Patents

Literature

87results about How to "Improve oxygen evolution performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foamed nickel-loaded iron-cobalt-nickel metal nano-catalyst and preparation method and application thereof

ActiveCN111495417AHigh catalytic activityImprove catalytic stabilityPhysical/chemical process catalystsElectrodesPtru catalystEngineering

The invention discloses a foamed nickel-loaded iron-cobalt-nickel metal nano-catalyst and a preparation method and application thereof. The method comprises the following steps: cutting foamed nickel,washing and drying for later use; dissolving three metal salts of cobalt nitrate, ferrous nitrate and nickel nitrate, ammonium fluoride and urea into deionized water; performing stirring to obtain ahydrothermal solution; then adding the pretreated foamed nickel and the prepared hydrothermal solution into a high-pressure reaction kettle, vertically putting the foamed nickel into the bottom of thehigh-pressure reaction kettle after the foamed nickel is inserted into a polytetrafluoroethylene base, fastening the high-pressure reaction kettle, putting the high-pressure reaction kettle into a blast drying oven, carrying out first-step hydrothermal treatment, performing cooling to room temperature, performing washing and drying to obtain an intermediate product; and putting the prepared precursor into a reaction kettle, carrying out a second-step hydrothermal reaction, performing cooling to room temperature, and performing washing and drying. The preparation method provided by the invention has good economy and environmental protection property, and the prepared product has excellent electro-catalytic oxygen evolution performance, high strength and good stability, and can be applied to the field of water electrolysis oxygen evolution.

Owner:YANCHENG INST OF TECH

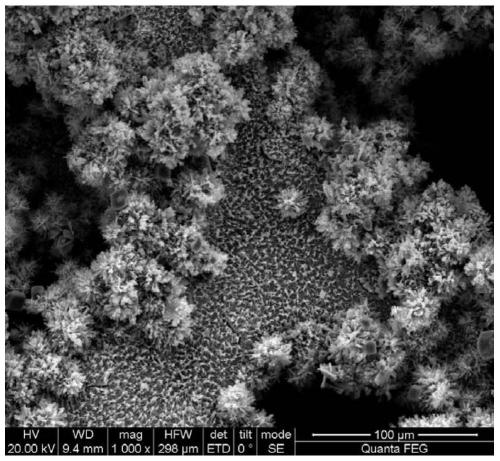

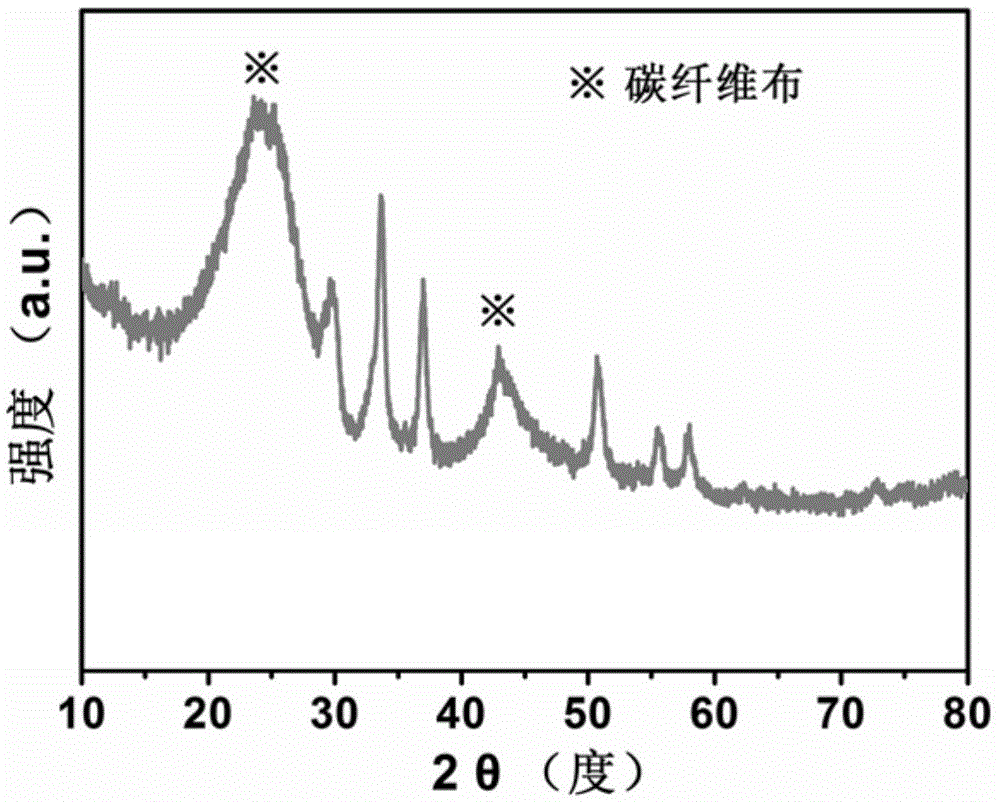

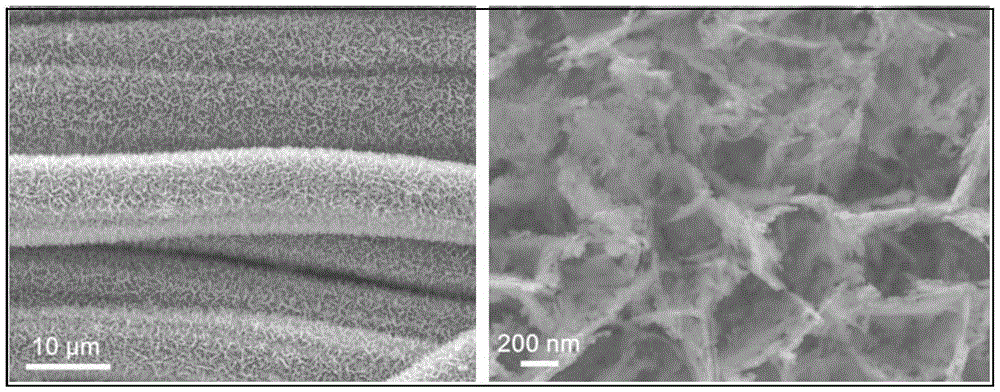

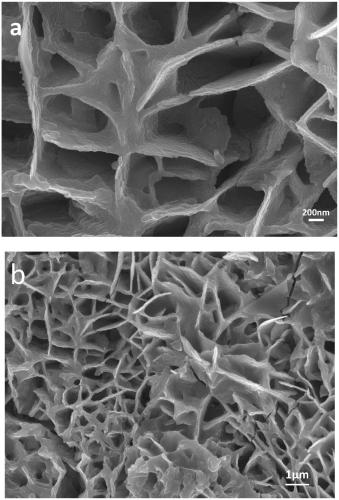

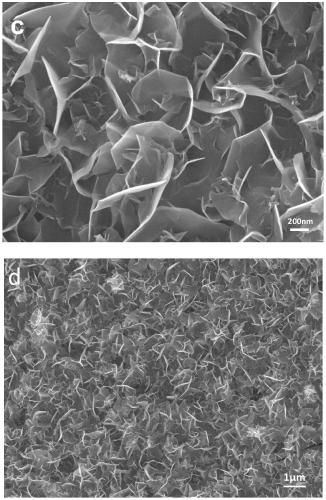

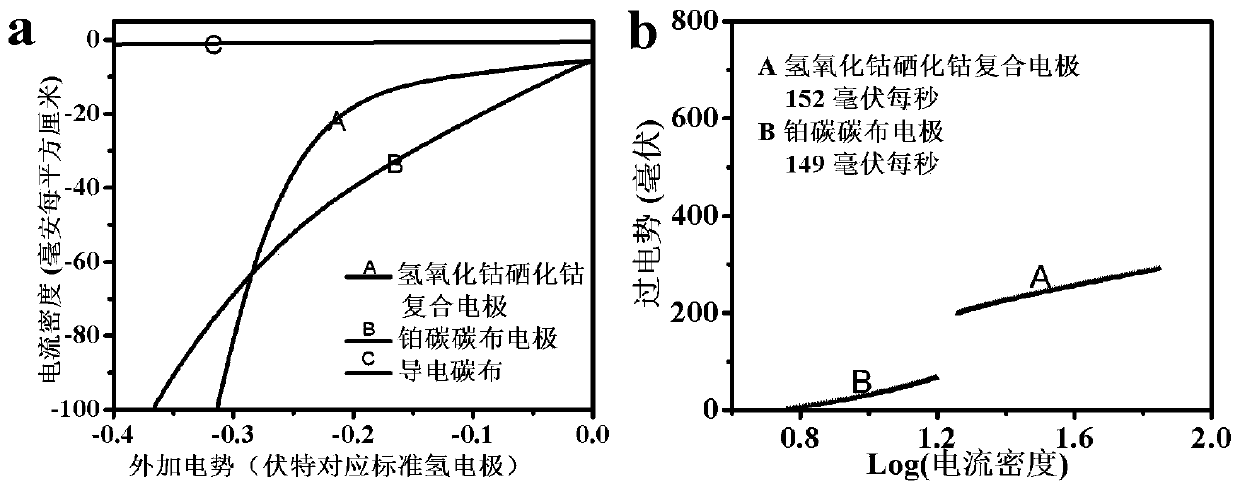

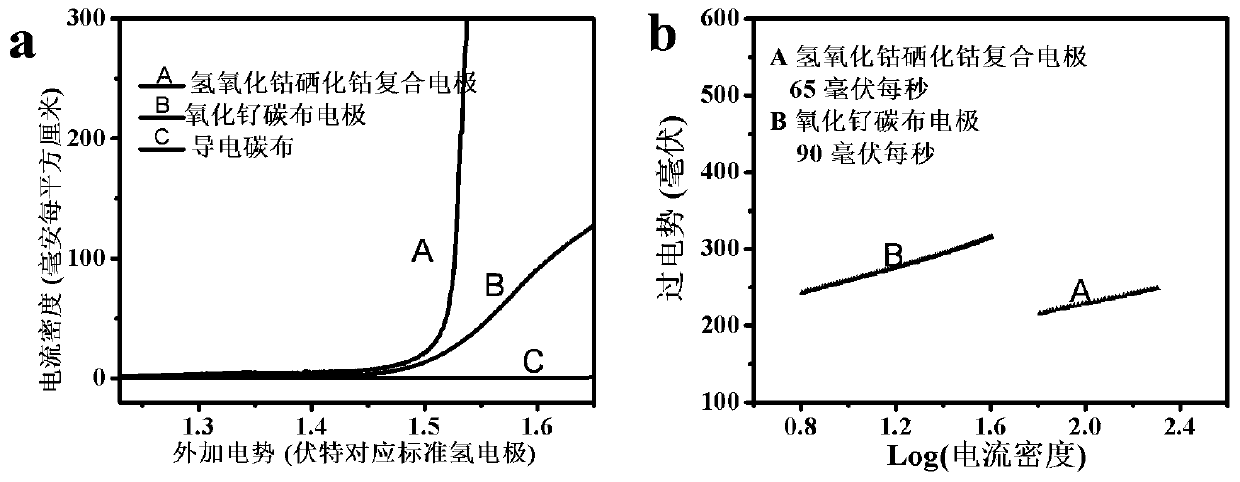

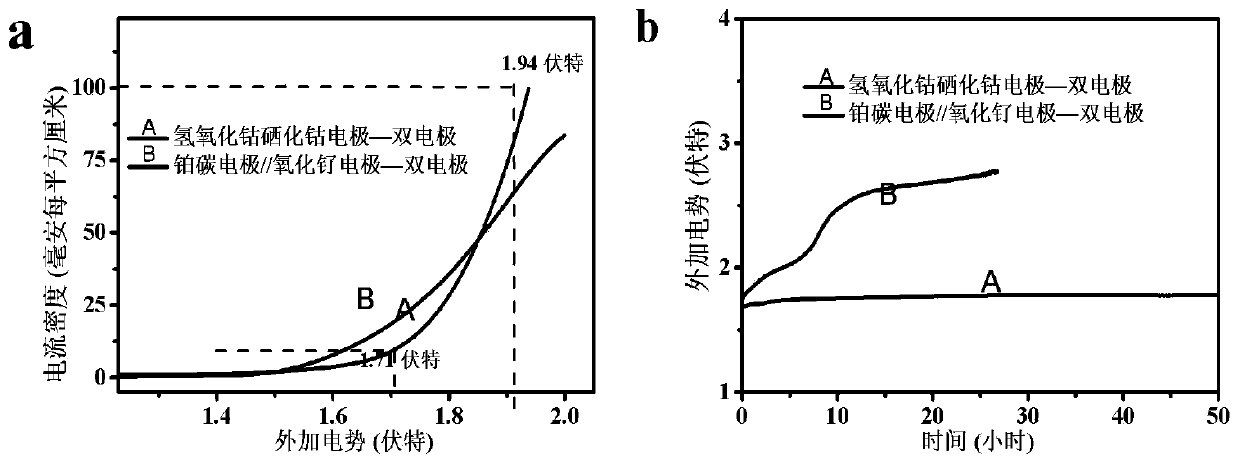

Mesoporous nanosheet structure ferronickel selenide material and preparing method and application thereof

ActiveCN105597792ALarge specific surface areaHighly electrocatalytically active sitesPhysical/chemical process catalystsElectrodesFiberElectrolysis

The invention relates to a mesoporous nanosheet structure ferronickel selenide material supported on carbon fiber cloth and a preparing method. The mesoporous nanosheet structure ferronickel selenide material can serve as a brine electrolysis catalytic oxygen evolution active material, ferronickel selenide mesoporous nanosheets are staggered and linked on carbon nanofibers to form a three-dimensional network structure, the ferronickel selenide mesoporous nanosheets are 1-3 micrometers long and 25-45 nanometers thick, and the diameter of the carbon nanofibers is 10-13 micrometers. The mesoporous nanosheet structure ferronickel selenide material has the advantages that the mesoporous nanosheet structure ferronickel selenide material supported on the carbon fiber cloth and serving as an oxygen evolution electrode has excellent catalytic activity and stability and is a potential application material for a high-catalytic-performance brine electrolysis catalytic oxygen evolution catalyst. The reaction conditions are mild, based on the unique advantages of a mesoporous structure and selenide, a controllable secondary hydrothermal method is adopted, and by changing the hydrothermal time, the mesoporous material supported on the carbon fiber cloth is prepared and meets the requirement of green chemistry; the requirement for equipment is low, which is beneficial for marketization popularization.

Owner:WUHAN UNIV OF TECH

Preparation method and product of cobalt manganese sulfide electrocatalyst

InactiveCN107855128ARaw materials are cheap and easy to getEasy to preparePhysical/chemical process catalystsElectrodesVulcanizationOxygen

The invention relates to a cobalt manganese sulfide electrocatalyst and a preparation method thereof. The preparation method comprises the following steps that 1, cobalt salt, manganese salt and ureaare weighed, the weighed cobalt salt, manganese salt and urea are dissolved in water, stirring is conducted, and evenly mixed solution is obtained; 2, the solution and carrier are placed into a reactor together to undergo a hydrothermal reaction, and supported cobalt manganese carbonate is obtained; 3, the supported cobalt manganese carbonate is put into aqueous solution containing vulcanizing agent to undergo a vulcanization reaction, and supported cobalt manganese sulfide is obtained. The cobalt manganese sulfide electrocatalyst and the preparation method have the following advantages that the adopted raw materials are cheap and easy to obtain, the preparation method is simple, operation is easy and convenient, and the cost is low; the manganese element is introduced into cobalt, binarycobalt manganese sulfide is prepared, meanwhile carbon paper, carbon cloth, foam nickel, foam copper, titanium mesh or stainless steel mesh are combined and used as substrate, the two-in-one structureof catalyst and electrode is directly formed, testing is convenient, and the catalyst is endowed with excellent electrochemical catalysis hydrogen evolution or oxygen evolution performance by means of the synergistic effect of cobalt manganese sulfide and the substrate.

Owner:JIANGHAN UNIVERSITY

Foam nickel@cobalt molybdenum phosphide/nickel iron double hydroxide electrode, preparation method and application thereof

ActiveCN110344078ALow priceReduce manufacturing costMaterial nanotechnologyElectrolytic inorganic material coatingNickel saltPhosphate

The invention relates to a foam nickel@cobalt molybdenum phosphide / nickel iron double hydroxide electrode, a preparation method and application thereof. Firstly, a three-dimensional porous coral skeleton-shaped cobalt molybdenum phosphide is formed on foam nickel, and then on the basis of the product, a vertically arranged nickel iron double hydroxide nanosheet array is prepared by electrodeposition process. The preparation method includes the steps of: first, placing foam nickel in a precursor solution of a cobalt salt and molybdate for hydrothermal reaction, under the coexistence of an inertgas and phosphate, conducting phosphatization treatment, and finally performing electrodeposition in an aqueous solution of a nickel salt and a ferrous salt, thus obtaining the foam nickel@cobalt molybdenum phosphide / nickel iron double hydroxide electrode material. The foam nickel@cobalt molybdenum phosphide / nickel iron double hydroxide electrode provided by the invention adopts a non-noble metalsalt precursor and hydrosolvent, is low in price and simple in preparation, has hydrogen evolution, oxygen evolution and full hydrolysis performance, and also has good stability.

Owner:HUBEI UNIV

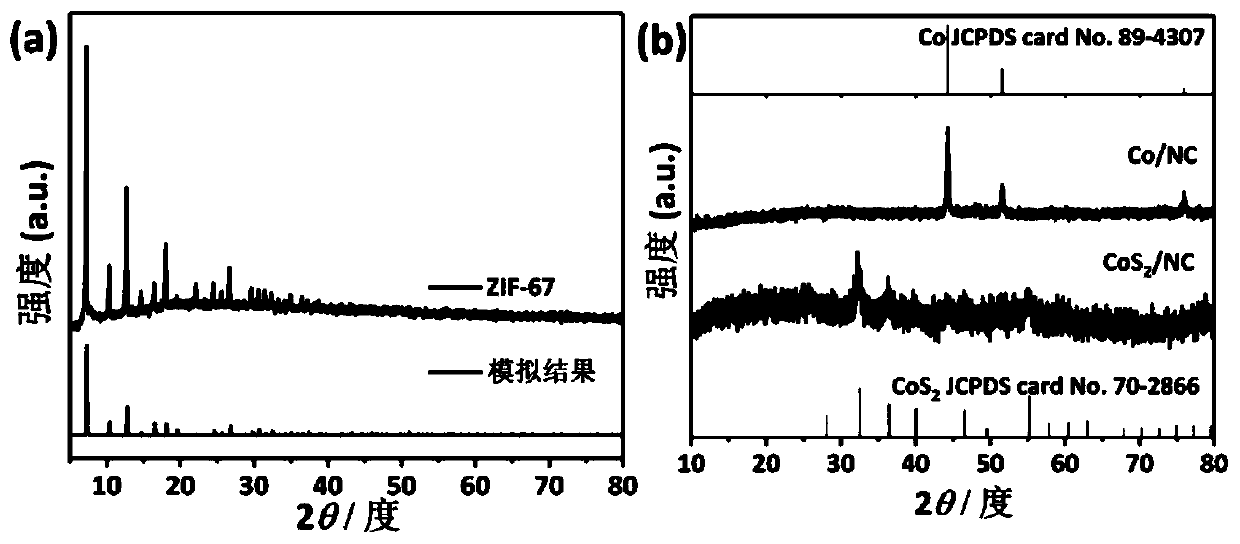

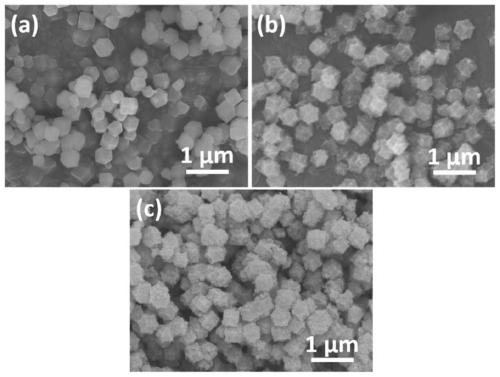

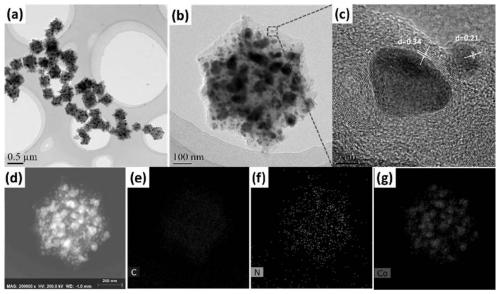

Cobalt disulfide/carbon-nitrogen composite material for water electrolysis oxygen evolution, and synthesis method thereof

ActiveCN109847778AUniform shapeImprove oxygen evolution performancePhysical/chemical process catalystsElectrodesGraphite carbonElectrolysis

The invention relates to a cobalt disulfide / carbon-nitrogen composite material for water electrolysis oxygen evolution, and a synthesis method thereof. The material is a porous dodecahedral structure,and CoS2 nanoparticles are coated with graphite carbon and are uniformly distributed on a dodecahedral carbon-nitrogen framework. The material has excellent activity and ultra-long-time stability inwater electrolysis oxygen evolution a water electrolysis anodic oxygen evolution catalyst, has excellent performances, has a far better catalysis effect than noble metals Ru and Ir, has far better performances than non-noble metal material catalysts obtained by other methods, and has a great application prospect in the field of water electrolysis oxygen evolution.

