Patents

Literature

47results about How to "Dyeing fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for tinting, dyeing or doping of moulded components made of transparent (co)polyamides in aqueous dye bath

InactiveUS20060230553A1Quality improvementStrong adhesionOrganic dyesPolymer scienceMagnifying glass

The present invention relates to a novel composition of dye baths or processing baths and a process for tinting, dyeing or doping of moulded components with functional additives in these aqueous dipping baths or processing baths. The moulded components contain transparent or translucent (co)polyamides. If the moulded components should be tinted or dyed according to an embodiment of the invention, the dyeing can be performed as homogeneous dyeing or as gradient dyeing. The process according to the present invention is particularly suitable for producing high-value objects like ophthalmic lenses, sun lenses for eyeglasses, magnifying glasses, all kinds of inspection glasses, polarization films and display films, particularly if changing depths of color (gradients) are desired. This generating of a dyeing gradient requires dyeing in a dipping process, whereby the desired depth of color is achieved by multiple times of dipping the surface areas of the moulded article in the dye bath.

Owner:EMS CHEM AG

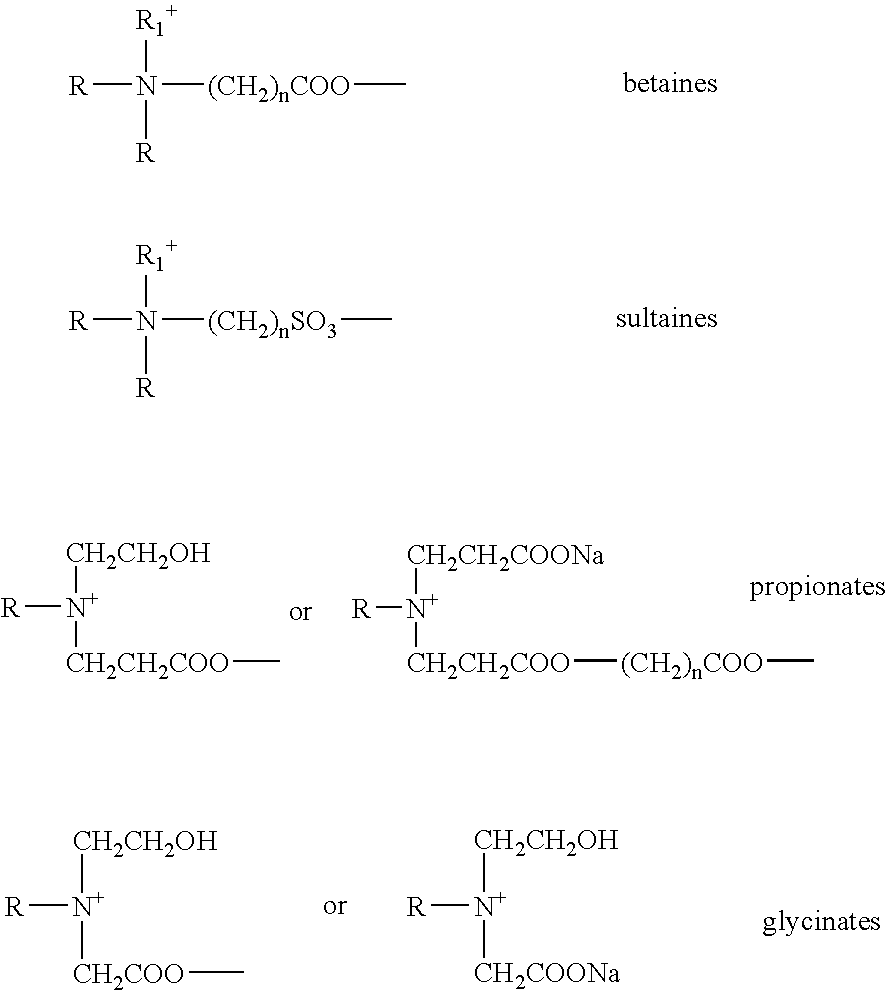

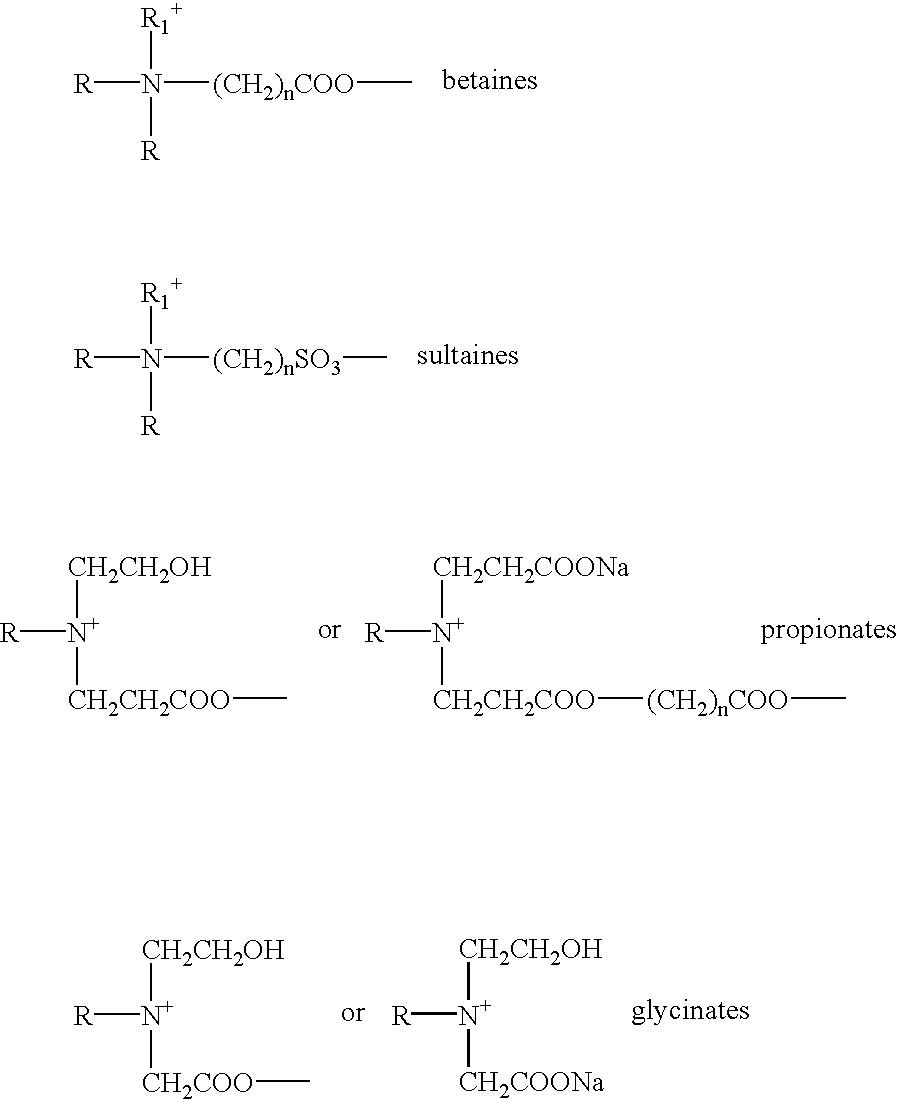

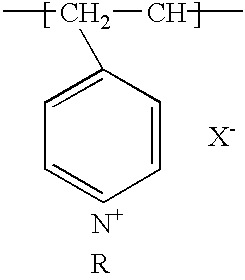

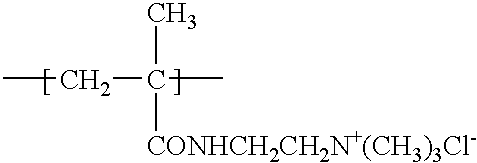

Two-part aqueous composition for oxidative coloration of hair

InactiveUS6764523B2Decrease in levelComposition is stableCosmetic preparationsHair cosmeticsActive agentSurface-active agents

