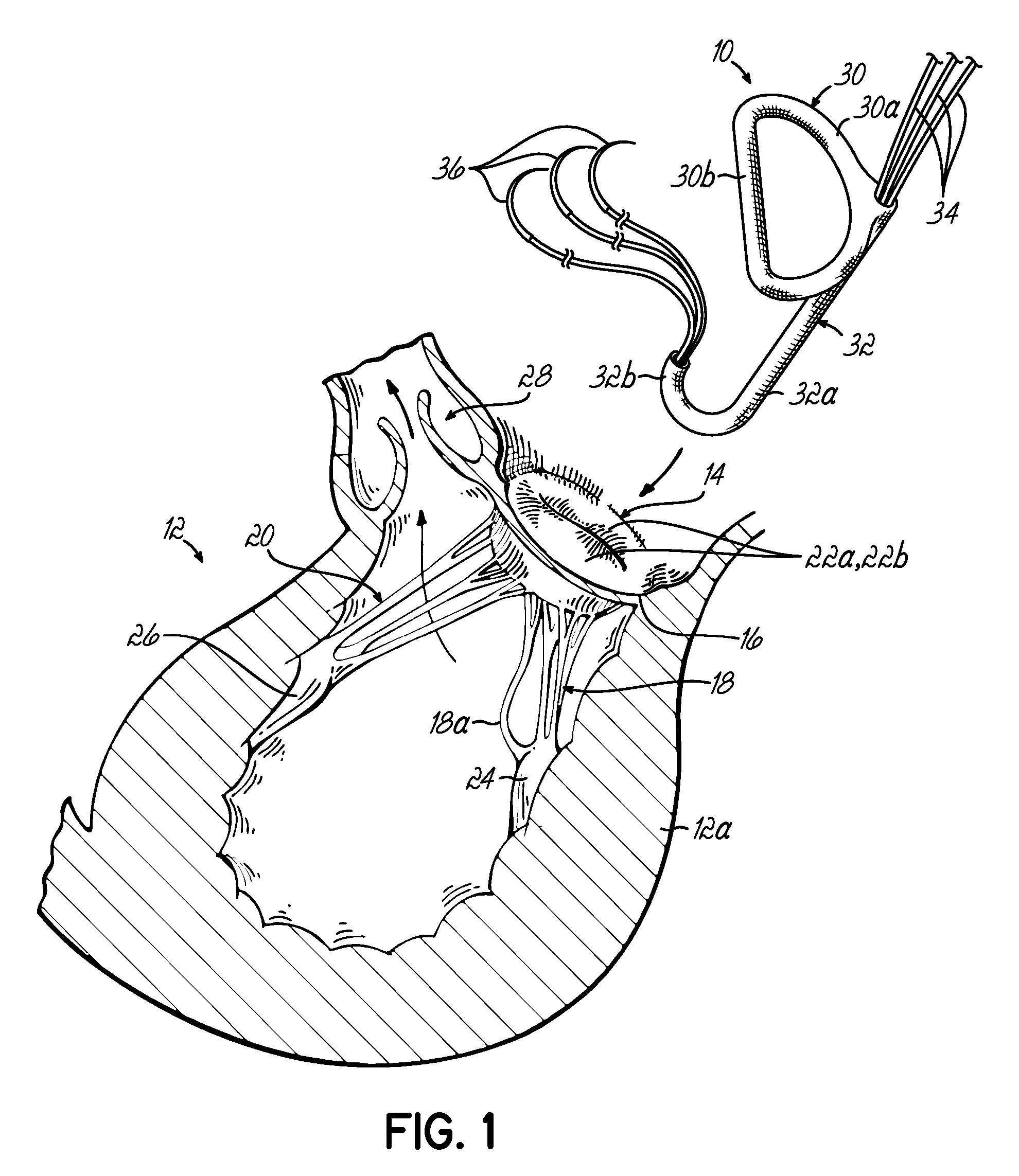

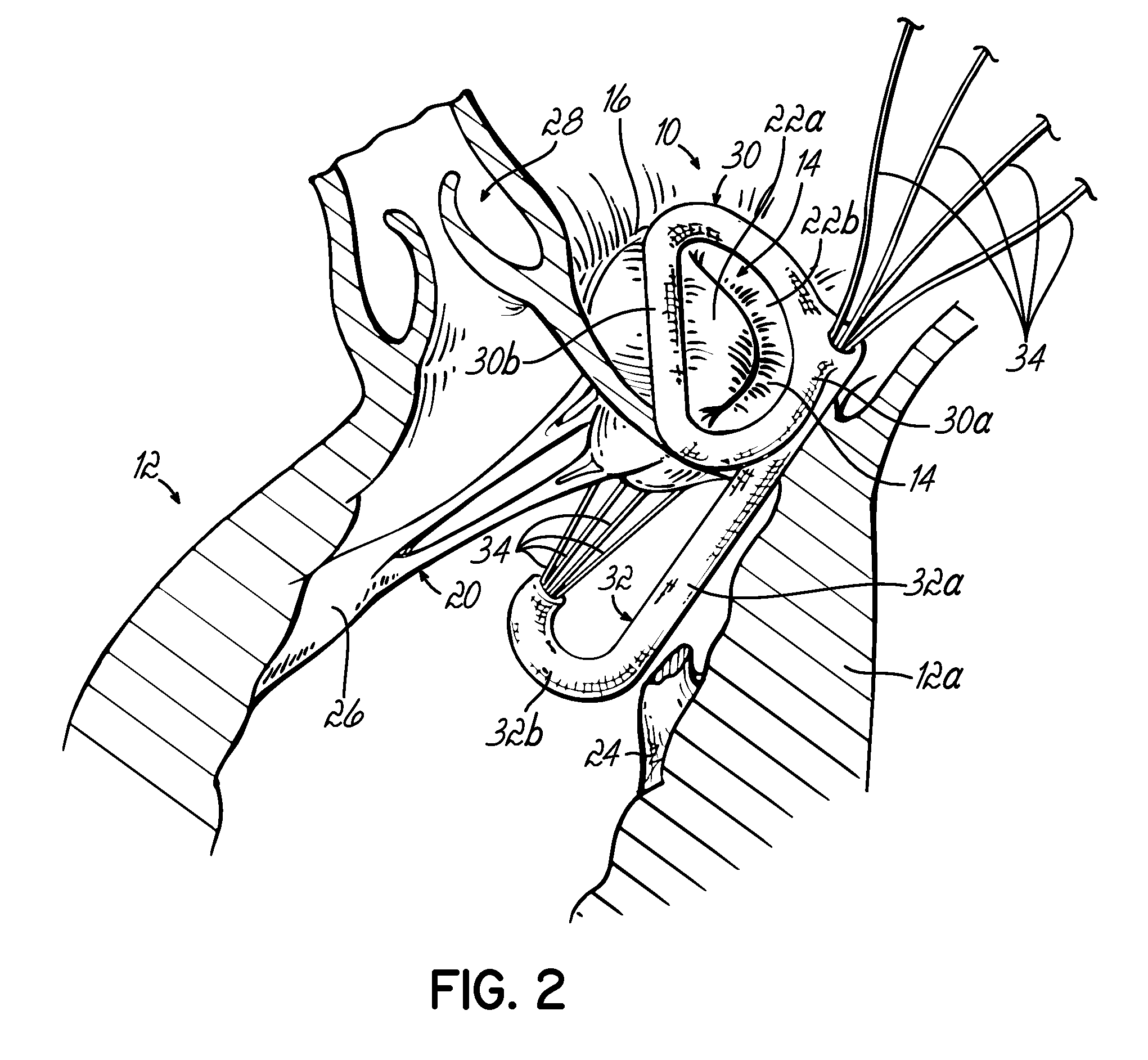

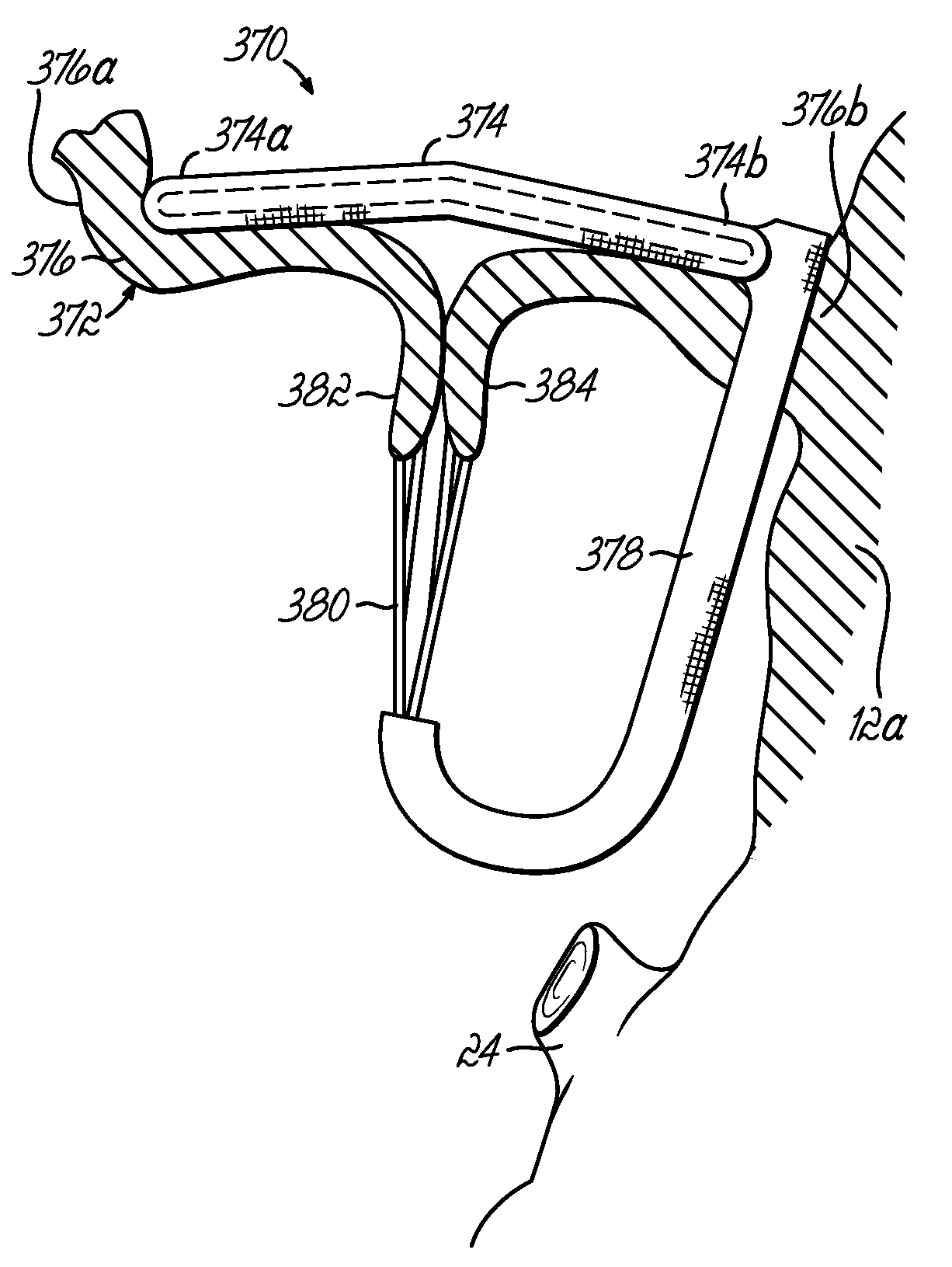

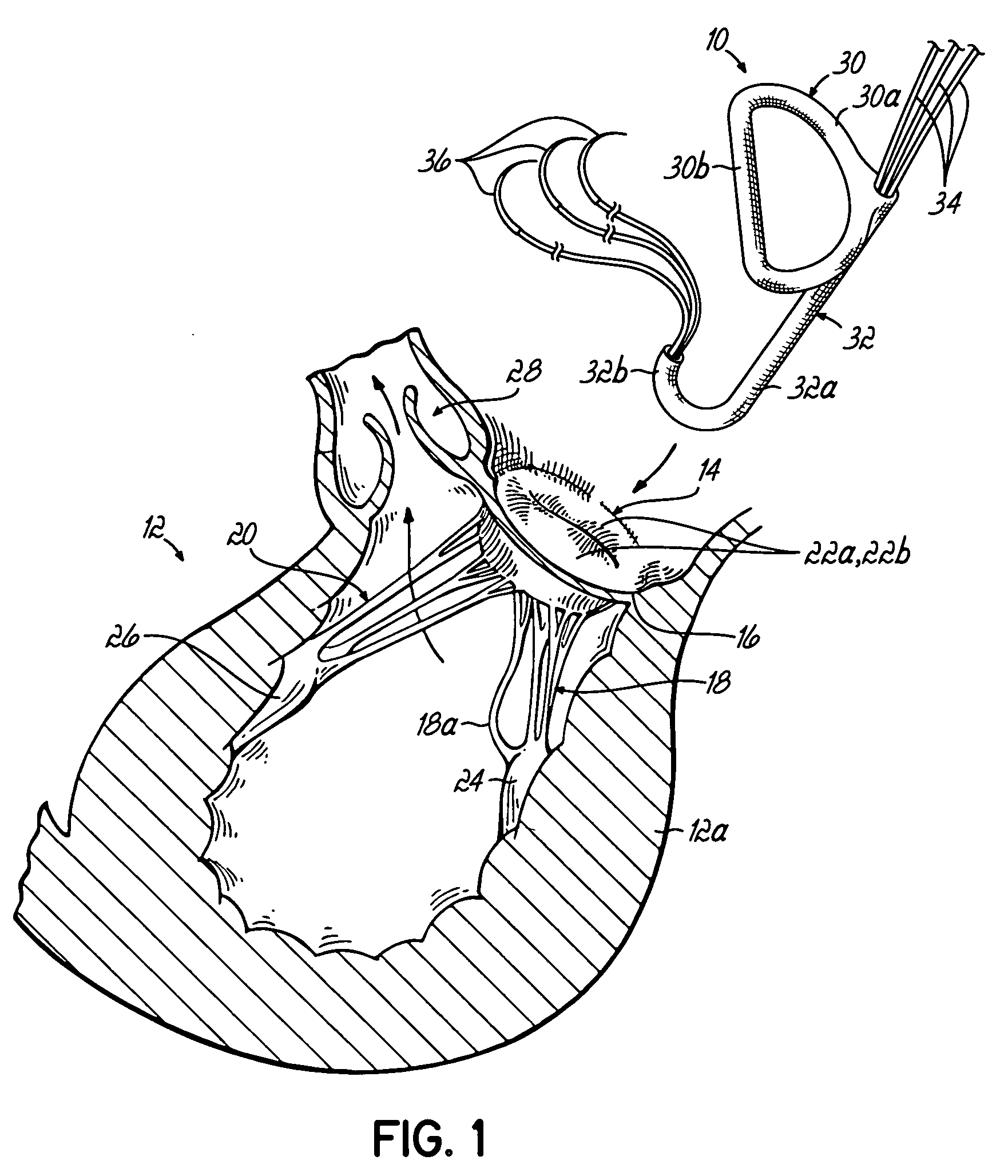

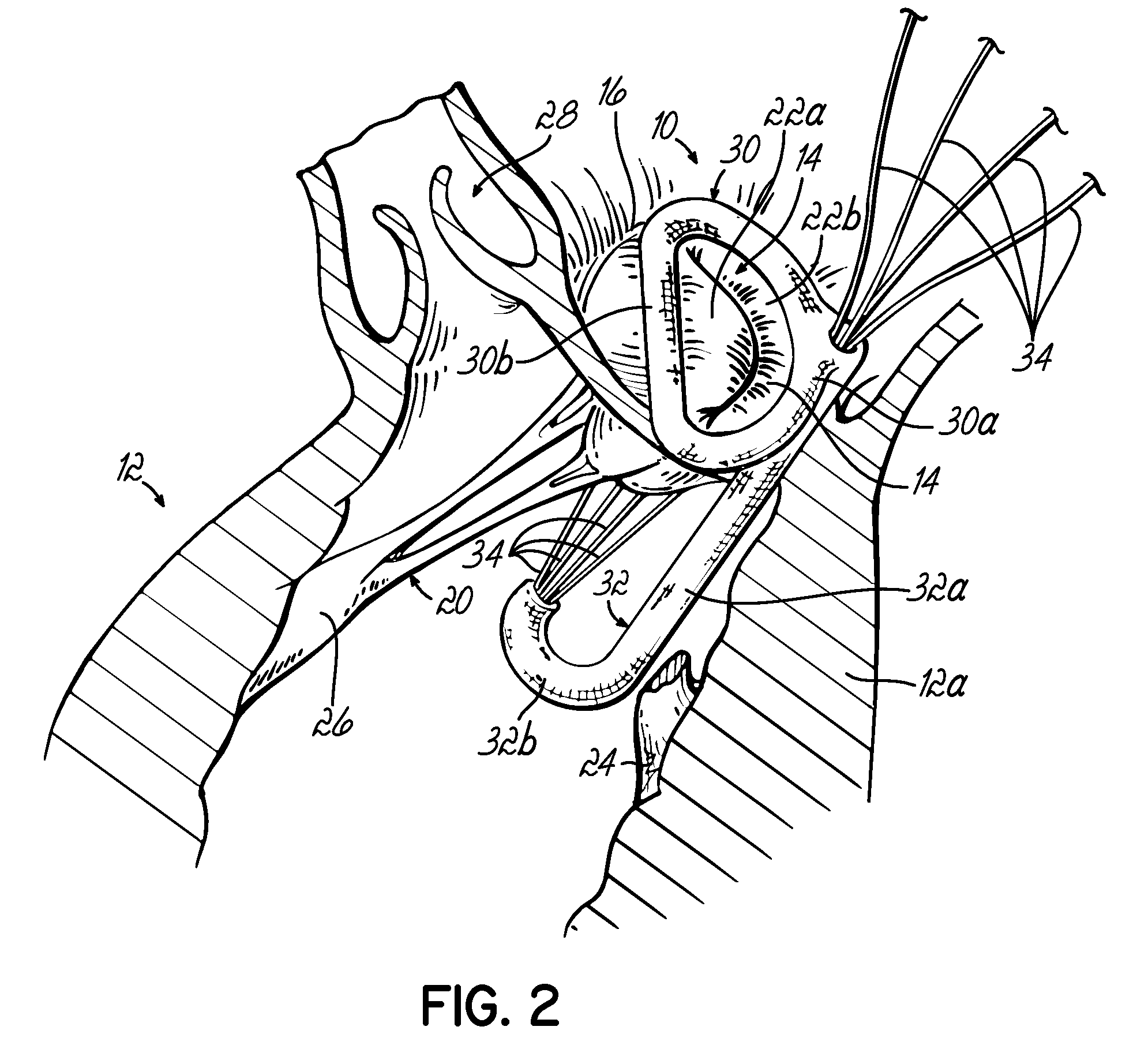

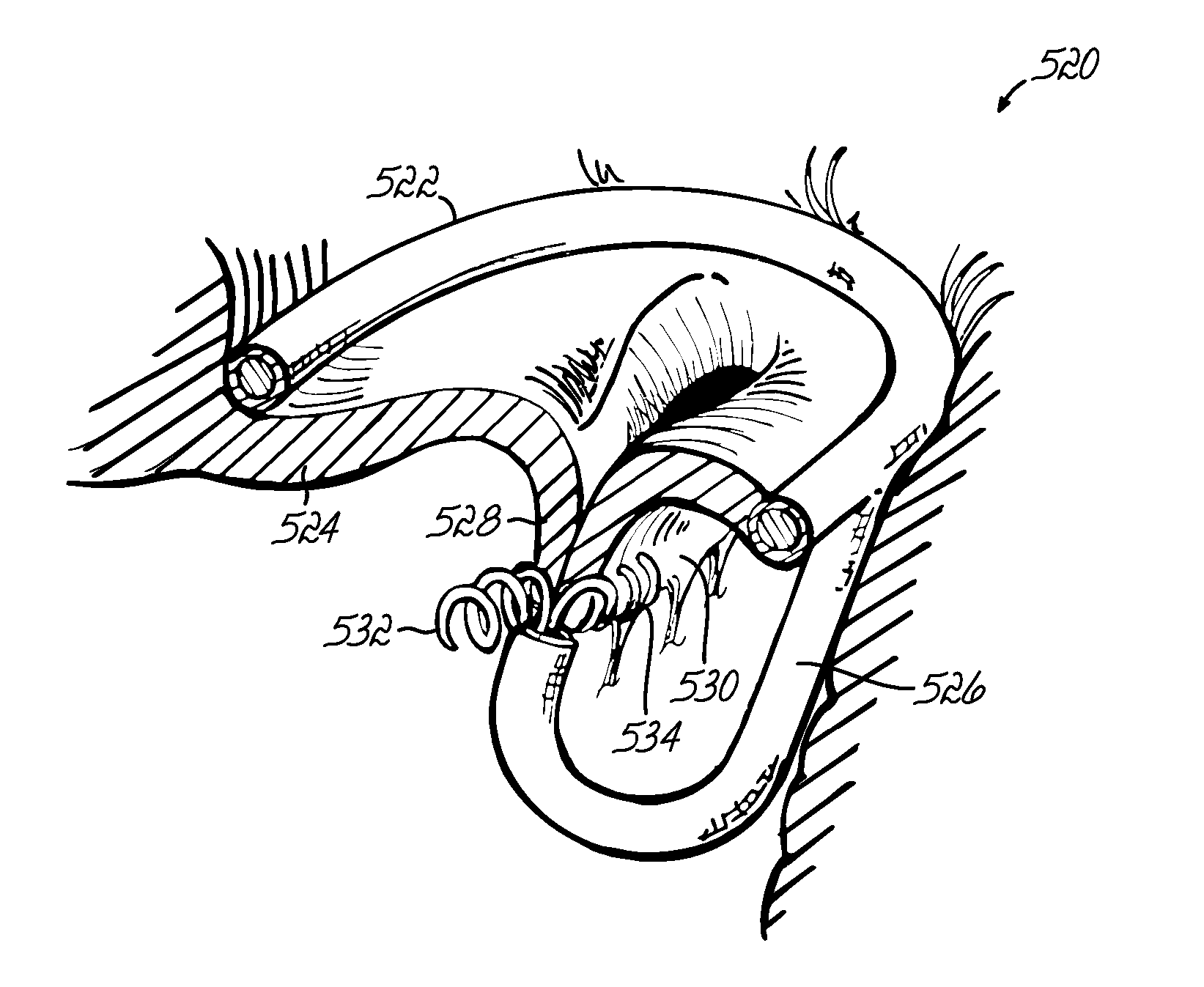

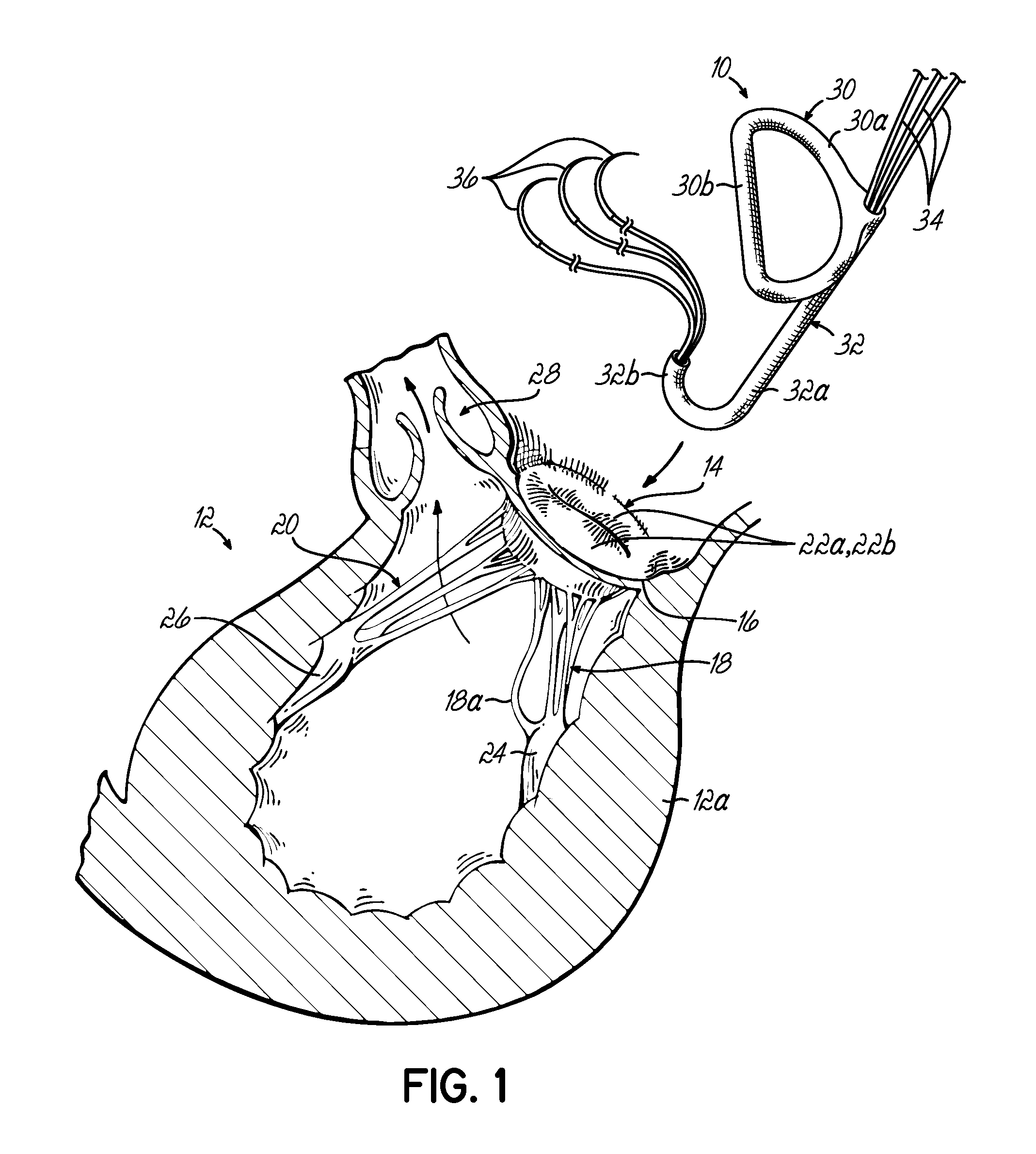

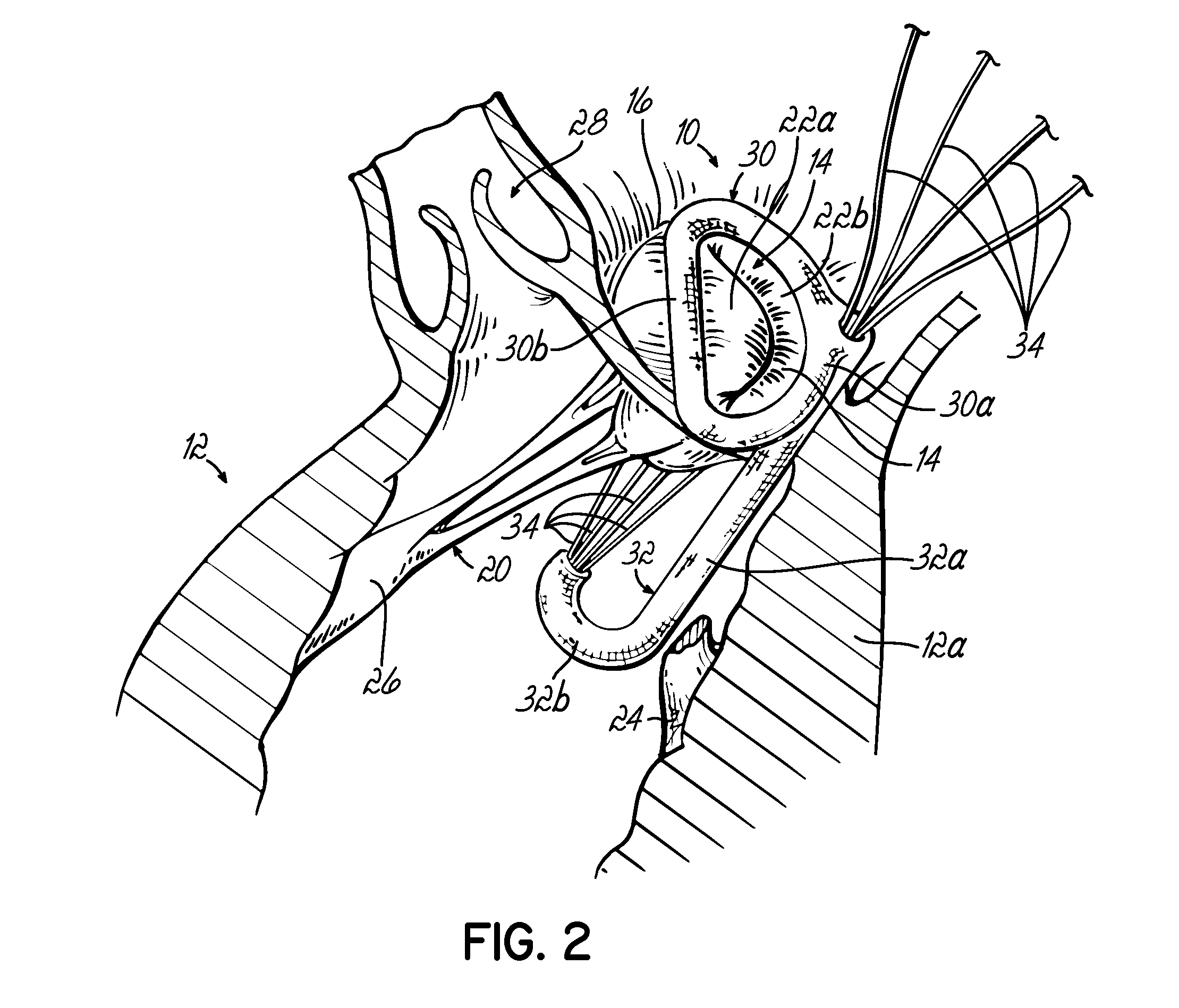

Valve repair apparatus and methods for ensuring proper coaptation and operation of the leaflets of a heart valve. Main aspects of the disclosure relate to devices including a support member configured for attachment to the heart valve annulus, a post extending from the support member away from the plane of the annulus and a connector coupled with the post and configured for attachment to at least one of the leaflets. The various embodiments may include a replacement heart valve connected with the support member for facilitating full replacement as opposed to near repair of an existing native heart valve. Various other devices include support structure and one or more posts connected to opposite sides of the support structure and extending from one side of the valve annulus to another to modify the shape of the annulus.

Owner:SPENCE PAUL A

Heart valve repair apparatus and methods

InactiveUS7527647B2More reliable and permanentEasy to implementBone implantAnnuloplasty ringsHeart valve repairVALVE PORT

Valve repair apparatus and methods for ensuring proper coaptation and operation of the leaflets of a heart valve. Main aspects of the disclosure relate to devices including a support member configured for attachment to the heart valve annulus, a post extending from the support member away from the plane of the annulus and a connector coupled with the post and configured for attachment to at least one of the leaflets. The various embodiments may include a replacement heart valve connected with the support member for facilitating full replacement as opposed to near repair of an existing native heart valve. Various other devices include support structure and one or more posts connected to opposite sides of the support structure and extending from one side of the valve annulus to another to modify the shape of the annulus.

Owner:CARDIAC VALVE TECH

Heart valve repair apparatus and methods

InactiveUS7166126B2More reliable and permanentEasy to implementBone implantAnnuloplasty ringsHeart valve repairVALVE PORT

Valve repair apparatus and methods for ensuring proper coaptation and operation of the leaflets of a heart valve. Main aspects of the disclosure relate to devices including a support member configured for attachment to the heart valve annulus, a post extending from the support member away from the plane of the annulus and a connector coupled with the post and configured for attachment to at least one of the leaflets. The various embodiments may include a replacement heart valve connected with the support member for facilitating full replacement as opposed to near repair of an existing native heart valve. Various other devices include support structure and one or more posts connected to opposite sides of the support structure and extending from one side of the valve annulus to another to modify the shape of the annulus.

Owner:CARDIAC VALVE TECH

Heart valve repair apparatus and methods

InactiveUS20070050020A1More reliable and permanentEasy to implementAnnuloplasty ringsHeart valve repairBiomedical engineering

Valve repair apparatus and methods for ensuring proper coaptation and operation of the leaflets of a heart valve. Main aspects of the disclosure relate to devices including a support member configured for attachment to the heart valve annulus, a post extending from the support member away from the plane of the annulus and a connector coupled with the post and configured for attachment to at least one of the leaflets. The various embodiments may include a replacement heart valve connected with the support member for facilitating full replacement as opposed to near repair of an existing native heart valve. Various other devices include support structure and one or more posts connected to opposite sides of the support structure and extending from one side of the valve annulus to another to modify the shape of the annulus.