Owner:HUAZHONG NORMAL UNIV

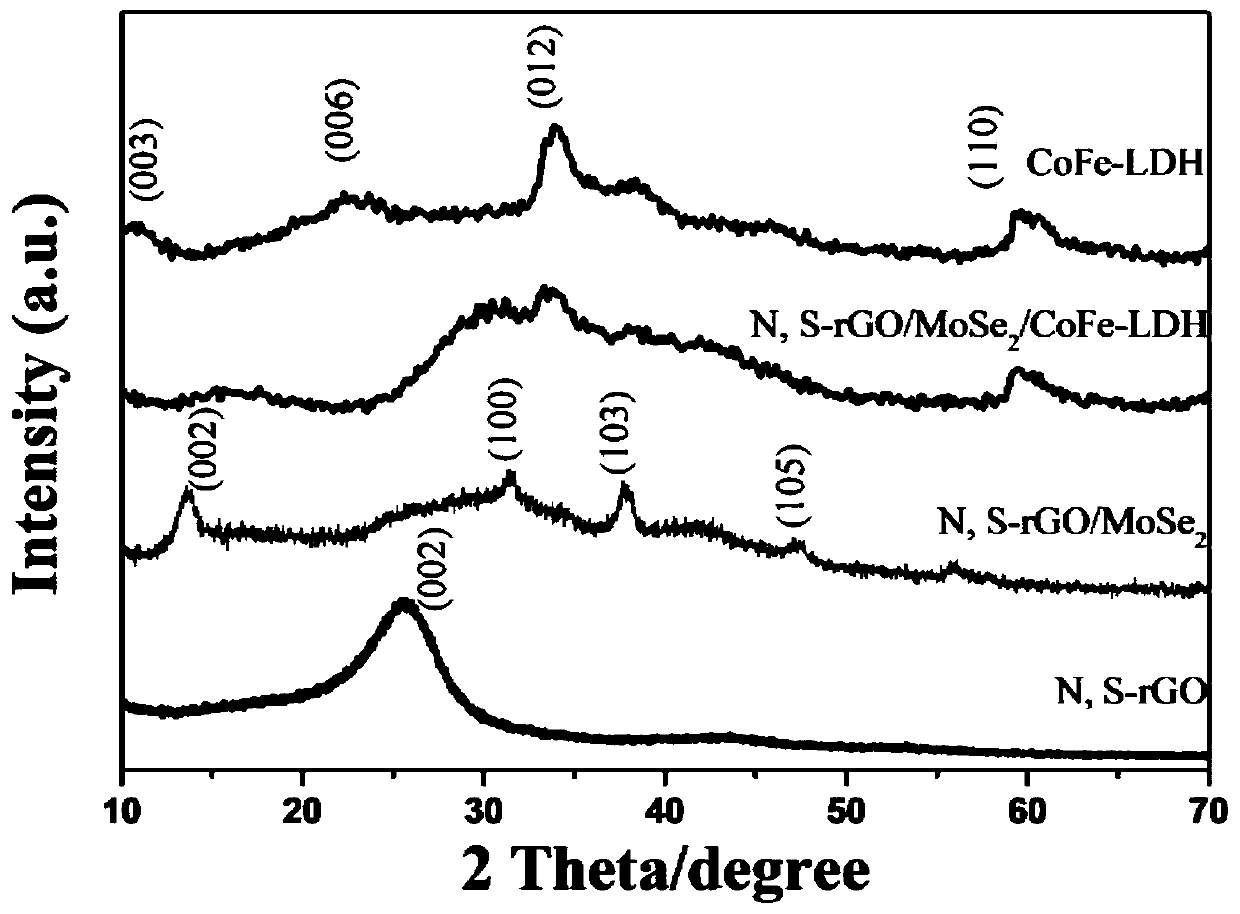

N,S-codoped graphene/molybdenum selenide/CoFe-LDH aerogel and preparation thereof

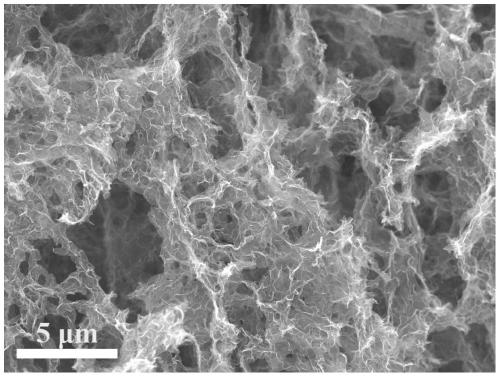

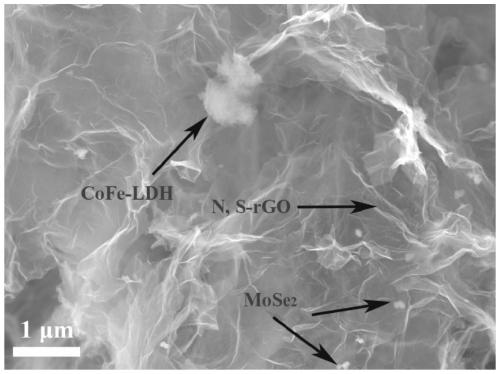

ActiveCN109778225AExcellent electrocatalytic water splitting performanceApplication value of large electrolyzed waterMaterial nanotechnologyGrapheneDoped grapheneHydrogen

A preparing method of N,S-codoped graphene / MoSe2 / CoFe-LDH aerogel is provided. The method is characterized by including S1) separately preparing a graphene oxide sheet dispersion, a MoSe2 nanosheet dispersion and a layered CoFe-LDH nanosheet dispersion; S2) mixing the graphene oxide sheet dispersion and the MoSe2 nanosheet dispersion, adding a reductant and a crosslinking agent, fully mixing the mixture, reacting the mixture to obtain N,S-codoped graphene / MoSe2 hydrogel, freeze-drying the hydrogel to obtain N,S-codoped graphene / MoSe2 aerogel; and S3) soaking the N,S-codoped graphene / MoSe2 aerogel in the layered CoFe-LDH nanosheet dispersion to obtain N,S-codoped graphene / MoSe2 / CoFe-LDH hydrogel, and freeze-drying the hydrogel to obtain the N,S-codoped graphene / MoSe2 / CoFe-LDH aerogel. The prepared ternary N,S-codoped graphene / MoSe2 / CoFe-LDH aerogel has more excellent hydrogen evolution and oxygen evolution properties under alkaline conditions.

Owner:SHANGHAI INST OF TECH

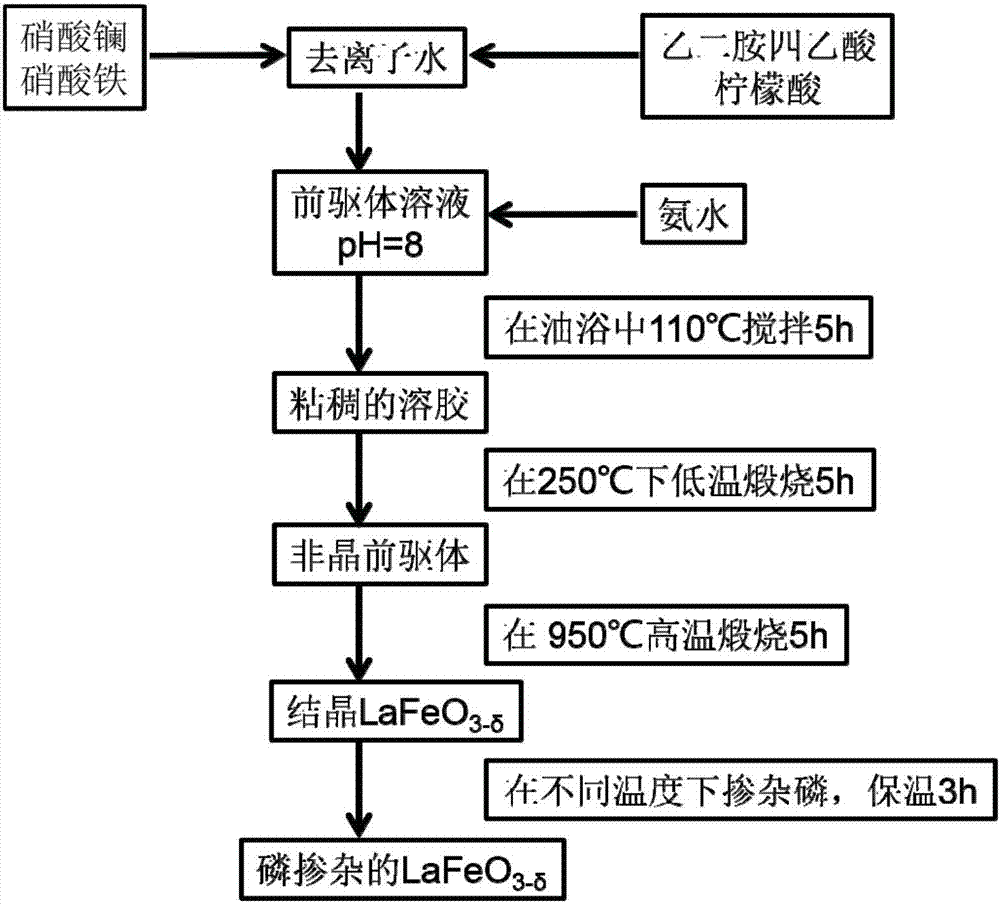

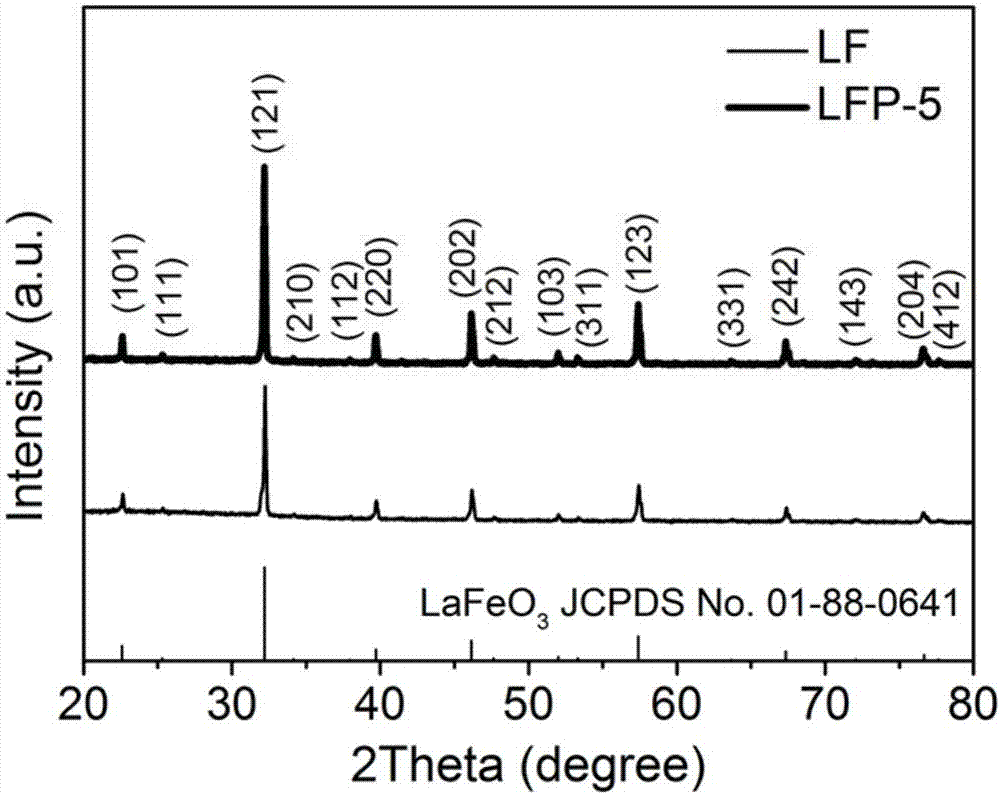

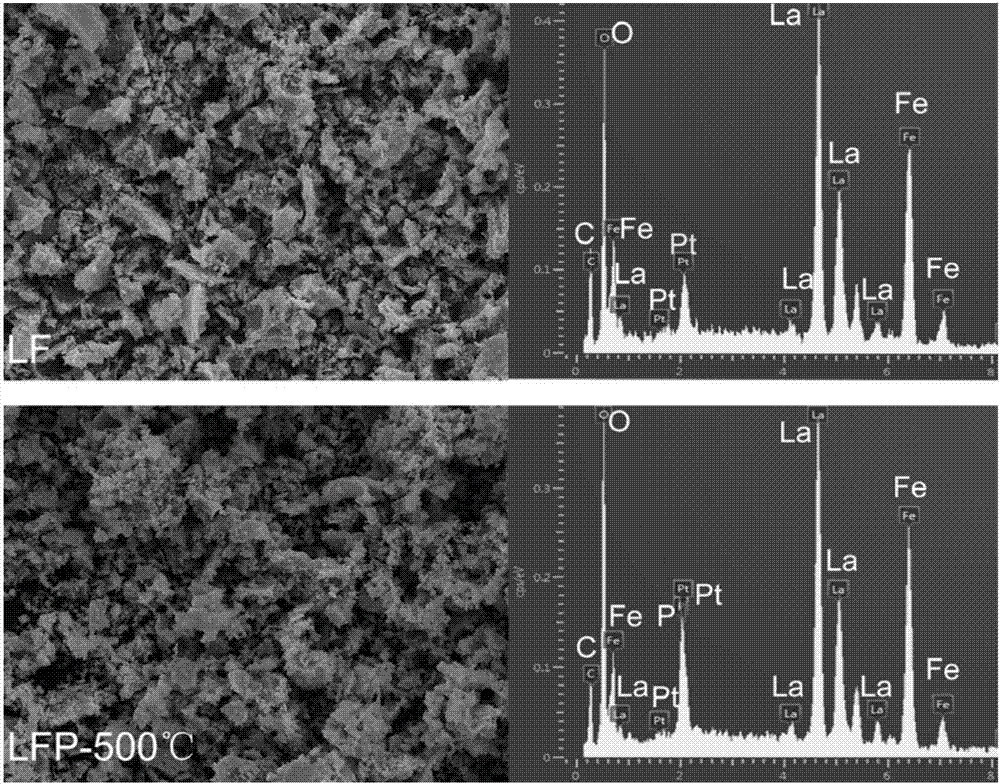

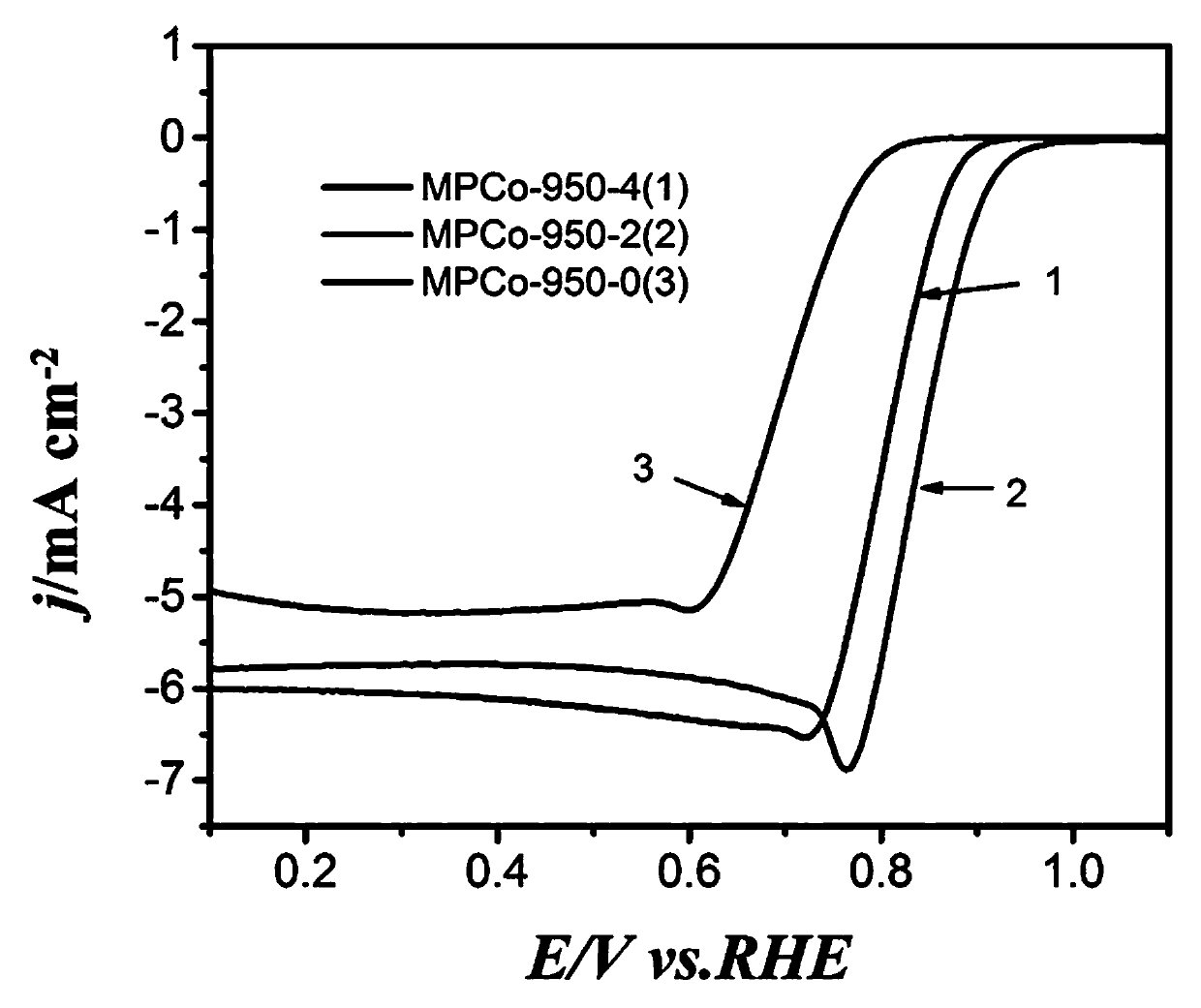

Phosphor-doped dual-function perovskite-based catalyst and preparation method thereof

InactiveCN107486212ANo pollution in the processLow costCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsEnvironmental resistanceOxygen

The invention discloses a phosphor-doped dual-function perovskite-based catalyst and a preparation method thereof. The method comprises the following steps: a perovskite oxide precursor and an organic complex are mixed to obtain a gel, the gel is subjected to low temperature calcining to remove the organic complex, a perovskite structure substance is formed through calcining under high temperature, a chemical vapor deposition technology is employed on the perovskite structure substance, then the phosphor is doped under inert gas, and the phosphor-doped dual-function perovskite-based catalyst is obtained. The catalyst breaks up the traditional metallic element doping, and the non metallic element phosphor is employed for doping perovskite to improve the oxygen reduction and oxygen evolution reaction capability and stability. The method has the advantages of simple and easy operation, short preparation period and no pollution, and can be used for substituting a method for preparing an electrode material by the noble metal catalyst with large scale.

Owner:HUAZHONG UNIV OF SCI & TECH

Carbon material with nitrogen, fluorine and transition metal co-doped graphene structure and one-step carbonization preparation method thereof

ActiveCN110148762ASimple design processEasy to operateCell electrodesCvd graphenePolytetrafluoroethylene

The invention provides a carbon material with a nitrogen, fluorine and transition metal co-doped graphene structure. Melamine, polytetrafluoroethylene and a metal salt are taken as raw materials for mixing and uniform grinding to prepare and obtain a nitrogen, fluorine and transition metal co-doped carbon material by employing a one-step carbonization method. The carbon material shows a graphene or graphene-like structure; the nitrogen, fluorine and metal elements are uniformly distributed, and the carbon material has excellent oxygen reduction and oxygen evolution performances. The one-step carbonization preparation method comprises the following steps of: 1) mixing of the raw materials; and 2) one-step carbonization method. The carbon material provided by the invention has excellent oxygen reduction and oxygen evolution performances. Besides, the excellent oxygen reduction and oxygen evolution performances of the material can be improved through regulation of the synergistic effect among the nitrogen, the fluorine and transition metal. The one-step carbonization method is good in repeatability, simple in process and easy to operate. The carbon material has wide application prospects in the fuel cell and metal-air cell electrode catalysis and the direction of functional carbon materials.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method for preparing double effect oxygen electrode catalyst

InactiveCN101425581AImprove oxygen evolution performanceThe preparation process is easy to operateCell electrodesFuel cell detailsSeawaterEfficient catalyst

The invention relates to a preparation method of a double-effect oxygen electrode catalyst, in particular to the preparation method of a regenerable fueling battery oxygen electrode catalyst taking Pt as a basis. The method comprises the following steps: directly mixing a certain amount of H2IrCI6 and H2 PtCl6 into an organic solvent; adjusting the proportion of the H2IrCI6 and the H2 PtCl6; dripping the mixture onto a conductive matrix; and preparing an IrO2 Pt efficient catalyst through the thermal decomposition method, thereby not only the oxygen-evolution catalytic activity of the catalyst can be greatly improved, the electric potential can be reduced, and the availability of the catalyst is improved, but also the preparation process is simple, and no impurity enters; the prepared product can also be used for cathodic and anodic catalysts for other fuel batteries and other fields such as gas reforming, organic matter schizolysis, pollutant treatment, seawater electrolysis, and the like.

