Method for improving dyeing performance through chinlon 6 textile plasma treatment

A dyeing performance, plasma technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of poor washing fastness, achieve soft color, good biodegradability and environmental compatibility, skin-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

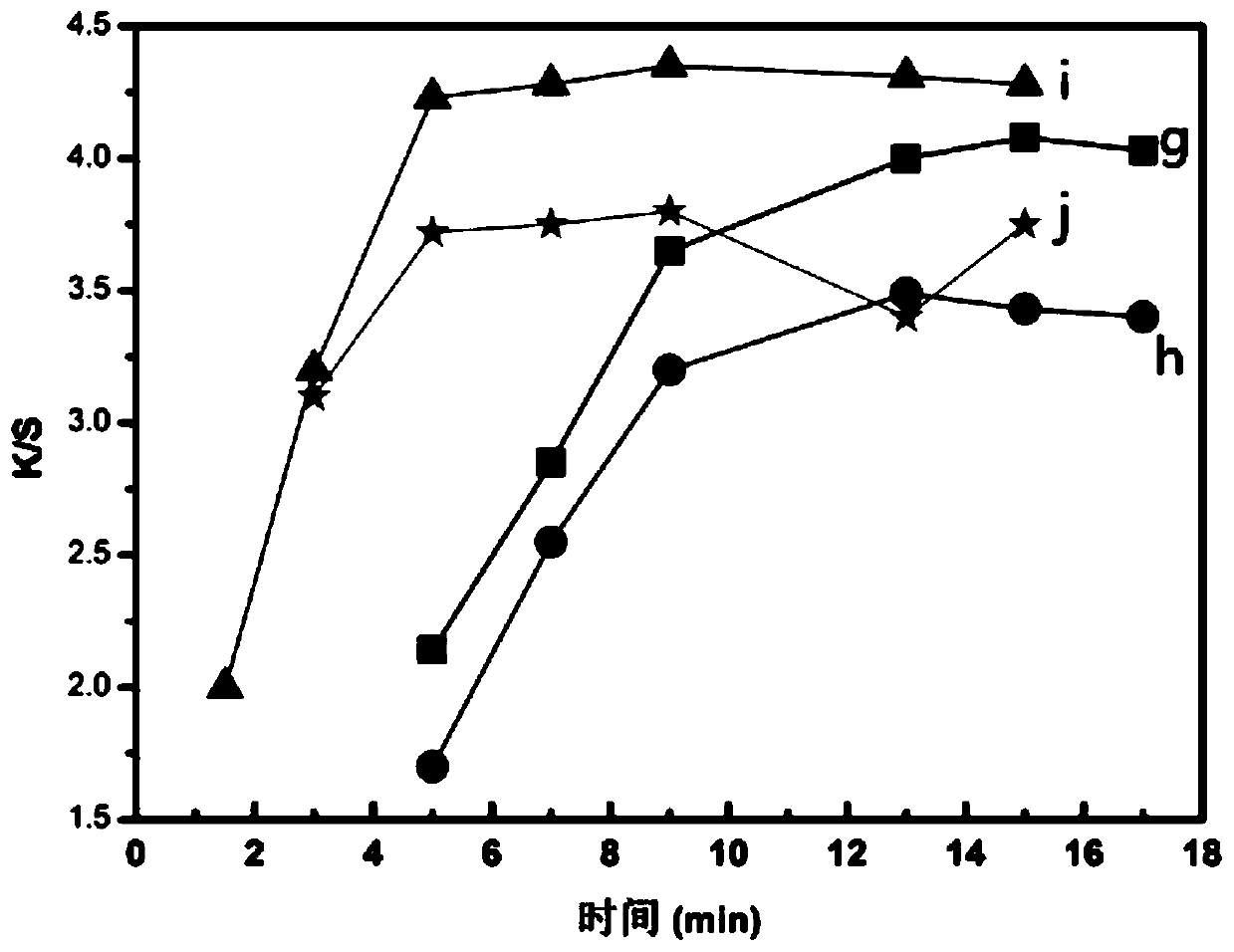

[0025] Specific Embodiment 1: In this embodiment, the nylon 6 fabric is subjected to normal-pressure air plasma treatment, the processing power is 320-380W, and the treatment time is 1s-15s, and then the treated nylon 6 fabric is dyed, and it is dyed at 50°C for 70 -80min, then oxidize statically in air for 30-120min, soap wash, wash with water, and dry to complete the method of plasma treatment of nylon 6 fabric to improve dyeing performance.

