Patents

Literature

72results about How to "Good surface feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clean production process for polyurethane synthetic leather base with ultramicro leather powder as filling material

InactiveCN103290701ARealize cleaner productionDevelop circular economySynthetic resin layered productsTextiles and paperWater basedFilling materials

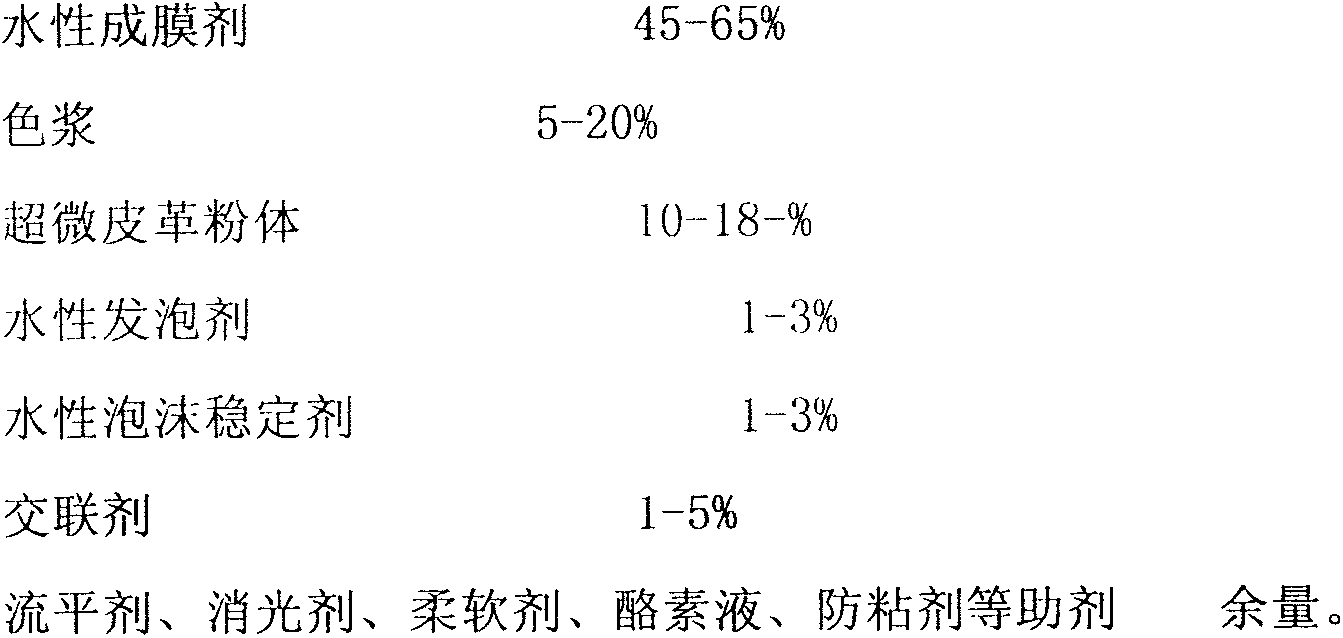

The invention discloses a clean production process for a polyurethane synthetic leather base with ultramicro leather powder as a filling material. The process comprises the following steps: introducing air and water-based finishing slurry blended with ultramicro leather powder into a mixer according to a certain proportion and allowing a high-quality micro-foaming finishing agent to be formed under high-speed dispersion action of a stirring head; and coating the micro-foaming finishing agent and then drying and curing the micro-foaming finishing agent so as to prepare the synthetic leather base. The method provided by the invention has the advantages of simple preparation, easy control and the like, eliminates pollution of dimethyl formamide (DMF) produced in a wet production method for synthetic leather and reduces pollution of the industry of synthetic leather; and introduction of the natural ultramicro leather powder enables moisture and air permeability of polyurethane synthetic leather to be improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

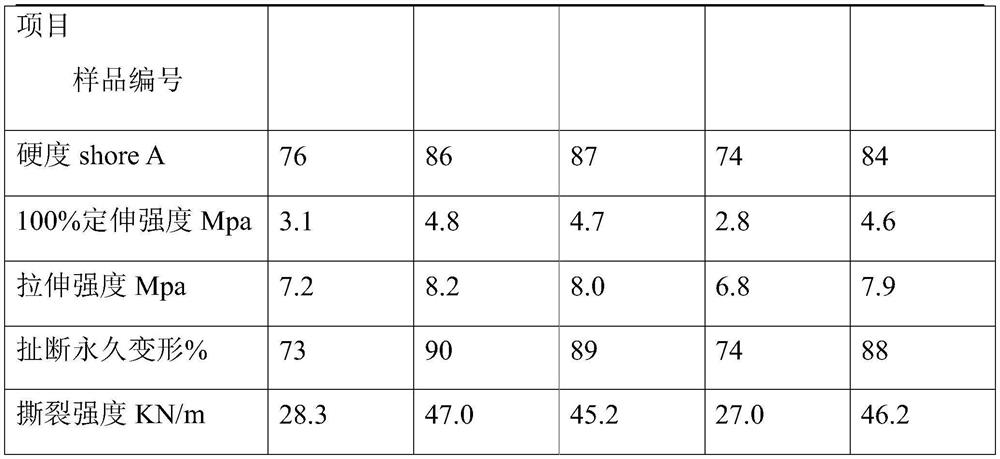

Dynamic vulcanized silicone rubber/thermoplastic polyurethane elastomer and preparation method thereof

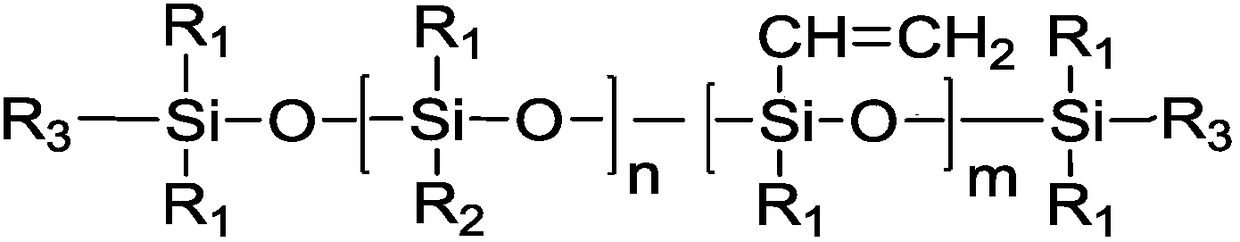

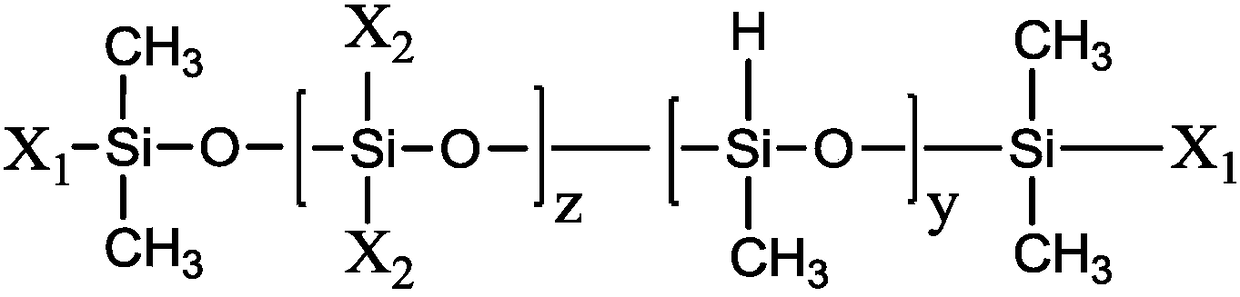

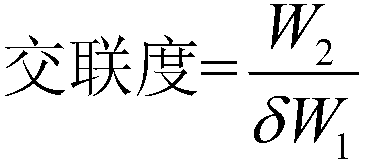

The invention provides a dynamic vulcanized silicone rubber / thermoplastic polyurethane elastomer material and a preparation method thereof. The material is prepared, by weight, the following components: vinyl polysiloxane: 100 parts, thermoplastic polyurethane elastomer: 10-500 parts, compatibilizer: 3-30 parts, hydrogen-containing silicone oil: 0.1-15 parts, platinum-based catalyst: 0.1-100 ppm (content of platinum atom in the vinyl polysiloxane and hydrogen-containing silicone oil), anti-poison agent: 0.1-20 parts. In the preparation process, no hydrogen is generated, and the process is simple and safe. The product integrates the advantages of two materials of silicon rubber and TPU, has excellent surface hand feeling, has excellent adhesion with PC, PC / ABS, ABS and the like, is easy toextrude and formed through injection molding, the additive amount of the platinum-based catalyst is low in the preparation process, the product has excellent endurance performance and low cost, and can be widely applied to the fields of intelligent wearable products and electronic and appliance products and the like with relatively high requirements.

Owner:WANHUA CHEM GRP CO LTD

Automobile door interior trimming plate manufacturing technology

The invention discloses an automobile door interior trimming plate manufacturing technology. The technology sequentially comprises the following steps: interior trimming plate skin and an injection molding interior trimming framework are obtained through thermoplastic polyolefin skin male mold formation; the skin is bonded with the framework in a foaming mode; a whole foaming element formed after the skin is bonded with the framework is milled; the thermoplastic polyolefin skin male mold formation is characterized in that thermoplastic polyolefin coiled materials are heated up and softened, and are sent into a vacuum formation device for male mold vacuum formation; the bonding between the skin and the framework in the foaming mode is characterized in that polyurethane foamed materials are poured on the inner side of the skin of an interior trimming plate, and are bonded with the framework; and the milling is characterized in that an automatic milling robot mills technology edge of a foaming element. The technology enables the surface of the interior trimming plate to have good handfeel; the size is accurate; the generation of a combined seam of the interior trimming plate and a sheet metal part in the subsequent production is reduced; the service life of a mold is prolonged; and the production cost is lowered.

Owner:JIANGSU CHANGSHU AUTOMOTIVE TRIM GRP CO LTD

Stereoscopic surface woodgrained ceramic tile, stereoscopic surface woodgrained ceramic tile emboss effect glaze layer and decoration technology

InactiveCN109291723AGood printing performance and firing performanceEasy to operateSpecial ornamental structuresCalciteCeramic glaze

The invention relates to a stereoscopic surface woodgrained ceramic tile, a stereoscopic surface woodgrained ceramic tile emboss effect glaze layer and a decoration technology. The ceramic tile is composed of a green body layer, a cover glaze layer, an emboss effect glaze layer, a pattern decoration layer and a surface protective glaze layer which are sequentially compounded. The stereoscopic surface woodgrained ceramic tile emboss effect glaze layer comprises the following materials including, by weight, 2.5-3 parts of zinc oxide, 20-30 parts of feldspar, 15-20 parts of frit, 10-12 parts of washed kaolin, 8-10 parts of calcite, 8-10 parts of burning talc and 20-30 parts of home-made quartz. The decoration technology comprises the steps that (1) long-strip-shaped green bodies are obtainedby pressing woodgrained brick powder, the surfaces of the green bodies are coated with cover glaze, and formulated emboss effect glaze materials are printed on the surfaces of the green bodies, coatedwith the cover glaze, in a rubber covered roller engraving mode; (2) decoration is performed by means of ink jet patterns, and the ink jet patterns cover the glaze surface and the printed emboss effect glaze on the whole; and (3) the green bodies are coated with clear protective glaze, and then kiln firing is performed.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +3

Automobile microfiber leather preparation method

ActiveCN103556489AHas antifouling and antibacterial propertiesSpecial antifouling and antibacterial propertiesLamination ancillary operationsSynthetic resin layered productsCar seatPolymer science

The invention provides a novel preparation method of microfiber leather being used for automobile seats in our nation and having antifouling and antibacterial performances. According to the method, one or more antifouling aids are added into wet-method impregnation polyurethane slurry; one or more antibacterial and antifouling aids are added into an oiling softening liquid; after thermosetting, nonwoven fabric is sequentially processed through the steps of wet-method impregnation, toluene reduction, widening and oiling, and tanning, such that a prepared unfixed-island microfiber base fabric has special antifouling and antibacterial functions; after dry-method coating, the surface of the coating is subjected to antifouling printing, such that the prepared microfiber leather has special comprehensive antifouling and antibacterial performances. The microfiber leather is used in automobile interiors such as automobile seats, armrests, door panels, and the like. The material has good surface texture and antifouling and antibacterial performances.

Owner:FUJIAN TOPSUN MICROFIBER

Coating liquid used for surface of environment-friendly rich mineral paper

ActiveCN102675989AGood surface feelImprove flatnessConjugated diene hydrocarbon coatingsSurface strengthButadiene-styrene rubber

The invention discloses a coating liquid used for the surface of environment-friendly rich mineral paper, which solves the problems of harsh surface handfeel, lack in gloss, low strength, poor bending performance and the like of the paper caused by the existing product. The coating liquid comprises the following components in percentage by weight: 14.8%-17.2% of butadiene styrene rubber latex, 31.0%-36.0% of inorganic mineral powder, 33.5%-42.7% of pure water, 0.4%-0.5% of glycol, 0.22%-0.25% of dispersing agent, 0.11%-0.13% of antifoaming agent, 0.18%-0.21% of thickening agent, 9.7%-11.3% of PVA (poli vinyl alcohol)-S and 0.8%-1.0% of lubricating agent. The invention also provides a preparation method of the coating liquid. The surface handfeel, the flatness, the flexibility and the printing performance of the environment-friendly paper can be observably improved, and the surface strength of the paper is improved.

Owner:孔令发

Thermoplastic elastomer door seal easy to weld and preparation method thereof

The invention relates to a thermoplastic elastomer door seal easy to weld. The door seal is prepared from, by weight, 40-55 parts of SEBS elastomers, 5-15 parts of tackifying resin, 10-15 parts of filler, 5-15 parts of processing oil, 10-15 parts of polypropylene, 1-2 parts of lubricating agent, 0.1-1 part of pigment, 0.1-0.5 part of antibacterial and antifungal agent, 0.1-0.5 part of antioxidant and 0.1-0.5 part of ultraviolet light absorber. The invention further provides a preparation method of the thermoplastic elastomer door seal. The thermoplastic elastomer door seal easy to weld is high in welding strength and good in rebound elasticity, still keeps the good elasticity in the low-temperature application environment such as refrigerators and other refrigeration appliances, prevents a flash seam from being produced, can better close the gap between a door body and a box body, reduces electric appliance energy consumption and makes a contribution to further energy conservation of the refrigeration appliances.

Owner:QINGDAO NEW MATERIAL TECH IND PARK DEV

Production method of skin-touch floor

The invention discloses a production method of a skin-touch floor. The production method comprises the following steps: (1) manufacturing a semi-finished floor plain plate; (2) sanding or polishing, coloring, applying an adhesive primer and filling an ultraviolet photocuring primer in sequence; (3) coating a matte primer, then coating an ultra-matte or matt UV (ultraviolet) photocuring finishing coat, and curing by using a UV mercury lamp; (4) coating one or more skin-feeling UV light curing paint on the cured semi-finished product floor plain board; (5) using an LED lamp and an excimer lamp to jointly carry out extinction pre-curing on the semi-finished product floor plain plate which is coated with the skin-feeling UV light-cured paint in a rolling manner; and (6) carrying out full curing by using a UV mercury lamp to finally obtain an ultra-matte or light-free floor finished product. The skin feeling and matte effect of the floor are achieved through multiple means, and therefore the texture and the visual sense are improved.

