Method for quality improvement of biological oil through catalytic esterification-deoxidize reforming in subcritical alcohol system

A bio-oil and subcritical technology, applied in the direction of biological raw materials, fatty acid esterification, fat production, etc., can solve the problems of inconspicuous cracking effect, high processing cost, reactor clogging, etc., and achieve easy large-scale quality improvement and operation The process is convenient and the effect of avoiding coking and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Non-limiting examples are described as follows:

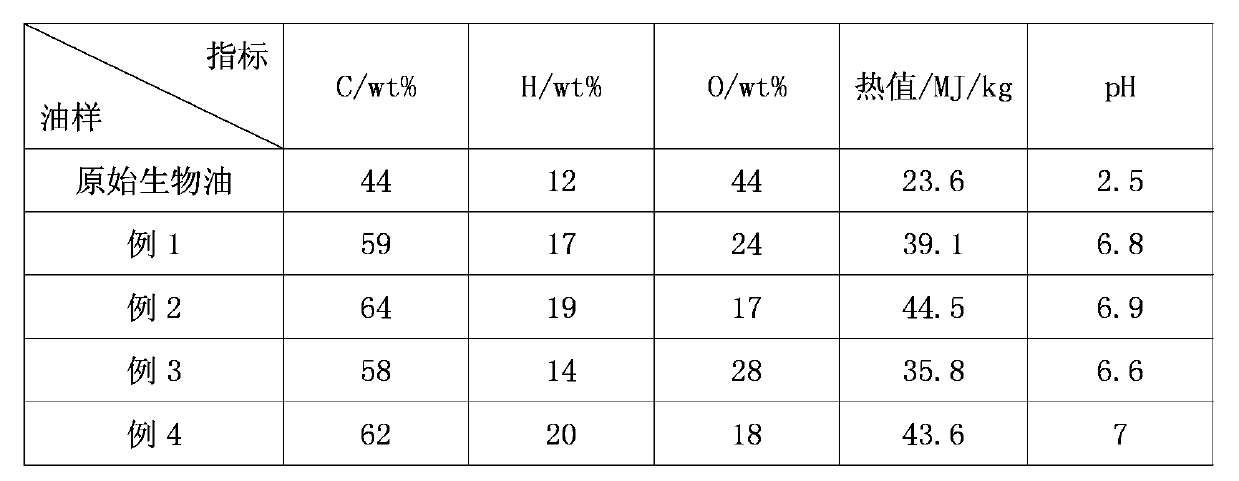

[0017] In this example, a bio-oil prepared by rapid pyrolysis and liquefaction of rice husk as a raw material is used as an example to describe. value 2.5.

[0018] (1) Catalyst preparation

[0019] Put 10 g of HZSM-5 zeolite with an average particle size of 12.6 μm and a porosity of 42% at a temperature of 50 o C, soak and stir in 100mL 0.5mol / L KF or NaF solution for 1h, then add 9.1g Ni(NO 3 ) 2 or 12.1g Fe(NO 3 ) 3 , after stirring and dissolving, raise the temperature of the solution to 60-80 o C, continue to stir for 2h, then drop to room temperature and stand for 24h, filter, separate the solid phase and place it in a muffle furnace at 900 o C calcined for 1h to obtain catalyst X-Y / Z (KF-NiO / HZSM-5, NaF-NiO / HZSM-5, KF-Fe 2 o 3 / HZSM-5, NaF-Fe 2 o 3 / HZSM-5, spare.

[0020] (2) Bio-oil upgrading method

[0021] 1. Add 50g of methanol, 100g of bio-oil, and 5g of KF-NiO / HZSM-5 into a 250mL pressure-resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com