Printing and dyeing equipment for textile dyeing

A technology for printing and dyeing equipment and fabric dyeing, which is used in equipment configuration of textile materials, processing of textile materials, textiles and papermaking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

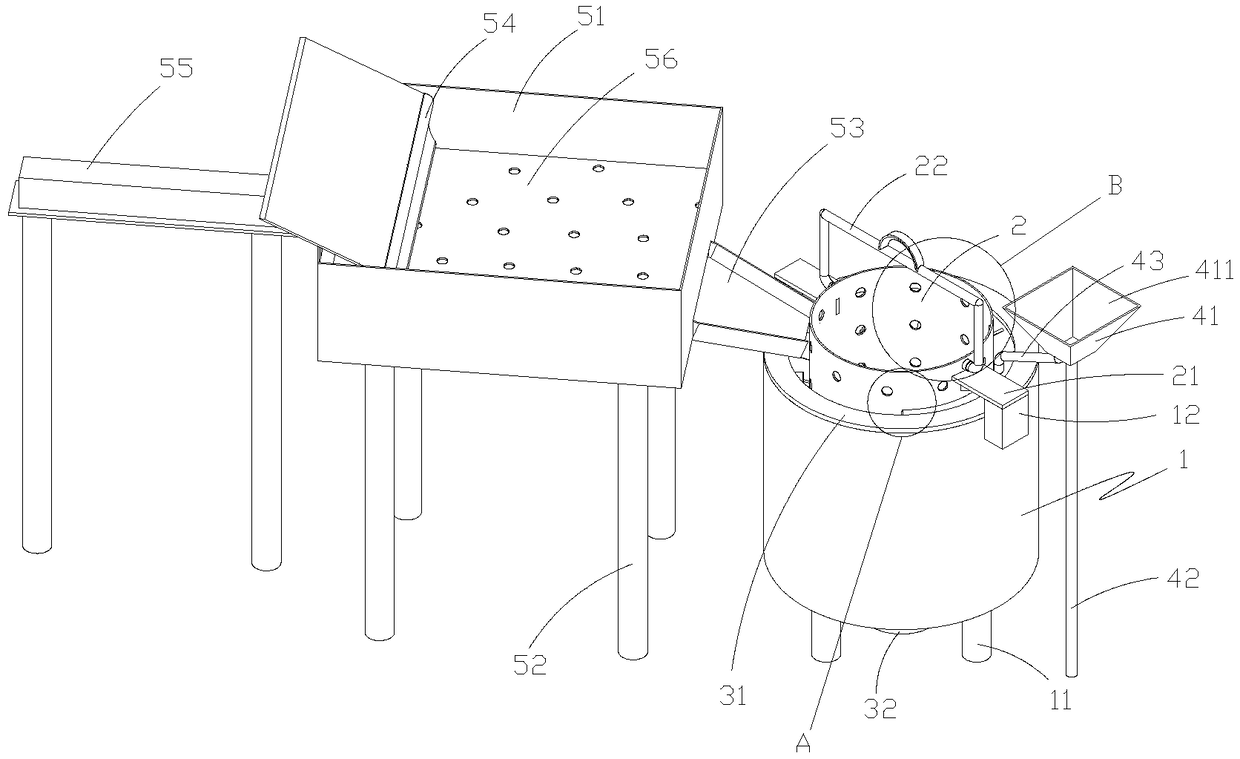

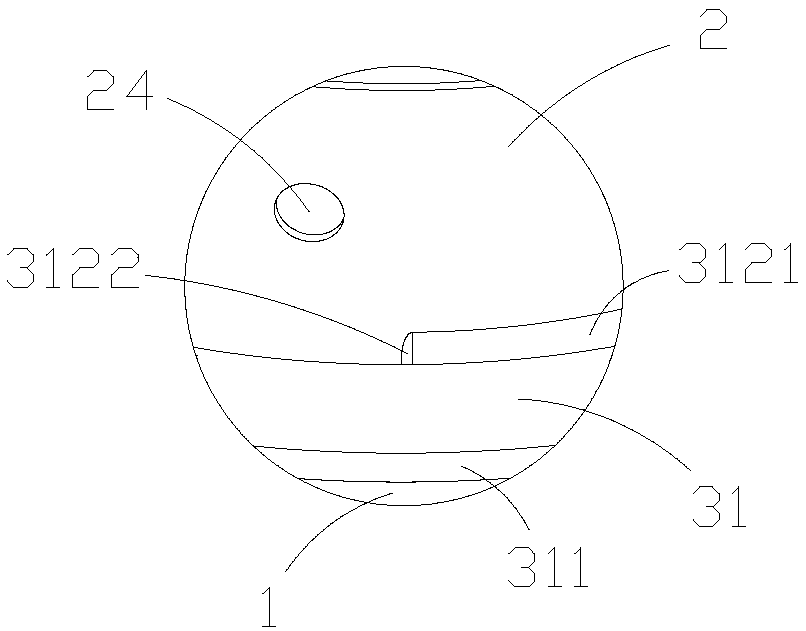

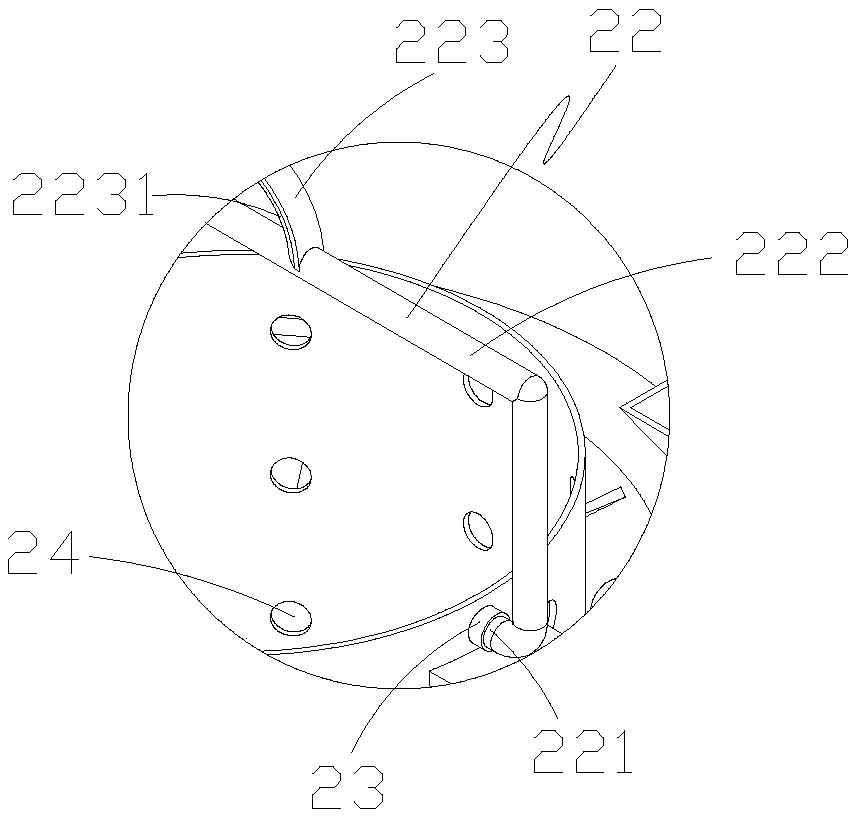

[0025] like Figure 1-11 As shown, a printing and dyeing equipment for fabric dyeing, including a base 1, a dyeing bucket 2, a stirring device, a recovery device and a feeding device; the bottom of the base is bolted to four columns 11 for supporting and fixing the base Specifically, the stirring device includes a dye bath barrel 31, a driving part 32 and a paddle structure; the dye bath barrel is installed in the base and can rotate relative to the base, and a bath barrel convex is installed on the upper surface of the dye bath barrel. part 311, the convex part of the bath barrel is evenly installed along the upper surface of the dye bath barrel, so that the dye bath barrel can be supported by the base; in order to realize the rotation fit between the base and the dye bath barrel, the A rotating structure is installed between the bathtubs, and the rotating structure includes a first chute 13, a second chute 14, a first ball 15 and a second ball 16; the first chute and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com