Owner:德宝新材料科技(浙江)有限公司

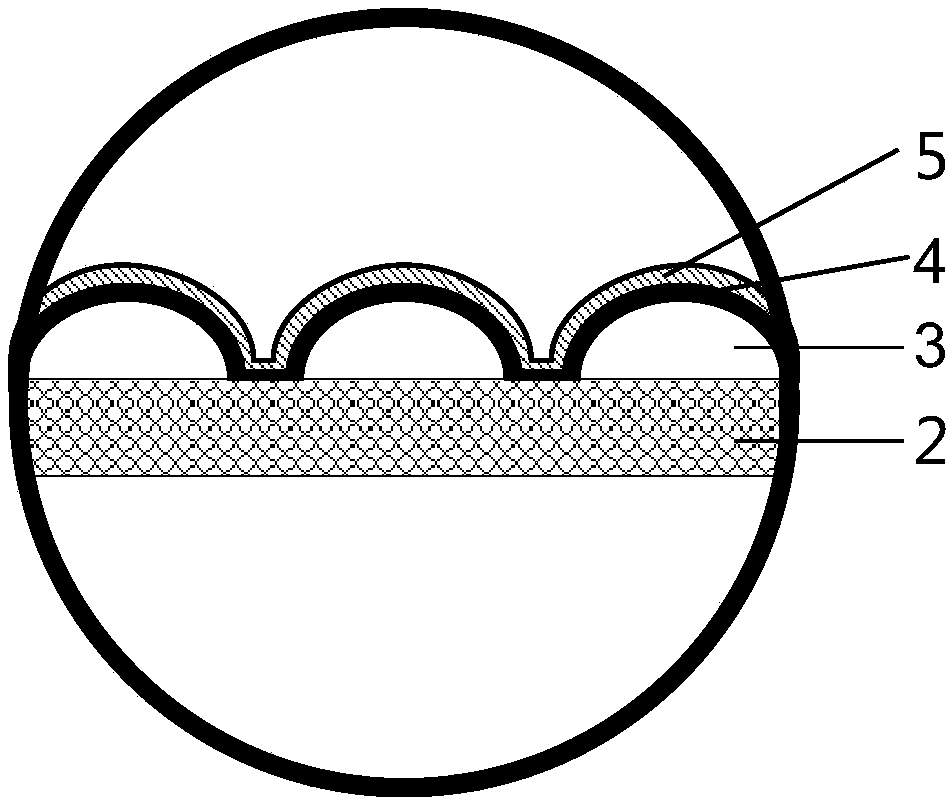

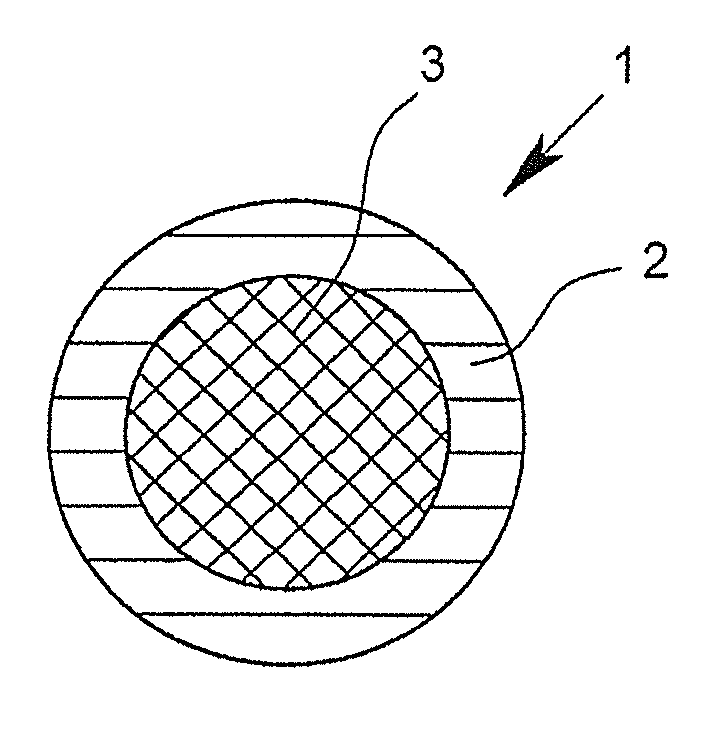

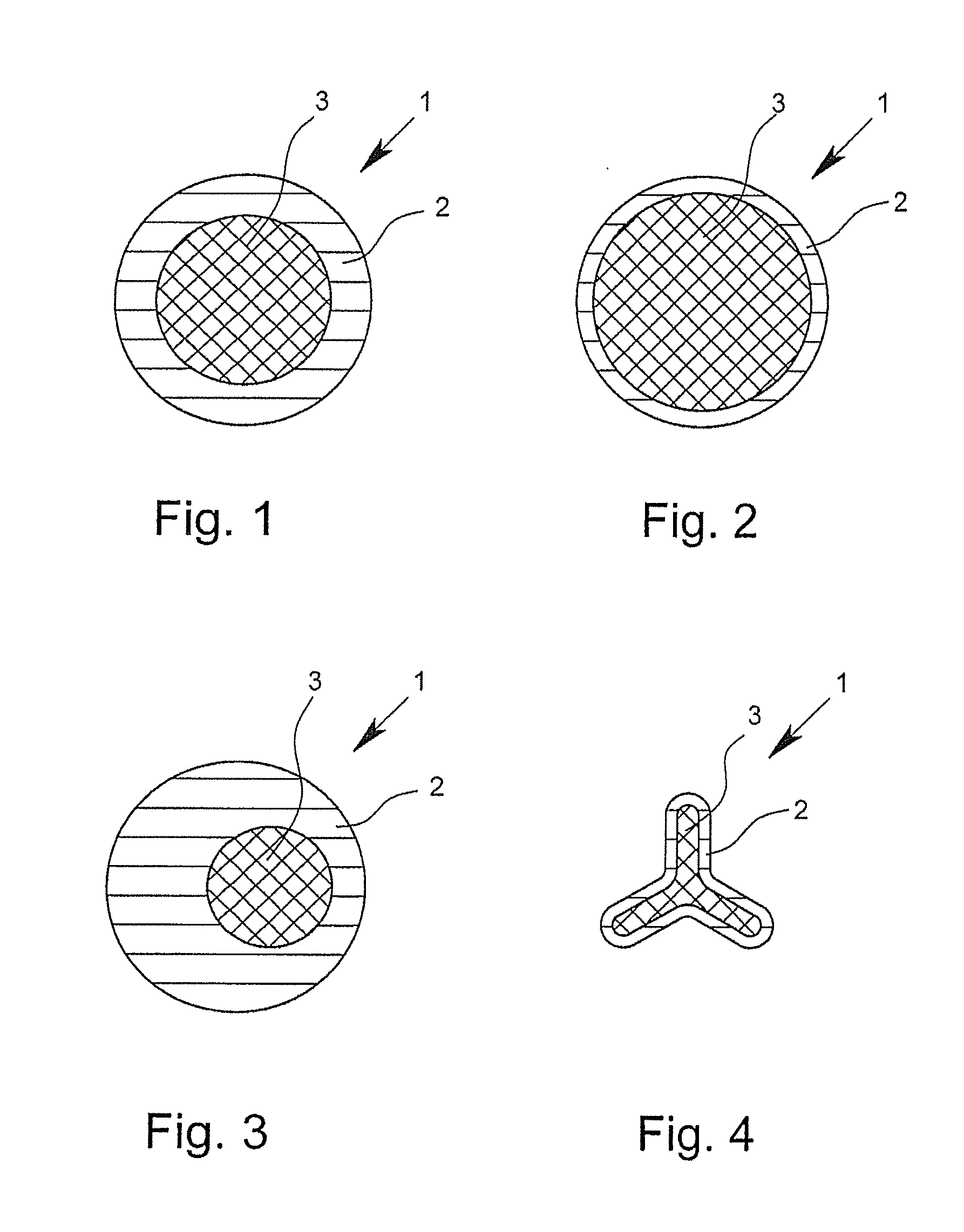

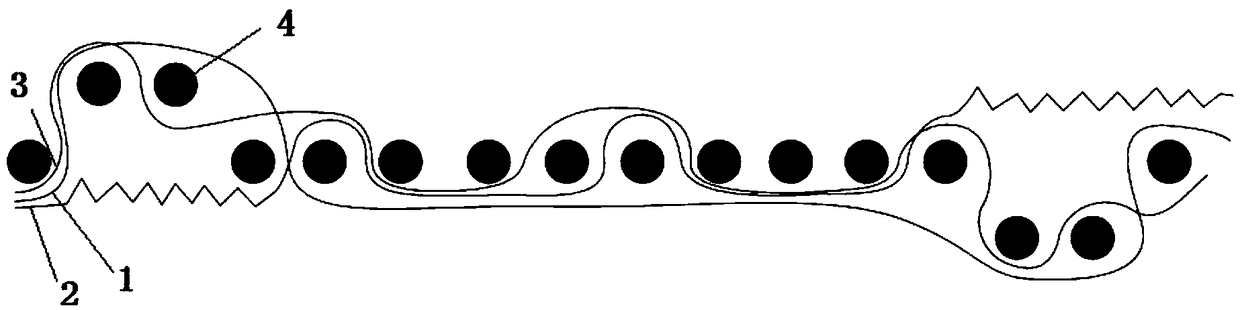

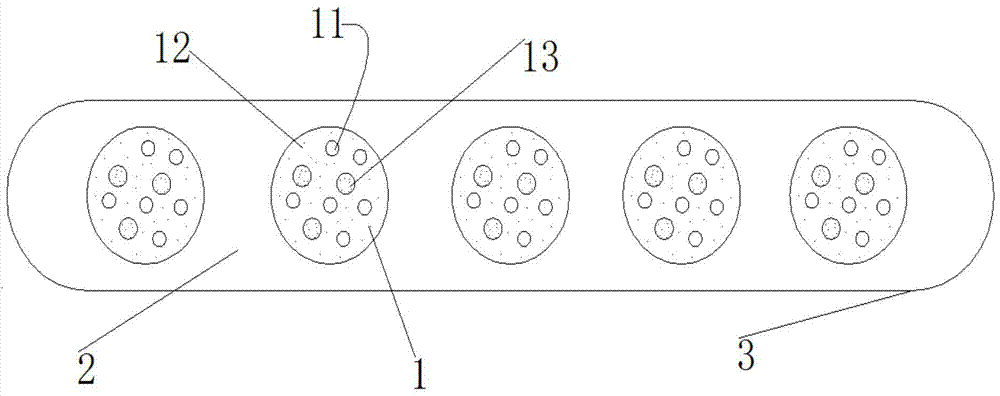

Bi-component fiber for the production of spunbonded fabric

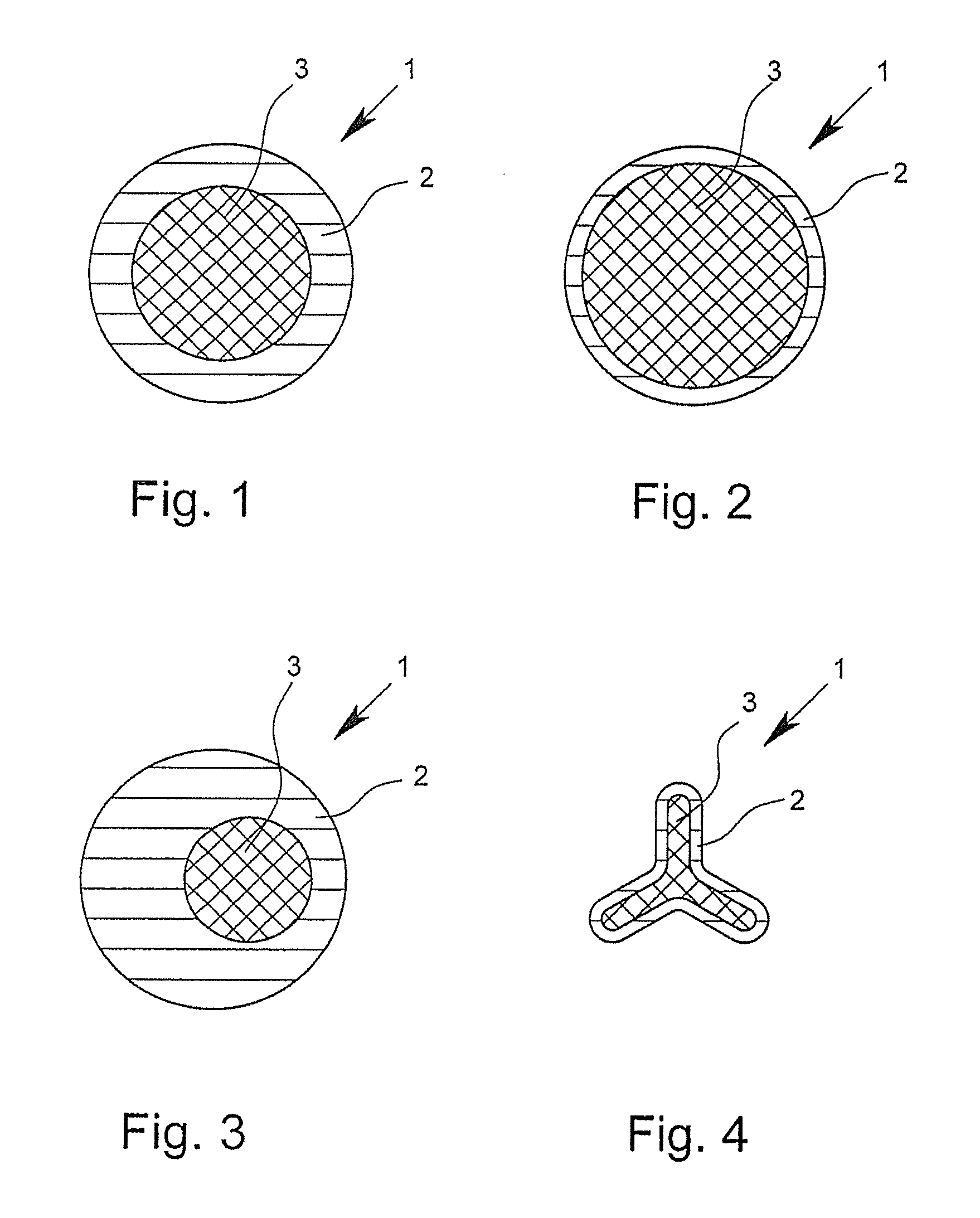

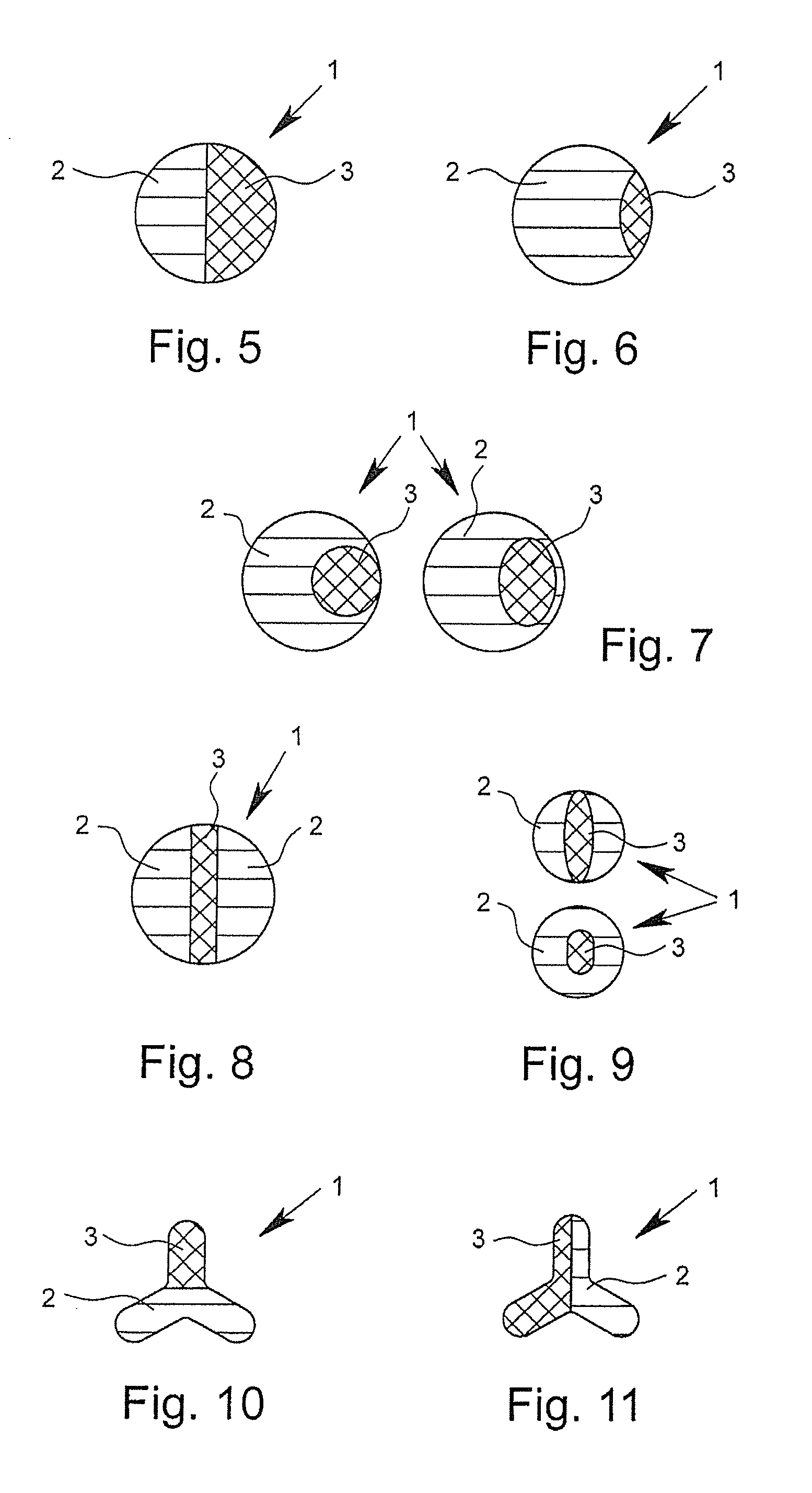

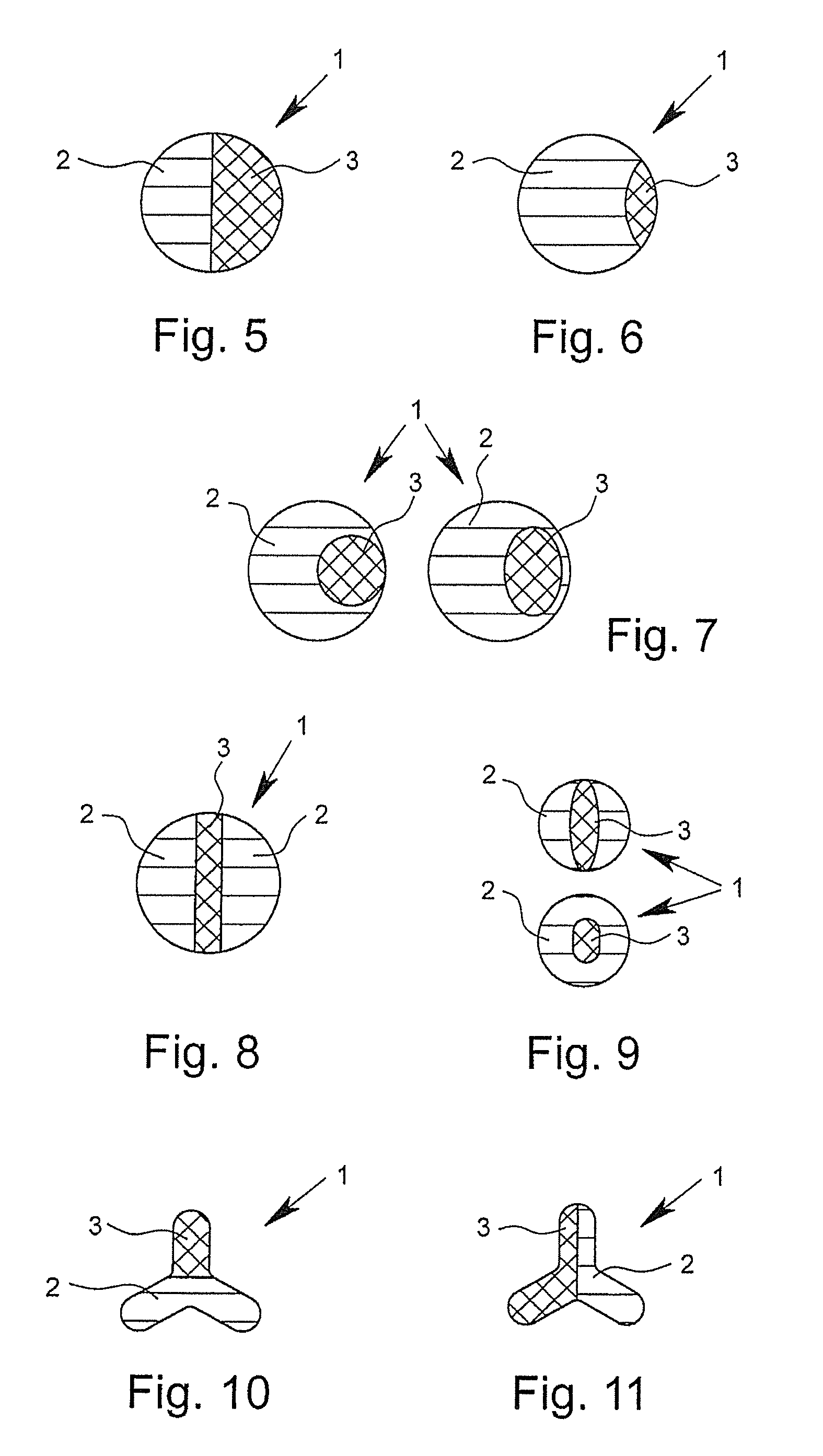

InactiveUS20150017865A1Raise the ratioChange propertiesWoven fabricsConjugated synthetic polymer artificial filamentsFiberPolymer science

A bi-component fiber (1), in particular for the production of spunbond fabrics (4), with a first component (2) and a second component (3), whereby the first component (2) has a first polymer as an integral part and the second component has a second polymer as an integral part. The first component (2) has an additive, and the second component (3) has a percentage by weight of the additive that is smaller than that in the first component (2).

Owner:EWALD DORKEN

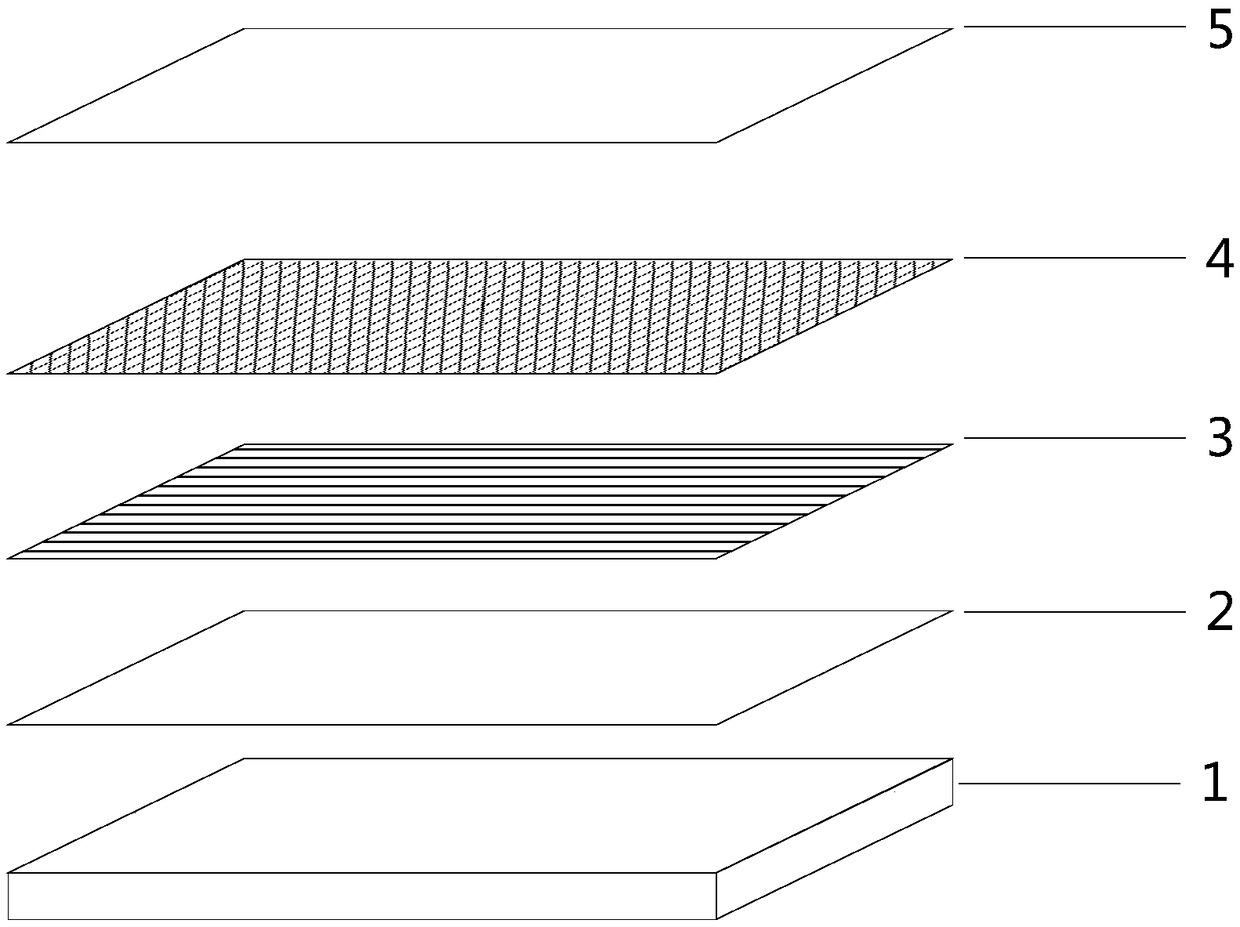

Multi-layer composite hand bag good in surface tactility and resistant to bending and preparation method thereof

InactiveCN110253977AImprove stiffnessGood surface feelSynthetic resin layered productsCellulosic plastic layered productsComposite filmUltimate tensile strength

The invention relates to a multi-layer composite hand bag good in surface tactility and resistant to bending and a preparation method thereof. The multi-layer composite hand bag comprises an outer composite film layer and an inner non-woven fabric layer, a brown paper layer can be added between the outer composite film layer and the inner non-woven fabric layer, and the layers are crisscross and tightly composited through polyethylene film laminating material. The multi-layer composite hand bag has the