A nickel-based oxygen vacancy carrier catalyst and its preparation method and application

A technology of oxygen vacancy and catalyst, which is applied in the field of nickel-based oxygen vacancy carrier catalyst and its preparation, can solve the problems of difficult to maintain high catalytic performance, poor catalytic stability, sulfur poisoning deactivation, etc., achieve excellent reforming performance, improve catalytic Effect of activity and coking improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the nickel-based oxygen vacancy supported catalyst described in the above technical solution, comprising the following steps:

[0031] Mixing soluble lanthanum salt, soluble cerium salt and water to obtain a mixed solution;

[0032] Mix the mixed solution with γ-Al 2 o 3 performing a first equal-volume impregnation to obtain a first impregnation;

[0033] performing first drying and first calcination on the first impregnated material in sequence to obtain an oxygen vacancy carrier;

[0034] performing a second equal-volume impregnation of the oxygen vacancy carrier and a soluble nickel salt solution to obtain a second impregnated product;

[0035] performing second drying and second calcination on the second impregnated material in sequence to obtain a catalyst precursor;

[0036] The catalyst precursor is activated to obtain the nickel-based oxygen vacancy supported catalyst.

[0037] The invention mixes ...

Embodiment 1

[0062] Ni / γ-Al 2 o 3 (10wt% Ni and 90wt% γ-Al 2 o 3 ) is prepared by the following method: Weigh 50g of activated alumina and calcinate it in an air atmosphere at 900°C for 6h to obtain γ-Al 2 o 3 . Add 22g of Ni(NO 3 ) 3 , Stir with a magnet for 6h at room temperature. Weigh 40g of γ-Al 2 o 3 Place in the solution for equal volume impregnation, put the beaker containing the solution and the carrier into a shaker at room temperature and shake for 2 hours. The catalyst precursor was dried in an oven at 100 °C for 12 h. The dried precursor was calcined in a tube furnace at 500 °C for 6 h in an air atmosphere. After the catalyst was cooled to room temperature, it was placed in the tube furnace again and heated at 550 °C in 5% H 2 / N 2 Restore in the atmosphere for 10h.

[0063] Ni / CeO 2 -γ-Al 2 o 3 (10wt% Ni, 13.5wt% CeO 2 and 76.5wt% γ-Al 2 o 3 ) is prepared by the following method: Weigh 50g of activated alumina and calcinate it in an air atmosphere at 900°C...

Embodiment 2

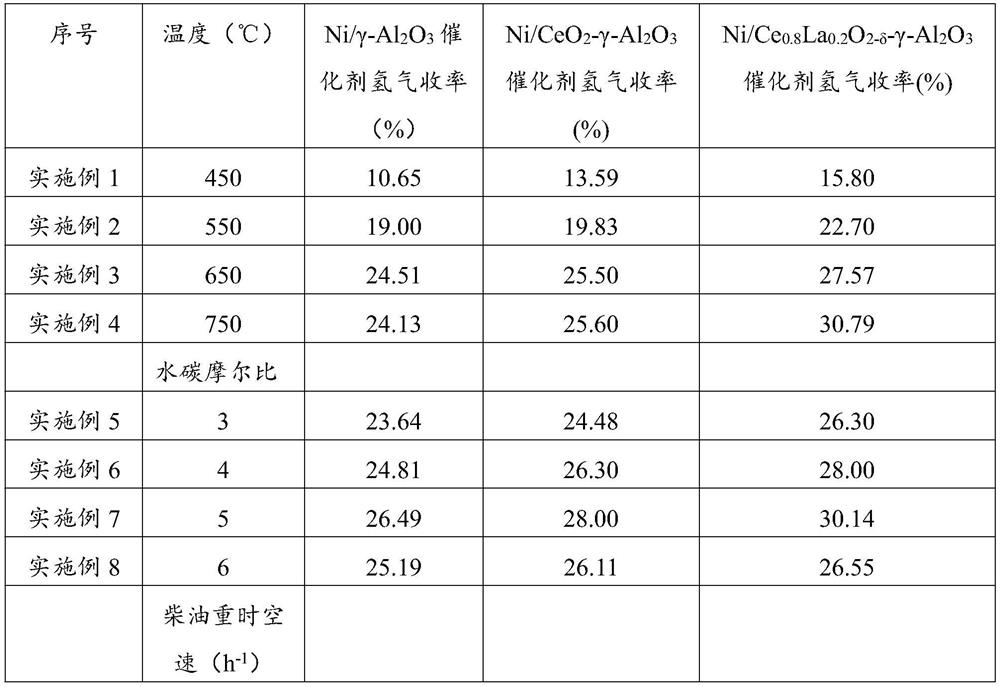

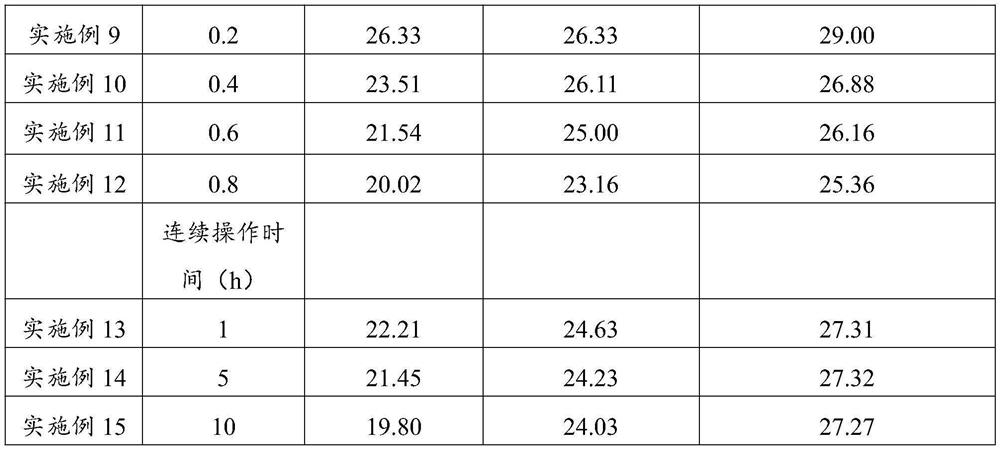

[0067] The national VI standard 0# diesel oil and deionized water are used as the reaction raw materials. Ni / γ-Al 2 o 3 , Ni / CeO 2 -γ-Al 2 o 3 and Ni / Ce 0.8 La 0.2 o 2-δ -γ-Al 2 o 3 Placed in a fixed bed reactor for comparison, T=550°C, S / C=4, WHSV=0.3h -1 , P=0.2MPa Take the dried product gas and measure H in gas chromatography 2 , N 2 , CO, CH 4 , CO 2 content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com