Owner:UNIV OF SCI & TECH BEIJING

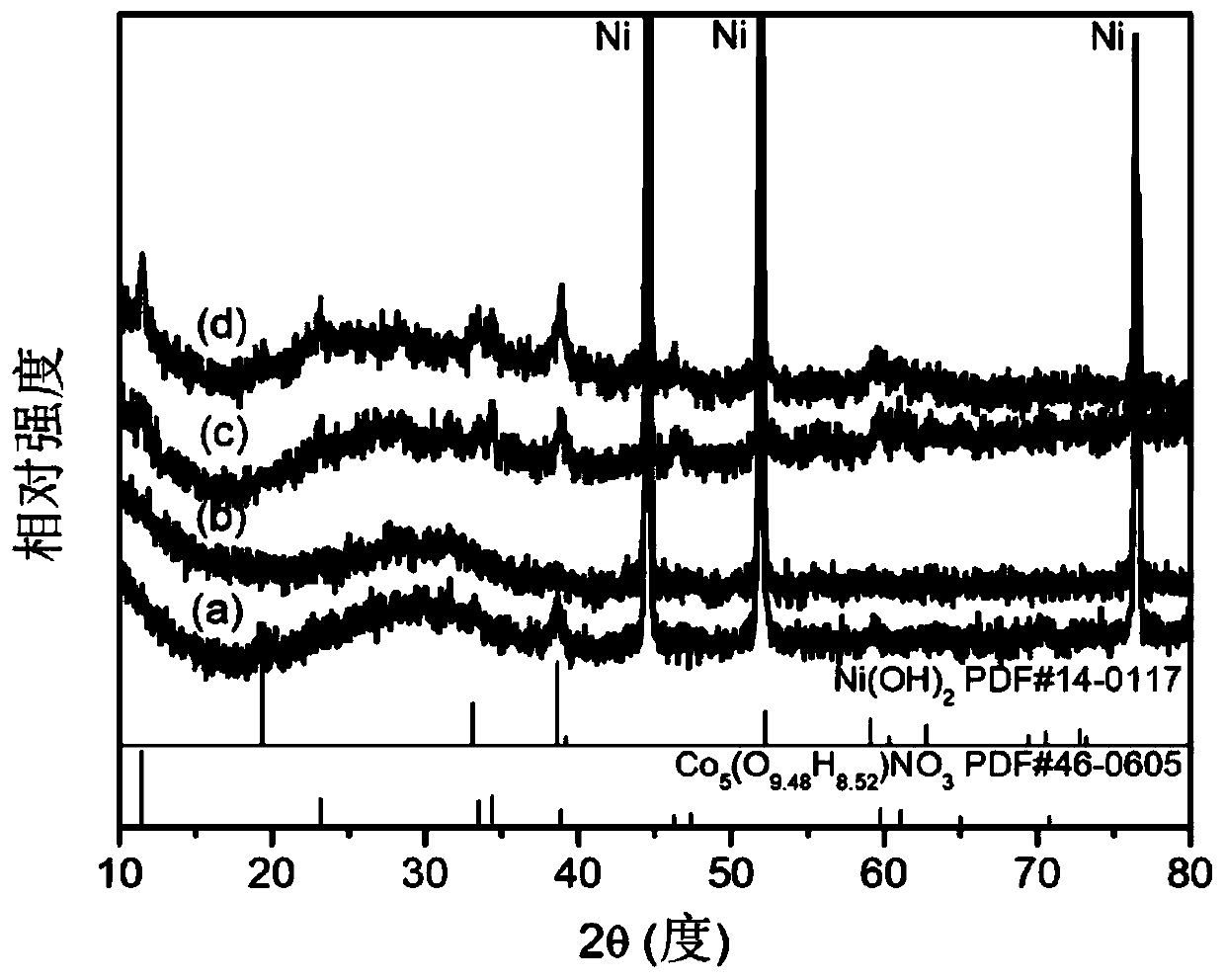

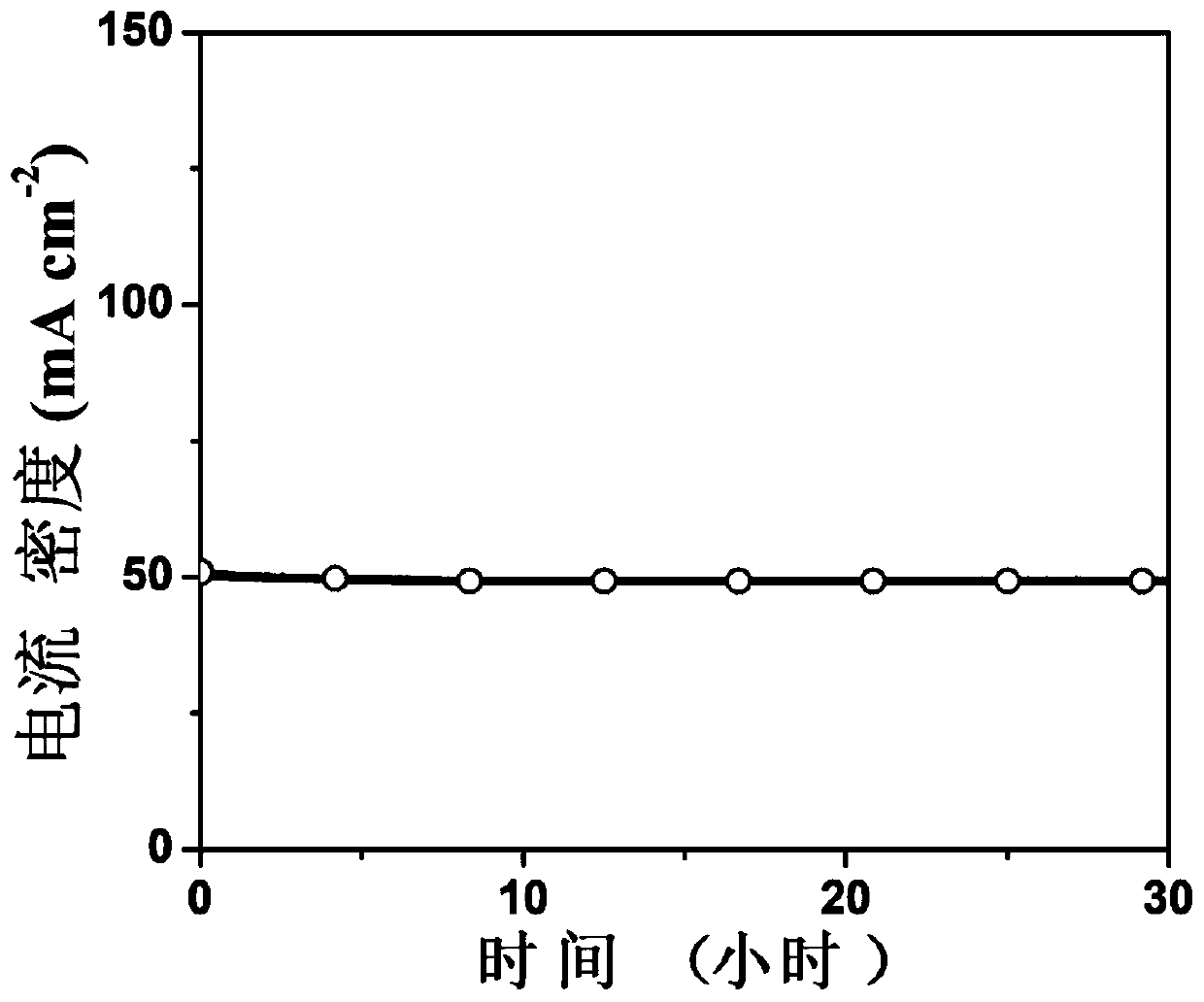

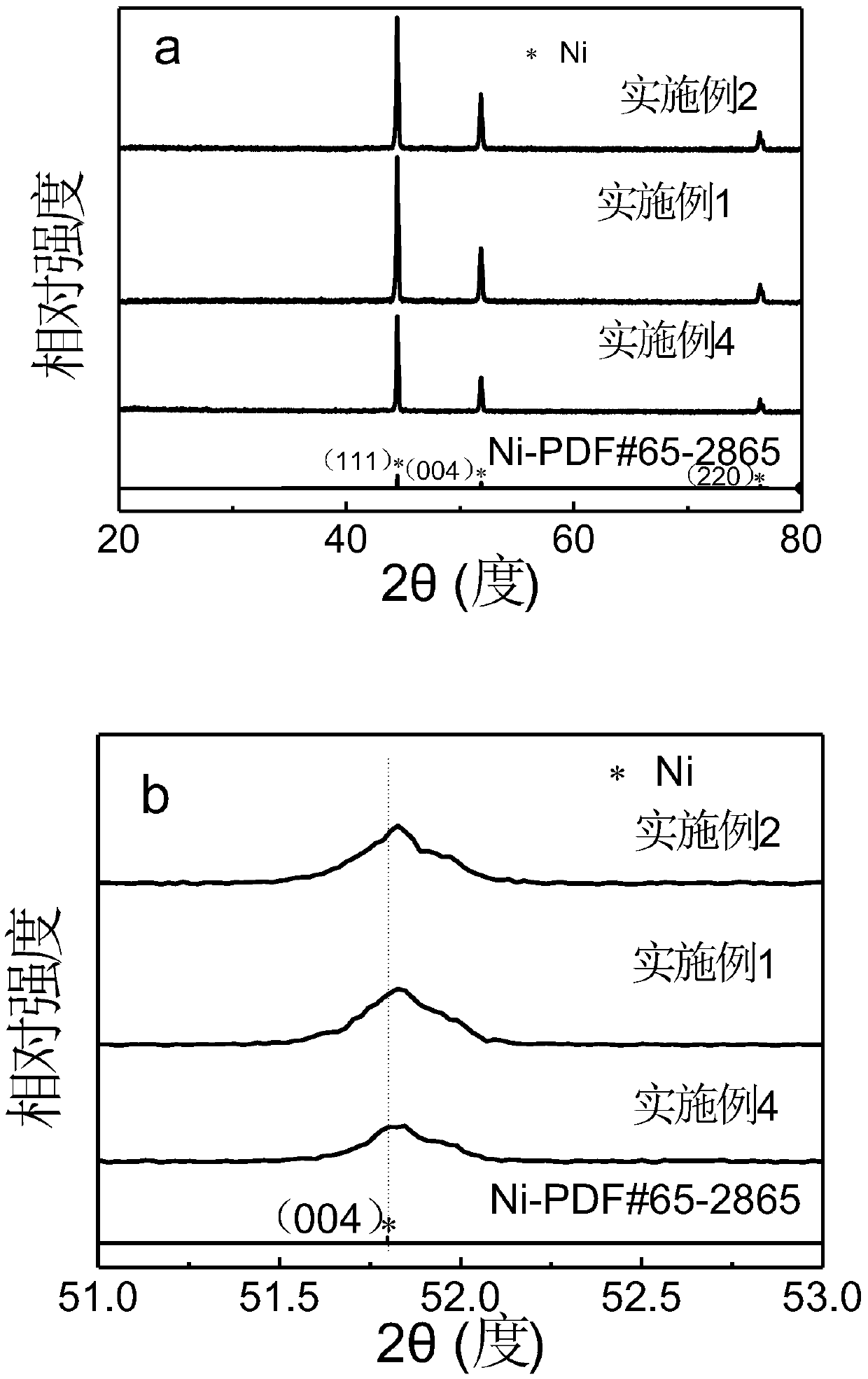

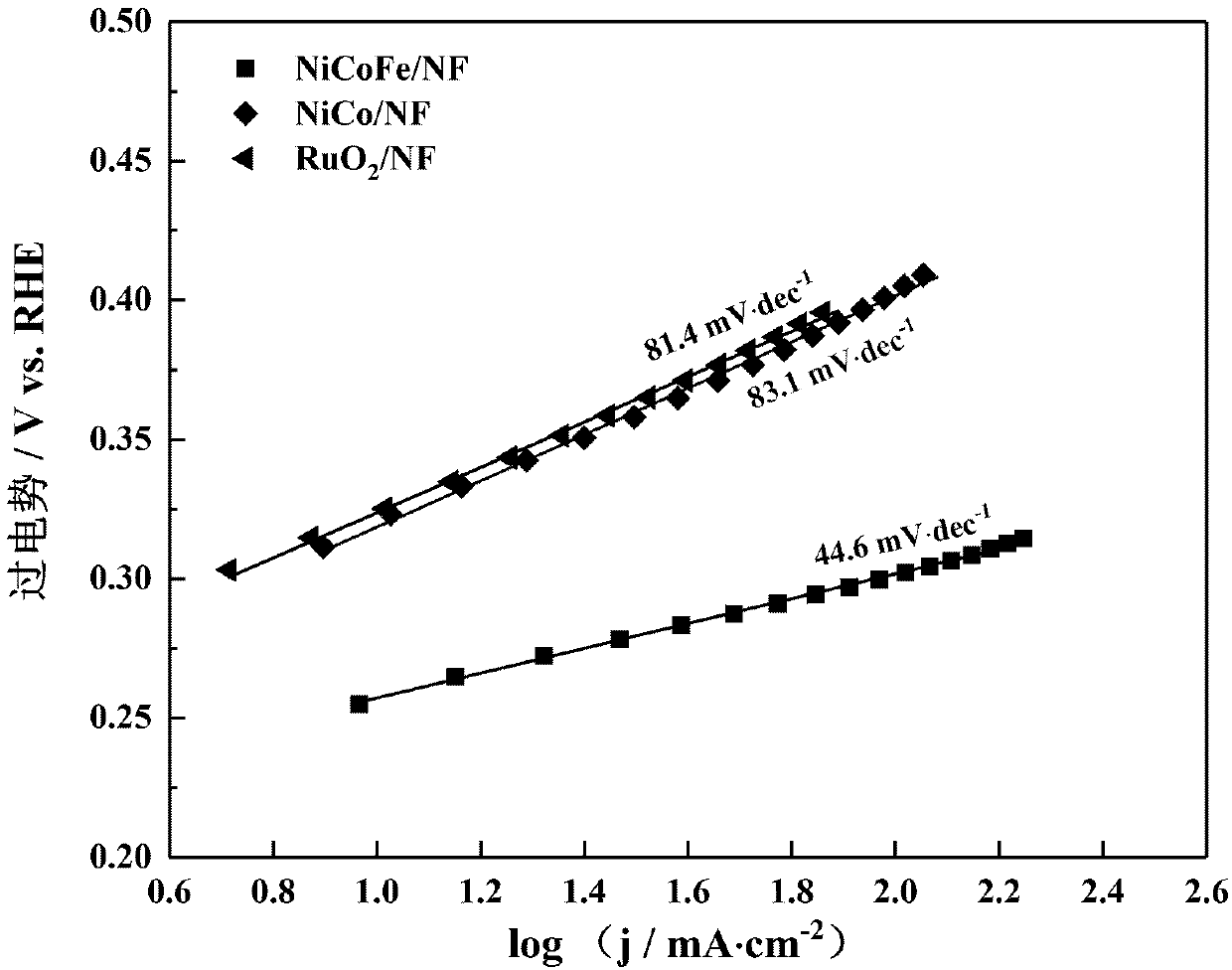

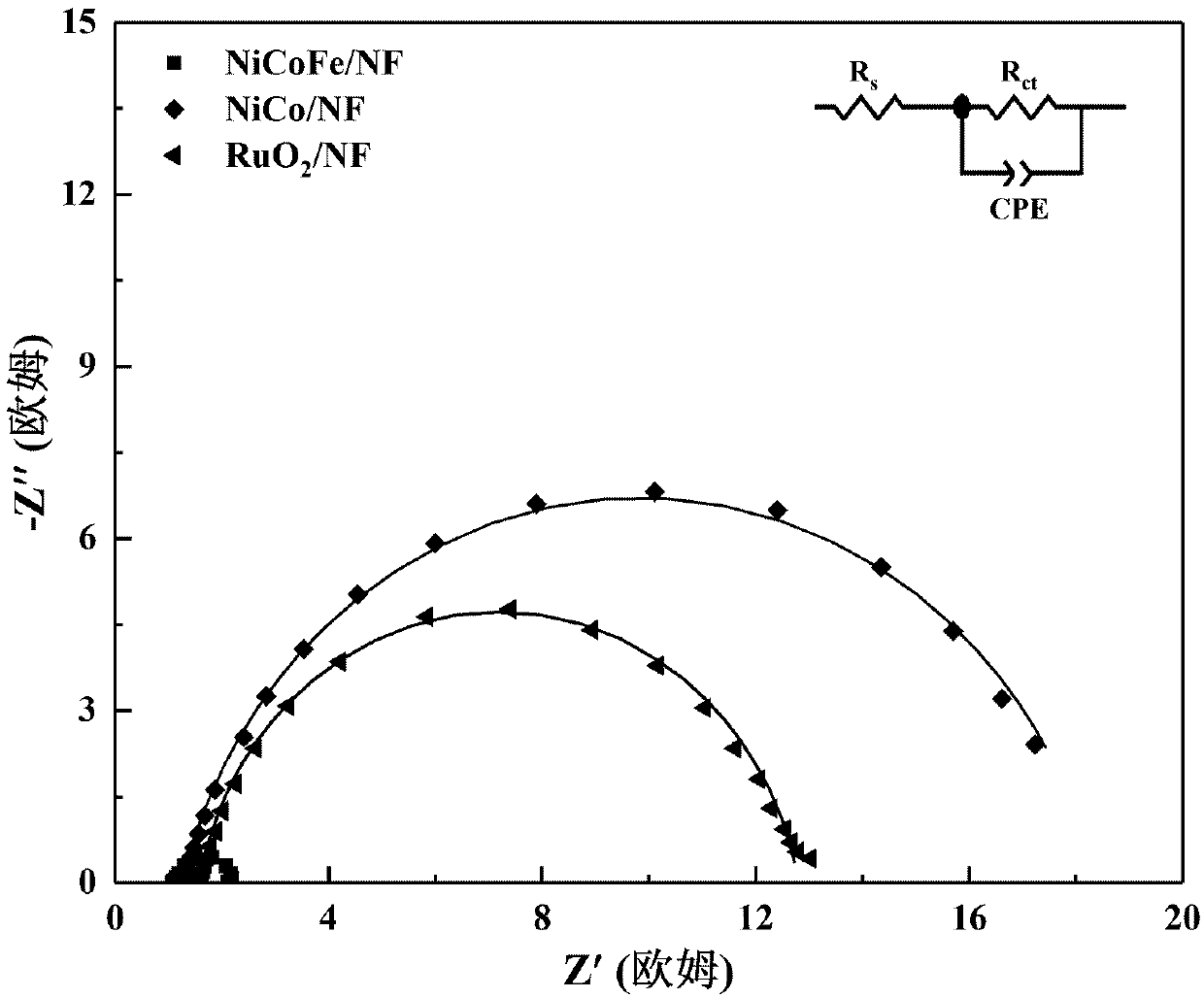

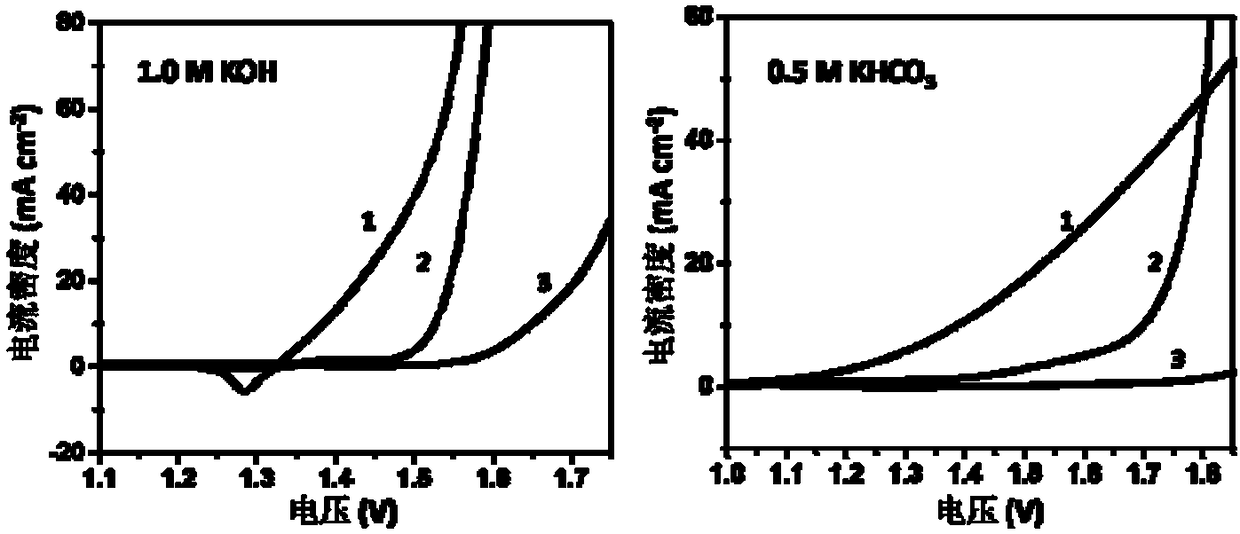

Preparation method of non-noble metal NiCoFe/NF electrocatalyst and application of electrocatalyst to oxygen evolution

ActiveCN110280249AEasy to makeRaw materials are cheap and easy to getMetal/metal-oxides/metal-hydroxide catalystsElectrodesCation exchange reactionIon exchange

The invention belongs to the technical field of electrocatalysis, and specifically relates to a preparation method of a non-noble metal NiCoFe / NF electrocatalyst and application of the electrocatalyst to oxygen evolution. The catalyst is mainly prepared by a hydrothermal reaction and a metal cation exchange reaction at room temperature in two steps, wherein in the first step, Ni-doped Co-MOF is grown on foam nickle in situ as a precursor for the next step of reaction; in the second step, obtained NiCo / NFis immersed in an aqueous solution containing ferrous sulfate, and after drying, the NiCoFe / NF catalyst is obtained. The catalyst obtained by the method can achieve the electric current density of 10 mA / cm<2> with only 252 mV of overpotential, has excellent long-term stability at the same time, and has higher oxygen evolution activity compared with other traditional non-noble metal catalysts. The preparation method involved in the invention is simple; raw materials are abundant and easy to get; large-scale production potential is realized.