particular advantages that a new film layer structure is adopted, the multi-layer composite hand bag is enable to be good in tactility and attractive in appearance, and by the aid of the middle brown paper layer and the unique compositing manner, the multi-layer composite hand bag is enabled to be high in strength, toughness and deflection and have no obvious bending marks after being bended for several times.

Owner:湖北康鼎包装有限公司

Preparation method of core-spun yarns

InactiveCN110760965AGood surface feelHigh strengthPhysical treatmentHollow filament manufactureYarnActivated carbon

The invention discloses a preparation method of core-spun yarns, and belongs to the technical field of textile preparation. The core-spun yarns disclosed by the invention help neutralize the characteristics of natural fibers, so that the strength and elasticity of cotton fibers are improved. According to the invention, the cotton yarns prepared from the natural plant fibers are immersed in a reinforcing adhesive with titanium dioxide; when in liquid media, especially in polar media, titanium dioxide particles can attract opposite charge to form a diffused double electrode layer since their surface is charged; the effective diameter of the particles is increased, so that fine particles are firmly attracted in pores of the cotton yarns due to an electrostatic effect when passing through thecotton yarns; activated carbon used herein is prepared by firing bamboo chips at high temperature without oxygen; as bamboo is acidic, the prepared activated carbon is also acidic; therefore, the antibacterial effect can be achieved, the moisture absorption characteristic of the cotton fibers can be improved, clothes, cotton quilt and the like prepared with the cotton fibers have sweat absorptioncapacity, are more comfortable to wear, are widely applicable.