Owner:CARDIAC VALVE TECH

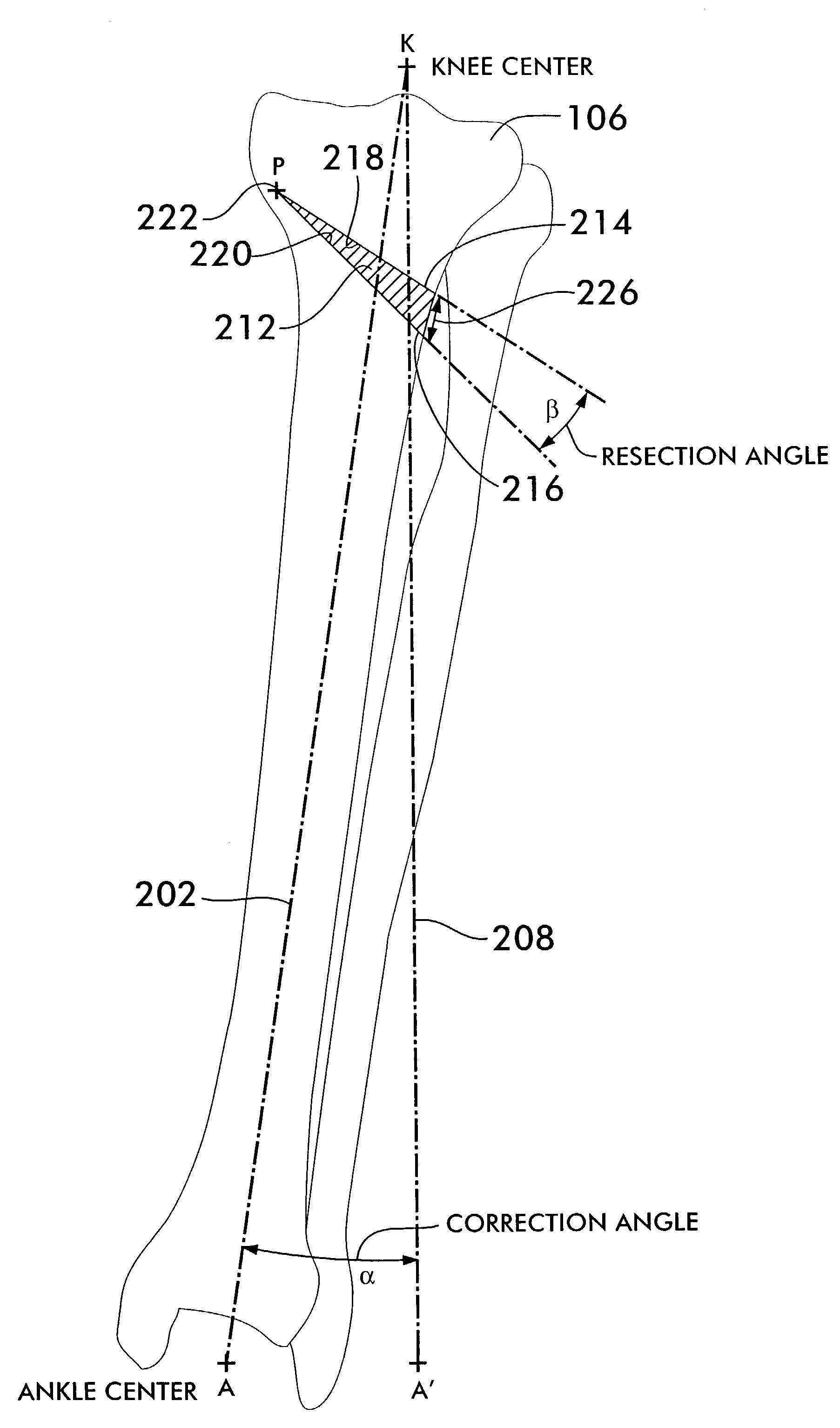

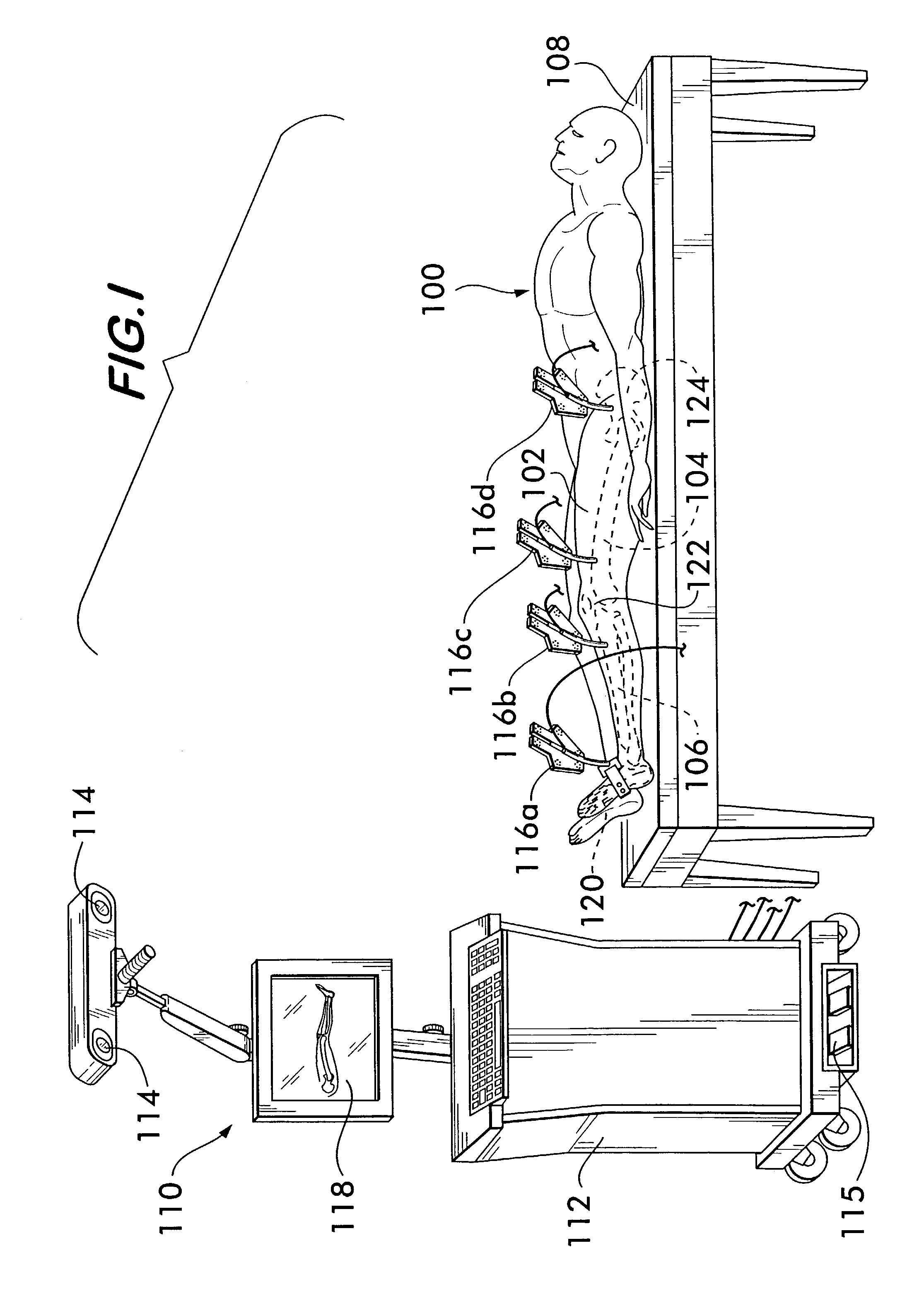

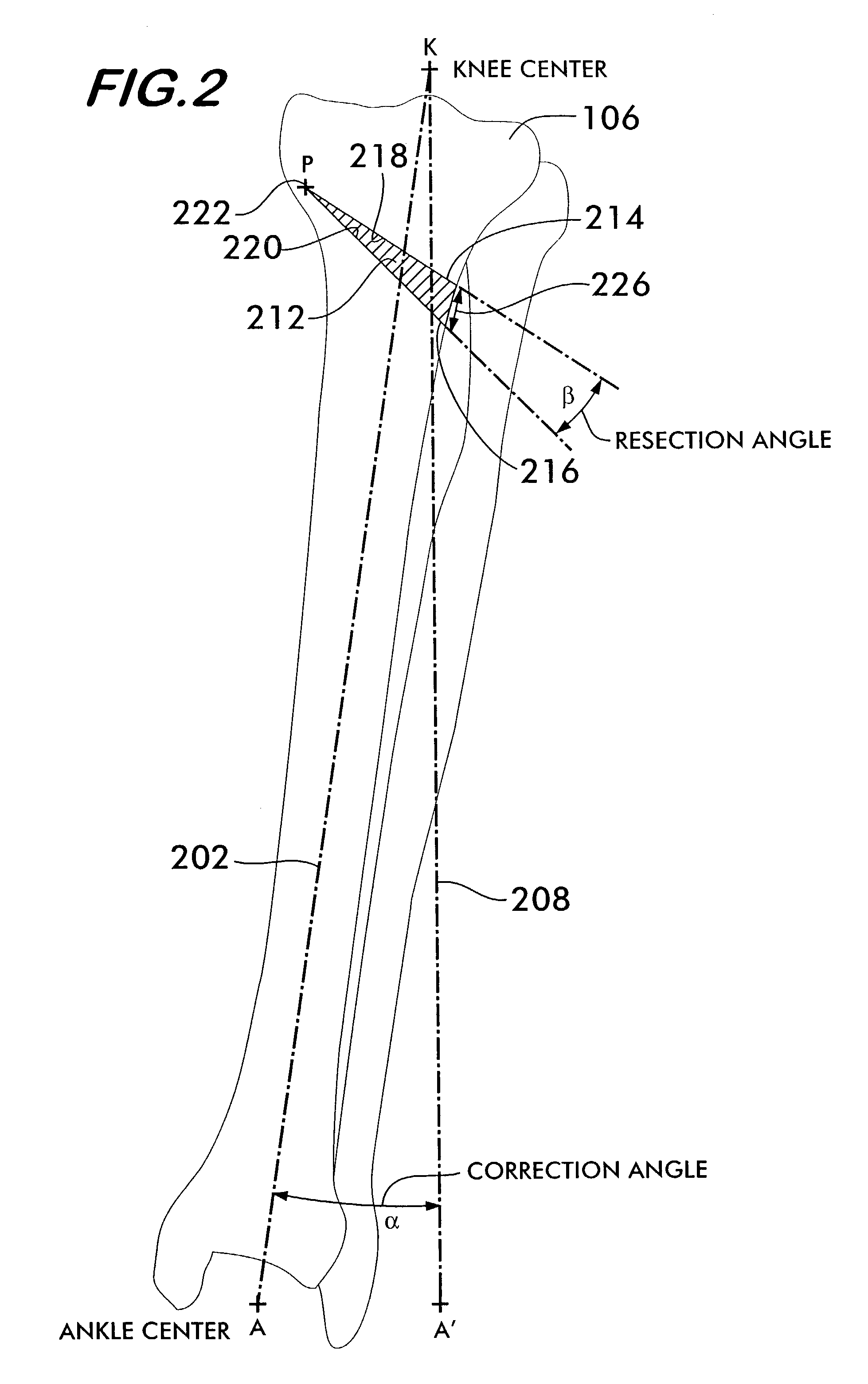

Osteotomy procedure

InactiveUS7318827B2Reliance has been minimizedAccurately determineSurgical navigation systemsDiagnostic markersOsteotomySurgical department

Owner:AESCULAP AG

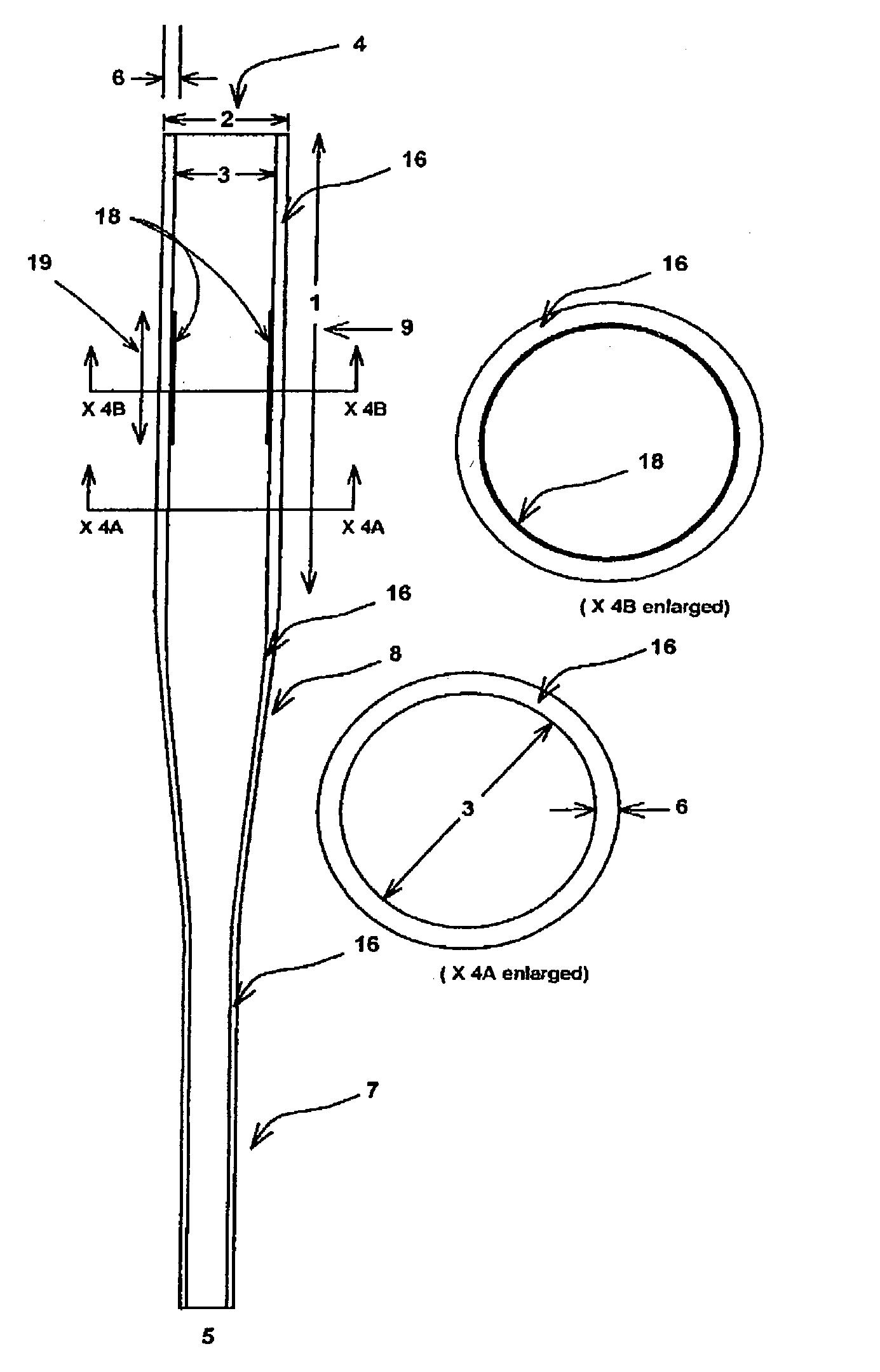

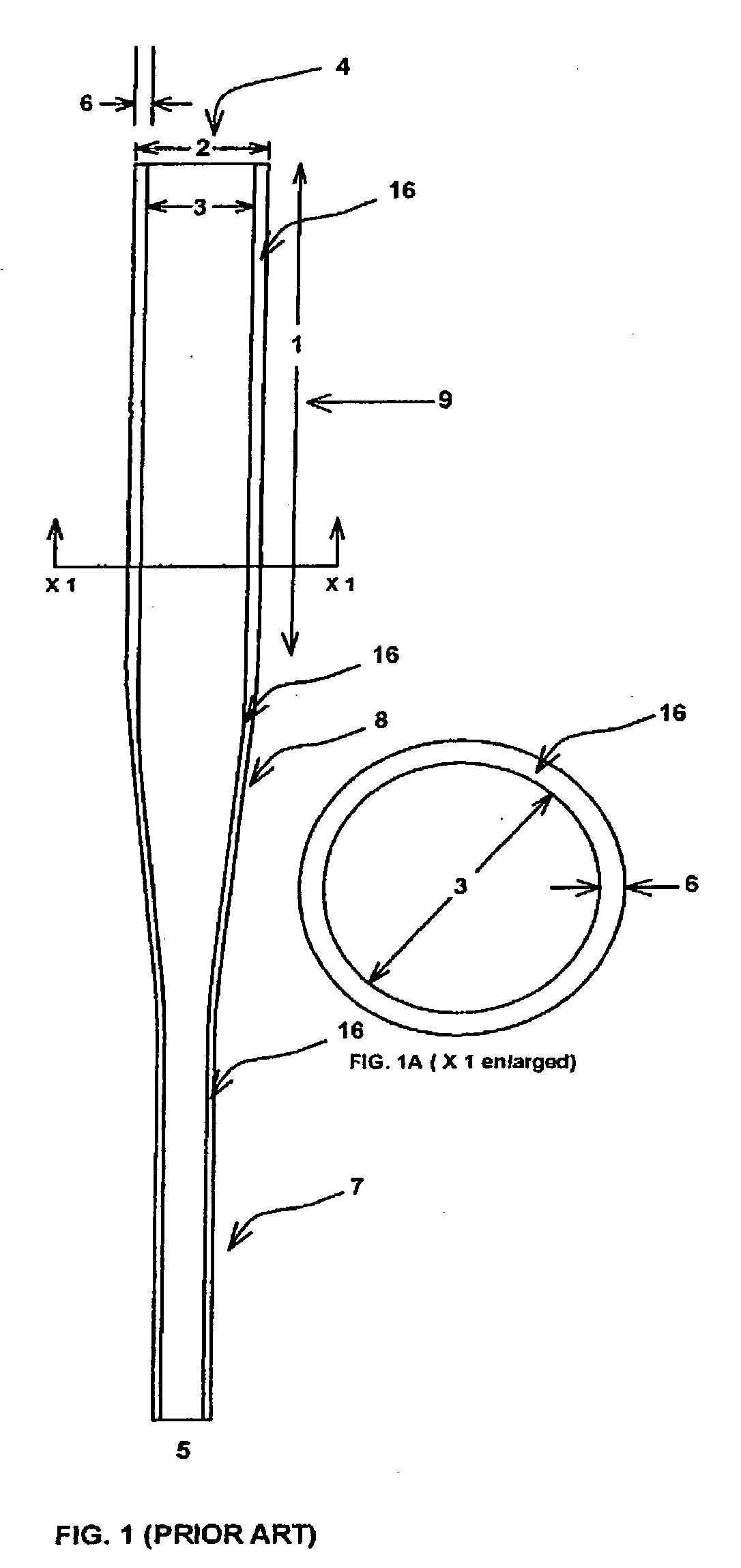

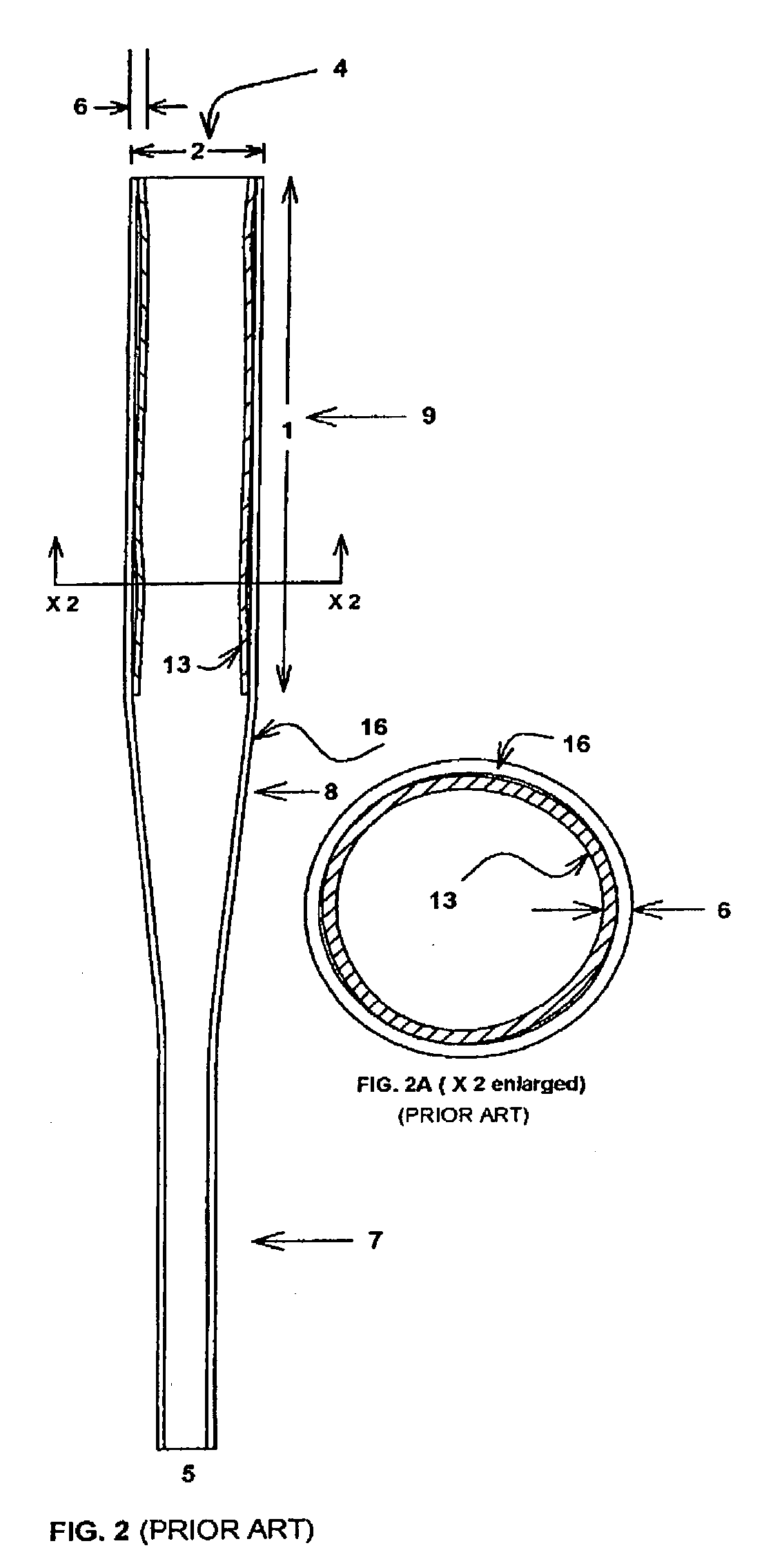

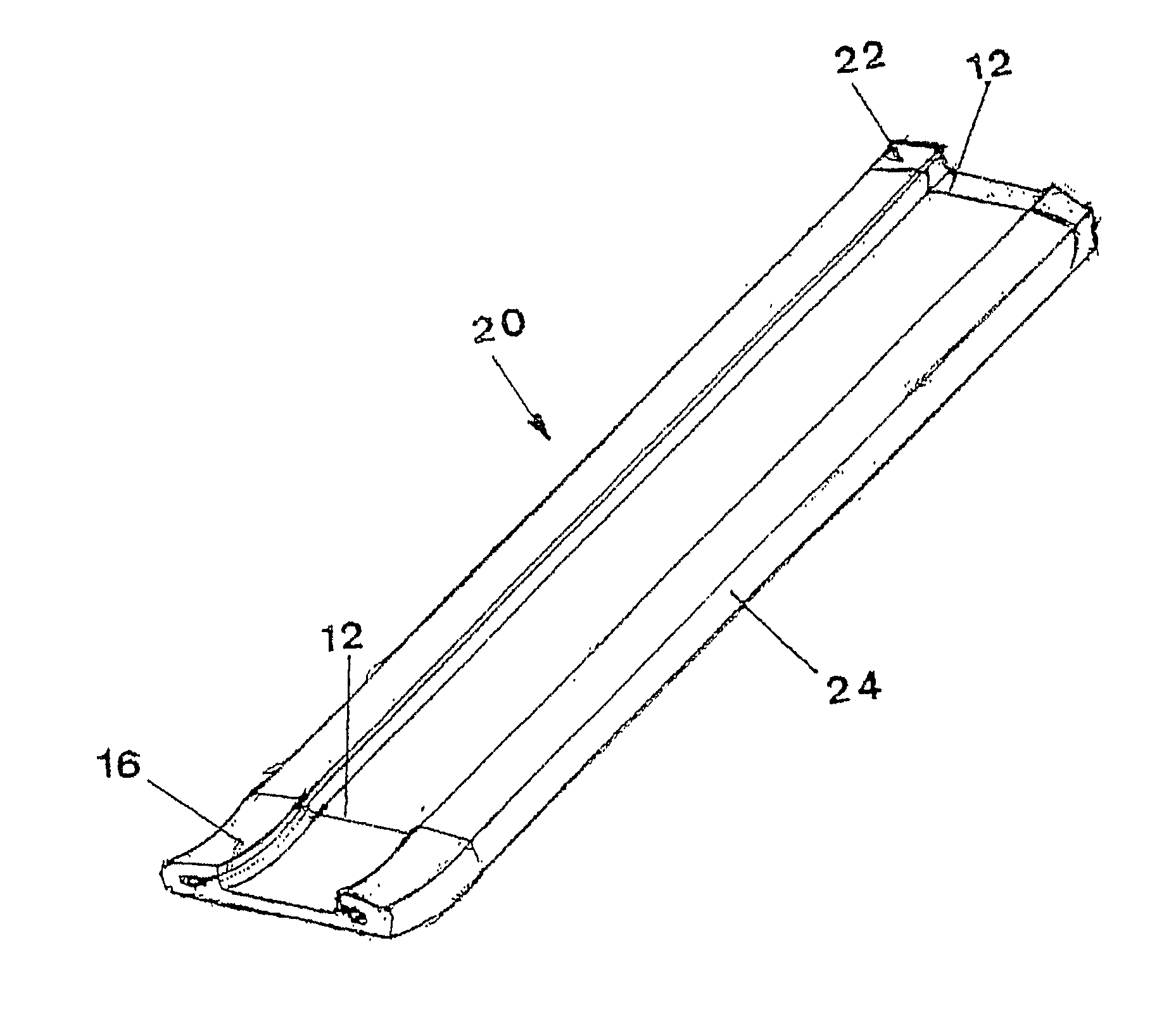

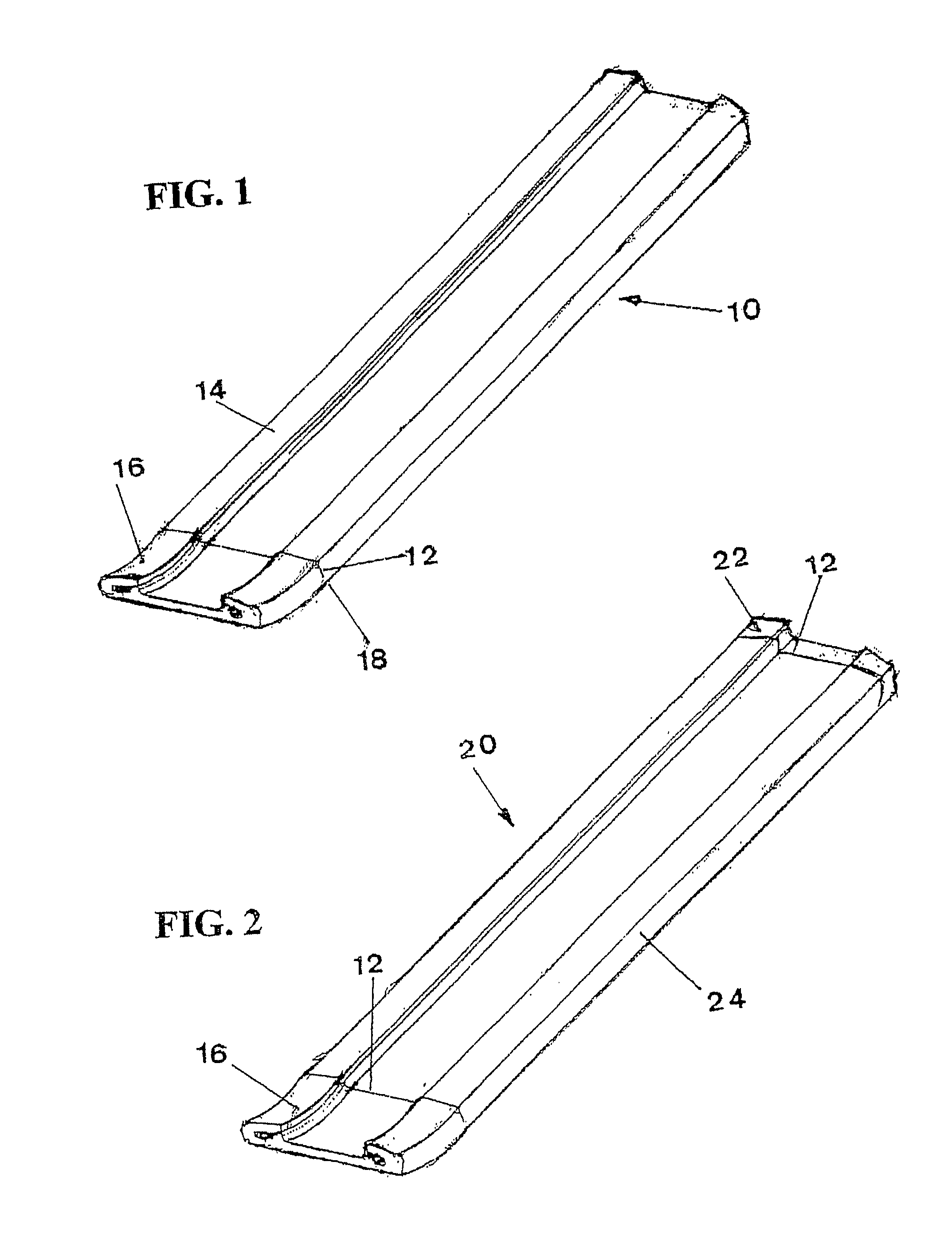

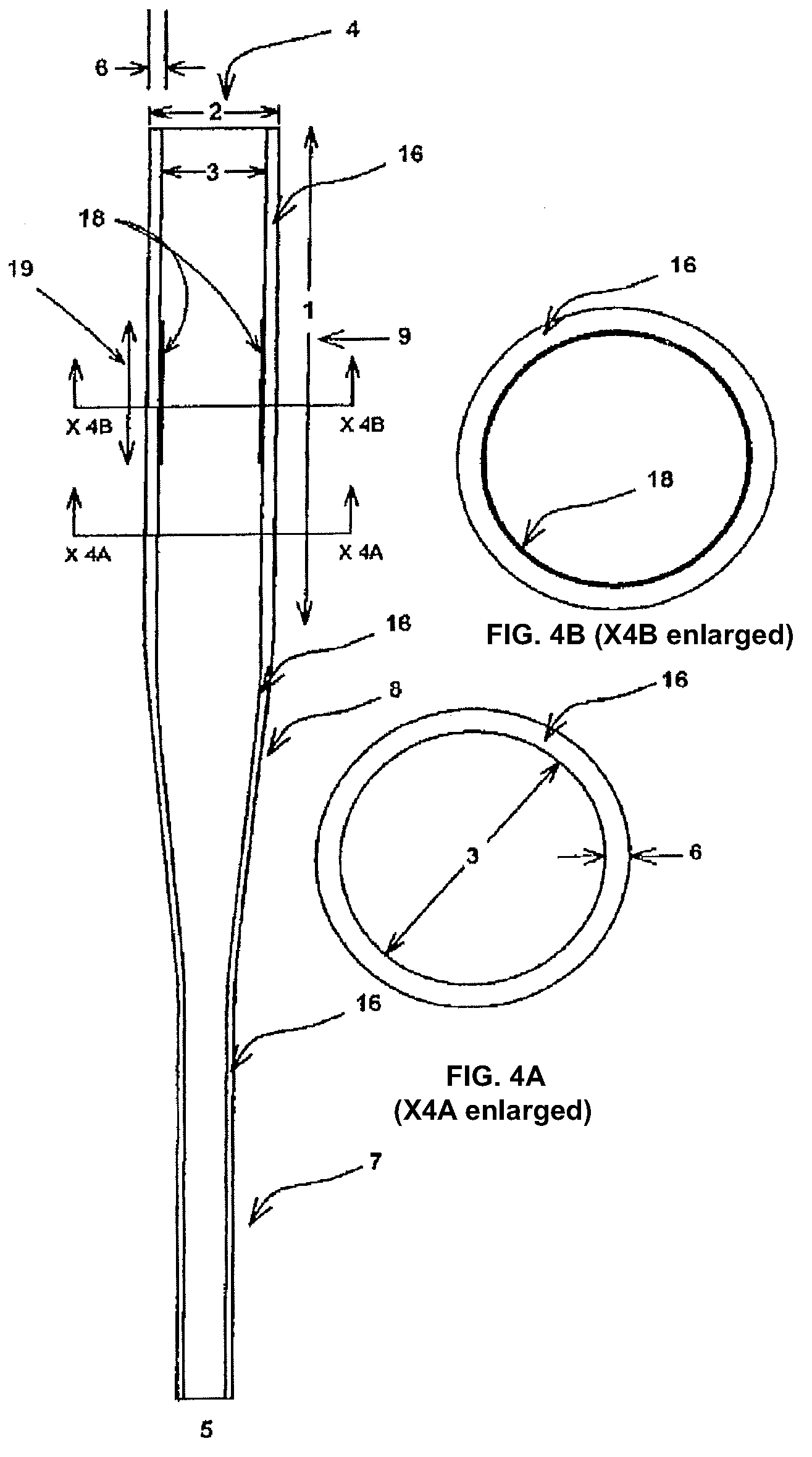

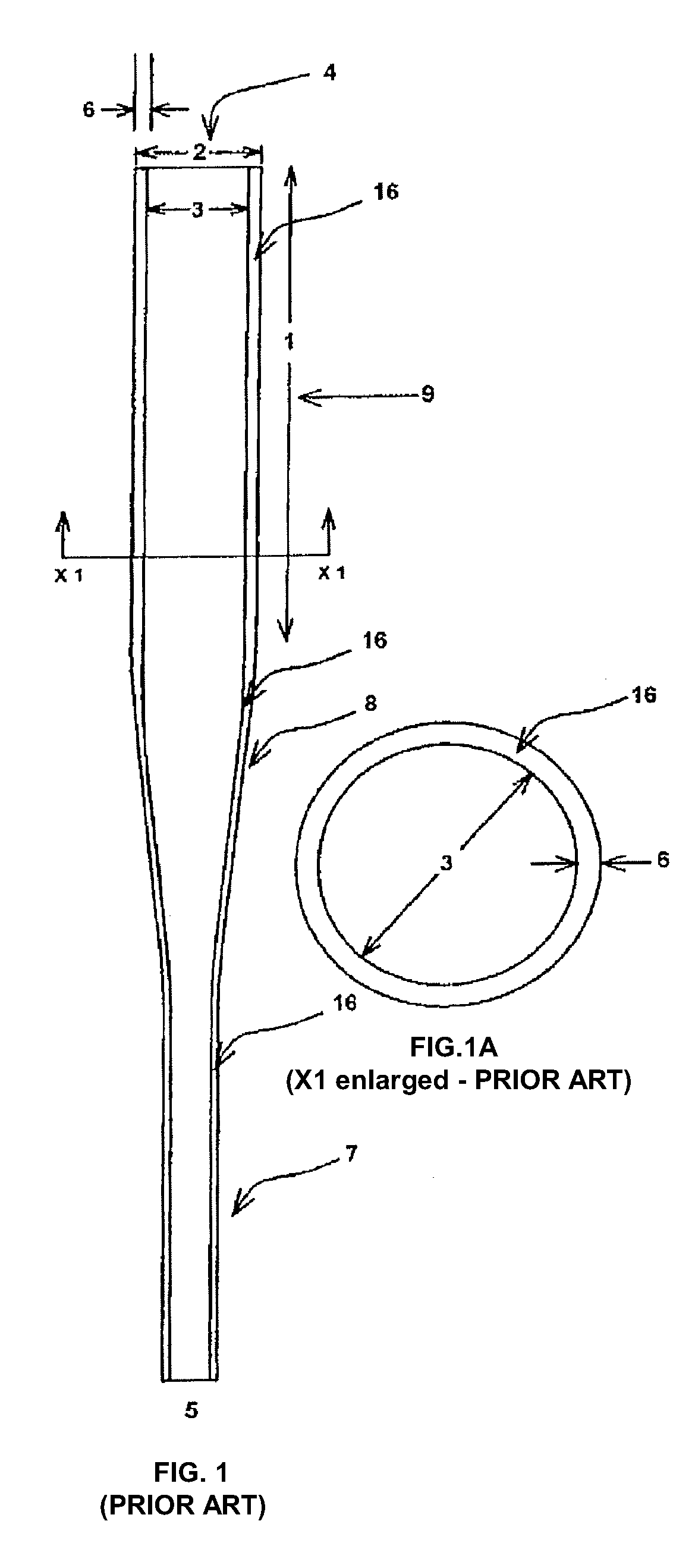

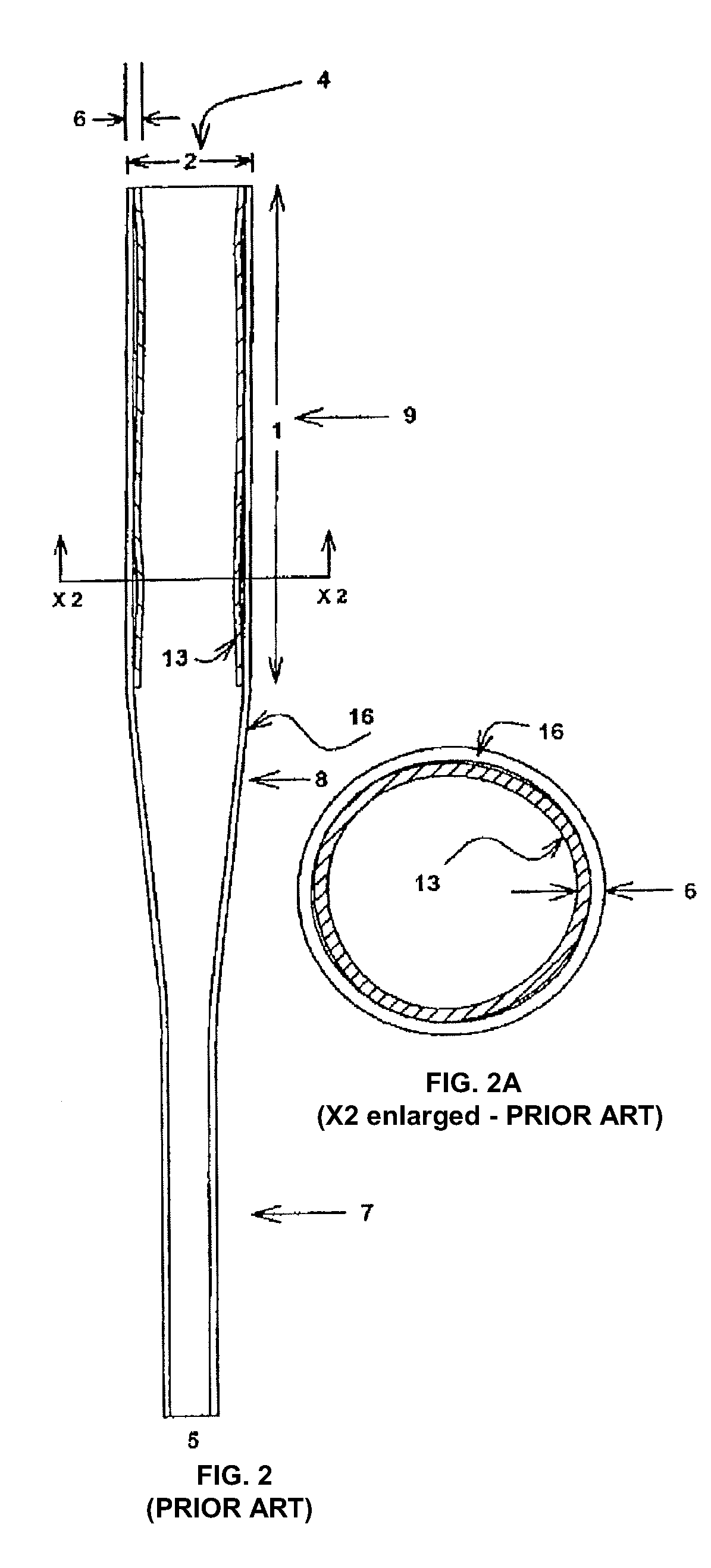

Tubular baseball bats with variable stiffened barrels

Tubular baseball bats comprised of an elongated handle portion and a striking or barrel portion wherein the barrel portion has variable stiffness along its length. One such bat has a circumferential low cost, low weight stiffener generally located in the sweetspot area designed to increase radial stiffness in a controlled manner which results in decreasing the bat performance to meet a changed bat performance standard and can be applied at low cost to both used field returned bats and bats being newly manufactured. Further, new tubular polymer composite bats can be designed with increased radial stiffness generally located in the sweetspot area or with radial stiffness graduated from highest, generally in the sweetspot area, to lowest at the barrel ends. All bats of the present invention result in calculated bat performance to meet applicable regulatory standards while also increasing the sweetspot size.