[0026] The beneficial effects of this embodiment are:

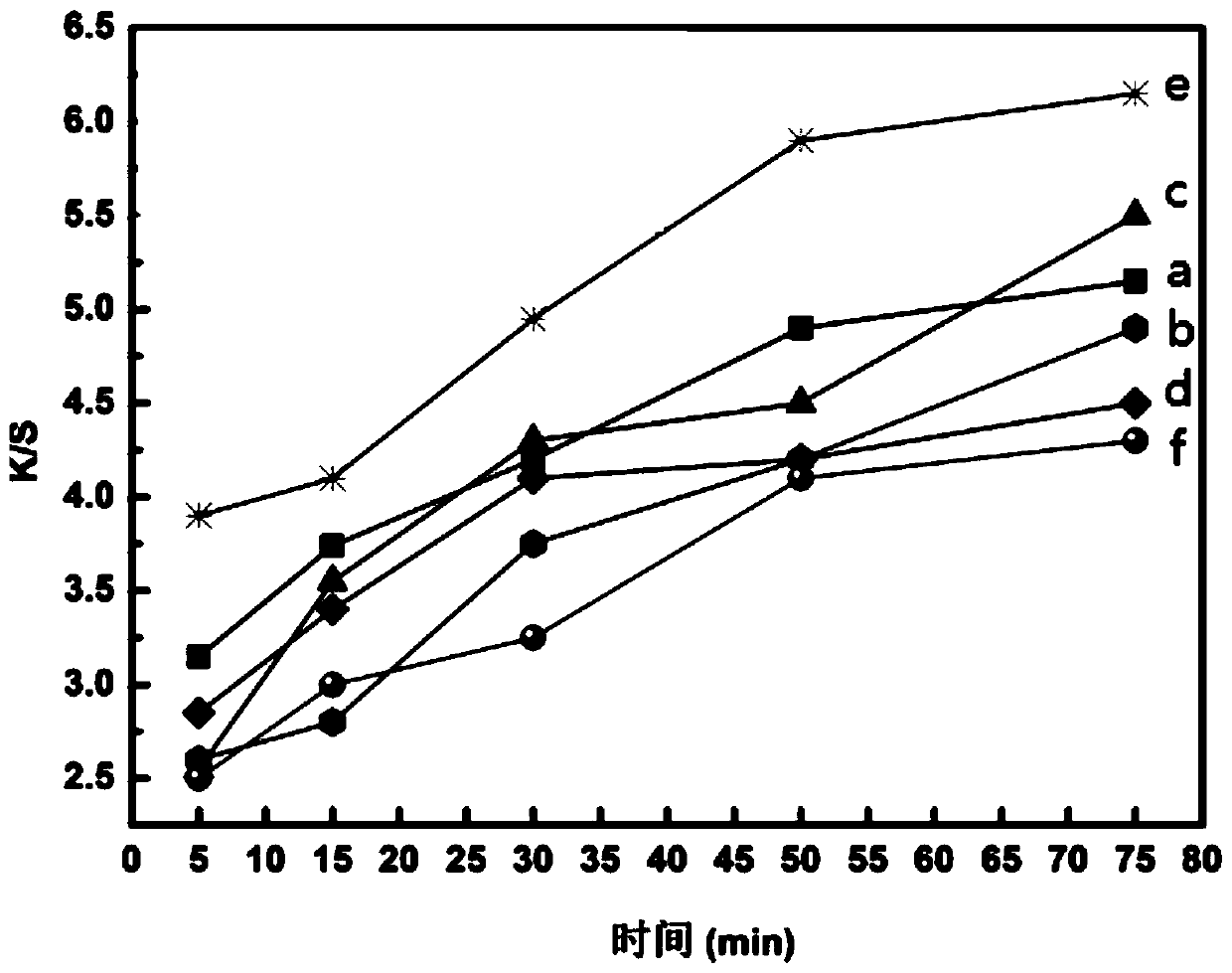

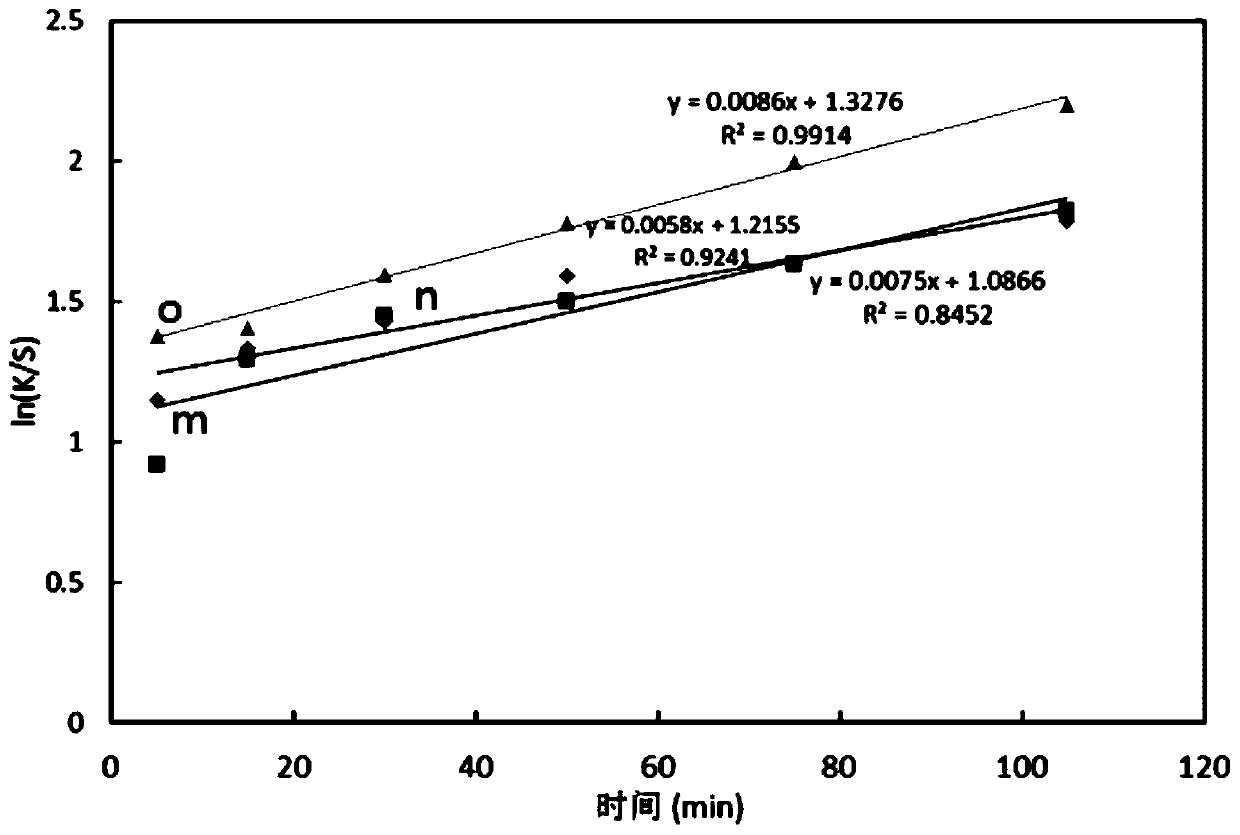

[0027] 1. Plasma treatment for 7s, with the treatment power from 0w to 325w, 350w, 375w and 400w, the formed polar groups such as amino, amide and carboxyl groups increased significantly with the increase of treatment power. This is because the oxidation of oxygen and nitrogen in the air is introduced to the fiber, so the polar groups on the fiber increase, the surface polarity of the fiber increases, and the surface electronegativity of the fiber increases, which promotes the dye...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the method of normal-pressure air plasma treatment of nylon 6 fabric is: the pretreated nylon 6 fabric is spread on the silicon rubber plate of CTP1200 electronic impact machine, and the use of The air between the pole plates is used as the medium to carry out atmospheric pressure air plasma treatment on the nylon 6 fabric. Others are the same as in the first embodiment.

[0037] The CTP1200 in the plasma equipment of this embodiment is produced by Nanjing Corona Laboratory. The dielectric barrier surface treatment device mainly consists of two parts: the transformer part and the discharge system. The transformer is used to adjust the input voltage, and the discharge system includes power supply, electrodes and discharge platform. Power supply: 0-1KW, adjustable power, 220V / 50HZ. There are two electrodes: a dielectric barrier electrode and a strip metal electrode. The dis...

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the atmospheric pressure air plasma processing power is 375W, and the processing time is 7s. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com