Owner:陈环英

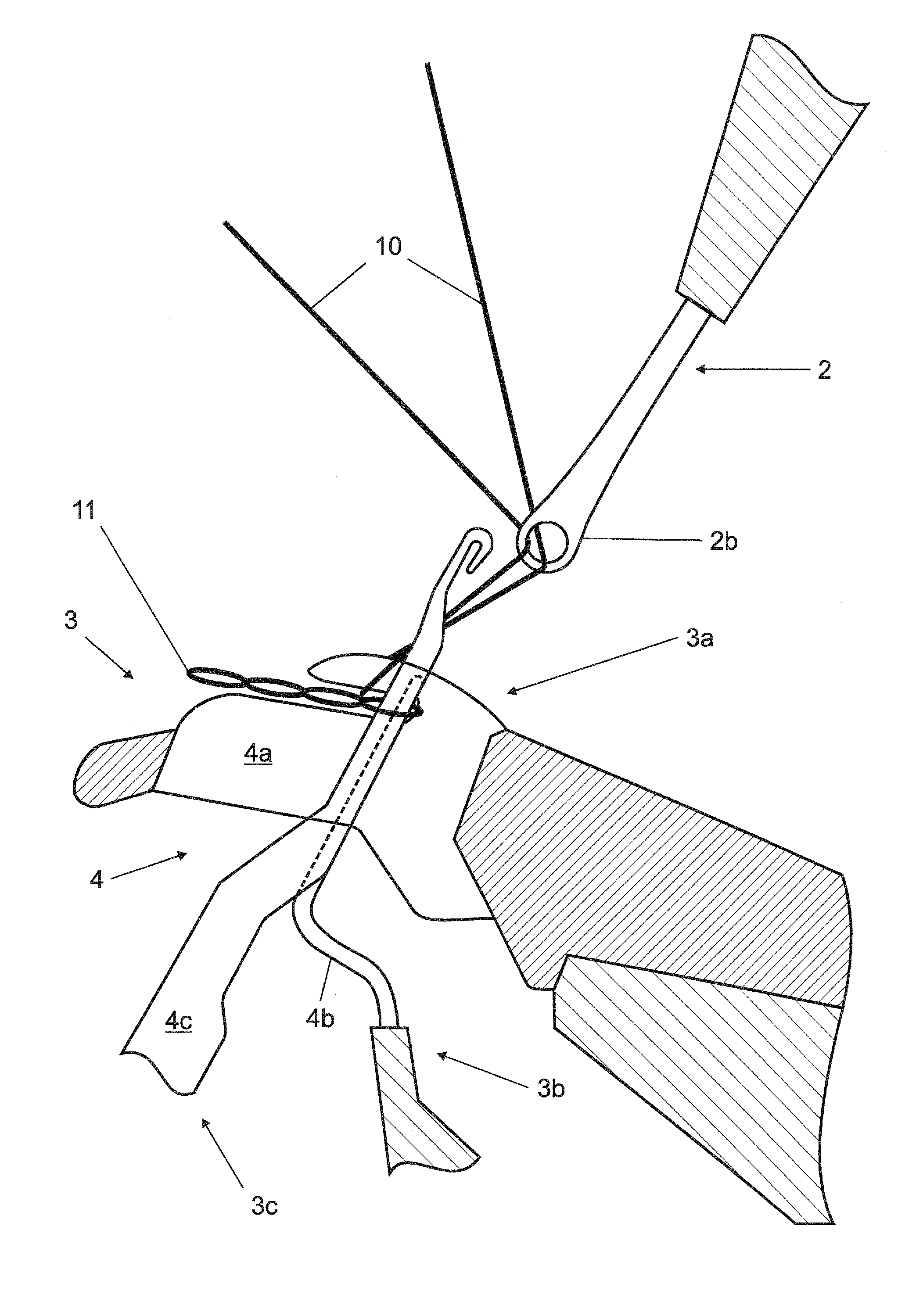

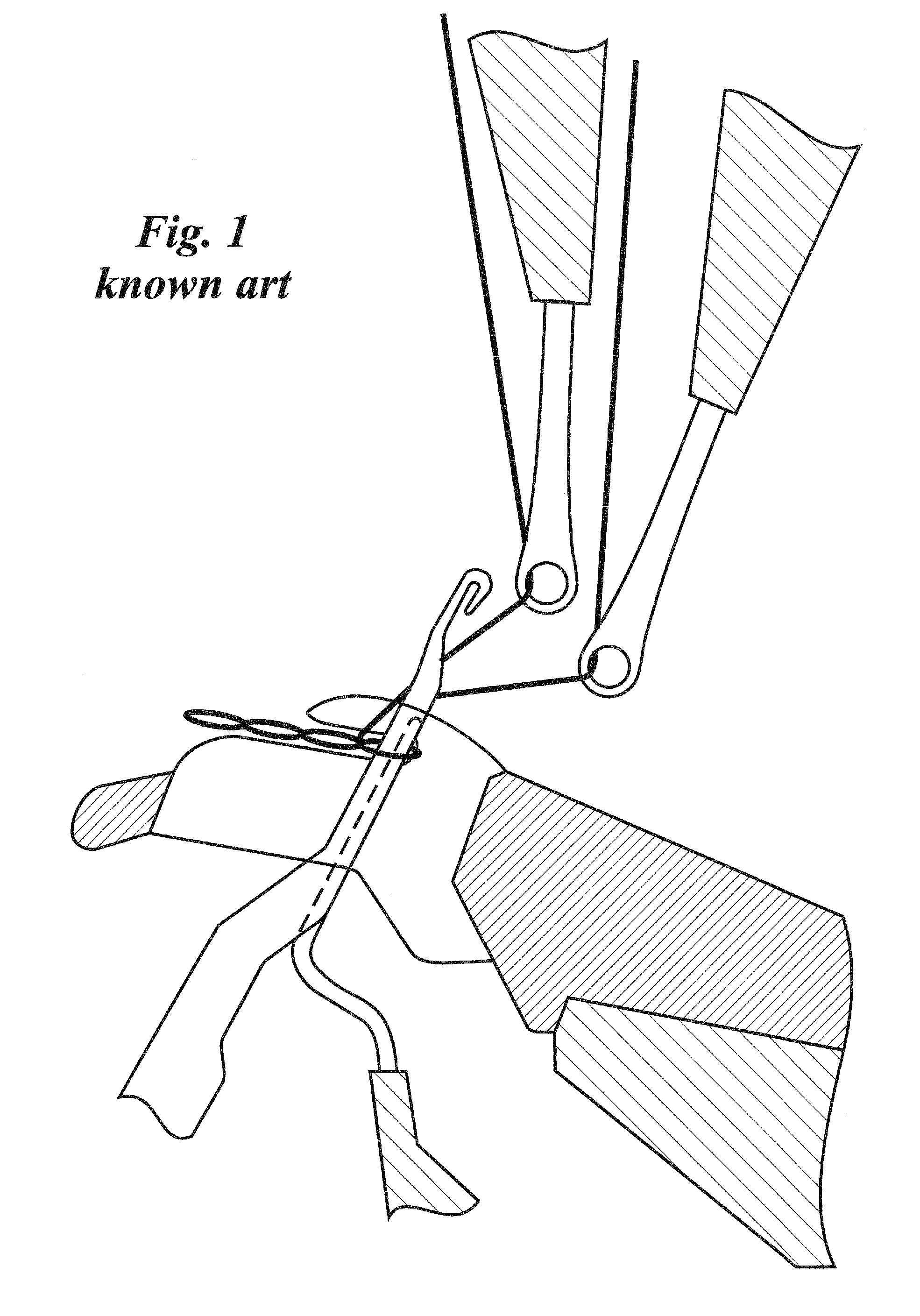

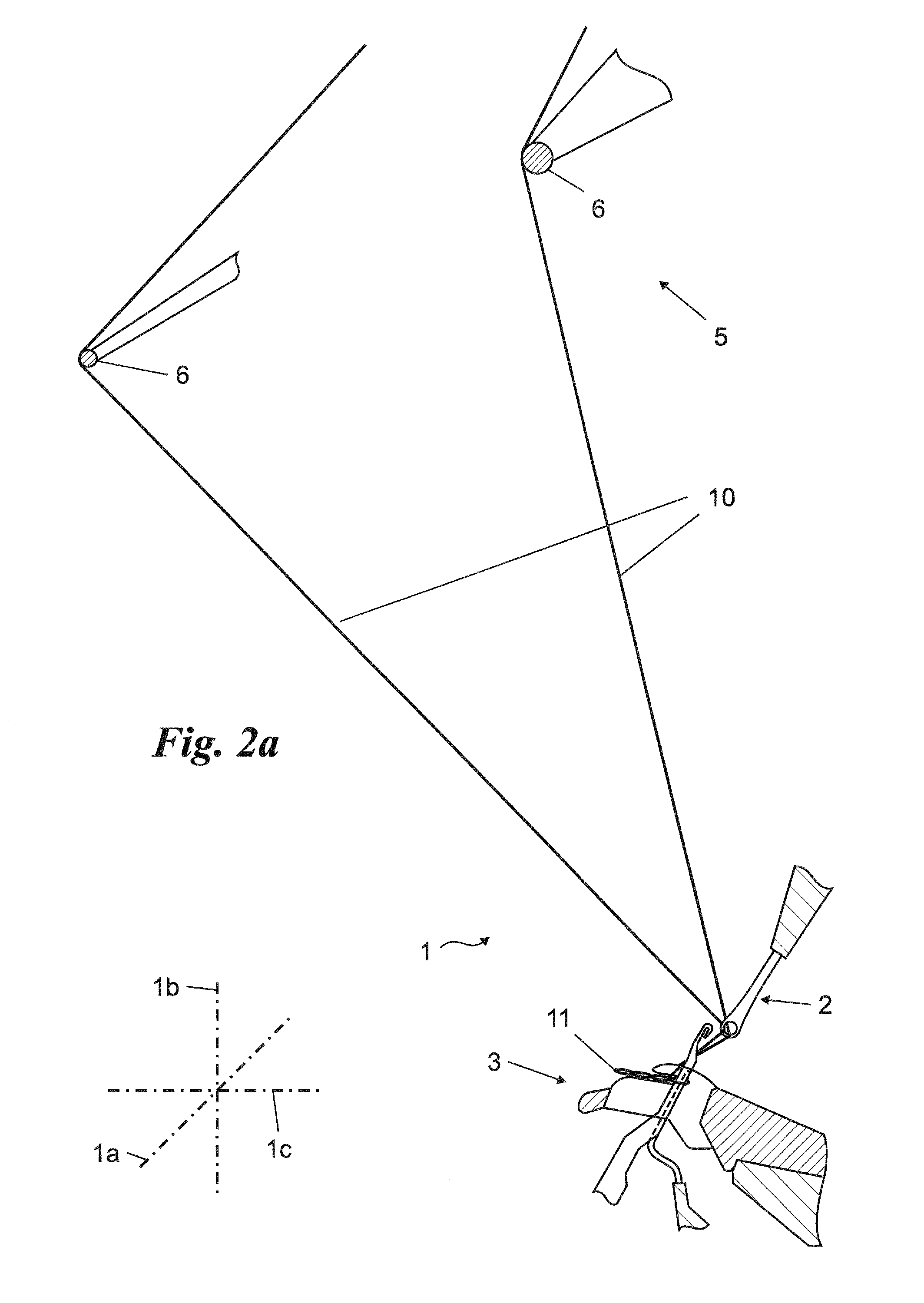

Procedure for manufacturing ladderproof fabrics

A procedure for manufacturing ladderproof fabrics on a warp knitting machine (1) comprising stitch-forming members (4) and at least one guide bar (2), with a plurality of guides (2a) for guiding a plurality of yarns (10) towards the stitch-forming members (4), wherein each of the guides (2a) belonging to at least one of the guide bars (2) guides a plurality of yarns (10).

Owner:CARVICO SPA

Polyurethane resin on surface of PVC leather and preparation method thereof

InactiveCN109280151AImprove cohesive energyPrevent precipitationTextiles and paperSolventPlasticizer

The invention discloses a preparation method for polyurethane resin on the surface of PVC leather. The preparation method mainly comprises the following steps: adding a certain amount of NPG polyol, isocyanate MDI and a solvent DMF into a reaction kettle, carrying out heating to 50-60 DEG C , and then performing a reaction for 0.5 to 1 h; then carrying out cooling to 35 DEG C or below, adding a certain amount of ethanolamine drop by drop, and continuing the reaction for 1 h; adding a certain amount of ethylene glycol and hydroxyl silicone oil, then carrying out heating to 70 to 75 DEG C, and performing a reaction for 2; and then, supplementing the isocyanate MDI, which is generally not more than 10% of a theoretical calculated amount, adjusting viscosity to 600-1200 CPS / 25 DEG C, and carrying out cooling and filtration so as to obtain a finished product. The polyurethane resin on the surface of PVC leather in the invention effectively solves the disadvantages that conventional polyurethane resin on the surface of the PVC leather has insufficient adhesion, a plasticizer is easy to precipitate and conventional polyurethane resin feels sticky and not dry enough.

Owner:浙江优尼科新材料有限公司

Preparation method of functional micronized leather buffing dust

ActiveCN108395692AGood surface feelGood water vapor permeabilityCoatingsPolymer modifiedCombinatorial chemistry

The invention provides preparation of functional micronized leather buffing dust. The preparation comprises the following steps: (1) pre-treating leather buffing dust; (2) preparing hyperbranched polymer modified leather dust; (3) blending with a negative ion releasing agent to prepare the functional micronized leather dust. The powder for a wet-process coating of synthetic leather, which is prepared by the method, has the advantages that the synthetic leather has negative ion releasing performance, endogenous formaldehyde capturing performance and good sanitary performance.

Owner:QILU UNIV OF TECH

Coating liquid used for surface of environment-friendly rich mineral paper

ActiveCN102675989BGood surface feelImprove flatnessConjugated diene hydrocarbon coatingsUltimate tensile strengthButadiene-styrene rubber

The invention discloses a coating liquid used for the surface of environment-friendly rich mineral paper, which solves the problems of harsh surface handfeel, lack in gloss, low strength, poor bending performance and the like of the paper caused by the existing product. The coating liquid comprises the following components in percentage by weight: 14.8%-17.2% of butadiene styrene rubber latex, 31.0%-36.0% of inorganic mineral powder, 33.5%-42.7% of pure water, 0.4%-0.5% of glycol, 0.22%-0.25% of dispersing agent, 0.11%-0.13% of antifoaming agent, 0.18%-0.21% of thickening agent, 9.7%-11.3% of PVA (poli vinyl alcohol)-S and 0.8%-1.0% of lubricating agent. The invention also provides a preparation method of the coating liquid. The surface handfeel, the flatness, the flexibility and the printing performance of the environment-friendly paper can be observably improved, and the surface strength of the paper is improved.

Owner:孔令发

Bi-component fiber for the production of spunbond fabric

InactiveUS20150017864A1Raise the ratioChange propertiesWoven fabricsConjugated synthetic polymer artificial filamentsFiberMaterials science

A bi-component fiber (1), in particular for the production of spunbond fabrics (4), has a first component (2) and a second component (3), whereby the first component (2) has a first polymer as an integral part and the second component has a second polymer as an integral part. It is provided that the difference between the melting points of the first component (2) and the second component (3) is less than or equal to 8° C.