Owner:CE COMPOSITES BASEBALL

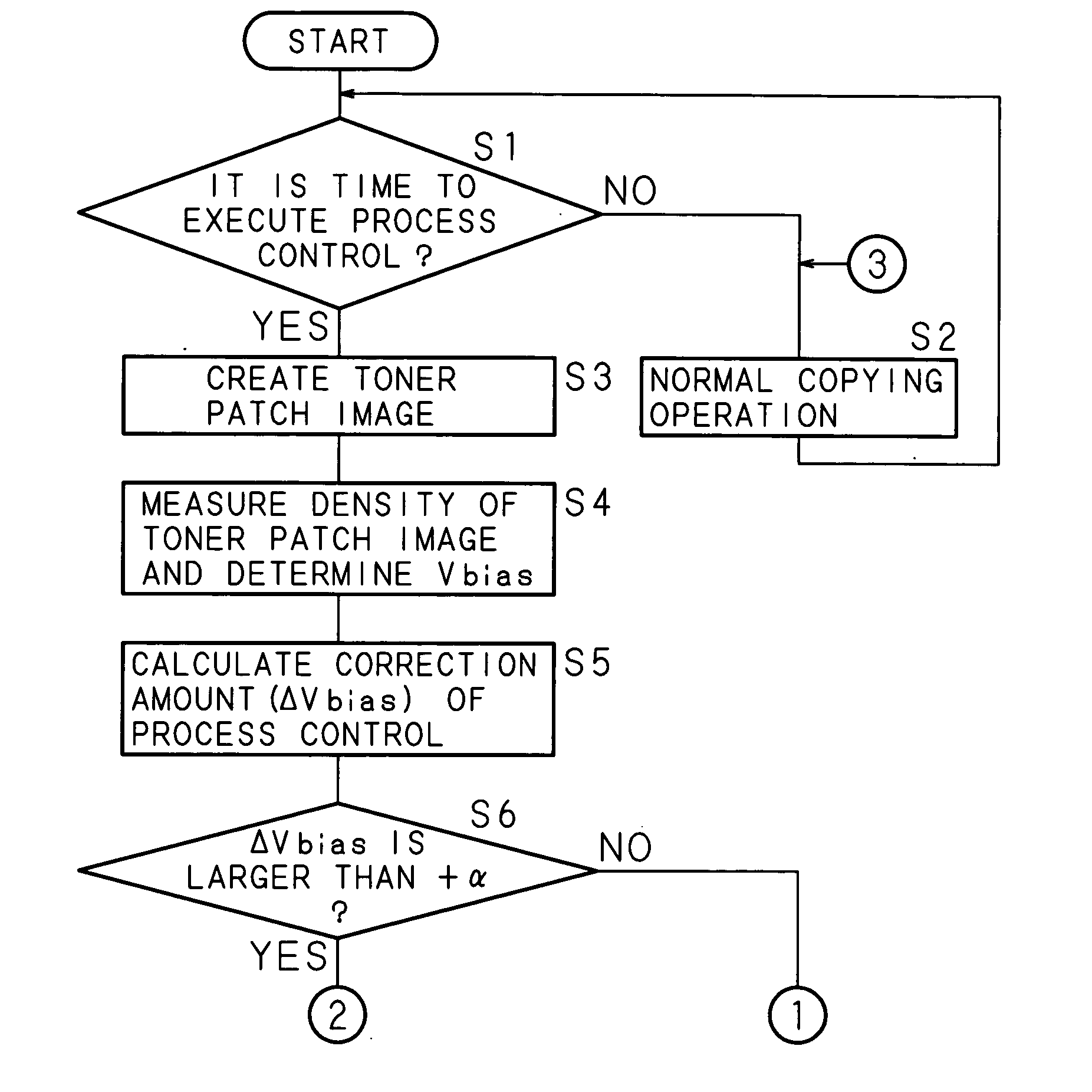

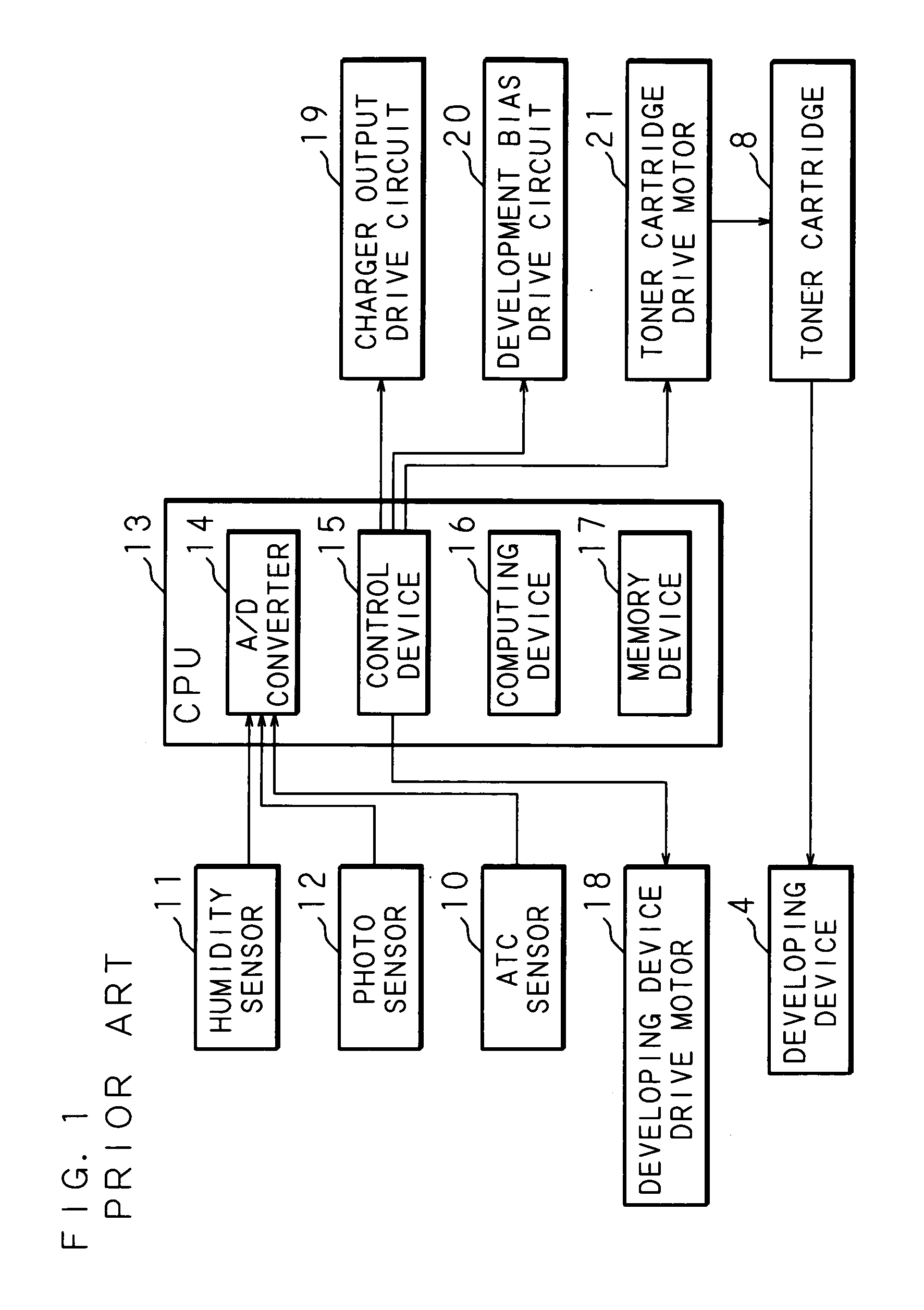

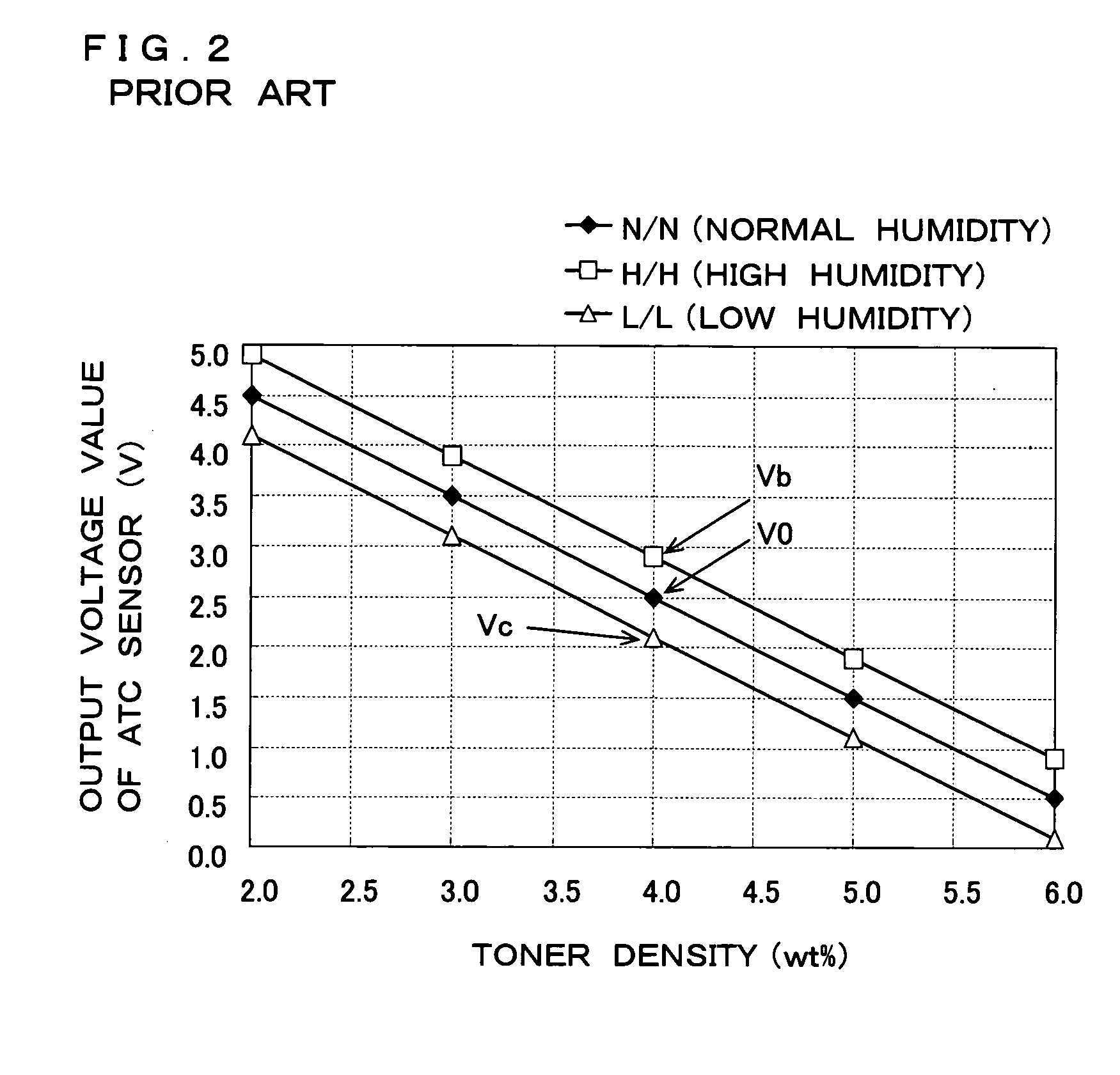

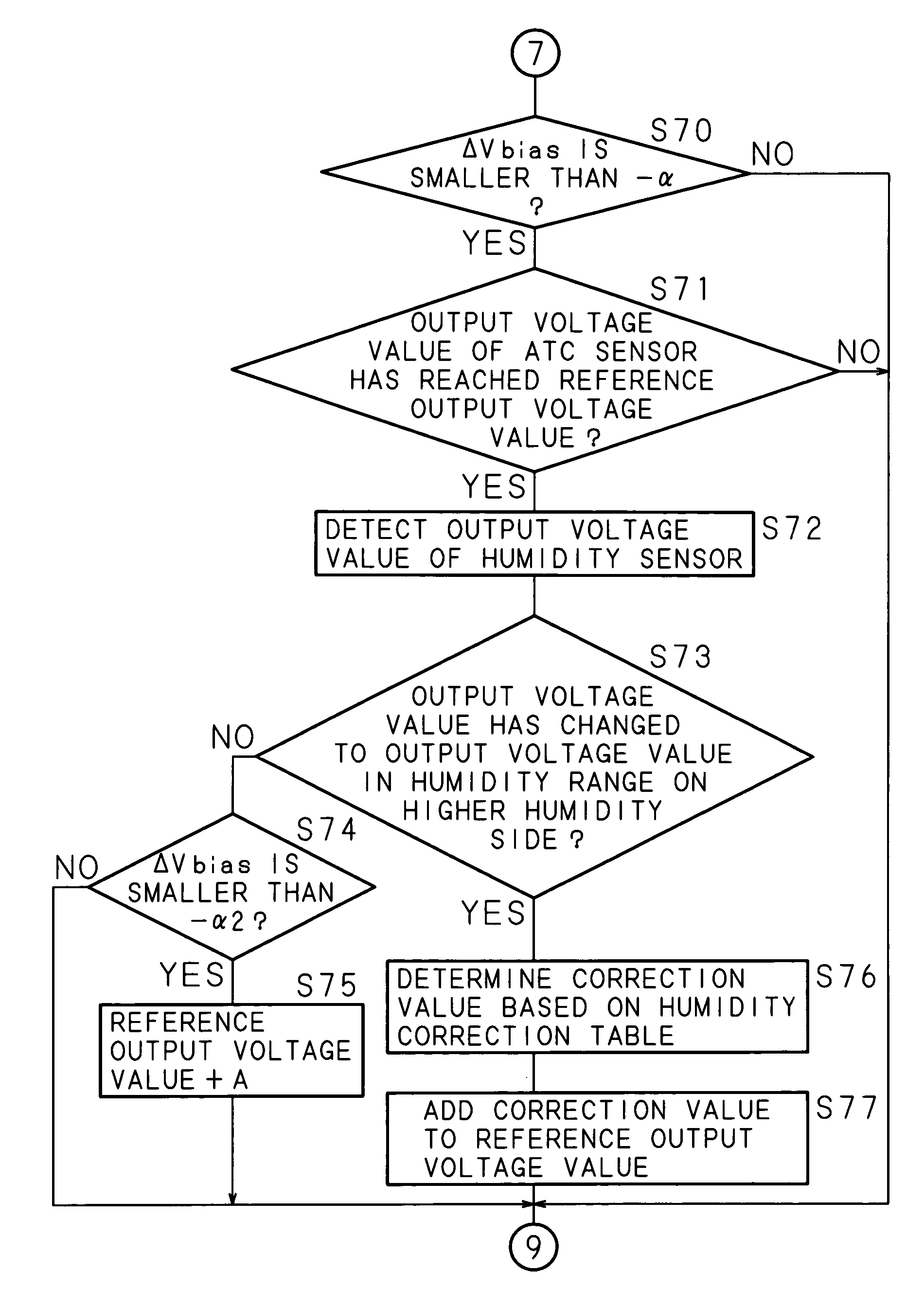

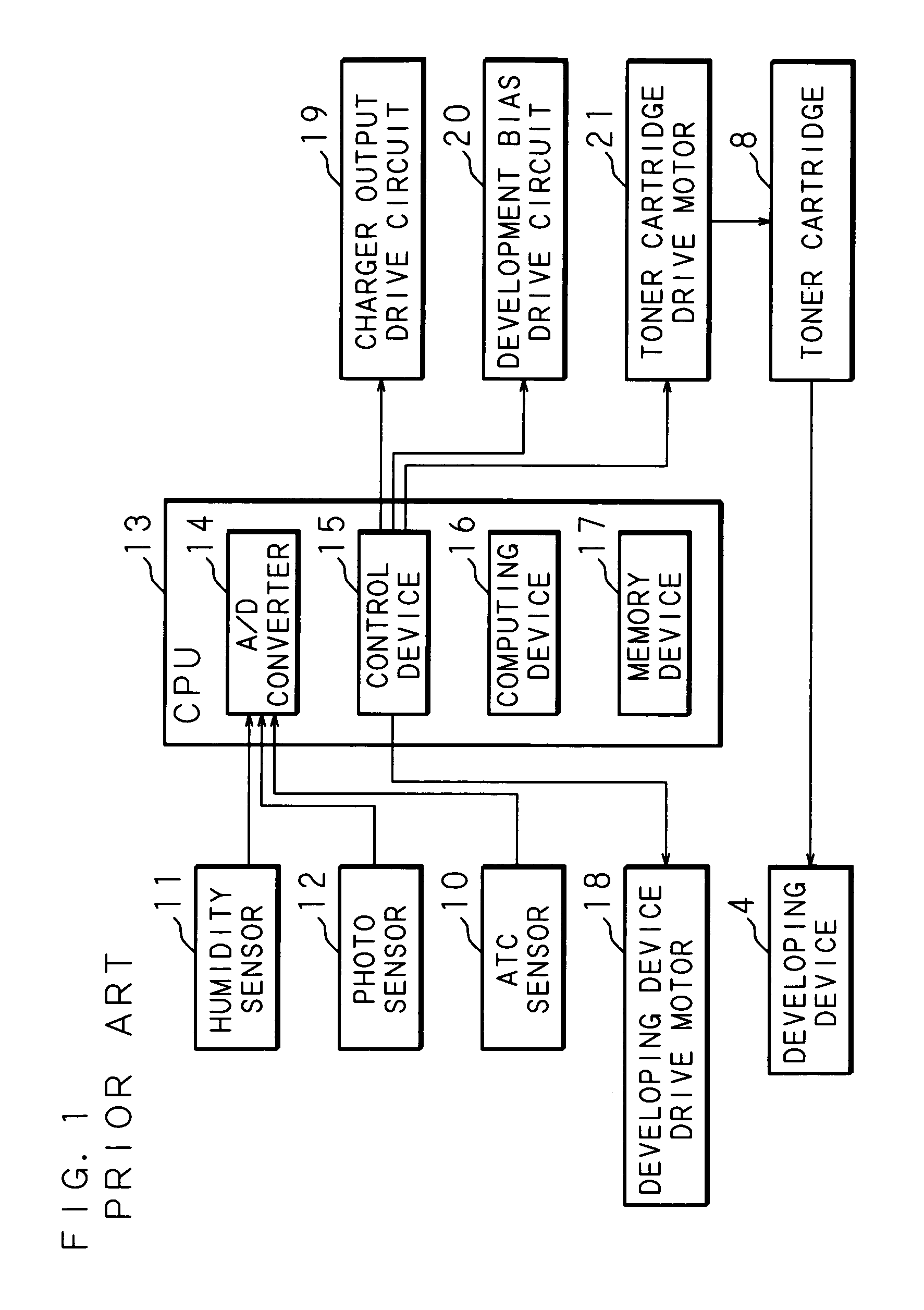

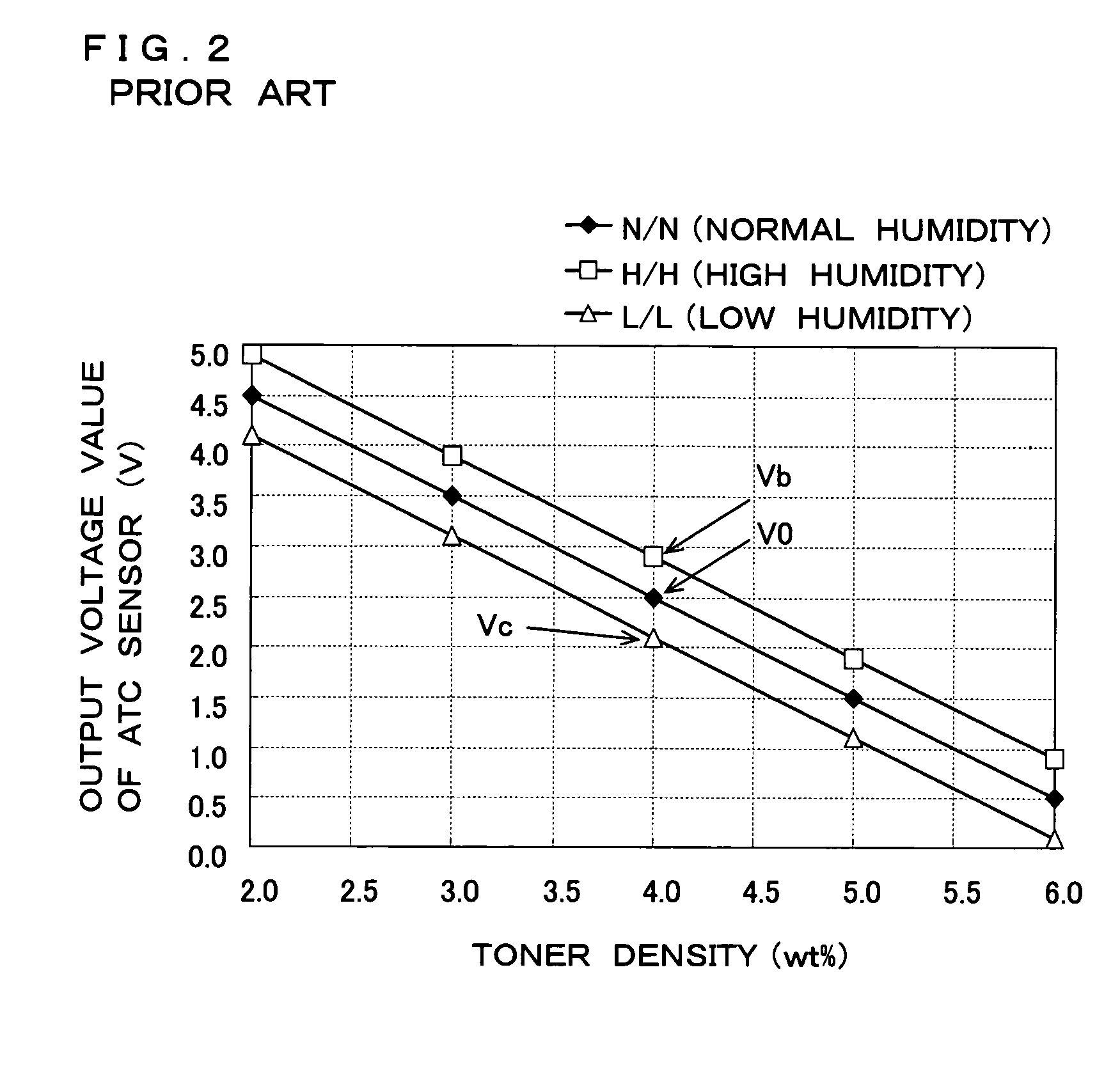

Image forming method and image forming device

InactiveUS20060152775A1Excellent developabilityAccurately metDigitally marking record carriersDigital computer detailsImage formationEngineering

A reference developing image is formed on a photoreceptor drum under an image forming condition measured in advance, and the density of this reference developing image is detected. A development bias voltage is corrected based on the detection result, and when a correction value of the development bias voltage exceeds a predetermined range, a reference output voltage of an ATC sensor for detecting the density of toner in a developing device is corrected based on the detected value of humidity around the developing device, the frequency of use of the apparatus, and the agitation stress of developer.

