Patents

Literature

106results about How to "Simple design process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

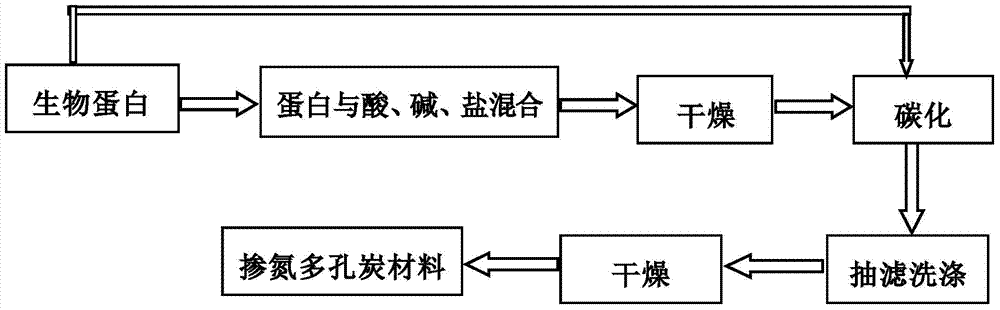

Method for preparing nitrogen doped porous carbon material by using biologic proteins

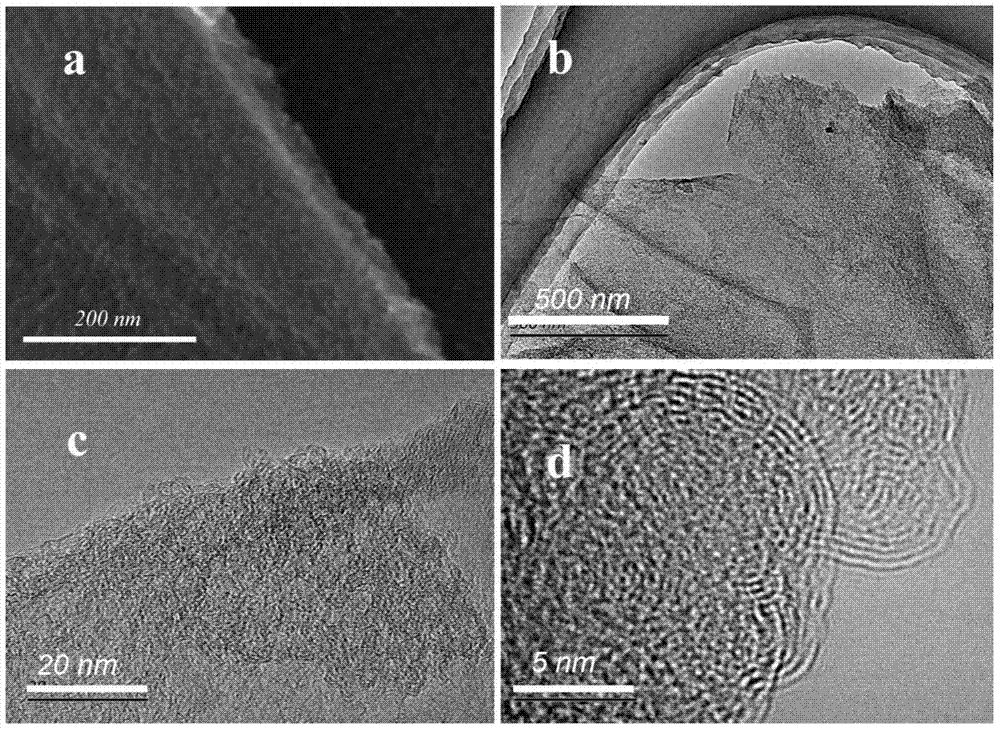

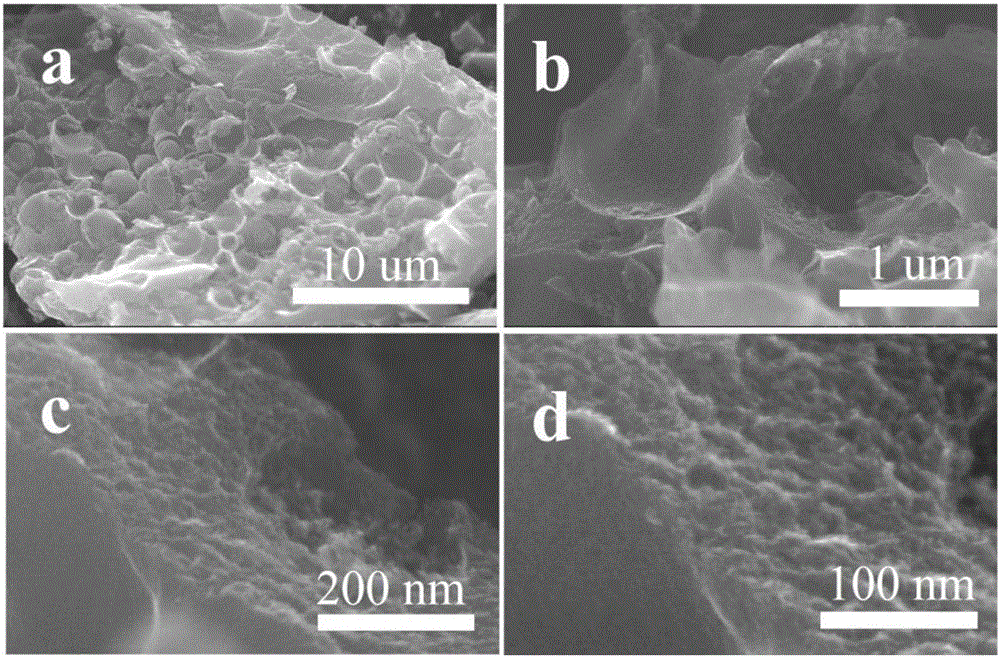

The invention provides a method for preparing a nitrogen doped porous carbon material by using biologic proteins. The method mainly comprises the following steps: 1, mixing the biologic proteins with an acid or alkali or salt solution; 2, carbonizing the above obtained dried mixture under the protection of inert gas; and 3, carrying out distilled water addition, pumping filtration and washing until the pH value is 6.4-7, and drying to obtain solid powder which is the nitrogen doped porous carbon material. The widely and easily available biologic proteins are adopted as raw materials, and the