Owner:EWALD DORKEN

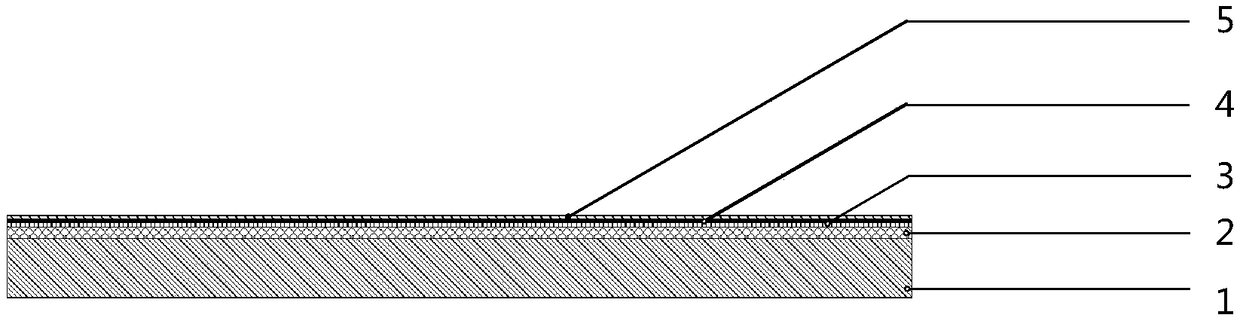

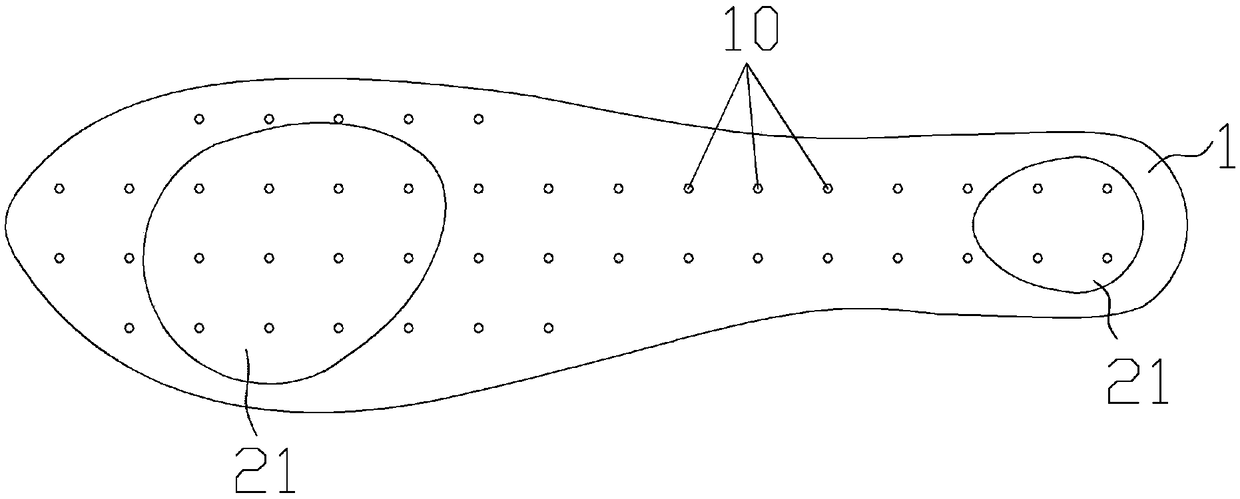

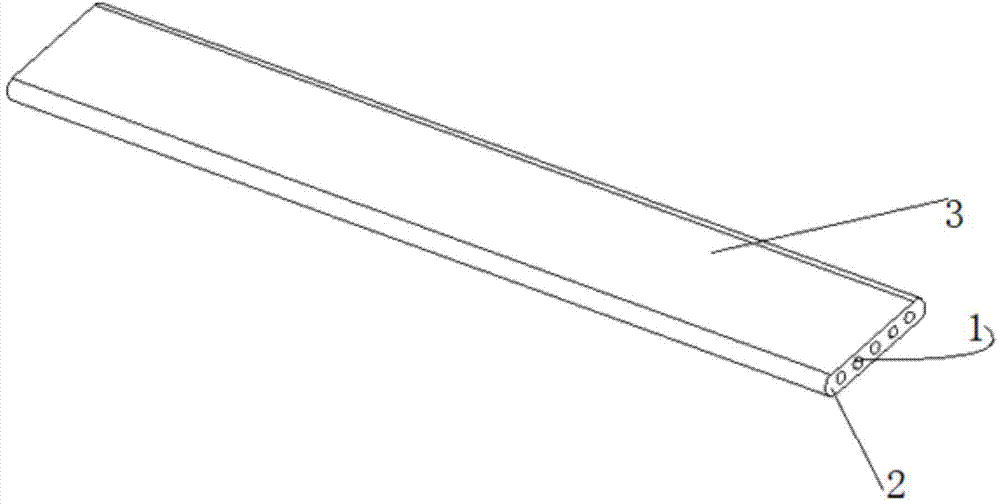

Infusion-molded breathable insole and manufacturing method thereof

PendingCN108523305AGuaranteed breathabilityImprove breathabilityInsolesSynthetic resin layered productsSurface layerHot melt

The invention discloses an infusion-molded breathable insole and a manufacturing method thereof. The infusion-molded breathable insole comprises a surface layer, a breathable layer and a hot melt filmwhich are connected in sequence. The surface layer is provided with a plurality of air holes that run through the surface layer, the hot melt film and the breathable layer. The breathable layer may ensure breathability of the insole; the surface layer may contact with the sole of a user, it is better to touch the insole, and the insole is more attractive; the hot melt film helps improve the connection strength for the breathable layer and the surface layer; during forming of the breathable layer, the breathable layer may arrive at the surface of the insole through the surface layer, thus affecting the use of the insole; the hot melt film with high compactness can prevent the above problem. The air holes can ensure that the hot melt film is penetrated; the hot melt film is avoided affecting the breathability of the insole; the breathability of the insole is further improved.

Owner:东莞市天强鞋材有限公司

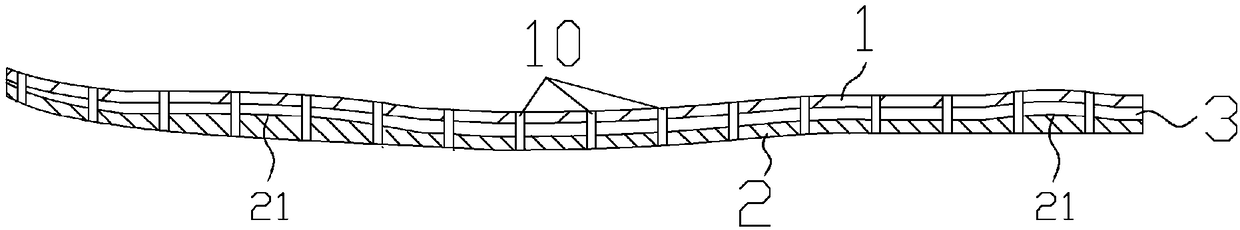

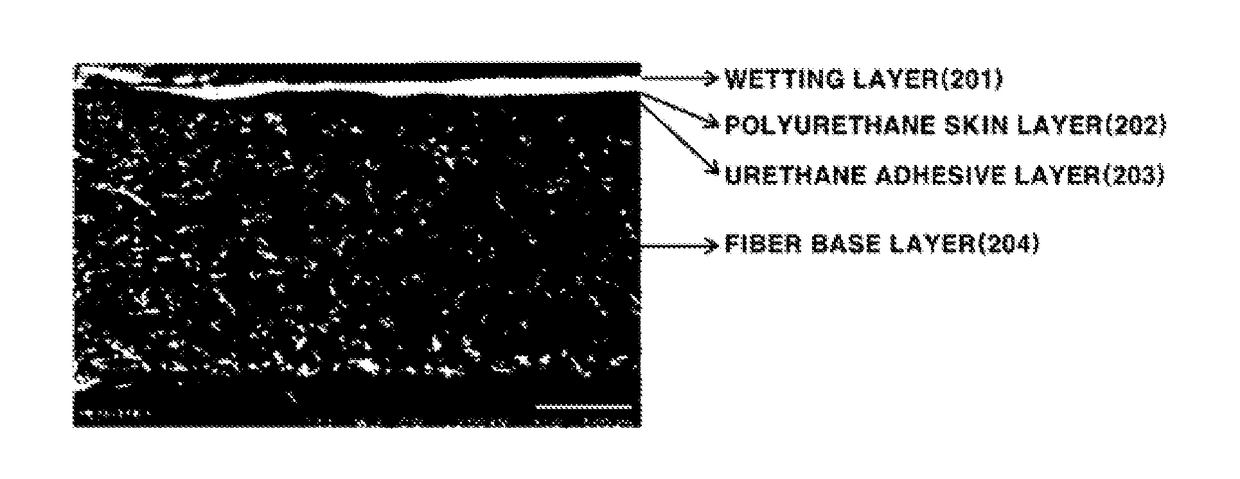

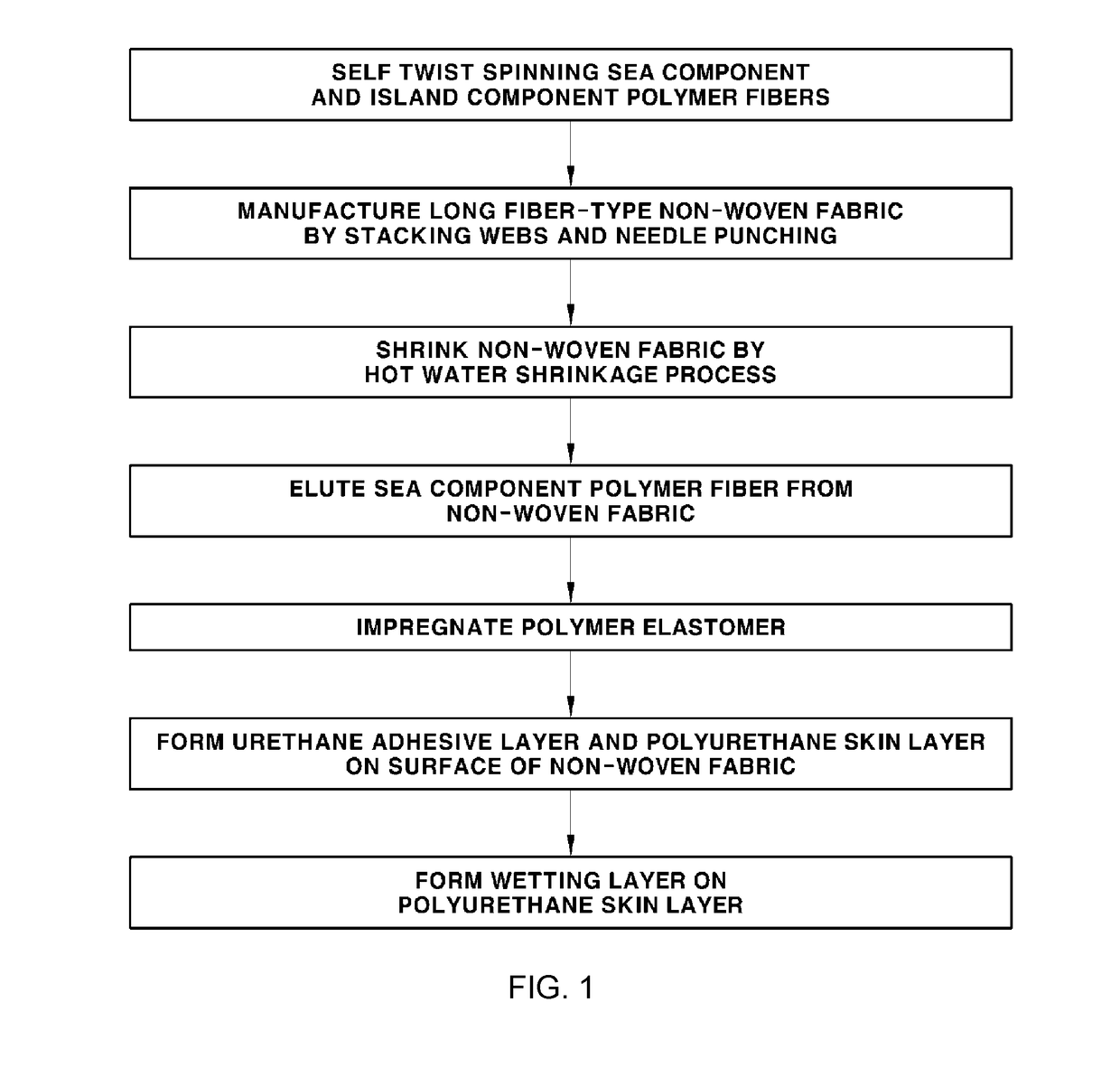

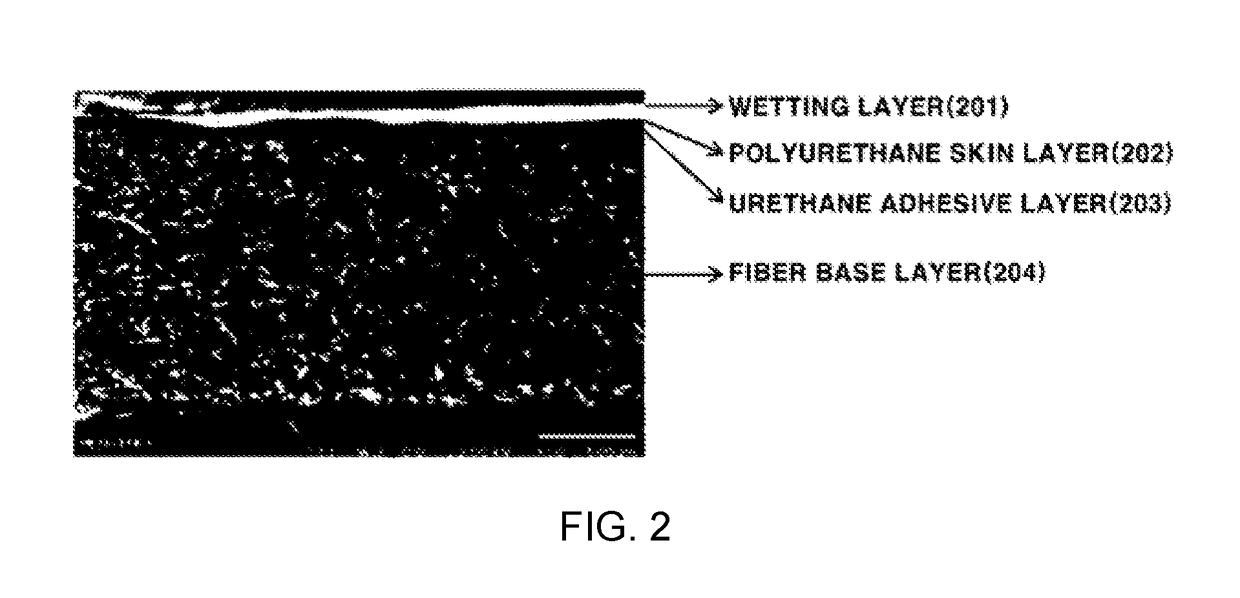

High density artificial leather having excellent surface touch and method of manufacturing the same

InactiveUS20180258584A1Excellent soft textureHigh densityLamination ancillary operationsSynthetic resin layered productsElastomerYarn

A method for manufacturing a high density artificial leather, may include (a) manufacturing a long fiber-type non-woven fabric having an areal weight of 400 to 500 g / m2 and an apparent density of 0.3 to 0.6 g / cm3 by self-twist spinning a sea component polymer fiber and an island component polymer fiber; (b) shrinking the long fiber-type non-woven fabric with hot water; (c) eluting the sea component polymer fiber from the shrunken non-woven fabric by immersing the shrunken non-woven fabric in an aqueous alkaline solution; and (d) impregnating a polymer elastomer in a non-woven fabric from which the sea component polymer fiber is eluted, to manufacture a long fiber-type fine yarn non-woven fabric.