Owner:SHARP KK

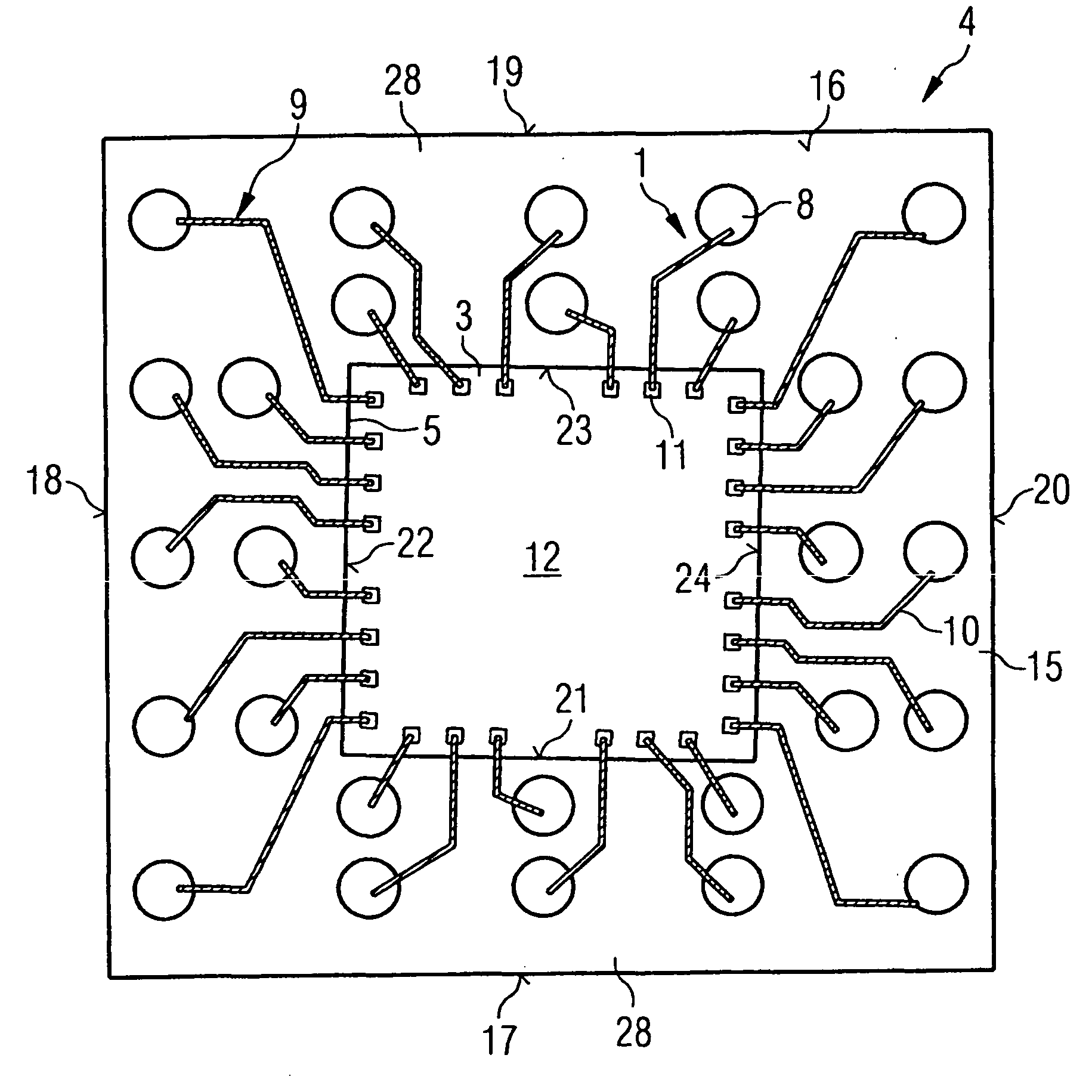

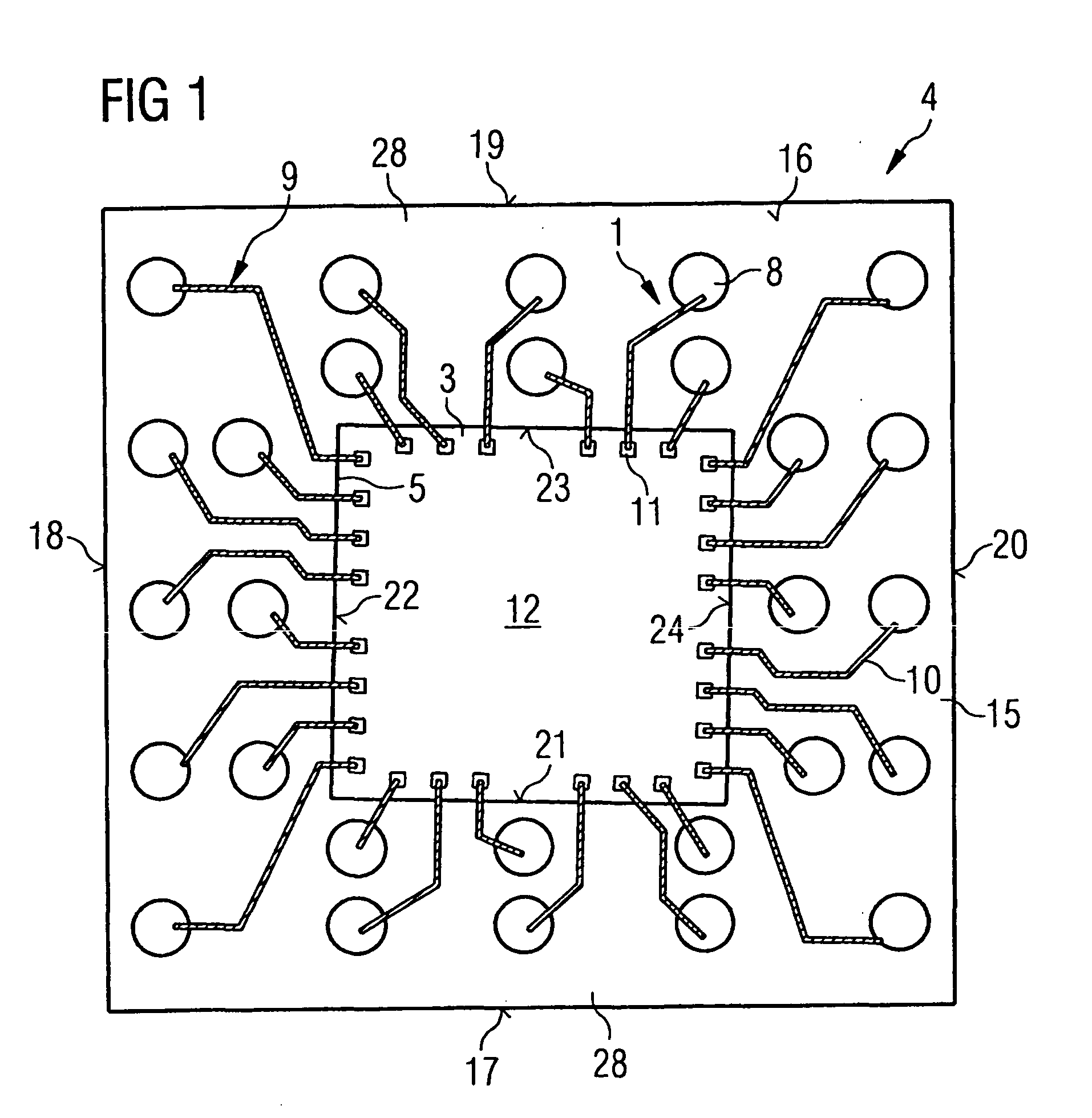

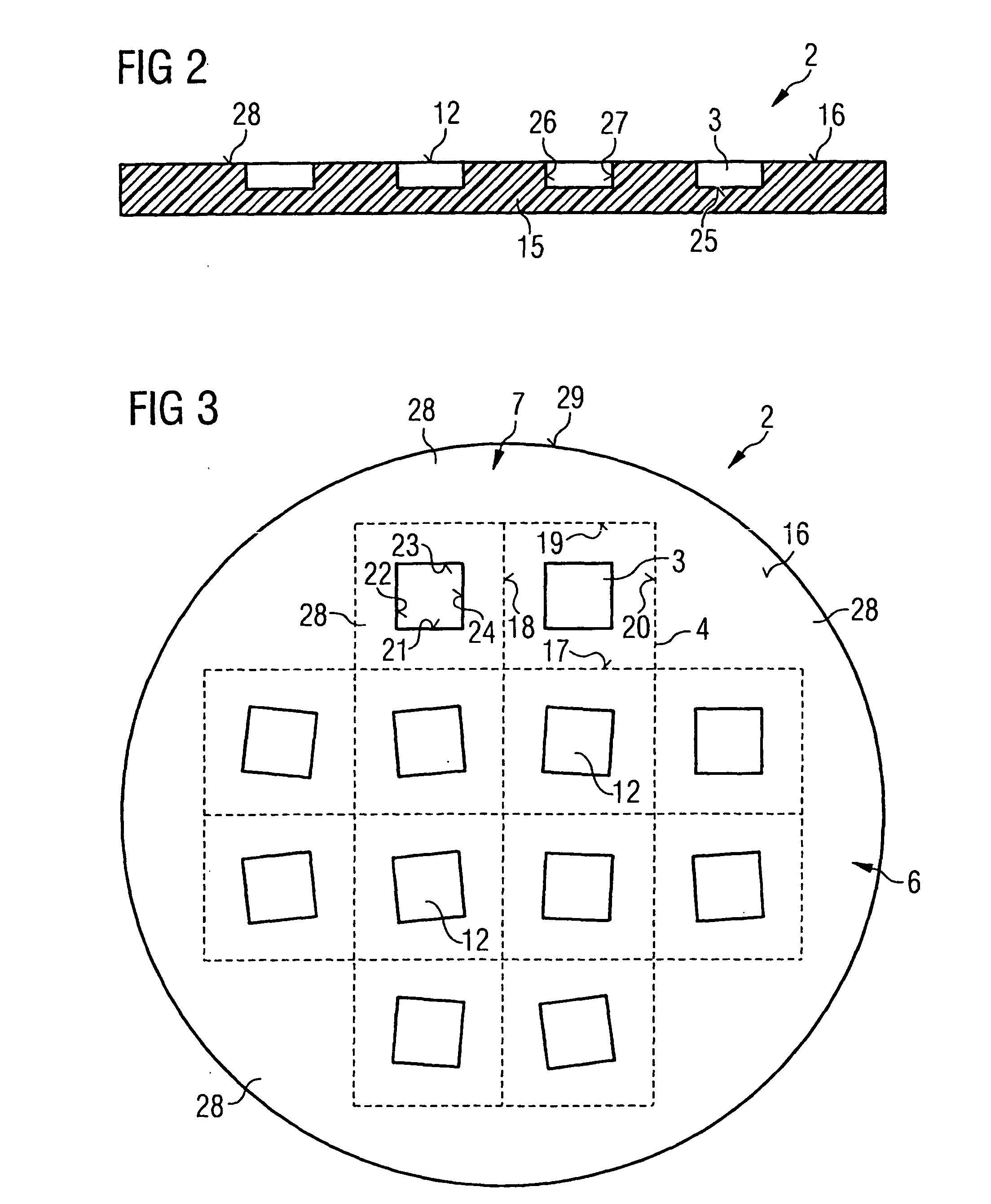

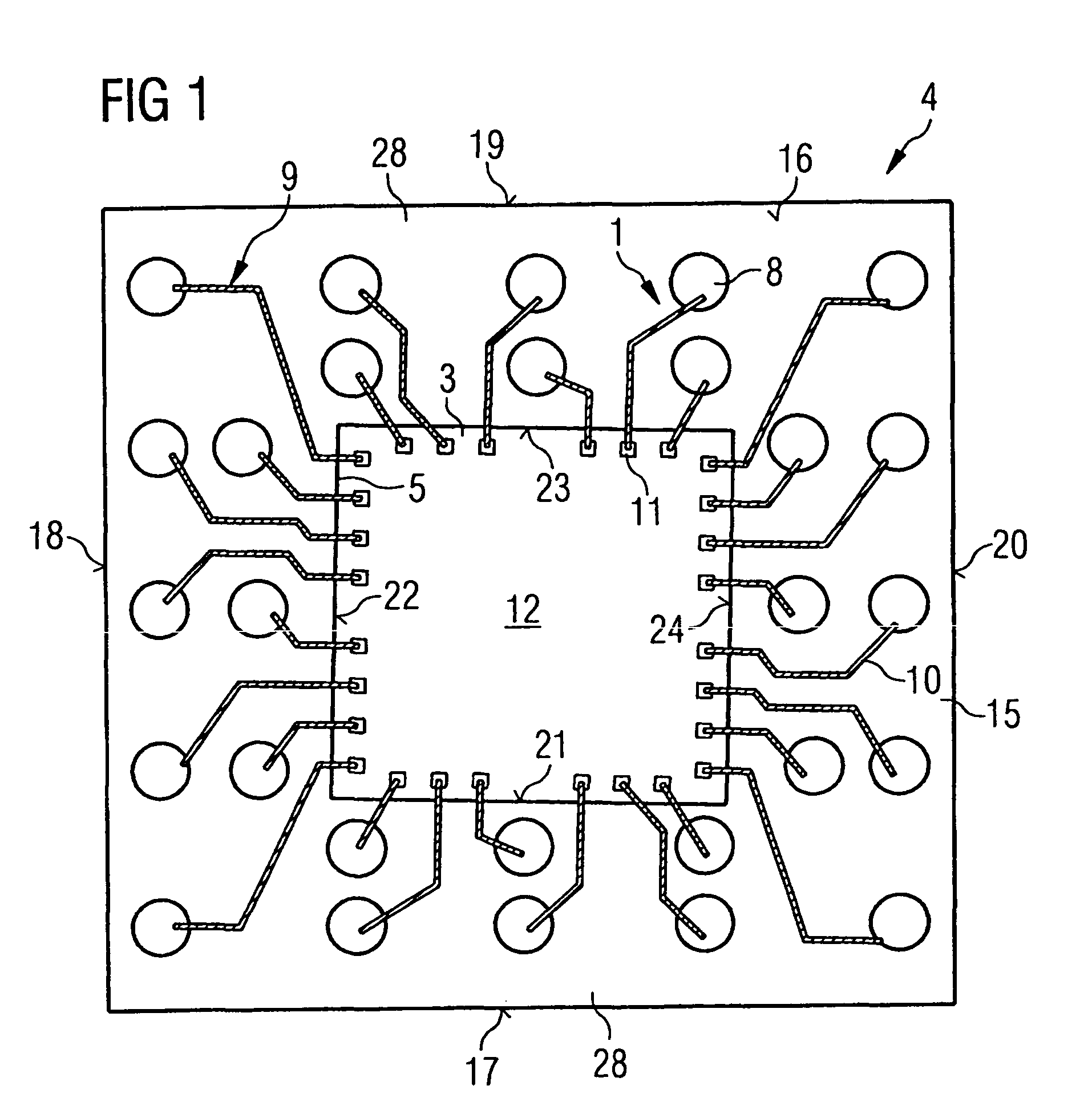

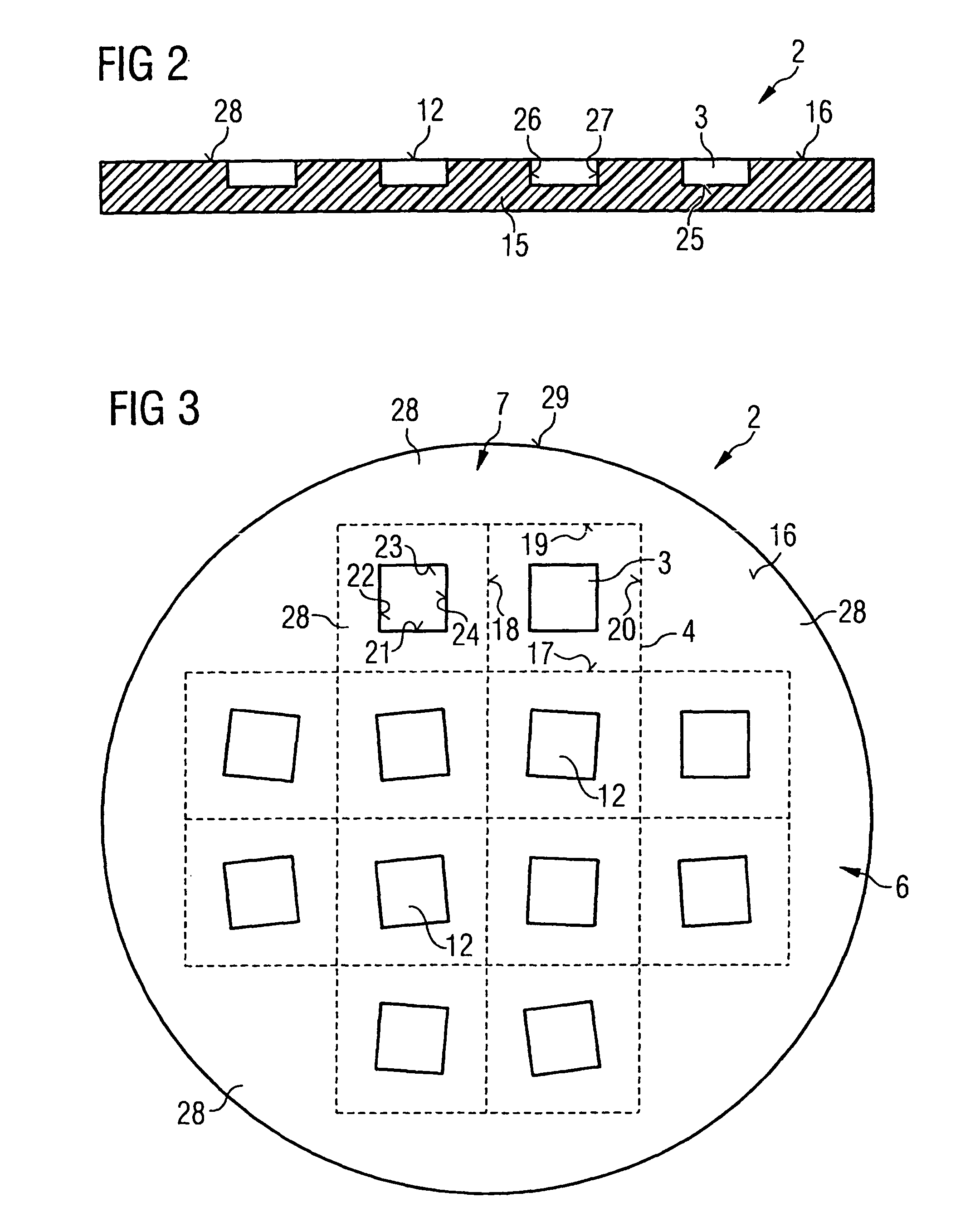

Method for Applying Rewiring to a Panel While Compensating for Position Errors of Semiconductor Chips in Component Positions of the Panel

InactiveUS20070249067A1Shorten process durationReduces rejectSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPosition errorCompound (substance)

The invention relates to a method for applying rewiring to a panel. For this purpose, a panel is provided which has a coplanar overall upper side of an upper side of a plastic compound and the upper sides of semiconductor chips. The method provides a rewiring layer with implementation of external contacts and rewiring lines which, by means of a two-stage exposure step, compensates for position errors of the semiconductor chips in the component positions of the panel.

Owner:POLARIS INNOVATIONS

Adjustable seal

ActiveUS8870189B2Shortened by the user accurately and easily at the site of useEasy to fallSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

The invention relates to external sealing of pipe joints. The invention provides a wide seal strip useful in combination with a coupling for pipes, the length, and hence the diameter of the seal strip being adjustable also on site. The invention provides a pipe clamp flexible seal strip adaptable to be easily shortened by the user to a required length. The seal strip being configured for use inside a pipe coupling, and having at least one narrow dividing cut which extends across the width of the seal to almost completely divide a major portion of the strip length from a minor portion thereof. The minor portion remaining connected to the major portion by at least one bridge member which can easily be severed on site for removal and disposal of the minor portion.

Owner:KRAUSZ INDS DEVMENT

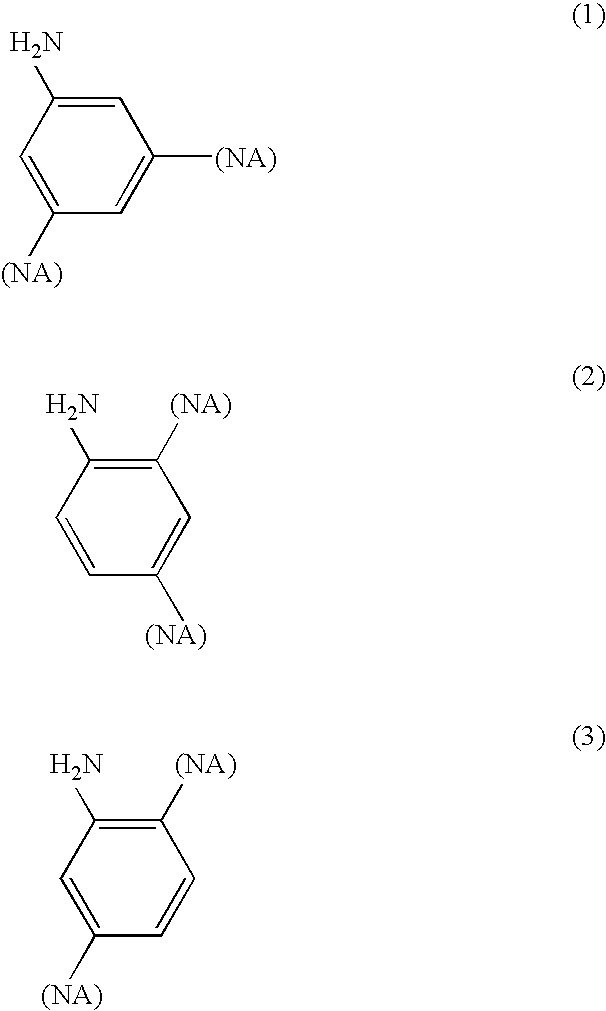

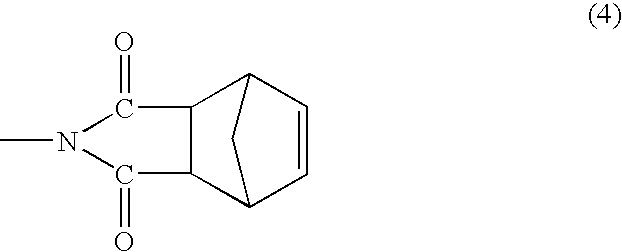

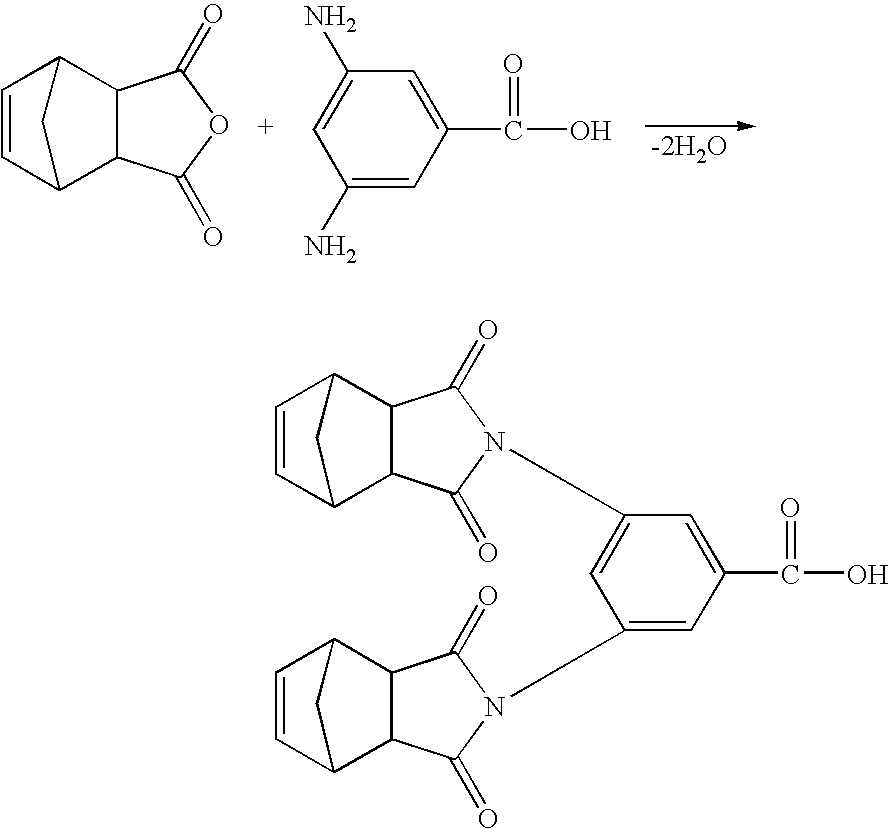

Dinadic phenyl amine reactive endcaps

InactiveUS20080300374A1Increase the degree of cross-linkingEasy to processOrganic chemistryEndcappingOligomer

Dinadic phenyl amine reactive endcap monomers for application in high-temperature polymeric composites are described. The amine group of the endcap is directly reacted with a desired chemical backbone to provide the preferred rigidity and chemical resistance. The ability of the amine group to react with a wide variety of chemical backbones allows the tailoring of formulations for various application temperatures, mechanical properties, processes and resistances while retaining the high degree of crosslinking that yields excellent temperature stability, ease of processing and the necessary toughness. Polyimide oligomers comprising the reaction product of at least one dinadic phenyl amine endcap monomer and a chemical backbone, preferably with a molecular weight not exceeding about 1000-3000, suitable for high-temperature composites are described. The dinadic phenyl amine endcaps may be reacted with an acid anhydride capped precursor to form polyimide resins suitable for high-temperature composites.

Owner:THE BOEING CO

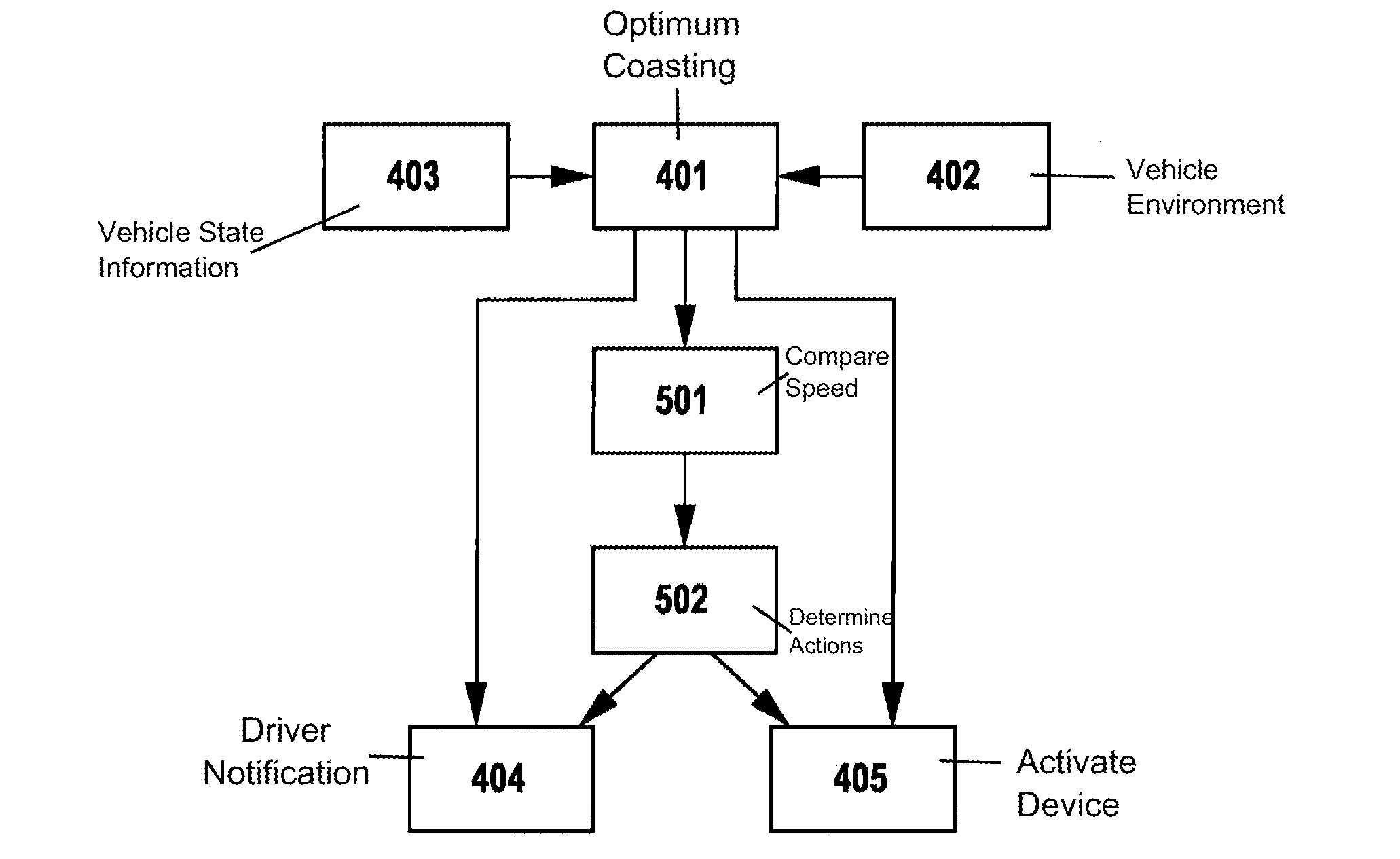

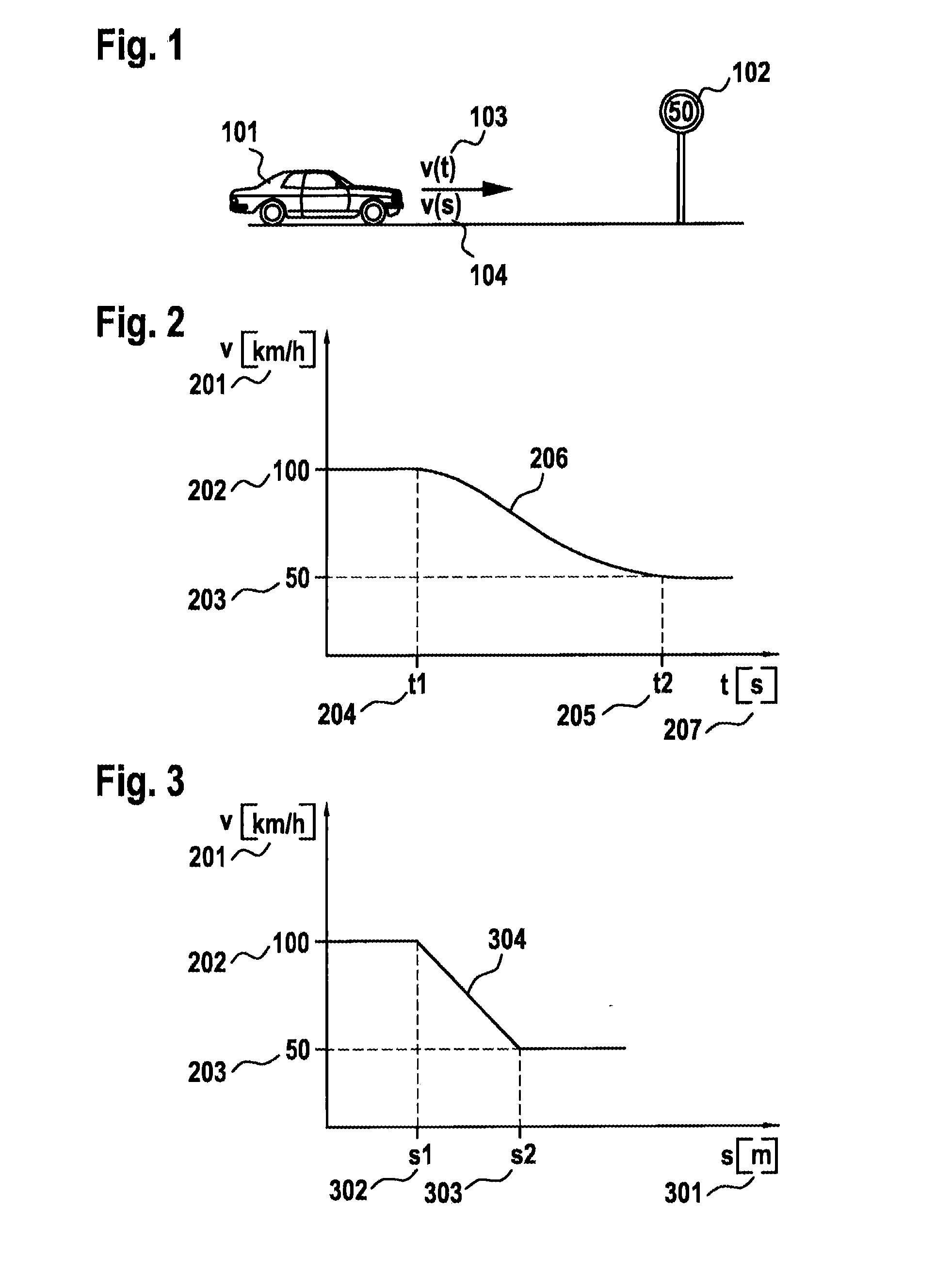

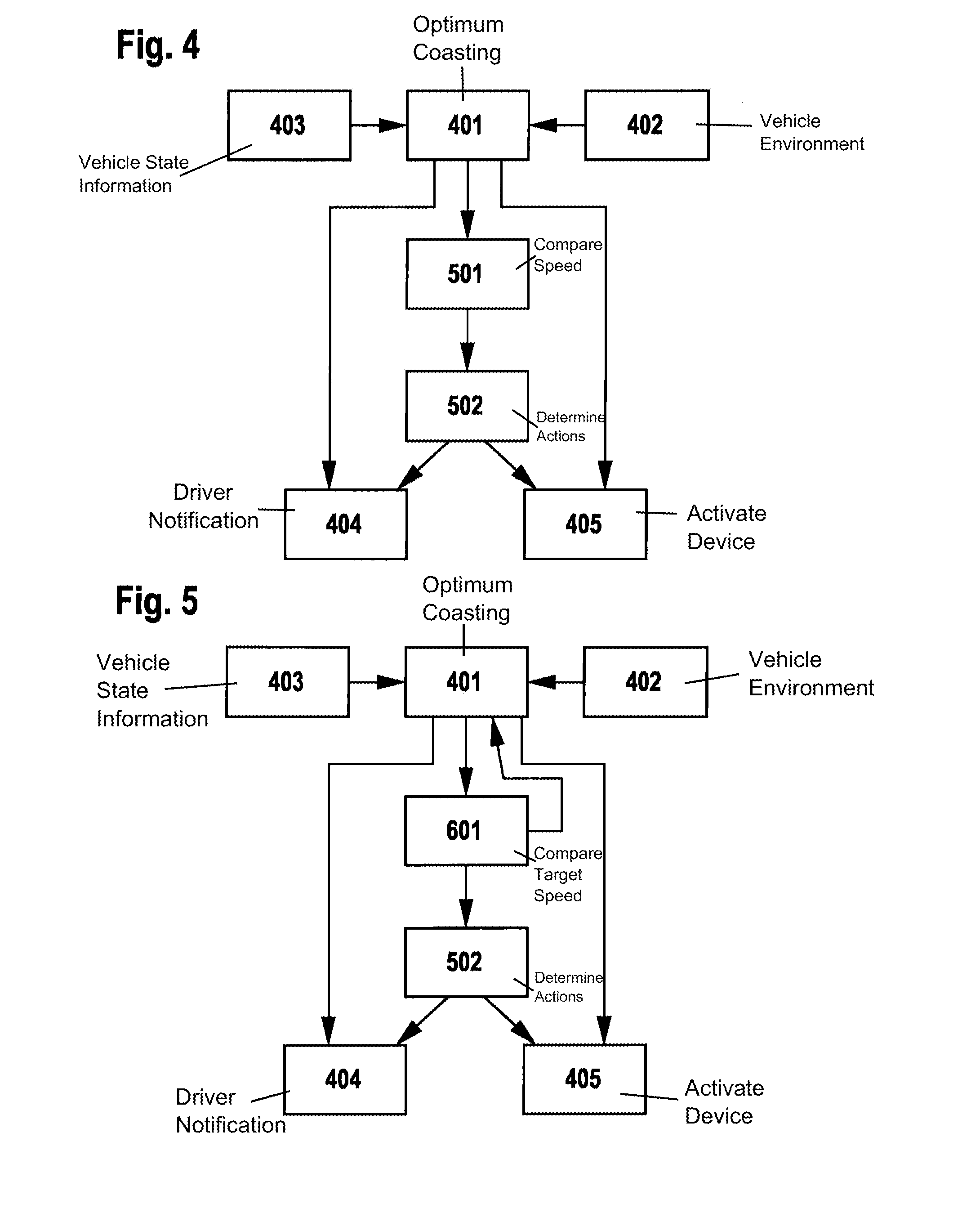

Method and device for operating a vehicle

InactiveUS20150298699A1Reduce consumptionPower is lowered and reducedInstruments for road network navigationDigital data processing detailsEngineeringComputer program

A method is provided for operating a vehicle, wherein during coasting of the vehicle, in order to reach a route position of a driving route that is still to be travelled, at a desired speed that is less than a vehicle speed at the start of coasting, a vehicle actual speed is compared with a vehicle target speed and an action is performed in dependence on the comparison. This renders possible a continuous adaptation of the driving resistance, so the desired speed is reliably reached. Interfering variables such as wind or gradient may be compensated for. A device is provided for operating a vehicle, and to a computer program.

Owner:ROBERT BOSCH GMBH

Tubular baseball bats with variable stiffened barrels

InactiveUS20090029810A1Minimal weightLower performance requirementsRacket sportsVariable stiffnessBarrel Shaped

Tubular baseball bats comprised of an elongated handle portion and a striking or barrel portion wherein the barrel portion has variable stiffness along its length. One such bat has a circumferential low cost, low weight stiffener generally located in the sweetspot area designed to increase radial stiffness in a controlled manner which results in decreasing the bat performance to meet a changed bat performance standard and can be applied at low cost to both used field returned bats and bats being newly manufactured. Further, new tubular polymer composite bats can be designed with increased radial stiffness generally located in the sweetspot area or with radial stiffness graduated from highest, generally in the sweetspot area, to lowest at the barrel ends. All bats of the present invention result in calculated bat performance to meet applicable regulatory standards while also increasing the sweetspot size.

