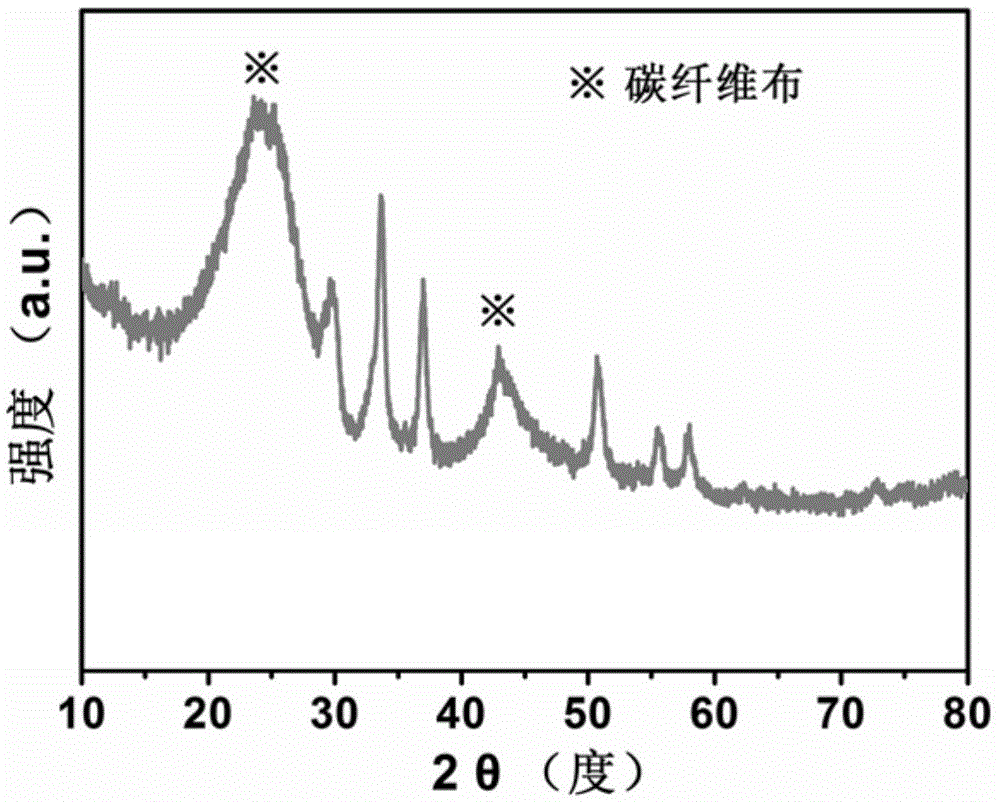

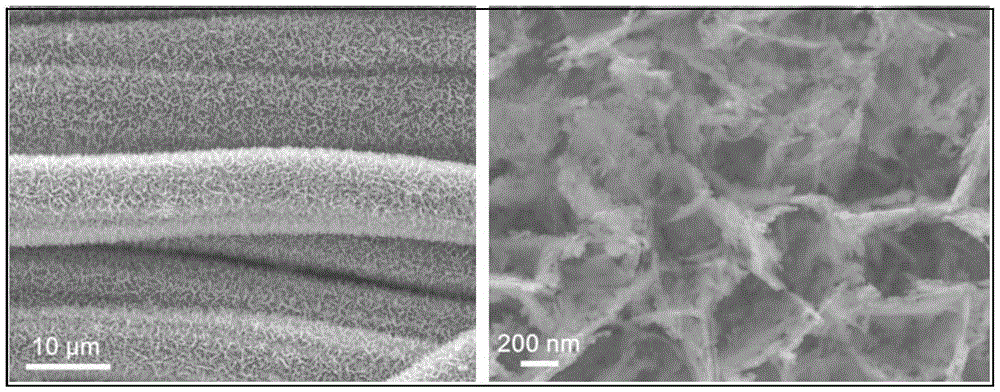

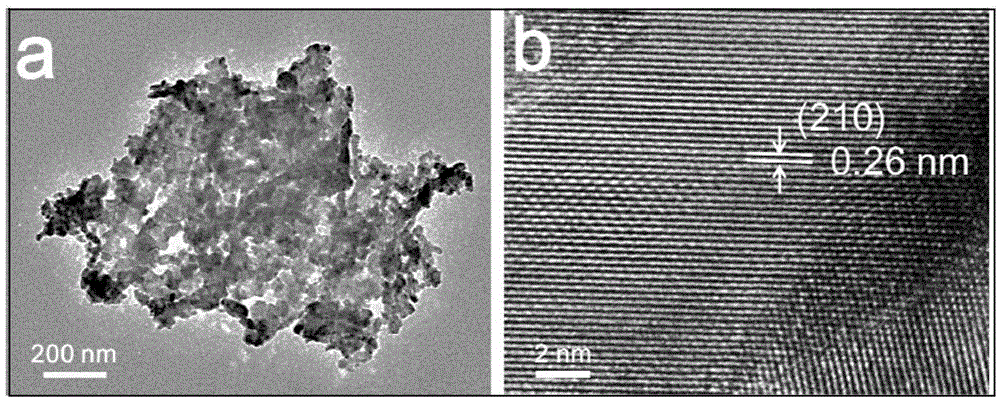

Mesoporous nanosheet structure ferronickel selenide material and preparing method and application thereof

A technology of nickel-ironselenide and nanosheets, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc. It can solve the problems of poor catalytic performance, high oxygen evolution overpotential, and low active sites and other problems, to achieve the effect of being conducive to market promotion, excellent oxygen evolution performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the mesoporous nano sheet structure nickel-iron selenide material supported on the carbon fiber cloth comprises the following steps:

[0030] 1) Add 0.75mmolNi(NO 3 ) 2 ·6H 2 O, 0.25mmolFe(NO 3 ) 3 9H 2 O, 3mmolNH 4 F and 5mmolCO(NH 2 ) 2 Dissolve in 24mL water and 12mL ethylene glycol mixed solution and stir for 30min;

[0031] 2) Set the size to 8cm 2 The carbon fiber cloth was added to the solution obtained in step 2), soaked for 30 minutes, then moved to a 50mL reaction kettle, and heated in water at 120°C for 12 hours;

[0032] 3) Take out the carbon fiber cloth in step 2), wash it twice with deionized water and absolute ethanol respectively, and dry it in an oven at 70°C;

[0033] 4) Mix 0.5mmol selenium powder, 1mmolNaBH 4 Dissolve in 36mL water and stir for 30min;

[0034] 5) Add the carbon fiber cloth dried in step 3) to the solution obtained in step 4), move it to a 50mL reaction kettle, and heat it in water at 180°C for 2...

Embodiment 2

[0039] The preparation method of the mesoporous nano sheet structure nickel-iron selenide material supported on the carbon fiber cloth comprises the following steps:

[0040] 1) Add 0.6mmolNi(NO 3 ) 2 ·6H 2 O, 0.20mmolFe(NO 3 ) 3 9H 2 O, 2 mmol NH 4 F and 5mmolCO(NH 2 ) 2 Dissolve in 20mL water and 16mL ethylene glycol mixed solution and stir for 20min;

[0041] 2) Set the size to 8cm 2 The carbon fiber cloth was added to the solution obtained in step 2), soaked for 20 minutes, then moved to a 50mL reaction kettle, and heated in water at 120°C for 9 hours;

[0042] 3) Take out the carbon fiber cloth in step 2), wash it twice with deionized water and absolute ethanol, and dry it in an oven at 65°C;

[0043] 4) Mix 0.4mmol selenium powder, 0.8mmolNaBH 4 Dissolve in 36mL water and stir for 20min;

[0044] 5) Add the carbon fiber cloth dried in step 3) to the solution obtained in step 4), move it to a 50mL reaction kettle, and heat it in water at 180°C for 24 hours to ...

Embodiment 3

[0047] The preparation method of the mesoporous nano sheet structure nickel-iron selenide material supported on the carbon fiber cloth comprises the following steps:

[0048] 1) 0.66mmolNi(NO 3 ) 2 ·6H 2 O, 0.33mmolFe(NO 3 ) 3 9H 2 O, 3mmolNH 4 F and 4mmolCO(NH 2 ) 2 Dissolve in 10mL water and 26mL ethylene glycol mixed solution and stir for 30min;

[0049] 2) Set the size to 8cm 2 The carbon fiber cloth was added to the solution obtained in step 2), soaked for 30 minutes, then moved to a 50mL reaction kettle, and heated in water at 120°C for 10 hours;

[0050] 3) Take out the carbon fiber cloth in step 2), wash it twice with deionized water and absolute ethanol, and dry it in an oven at 65°C;

[0051] 4) Mix 0.3mmol selenium powder, 0.6mmolNaBH 4 Dissolve in 36mL water and stir for 30min;

[0052] 5) Add the carbon fiber cloth dried in step 3) to the solution obtained in step 4), move it to a 50mL reaction kettle, and heat it in water at 180°C for 18 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com