Owner:CLAIROL +1

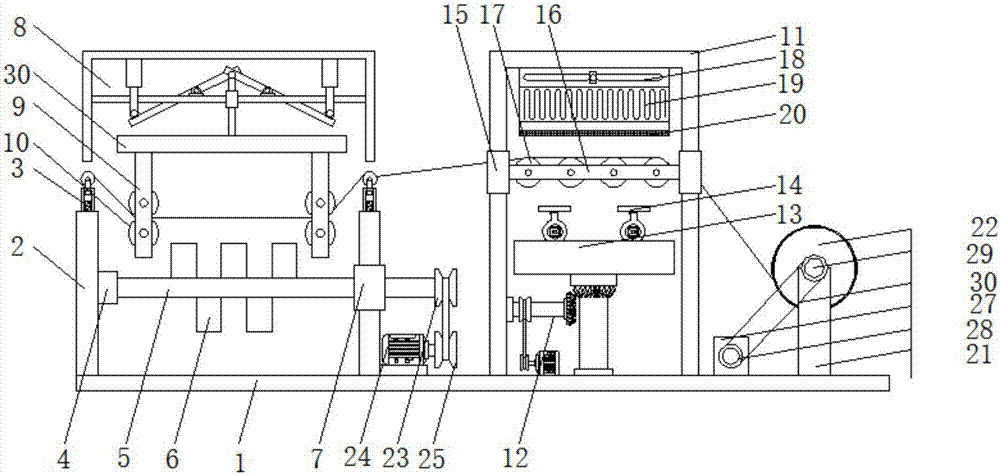

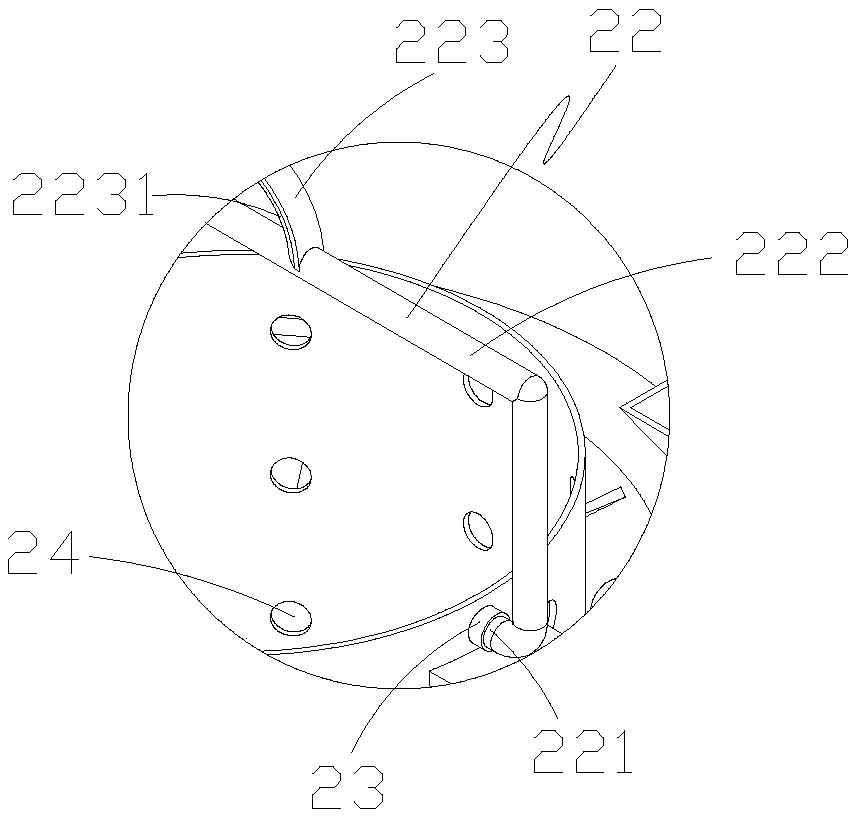

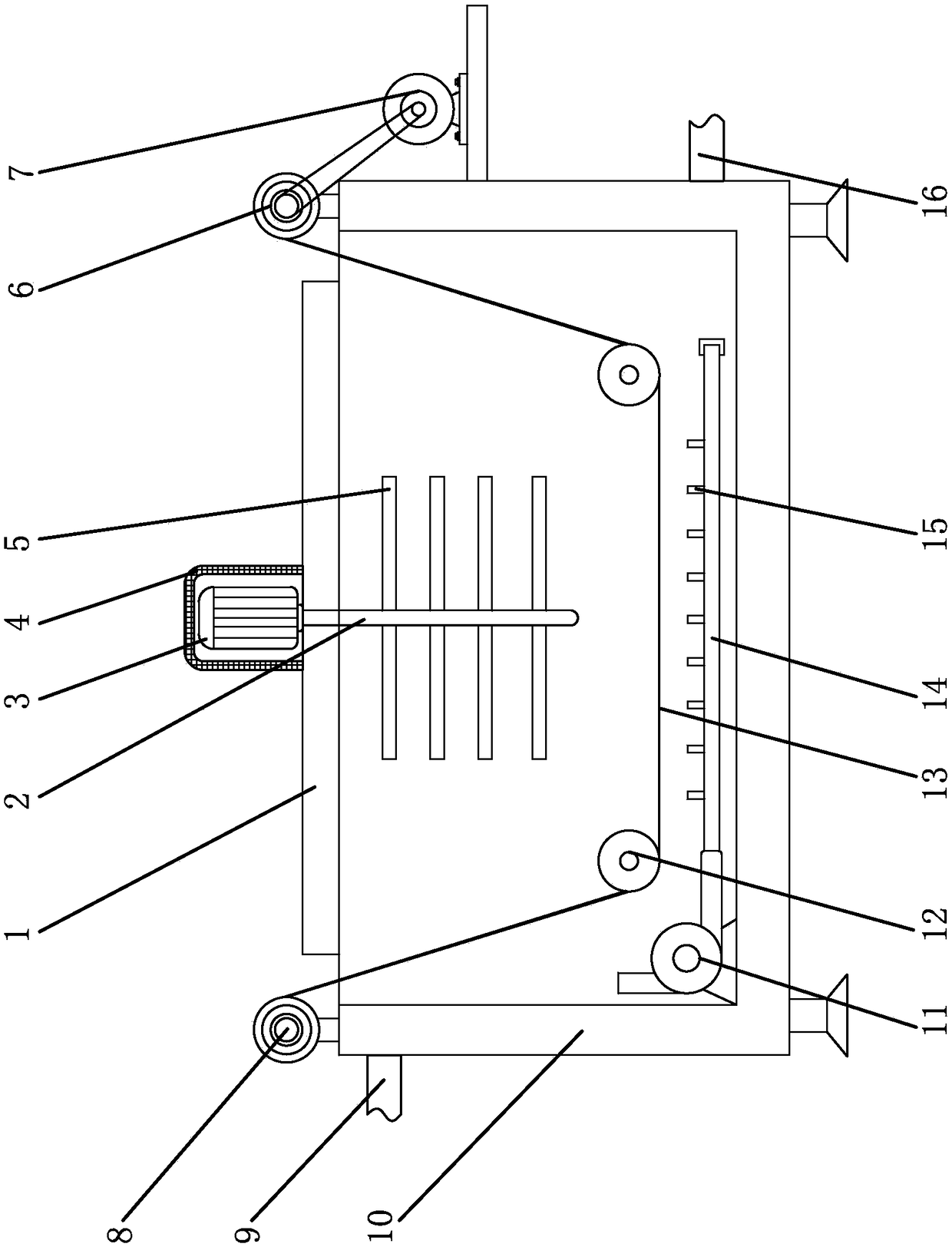

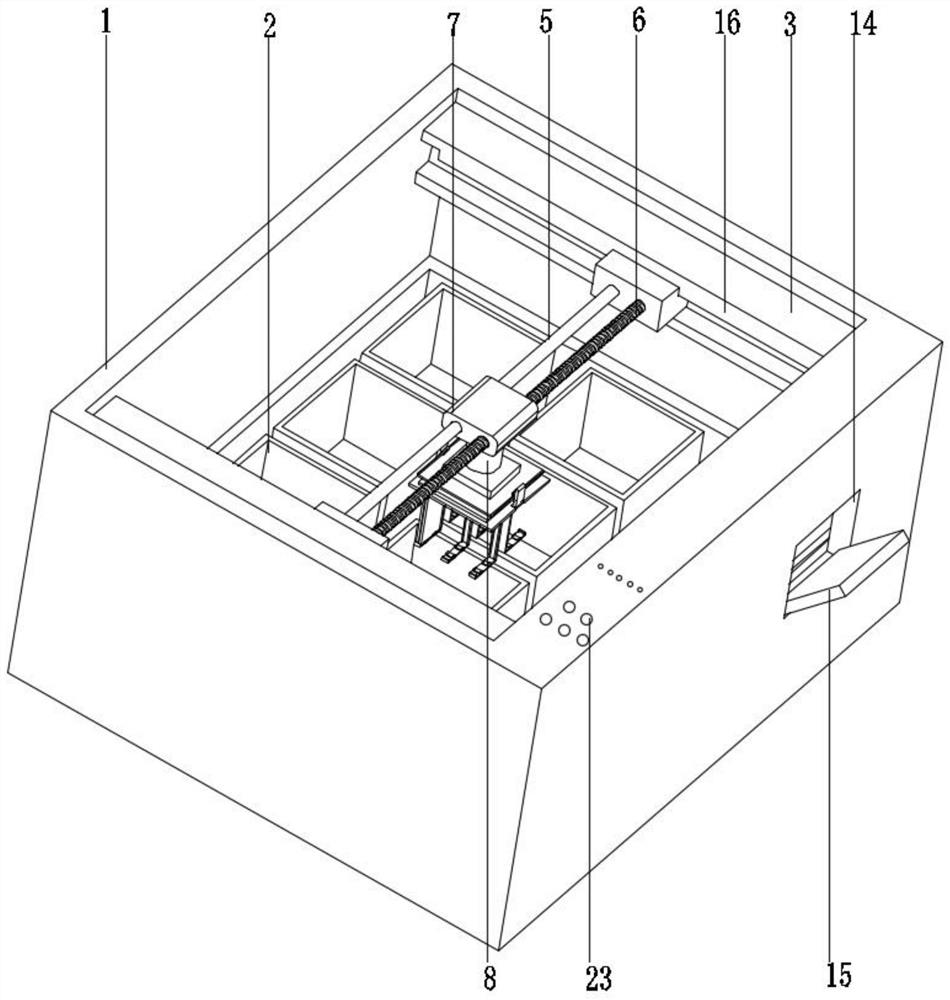

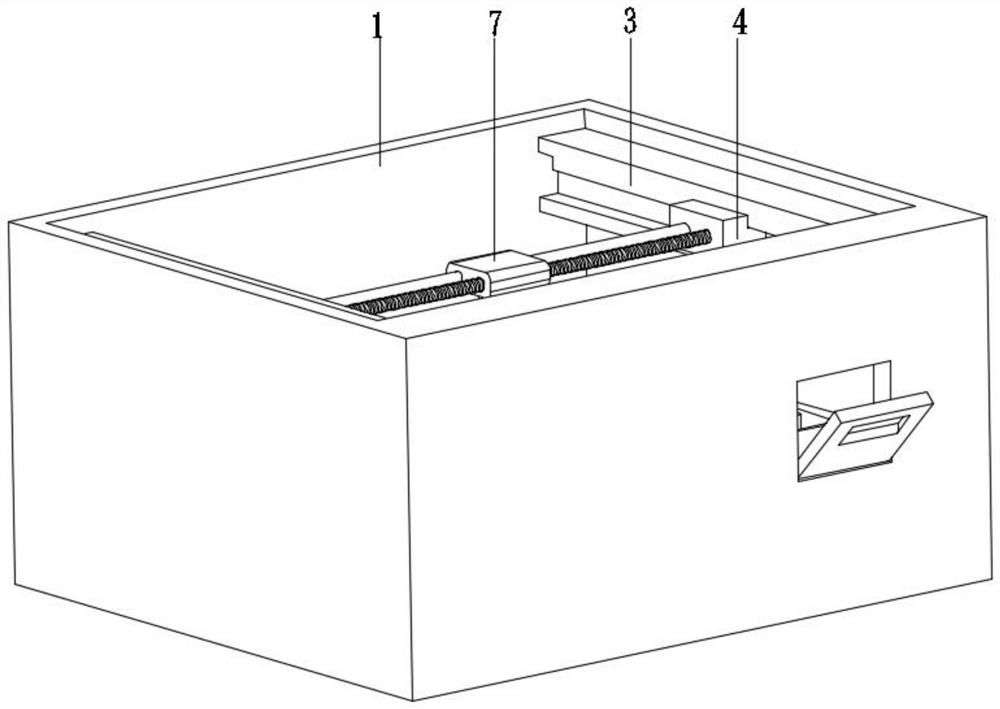

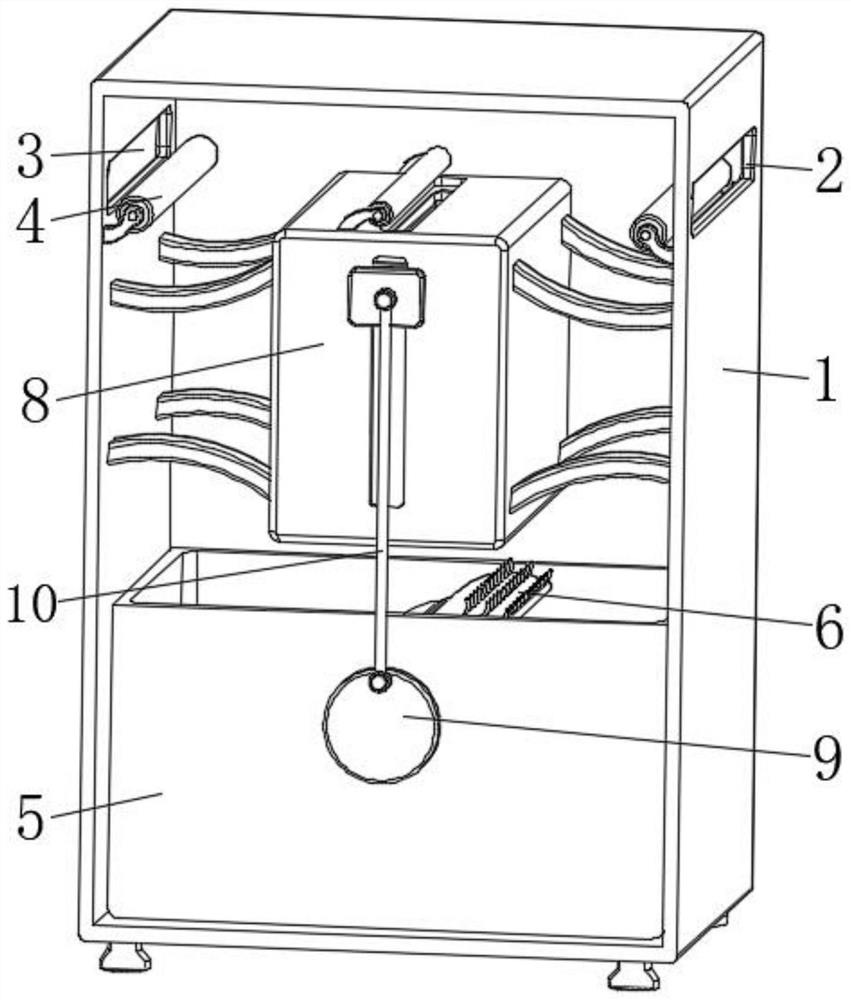

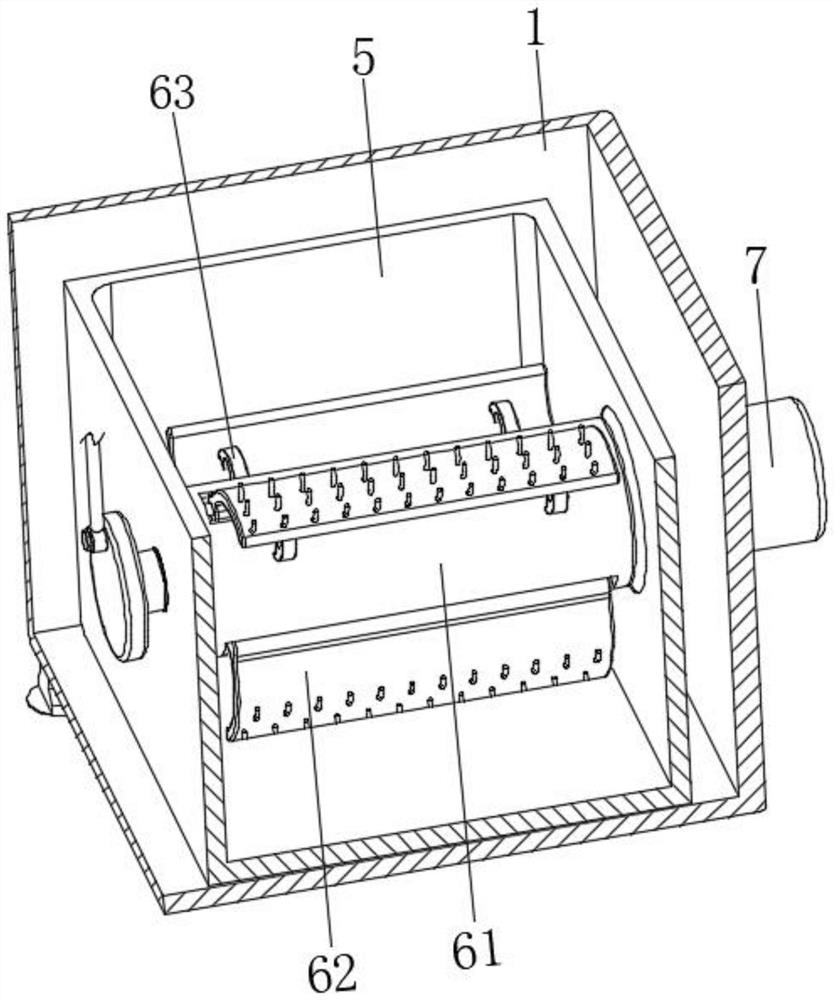

Textile fabric uniform dyeing and drying integrated device

InactiveCN107419457AReach without being damagedTo achieve the purpose of drying textile cloth in all directionsLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalRotary stageEngineering

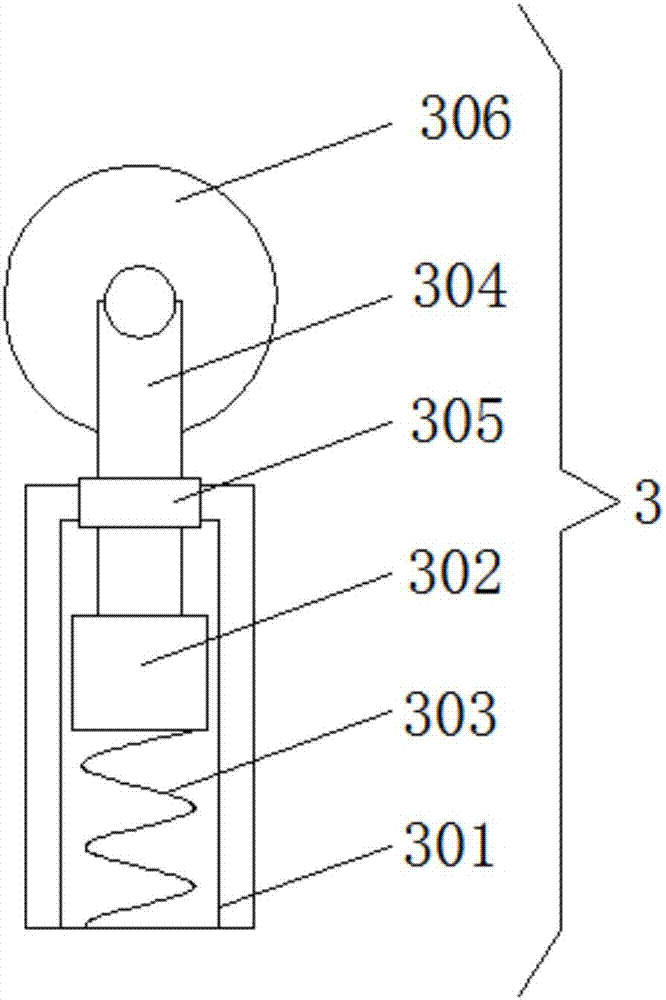

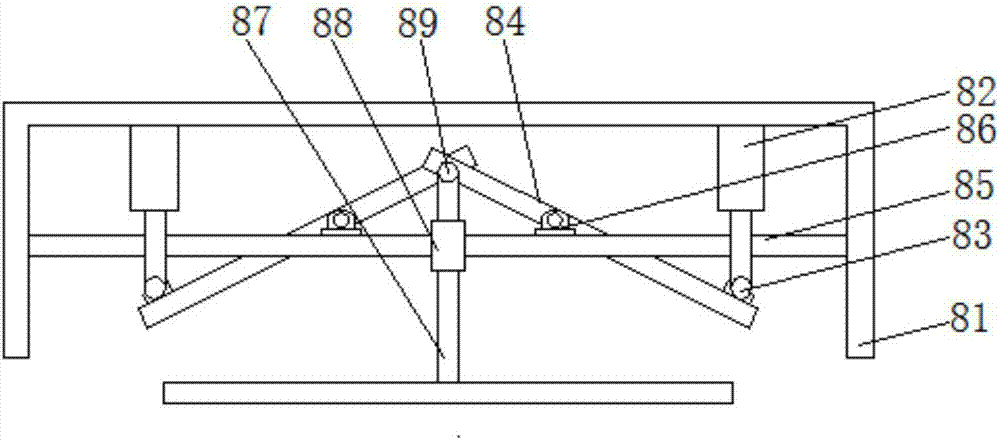

The invention discloses a textile fabric uniform dying and drying integrated device. The textile fabric uniform dying and drying integrated device comprises a base plate, a dyeing tank is fixedly connected to the top of the base plate, constant tension devices are fixedly connected to both top ends of the two walls of the dyeing tank, a rotary shaft is rotatably connected to a rotary shaft fixing block, stirring blades are fixedly connected to the rotary shaft, a shaft rotary tank is arranged at the end, away from the rotary shaft fixing block, of the inner wall of the dyeing tank, one end of the rotary shaft penetrates through and is rotatably connected to the shaft rotary tank, a movable device is arranged over the dyeing tank, a rotary device is fixedly connected to the top of the inside of a drying chamber, and two air blowers are fixedly connected to the bottom of a rotary table. The invention relates to the technical field of textile equipment machinery. The textile fabric uniform dying and drying integrated device solves the problems that a textile fabric dyeing device does not have the drying capability and is low in dyeing efficiency and long in consumed time, the textile fabric dyeing and production efficiency is improved, and the worker labor is lowered.

Owner:HUZHOU BOREN TEXTILES

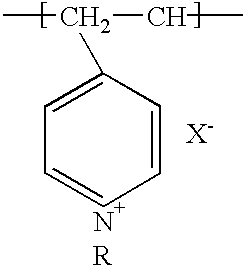

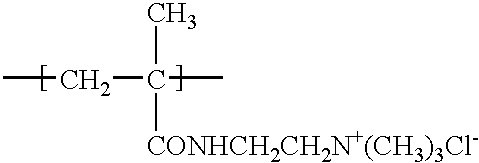

Two-part aqueous composition for oxidative coloration of hair

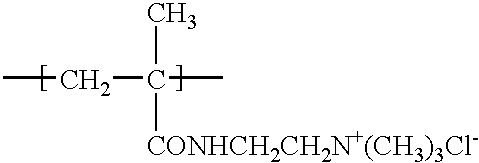

InactiveUS20020194683A1Decrease in levelComposition is stableCosmetic preparationsHair cosmeticsLotionDimethylammonium chloride

Owner:CLAIROL +1

Preparation method of nylon 6 having high hygroscopicity, high dyeing property and high elasticity

InactiveCN102911366AIncrease elasticityIncrease the content of terminal amino groupsFiberPolymer science

The invention provides a preparation method of nylon 6 having high hygroscopicity, high dyeing property and high elasticity, The method is characterized by adding 50-85 parts of caprolactam, 5-8.5 parts of ring-opening agent, 0.3-6 parts of dicarboxylic acid blocking agent and 0.3-6 parts of composite amine modifier into to a reaction vessel; under the protection of nitrogen, preparing composite amine / polyamide performed polymer through ring opening, normal-pressure polymerization and reduced-pressure polymerization; adding polyether with same number of moles as the dicarboxylic acid blocking agent, preparing composite amine / polyether / polycaprolactam copolymer in the