Owner:CE COMPOSITES BASEBALL

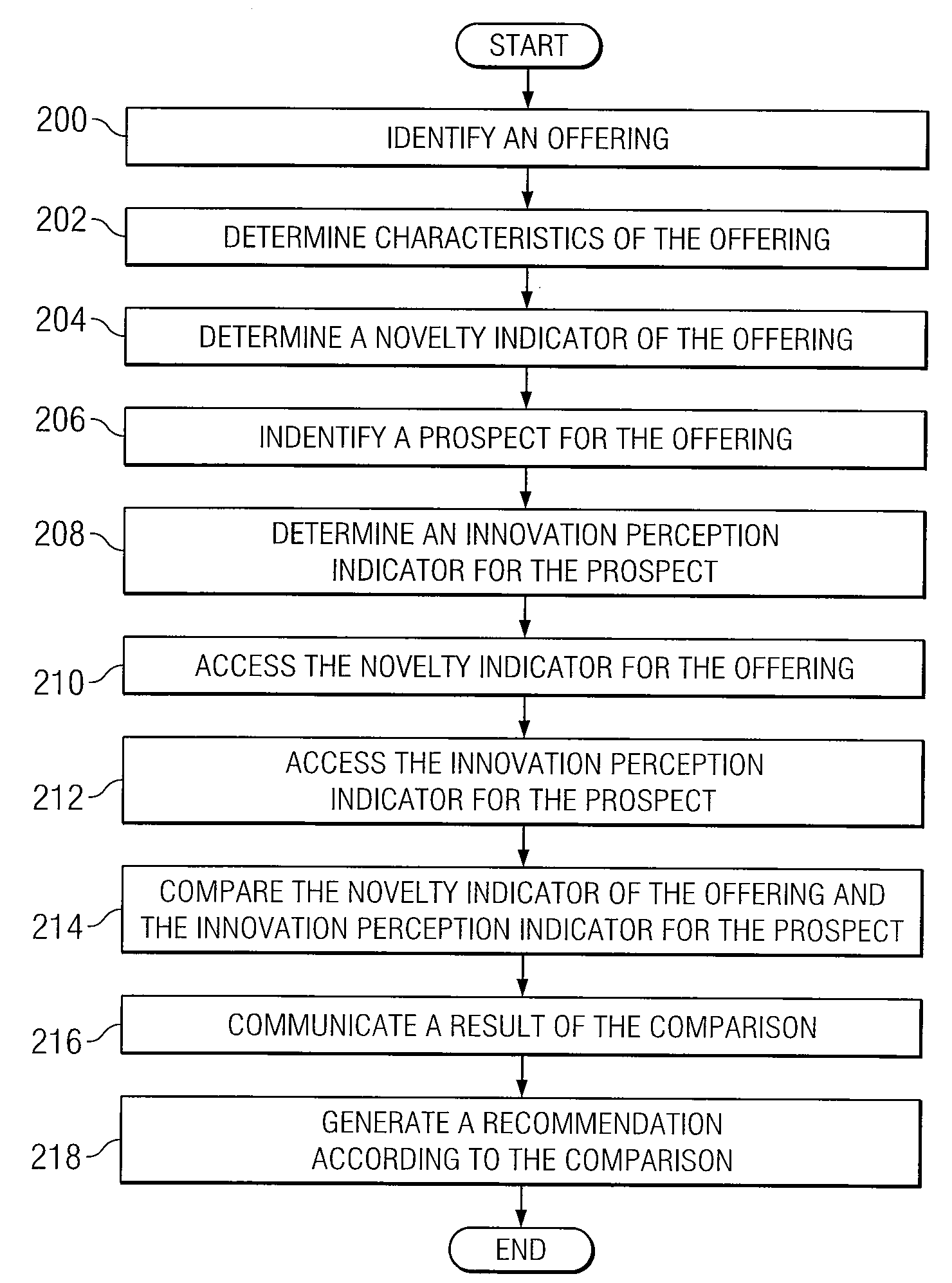

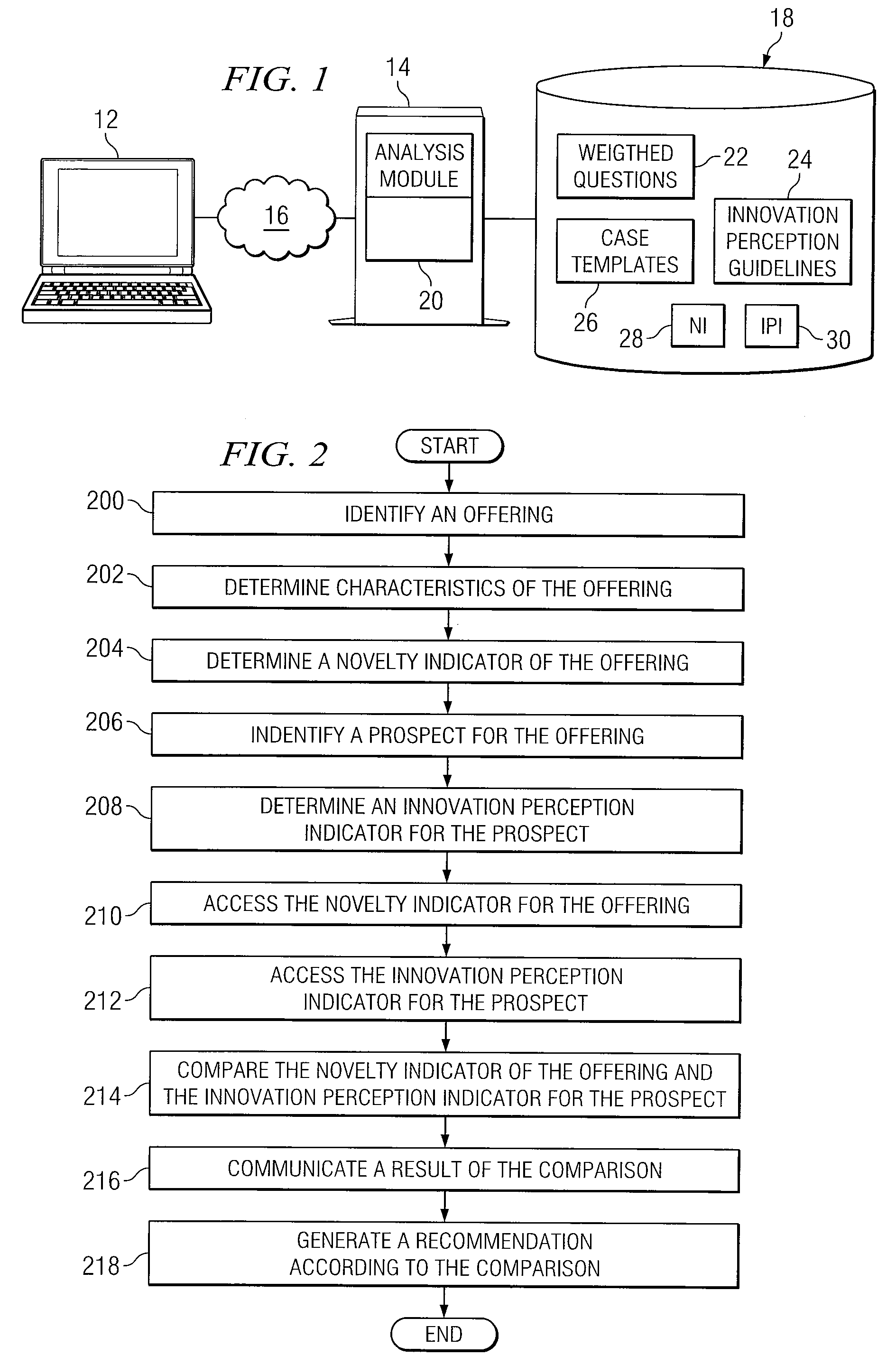

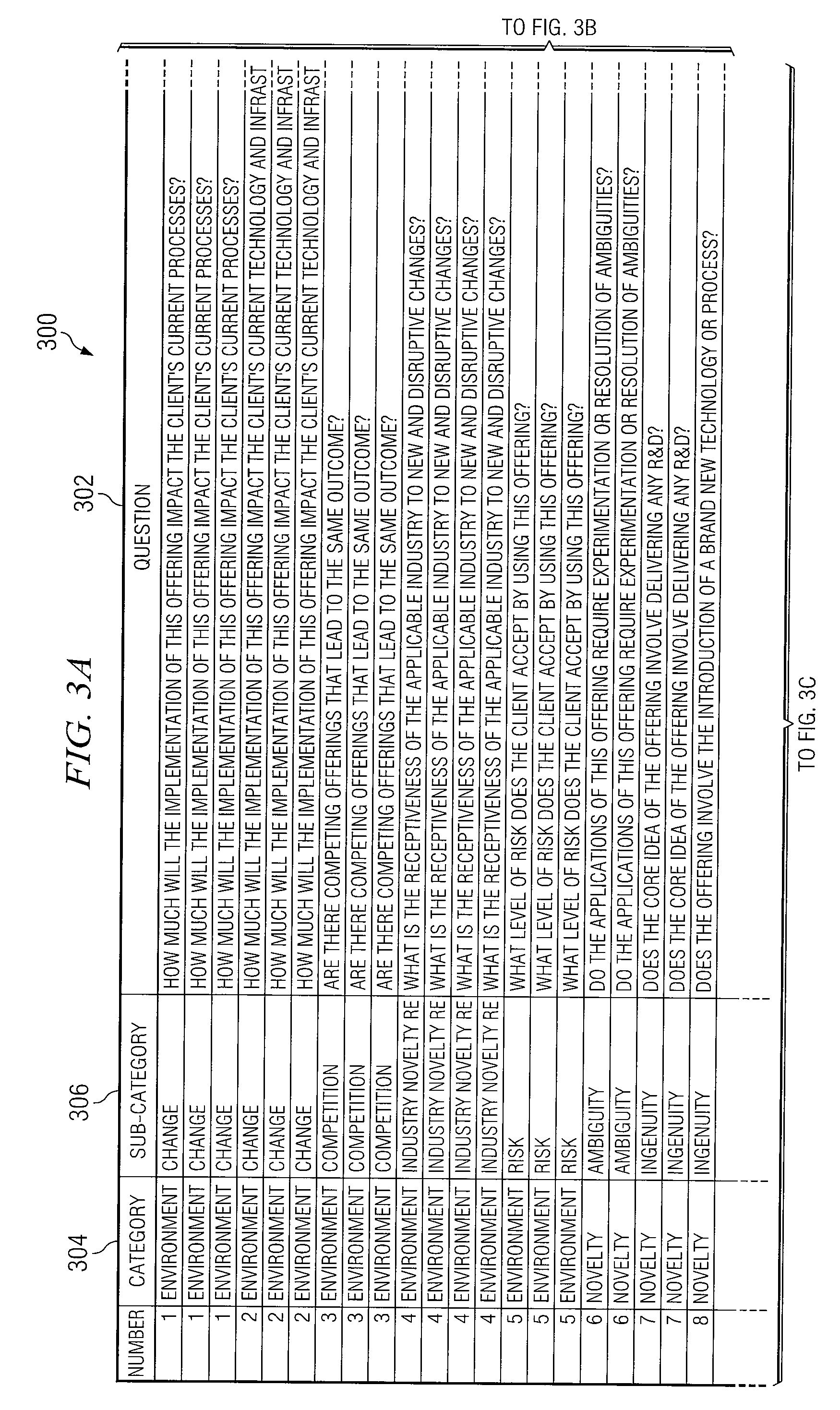

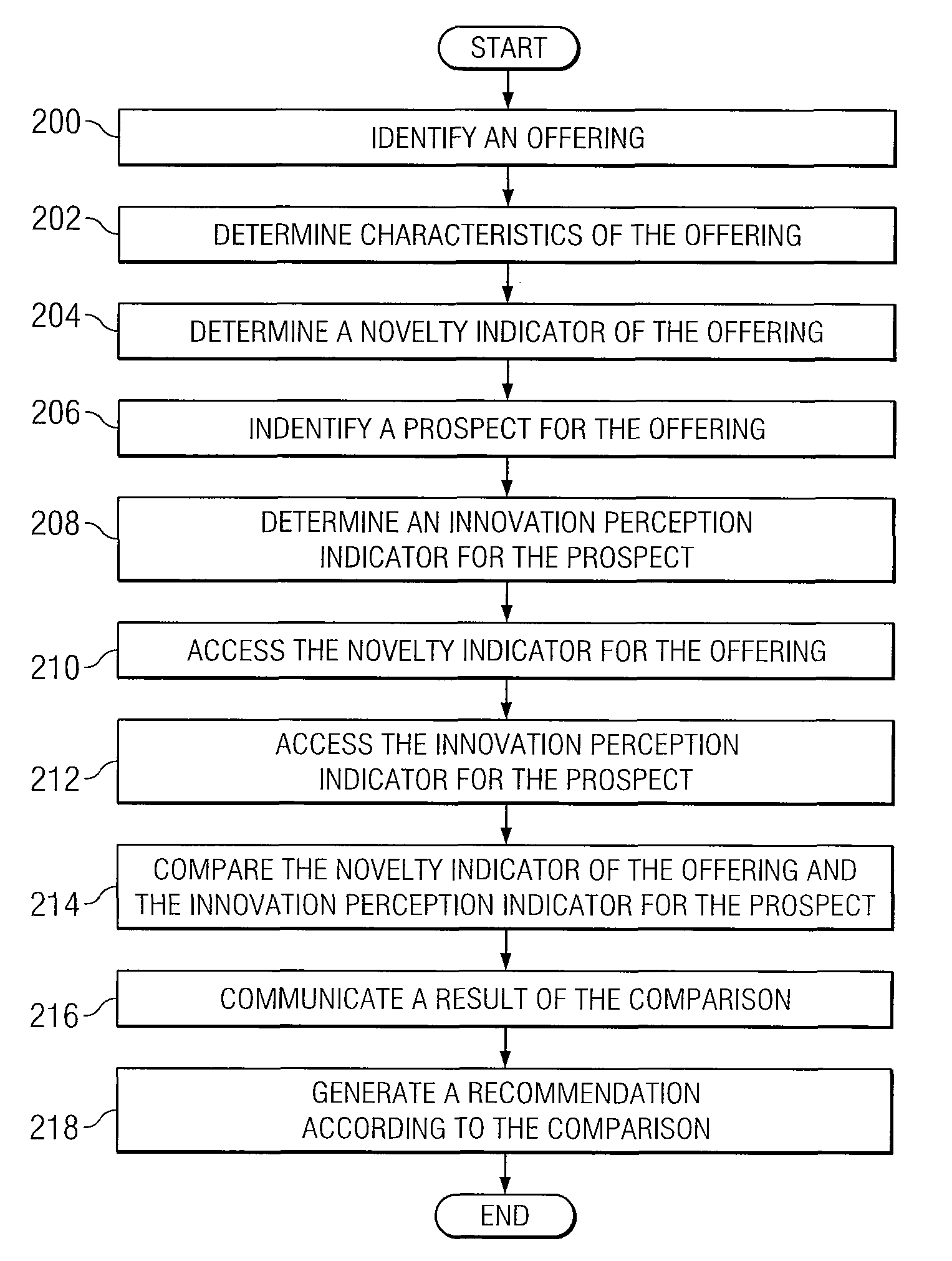

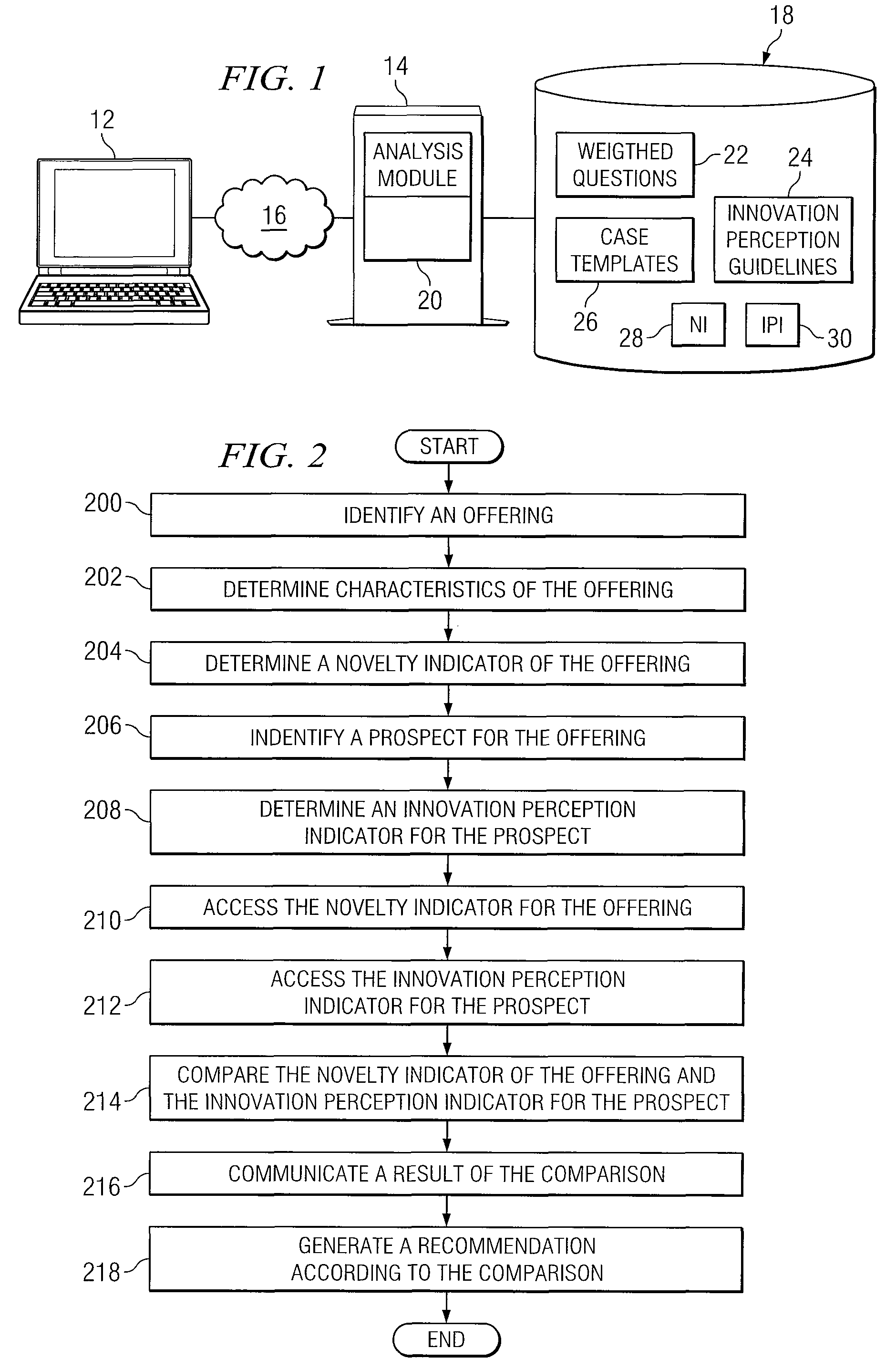

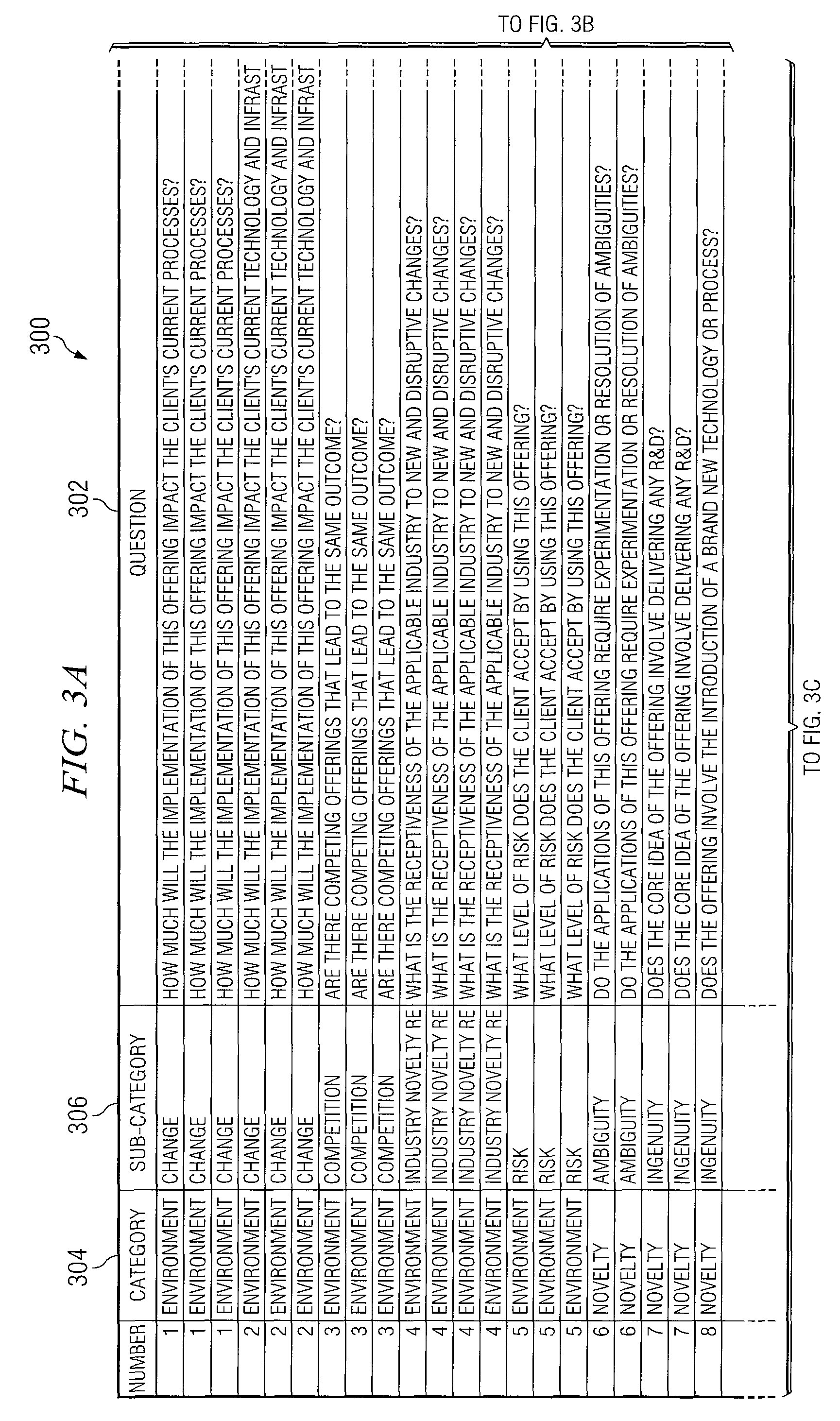

Quantitative Alignment of Business Offerings with the Expectations of a Business Prospect

InactiveUS20090070160A1Expectation can be reduced and eliminatedIncrease probabilityMarket predictionsData acquisition and loggingEngineeringPerception

In certain embodiments, a method for quantitative alignment of business offerings with the expectations of a business prospect includes accessing a novelty indicator for an offering, the novelty indicator being based on one or more characteristics of the offering and rating an innovation level of the offering. The method further includes accessing an innovation perception indicator for a prospect of the offering, the innovation perception indicator providing an indication of how the prospect views innovation. The method further includes comparing the novelty indicator for the offering with the innovation perception indicator for the prospect to determine if the offering is aligned with the expectations of the prospect. In certain embodiments, the method includes generating a recommendation, possibly in the form of a report, based on the comparison of the novelty indicator for the offering and the innovation perception indicator for the prospect.

Owner:ENT SERVICES DEV CORP LP

Method for applying rewiring to a panel while compensating for position errors of semiconductor chips in component positions of the panel

InactiveUS7514273B2Increase heightProcessing duration reducedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor chipEngineering

The invention relates to a method for applying rewiring to a panel. For this purpose, a panel is provided which has a coplanar overall upper side of an upper side of a plastic compound and the upper sides of semiconductor chips. The method provides a rewiring layer with implementation of external contacts and rewiring lines which, by means of a two-stage exposure step, compensates for position errors of the semiconductor chips in the component positions of the panel.

Owner:POLARIS INNOVATIONS LTD

Packeted energy delivery system and methods

ActiveUS20150142198A1Targeted power supplyImprove efficiencyMechanical power/torque controlLevel controlVoltage pulseElectricity delivery

Methods and apparatus for packetized energy distribution are provided. A data and power delivery network, called a digital grid, is provided to facilitate delivery of power upon request. Energy bits (quanta) serve as a means to deliver energy as well as coding. Voltage pulses of varying time scales are used for coding and current levels help to accurately meet customer's demand. Energy is sent as packets (a combination of energy bits), and specific energy packets are addressed to specific customers permitting accurate monitoring and distribution of electrical energy.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

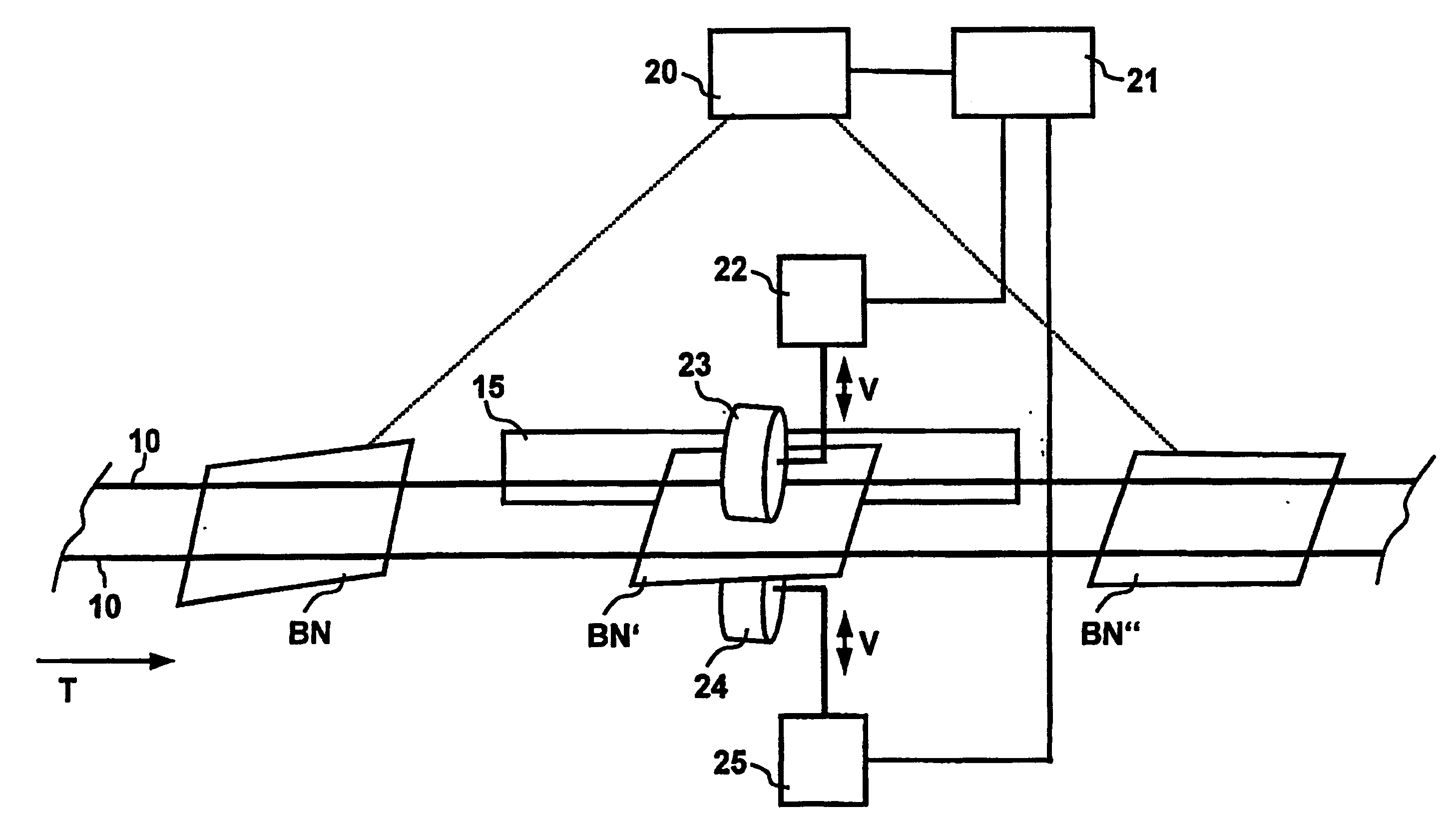

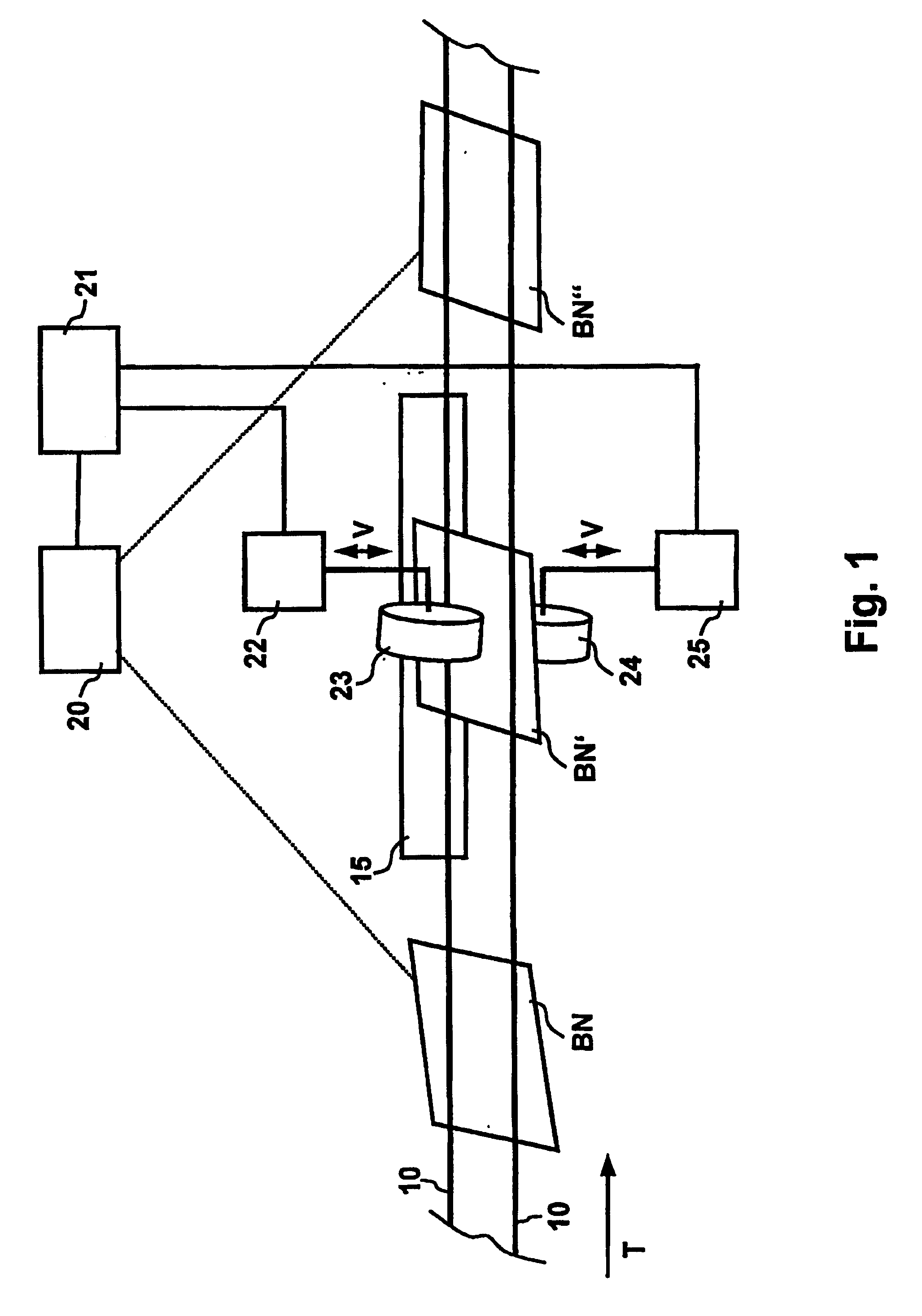

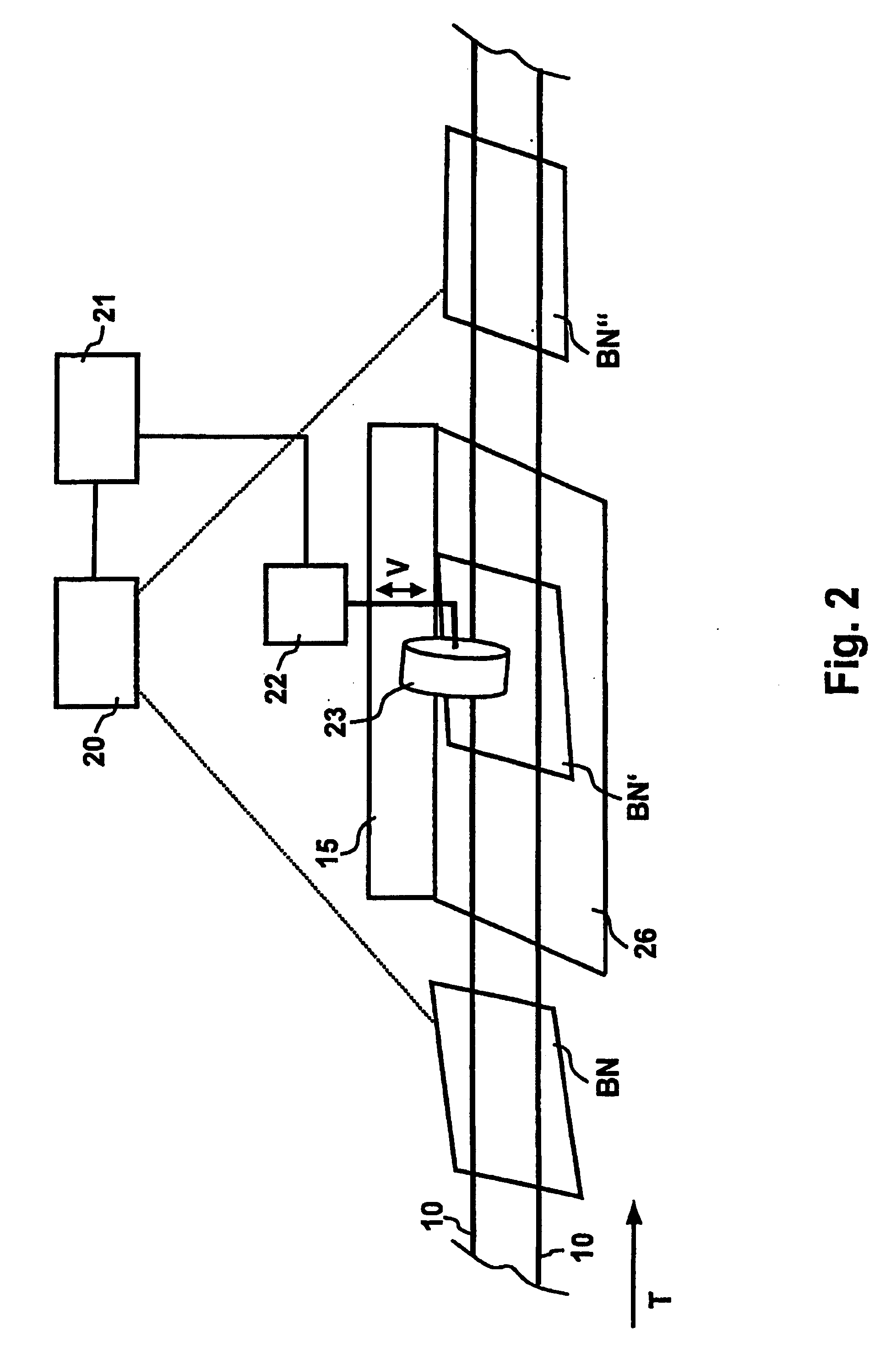

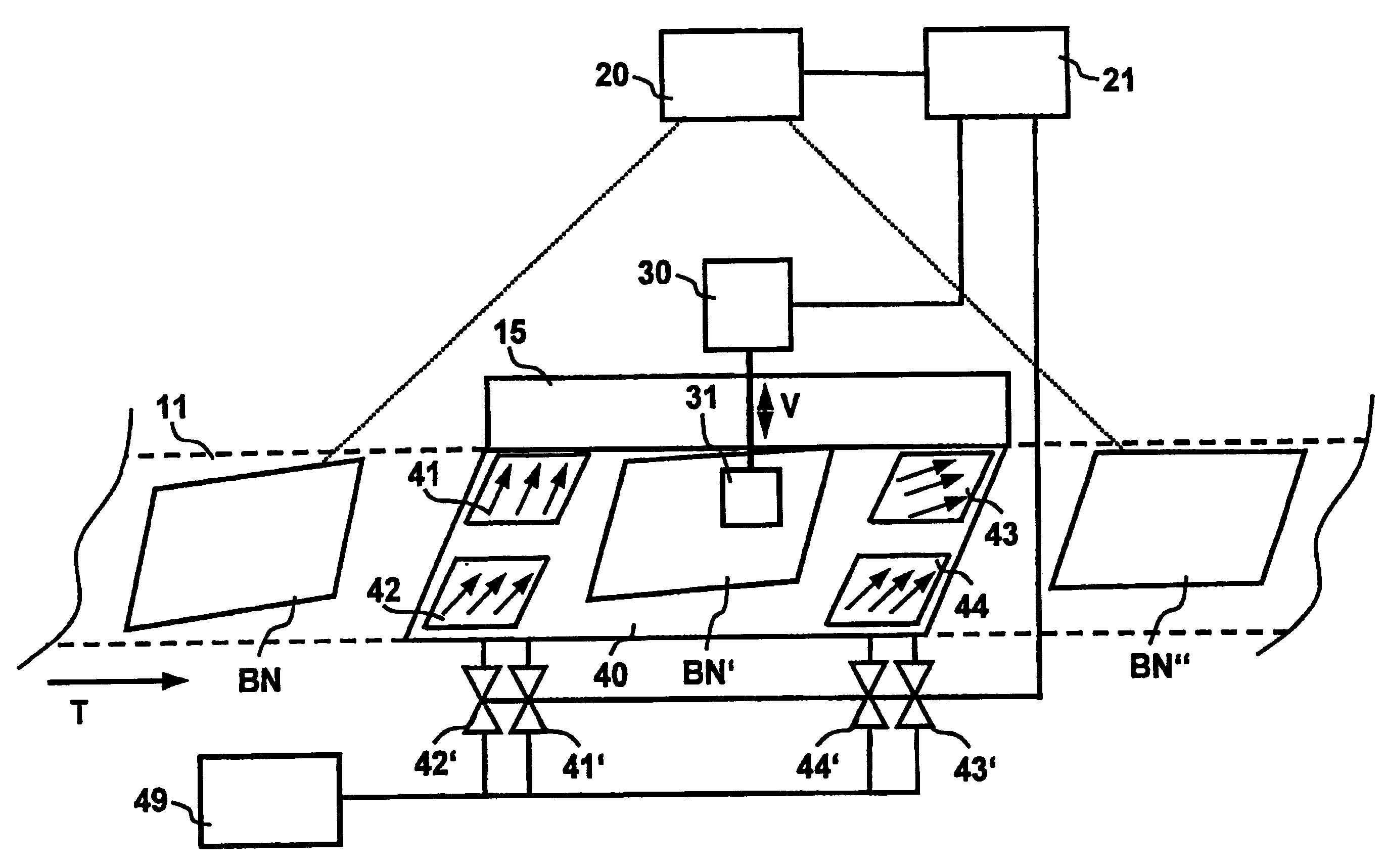

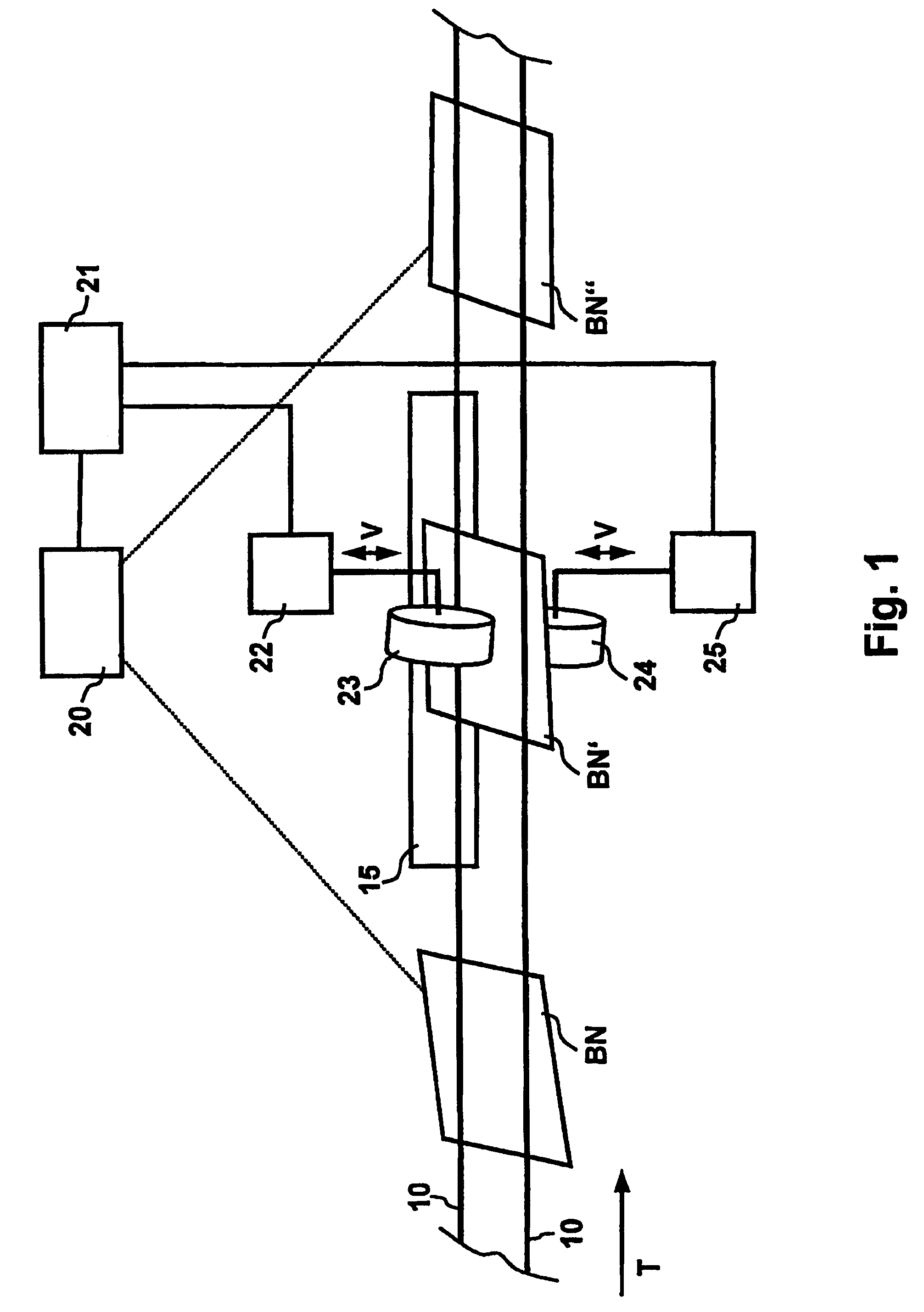

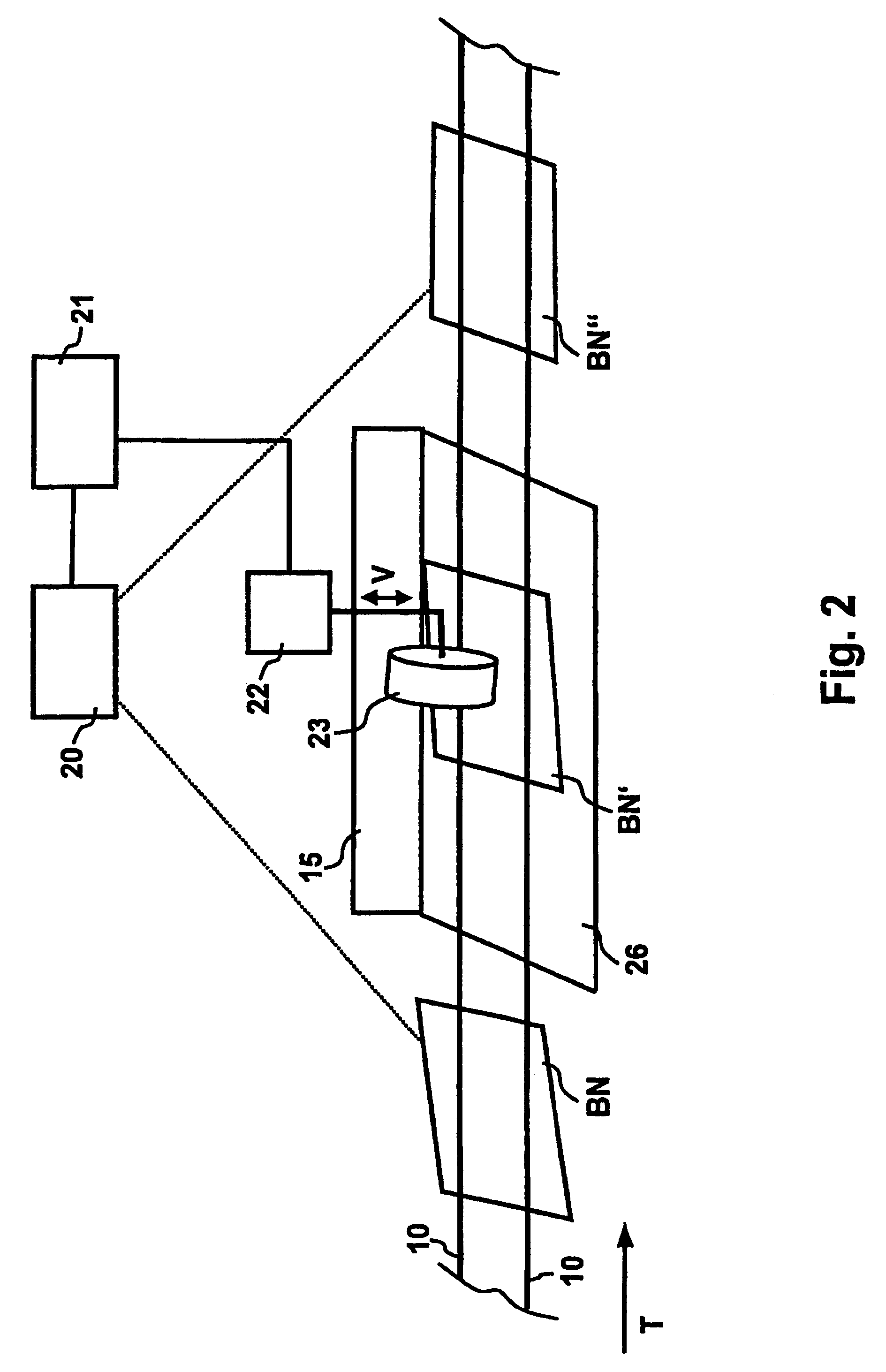

Device and method for aligning bank notes

InactiveUS20060038340A1Reduce impactPrecise alignmentRegistering devicesCoin countersTransport systemEngineering

An apparatus and a method for aligning bank notes in a transport system in which, when aligning bank notes in a transport system the alignment of a bank note transported separately in the transport system is detected, that it is checked, whether the detected alignment of the single bank note is a misalignment, that the single bank note according to the detected misalignment is aligned in a desired alignment by a movement of the single bank note in a direction deviating from the transport direction of the transport system, the alignment of the single bank note during the aligning being detected, and the aligning being terminated, as soon as the single bank note has the desired alignment.

