TPV easy for ink dyeing and printing and preparation method thereof

A technology of ink and white oil, which is applied in the field of easy ink printing and dyeing TPV, can solve the problems of ink printing not firm, poor wear resistance, ink printing and dyeing difficulties, etc., and achieve the effect of improving elasticity, good printing effect and less volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

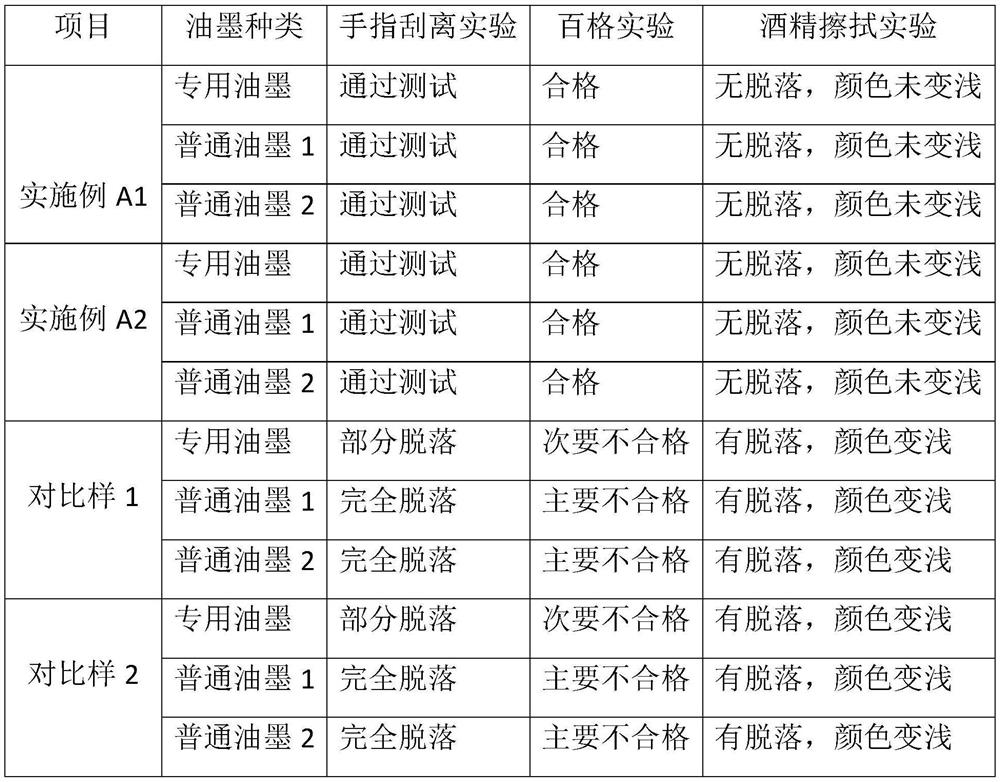

Embodiment 1

[0042] 50 parts of EPDM, 20 parts of white oil, 10 parts of PP, 6 parts of grafted PP, 10 parts of CaCO3, 10 parts of EVA, 0.5 parts of DCP, 1 part of TATC, 0.5 parts of antioxidant, 0.5 parts of light stabilizer, surface modification 2 doses.

[0043] 1. After weighing EPDM, PP, grafted PP, EVA, and CaCO3 on an electronic balance according to the above formula, put them into a low-speed stirring pot, add antioxidants, light stabilizers, and surface modifiers at the same time, and stir for 3 minutes.

[0044] 2. Put the mixture evenly stirred in 1 into a twin-screw extruder with an aspect ratio of 56, rotate at a speed of 300 rpm, and plasticize at a temperature of 180°C, and granulate to form a premix.

[0045] 3. The cross-linking agent DCP and auxiliary cross-linking agent TAIC weighed according to the above formula are added to a high-speed stirring pot at 500-600 rpm, and mixed for 3 minutes.

[0046] 4. Add the mixture obtained in 3 into a twin-screw extruder with an as...

Embodiment 2

[0048] 60 parts of EPDM, 25 parts of white oil, 15 parts of PE, 6 parts of grafted PE, 10 parts of EMA, 0.5 parts of BIBP, 1 part of TMPTA, 0.5 parts of antioxidant, 0.5 parts of light stabilizer, and 2 parts of surface modifier.

[0049] After weighing EPDM, PP, grafted PP, EVA, CaCO3, according to the above formula on an electronic balance, put them into a low-speed stirring pot, add antioxidants, light stabilizers, and surface modifiers at the same time, and stir for 3 minutes.

[0050] 2. Put the mixture evenly stirred in 1 into a twin-screw extruder with an aspect ratio of 56, rotate at a speed of 300 rpm, and plasticize at a temperature of 180°C, and granulate to form a premix.

[0051] 3. The cross-linking agent DCP and auxiliary cross-linking agent TAIC weighed according to the above formula are added to a high-speed stirring pot at 500-600 rpm, and mixed for 3 minutes.

[0052] 4. Add the mixture obtained in 3 into a twin-screw extruder with an aspect ratio of 52 for ...

Embodiment 3

[0054] 50 parts of EPDM, 20 parts of white oil, 10 parts of PP, 6 parts of grafted PP, 10 parts of CaCO3, 5 parts of EMA, 5 parts of EVA, 0.5 parts of DCP, 1 part of TATC, 0.5 parts of antioxidant, 0.5 parts of light stabilizer , 2 parts of surface modifier.

[0055] 1. After weighing EPDM, PP, grafted PP, EMA, and CaCO3 on an electronic balance according to the above formula, put them into a low-speed stirring pot, add antioxidants, light stabilizers, and surface modifiers at the same time, and stir for 3 minutes.

[0056] 2. Put the mixture evenly stirred in 1 into a twin-screw extruder with an aspect ratio of 56, rotate at a speed of 300 rpm, and plasticize at a temperature of 180°C, and granulate to form a premix.

[0057] 3. The cross-linking agent DCP and auxiliary cross-linking agent TAIC weighed according to the above formula are added to a high-speed stirring pot at 500-600 rpm, and mixed for 3 minutes.

[0058] 4. Add the mixture obtained in 3 into a twin-screw extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com