raw materials comprise silk fibroin, albumen and soybean proteins, so the method has the advantages of simple operating technology, convenient control, cleanness, environmental protection, and easy industrial realization. The prepared nitrogen doped porous carbon material has the advantages of large specific surface area, low ash content and good conductivity. The nitrogen doped porous carbon material can be used in lithium ion batteries, lithium sulfur batteries, super capacitors and other electrode materials, and fields of carbon dioxide capture, hydrogen storage, catalyst carriers, active carbon adsorbents and biologic applications.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

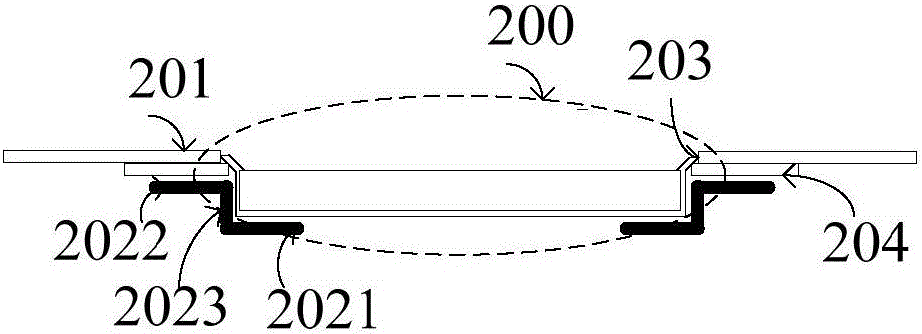

Super capacitor device containing millet-husk-based porous active carbon material

InactiveCN106276888ALow ashLow wettability of the surfaceHybrid capacitor electrodesMicrowave methodFiltration