Owner:GIESECKE & DEVRIENT CURRENCY TECHNOLOGY GMBH

Image forming method and image forming device

InactiveUS7619791B2Excellent developabilityAccurately metDigitally marking record carriersDigital computer detailsImage formationEngineering

A reference developing image is formed on a photoreceptor drum under an image forming condition measured in advance, and the density of this reference developing image is detected. A development bias voltage is corrected based on the detection result, and when a correction value of the development bias voltage exceeds a predetermined range, a reference output voltage of an ATC sensor for detecting the density of toner in a developing device is corrected based on the detected value of humidity around the developing device, the frequency of use of the apparatus, and the agitation stress of developer.

Owner:SHARP KK

Quantitative alignment of business offerings with the expectations of a business prospect

InactiveUS7966212B2Expectation can be reduced and eliminatedIncrease probabilityMarket predictionsMarket data gatheringEngineeringPerception

Owner:ENT SERVICES DEV CORP LP

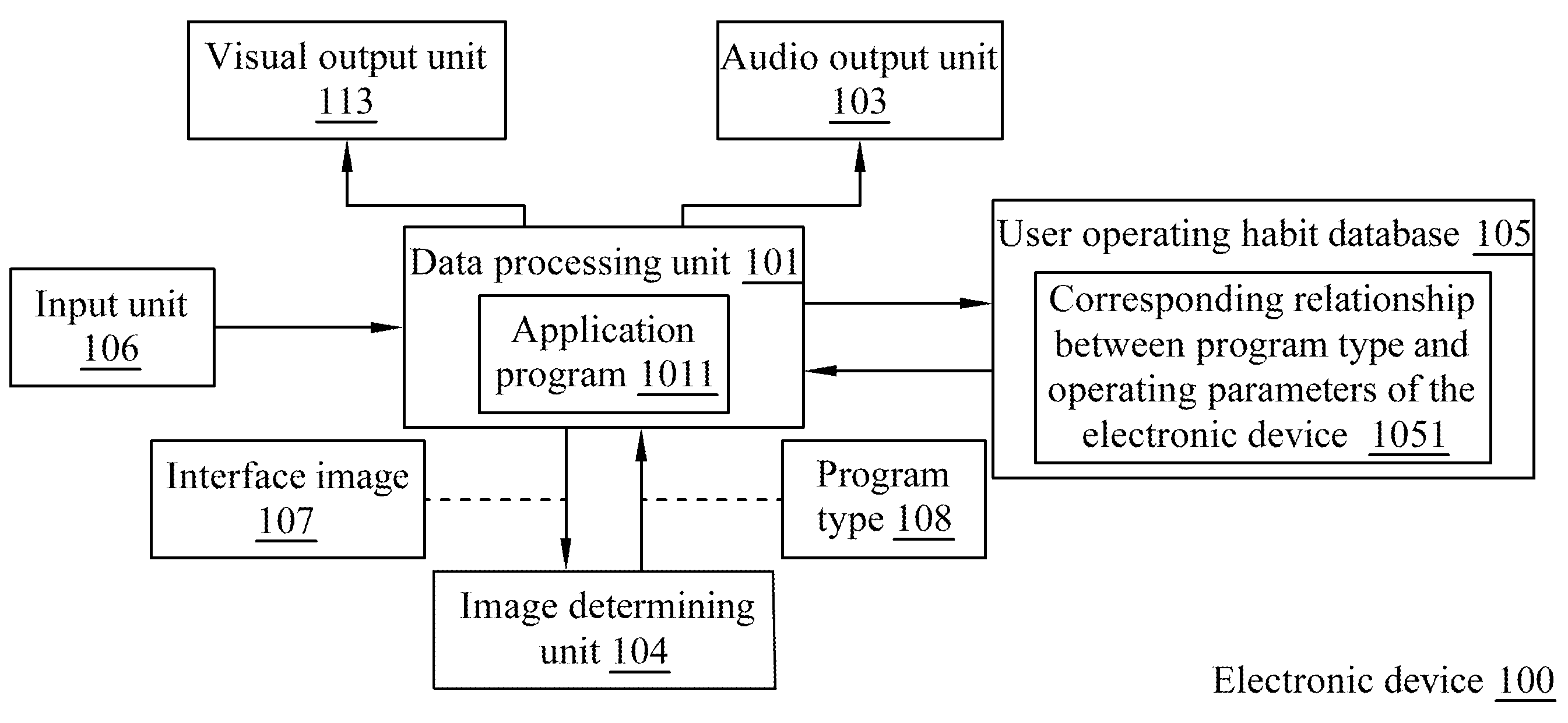

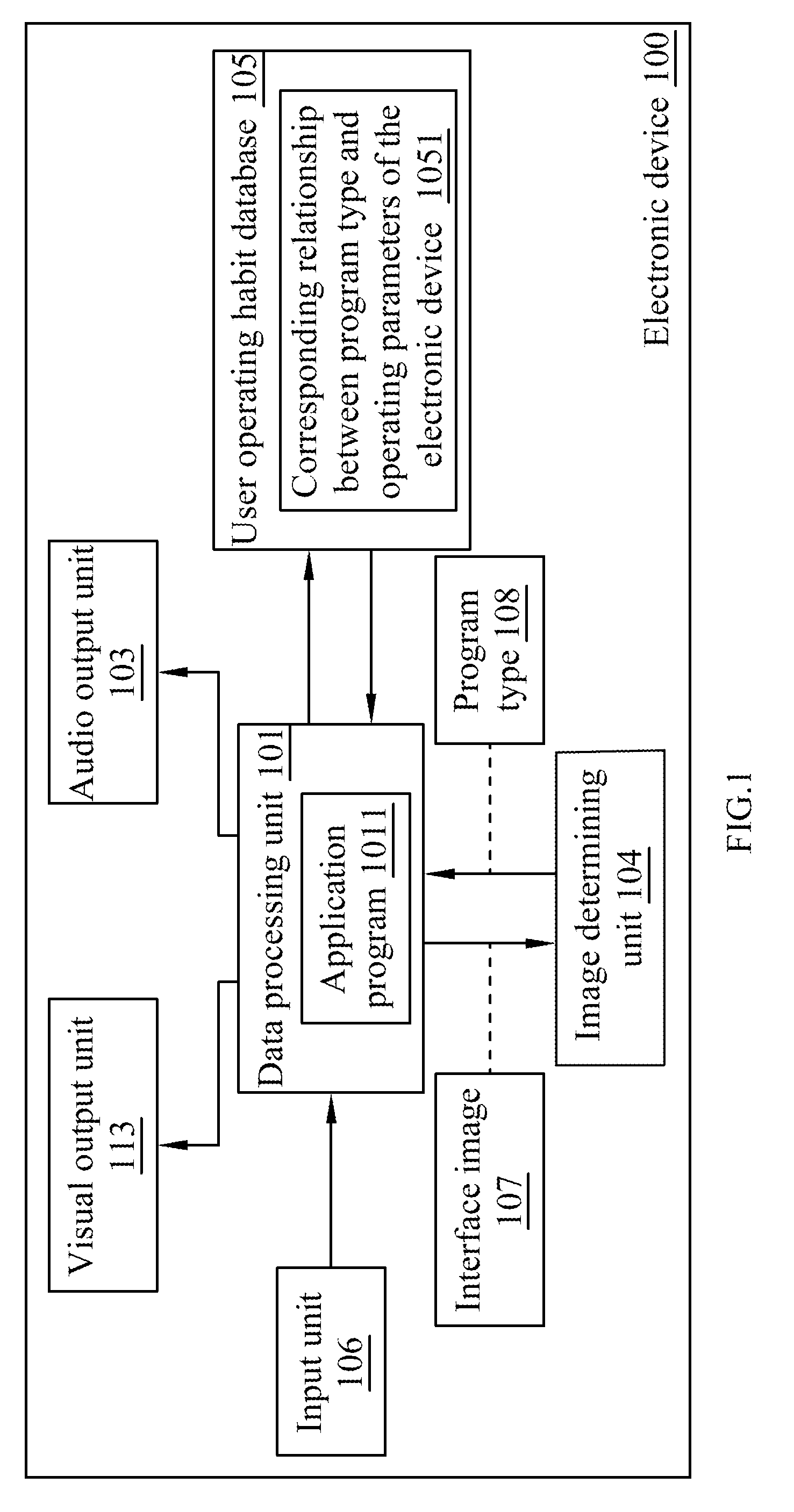

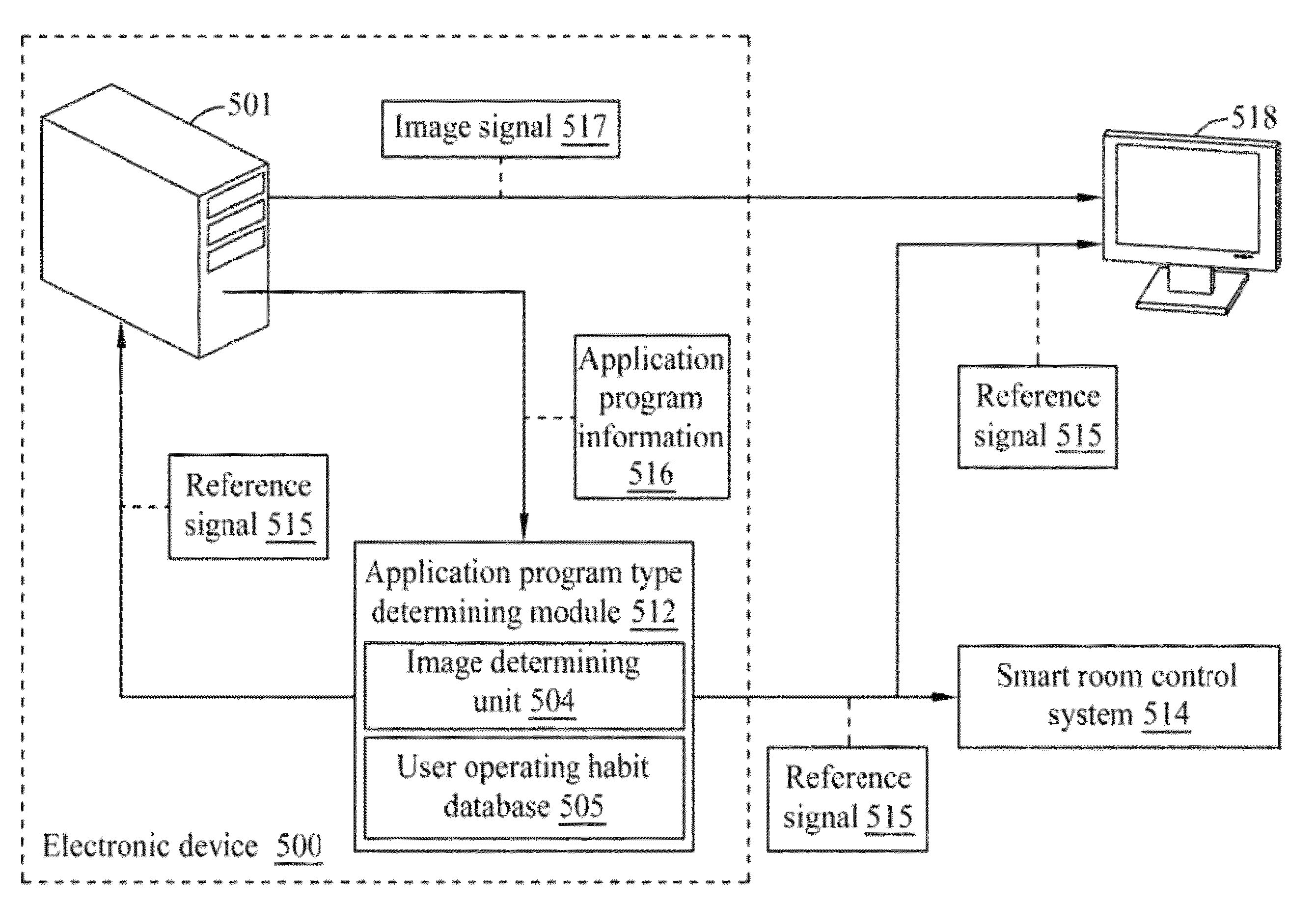

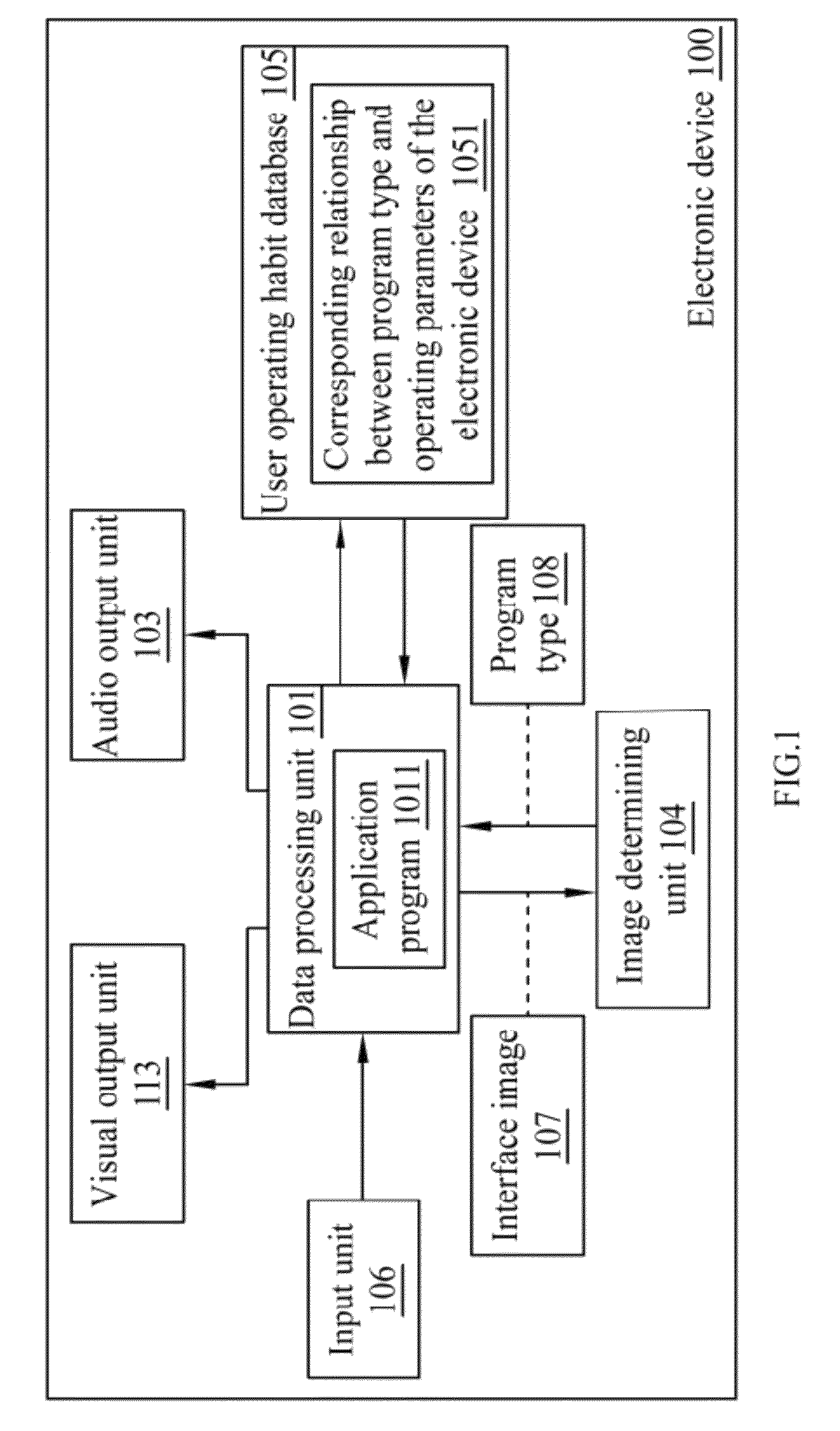

Eletronic device, display device, and method of controlling audio/video output of an electronic device

ActiveUS20100220244A1Accurately metTelevision system detailsComputer controlDisplay deviceAudio frequency

An electronic device, a display device, and a method of controlling audio / video output of the electronic device are disclosed. The electronic device includes a data processing unit, a visual output unit, an audio output unit, and a user operating habit database. The data processing unit executes an application program, the visual output unit outputs an image signal, the audio output unit outputs an audio signal, and the user operating habit database records a corresponding relationship between different program types and operating parameters of the visual output unit or the audio output unit. And, the data processing unit acquires the program type of the application program being run for controlling the operating parameters of the visual output unit or the audio output unit.

Owner:ACER INC

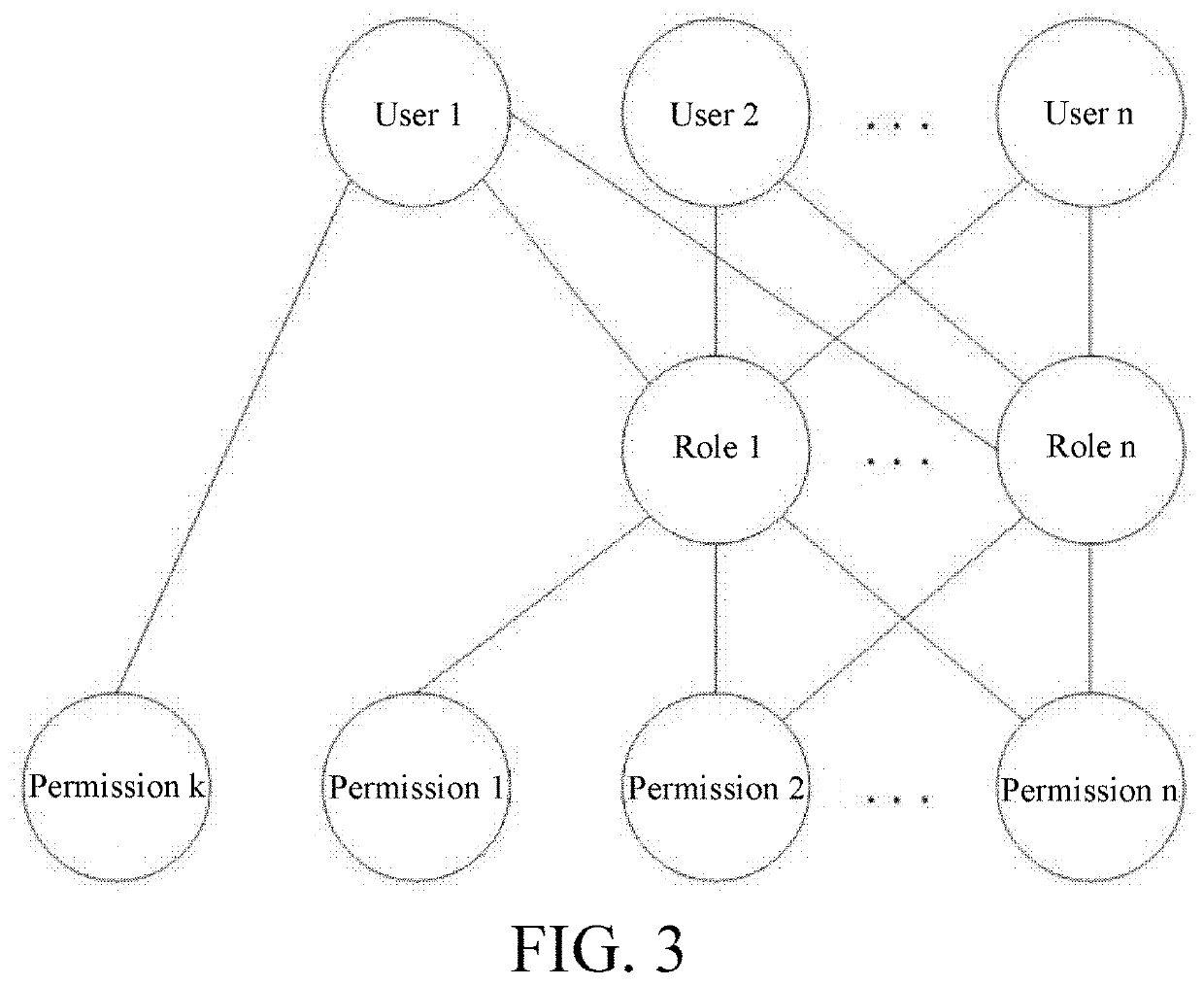

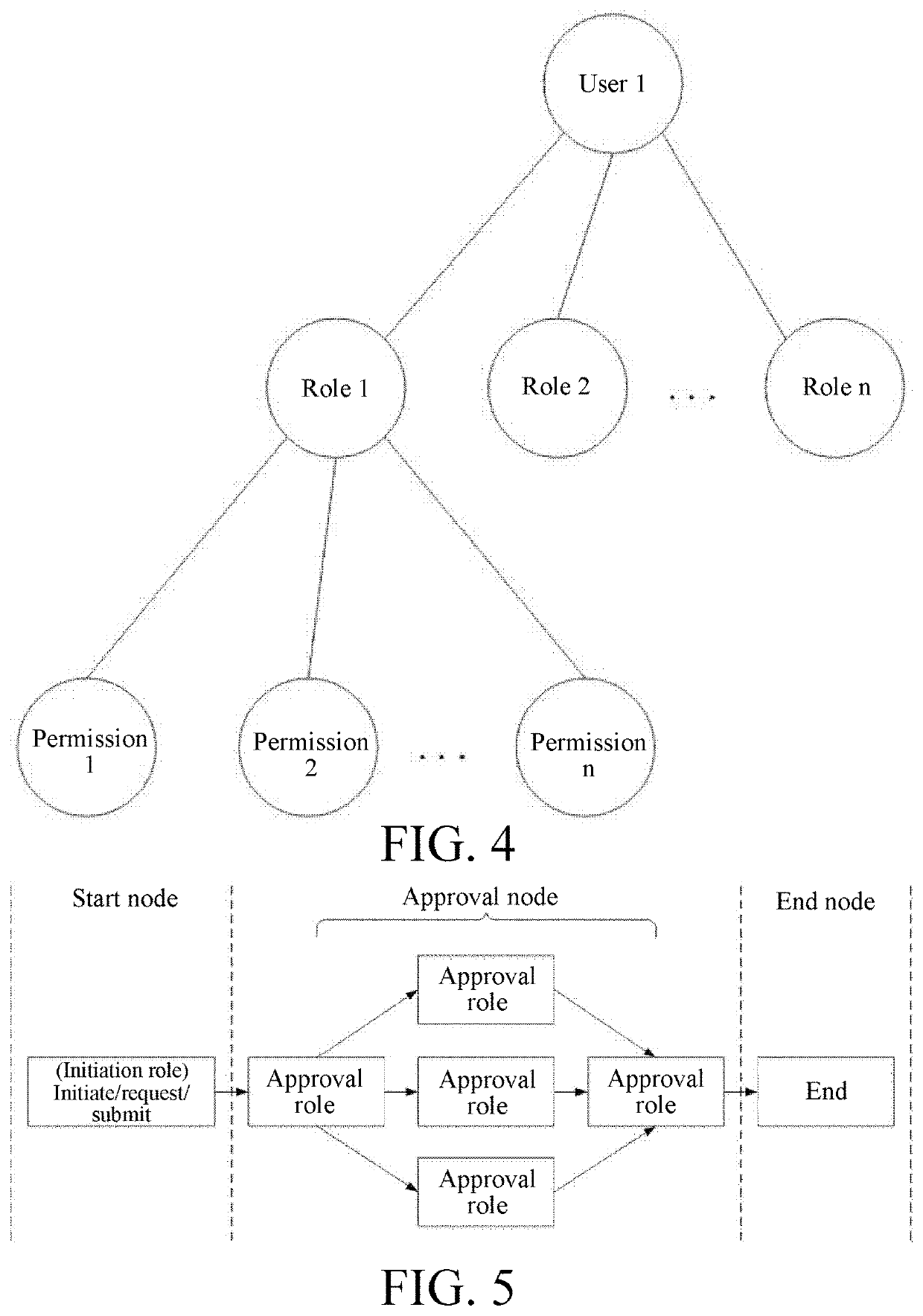

Method for setting approval procedure based on base fields

PendingUS20200134527A1The process is simple and clearEasy to understandComputer security arrangementsResourcesSoftware engineeringData science

A method for setting an approval process based on basis fields is disclosed in the present invention, including a step of creating an approval process: S1: selecting a form corresponding to the approval process; S2: selecting a basis field for the approval process, where one basis field can be selected by one or more approval processes; and S3: setting a field value set of the selected basis field of the approval process, wherein each field value can only exist in a field value set of one approval process under the basis field. During relation to the approval process, it is determined, according to the field value of the basis field in the approval form, the approval form belongs to which approval process's field value set of the corresponding basis field. In the present invention, when a form is submitted to be approved in an approval process, the form may be automatically related to an approval process according to a field value of a basis field in the form. The process is determined according to content of the basis field in the form, which is simple, clear, and easy to operate. The basis field in the form is changeable, so that different approval requirements in actual management can be met.

Owner:CHENGDU QIANNIUCAO INFORMATION TECH CO LTD

Device and method for aligning bank notes

InactiveUS7780163B2Reduce impactPrecise alignmentRegistering devicesCoin countersTransport systemMechanical engineering

Owner:GIESECKE & DEVRIENT CURRENCY TECHNOLOGY GMBH

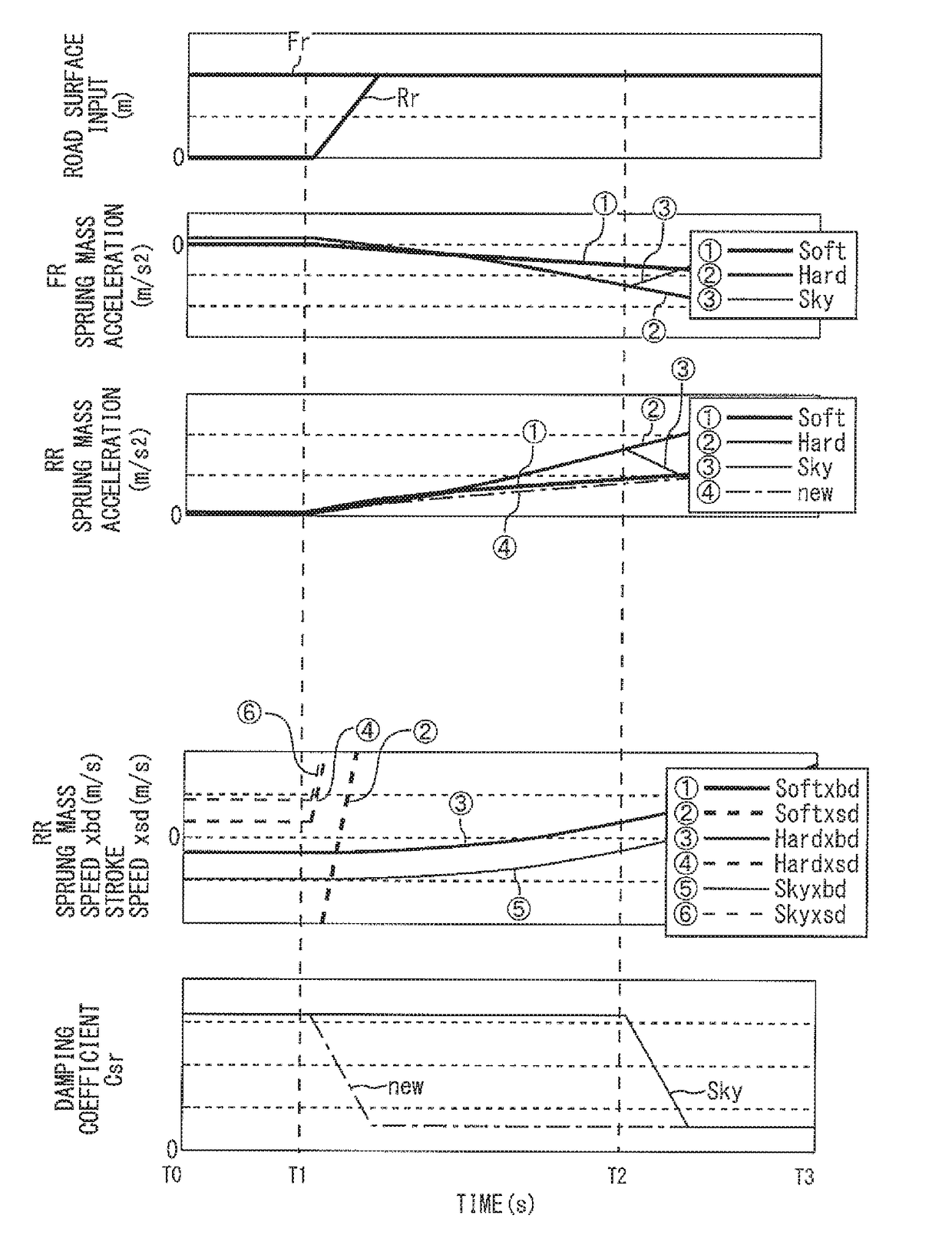

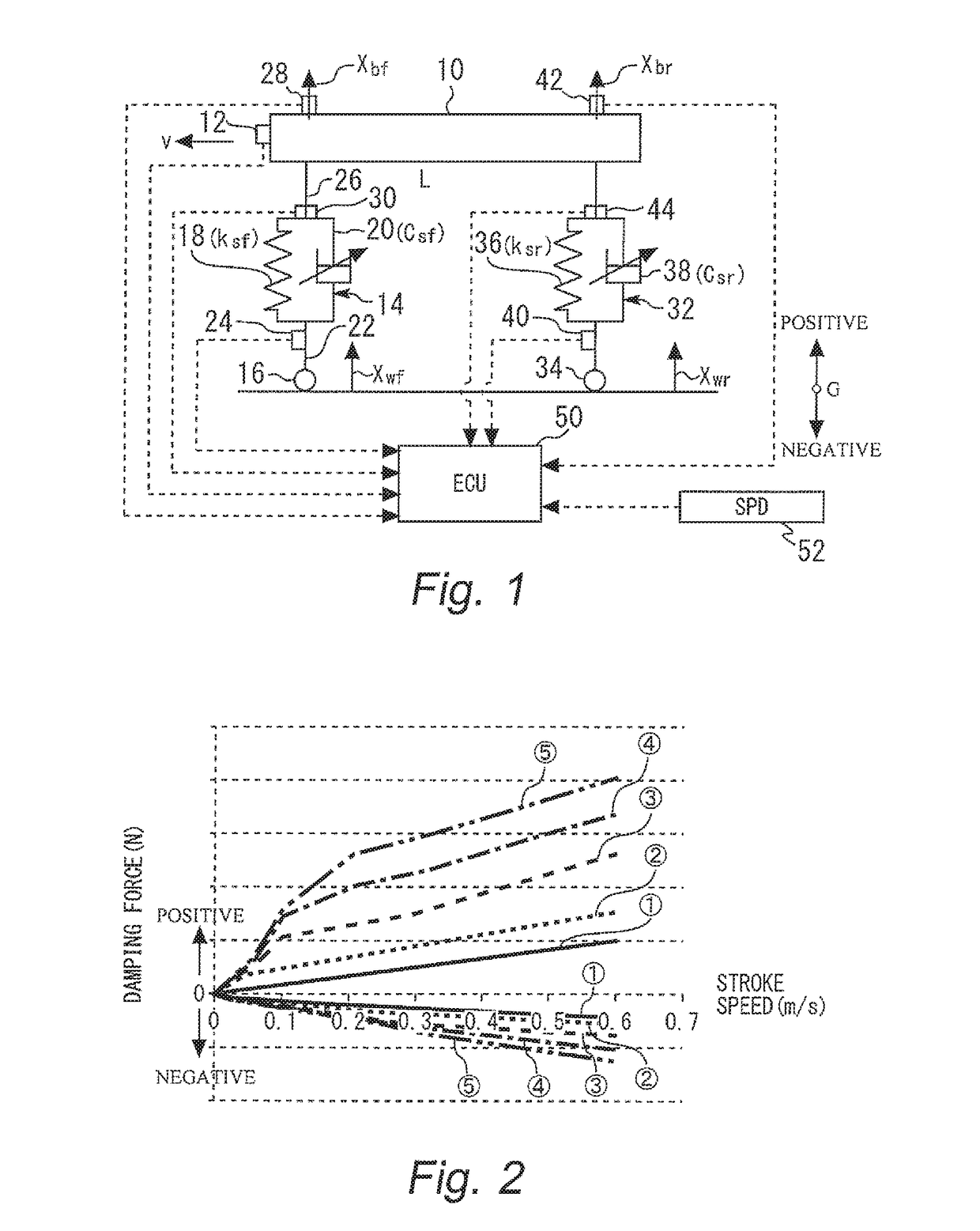

Control device for vehicle suspension

InactiveUS20170174034A1Stable vehicle behaviorComfortable rideResilient suspensionsVibration suppression adjustmentsDamping factorNormal control

A vehicle suspension includes a shock absorber whose damping coefficient is variable. A control device includes: a road surface input sensor that generates a first signal corresponding to a vertical movement of each wheel; a sprung mass behavior sensor that generates a second signal corresponding to a vertical movement of a vehicle body at a position of each wheel; and a control unit that controls the damping coefficient. The control unit performs: a normal control that sets the damping coefficient to a hard-side value with regard to a wheel where the second signal indicates occurrence of a sprung mass behavior exceeding a standard; and a rear wheel softening control that sets the damping coefficient regarding a rear wheel to a soft-side value lower than the hard-side value, when determining, based on the first signal, that a rear-wheel-rising-time-point when the rear wheel reaches a rising point on a road surface comes.