presence of a catalyst through normal-pressure polymerization and reduced-pressure polymerization; and extracting and drying to obtain the final product of nylon 6 with high hygroscopicity, high dyeing property and high elasticity. According to the invention, the method has simple process, production can be performed by using existing equipment, and nylon 6 not only has excellent physical and mechanical properties, but also has good spinnability, optical / thermal stability, elasticity, hygroscopicity and dyeing property, thus not only having enhanced dying depth and dying uniformity, but also being capable of being applied to chemical fiber, engineering plastics, membrane materials and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Wool and cashmere printing and dyeing auxiliary

The invention relates to the field of production auxiliaries of wool products, in particular to a wool and cashmere printing and dyeing auxiliary. The wool and cashmere printing and dyeing auxiliary comprises sodium carboxy methyl cellulose, sodium diethylhexyl sulfosuccinate, citric acid, ethylene oxide, amino silicon oil, di-rhamnolipid, peroxidase and deionized water. The wool and cashmere printing and dyeing auxiliary comprises, by mass, 10-15 parts of sodium carboxy methyl cellulose, 3-8 parts of sodium diethylhexyl sulfosuccinate, 12-16 parts of citric acid, 8-14 parts of ethylene oxide, 5-10 parts of amino silicon oil, 3-6 pars of di-rhamnolipid, 1-3 parts of peroxidase and 40-60 parts of deionized water. According to the wool and cashmere printing and dyeing auxiliary, due to the combination ratio of the carboxy methyl cellulose, the citric acid and the amino silicon oil, dyeing and fixation of the dye on a wool and cashmere product are effectively improved, color fastness is improved, the color increasing and protecting performance can be improved, and the dyeing effect is ensured.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

Process for Tinting, Dyeing or doping or moulded Components Made of Transparent (Co)Polyamides in Aqueous Dye Bath

InactiveUS20070294841A1Quality improvementStrong adhesionOrganic dyesDyeing processPolymer scienceMagnifying glass

The present invention relates to a novel composition of dye baths or processing baths and a process for tinting, dyeing or doping of moulded components with functional additives in these aqueous dipping baths or processing baths. The moulded components contain transparent or translucent (co)polyamides. If the moulded components should be tinted or dyed according to an embodiment of the invention, the dyeing can be performed as homogeneous dyeing or as gradient dyeing. The process according to the present invention is particularly suitable for producing high-value objects like ophthalmic lenses, sun lenses for eyeglasses, magnifying glasses, all kinds of inspection glasses, polarization films and display films, particularly if changing depths of color (gradients) are desired. This generating of a dyeing gradient requires dyeing in a dipping process, whereby the desired depth of color is achieved by multiple times of dipping the surface areas of the moulded article in the dye bath.