Owner:HYUNDAI MOTOR CO LTD +2

Tissue products containing deliquescent materials and non-ionic surfactants

InactiveUS20060243406A1Reduce surface tensionOptimize tactile sheet propertyBiocideNatural cellulose pulp/paperPaper towelEquilibrium moisture content

Tissue products, such as facial tissue, bath tissue, paper towels, table napkins and the like can be improved by incorporating a sufficient amount of a deliquescent material and a non-ionic surfactant into the product. The deliquescent material is capable of maintaining a very high equilibrium amount of water in the product which can be advantageous in preventing the products from drying out and improving hand feel. The non-ionic surfactant improves the ability to incorporate the deliquescent materials into the tissue products quickly during manufacture and can help control the equilibrium moisture content of the product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

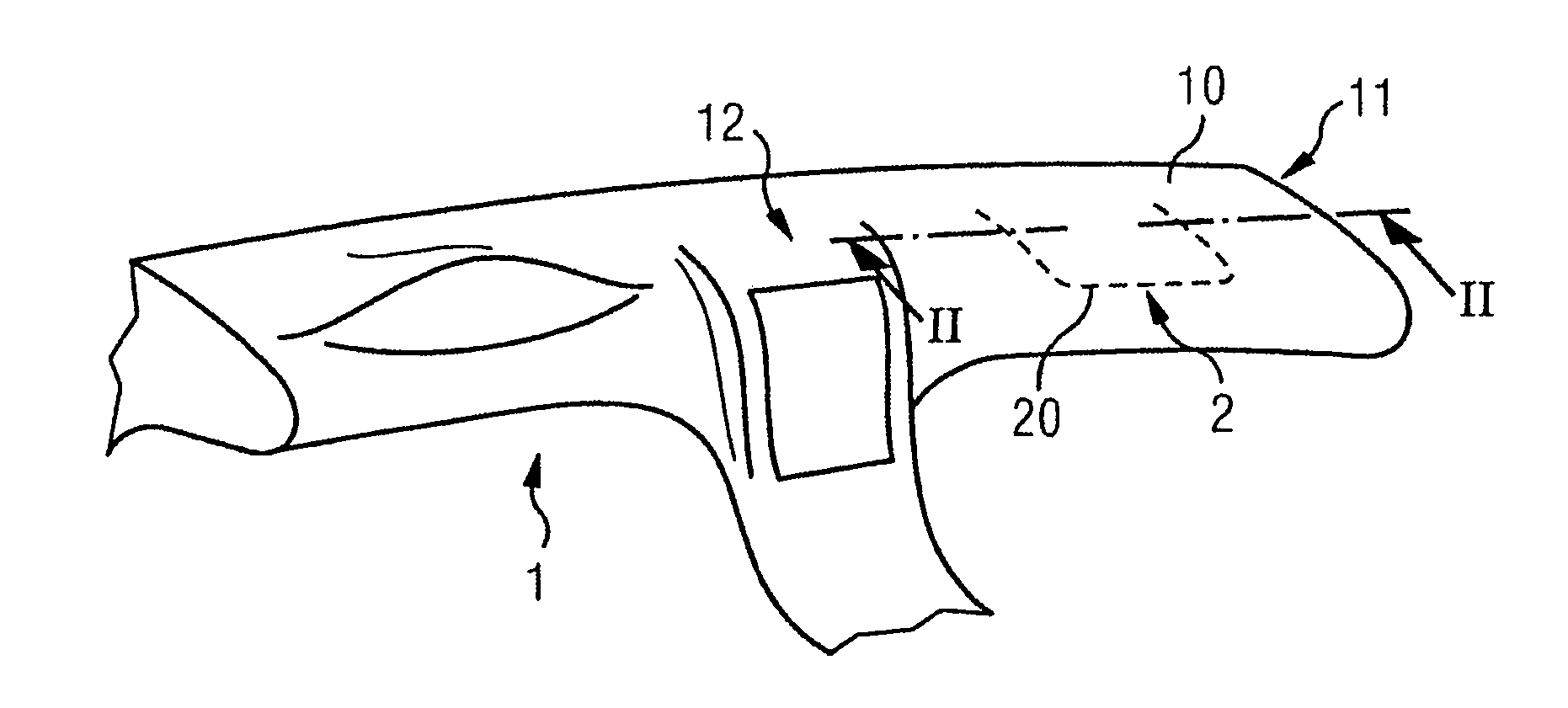

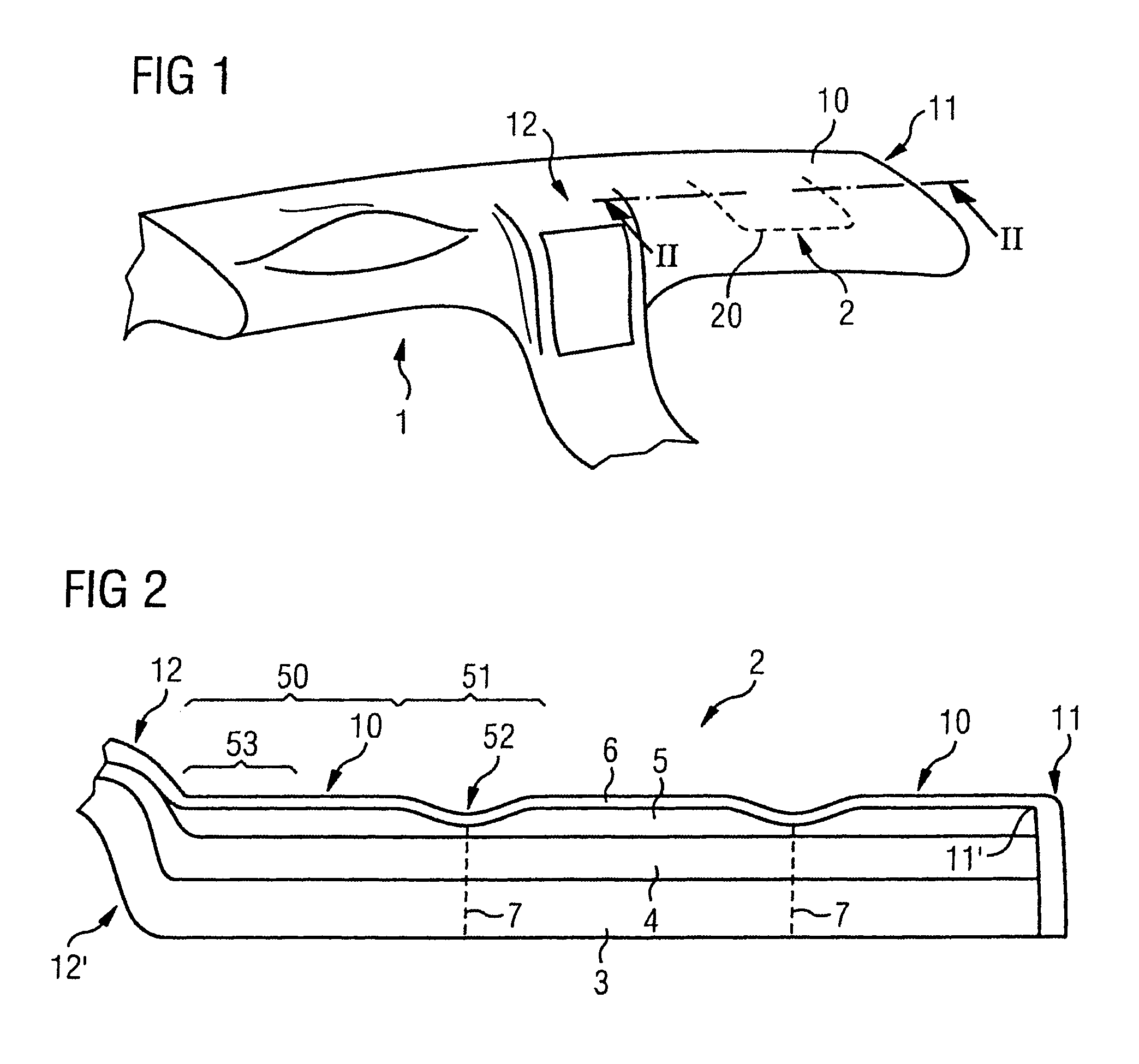

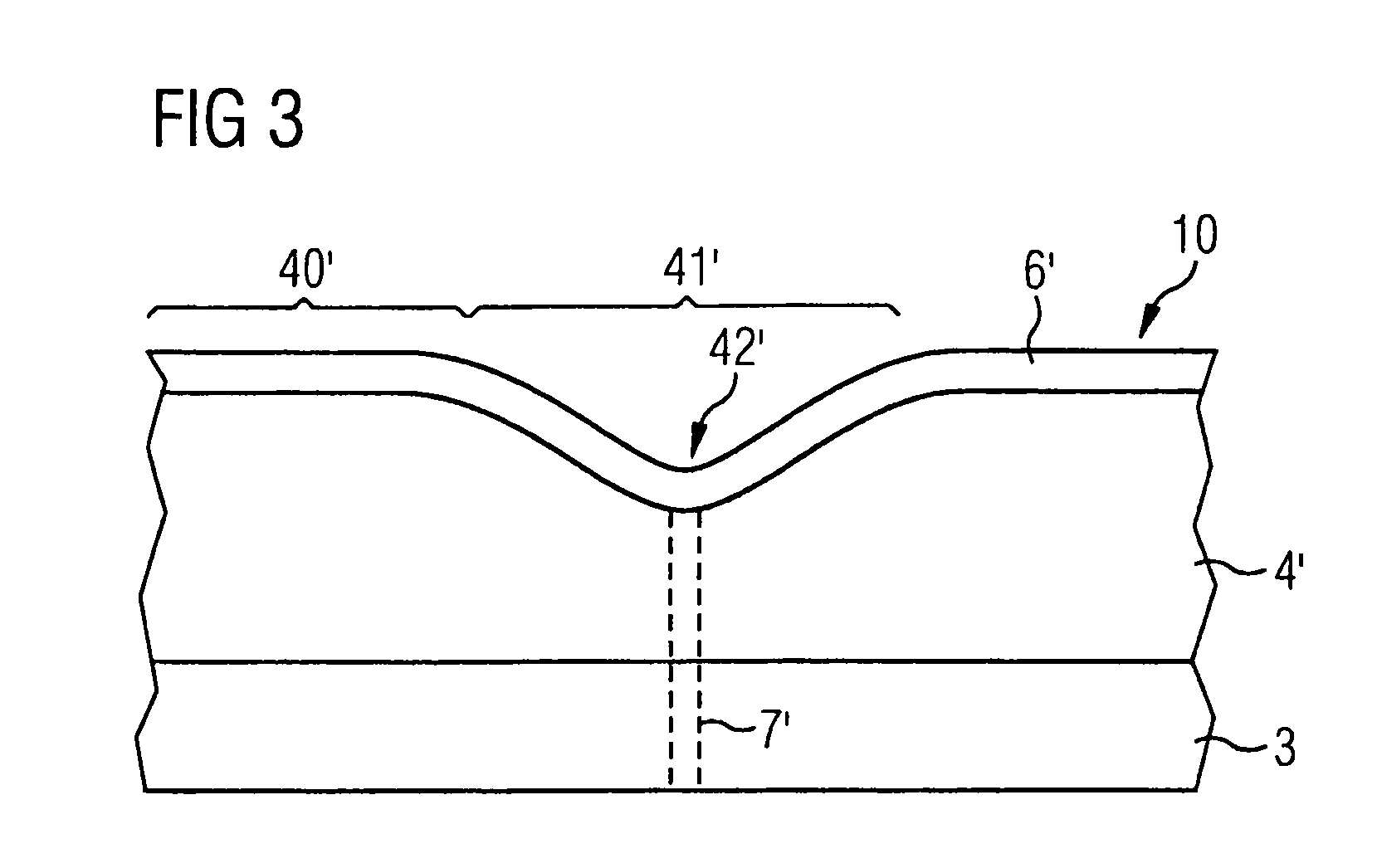

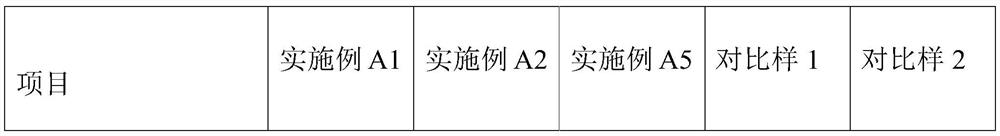

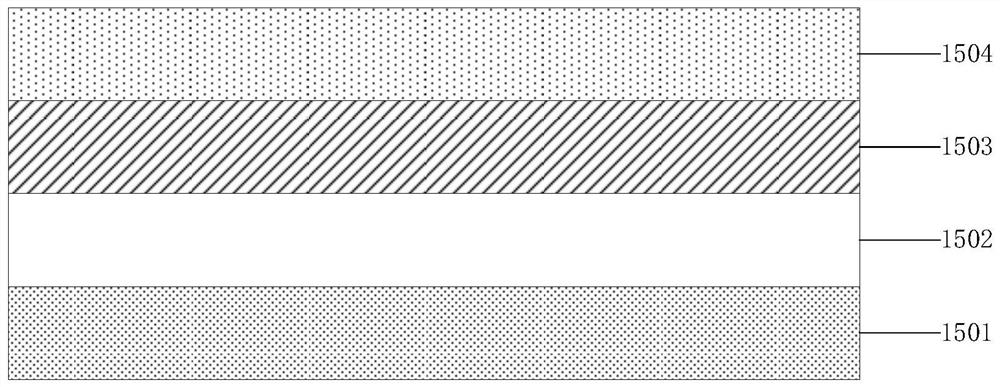

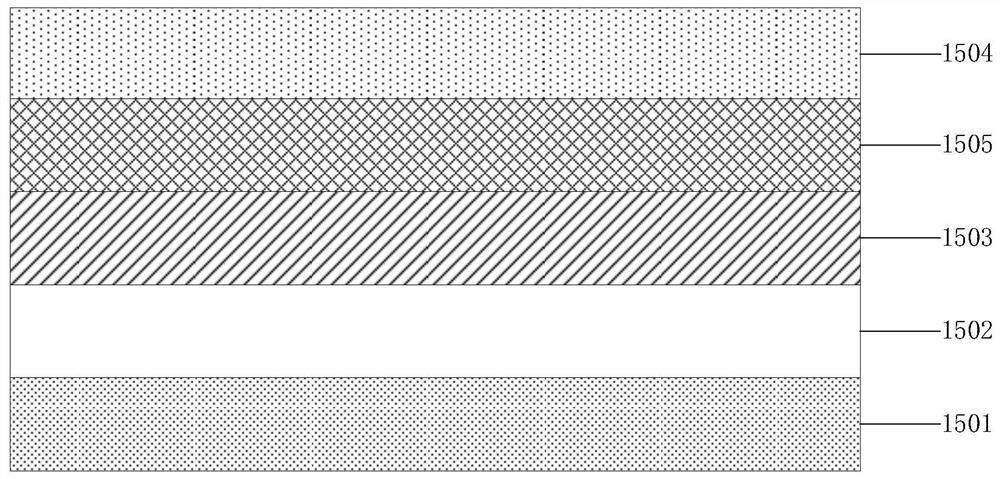

Airbag cover and method of producing same

InactiveUS8496264B2Tight tolerance rangeUniform thicknessPedestrian/occupant safety arrangementSynthetic resin layered productsEngineeringAirbag

The invention relates to an airbag cover having a carrier and a visible-side surface made of leather or an imitation leather arranged on the carrier, wherein the surface has a uniform thickness and the carrier has a carrier thinning introduced along a tear line, and a reinforcing layer having a local weakening is arranged between the carrier and the surface, wherein the surface is attached directly to the reinforcing layer. The local weakening is formed by a minimal thickness of the reinforcing layer in the area of the tear line. The uniform thickness of the surface is less than or equal to 1 mm.

