Polishable high-hardness polyurethane bright white finish and preparation method thereof

A polyurethane, high-hardness technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of scratching the paint film and affecting production efficiency, and achieve the effect of good leveling, good fullness and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] A polishable high-hardness polyurethane bright white finish, which is prepared by mixing a main agent, a curing agent and a diluent in a mass ratio of 1-1.4:0.8-1:0.5-0.7, wherein the main agent, curing agent and diluent are respectively It is prepared from the following components and weight ratio:

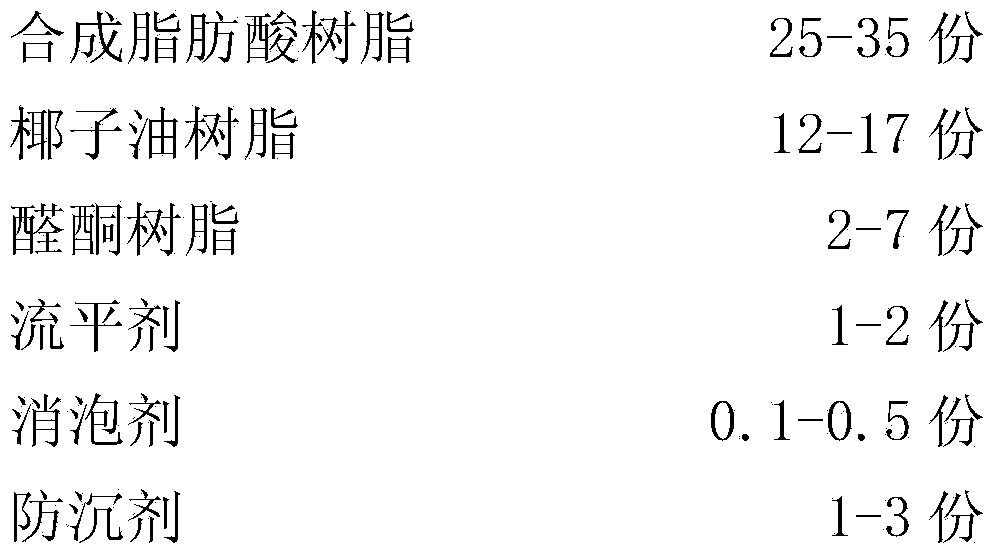

[0043] Wherein the composition and parts by weight ratio of main agent are as follows:

[0044]

[0045] The titanium white slurry is prepared according to the following components and weight ratios: 6-10 parts of butyl acetate, 25-35 parts of synthetic fatty acid, 1-3 parts of dispersant, 0.4-0.6 parts of fumed silica, titanium White powder 55-65 parts;

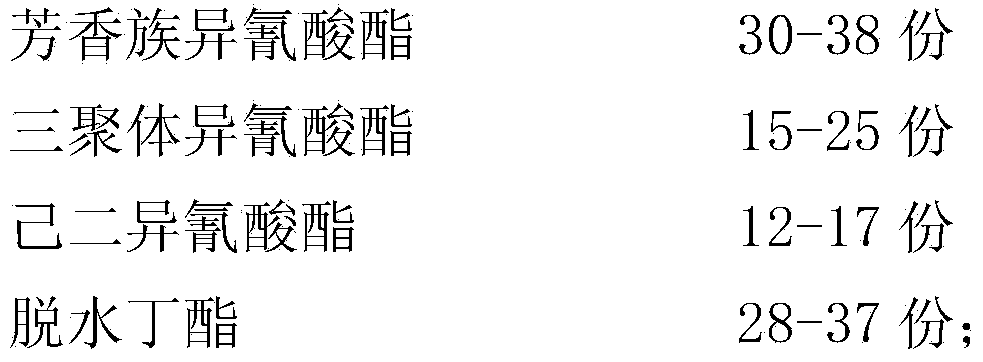

[0046] Wherein the component of curing agent and the ratio of parts by weight are as follows:

[0047]

[0048] Wherein the component of diluent and the ratio of parts by weight are as follows:

[0049] Xylene 25-35 parts

[0050] Butyl acetate 50-60 parts

[0051] 10-20 parts of propylene glycol methyl ether ...

Embodiment 1

[0062] Embodiment 1: a kind of polishable high hardness polyurethane bright white topcoat is formed by mixing the main agent, curing agent and thinner in a mass ratio of 1:0.8:0.5, wherein the main agent, curing agent and thinner are respectively composed of the following Components and parts by weight ratio are formulated:

[0063] Wherein the composition and parts by weight ratio of main agent are as follows:

[0064]

[0065] Wherein the component of curing agent and the ratio of parts by weight are as follows:

[0066]

[0067] Wherein the component of diluent and the ratio of parts by weight are as follows:

[0068] Xylene 25 parts

[0069] Butyl acetate 60 parts

[0070] 10 parts of propylene glycol methyl ether acetate.

[0071] The preparation method of the above-mentioned polishable high-hardness polyurethane bright white topcoat comprises the following steps:

[0072] Titanium white slurry is prepared according to the following preparation method: mix 25 p...

Embodiment 2

[0081] Embodiment 2: A kind of polishable high hardness polyurethane bright white topcoat is formed by mixing the main agent, curing agent and thinner in a mass ratio of 1.4:1:0.7, wherein the main agent, curing agent and thinner are respectively composed of the following Components and parts by weight ratio are formulated:

[0082] Wherein the composition and parts by weight ratio of main agent are as follows:

[0083]

[0084] Wherein the component of curing agent and the ratio of parts by weight are as follows:

[0085]

[0086] Wherein the component of diluent and the ratio of parts by weight are as follows:

[0087] Xylene 35 parts

[0088] Butyl acetate 50 parts

[0089] 20 parts of propylene glycol methyl ether acetate.

[0090] The preparation method of the above-mentioned polishable high-hardness polyurethane bright white topcoat comprises the following steps:

[0091] Titanium white slurry is prepared according to the following preparation method: mix 30 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com