Owner:EMS CHEM AG

PBT (polybutylece terephthalate) fiber manufacturing process

InactiveCN107313128AImprove hydrophilicityImprove breathabilityElectroconductive/antistatic filament manufactureFilament/thread formingSulfonatePolyester

The invention discloses a PBT (polybutylece terephthalate) fiber manufacturing process. The manufacturing process comprising the following steps: copolymerizing ethylene glycol terephthalate, butanediol, sulfonate and a hydrophilic group to obtain modified PBT polyester, preparing the modified PBT polyester into modified PBT polyester chips; drying the modified PBT polyester chips, and placing the dried modified PBT polyester chips and dried metal oxide, PET, PTT into a screw extruder to be heated and blended to obtain blended modified PBT spinning melt; preparing the blended modified PBT spinning melt and spinning solution prepared from an aramid polymer into a core-sheath compound fiber through two-component compound spinning. The PBT fiber prepared by the invention has good air permeability and dyefastness, high elasticity, antibacterial property and excellent chemical and mechanical performance, and has antistatic performance of PTT and relatively good heat resistance.

Owner:TAICANG RONGWEN SYNTHETIC FIBER

Purely natural plant hair dye and preparation method thereof

InactiveCN105476925AGood dyeing effectPromote blood circulationCosmetic preparationsHair cosmeticsEvaporationChemical products

The invention relates to a purely natural plant hair dye and a preparation method thereof, and belongs to the technical field of daily chemical products. The method comprises the following steps: grinding walnut green seedcases, and extracting for 2-4 times with an ethanol aqueous solution having a volume percentage of 50-80 percent; concentrating an extracting solution by rotary evaporation, and reclaiming solvent to obtain extract; adding virgin tea oil which is 9.9-10.1 percent of the mass of the extract into the extract, and adding vitamin B5 which is 1.9-2.1 percent of the mass of the extract; and homogenizing by adopting a high-pressure homogenizer, and sterilizing to obtain the purely natural plant hair dye. The hair dye does not contain chemical preparation, has an excellent hair dyeing effect, can be used for maintaining glossy hair for a long time, promoting scalp blood circulation and metabolism, preventing hair breakage and hair loss and effectively protecting hair, and is easy to popularize and apply.

Owner:YUNNAN ACAD OF FORESTRY

Printing and dyeing auxiliaries for wool and cashmere

The invention provides printing and dyeing auxiliaries for wool and cashmere. The printing and dyeing auxiliaries comprise, by weight, 2-4 part of ethylene glycol, 3-4 parts of amino-silicone oil, 40-52 parts of deionized water, 10-12 parts of benzyl sodium naphthalene sulfonate, 6-7 parts of high-permeability agent OP-6, 10-11 parts of citric acid, 3-5 parts of methyl siloxane, 6-7 parts of sodium diethylhexyl sulfosuccinate and 8-10 parts of ethylene oxide. Compared with the prior art, the printing and dyeing auxiliaries have the advantages that the citric acid and the amino-silicone oil are combined, the dyeing effect and fixation effect of dye on wool and cashmere products can be increased, color fastness is increased, color improving and protection performance can be increased, the dyeing effect can be guaranteed, dust and impurities on the surface of wool can be removed favorably, and wool yarn spun by the processed wool is good in softness, excellent in anti-pilling performance and the like.

Owner:ZHONGSHAN LVLANG ADDITIVES CO LTD

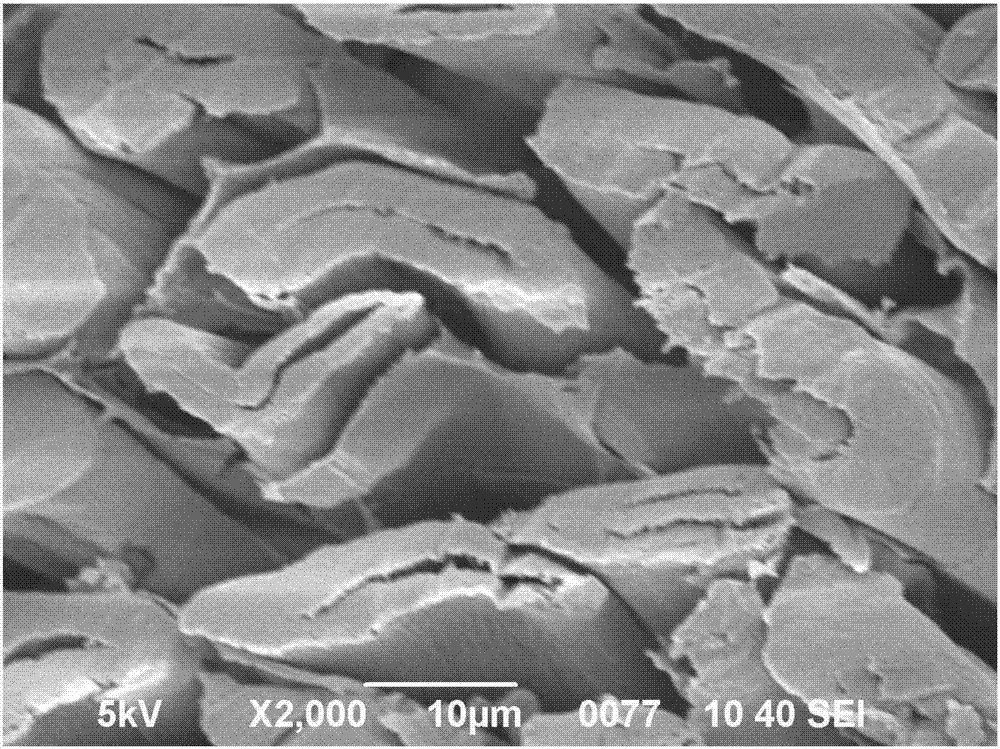

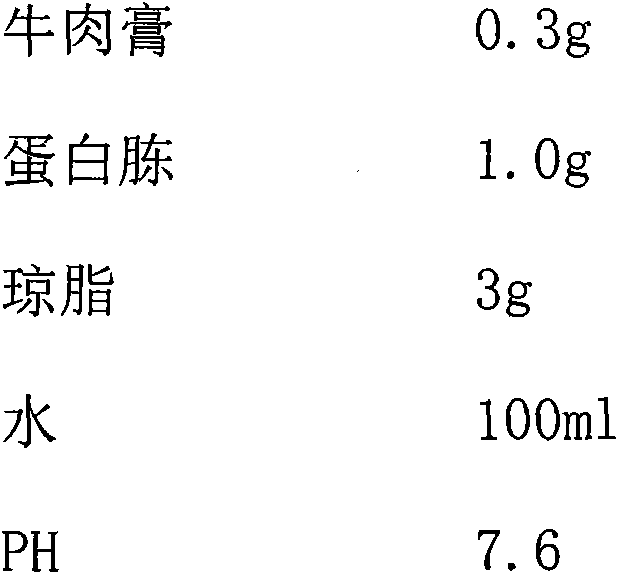

Plant tissue integral staining method for ultrathin slice

ActiveCN110455595ADyeing fastEnhanced Electronic ContrastPreparing sample for investigationOsmic AcidPollen

The invention discloses a plant tissue integral staining method for ultrathin slice. The method comprises the following experiment steps of (1) fixing, in which matured picea wilsonii pollen is collected, is pre-fixed by glutaraldehyde and paraformaldehyde and is post-fixed by 1% osmic acid, the matured picea wilsonii pollen is processed by TCH, and osmium is further deposited by 1% osmic acid; (2) block staining, in which block staining is performed with 2.5% gadolinium acetate, 2.5% samarium acetate and 2% uranyl acetate; (3) gradient dehydration with ethyl alcohol, in which dehydration is performed with 30% ethyl alcohol, 50% ethyl alcohol, 60% ethyl alcohol, 70% ethyl alcohol, 80% ethyl alcohol, 90% ethyl alcohol, 95% ethyl alcohol and 100% ethyl alcohol; (4) permeation, in which permeation is performed with an ethyl alcohol and acetone mixed solution, 100% acetone, an acetone and spurr resin mixed solution and 100% spurr resin; and (5) embedding and polymerization, in which 100% spur resin is added into an embedment plate, and a sample is placed and then placed in an oven for polymerization. The method is simple to operate, is relatively good in staining effect and obvious inimage contrast, ultrathin and continuous slicing is also facilitated, and a technical foundation is laid for achieving of plant tissue three-dimensional reconstruction.

Owner:BEIJING FORESTRY UNIVERSITY

Two-part aqueous composition for oxidative coloration of hair

InactiveUS20030005526A1Decrease in levelComposition is stableCosmetic preparationsHair cosmeticsActive agentSurface-active agents

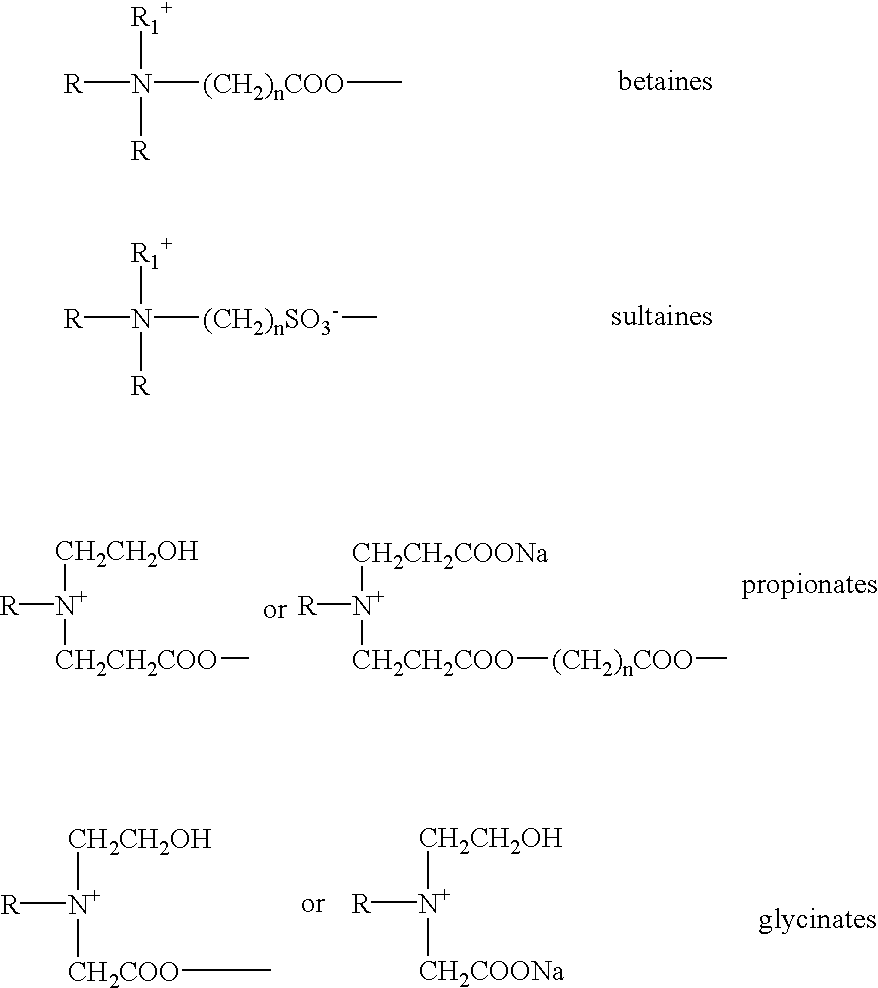

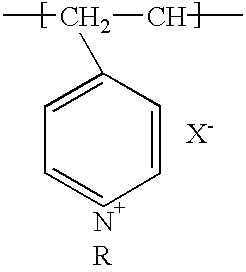

A two-part high aqueous-content system for oxidative coloration of hair utilizing an aqueous dye lotion formulation containing hydroxypropyl bisisosteramidopropyidimonium chloride conditioner, optionally with one or more surfactants, preferably a monomeric quaternary surfactant.