Owner:FAURECIA INNENRAUM SYST

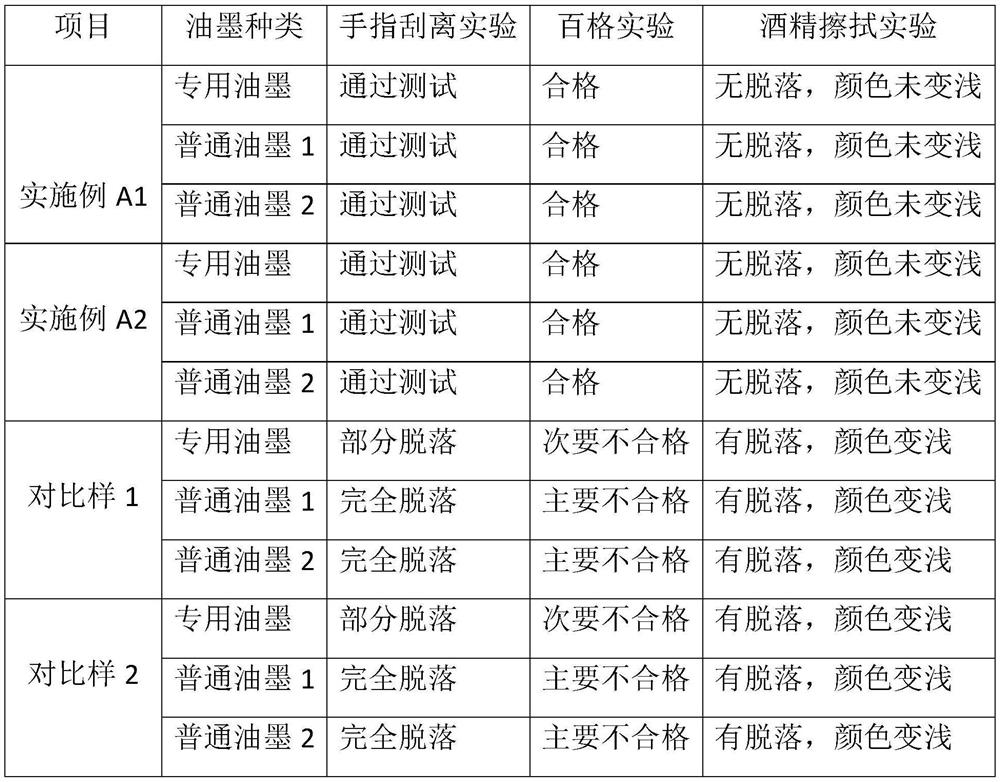

TPV easy for ink dyeing and printing and preparation method thereof

The invention relates to the technical field of thermoplastic elastomer materials, and discloses a TPV easy for ink dyeing and printing and a preparation method of the TPV. The TPV is mainly preparedfrom polyolefin rubber, polyolefin resin, white oil, maleic anhydride graft modified polyolefin resin, an ethylene-vinyl acetate copolymer, an ethylene-methyl acrylate copolymer, a peroxide, a crosslinking assistant, an antioxidnt, a light stabilizer and a surface modifier. The preparation method includes: firstly premixing the raw materials in a twin-screw extruder according to a certain ratio toobtain a premixed product, and adding a crosslinking agent and a crosslinking aid to vulcanize the premixed product, thereby obtaining the TPV material easy for ink dyeing and printing. The TPV material provided by the invention has the advantages of simple preparation process, good printing / dyeing properties, and strong adsorption effect on common printing ink, and has important significance inwidening the application field of thermoplastic elastomers.

Owner:江苏金陵奥普特高分子材料有限公司

Slow recovery latex space cotton pillow

The invention belongs to the technical field of space cotton pillows, and discloses a slow recovery latex space cotton pillow. The pillow comprises a pillow inner and a natural latex layer; the pillowinner is formed by a polyether urethane sponge with anti-flaming and antibacterial functions, the natural latex layer is formed by foaming pure natural latex, the natural latex layer wraps the pillowinner, and the thickness of the natural latex layer is 2-5 mm. The slow recovery latex space cotton pillow has the good surface touch and has the slow rebound resilience, proper hardness and good anti-flaming effect; special antibacterial treatment is performed in holes of the polymeric sponge in the slow recovery latex space cotton pillow, and the problem that bacteria and other harmful microbesare likely to be bred / enriched in the sponge holes is solved.

Owner:德清舒华泡沫座椅有限公司

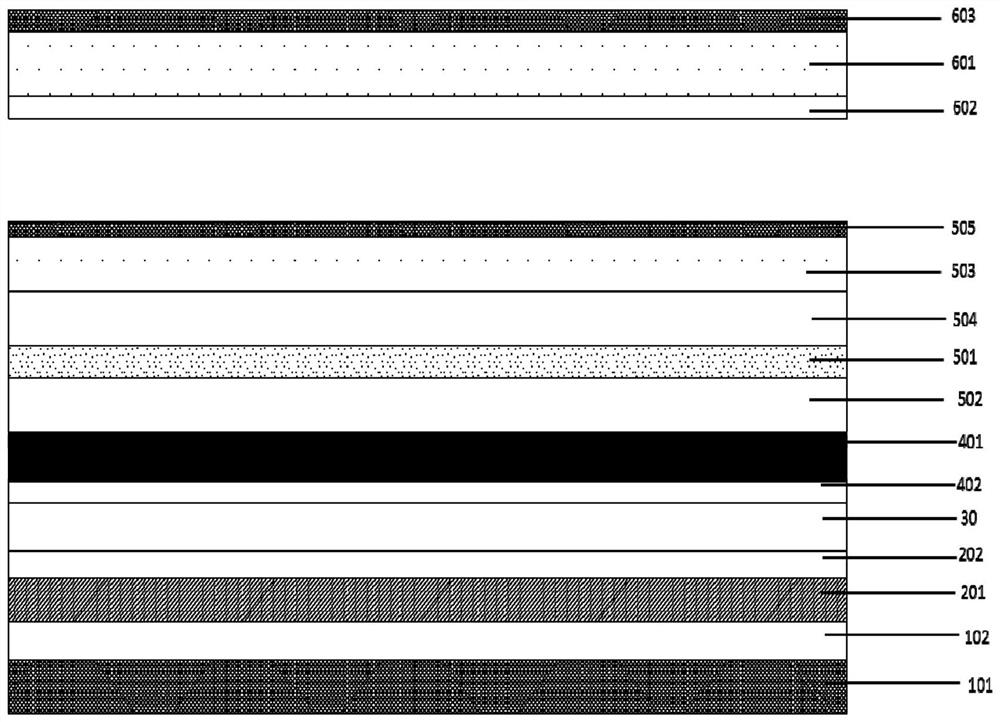

Flexible display cover plate assembly and manufacturing method thereof, display panel and display device

PendingCN113643614AEnsure safetyEasy to realize all-in-one replacementSolid-state devicesIdentification meansDisplay deviceEngineering

The invention provides a flexible display cover plate assembly which comprises a first cover plate, an adhesion layer, a buffer layer and a second cover plate, the adhesion layer, the buffer layer and the second cover plate are sequentially stacked on one side of the first cover plate, and when the second cover plate is damaged, the buffer layer can protect the first cover plate from being damaged; the adhesion layer can reduce the viscosity between the first cover plate and the explosion-proof material easy-to-tear buffer layer, so that the buffer layer and the second cover plate are separated from the first cover plate together; the outer pasting film is replaced by the second cover plate, then the surface touch sense and the light emitting effect of the flexible display screen are improved, the safety of the first cover plate is guaranteed through the arrangement of the buffer layer and the adhesion layer, and meanwhile integrated replacement of the first cover plate is conveniently achieved.

Owner:BOE TECH GRP CO LTD

Non-porous self-breathing PVC artificial leather and preparation method thereof

ActiveCN111040240AKeep dryIncreased durabilityPolyurea/polyurethane coatingsComposite materialCarboxylate

The invention provides non-porous self-breathing PVC artificial leather which comprises a non-porous self-breathing surface layer and a breathable bottom layer with a microporous structure, the self-breathing surface layer and the breathable bottom layer are attached together by adopting a transfer method and (or) a direct coating method, the self-breathing surface layer contains water-soluble polyhydric alcohol and carboxylate, and the breathable bottom layer is a breathable PVC foaming layer. According to the non-porous self-breathing PVC artificial leather, water vapor is discharged out ofthe leather through the temperature difference and the humidity difference, self-breathing is achieved, the moisture and air discharging effect is achieved, the outer layer is of a non-porous structure, the waterproof effect is achieved, and the problem that PVC leather is poor in breathability is effectively solved.

Owner:清远市美佳乐环保新材股份有限公司

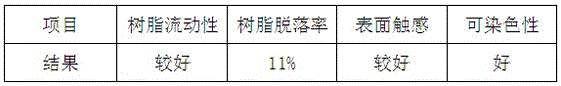

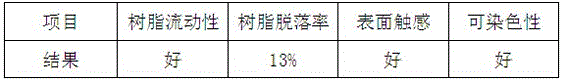

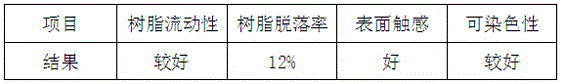

Polyurethane resin for impregnation of superfine fiber and preparation method thereof

The invention relates to polyurethane resin, in particular to polyurethane resin for impregnation of superfine fiber and a preparation method thereof. The polyurethane resin is prepared from the following components in percentage by weight: 8%-15% of MDI (4, 4-diphenylmethane diisocyanate), 3%-8% of polyether polyol PTMEG-1000, 5%-7% of caprolactone PCL-2000, 3%-8% of polyester polyol PEG-2000, 2%-5% of ethylene glycol EG and 65%-70% of DMF (N,N-dimethylformamide). The polyurethane resin has the advantages that by utilization of the characteristics of the polyester polyol and the polyether polyol, the synthesized polyurethane resin is used for impregnation of the superfine fiber; when the superfine fiber is used for alkali decrement under the action of sodium hydroxide with the concentration of 10%-15%, the resin dropping rate is high, and good surface touch feel can be generated, so that the dyeable performance of the superfine fiber can be improved and the quality of a product is excellent.

Owner:ZHEJIANG JOYA POLYMER TECH

Rubber non-slipping sole and preparation method thereof

The invention discloses a rubber anti-slip bottom and a preparation method thereof. The components of the rubber anti-slip bottom and the parts by mass of each component are as follows: hemp fiber: 20-30 parts; rice husk powder: 45-55 parts; butyl Rubber: 50-70 parts; EPDM rubber: 10-20 parts; plasticizer: 2-4 parts; foaming agent: 2-4 parts; anti-aging agent: 2-4 parts; vulcanizing agent: 2 parts ~ 4 servings. The invention is not only elegant in appearance, but also has excellent anti-skid performance, acid and alkali resistance, and long service life.

Owner:NANTONG LONGBANG PLASTIC

Jacquard fabric processing technology with stereoscopic crease effect

InactiveCN108950819ARealize three-dimensional wrinkle effectGood surface feelWoven fabricsYarnPolyesterYarn

The invention discloses a jacquard fabric processing technology with a stereoscopic crease effect. The technology includes the following steps of 1, designing a crease mode, wherein a design map is drawn for designing the crease mode and involves convex crease areas, concave crease areas and non-crease areas; 2, selecting warp yarn and weft yarn, wherein 22.2 dtex mulberry silk is adopted as the warp yarn, the proportion of non-elastic yarn and elastic yarn in the weft yarn is 2:1, 83.3 dtex polyester silk is adopted as first weft, 83.3 dtex polyester silk with the same density as that of thefirst weft is adopted as third weft, and spandex wrapping yarn is adopted as second weft; 3, designing texture; 4, adopting a 2,720 needle electronic jacquard machine for weaving jacquard fabric, wherein the actual weaving needle number of the machine is 2,400. By means of the jacquard fabric processing technology, the stereoscopic crease effect of the fabric is achieved, the cost is reduced greatly, the stereoscopic crease effect on the surface of the fabric is great, the style is unique, and the added value of products is significantly increased.

Owner:ZHEJIANG SCI-TECH UNIV

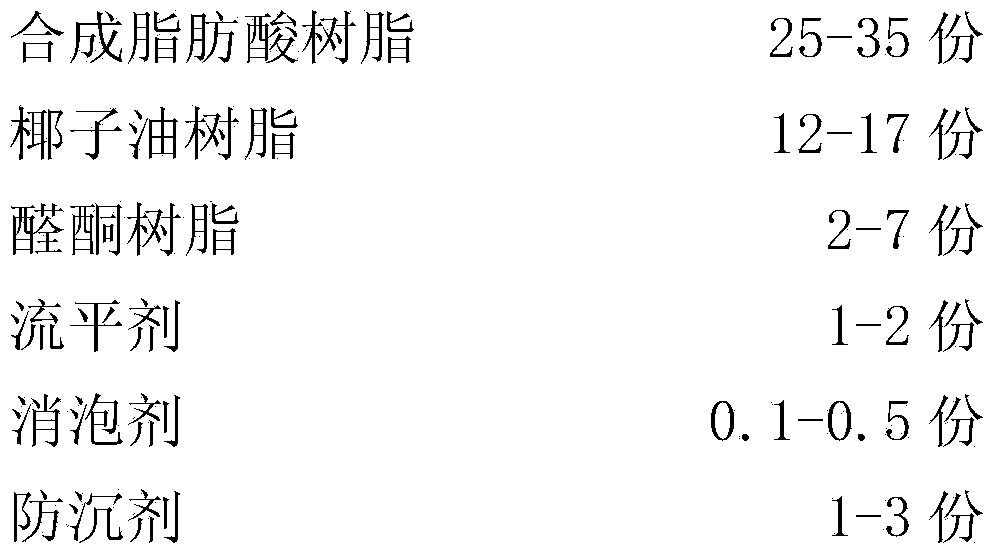

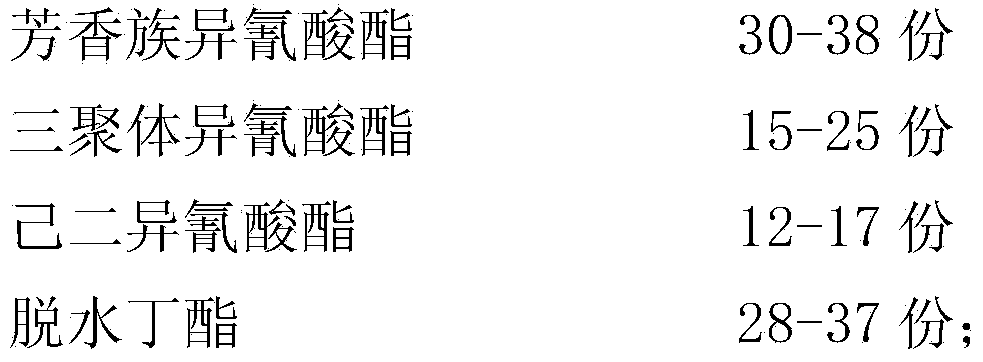

Polishable high-hardness polyurethane bright white finish and preparation method thereof

The invention relates to a polishable high-hardness polyurethane bright white finish and a preparation method thereof. The polishable high-hardness polyurethane bright white finish is prepared by mixing a main agent, a curing agent and a diluent according to the mass ratio of (1-1.4) to (0.8-1) to (0.5-0.7), wherein the main agent comprises the following components in parts by weight: 25-35 parts of synthetic fatty acid resin, 12-17 parts of coconut oil resin, 2-7 parts of aldehyde ketone resin, 1-2 parts of a flatting agent, 0.1-0.5 part of a defoaming agent, 1-3 parts of an anti-settling agent, 40-50 parts of titanium dioxide pulp and 0.5-1.5 parts of a drier. The polishable high-hardness polyurethane bright white finish prepared by the preparation method has the characteristics of high glossiness, good fullness and good levelling property, and simultaneously can meet the requirement for polishing after being sprayed for 24 hours.

