Polypropylene composite material for automobile sprayed exterior trimming parts and preparation method thereof

A composite material and polypropylene technology, which is applied in the fields of materials, automotive exterior parts, and chemistry, can solve problems that affect the performance of polypropylene composite materials, difficulty in adapting to large-scale production, and interface compatibility issues, and achieve spraying effects and Improvement of paint adhesion, improvement of adhesion and aging resistance, and effect of enhancing surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

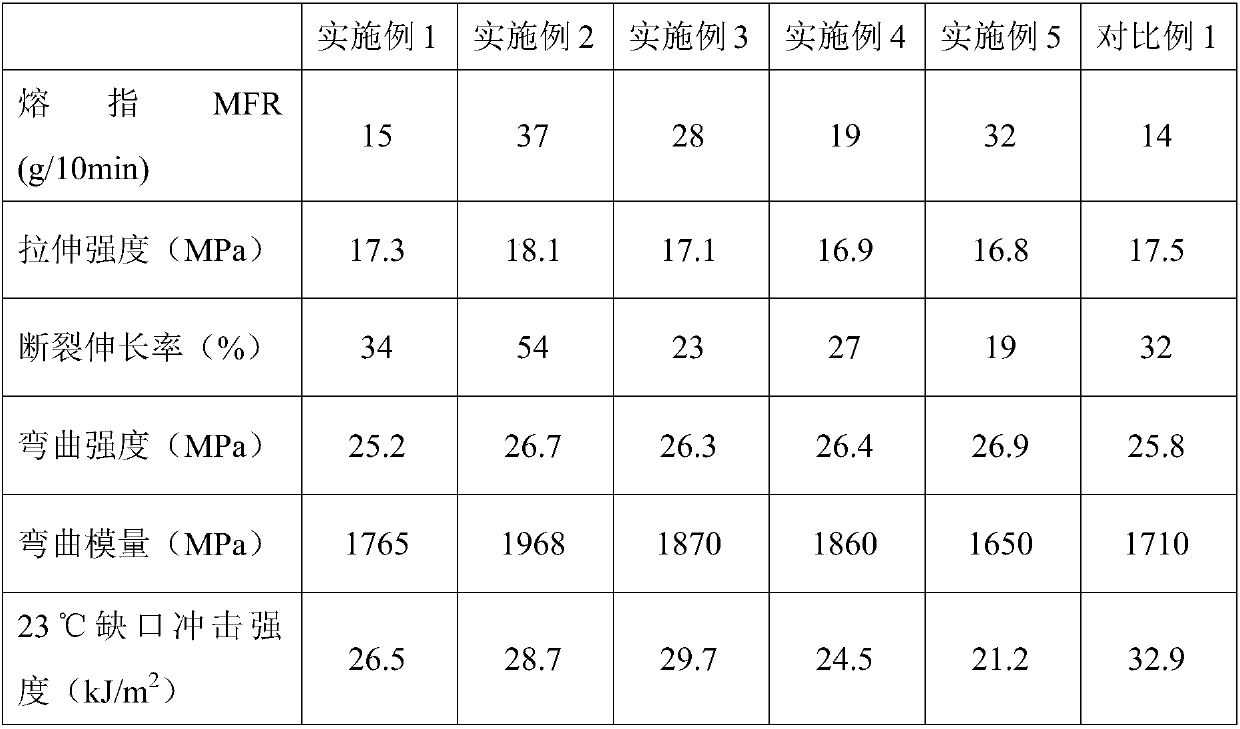

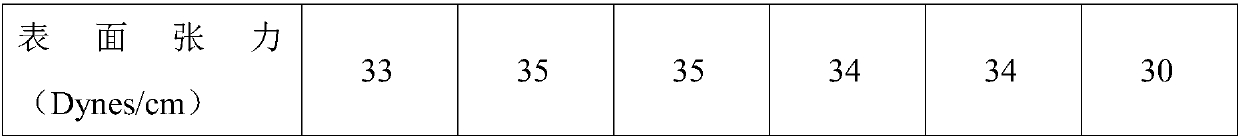

Examples

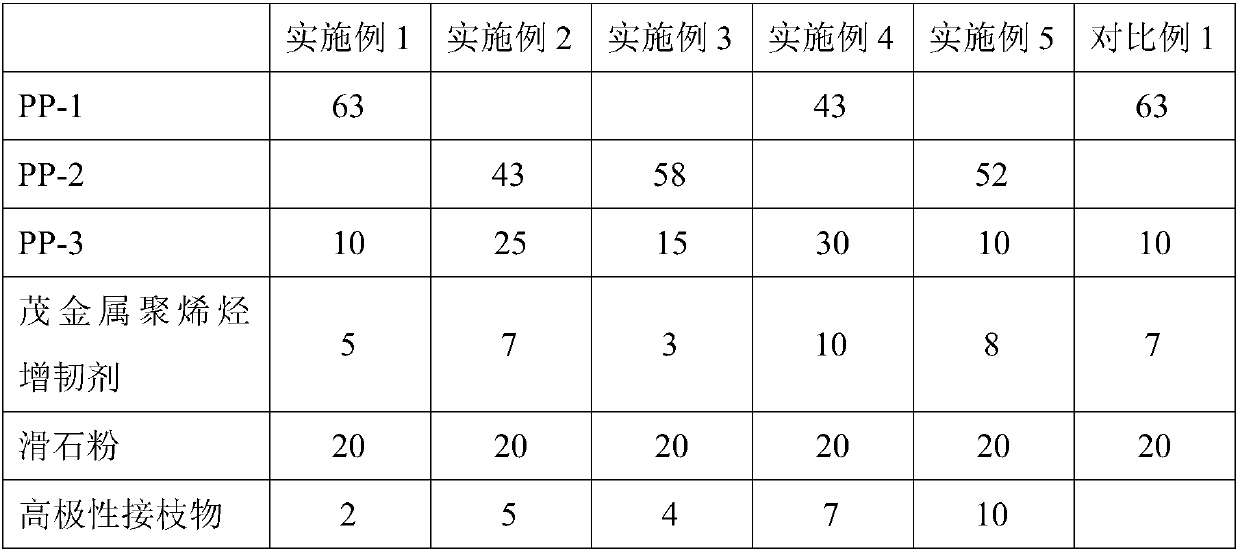

Embodiment 1

[0028] A method for preparing a polypropylene composite material, comprising the following steps.

[0029] Step S1) Obtain the raw materials according to Table 1. Wherein, in the highly polar graft, the polyethylene resin accounts for 94.5% of the highly polar graft; the glycidyl methacrylate accounts for 94.5% of the highly polar graft. 5% of the amount of the grafted substance; the quality of the peroxide initiator accounts for 0.5% of the amount of the highly polar grafted substance. The peroxide initiator is selected from ethyl 3,3-bis(tert-butylperoxy)butyrate.

[0030] Step S2) mixing the high-impact copolymerized polypropylene, high-melting high-rigidity homopolypropylene, metallocene polyolefin toughening agent, and talcum powder among the raw materials to obtain a first mixture.

[0031] Step S3) preparing a melt of the highly polar graft. The step S3) includes the following steps.

[0032] Step S31) Obtain the ingredients for preparing the high polarity graft: po...

Embodiment 2

[0040] A method for preparing a polypropylene composite material, comprising the following steps.