Owner:CLAIROL

Method of improving luster and anti-wrinkle property of cotton fabric by steaming dyeing method

InactiveCN107574683AEmission reductionImprove qualitySucessive textile treatmentsLiquid/gas/vapor removalCompound aHigh energy

The invention discloses a method for luster and anti-wrinkle property of cotton fabric by a steaming dyeing method, and specifically discloses a method for improving the luster and anti-wrinkle property of the cotton fabric through compounding a bifunctional reactive dye, a color fixing alkali agent, a surfactant and a crosslinking agent as a dyeing finishing agent, which is used for dyeing, luster and anti-wrinkle finishing of the cotton fabrics in one-step process. The method provided by the invention solves the problems of long production process flow, high energy consumption and formaldehyde releasing in the prior art caused by separately dyeing, anti-wrinkle finishing and luster processing. The product produced by using the method provided by the invention has the advantages of high color fastness, small power loss, good anti-wrinkle property and high lustrousness and the like.

Owner:QINGDAO UNIV

Antibacterial health-care fabric

InactiveCN104060369AAntibacterialGood moisture absorption and air permeabilityCarbon fibresWoven fabricsFiberMilk protein

The invention discloses an antibacterial health-care fabric. The antibacterial health-care fabric is formed by interweaving warps and wefts, and is characterized in that the warps are jade fiber and chitin fiber blended yarns, the wefts are milk protein fiber and coconut carbon fiber blended yarns, the warps and the wefts are spun, woven and finished, and a natural antibacterial finishing agent is added to the finishing process. The antibacterial health-care fabric has not only the antibacterial, anti-inflammation, deodorant and ventilated effects but also the ultraviolet-proof and antistatic functions, is comfortable, soft and smooth in hand feeling, has the moisture absorbing and holding functions, panders to the environment-friendly, healthy and fashionable consumption concepts of people and is convenient to process.

Owner:NANTONG FANGKE TEXTILE TECH

Handcrafted figured cloth dyeing method with deep-light effect

InactiveCN103835149ATexture tightness is obviousHigh coloring rateSucessive textile treatmentsDyeing processFiberEngineering

The invention discloses a handcrafted figured cloth dyeing method with a deep-light effect. The handcrafted figured cloth dyeing method comprises the following steps in sequence: pre-treating, alkali-concentrating, preparing dyeing liquid, dip-dyeing, washing and oxidizing, scotching, soaping, tendering, calendering and baking, wherein concentrated alkali is applied to carry out alkali-concentrating before dyeing gray fabric to enable figured cloth line tightness to be more obvious, so that dyeing is promoted to achieve action of an dyeing accelerant, and therefore, degree of dyeing of the figured cloth is improved; the concentrated alkali and sodium hydrosulfite are applied to carry out pre-reduction on the reducing dye, so that the reducing dye which is insoluble in water can be dissolved in leuco body of the water, and therefore, appetency of the cotton fibers in the figured cloth is improved. According to the invention, a technical problem about how to enable the figured lines on the cloth to be inconsistent in depth can be solved.

Owner:XIN TIANLONG GROUP

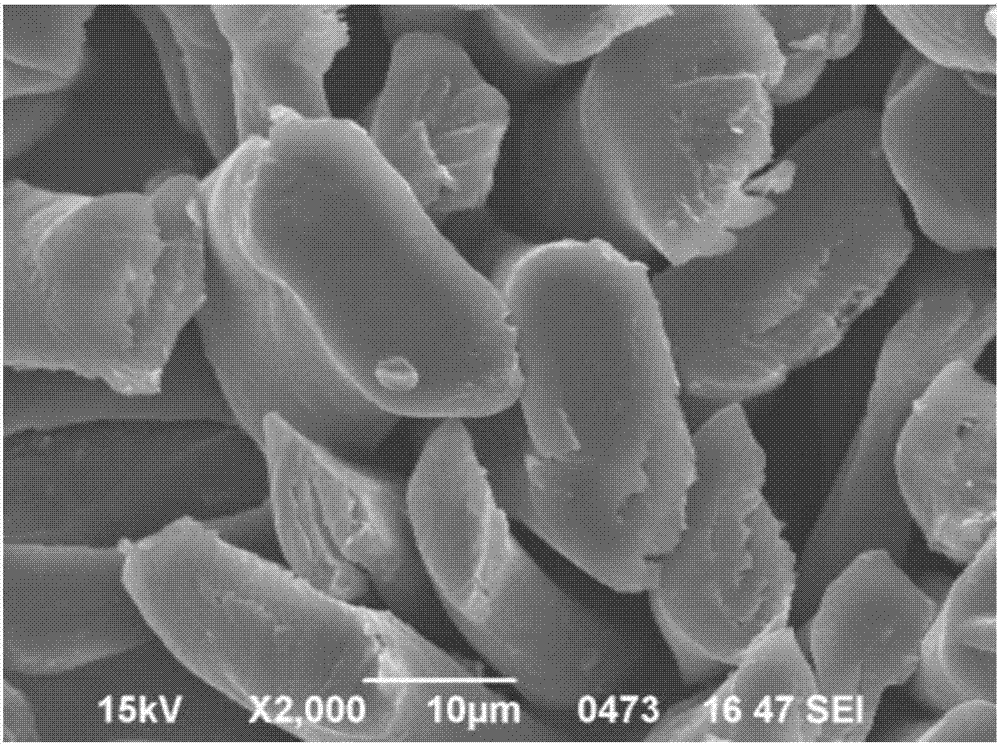

One-bath and one-step gelation crystallization dyeing method for ultrahigh strength and high-modulus polyethylene fibers

The invention discloses one-bath and one-step gelation crystallization dyeing method for ultrahigh strength and high-modulus polyethylene fibers. The method directly selects and introduces a planar molecular structure dye with specific size into a gel original liquid. By adding a certain phase inversion agent and at the same time, applying a programmed temperature phase inversion, preparation of the original liquid is realized by combining and cooperating the dye and gelation in the one bath and one step, thereby reducing adverse influences brought by a lot of tedious processes and a lot of auxiliary agents in a conventional method. With the dyeing method provided by the invention, the utilization rate of the dye can be increased greatly. The mesomorphic dye planar molecular effects can promote formation and orientation stability of a PE chain condensed submicroscopic nano-micron fiber scale lamellar crystal phase, and can improve and increase gelation spinning performance of colored ultrahigh strength and high-modulus UHMWPE. The method is environment-friendly and can save energy.

Owner:JIANGSU JONNYMA NEW MATERIALS CO TLD

Compound printing gum

InactiveCN107974848AGood water solubilityImprove liquidityDyeing processCarboxymethyl starchViscosity

The invention relates to compound printing gum. The compound printing gum is prepared from the following components in parts by mass: 2 to 5 parts of sodium carboxymethyl starch, 30 to 50 parts of hydroxyethyl modified tamarind gum, 1 to 5 parts of anhydrous sodium sulfate and 5 to 10 parts of sodium alginate. The printing gum provided by the invention has proper viscosity, a clear printing outline and a good levelling property; the compound printing gum has relatively good paste removing performance and net passing performance, can be directly dissolved with cold water and is convenient to use; the paste has good stability and is convenient to store for a long time.

