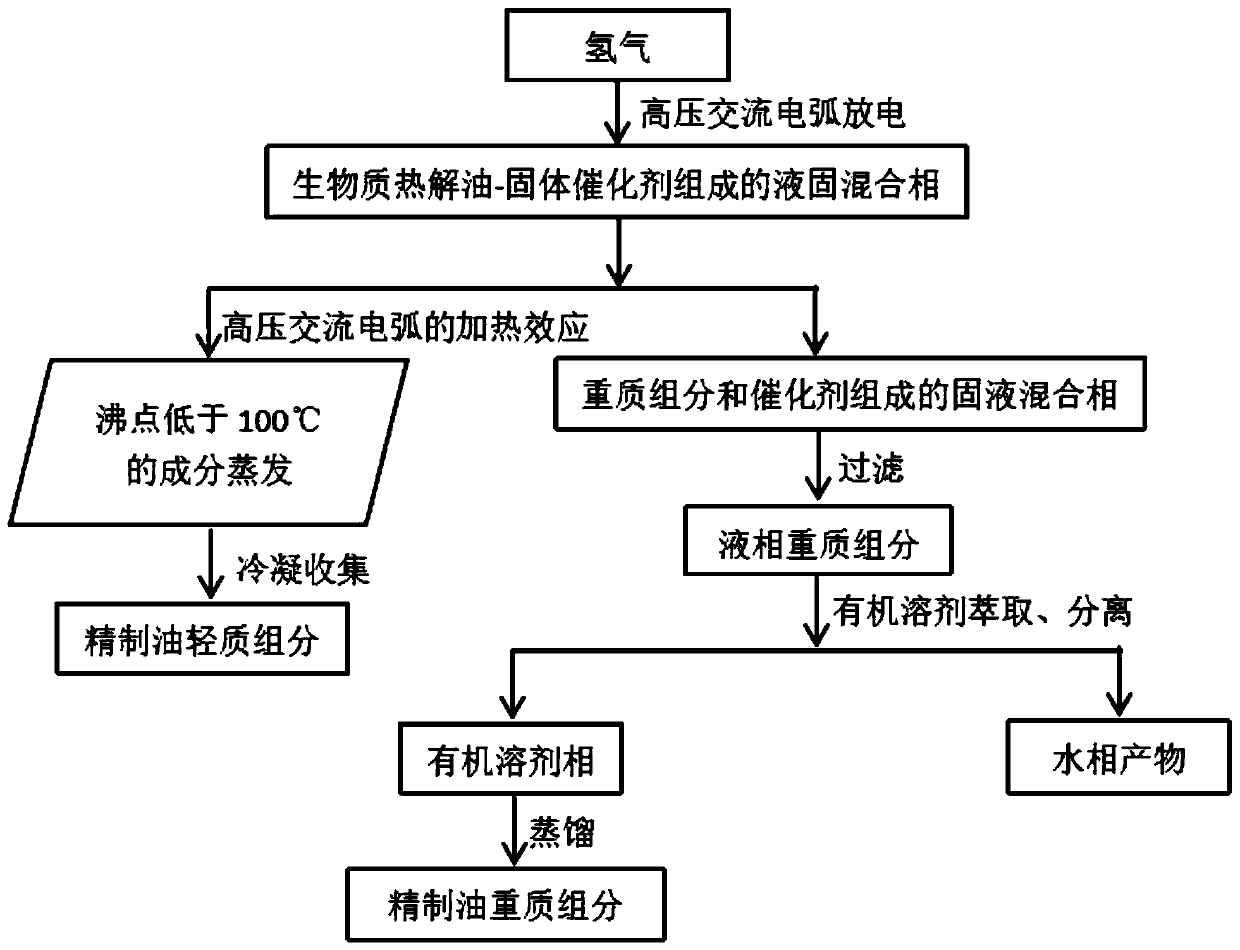

A method for refining and upgrading biomass pyrolysis oil

A biomass pyrolysis oil and reactor technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, refining to remove heteroatoms, etc., can solve the problems of catalyst carbonization and coking deactivation, poor thermal stability, high catalyst cost, etc. The effect of temperature and density, reducing equipment requirements, improving efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