Owner:QUFU NORMAL UNIV

Preparation method and application of one-dimensional/one-dimensional nanostructure assembled nickel sulfide/nickel phosphide

ActiveCN108380228AThe synthesis method is simpleEasy to operatePhysical/chemical process catalystsElectrodesDecompositionTube furnace

The invention relates to a preparation method and application of nickel sulfide / nickel phosphide formed by epitaxial growth of a one-dimensional nano-wire on a one-dimensional nano-rod. The preparation method comprises the following steps: preparing a nickel sulfide (Ni3S2) nano-rod through a hydrothermal method; then putting the Ni3S2 nano-rod into a tubular furnace and calcining under a PH3 atmosphere; while PH3 gas with strong reducibility is used for displacing S, promoting the epitaxial growth of the nano-wire on the nano-rod; finally, obtaining a one-dimensional / one-dimensional structureassembled Ni3S2-Ni12P5 material. The material plays an important role on electro-catalytic water decomposition anode oxygen evolution reaction. The one-dimensional / one-dimensional nickel sulfide / nickel phosphide material can be used as a working electrode of electro-catalytic oxygen evolution reaction; meanwhile, the one-dimensional / one-dimensional nickel sulfide / nickel phosphide material also can be used for fields including a water electrolysis technology, solar water electrolysis for producing oxygen, carbon dioxide reduction and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

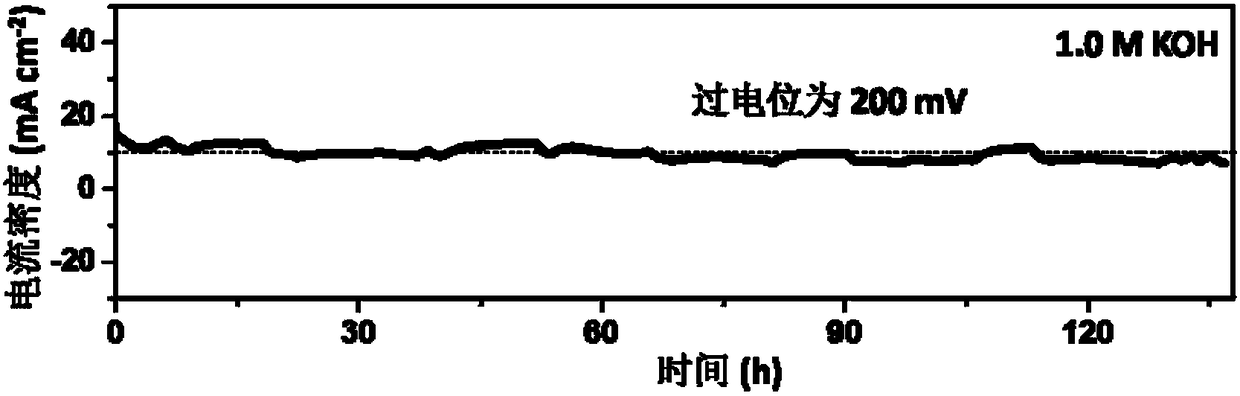

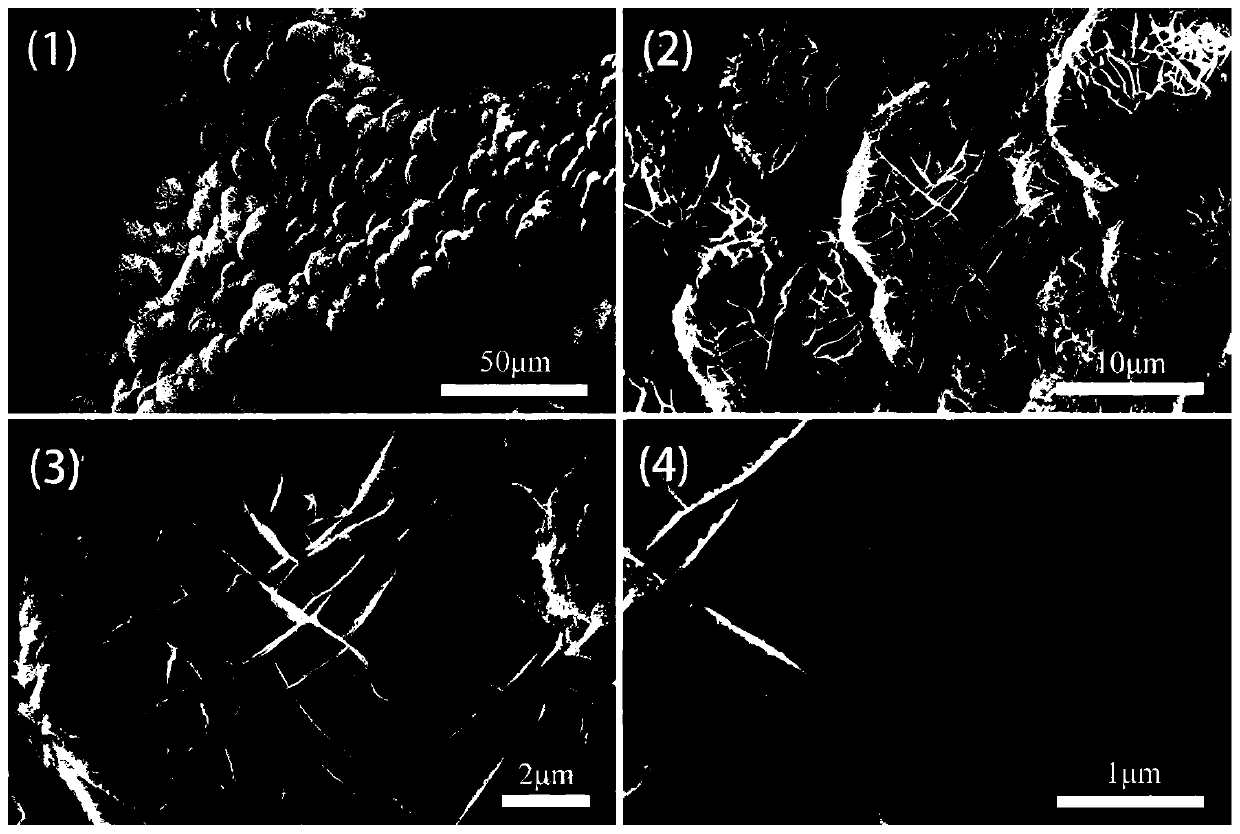

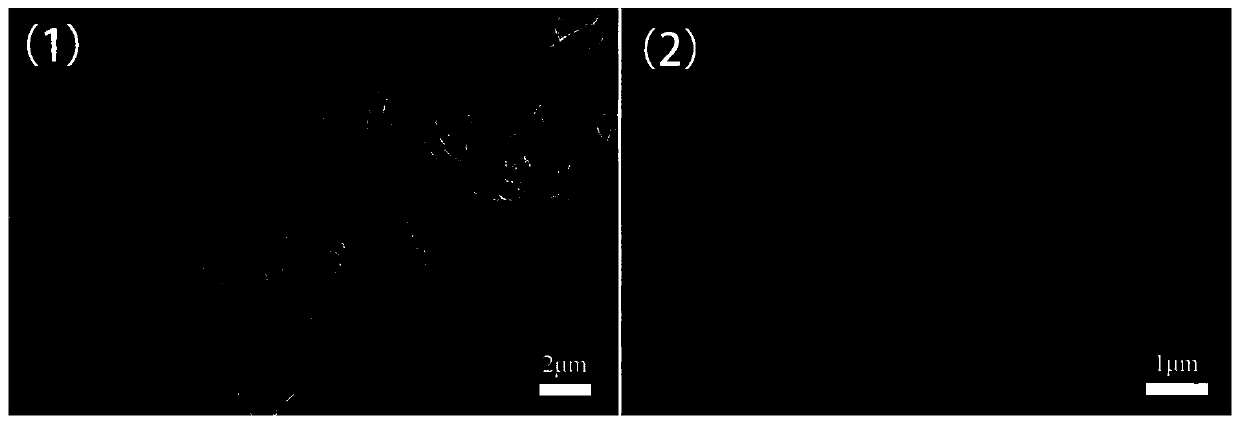

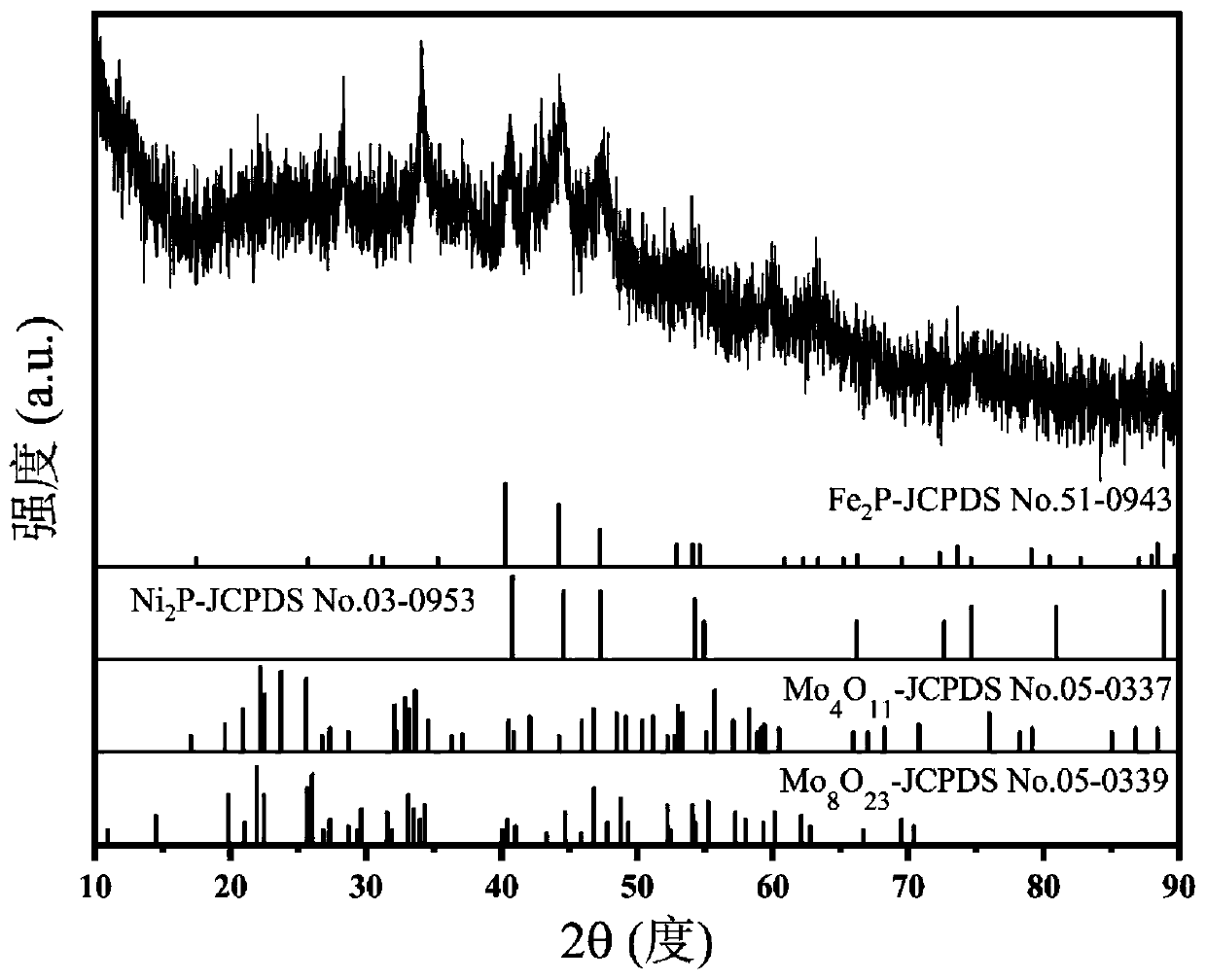

Efficient total water splitting electrocatalyst IPBAP/Ni2P@MoOx/NF and preparation method thereof

ActiveCN110711596ASimple manufacturing methodIncrease intrinsic activityPhysical/chemical process catalystsElectrodesPtru catalystPotassium ferricyanide

The invention belongs to the field of new energy materials, and particularly relates to an efficient total water splitting electrocatalyst IPBAP / Ni2P@MoOx / NF and a preparation method thereof. The electrocatalyst is an in-situ composite material of a Prussian blue analogue phosphide, nickel phosphide, molybdenum oxide and foamed nickel and is prepared by subjecting ammonium molybdate and nickel nitrate in a certain proportion to a hydrothermal reaction to synthesize a nanometer flower-ball-shaped precursor, then dipping and loading with a potassium ferricyanide solution, and carrying out low-temperature phosphating treatment. According to the electrocatalyst, the excellent hydrogen evolution performance of the molybdenum oxide and the excellent oxygen evolution performance of the Prussian blue analogue are combined, the excellent hydrogen evolution performance is kept, meanwhile, the oxygen evolution performance is improved to a great extent, and the electrocatalyst with the efficient total water splitting performance is obtained.

Owner:JIANGXI UNIV OF SCI & TECH

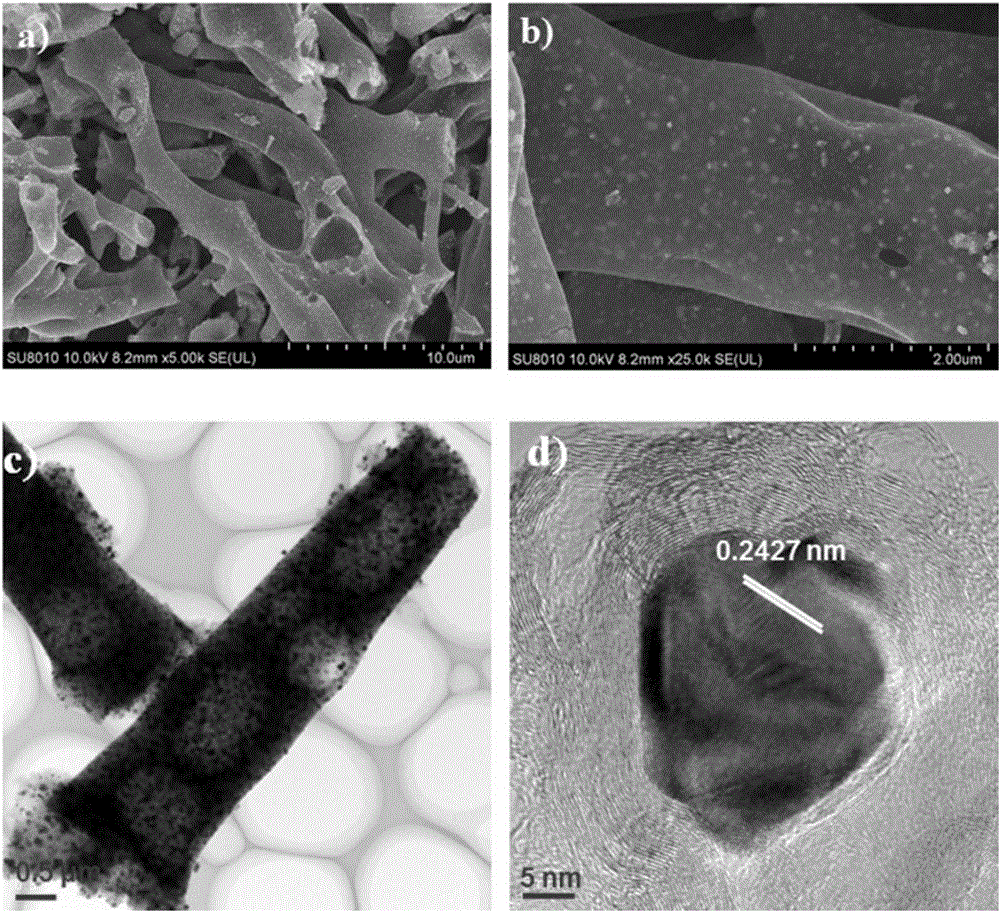

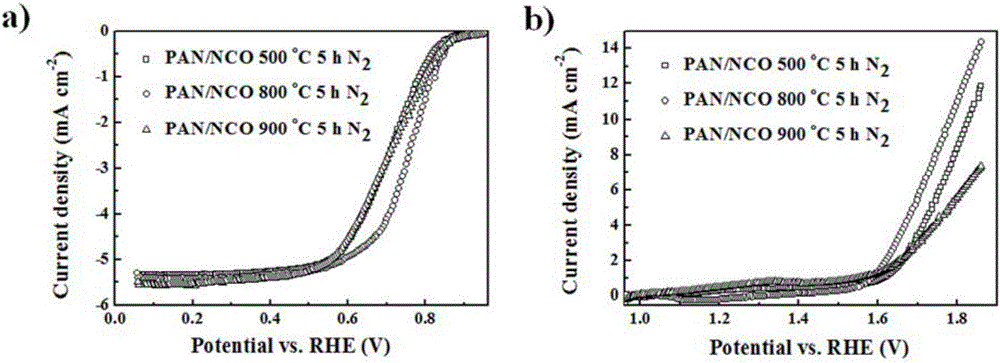

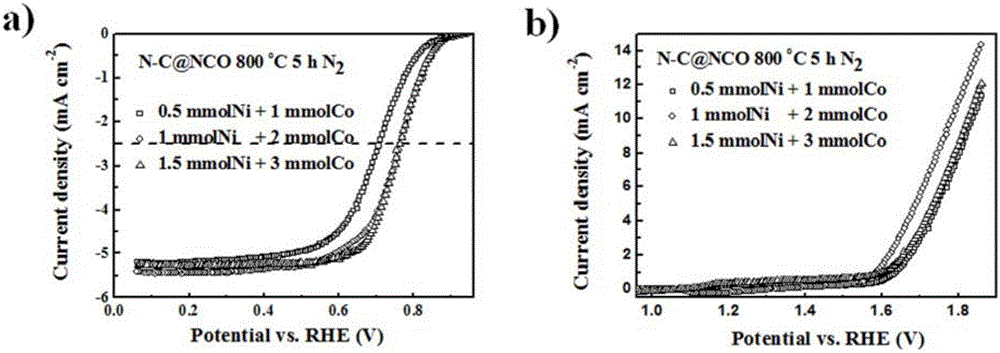

Preparation method for carbon/metal oxide nanofiber composite catalyst

InactiveCN106654301AImprove conductivityEnhanced electrocatalytic performance for oxygen reductionFuel and secondary cellsCell electrodesOxygenOxygen evolution

The invention relates to a preparation method for a carbon / metal oxide nanofiber composite catalyst. The preparation method comprises the following steps of (a), dissolving a metal ion-containing salt solution and a high-molecular polymer into an organic solvent, and stirring to form a spinning precursor mixed solution, wherein the metal ion concentration is weighed based on a stoichiometric ratio; (b), performing electrostatic spinning on the spinning precursor mixed solution to form a composite non-woven material; and (c), putting the composite non-woven material into an inert atmosphere to be subjected to high-temperature calcining to obtain the carbon / metal oxide nanofiber composite catalyst. The carbon / metal oxide nanofiber composite catalyst has high electrical conductivity, reinforced oxygen reduction electro-catalytic property and excellent oxygen evolution performance, and is a dual-functional catalyst with efficient catalytic property.

Owner:SUZHOU UNIV

High-efficiency bifunctional water decomposition electrocatalyst and preparation method thereof

ActiveCN110479320AGood hydrogen evolutionHigh activityMaterial nanotechnologyCatalyst activation/preparationHigh current densityDecomposition

The invention provides a high-efficiency bifunctional water decomposition electrocatalyst and a preparation method thereof, and relates to the technical field of electrocatalytic water decomposition.The preparation method comprises the following steps: mixing cobalt acetate, ammonium fluoride, urea and a solvent to obtain a mixed solution; immersing carbon cloth into the mixed solution for hydrothermal reaction to obtain carbon cloth with a cobalt nanorod precursor growing on the surface; and then carrying out electrochemical conversion on the carbon cloth with the cobalt nanorod precursor growing on the surface to obtain the efficient bifunctional water decomposition electrocatalyst. A three-electrode system is adopted in electrochemical conversion, carbon cloth with a cobalt nanorod precursor growing on the surface serves as a working electrode, a saturated calomel electrode serves as a reference electrode, and a mixed solution of selenium dioxide, potassium chloride and water serves as an electrolyte. The electrocatalyst prepared by the invention has high hydrogen evolution activity, high oxygen evolution activity and good stability, can efficiently realize full water decomposition, and promotes the electrocatalytic water decomposition to develop towards the practical direction of higher current density and lower external potential.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES

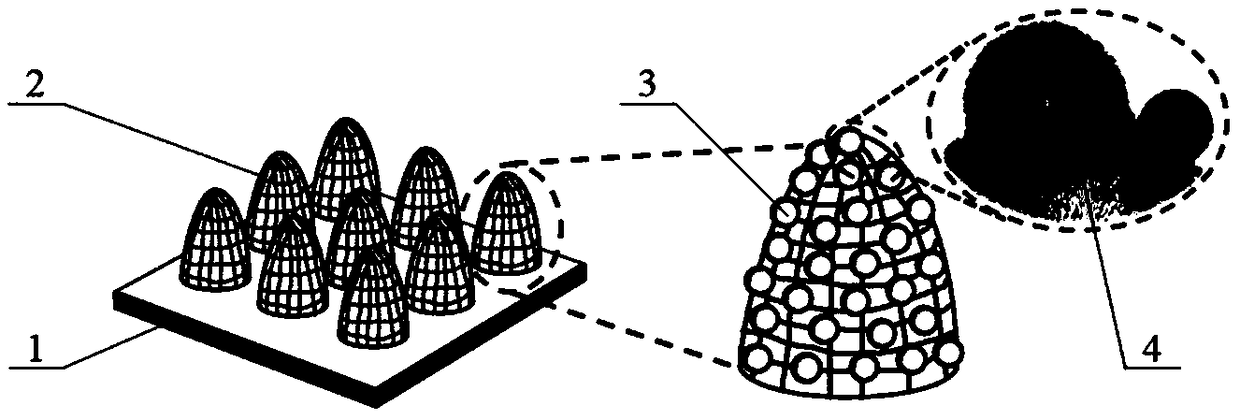

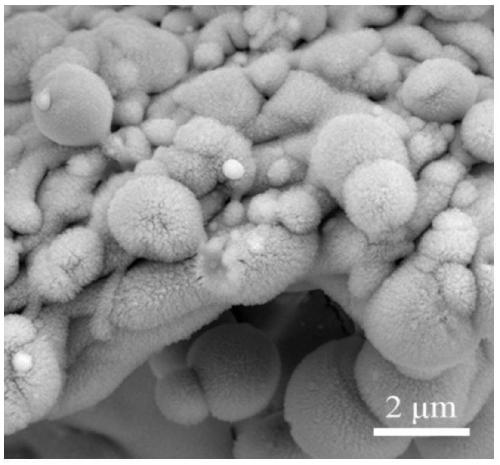

Stainless steel base water electrolysis catalytic electrode and manufacturing method thereof

The invention belongs to the technical field of manufacturing of electro-catalysis materials and provides a stainless steel base water electrolysis catalytic electrode and a manufacturing method of the stainless steel base water electrolysis catalytic electrode. According to the stainless steel base water electrolysis catalytic electrode, a three-dimensional micron protrusion array is distributedon a stainless steel matrix. Micro-spheres of different sizes are distributed on the surface of the protrusion array at random. The surfaces of the micro-spheres are covered with oxide nanometer flossy structures formed by disordered stacking of nanometer particles. The manufacturing method of the stainless steel base water electrolysis catalytic electrode comprises the steps that firstly, high-energy-density pulse laser is utilized to conduct ablation on the surface of the stainless steel matrix so that the micron protrusion array can be formed; then, nanosecond pulse laser is utilized to conduct ablation on the surface of the protrusion array so that the micro-spheres and the nanometer flossy structures can be formed, and then the self-supporting electrolytic electrode without the need for an adhesion agent is obtained. The stainless steel base water electrolysis catalytic electrode has excellent water electrolysis hydrogen and oxygen evolution performance, overall water splitting performance and high stability; the manufacturing method is simple and controllable, large-area manufacturing can be achieved, raw materials are low in cost and easy to obtain, and the stainless steel base water electrolysis catalytic electrode can be used for wide application fields such as the field of hydrogen for fuel cell cars, the field of underwater equipment oxygen generation, the field of medical oxygen generation, the field of hydrogen water cups, the field of highland oxygen generation and the field of portable hydrogen and oxygen generating devices.