Owner:SUZHOU RUNHONG TRADING

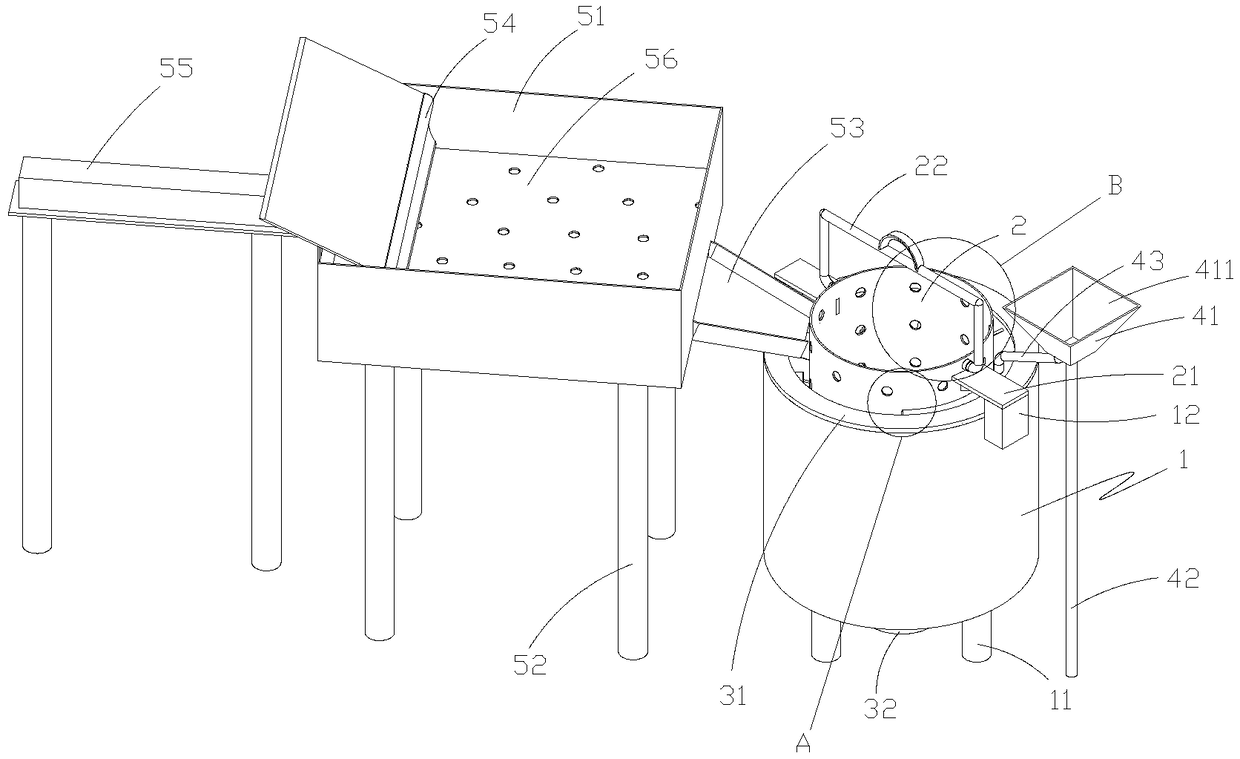

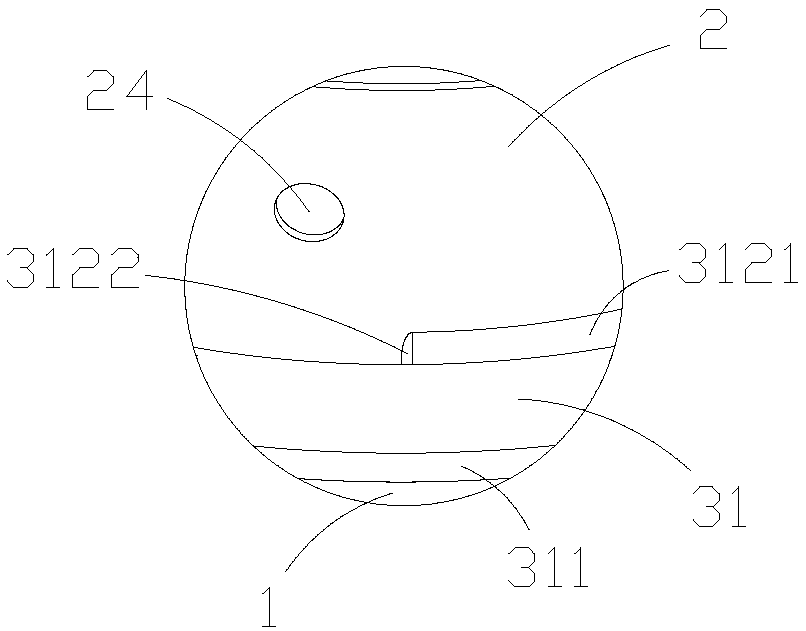

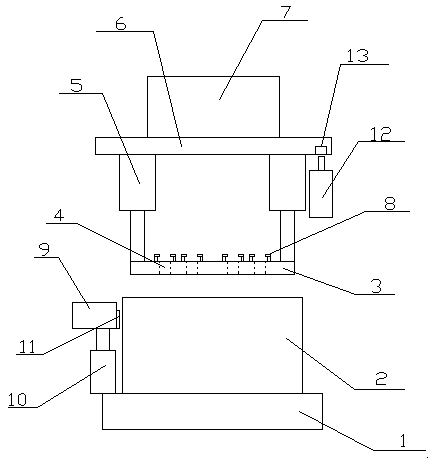

Printing and dyeing equipment for textile dyeing

ActiveCN109234948AEasy to take outGuaranteed dyeing effectTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringTextile dyeing

The invention discloses printing and dyeing equipment for textile dyeing. The equipment comprises a base, a dip dyeing bucket arranged on the base and a stirring device cooperating with the base, andthe stirring device comprises a dye bath bucket rotationally cooperating with the base; and the base is provided with a rotating structure used for achieving the rotating cooperation between the dye bath bucket and the base. The printing and dyeing equipment for textile dyeing has the advantages that through the cooperative arrangement of the dye bath bucket, the dip dyeing bucket and the base, dyeing of textile can be completed by soaking the textile in a dye liquor, and the textile cannot be pulled by external force, thereby avoiding the problem that the textile is damaged; the dye bath bucket can rotate relative to the base, so that the dye liquor in the dye bath bucket flows, not only can dyestuff deposition be avoided, but also textile dyeing can be accelerated, thereby greatly improving the printing and dyeing effect and efficiency.

Owner:SHAOXING UNIVERSITY

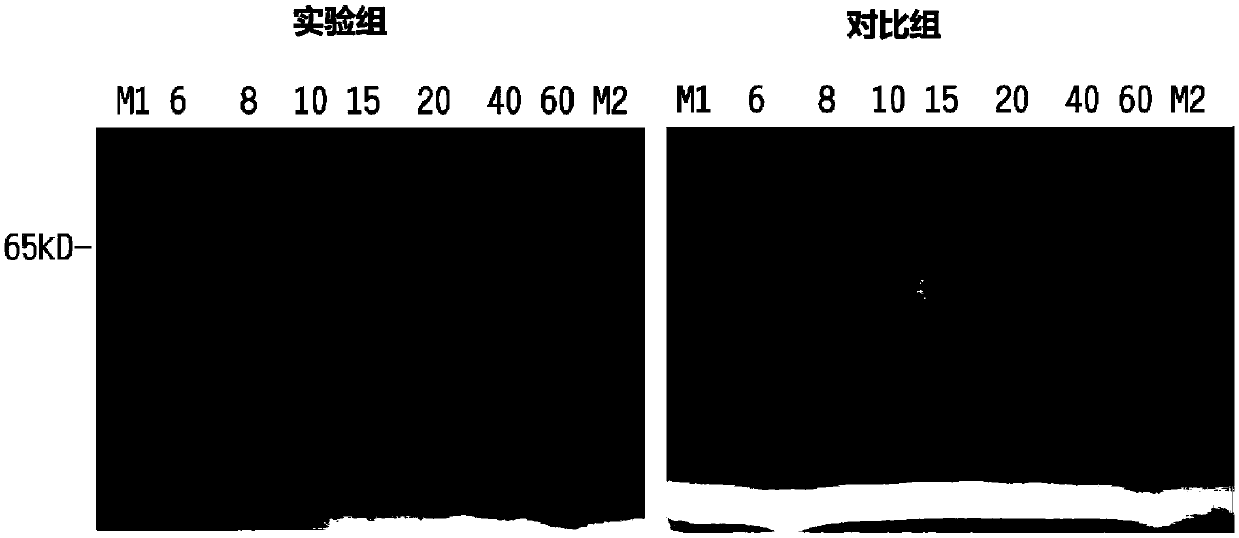

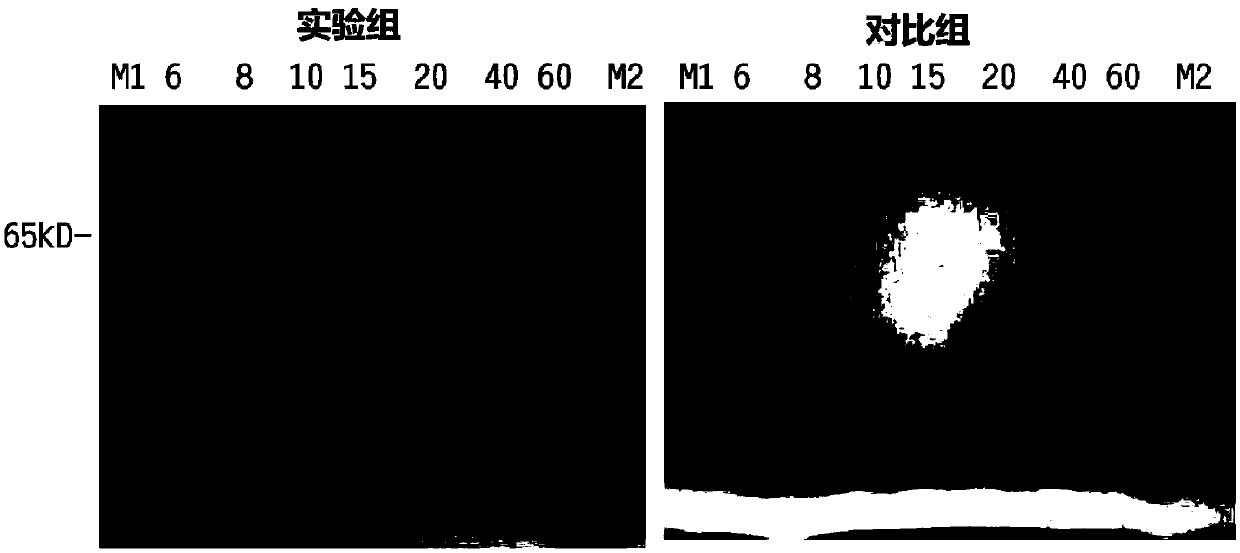

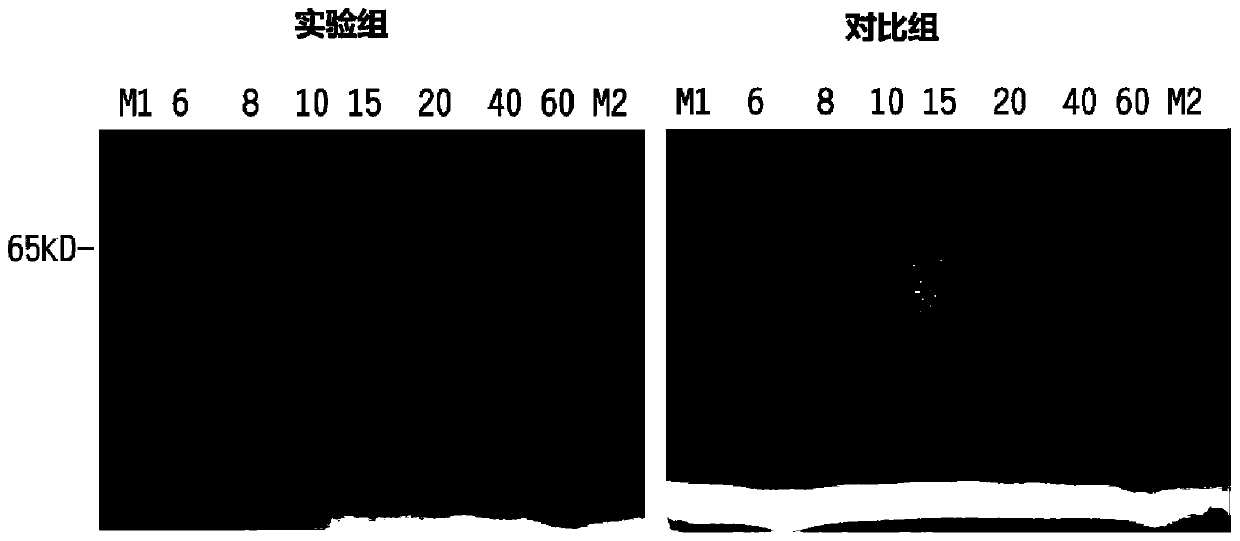

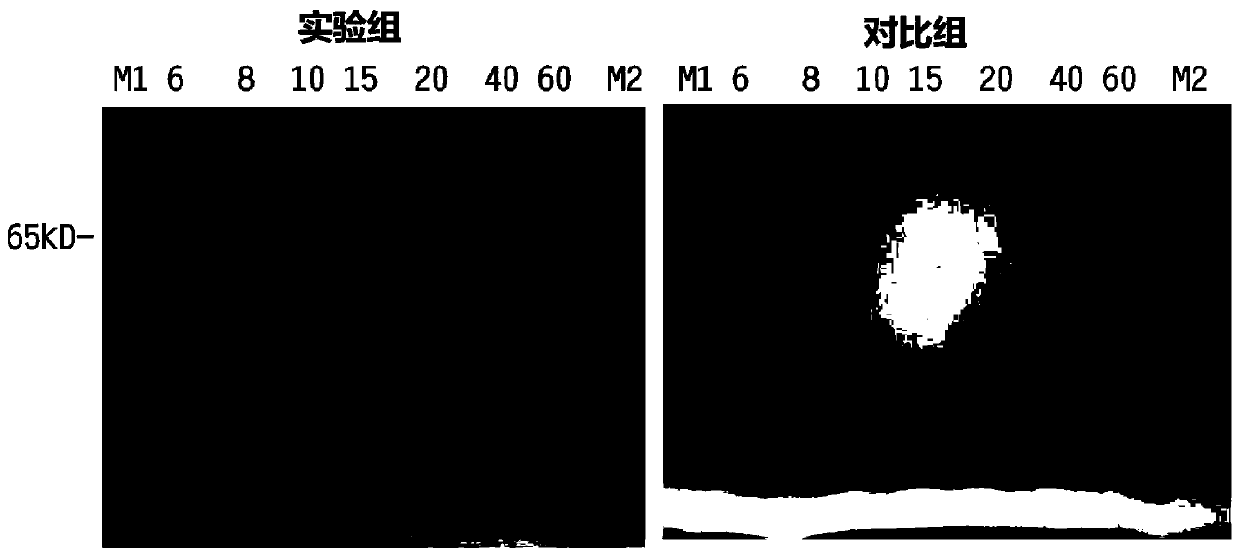

Rapid Commassie brilliant blue staining solution

ActiveCN109520804AHigh dyeing sensitivityHigh sensitivityPreparing sample for investigationMaterial analysis by electric/magnetic meansAcetic acidAlcohol

The invention discloses a rapid Commassie brilliant blue staining solution, containing Coomassie brilliant blue, water, alcohol, acid and xylo-oligosaccharide. According to the invention, methyl alcohol and acetic acid are not used, thus being more economical and environment-friendly, furthermore, compared with general Commassie brilliant blue staining, the staining sensitivity is improved; xylo-oligosaccharide is added to the staining solution, so that staining is rapid, a protein band can be seen only after 5 minutes of staining, the sensitivity is high, and mass spectrum compatibility is good; decoloring is not needed after staining, observation can be performed by rinsing simply with distilled water, the operation is simple and convenient, and the efficiency is high.