Owner:SKSHU PAINT

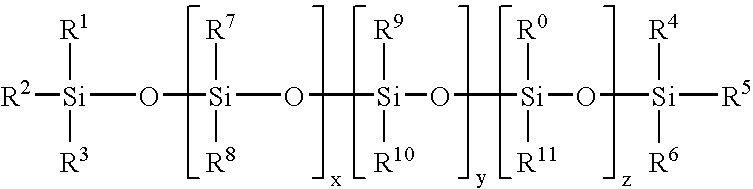

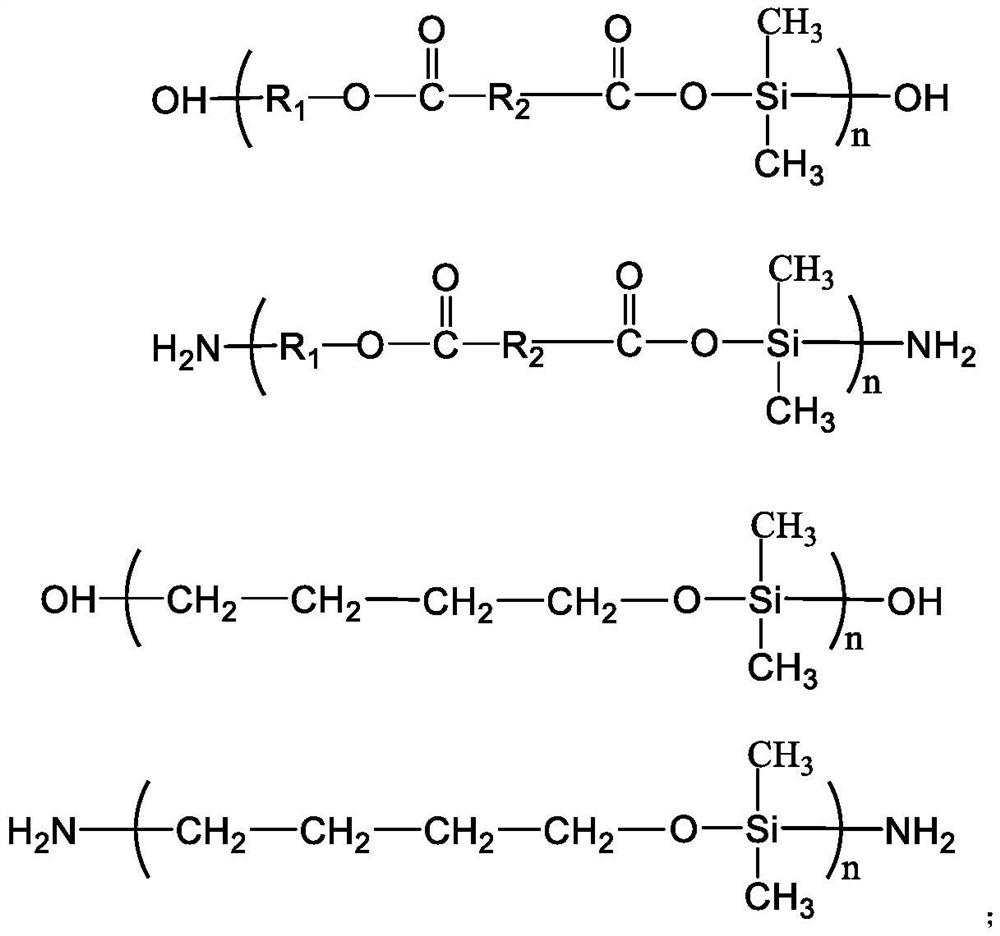

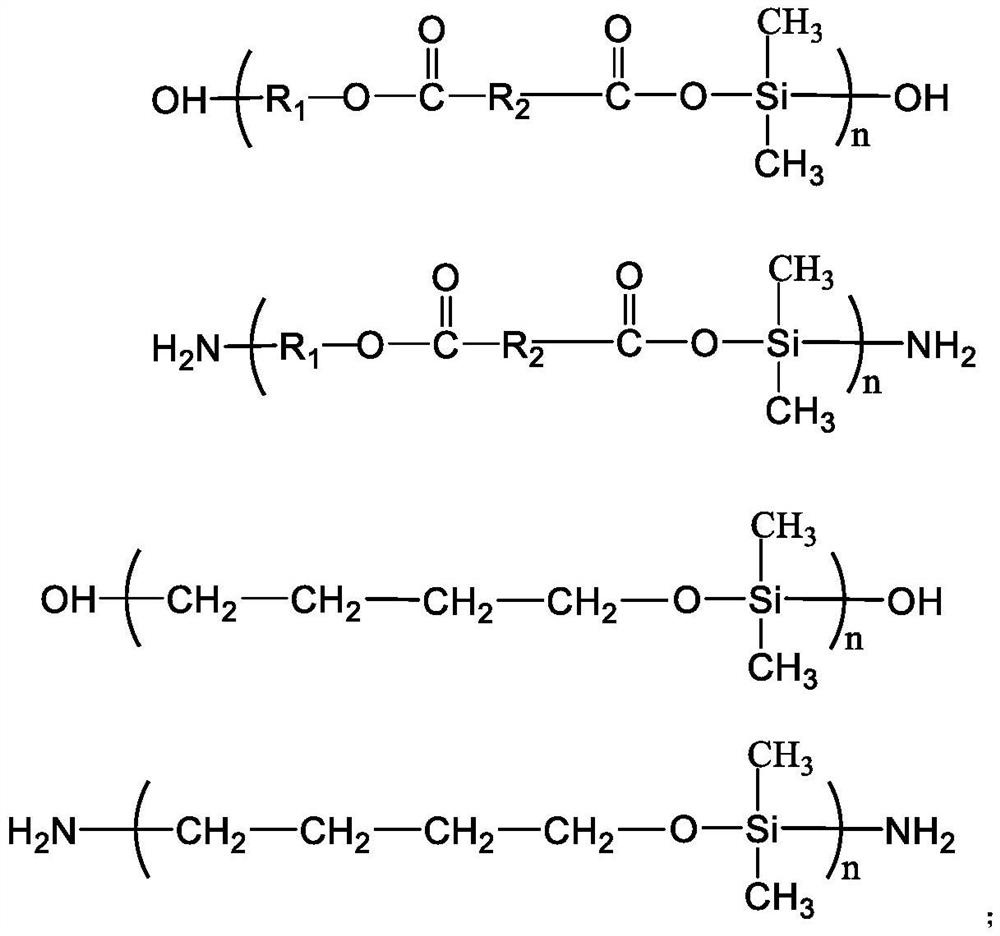

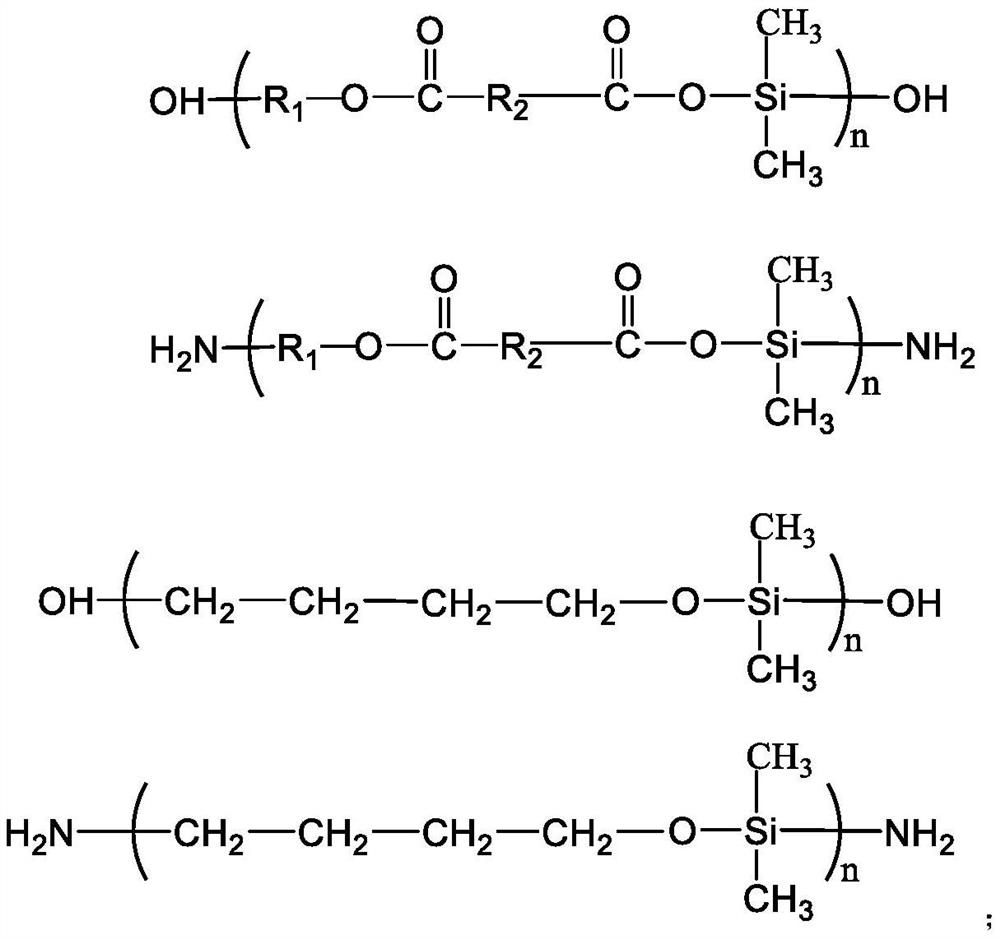

Silicon-containing thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN112159512AImprove wear resistanceImprove hydrolysis resistancePolymer scienceMixed materials

The invention discloses a silicon-containing thermoplastic polyurethane elastomer (TPU) and a preparation method thereof. The method comprises the following steps: mixing diisocyanate, a chain extender, polyol and group-containing terminated silicone oil in a twin-screw extruder; and reacting and extruding the mixed materials. The squeezed material is diced underwater, thus to obtain silicon contained TPU particles. The hardness range of the finished product is 55A-72D, the finished product has excellent wear resistance, hydrolysis resistance, chemical reagent resistance and high temperature resistance, and has more excellent coating property and surface touch, and the product is synthesized and granulated by adopting a one-step method of a double-screw extruder, so that the production efficiency is improved, and the cost is reduced.

Owner:江苏登科聚氨酯材料有限公司

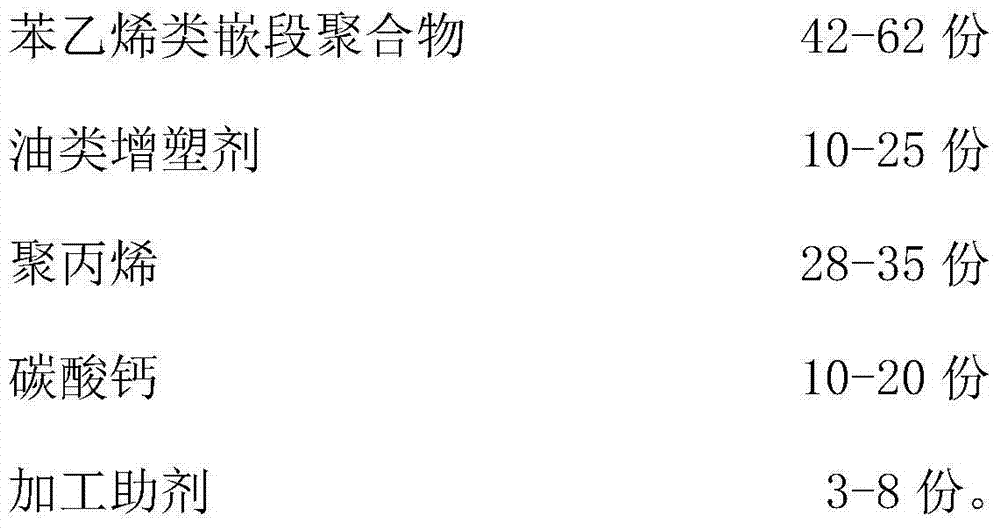

Preparation method of nanometer coated earphone line and product thereof

ActiveCN104505171AEasy to identifyEasy to distinguishPlastic/resin/waxes insulatorsCable/conductor manufacturePlasticizerPlasticulture

The invention discloses a preparation method of a nanometer coated earphone line. The preparation method comprises the following steps: preparing single lines, preparing an insulating jacket, preparing a nanometer coating film and the like. The invention also discloses a nanometer coated earphone line product prepared by using the method. The product comprises a plurality of strands of single lines and the insulating jacket layer which wraps the single lines, wherein the surface of the insulating jacket layer is provided with the nanometer coating layer; more than four strands of single lines are arranged side by side; the insulating jacket layer is flat; the thickness of the nanometer coating layer is 50-100 nm and is deposited on the surface of the insulating jacket layer by using the principle of vapor deposition; the insulating jacket is formed of styrene block polymer, an oil type plasticizer, polypropylene, calcium carbonate and a processing aid through extrusion plasticizing. The unique flat appearance facilitates the recognition, and the unique nanometer coating layer guarantees that the product has the superior performances such as water resistance, oxidation resistance, dirt resistance, scratch resistance and ultraviolet protection.

Owner:DONGGUAN YINGTONG WIRE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com