Owner:TSINGHUA UNIV

NiS/NiO heterojunction-loaded nitrogen-doped carbon nano composite material and preparation method and application thereof

ActiveCN111659439ALarge specific surface areaIncrease contactCatalyst activation/preparationElectrodesFiberAir atmosphere

The invention provides a NiS / NiO heterojunction-loaded nitrogen-doped carbon nano composite material and a preparation method and application thereof. The preparation method comprises the following steps: S1, preparing Ni < 2 + > / PVP mixed sol; S2, performing electrostatic spinning on the Ni < 2 + > / PVP mixed sol to obtain a solid carbon fiber film; and S3, pre-oxidizing the solid carbon fiber film in an air atmosphere, and sequentially carrying out heat treatment in an inert atmosphere, oxidation treatment in the air atmosphere and sulfuration vapor deposition to obtain the NiS / NiO heterojunction-loaded nitrogen-doped carbon nano composite material. PVP selected in the method is cheap and easy to obtain, and compared with a traditional method for preparing the water electrolysis oxygen evolution electrocatalyst material, the method is simple and feasible in process, low in cost and easy to operate, and large-scale production can be achieved.

Owner:NANJING NORMAL UNIVERSITY

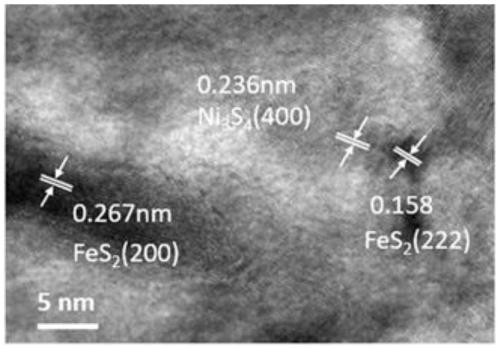

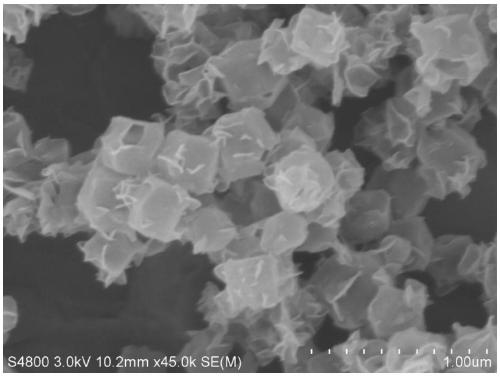

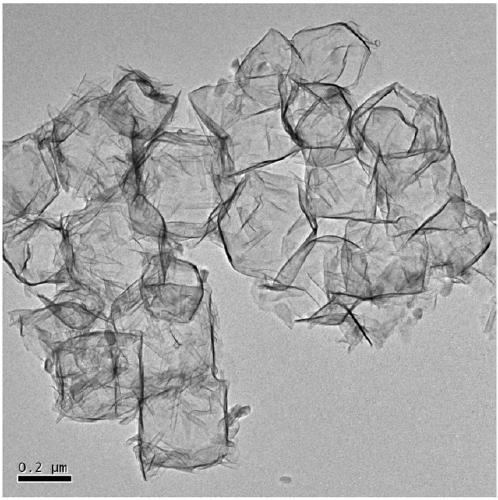

High-performance ferronickel-based oxygen evolution electrocatalytic nano composite material as well as preparation method and application thereof

ActiveCN111589458ARaw materials are cheap and easy to getSimple and mild preparation conditionsPhysical/chemical process catalystsElectrodesActive siteOxygen evolution

The invention relates to a high-performance ferronickel-based oxygen evolution electrocatalytic nano composite material as well as a preparation method and application thereof. The composite materialis composed of uniform nanosheets formed by mutually crosslinking nickel tetrasulfide and iron disulfide. The composite material contains high-valence metal ions Ni3+, so that the active sites of OERare increased, the coordination effect between ferronickel is enhanced, and the electro-catalytic performance is further improved. The composite material has the advantages of simple preparation process, high efficiency, mild synthesis conditions, environmental friendliness and the like, has higher catalytic activity and good electrochemical stability, is suitable for the field of electrochemistry, and has higher potential practical value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

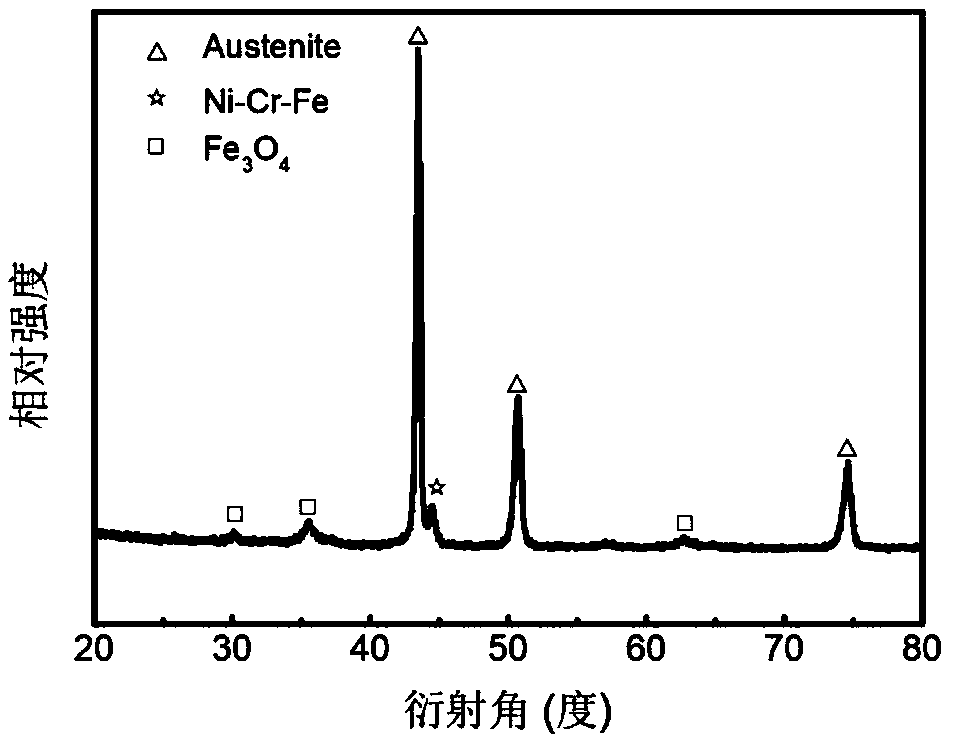

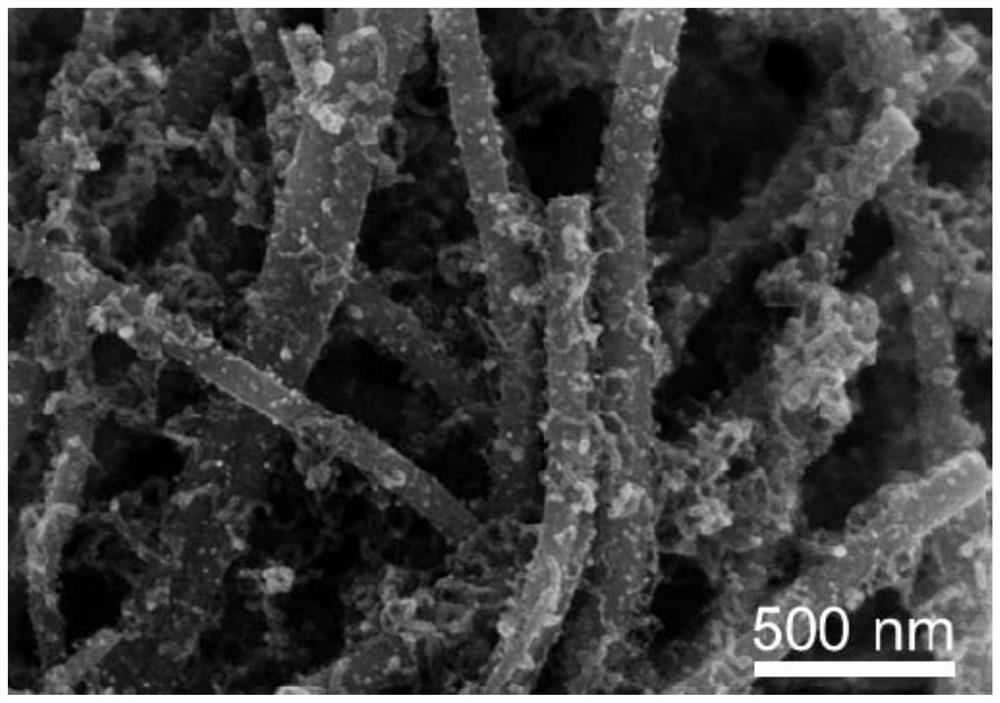

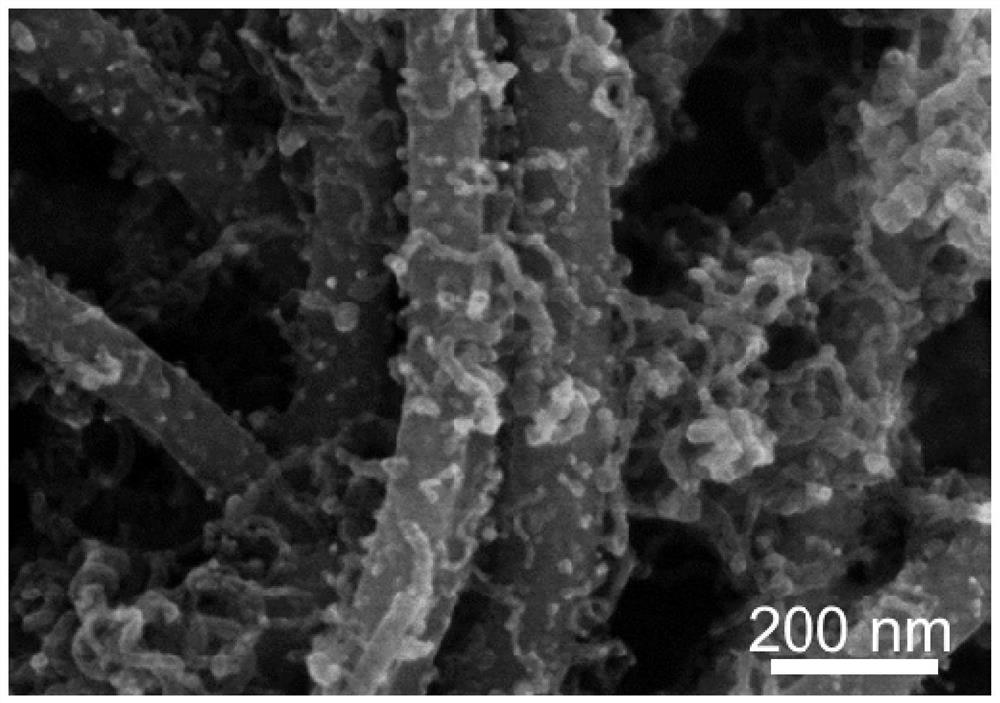

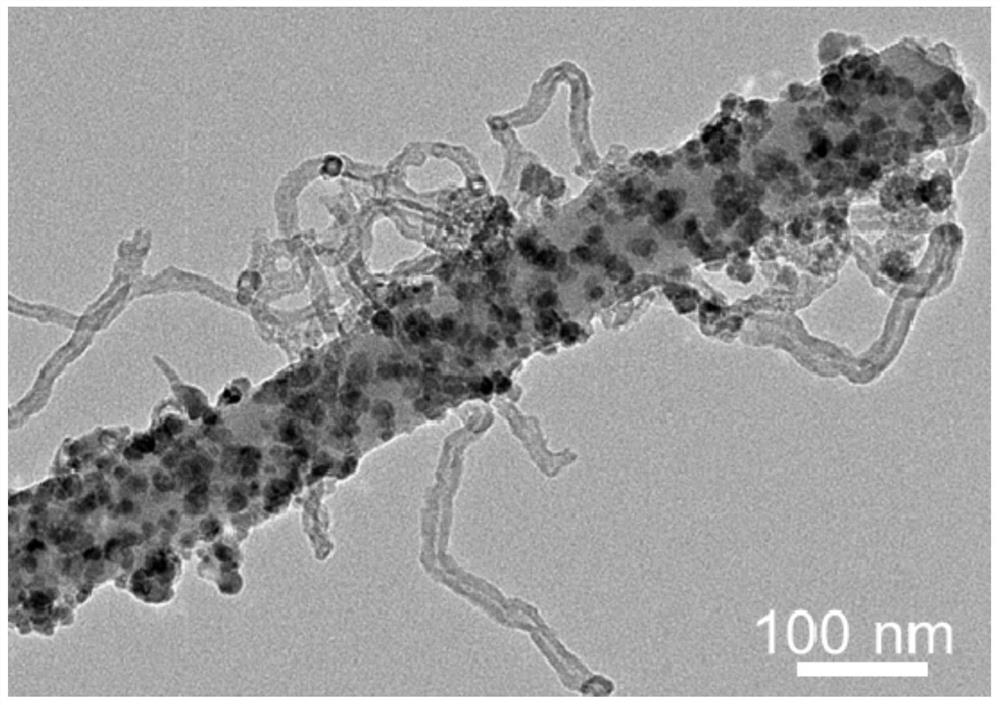

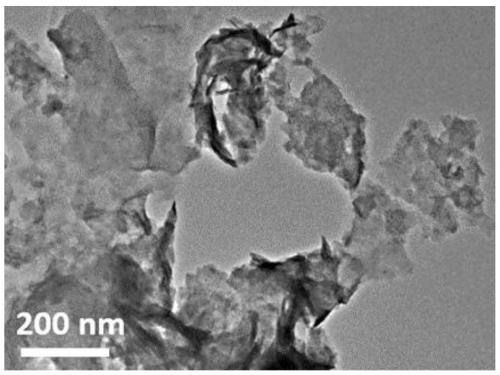

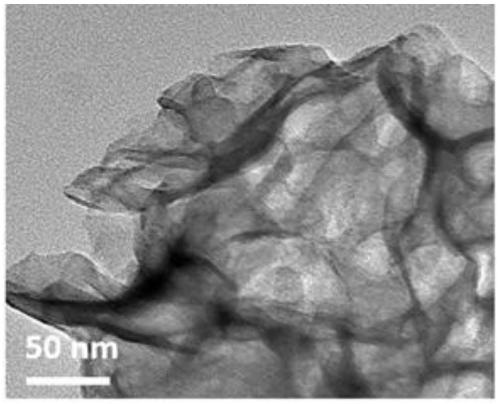

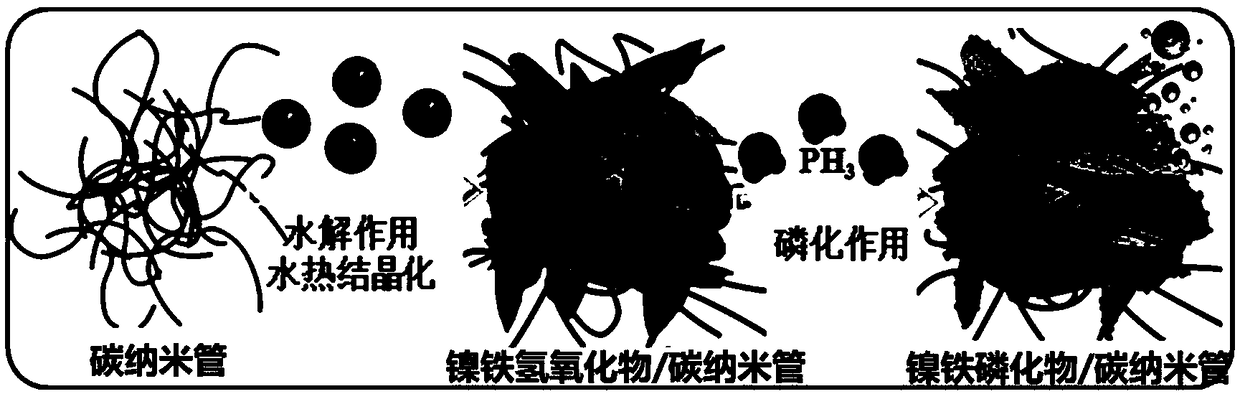

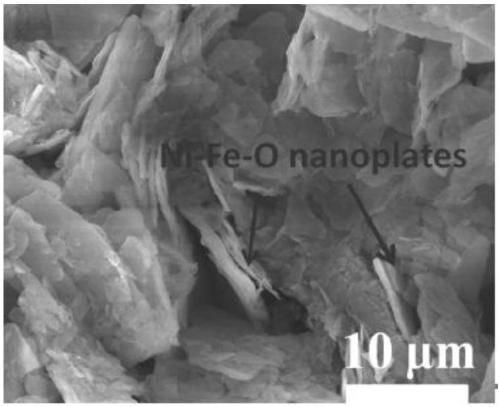

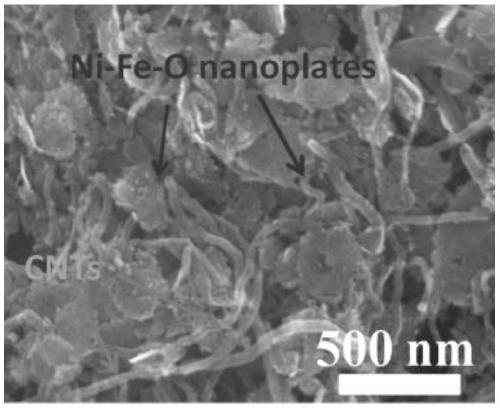

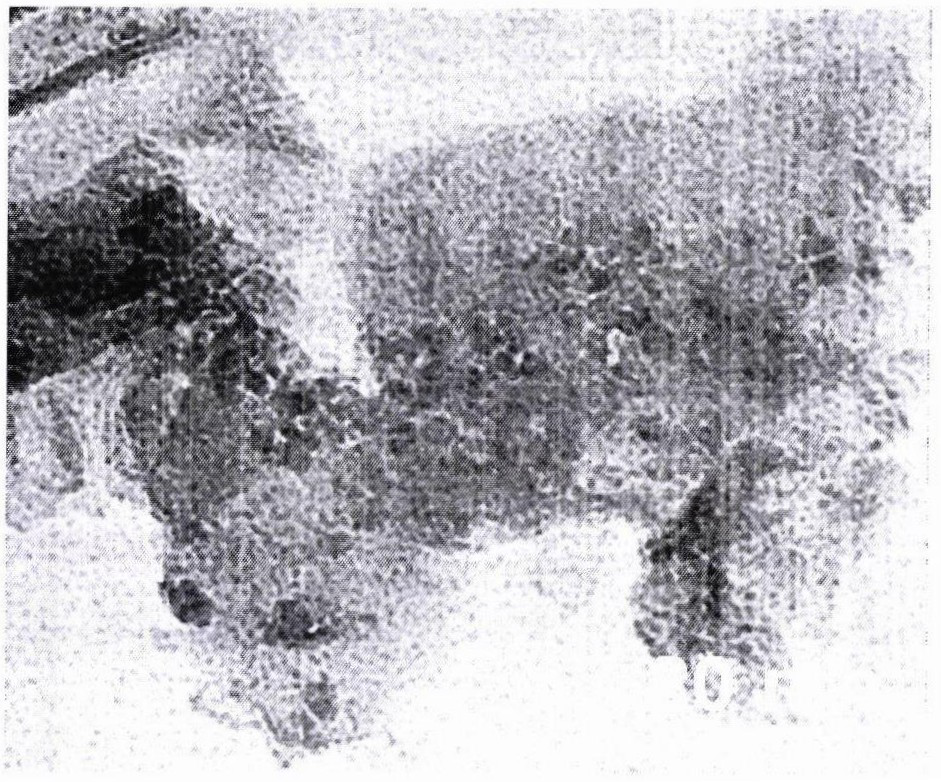

Ferro-nickel phosphate/carbon nanotube composite material and preparation method and application thereof

ActiveCN109433234AAvoid accumulationImprove performancePhysical/chemical process catalystsElectrodesNickel phosphateNanoparticle

The invention discloses a ferro-nickel phosphate / carbon nanotube composite material and a preparation method and application thereof. A structure unit of the ferro-nickel phosphate / carbon nanotube composite material takes porous three-dimensional carbon nanotubes as a net-shaped framework, and ferro-nickel phosphate nanoparticles are wound on the carbon nanotubes. The preparation method comprisesthe following steps: pretreatment of the carbon nanotubes, preparation of a ferro-nickel hydroxide / carbon nanotube precursor, and in-situ conversion reaction of the ferro-nickel phosphate / carbon nanotube composite material. By the prepared ferro-nickel phosphate / carbon nanotube composite material, the problem that in a traditional preparation technological process, ferro-nickel phosphate nanoparticle unit structures are severely agglomerated can be solved effectively, and a new method is provided for preparing an electrode material which has a completely exposed active site, and is high in catalytic activity, good in electrical conductivity, low in overpotential and high in stability.