Owner:北京启维益成科技有限公司

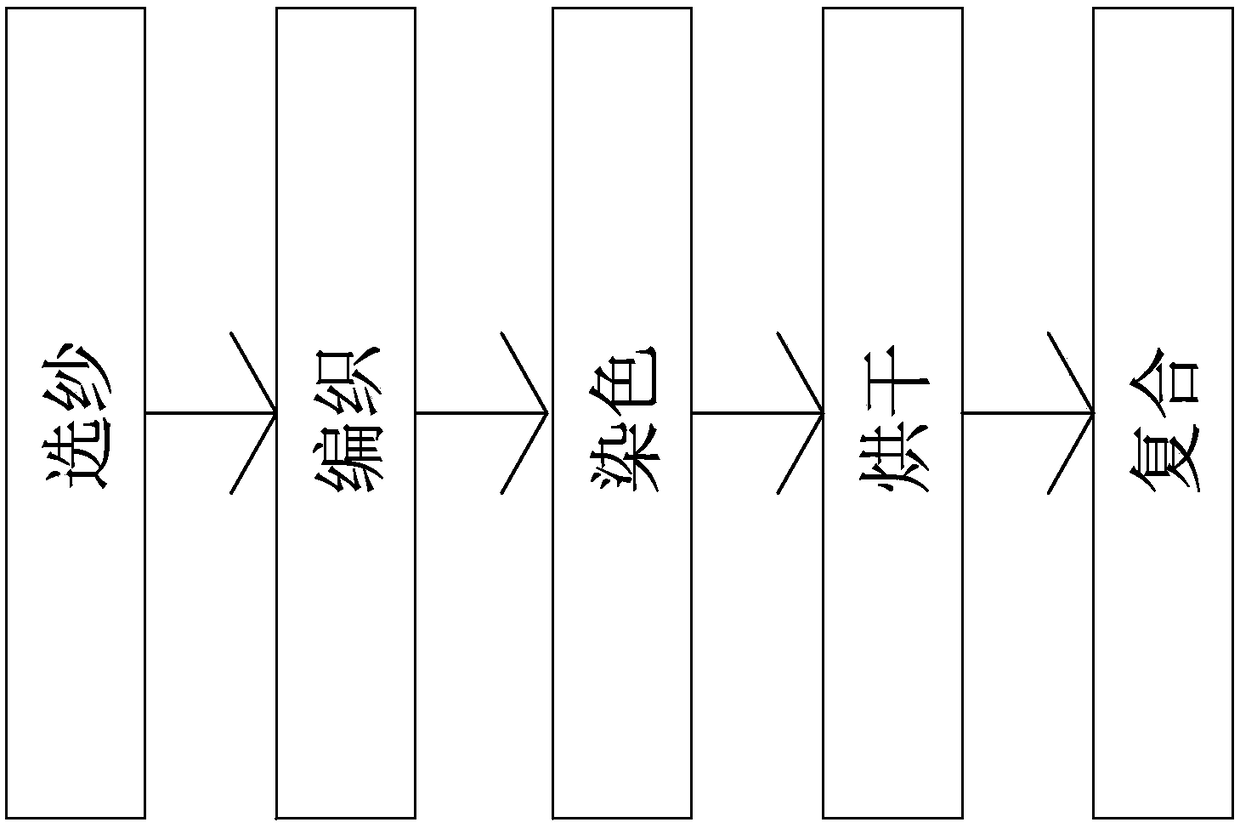

Dyeing process of textile fabric

The invention provides a dyeing process of a textile fabric. The dyeing process comprises the following steps: 1, putting the textile fabric into a high-pressure dye vat; after injecting water into the high-pressure dye vat, injecting steam; 2, when the temprature of the water in the high-pressure dye vat is raised to 80 DEG C to 100 DEG C, adding a scouring agent into the high-pressure dye vat and stirring a solution; meanwhile, adding an alkaline solution and regulating the pH (Potential of Hydrogen) value; carrying out sealing treatment; 3, raising the pressure and temperature in the high-pressure dye vat; 4, keeping the pressure and temperature in the high-pressure dye vat and continually scouring; 5, after finishing scouring, reducing the pressure and temperature in the high-pressure dye vat to normal temperature and normal pressure; then draining the solution in the high-pressure dye vat; 6, carrying out water washing treatment on the textile fabric obtained by step 5 under normal temperature and normal pressure conditions; 7, putting the textile fabric washed with the water in step 6 into the dye vat and carrying out dyeing treatment. According to the dyeing process of the textile fabric, the dyeing effect of the textile fabric is excellent; the method is simple and convenient to operate, the dyeing is rapid and the coloring time is short, so that the dyeing process of the textile fabric is suitable for industrial and large-batch production.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Vagina microbial immunofluorescence staining solution

PendingCN114199653AExtended retention timeImprove permeabilityPreparing sample for investigationBiological testingBiotechnologyImmunofluorescence staining

The invention relates to the technical field of medical detection, and discloses a vagina microorganism immunofluorescence staining solution. Comprising the following raw materials in parts by weight: 5-8 parts of a fluorescent coloring agent, 2-3 parts of an auxiliary dye, 1-3 parts of a stabilizer, 1-3 parts of a penetrant, 2-5 parts of a bacteriostatic agent, 1-2 parts of an anti-quenching agent, 2-4 parts of a permeable agent, 2-4 parts of a buffer solution, 5-6 parts of a cell protective agent and 20-40 parts of purified water. According to the vagina microbial immunofluorescence staining solution, the stability of the fluorescent staining solution during staining can be improved by adding the stabilizer, the fluorescence retention time is prolonged, the problem that the staining fluorescence is not obvious due to poor staining stability and the detection data is influenced is avoided, and meanwhile, the antibacterial activity of the fluorescent staining solution is improved by adding the bacteriostatic agent; the fluorescent staining solution can be stored for a longer time, the permeability agent and the penetrant added in the fluorescent staining solution can improve the permeability to cell membranes, staining of cells by fluorescein can be accelerated, and the practicability of the vagina microbial immunofluorescence staining solution is enhanced.

Owner:济南德亨医学科技有限公司

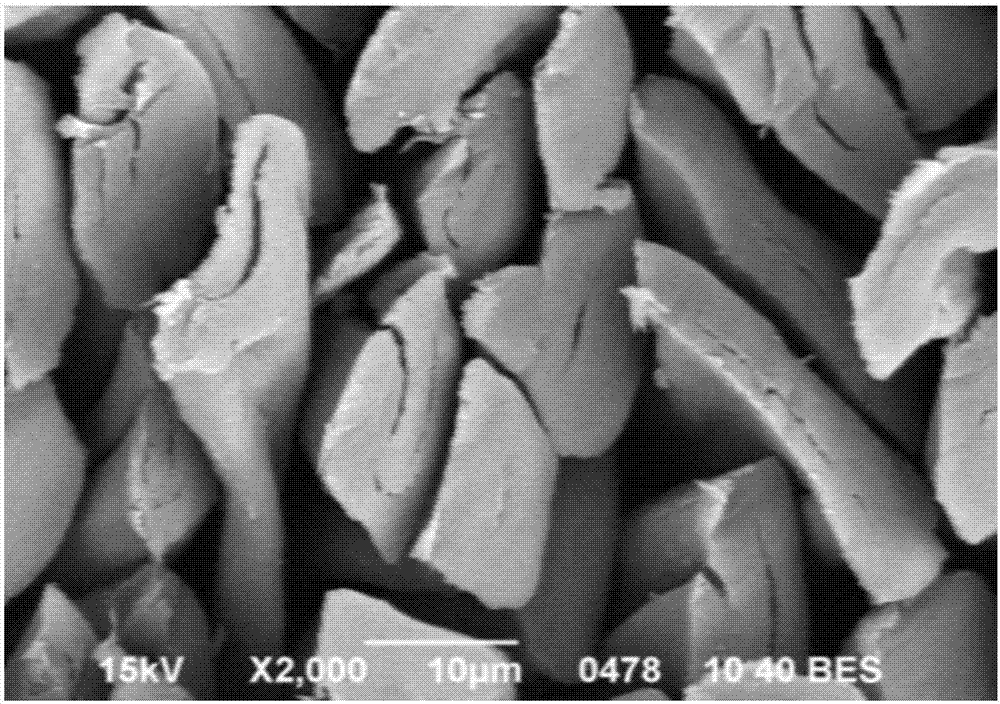

Method for improving dyeing performance through chinlon 6 textile plasma treatment

InactiveCN109706753AIncrease surface polarityEnhanced surface electronegativityDyeing processTextile printerNuclear chemistry

The invention relates to a method for improving dyeing performance through chinlon 6 textile plasma treatment, and aims at solving the problem of poor dyeing color firmness of a plant indigo blue powder body dye on a chinlon textile. The method comprises the steps that normal pressure air plasma treatment is conducted on the chilon 6 textile, low-temperature dyeing is conducted on the treated chinlon 6 textile using the plant indigo blue powder body dye, the chinlon 6 textile is placed in air to be statically oxidized, soaped, washed and dried, and the treatment is completed. The plant indigoblue powder body dye dyed chinlon 6 has the advantages of low temperature, rapidness and environmental-friendliness, an obtained color is deeper, and washing firmness can reach up to 4-5 scales. The method is applied to the field of textile printing dyeing.

Owner:WUYI UNIV

A rapid Coomassie brilliant blue staining solution

ActiveCN109520804BHigh dyeing sensitivityHigh sensitivityPreparing sample for investigationMaterial analysis by electric/magnetic meansAcetic acidAlcohol

The invention discloses a rapid Commassie brilliant blue staining solution, containing Coomassie brilliant blue, water, alcohol, acid and xylo-oligosaccharide. According to the invention, methyl alcohol and acetic acid are not used, thus being more economical and environment-friendly, furthermore, compared with general Commassie brilliant blue staining, the staining sensitivity is improved; xylo-oligosaccharide is added to the staining solution, so that staining is rapid, a protein band can be seen only after 5 minutes of staining, the sensitivity is high, and mass spectrum compatibility is good; decoloring is not needed after staining, observation can be performed by rinsing simply with distilled water, the operation is simple and convenient, and the efficiency is high.