Owner:TOYOTA JIDOSHA KK

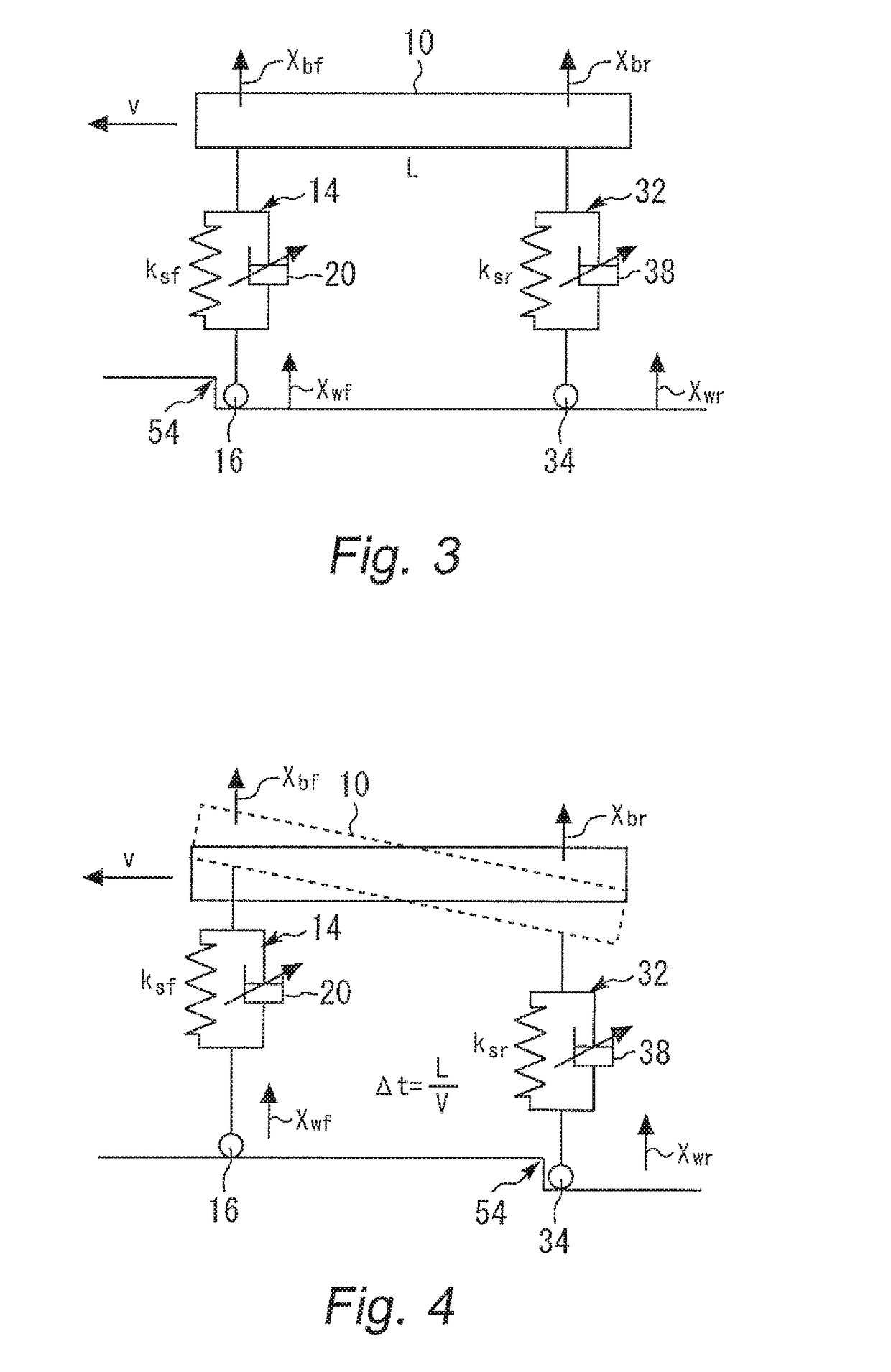

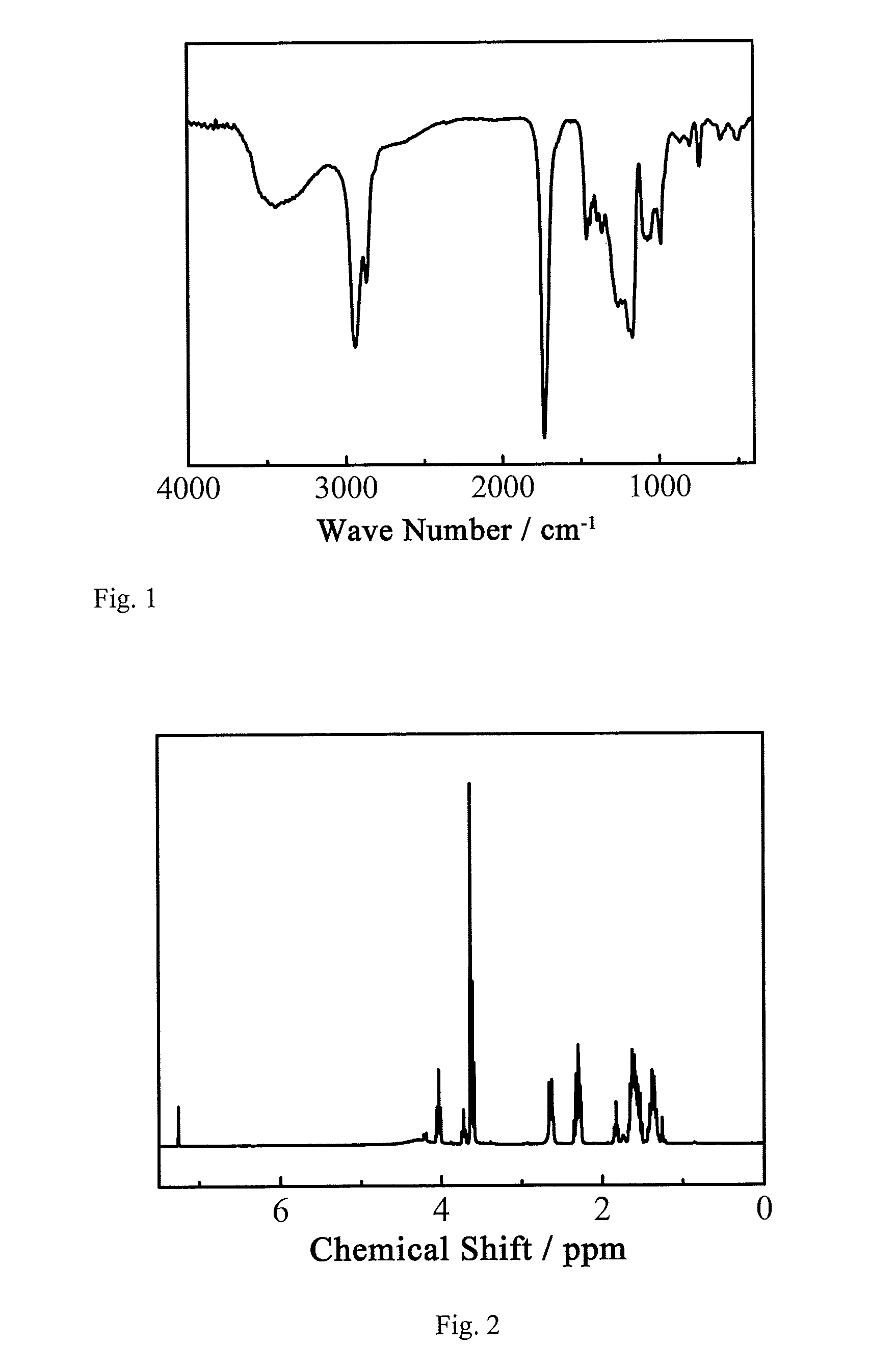

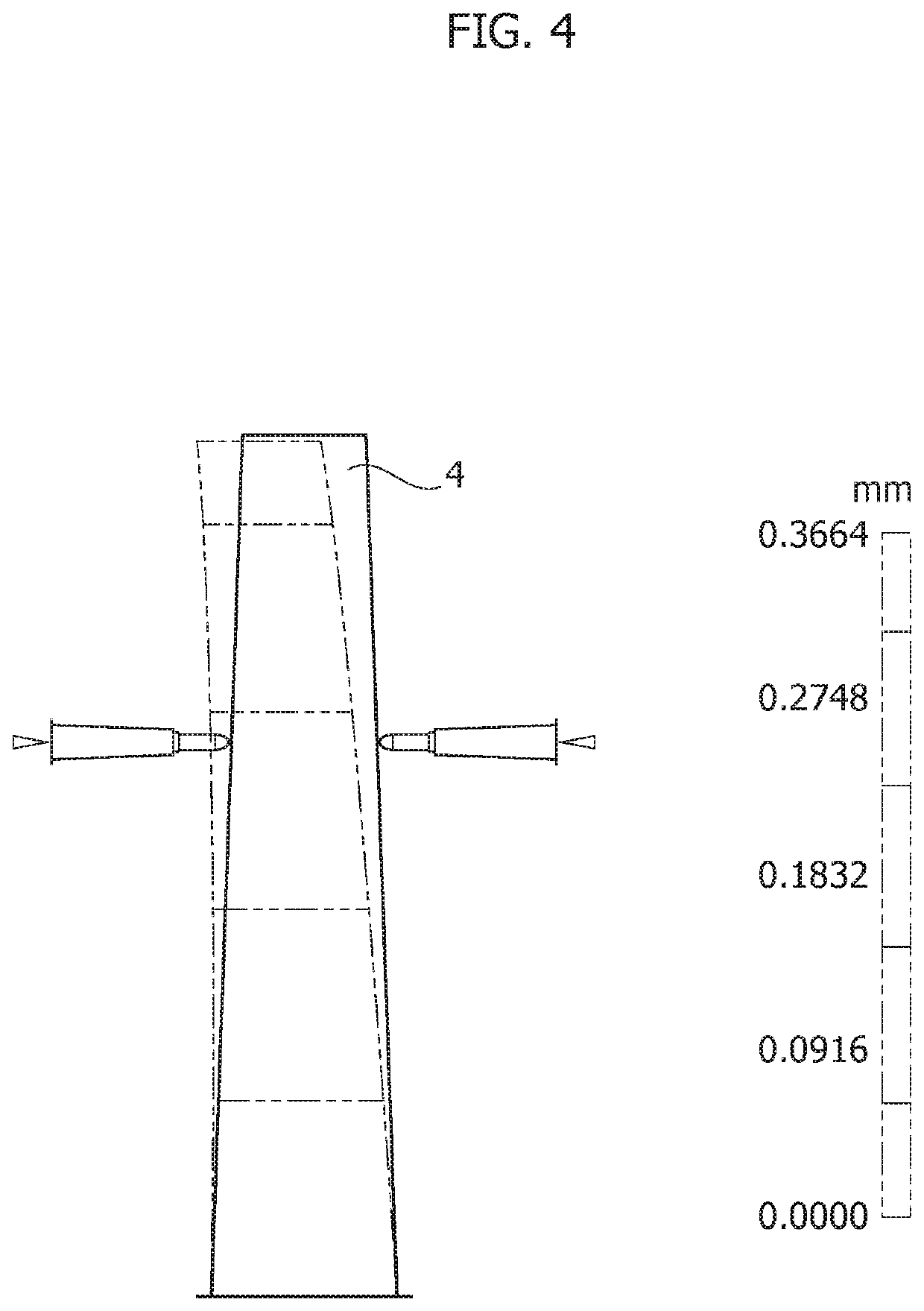

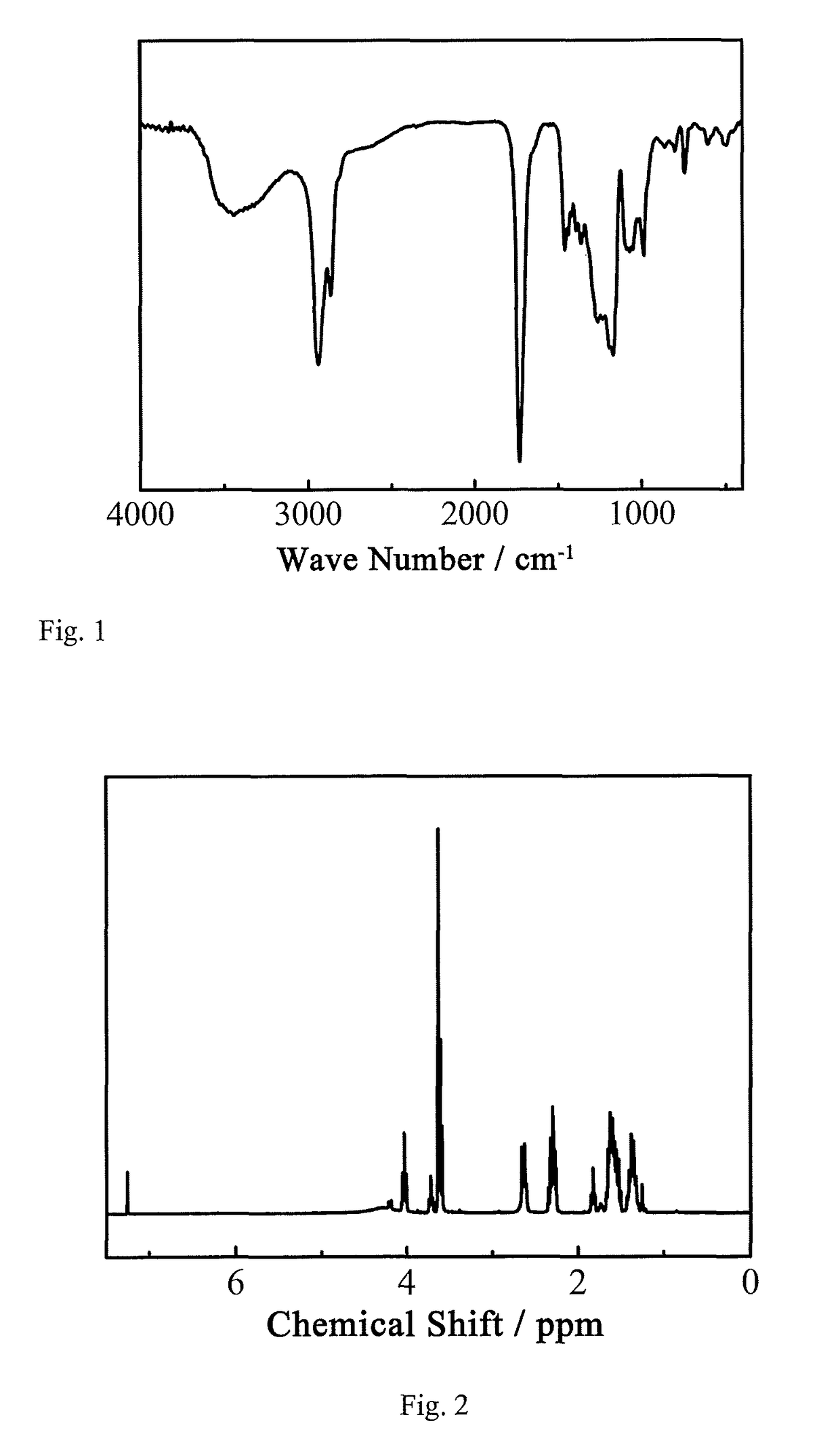

Method for preparing main chain scission-type polysilyl (METH)acrylate resin and application thereof

ActiveUS20160185913A1Effective controlAccurately metAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

A method for preparing a main chain scission-type polysilyl (meth)acrylate resin and application thereof. The method comprises: a cyclic monomer, vinyl monomer and vinyl silyl ester monomer are mixed in a solvent at a formulation ratio, then added a composite initiator in a mass percentage of 0.01-5% based on the total amount of the monomers, and reacted at a temperature of 25-150° C., and under the protection of argon or nitrogen gas, so as to prepare the main chain scission-type polysilyl (meth)acrylate resin, wherein the monomers are consisted of 5-95% by mass of cyclic monomer, 0-90% by mass of vinyl monomer and 5-95% by mass of vinyl silyl ester monomer. The resulting resin can not only be hydrolyzed on the side chain silyl ester segment under the effect of the sea water, but also occur chain scission on the main chain polyester segment under the effect of the seawater, so as to solve the dependency of the traditional self-polishing material on the sailing speed, effectively control the release of the antifouling agent at a constant rate, ensure the active substance preserved on the coating surface of the ships, and properly meet the antifouling requirements on the low sailing speed ships, submarines and off-shore oil platform facilities.

Owner:SOUTH CHINA UNIV OF TECH

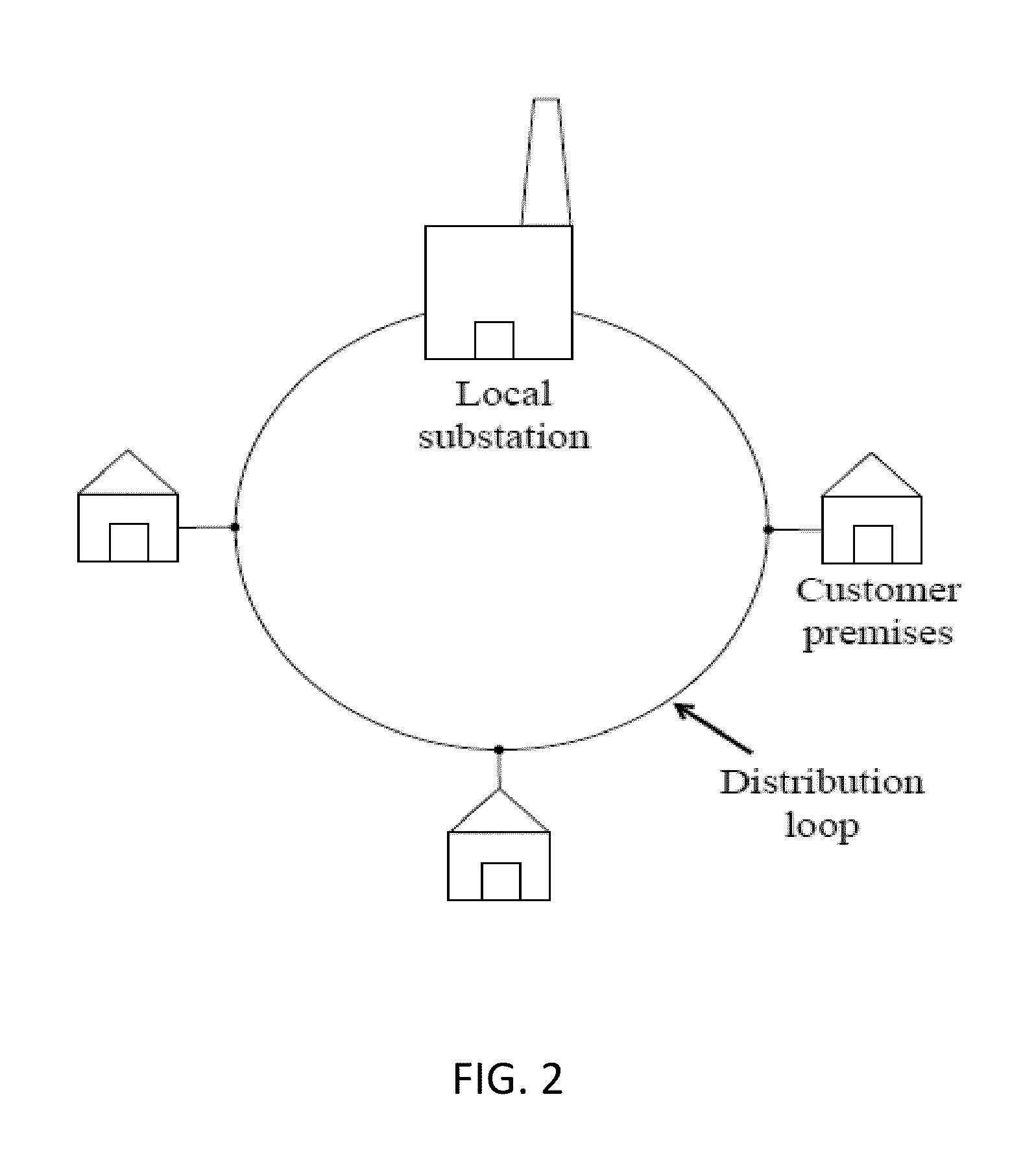

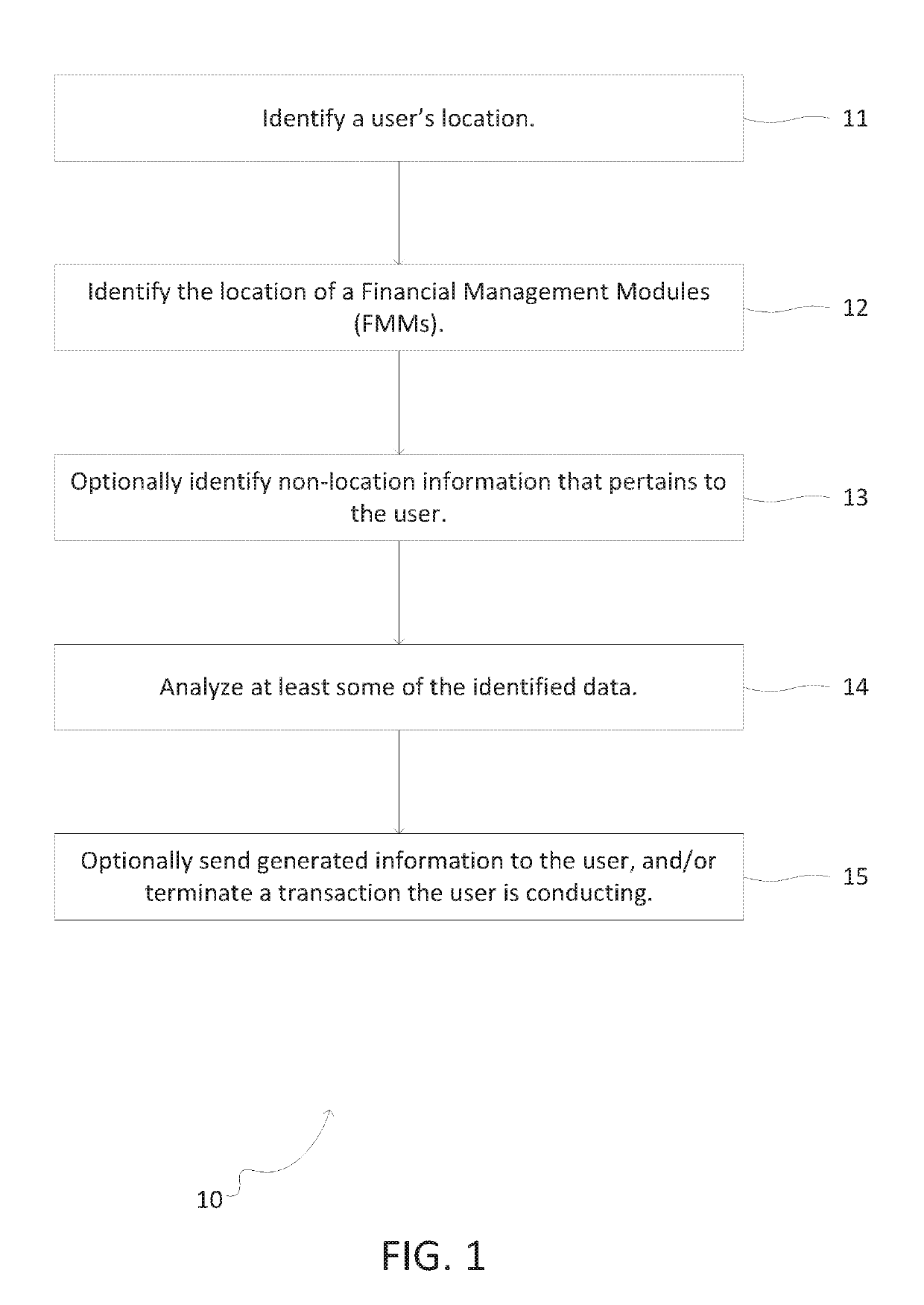

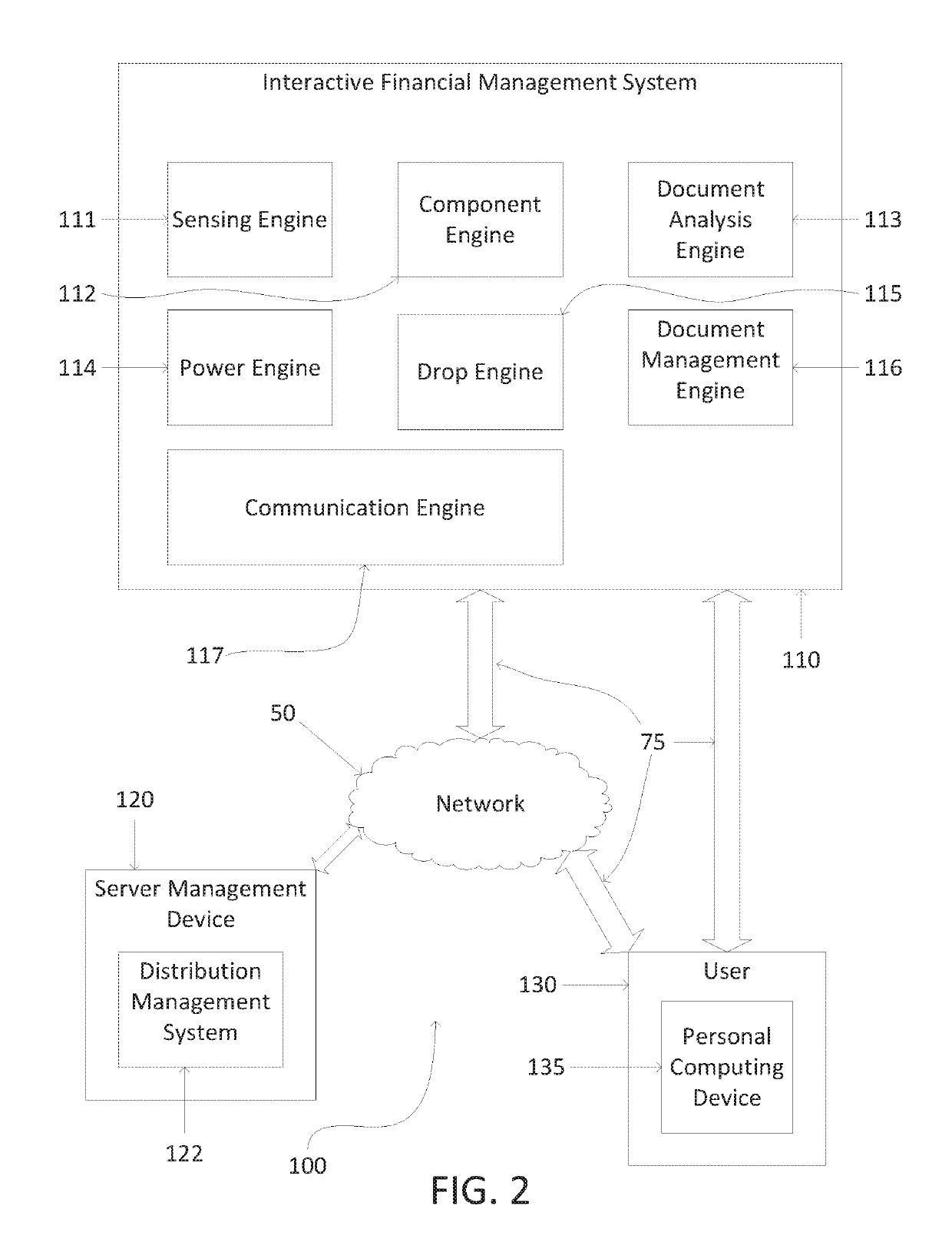

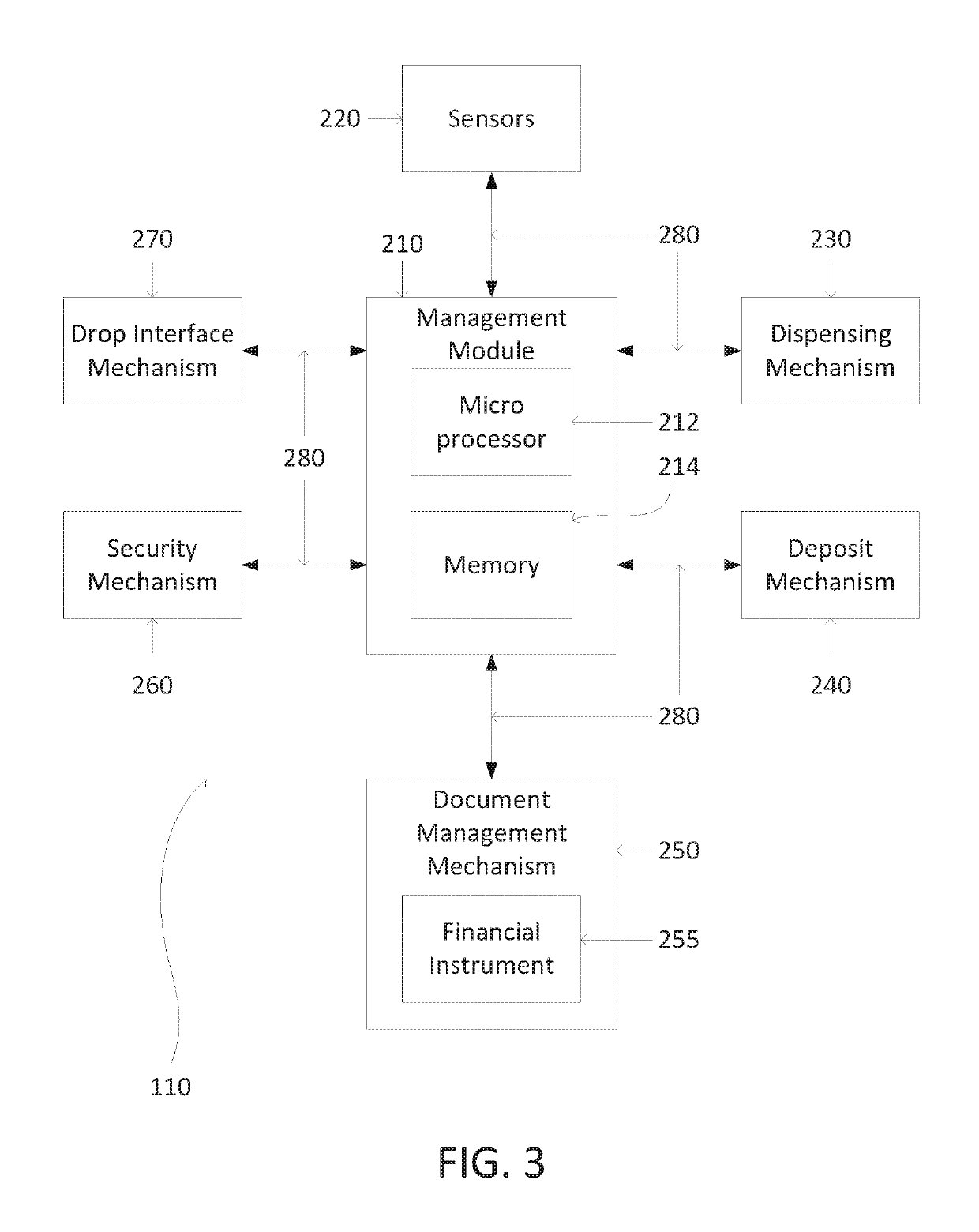

Systems and methods for distributed currency management

ActiveUS10332358B1Accurately metReduce expensesComplete banking machinesInstruments for road network navigationPasswordModularity

This application relates to methods and systems for managing and distributing currency. One system includes modularized components and interacts with a user via the user's cell phone. The user may authenticate to the system via a password and biometrics, pre-stage interactions such as deposits or withdrawals, and then conduct a transaction. The system may also analyze the documents, such as currency and / or checks, that are deposited with the system, and determine whether they are valid.

Owner:USAA

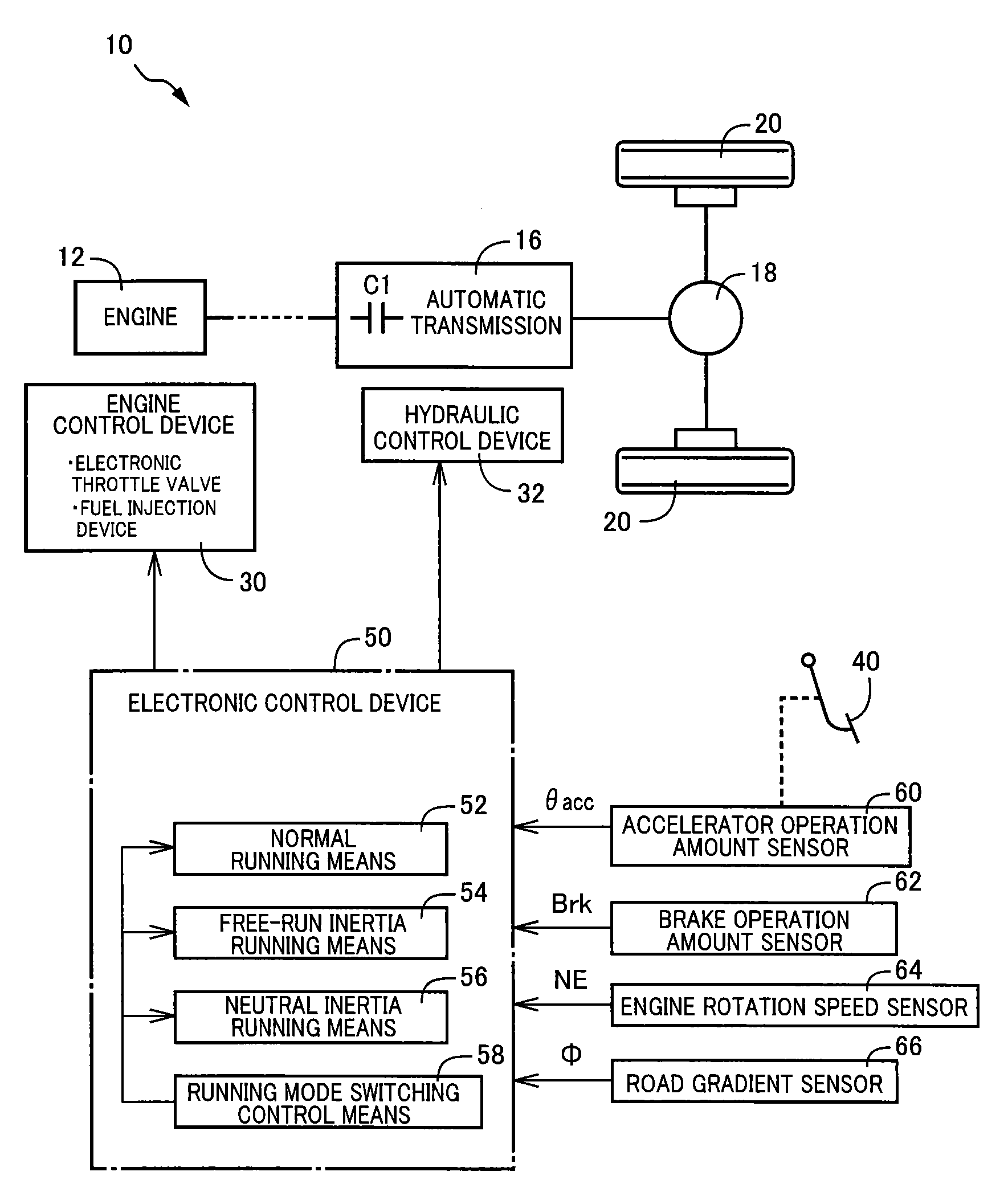

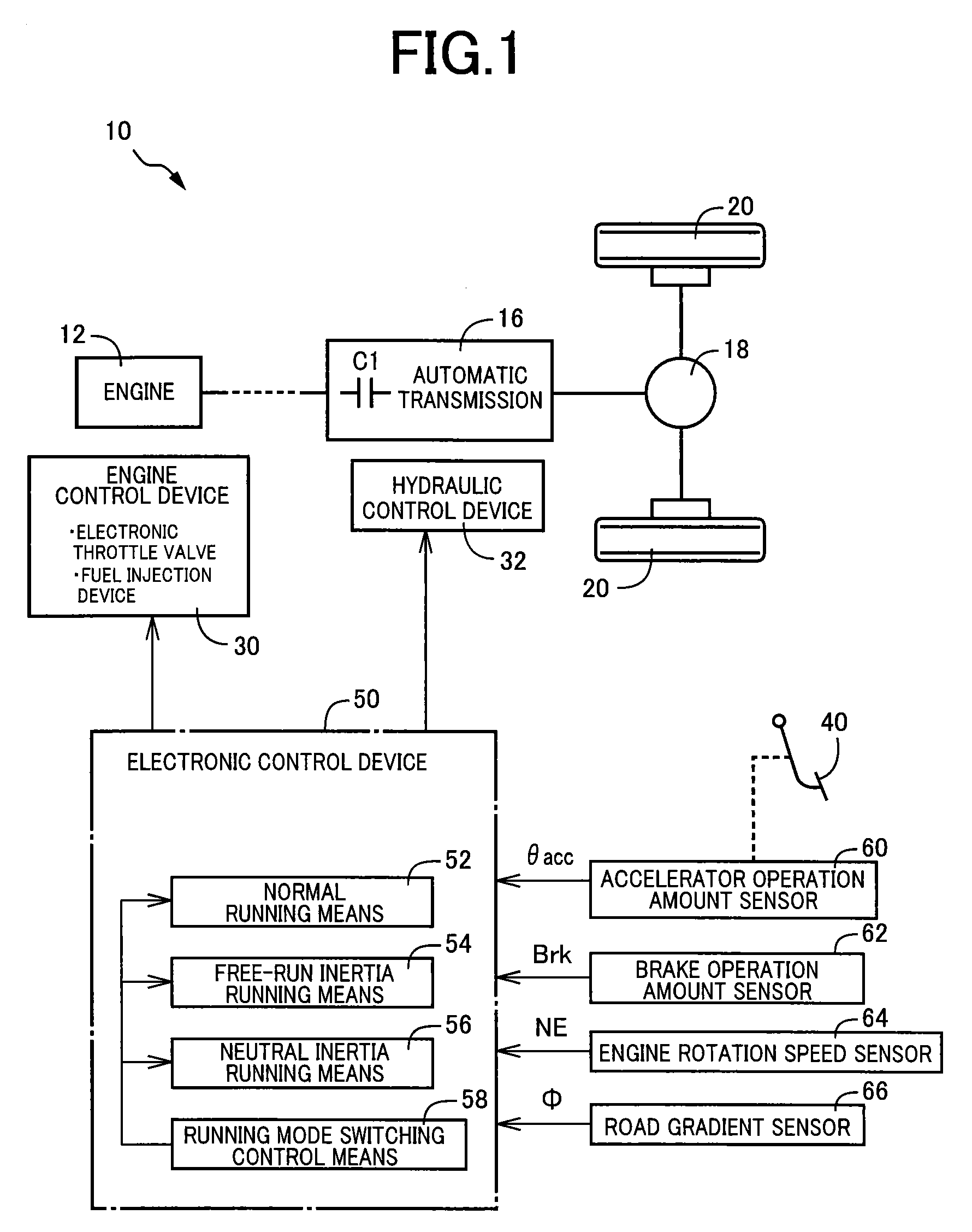

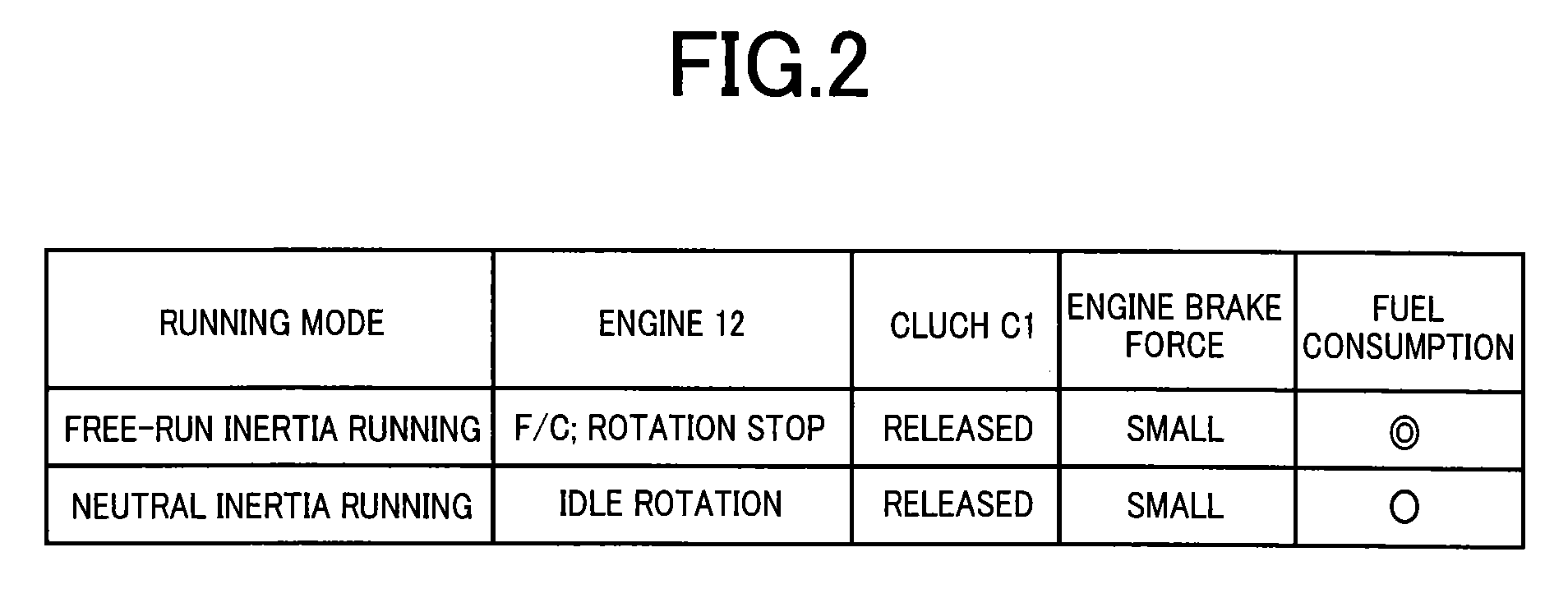

Vehicle drive controller

ActiveUS9421977B2Without the risk of deterioration of fuel consumption and riding comfortImprove responseClutchesElectrical controlRunning timeFuel supply

A running control device is configured to execute an engine coupling running mode performed with an engine and wheels connected by a connecting / disconnecting device, a neutral inertia running mode performed with the engine separated from the wheels by the connecting / disconnecting device while the engine is supplied with fuel and allowed to perform self-sustaining rotation, and a free-run inertia running mode performed with the engine separated from the wheels by the connecting / disconnecting device while fuel supply to the engine is stopped to stop rotation. The neutral inertia running mode is terminated when an operation amount of the accelerator pedal becomes equal to or greater than a predefined first determination value. The free-run inertia running mode is terminated when an operation amount of the accelerator pedal becomes equal to or greater than a predefined second determination value larger than the first determination value.