Owner:ZHEJIANG SCI-TECH UNIV

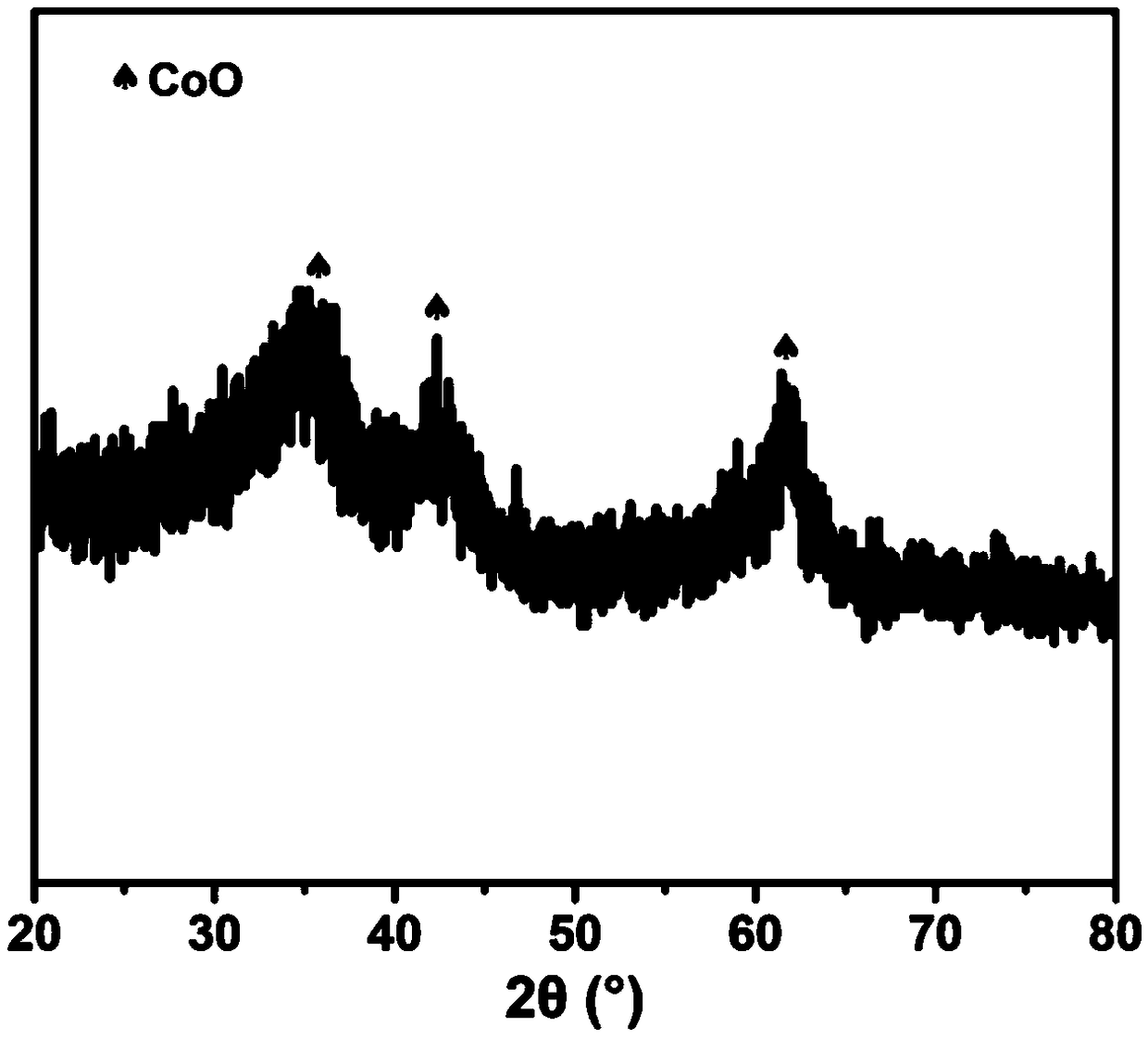

Cobalt iron oxide hollow nano-cage material, preparation method and uses thereof

ActiveCN109289852AEfficient use ofQuality improvementMetal/metal-oxides/metal-hydroxide catalystsElectrodesIron oxideOxygen evolution

The present invention discloses a cobalt iron oxide hollow nano-cage material, which has an inner cavity and an outer shell. The invention further discloses a preparation method of the cobalt iron oxide hollow nano-cage material, and uses of the cobalt iron oxide hollow nano-cage material in oxygen evolution electrode materials. According to the present invention, the cobalt iron oxide hollow nano-cage material has good performance superior to the commercial noble metal RuO2 material.

Owner:TIANJIN UNIV

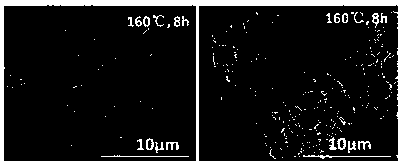

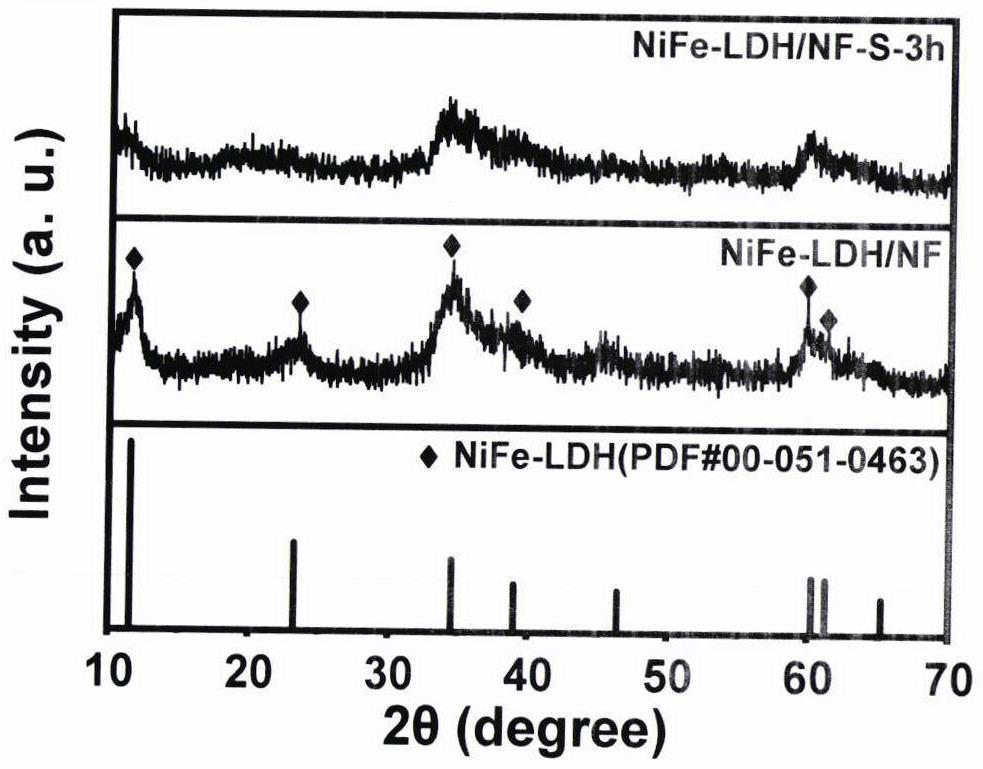

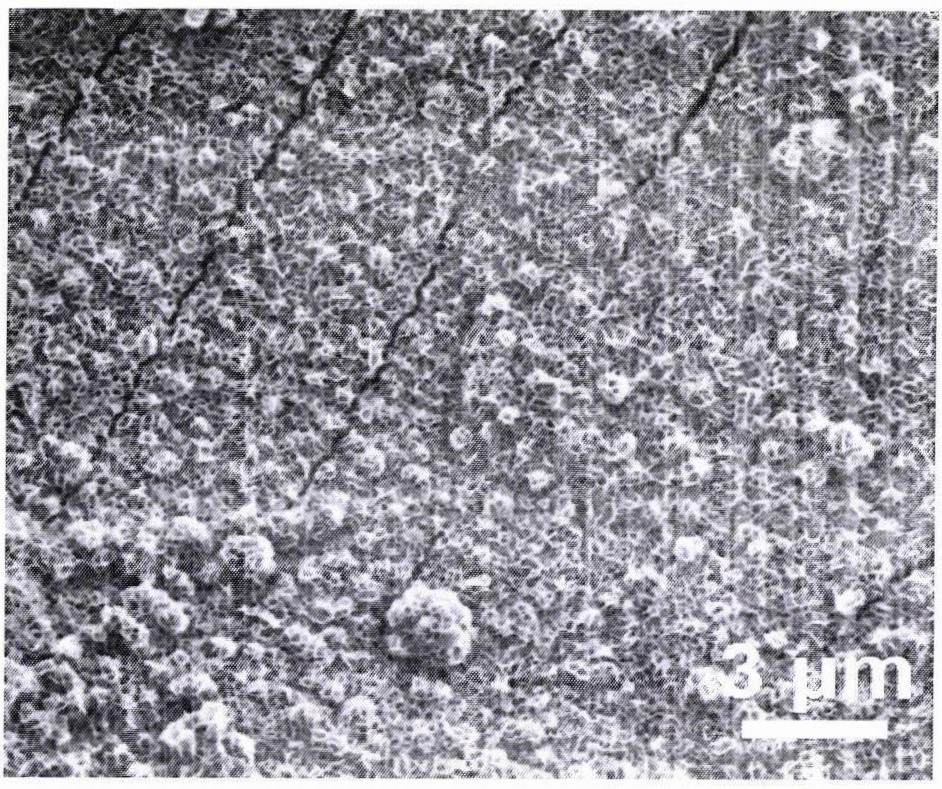

Method for preparing sulfur-doped porous NiFe-LDH electrocatalyst at room temperature

The invention provides a method for preparing a sulfur-doped porous NiFe-LDH nanosheet oxygen evolution electrocatalyst at room temperature. The method comprises the following steps: preparing a NiFe-LDH nanosheet by using a hydrothermal method, infiltrating and etching the NiFe-LDH nanosheet by using a Na2S. 9H2O solution with a certain molar concentration at room temperature, and carrying out vacuum drying to obtain the sulfur-doped porous NiFe-LDH nanosheet. According to the invention, high-temperature and high-pressure conditions needed by traditional sulfur doping are not needed, strong agglomeration of sulfides in material processing under a high-temperature condition can be avoided, and generation of harmful by-products is reduced. Metal cations are usually used as actual active sites of oxygen evolution reaction (OER), and sulfur anions doped at room temperature can be used as electron donors to adjust the polarization degree of the active sites of the metal cations, so an electronic structure beneficial to an electrocatalyst is generated. Meanwhile, a unique three-dimensional porous nanosheet structure is generated on the NiFe-LDH nanosheet due to etching, so the electrocatalyst exposes a large number of active sites and charge transfer channels, and shows excellent catalytic performance when being used as an electrochemical OER catalyst.

Owner:TAIYUAN UNIV OF TECH

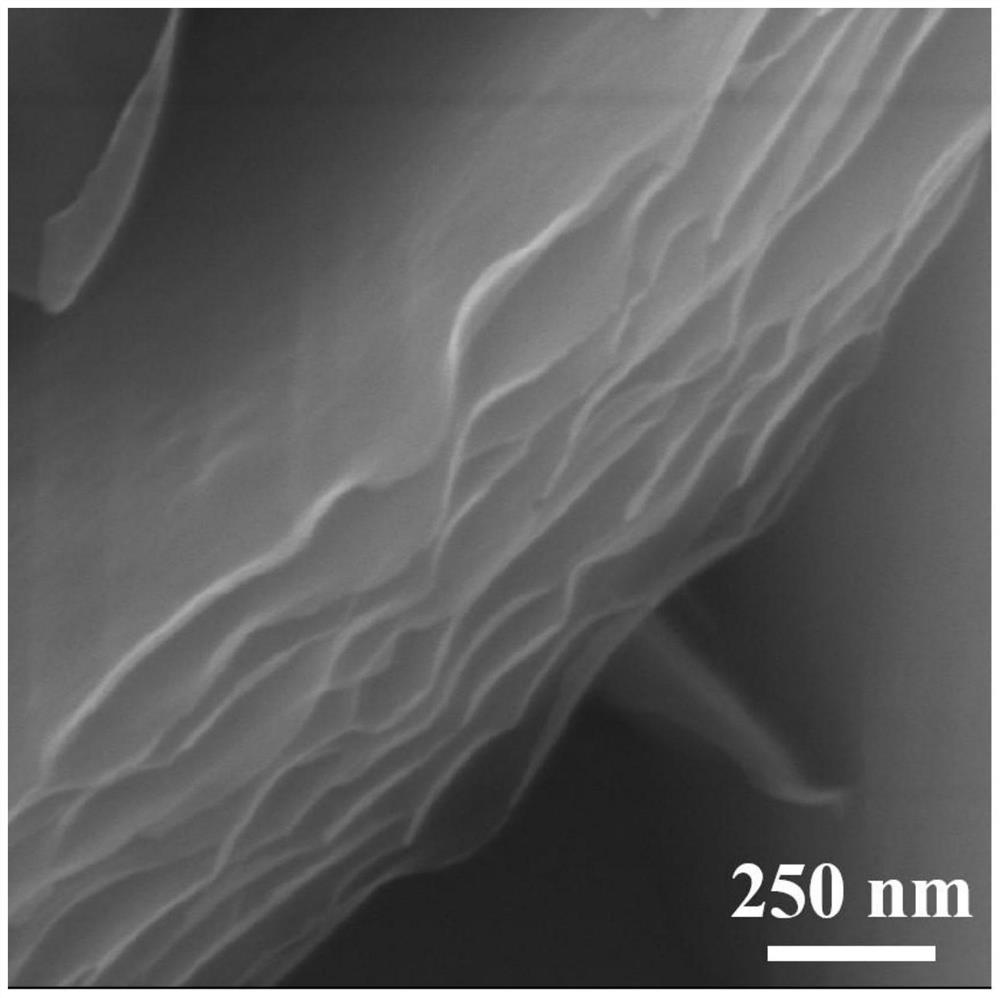

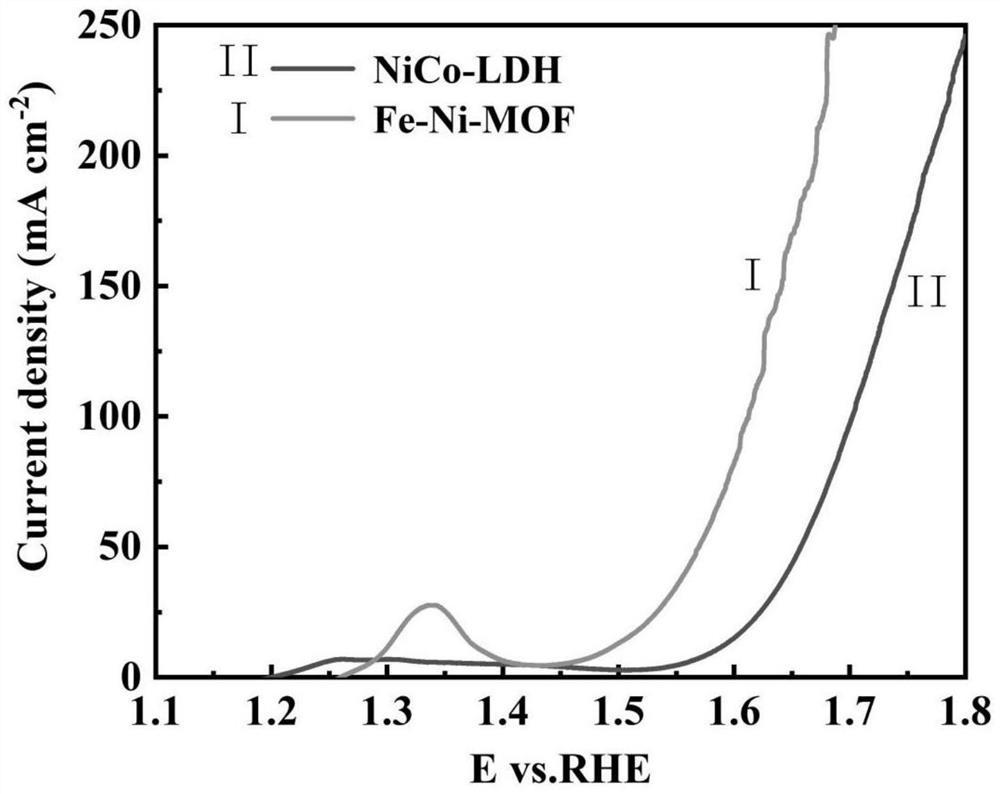

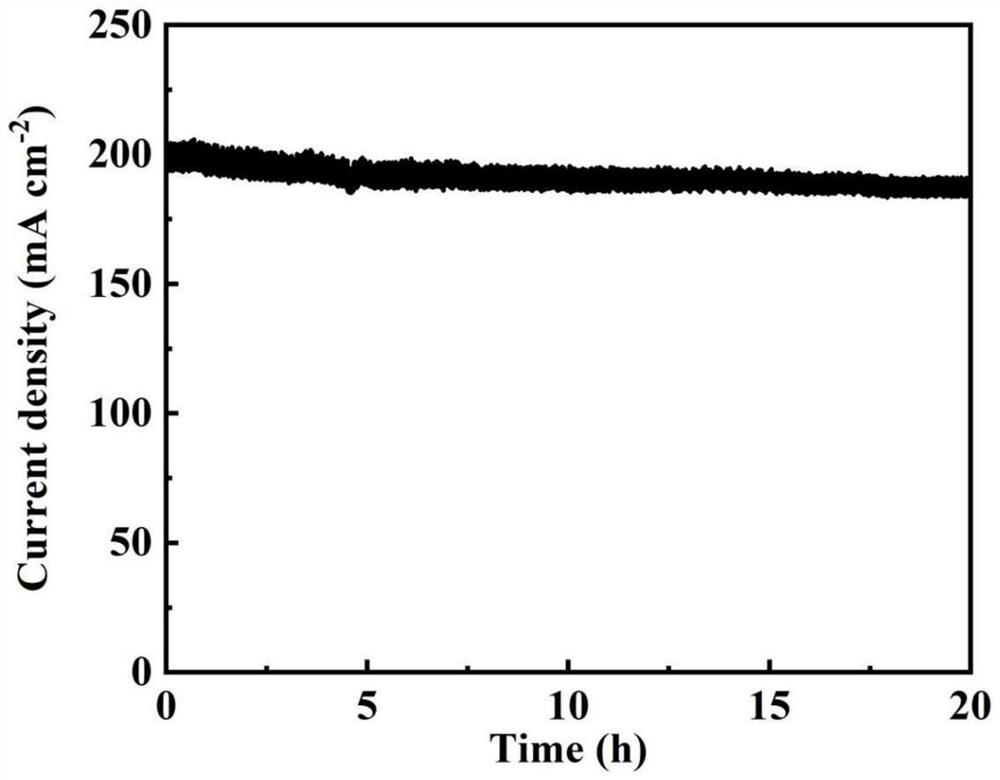

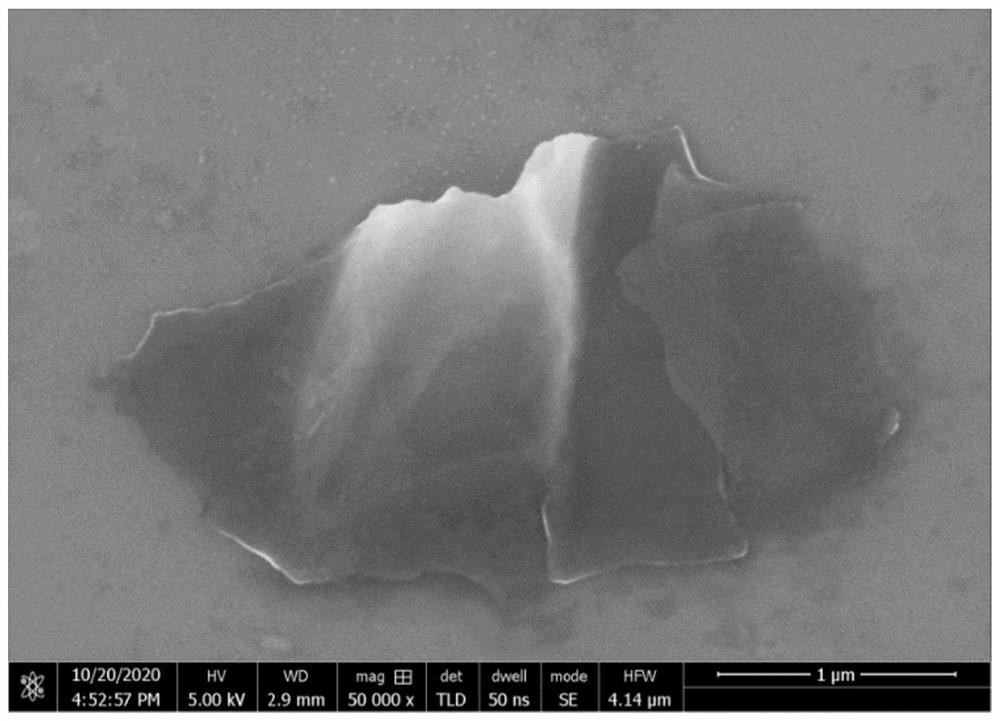

Fe-doped Ni-MOF nanosheet as well as preparation method and application thereof

ActiveCN113563596AInexpensive to synthesizeImprove electrocatalytic performanceCell electrodesElectrodesElectro catalystPtru catalyst