[0041] Step S1) Obtain the raw materials according to Table 1. Wherein, in the highly polar graft, the polyethylene resin accounts for 94.5% of the highly polar graft; the glycidyl methacrylate accounts for 94.5% of the highly polar graft. 5% of the amount of the grafted substance; the quality of the peroxide initiator accounts for 0.5% of the amount of the highly polar grafted substance. The peroxide initiator is selected from ethyl 3,3-bis(tert-butylperoxy)butyrate.

[0042] Step S2) mixing the high-impact copolymerized polypropylene, high-melting high-rigidity homopolypropylene, metallocene polyolefin toughening agent, and talcum powder among the raw materials to obtain a first mixture.

[0043] Step S3) preparing a melt of the highly polar graft. The step S3) includes the following steps.

[0044] Step S31) Obtain the ingredients for preparing the high polarity graft: po...

Embodiment 3

[0052] A method for preparing a polypropylene composite material, comprising the following steps.

[0053] Step S1) Obtain the raw materials according to Table 1. Wherein, in the highly polar graft, the polyethylene resin accounts for 94.5% of the highly polar graft; the glycidyl methacrylate accounts for 94.5% of the highly polar graft. 5% of the amount of the grafted substance; the quality of the peroxide initiator accounts for 0.5% of the amount of the highly polar grafted substance. The peroxide initiator is selected from ethyl 3,3-bis(tert-butylperoxy)butyrate.

[0054] Step S2) mixing the high-impact copolymerized polypropylene, high-melting high-rigidity homopolypropylene, metallocene polyolefin toughening agent, and talcum powder among the raw materials to obtain a first mixture.

[0055] Step S3) preparing a melt of the highly polar graft. The step S3) includes the following steps.

[0056] Step S31) Obtain the ingredients for preparing the high polarity graft: po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com