Owner:北京启维益成科技有限公司

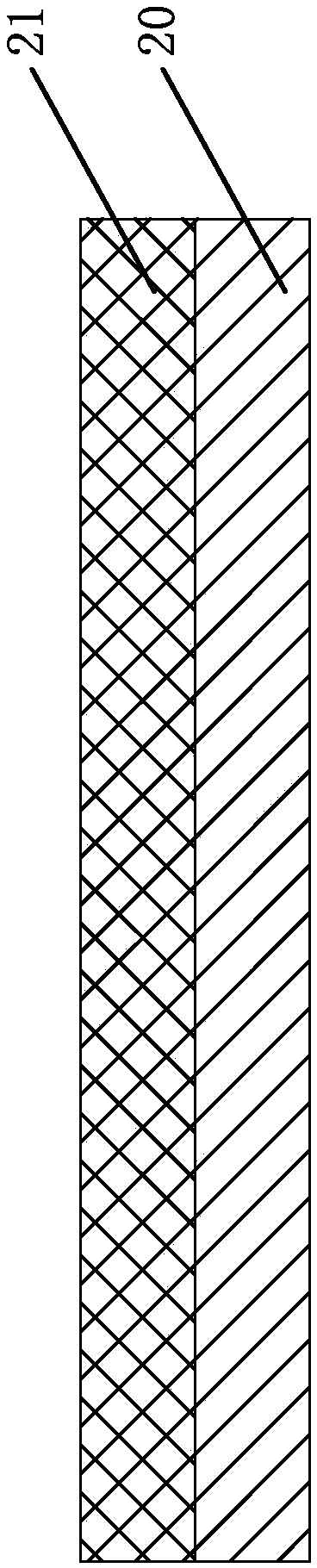

Manufacturing process of flame-retardant fabric

InactiveCN108340635AFlame retardant hasDyeing fastSynthetic resin layered productsTextile treatment machine arrangementsPolyesterYarn

The invention provides a manufacturing process of a flame-retardant fabric, and belongs to the technical field of textile industry. The invention solves the problem of low manufacturing efficiency inthe prior art. The manufacturing process of the flame retardant fabric comprises the following steps: a, selecting yarn: selecting flame-retardant yarn and polyester yarn; b, carrying out weaving: weaving a base cloth layer with the polyester yarn, and weaving a flame-retardant layer through the flame-retardant yarn, wherein the line density of the warps of the base cloth layer is 6.2-6.8 tex, theline density of the wefts of the base cloth layer is 6.2-7.2 tex, the line density of the warps of the flame-retardant layer is 6-6-7.4tex, and the line density of the wefts of the flame-retardant layer is 6.6-7.6 tex; and c, carrying out dyeing: separately dyeing the base cloth layer and the flame-retardant layer by a dye vat for textile fabric processing, wherein the dyeing time is 1-2 hours, and the dye vat for textile fabric processing comprises a dye vat main body. The manufacturing process has the advantages of high manufacturing efficiency.

Owner:海宁市纵达新材料股份有限公司

Anti-fouling self-cleaning blended fiber fabric for curtains and preparation method of fabric

InactiveCN107142724AImprove toughnessGood antifoulingStain/soil resistant fibresVegetal fibresFiberHazardous substance

The invention provides an anti-fouling self-cleaning blended fiber fabric for curtains and a preparation method of the fabric. The fiber fabric comprises, by weight, 80-100 parts of functional fiber, 3-6 parts of nano chitosan, 3-5 parts of nano maya blue, 4-6 parts of sodium anthraquinone-2-sulfonate, 3-6 parts of polyethylene glycol oleate, 2-10 parts of sodium silicate, 2-5 parts of isopropyl alcohol, 3-10 parts of N,N-dimethyl formamide and 1-3 parts of silane coupling agent. By reasonable modification on fibers, toughness, adsorption, antifouling and dyeing properties and the like of the fiber fabric are improved effectively; by means of photocatalysis, the capability of the fiber of adsorbing and decomposing foreign flavor, odor and hazardous substances is enhanced, the fabric has self-cleaning effect and is green and environment friendly, and service life is prolonged.

Owner:马鞍山市永运家纺有限公司

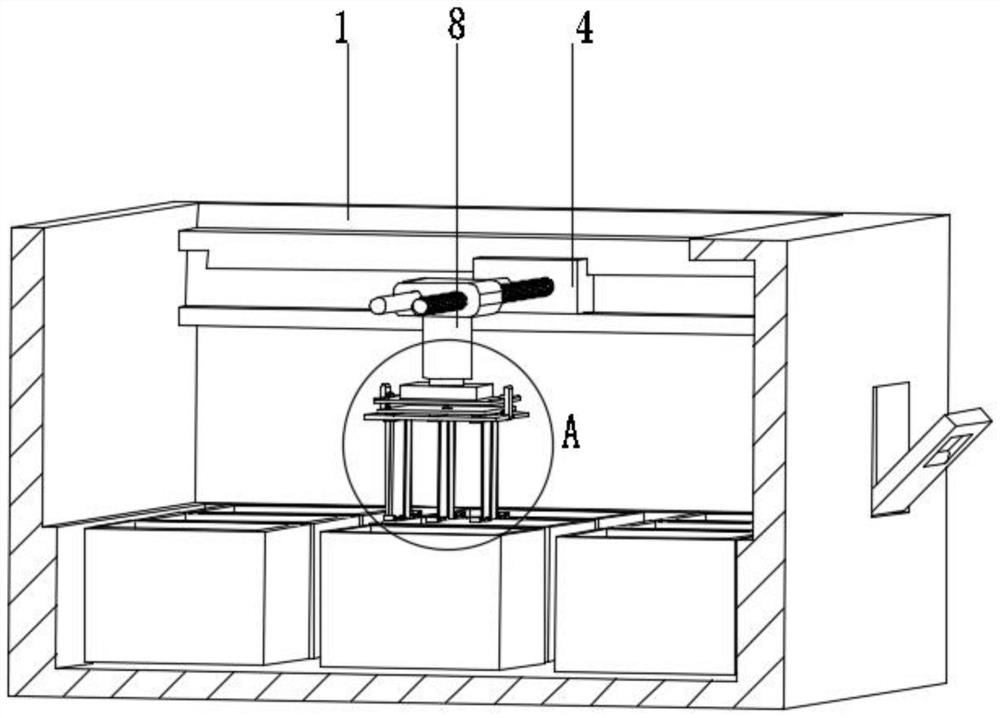

Automatic staining analysis device for pathological diagnosis

The invention discloses an automatic staining analysis device for pathological diagnosis, and belongs to the technical field of medical instruments. The automatic staining analysis device includes a staining box, a plurality of kits are placed in the staining box; vertical sliding rails are fixedly connected to the two side walls of the staining box; a moving block is connected into each verticalsliding rail in a sliding manner; a smooth guide rod is fixedly connected between the moving blocks, and a driving lead screw is rotationally installed between the moving blocks. A hoisting plate is slidably connected to the outer wall of the smooth guide rod; the driving lead screw penetrates through the hoisting plate and is in threaded connection with the hoisting plate; a lifting push rod is fixedly mounted at the bottom of the hoisting plate; a mounting plate is fixedly connected to the bottom of the lifting push rod; the mounting plate is connected with a staining plate through a connecting assembly; a plurality of inserting openings are formed in the middle of the staining plate, slide frames are fixedly connected to the bottoms of the inserting openings, side wall plates are fixedly connected to the side walls of the slide frames, a top plate is fixedly arranged above the staining plate, staining openings are formed in the side wall of the staining box, sealing doors are rotatably connected to the bottoms of the staining openings, and the automatic staining analysis device is stable in fixation, not prone to falling, convenient to take and capable of improving efficiency.

Owner:穆宝忠

Pretreatment process for silk dyeing

ActiveCN104611865AHigh color reproductionDyed wellTwo or more solvent application treatmentDyeing processPhosphoric acidChemistry

The invention discloses a pretreatment process for silk dyeing. According to the pretreatment process for silk dyeing, silk is soaked in an ammonia-water solution to be heated to 40-50 DEG C, and then the solution stays for 40-60 min; the processed silk is soaked in a 20-30% ethanol solution to be heated to boiling, the solution stays for 10-20 min, then the silk is soaked in a calcium chloride solution to be heated to 70-80 DEG C and stirred for 20-40 min, and then temperature is reduced to indoor temperature; the processed silk is soaked in a 0.1 mol / L phosphoric acid solution, temperature is maintained to be 30-40 DEG C, and stirring is conducted for 10-20 min; finally, the processed silk is cleaned through phosphoric acid so that dyeing can be conducted. By the adoption of the pretreatment process for silk dyeing, the processed silk can be dyed quickly, color revivification degree is high, testing shows that light fastness can reach over six grade, crockfastness can reach over four grade and color fastness to washing reaches four grade, and therefore dyeing can be well achieved.

Owner:WUXI CANMEI TECH

Household washing and dyeing agent for clothes made of polyester fibers and application of household washing and dyeing agent

InactiveCN109403095ADyeing fastUniform dyeingDyeing processInorganic non-surface-active detergent compositionsPolyesterFiber

The invention relates to a household washing and dyeing agent for clothes made of polyester fibers and applicationof the household washing and dyeing agent. The household washing and dyeing agent is prepared from the following raw materials in parts by weight: 2-10 parts of dye packs, 5-60 parts of dye promoting packs, 5-55 parts of dye fixing packs, and 5-60 parts of washing packs; and the washing packs are sodium percarbonate. A method includes the steps that after the clothes are added, a reactive dye is added into a washing machine, then salt is added to promote dyeing, then sodium carbonate anhydrous is added to fix color, sodium percarbonate is added for soaping, and thus the color fastness is improved. According to the method, operation is easy, household washing machines can be used through the method, dyeing is uniform, the color is brighter after soaping of the sodium percarbonate, and the color fastness is high.

Owner:濮阳圣恺环保新材料科技股份有限公司

Efficient coloring equipment for fabric textile processing

InactiveCN114836927ATimely processingReduce limitationsTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingMechanical engineeringIndustrial engineering

The efficient coloring equipment for fabric textile processing comprises a machine body, guide rollers are arranged at the positions, close to a feeding port and a discharging port, in the machine body, a dyeing tank is fixedly connected to the center of the bottom of the inner wall of the machine body, and a shifting device is arranged at the position, close to the center, of the inner wall of the dyeing tank; a power mechanism is arranged on one side of the bottom of the surface of the machine body, the output end of the power mechanism is fixedly connected with one end of a shifting device through a coupler, an excess material treatment device is arranged in the machine body and close to the top, and the end, away from the power mechanism, of the shifting device is fixedly connected with a rotating disc. And the top end of the connecting rod is rotationally connected with the excess material treatment device. According to the efficient coloring equipment for fabric textile processing, the effect of high adaptability is achieved, cloth with the surface covered with fluff can be treated in time, the influence of fluff covering is reduced, uniform coloring is facilitated, safety and reliability are achieved, and the working efficiency and the use performance are improved.

Owner:南通栋楹新材料科技有限公司

Nylon yarn dyeing and dip-dyeing device

InactiveCN111364186ADyeing fastImprove work efficiencyTextile treatment machine arrangementsTextile treatment carriersYarnPolymer science

The invention provides a nylon yarn dyeing and dip-dyeing device. The nylon yarn dyeing and dip-dyeing device comprises a base, a dyeing tank is arranged on the base, dyeing liquid is contained in thedyeing tank, a yarn roller containing frame is arranged above the dyeing tank, a containing groove with a fastening clamping block is formed in the yarn roller containing frame, a yarn roller wound with yarn is inserted into the containing groove, lifting air cylinders are arranged on the two sides of the upper end of the yarn roller containing frame and drive the yarn roller containing frame tomove up and down, a rotating disc is arranged at the upper ends of the lifting air cylinders, a rotating motor is arranged at the top of the rotating disc, and the rotating disc is driven by the rotating motor to rotate. Dye makes contact with yarn through soaking and stirring, dyeing is carried out rapidly, the yarn does not need to be detached, the working efficiency is improved, the whole yarnroller containing frame is driven by the rotating disc to rotate, the yarn roller is stirred in the dyeing tank, the soaking degree is improved, and the dyeing efficiency is improved.

Owner:HAIAN HUARONG CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com