The invention provides a Fe-doped Ni-MOF nanosheet as well as a preparation method and application thereof, and belongs to the technical field of electrochemical material preparation. The method comprises the following steps that: S1, terephthalic acid and soluble iron salt are fully dissolved in a solvent to obtain a solution B, wherein the mass ratio of the terephthalic acid to the soluble ferric salt is 1: (0.1-0.3); and S2, a NiCo-LDH nanosheet material taking foamed nickel as a substrate and the solution B obtained in the step S1 are put into a closed container, then solvothermal high-pressure reaction is carried out at 100-120 DEG C, and after the reaction is completed, filtering and drying are performed to obtain the Fe-Ni-MOF nanosheet. The electro-catalyst of the Fe-Ni-MOF layered nanosheet structure, which is low in price and excellent in electro-catalytic performance, is synthesized by a method of combining a technology of creating a high-temperature and high-pressure environment through a solvothermal method and a metal ion synergistic effect, and the method is simple and convenient to operate.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

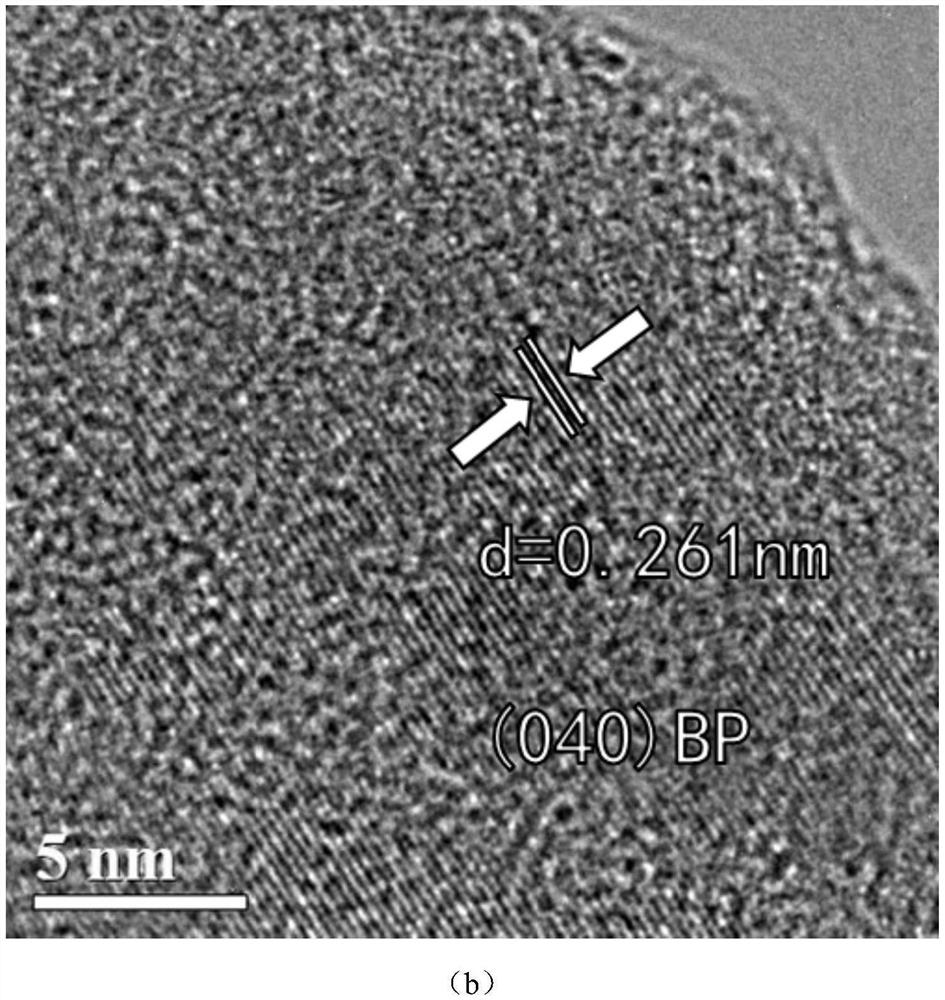

Oxygen evolution reaction electrocatalyst and preparation method thereof

ActiveCN113235107AImprove oxygen evolution performanceImprove stabilityElectrodesPtru catalystPhysical chemistry

The invention discloses an oxygen evolution reaction electrocatalyst and a preparation method thereof. The oxygen evolution reaction electrocatalyst is a BP (metal Ax metal By) composite material, wherein BP is black phosphorus nanosheets, the metal A and the metal B are transition metal elements respectively, and x:y is the molar weight ratio of metal salts of the metal A and the metal B. Compared with a noble metal catalyst, the black phosphorus-based catalyst prepared by the invention has the advantages that the cost is low, but the catalytic performance and stability are comparable to those of the noble metal catalyst; and compared with other black phosphorus-based composite catalysts, black phosphorus-based catalyst prepared by the invention is simple in method, and the time cost and the energy cost can be saved.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

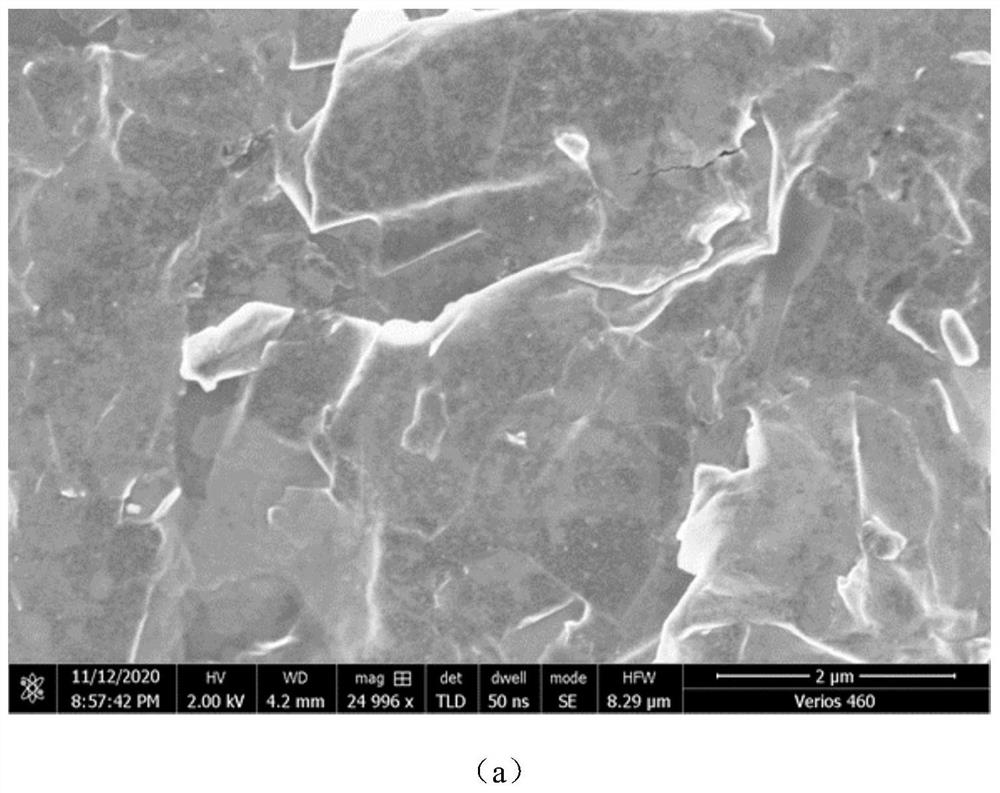

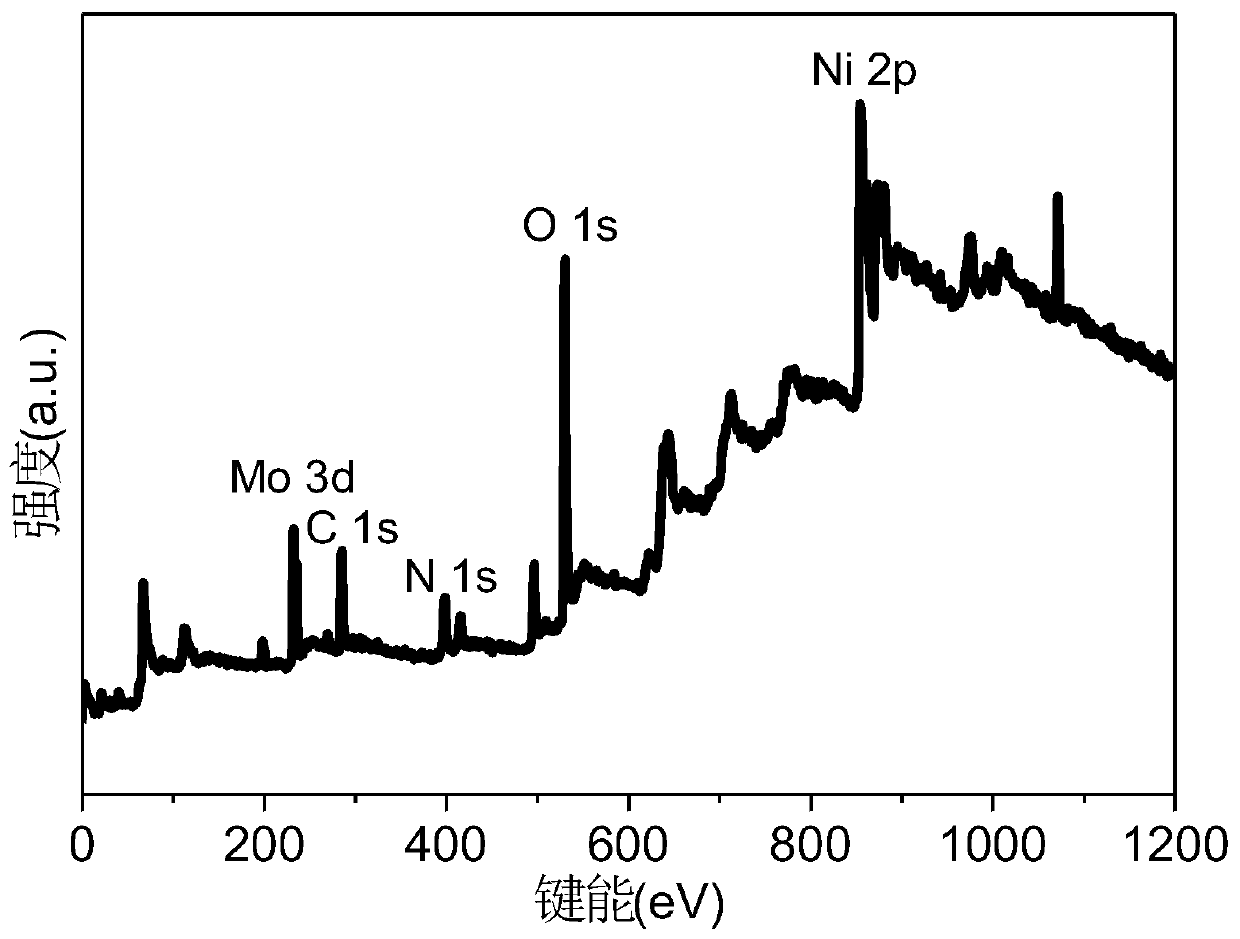

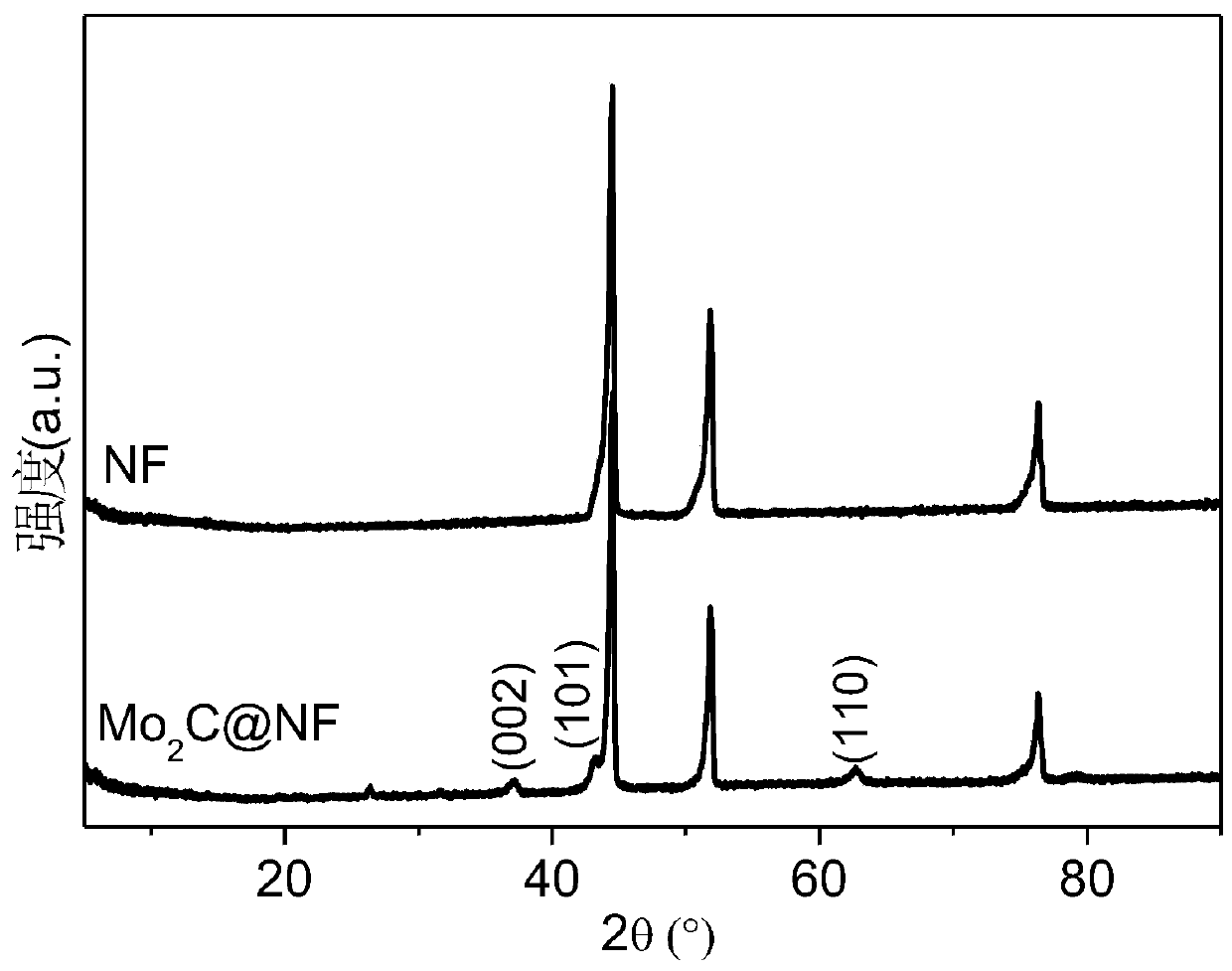

Molybdenum carbide/foamed nickel composite material, preparation method, and application thereof in electrocatalytic oxygen evolution

PendingCN111558387AStable growthStable and uniform growthCatalyst activation/preparationElectrodesMolybdenum carbideOxygen evolution

The invention discloses a molybdenum carbide / foamed nickel composite material, a preparation method, and application thereof in electrocatalytic oxygen evolution. The molybdenum carbide / foamed nickelcomposite material comprises molybdenum carbide and foamed nickel, and the molybdenum carbide is loaded on the foamed nickel. The preparation method of the molybdenum carbide / foamed nickel composite material comprises the following steps: preparing a molybdenum carbide precursor solution, covering the foamed nickel with a molybdenum carbide precursor, and calcining to obtain the molybdenum carbide / foamed nickel composite material. The molybdenum carbide / foamed nickel composite material has the advantages of large specific surface area, stable structure, good electrocatalytic performance and the like, is a novel electrocatalyst which is good in oxygen evolution effect, stable in performance and capable of being widely applied to electrocatalytic oxygen evolution, can be directly used as anelectrode material for electrocatalytic oxygen evolution reaction, and has very high use value and very good application prospect. The preparation method of the molybdenum carbide / foamed nickel composite material has the advantages of controllable preparation process, simple preparation process, low preparation cost and the like, is suitable for large-scale preparation, and is beneficial to industrial application.

Owner:HUNAN UNIV

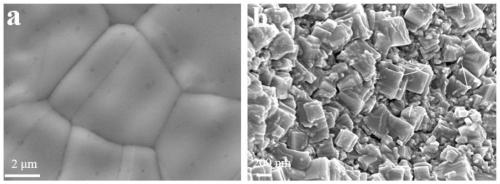

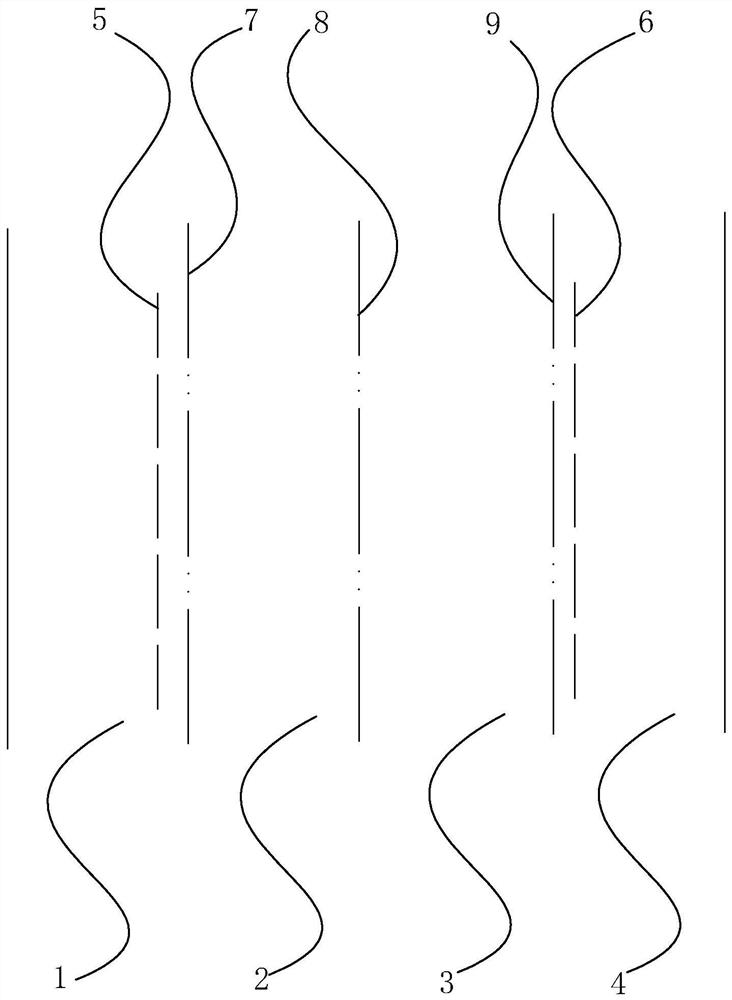

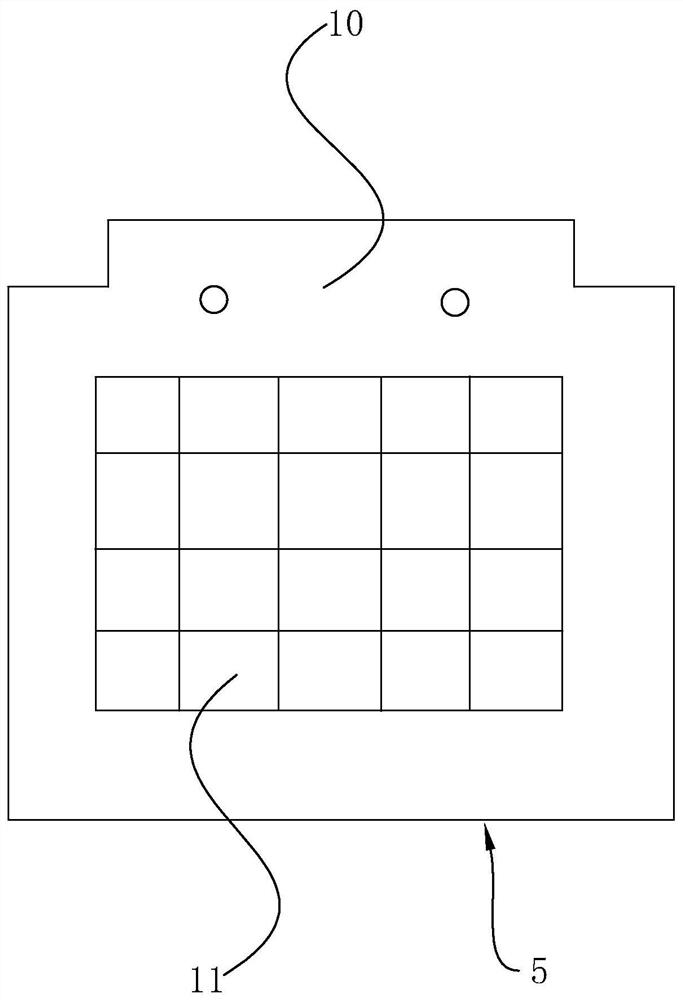

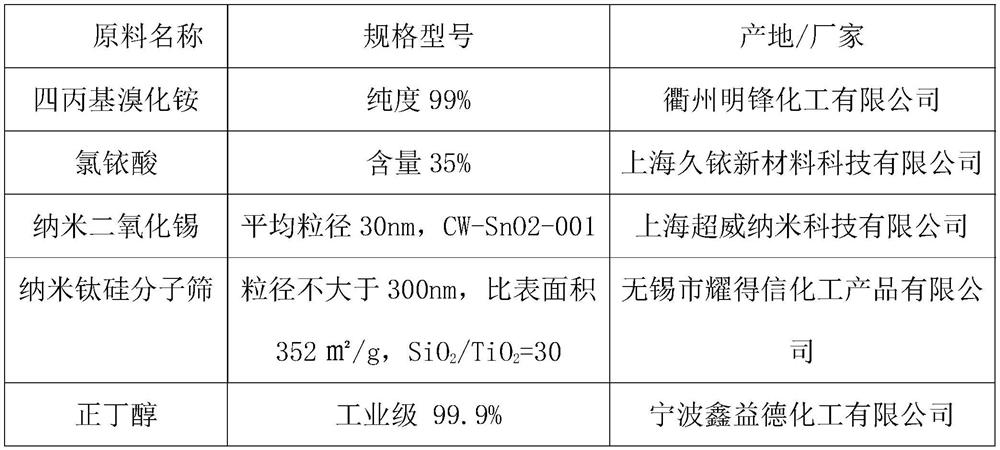

Energy-saving production process of tetrapropylammonium hydroxide and tetrapropylammonium hydroxide aqueous solution prepared by energy-saving production process

ActiveCN113463118AImprove oxygen evolution capacityReduce energy consumptionElectrolytic organic productionElectrodesPropyl bromideMolecular sieve

The invention discloses an energy-saving production process of tetrapropylammonium hydroxide and a tetrapropylammonium hydroxide aqueous solution prepared by the energy-saving production process, and relates to the technical field of organic alkali production. According to the energy-saving production process, an electrolytic bath is used for production through an electrolytic method, and the electrolytic bath is provided with an anode plate and a cathode plate; and the process comprises the following steps: taking tetrapropylammonium bromide, adding water to prepare a tetrapropylammonium bromide aqueous solution, electrolyzing, combining tetrapropylammonium cations with hydroxyl ions generated in a cathode chamber to form tetrapropylammonium hydroxide, and preparing the tetrapropylammonium hydroxide aqueous solution; wherein the anode plate comprises a titanium substrate and a catalytic coating coated on the titanium substrate, and the catalytic coating is mainly prepared from the following coating raw materials in parts by weight: 15-25 parts of chloroiridic acid, 40-50 parts of nano tin dioxide, 0.8-1.2 parts of a nano titanium silicalite molecular sieve and 150-200 parts of n-butyl alcohol. The energy-saving production process has the advantage of low energy consumption.

