Carbon material with nitrogen, fluorine and transition metal co-doped graphene structure and one-step carbonization preparation method thereof

A technology of transition metals and carbon materials, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of complex preparation process, unsuitable for large-scale industrialization, high preparation environment requirements, etc., and achieve simple design process and easy industrialization Achieving, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] When the transition metal is cobalt and the carbonization temperature is 950°C, it is a one-step carbonization preparation method of a carbon material with nitrogen, fluorine and transition metal co-doped graphene structure.

[0038] Step 1, the mixing of raw materials, with the mass ratio of melamine powder, polytetrafluoroethylene powder and metal salt cobalt acetate meeting 1:1.5:0.002, weigh 2.0 g of melamine powder and 3.0 g of polytetrafluoroethylene powder, add 2 mL of 0.035 The ethanolic solution of cobalt acetate of M was mixed and ground, and after being manually ground for 1 hour to dry, a uniformly mixed powder sample was obtained;

[0039] Step 2, one-step carbonization method, put the homogeneous powder sample obtained in step 1 under a nitrogen atmosphere for carbonization, at a heating rate of 5°C / min, from room temperature to 950°C, and then keep warm for carbonization for 1 hour.

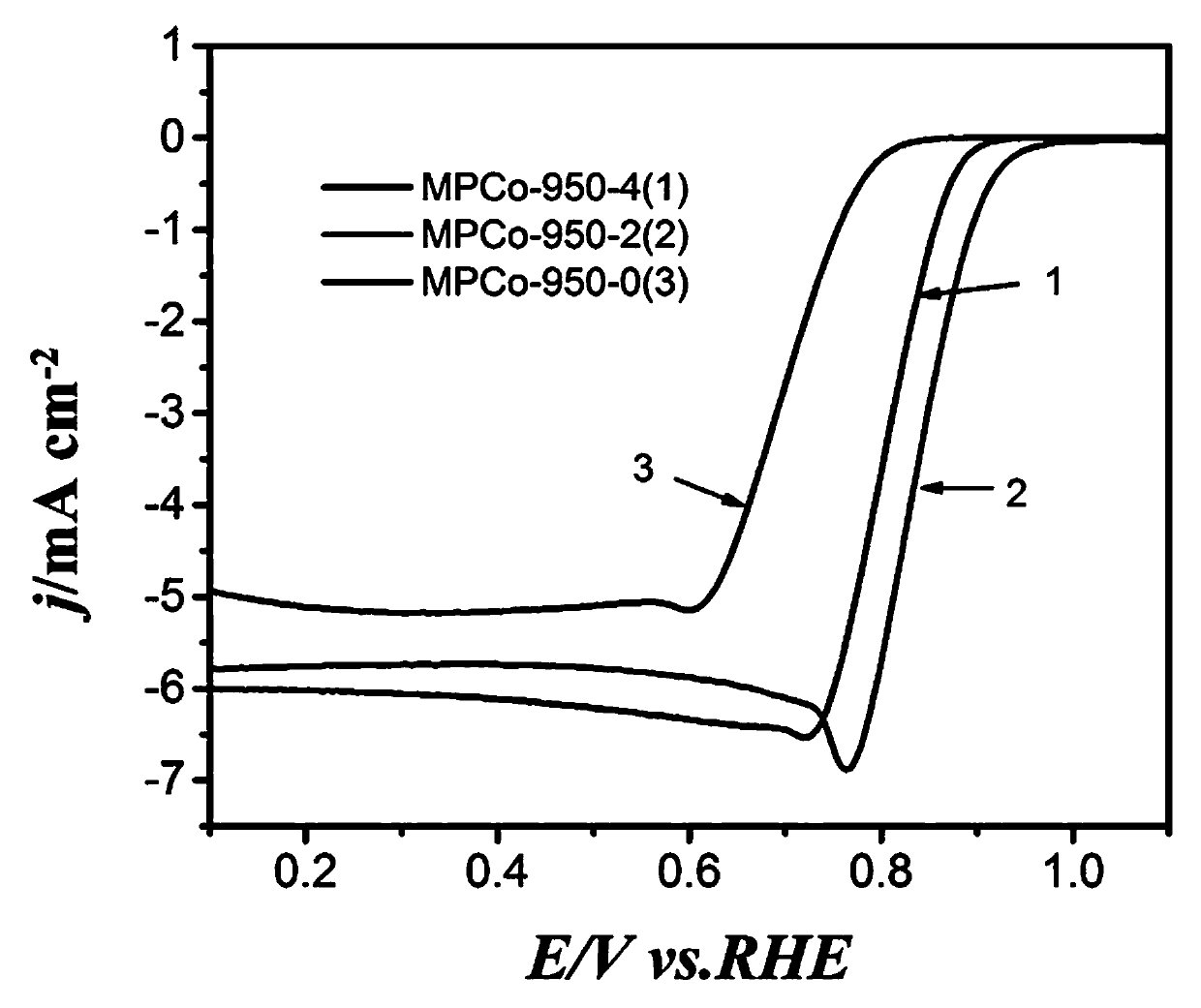

[0040] For the ORR performance of this embodiment, see figure 1 , pola...

Embodiment 2

[0049] When the transition metal is cobalt and the carbonization temperature is 950°C, a one-step carbonization preparation method of a carbon material with nitrogen, fluorine and transition metal co-doped graphene structure.

[0050] The steps not specified in the specific steps are the same as the preparation method described in Example 1, except that the mass ratio of melamine powder, polytetrafluoroethylene powder and metal salt in step 1 satisfies 1:1.5:0.004, adding 4 mL of 0.035 M cobalt acetate in ethanol.

[0051] For the ORR performance of this embodiment, see figure 1 , polarization curve 1.

[0052] The results of the oxygen reduction performance characterization of embodiment 1, comparative example and embodiment 2 are as follows figure 1 shown by figure 1 Concluded as follow:

[0053] 1. Doping transition metal elements can significantly improve the oxygen reduction catalytic performance of the material;

[0054] 2. The content of different transition metal ...

Embodiment 3

[0058] When the transition metal is cobalt and the carbonization temperature is 900°C, it is a one-step carbonization preparation method of a carbon material with nitrogen, fluorine and transition metal co-doped graphene structure.

[0059] The steps not specifically described in the specific steps are the same as the preparation method described in Example 1, except that the temperature in Step 2 is raised to 900°C.

[0060] For the ORR performance of this embodiment, see figure 2 , polarization curve 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com