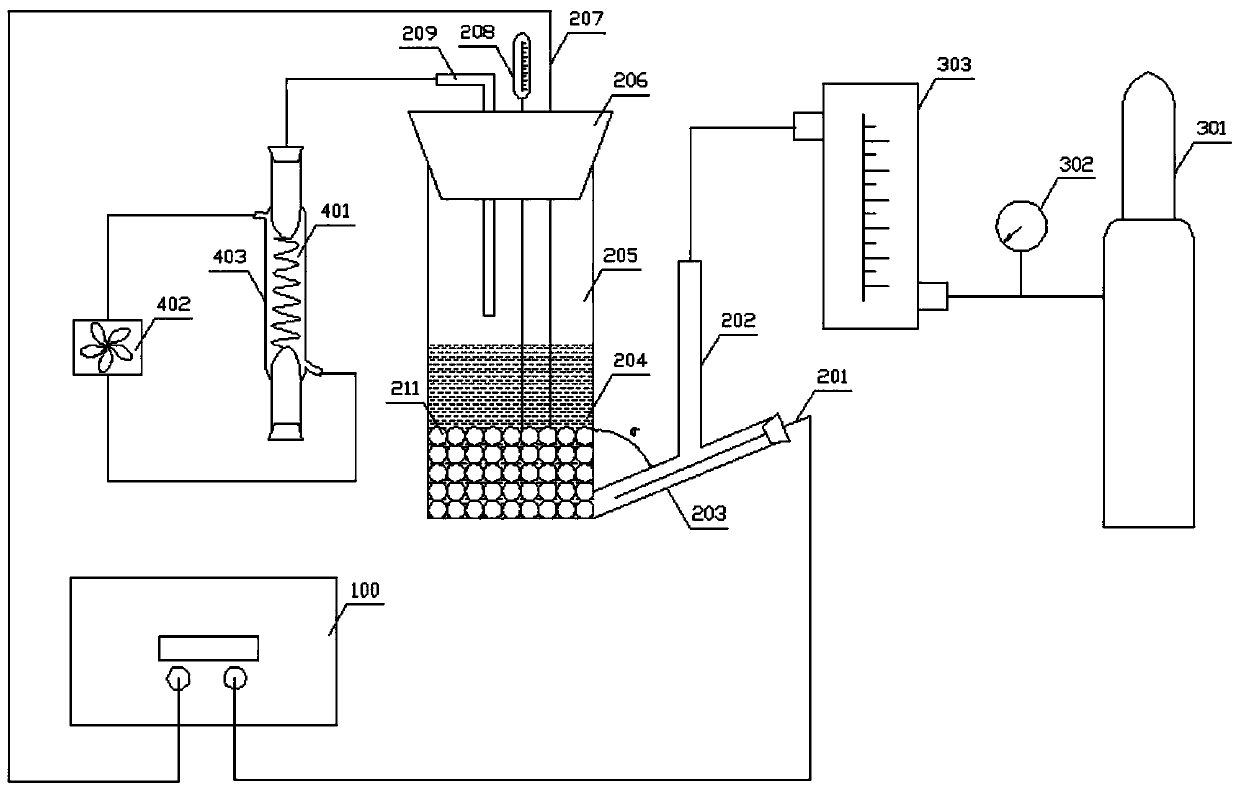

[0033] (1) Before the reaction, 3g of NiMo / Al 2 o 3 The catalyst is pulverized into fine powder with a particle size of 0.5 mm, mixed evenly with 30 g of pine sawdust biomass pyrolysis oil, and the solid-liquid mixed phase composed of catalyst and biomass pyrolysis oil is placed in the reaction vessel;

[0034] (2) The hydrogen flow rate is set to 60mL / min and passed into the reactor to completely remove the air in the device;

[0035] (3) Adjust the power supply frequency to 9.5kHz, the working voltage to 20kV, the hydrogen flow rate to 80mL / min, the reaction time to 1h, and the measured reaction temperature during the reaction to be 83.5°C;

[0036] (4) After the reaction finishes, continue to feed gas, and cool the reactor to room temperature;

[0037] (5) Collect the refined oil light components obtained by condensation, weigh them and analyze their chemical components. The weight of the light components of the obtained refined oil is 5.5g, mainly C5-C8 liquid hydrocarb...

Embodiment 2

[0042] (1) Before the reaction, 3g of NiMo / Al 2 o 3 The catalyst is pulverized into fine powder with a particle size of 0.5 mm, mixed evenly with 30 g of pine sawdust biomass pyrolysis oil, and the solid-liquid mixed phase composed of catalyst and biomass pyrolysis oil is placed in the reaction vessel;

[0043] (2) The hydrogen flow rate is set to 40mL / min and passed into the reactor to completely remove the air in the device;

[0044] (3) Adjust the power supply frequency to 9.5kHz, the working voltage to 15kV, the hydrogen flow rate to 20mL / min, the reaction time to 2h, and the measured reaction temperature during the reaction to be 77.6°C;

[0045] (4) After the reaction finishes, continue to feed gas, and cool the reactor to room temperature;

[0046] (5) Collect the refined oil light components obtained by condensation, weigh them and analyze their chemical components. The weight of the light components of the obtained refined oil is 5.1g, mainly C5-C8 liquid hydrocarb...

Embodiment 3

[0051] (1) Before the reaction, 3g of NiMo / Al 2 o 3 The catalyst is pulverized into fine powder with a particle size of 0.5 mm, mixed evenly with 30 g of pine sawdust biomass pyrolysis oil, and the solid-liquid mixed phase composed of catalyst and biomass pyrolysis oil is placed in the reaction vessel;

[0052] (2) The hydrogen flow rate is set to 55mL / min and passed into the reactor to completely remove the air in the device;

[0053] (3) Adjust the power supply frequency to 9.5kHz, the working voltage to 25kV, the hydrogen flow rate to 65mL / min, the reaction time to 1.5h, and the measured reaction temperature during the reaction to be 86°C;

[0054] (4) After the reaction finishes, continue to feed gas, and cool the reactor to room temperature;

[0055] (5) Collect the refined oil light components obtained by condensation, weigh them and analyze their chemical components. The weight of the light components of the obtained refined oil is 5.6g, mainly C5-C8 liquid hydrocarb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com