Owner:KENTE CATALYSTS INC

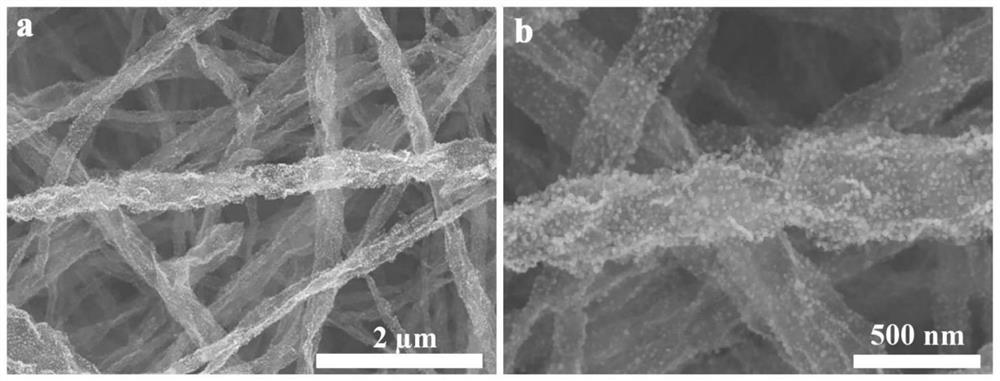

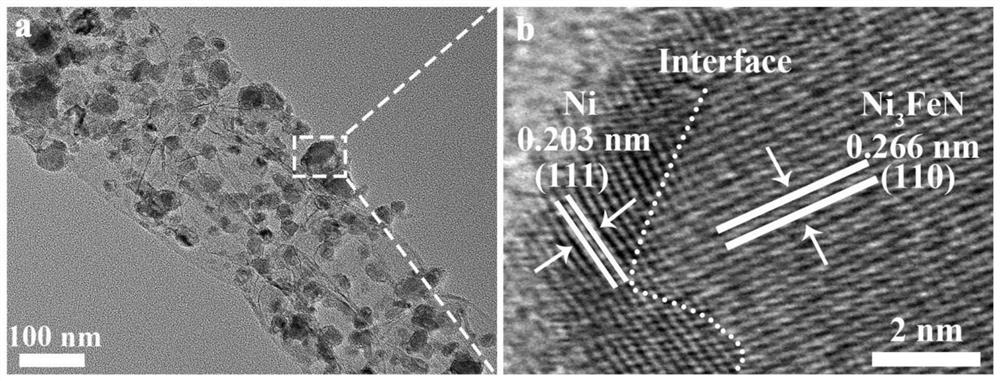

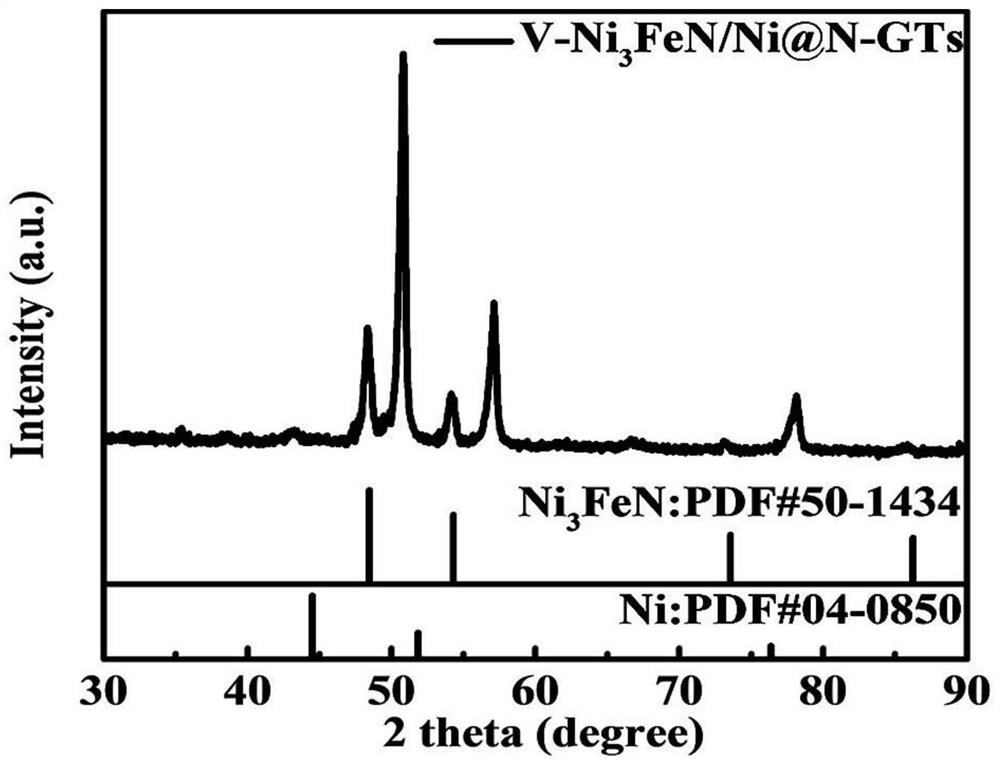

V-Ni3FeN/Ni-coated N-GTs full-electrolysis water electric catalyst constructed based on doping and heterojunction strategies

PendingCN114164445AImprove electrocatalytic performanceImprove stabilityElectrodesHeterojunctionDoped graphene

The invention discloses a V-Ni3FeN / Ni (at) N-GTs full electrolysis water electric catalyst constructed on the basis of doping and heterojunction strategies. The preparation method comprises the following steps: firstly, growing a V-doped Ni Fe precursor on a nitrogen-doped graphene tube carrier through a hydrothermal method, then heating to 470 DEG C in a tubular furnace, introducing ammonia gas, and nitriding for 2 hours to obtain the electrocatalyst consisting of V-doped Ni3FeN and Ni nanoparticles grown on the nitrogen-doped graphene tube in situ, namely V-Ni3FeN / Ni-N-GTs. Based on the synergistic effects of effective regulation and control of V doping on Ni and Fe electronic structures in Ni3FeN, rearrangement of charges induced by a heterojunction interface of V-Ni3FeN and Ni, good conductivity of a nitrogen-doped graphene tube carrier and the like, the electrocatalyst shows excellent electrocatalytic activity and stability in hydrogen evolution reaction and oxygen evolution reaction in an alkaline medium; the catalyst can be used as an anode catalyst and a cathode catalyst at the same time, is used for catalyzing a full hydrolysis reaction, can reach the current density of 10mA cm <-2 > only by needing the cell voltage of 1.55 V, and shows excellent stability.

Owner:QINGDAO UNIV OF SCI & TECH

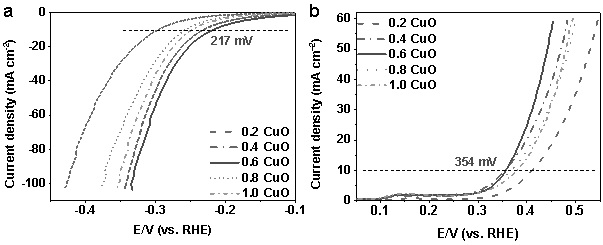

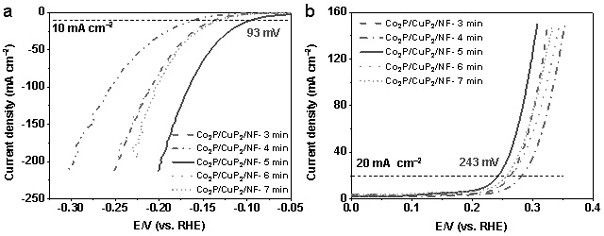

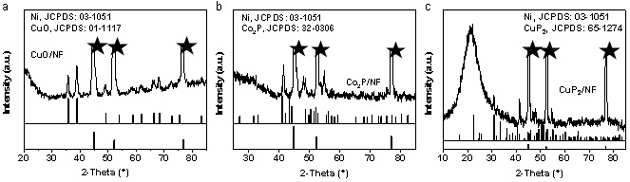

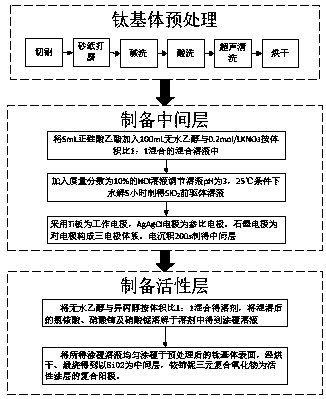

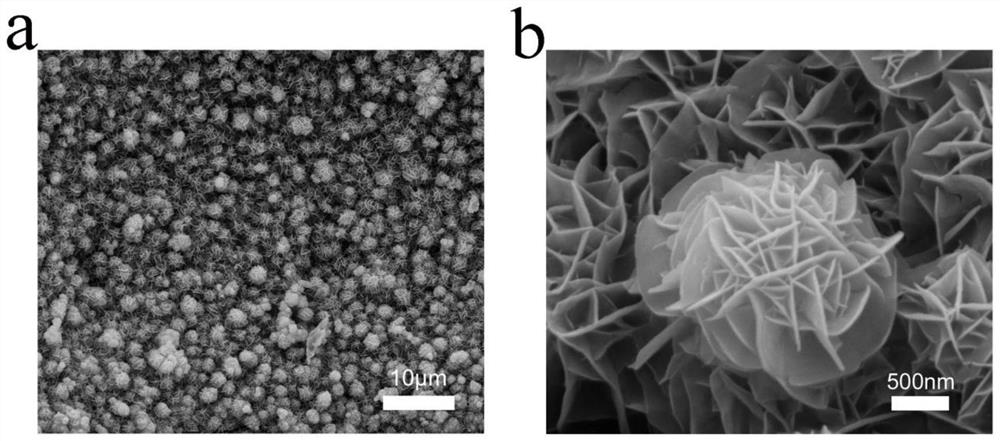

Preparation method of Co2P/CuP2/NF hydrogen and oxygen evolution electrocatalyst

ActiveCN113637997AEasy to prepareImprove oxygen evolution performanceElectrodesPtru catalystNitrogen gas

The invention relates to the technical field of electro-catalysis water decomposition, in particular to a preparation method of a Co2P / CuP2 / NF hydrogen and oxygen evolution electro-catalyst, a Co2P / CuP2 / NF composite material is obtained through a low-temperature hydrothermal method, a constant-potential electro-deposition method and a low-temperature phosphating treatment method, and the hydrothermal method is characterized in that CuO is grown on foamed nickel to obtain a Cu-based precursor; co species are electrodeposited on the surface of CuO at constant potential, a Cu-Co composite material precursor is obtained, and low-temperature phosphating treatment is carried out in the nitrogen atmosphere. The preparation method is simple, the Co2P / CuP2 / NF composite material is obtained by performing low-temperature hydrothermal and constant-potential electro-deposition and low-temperature phosphating treatment by taking the foamed nickel as a substrate, and the Co2P / CuP2 / NF composite material has excellent electro-catalytic hydrogen evolution and oxygen evolution performance under an alkaline condition, can also be applied to a zinc-water battery and is relatively long in service life.

Owner:江西新节氢能源科技有限公司

Preparation method of titanium-based composite anode for heavy metal wastewater treatment

Owner:LANZHOU JIAOTONG UNIV

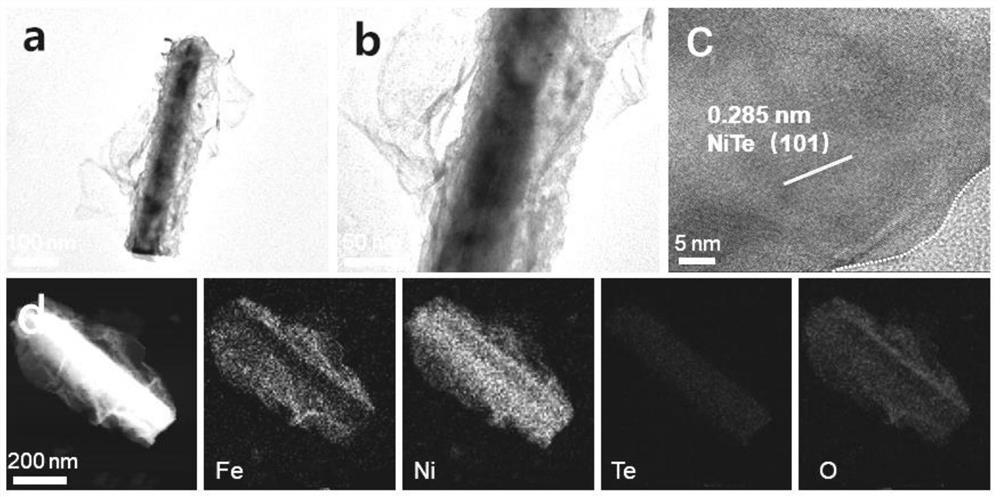

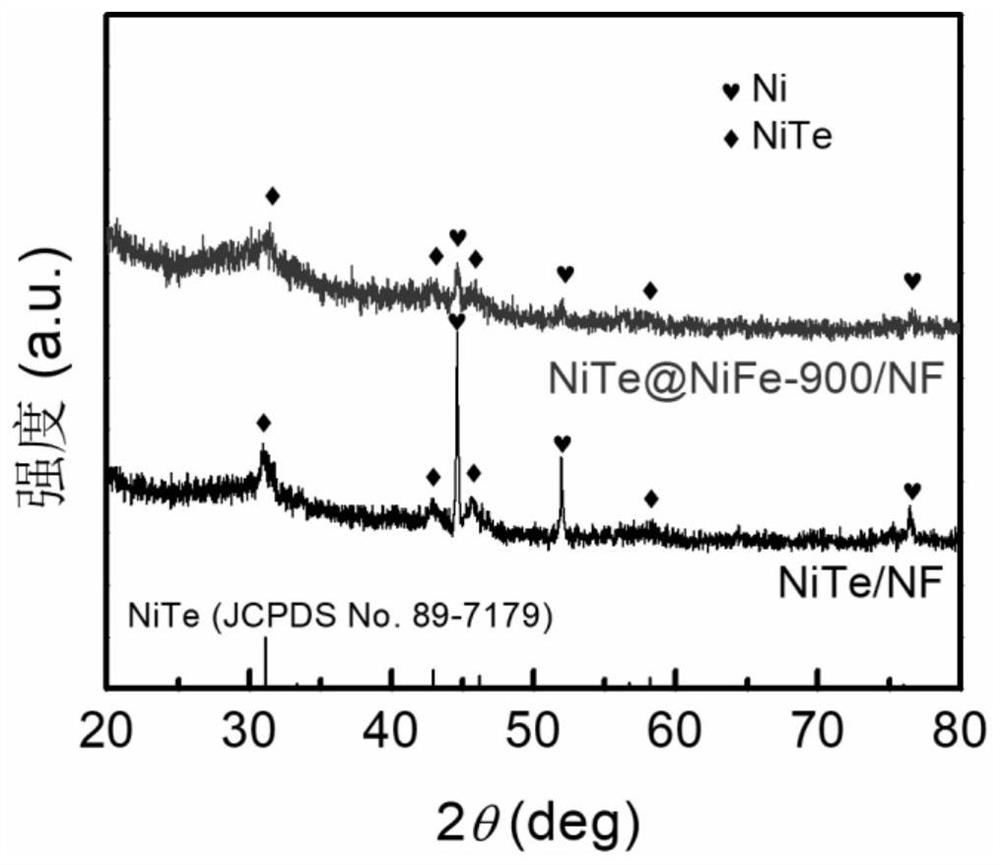

Composite catalyst with NiTe and NiFe loaded on foamed nickel as well as preparation method and application of composite catalyst

PendingCN113136587AEffective exposureImprove the shortcomings of poor intrinsic conductivityElectrodesNickel saltPtru catalyst

The invention provides a composite catalyst with NiTe and NiFe loaded on foamed nickel as well as a preparation method and application of the composite catalyst, and belongs to the technical field of preparation of composite materials. The preparation method comprises the following steps: firstly, loading NiTe on foamed nickel to obtain a catalyst NiTe / NF, then taking the catalyst NiTe / NF as a working electrode, and taking a solution containing ferric salt and nickel salt as an electroplating solution to prepare a composite catalyst with NiTe@NiFe loaded on the foamed nickel, and recording the composite catalyst as the NiTe@NiFe / NF composite catalyst, wherein the NiTe@NiFe / NF composite catalyst shows an excellent electro-catalytic property on an oxygen evolution half reaction of water decomposition.

Owner:JIANGSU UNIV

Glass refining agent and preparation method thereof

InactiveCN109534674AImprove adsorption capacityLarge specific surface areaOxygen evolutionAir bubble

The invention relates to a glass refining agent and a preparation method thereof, and belongs to the field of the glass refining agents. Catalytic oxygen evolution is performed through catalyst additive release by gas; meanwhile, the assembly is formed with ferriporphyrin; the catalysis active center sites are increased; the catalysis process is promoted; water steam and glass melt take reaction at the molten high temperature; the viscosity and surface tension of the glass are reduced; the bubble discharge is promoted; a branched structure is formed through an extrusion foam discharge agent; the flowability of a refining agent is improved; substances with elastic structures and good mechanical performance form elastic deformation, so that the extrusion discharging of bubbles is further promoted; the glass crystallization is induced through light transmission nucleation additives; the light effect of the glass is improved, so that the transparency of the glass is improved; auxiliary additives are added in an auxiliary way to realize the coordination participation into a glass silica network structure; the softening point of the glass is improved; the better melting is realized. Theglass refining agent and the preparation method solve the problems that by using the existing glass refining agent, micro bubbles liable to occur on the glass plate surface, and flaws are caused.

Owner:胡莉

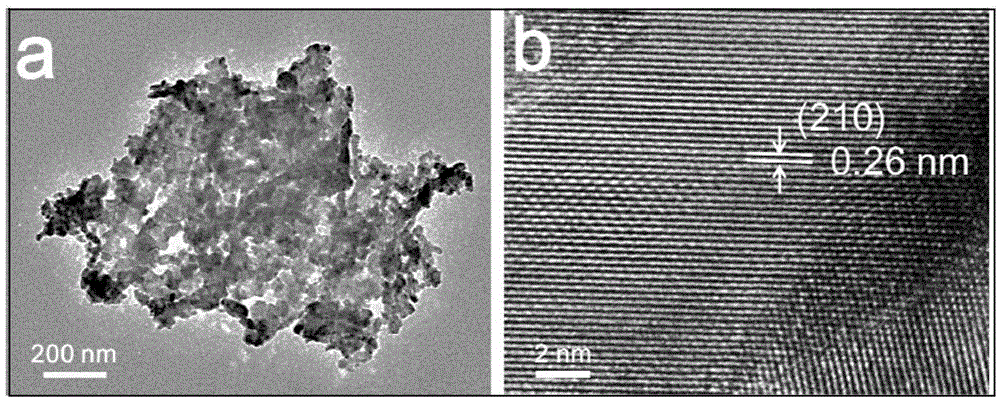

a kind of nife 3 n/nf electrochemical catalyst and its preparation method and application

ActiveCN107159293BLower resistanceImprove conductivityPhysical/chemical process catalystsElectrodesPtru catalystPhysical chemistry

The invention discloses a NiFe 3 N / NF electrochemical catalyst and its preparation method and application. The electrochemical catalyst is derived by heat treatment of bimetallic MOF, with K 4 Fe(CN) 6 As a ligand, the ligand contains Fe, which provides an Fe source. The complexing agent ligand is combined with the central metal Ni to form a bimetallic MOF. It is synthesized in situ on the Ni substrate, which not only utilizes the conductivity of the Ni substrate, but also passes The in-situ synthesis reduces the resistance between the MOF and the Ni substrate, synthesizes the bimetallic MOF in one step, and takes advantage of the porosity of the MOF. At the same time, the MOF is heat-treated after being wrapped with an alkali metal salt to maintain the morphology of the MOF. The preparation method of the present invention has simple process, low raw material cost, easy operation and high repeatability. The prepared NiFe 3 N / NF electrochemical catalyst is used to electrocatalyze oxygen evolution reaction.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com