Owner:TOYOTA JIDOSHA KK

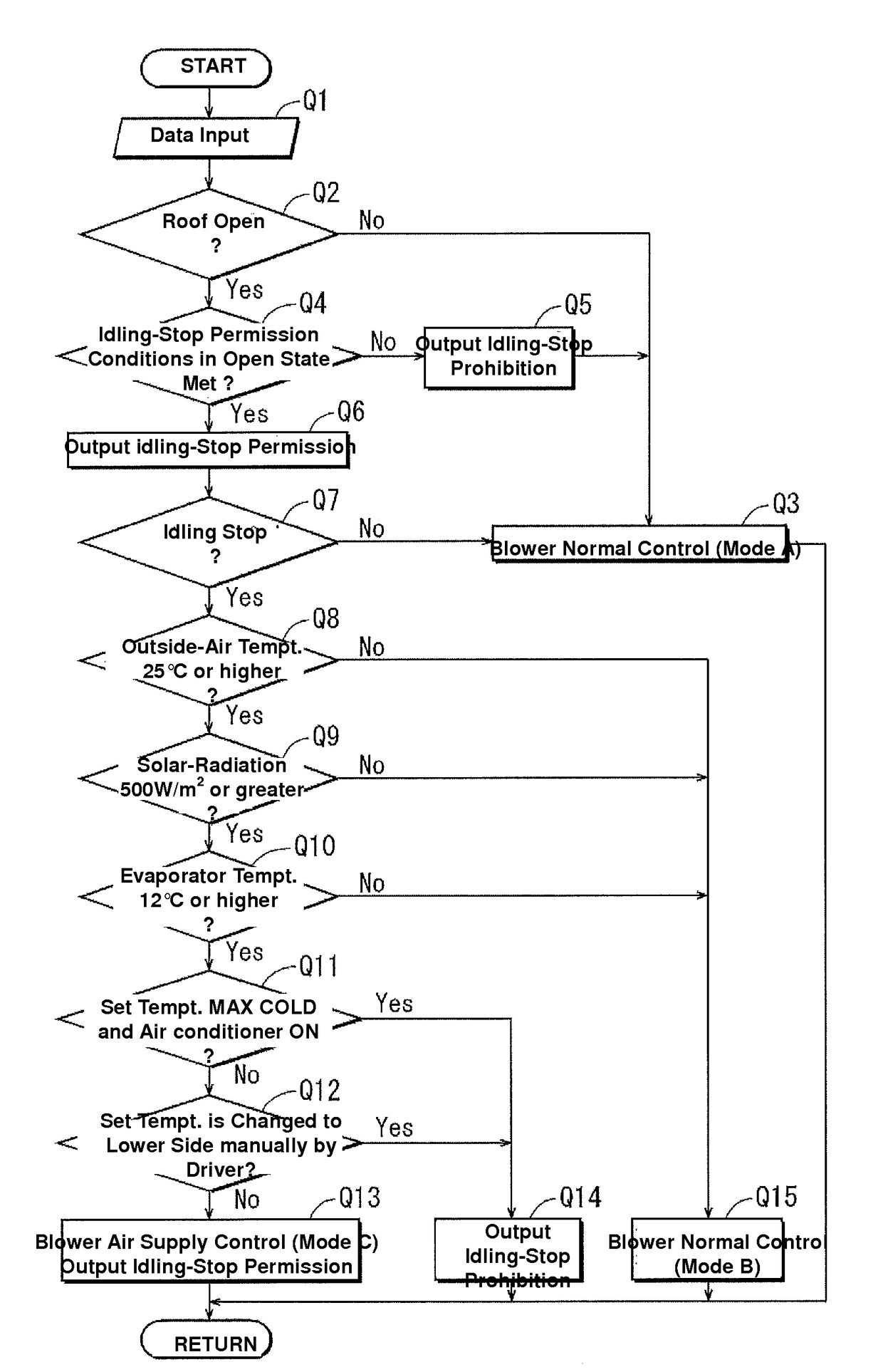

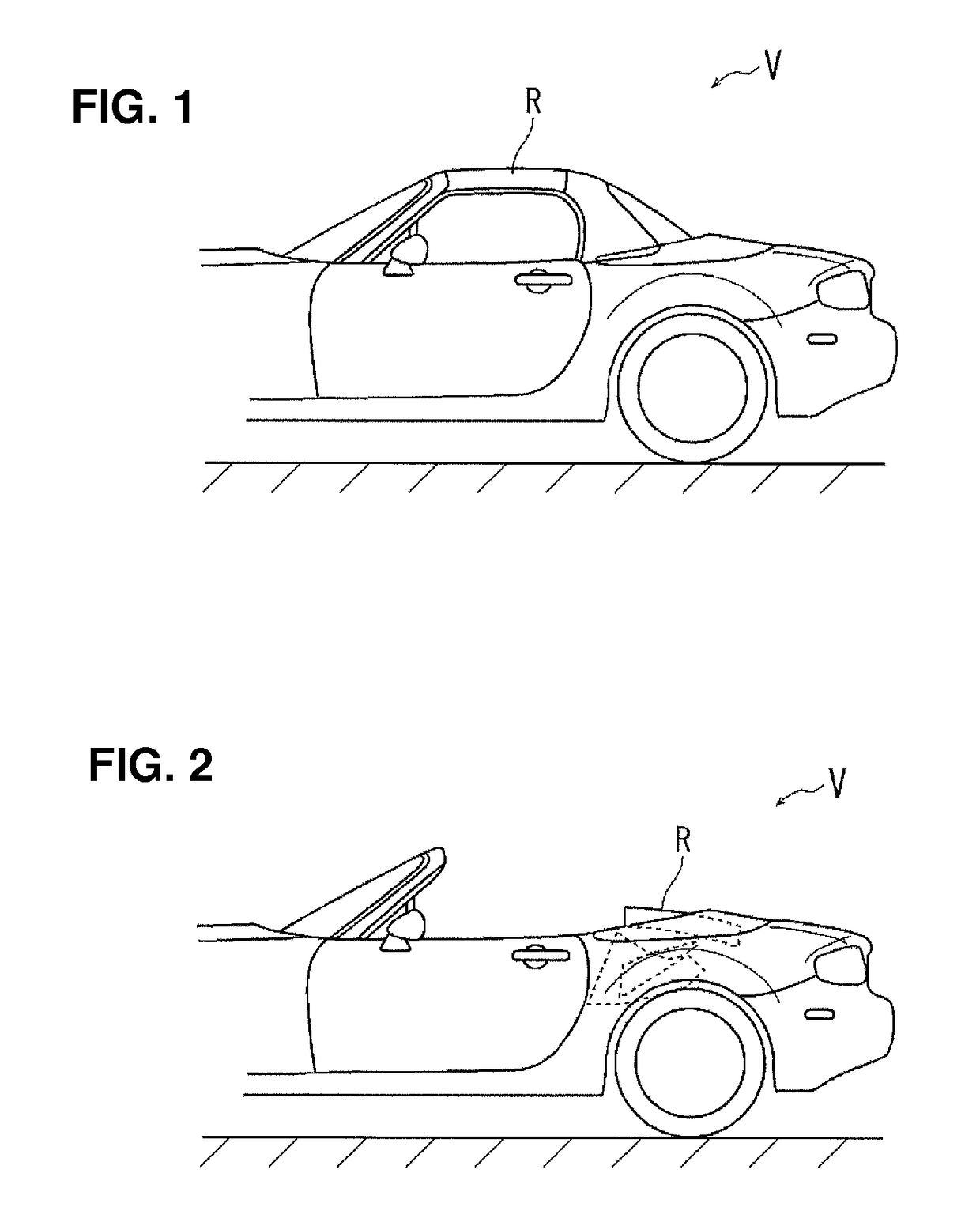

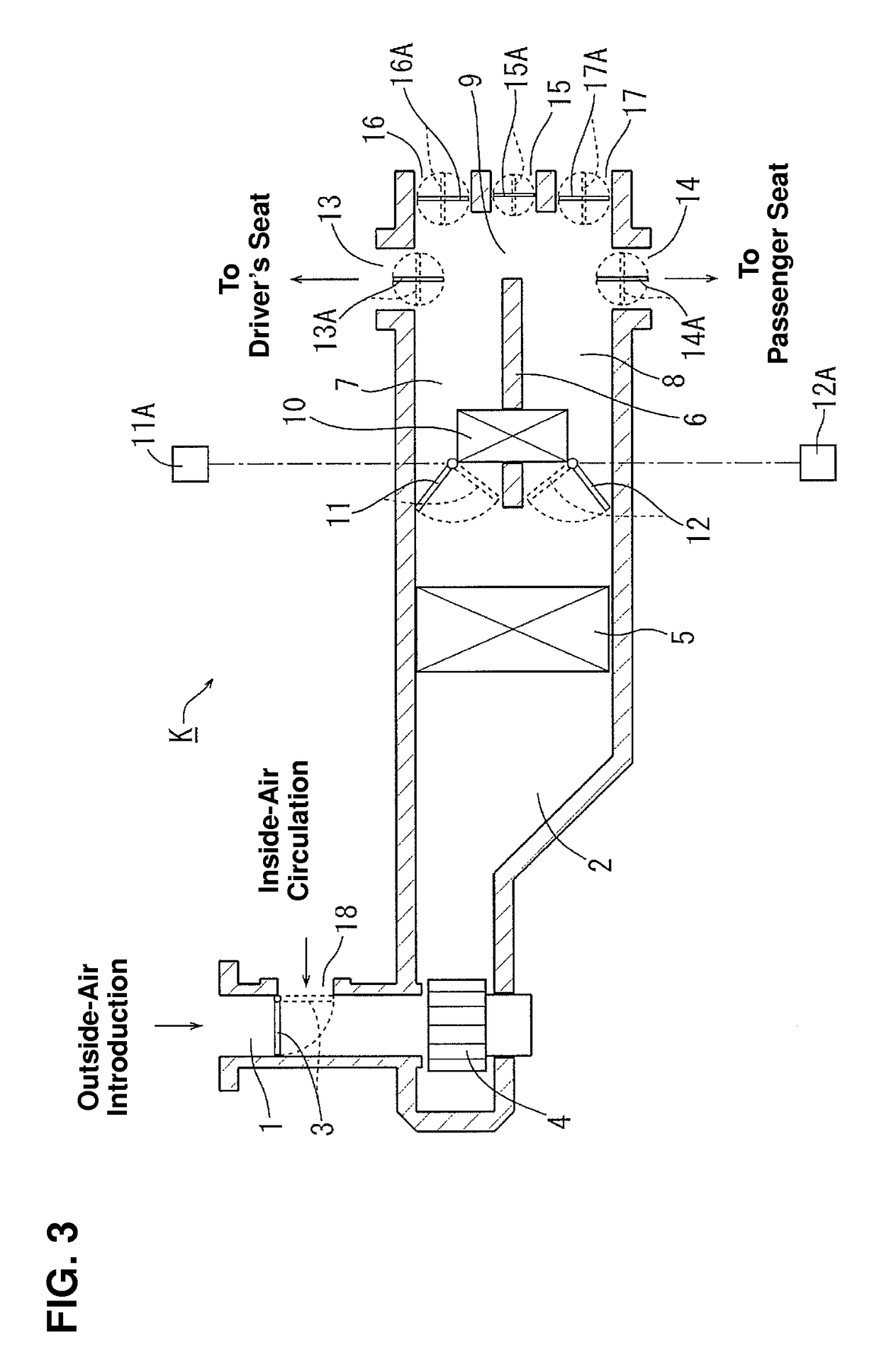

Air-conditioning control device for vehicle

ActiveUS9610826B2Increase opportunitiesAccurately metAir-treating devicesInternal combustion piston enginesOutside air temperatureClosed state

Owner:MAZDA MOTOR CORP

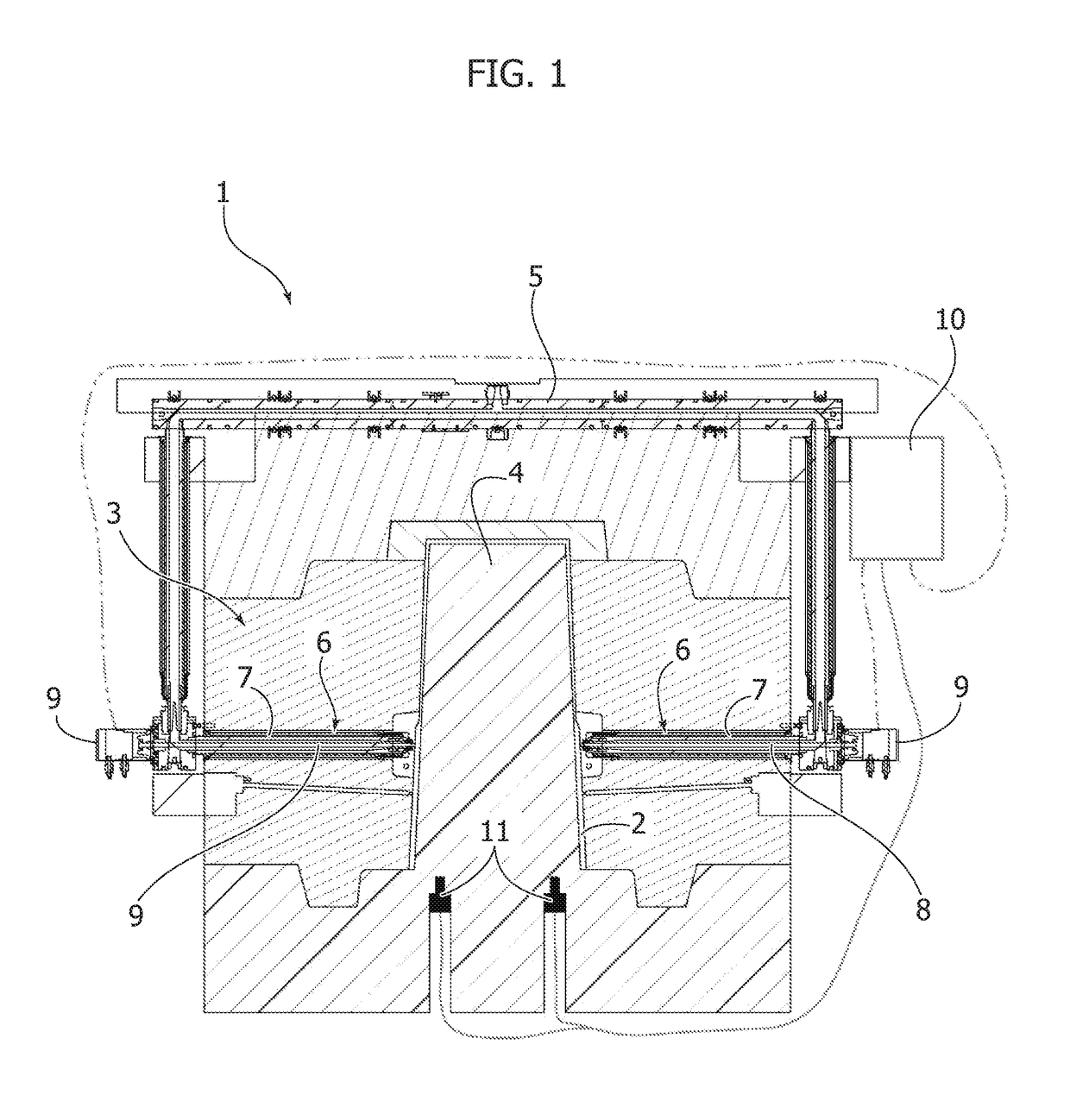

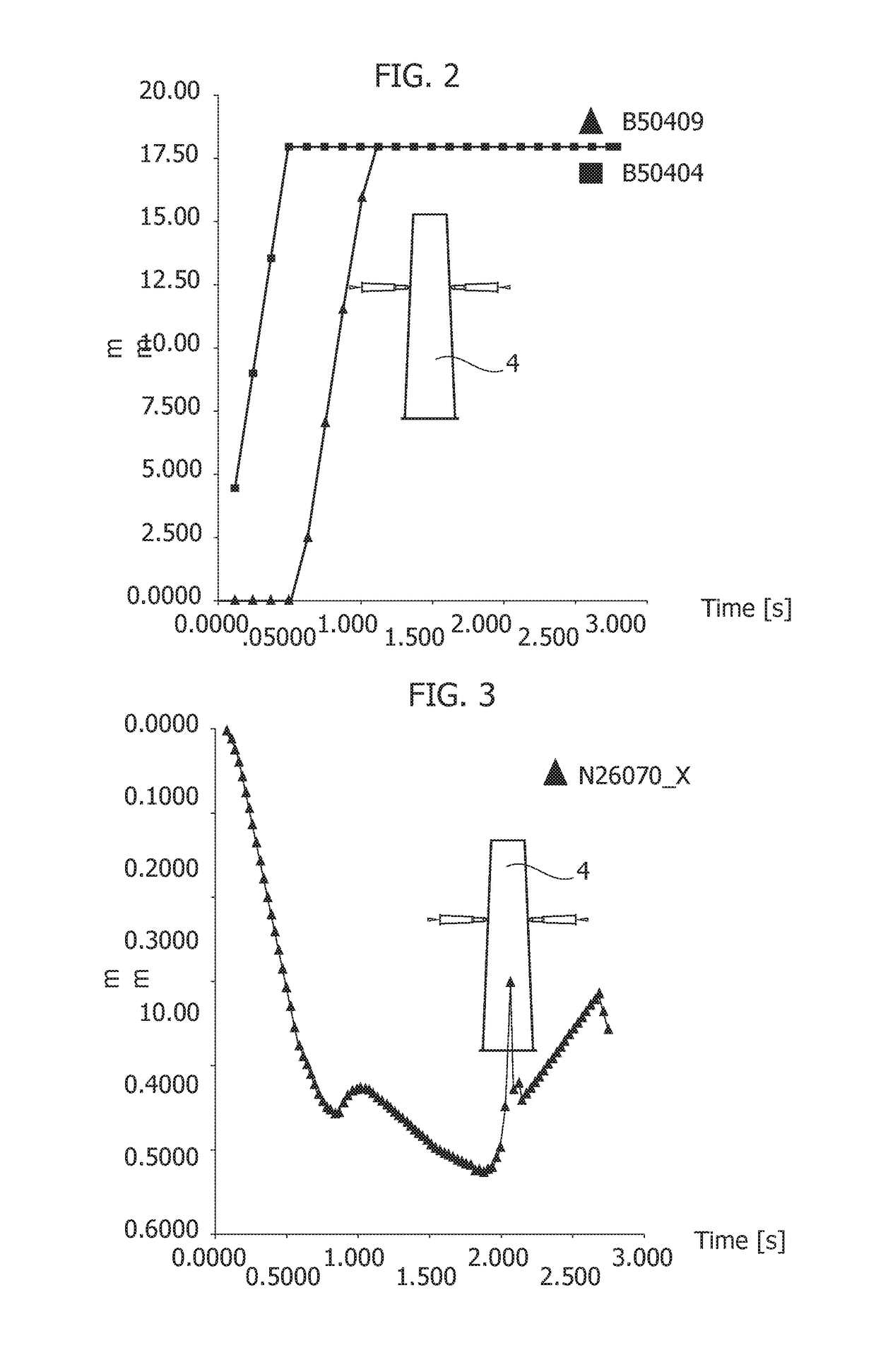

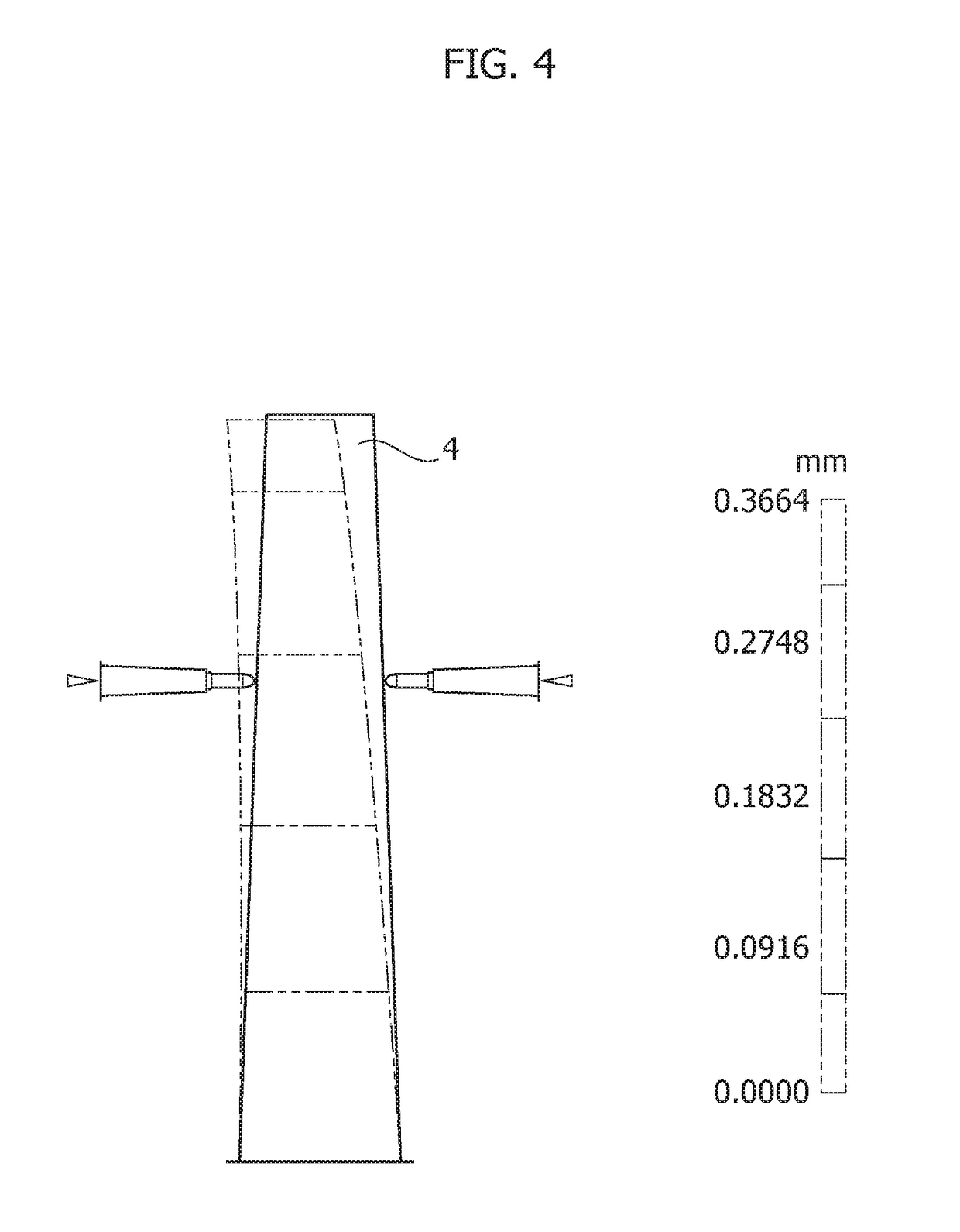

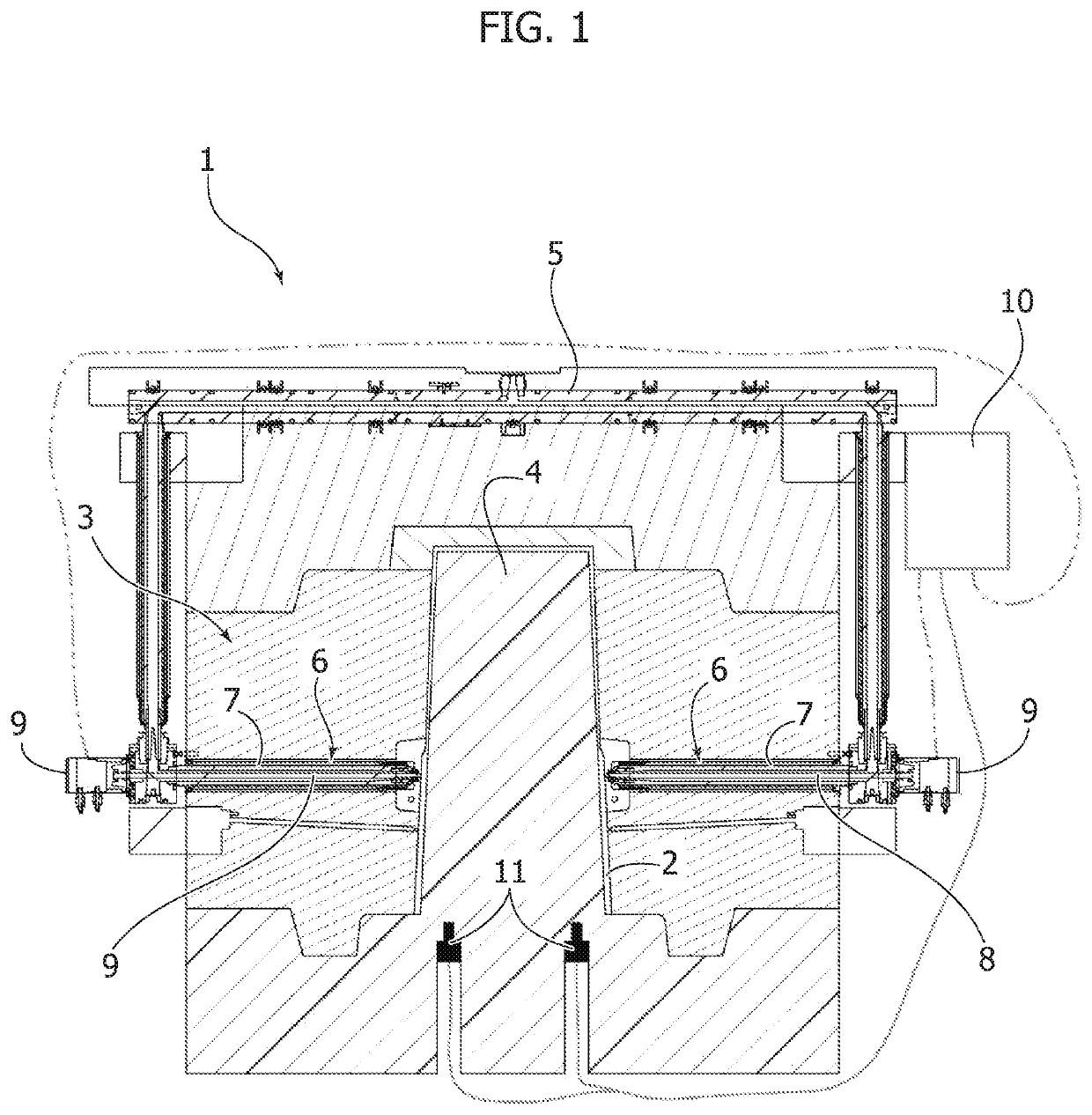

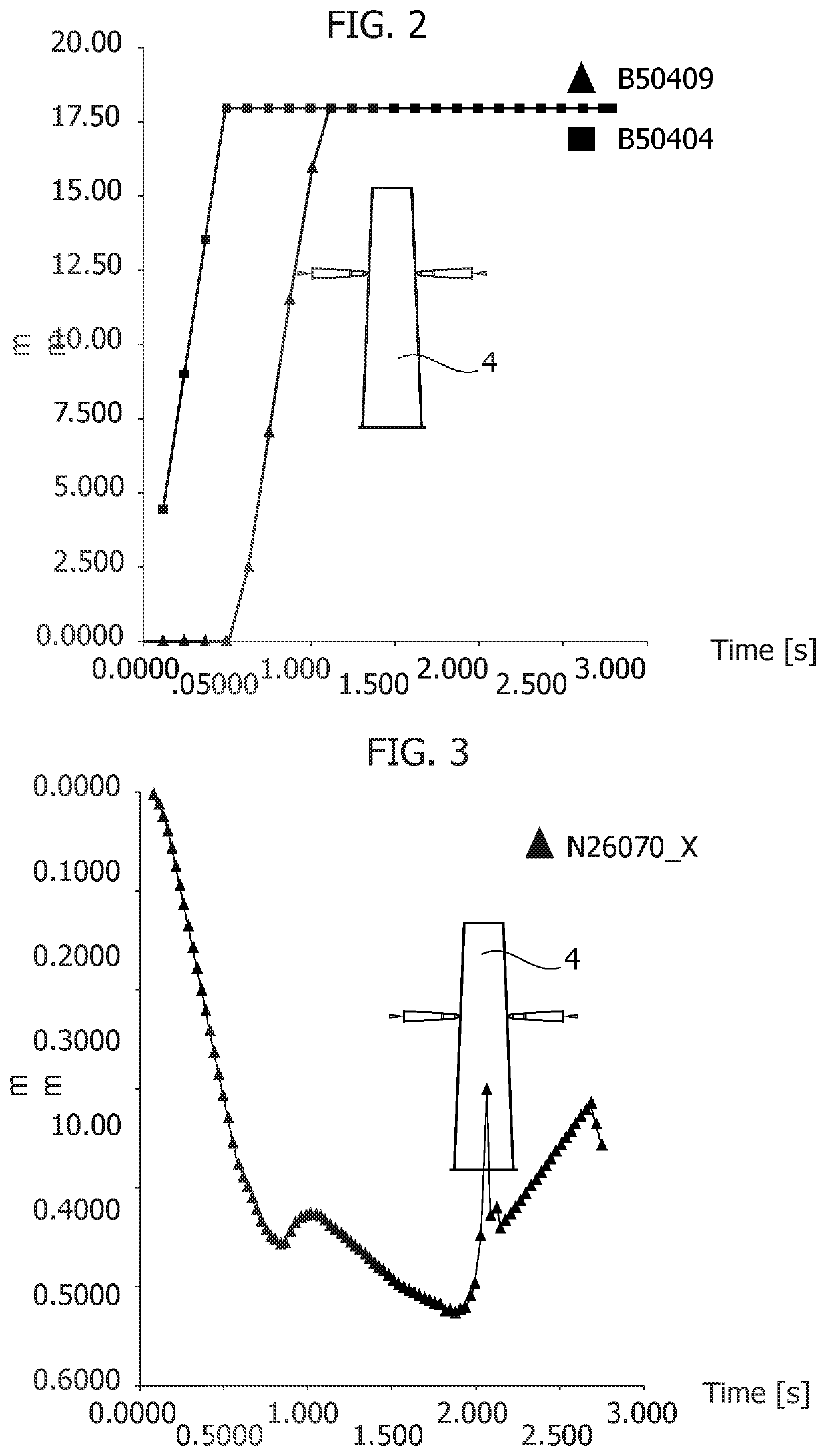

Method and apparatus for producing hollow articles made of injection moulded plastic material

A method and apparatus for producing hollow articles made of injection moulded plastic material by a mould having a die within which there is inserted a core, and at least one injector including a pin valve displaceable between a closing position and an opening position for injecting the pressurized plastic material into a space comprised between the die and the core. During the injection, any flexural deflection of the core is detected and the pin valve of the or of each injector is displaced in a controlled fashion to adjust a pressure and a flow rate of the injected plastic material, so as to reduce or eliminate such deflection of the core.

Owner:INGLASS SPA

Eletronic device, display device, and method of controlling audio/video output of an electronic device

An electronic device, a display device, and a method of controlling audio / video output of the electronic device are disclosed. The electronic device includes a data processing unit, a visual output unit, an audio output unit, and a user operating habit database. The data processing unit executes an application program, the visual output unit outputs an image signal, the audio output unit outputs an audio signal, and the user operating habit database records a corresponding relationship between different program types and operating parameters of the visual output unit or the audio output unit. And, the data processing unit acquires the program type of the application program being run for controlling the operating parameters of the visual output unit or the audio output unit.

Owner:ACER INC

Method and apparatus for producing hollow articles made of injection moulded plastic material

A method and apparatus for producing hollow articles made of injection moulded plastic material by a mould having a die within which there is inserted a core, and at least one injector including a pin valve displaceable between a closing position and an opening position for injecting the pressurized plastic material into a space comprised between the die and the core. During the injection, any flexural deflection of the core is detected and the pin valve of the or of each injector is displaced in a controlled fashion to adjust a pressure and a flow rate of the injected plastic material, so as to reduce or eliminate such deflection of the core.

Owner:INGLASS SPA

Method for preparing main chain scission-type polysilyl (meth)acrylate resin and application thereof

ActiveUS9701794B2Effective controlAccurately metAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

A method for preparing a main chain scission-type polysilyl (meth)acrylate resin and application thereof. The method comprises: a cyclic monomer, vinyl monomer and vinyl silyl ester monomer are mixed in a solvent at a formulation ratio, then added a composite initiator in a mass percentage of 0.01-5% based on the total amount of the monomers, and reacted at a temperature of 25-150° C., and under the protection of argon or nitrogen gas, so as to prepare the main chain scission-type polysilyl (meth)acrylate resin, wherein the monomers are consisted of 5-95% by mass of cyclic monomer, 0-90% by mass of vinyl monomer and 5-95% by mass of vinyl silyl ester monomer. The resulting resin can not only be hydrolyzed on the side chain silyl ester segment under the effect of the sea water, but also occur chain scission on the main chain polyester segment under the effect of the seawater, so as to solve the dependency of the traditional self-polishing material on the sailing speed, effectively control the release of the antifouling agent at a constant rate, ensure the active substance preserved on the coating surface of the ships, and properly meet the antifouling requirements on the low sailing speed ships, submarines and off-shore oil platform facilities.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com