The invention discloses a super capacitor device containing a millet-husk-based porous active carbon material. The millet-husk-based porous active carbon material is prepared by uniformly mixing dried millet husks and an activator, performing carbonization and activation with a microwave device in the protection of an inert gas, adding distilled water to obtained black powder for suction filtration washing till the pH value is 6.4-7, and performing drying to obtain black powder. The black powder is the prepared millet-husk-based porous active carbon material. The millet-husk-based porous active carbon material (an active substance) prepared through the microwave method is mixed with a binder according to a certain mass ratio, distilled water is added for mixing to prepare a thick liquid, and the thick liquid is repeatedly rolled to obtain a sheet electrode material. The electrode material is put on a current collector with the corresponding size, cold pressing is carried out at 1-40 Mpa for 10-200 s, and drying is performed at 120 DEG C to obtain an electrode plate of the super capacitor device. The electrode material in the electrode plate is more than 14 mg per square centimeter. An electrode plate, a membrane, and an electrode plate are assembled into a sandwich structure, then different electrolytes are dropwise added, so that the super capacitor device is assembled.

Owner:YANGZHOU UNIV

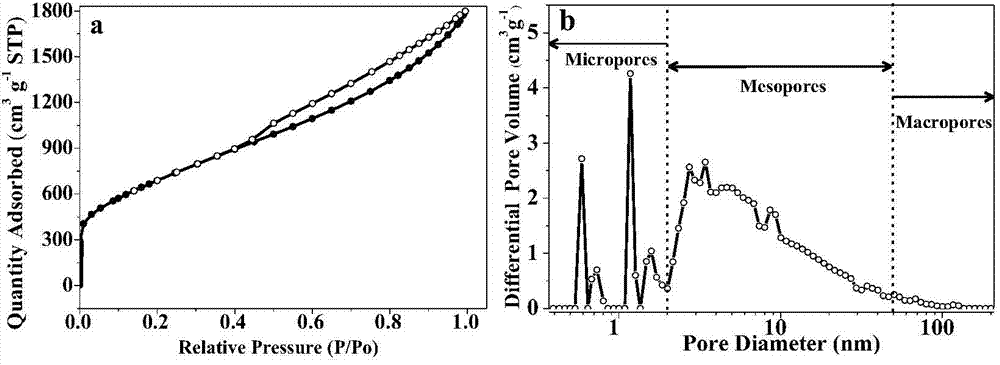

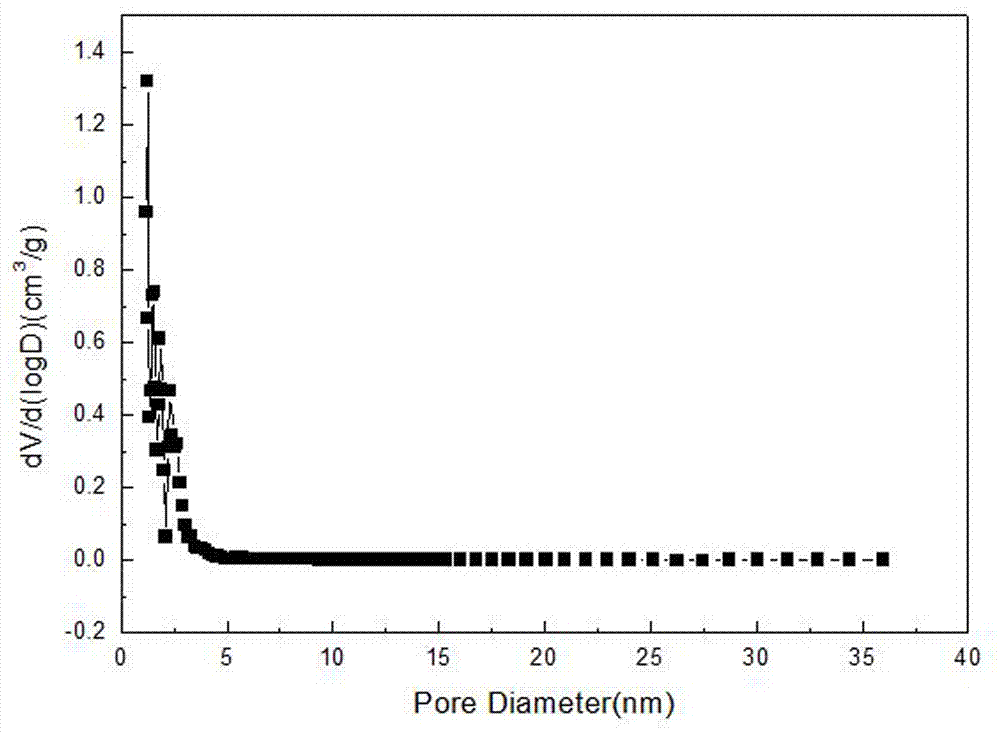

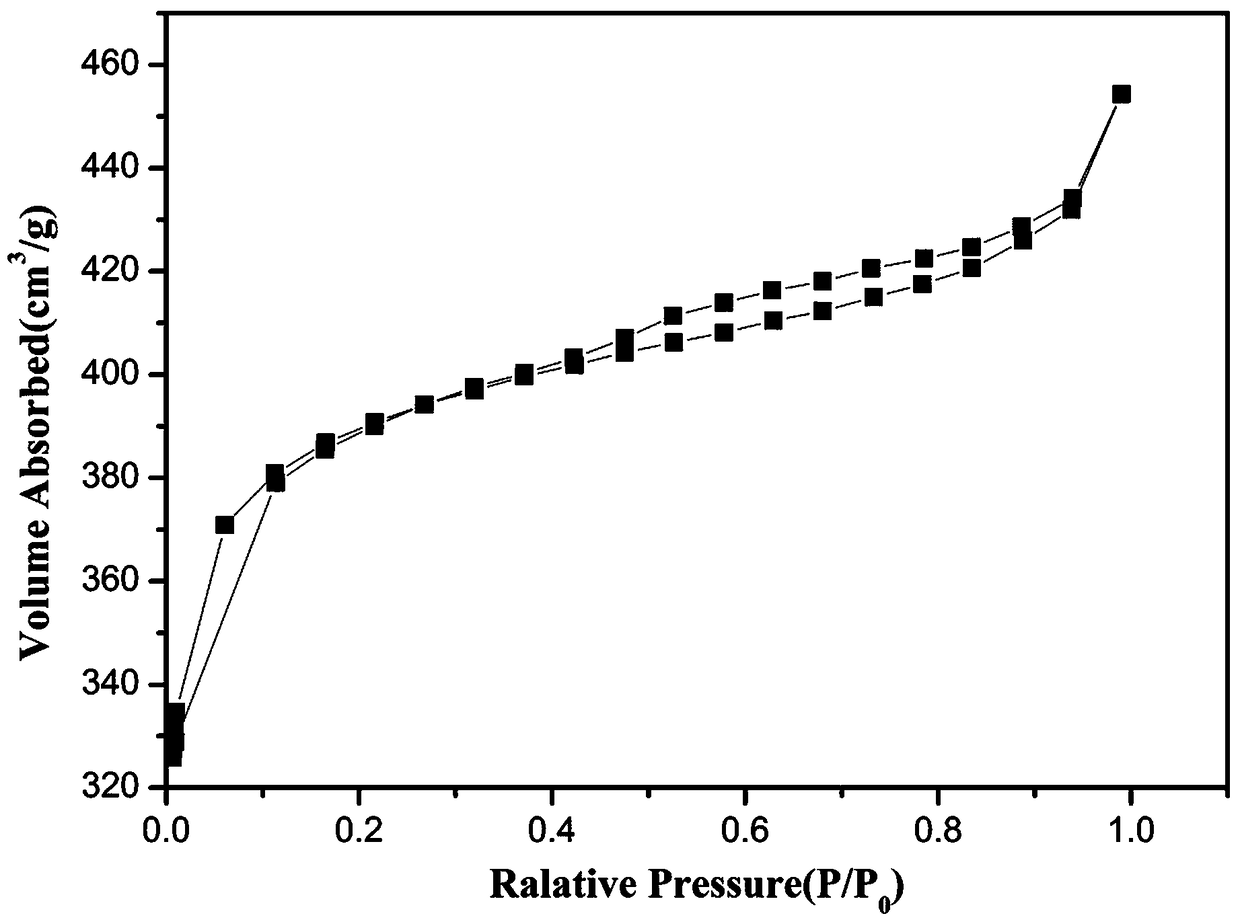

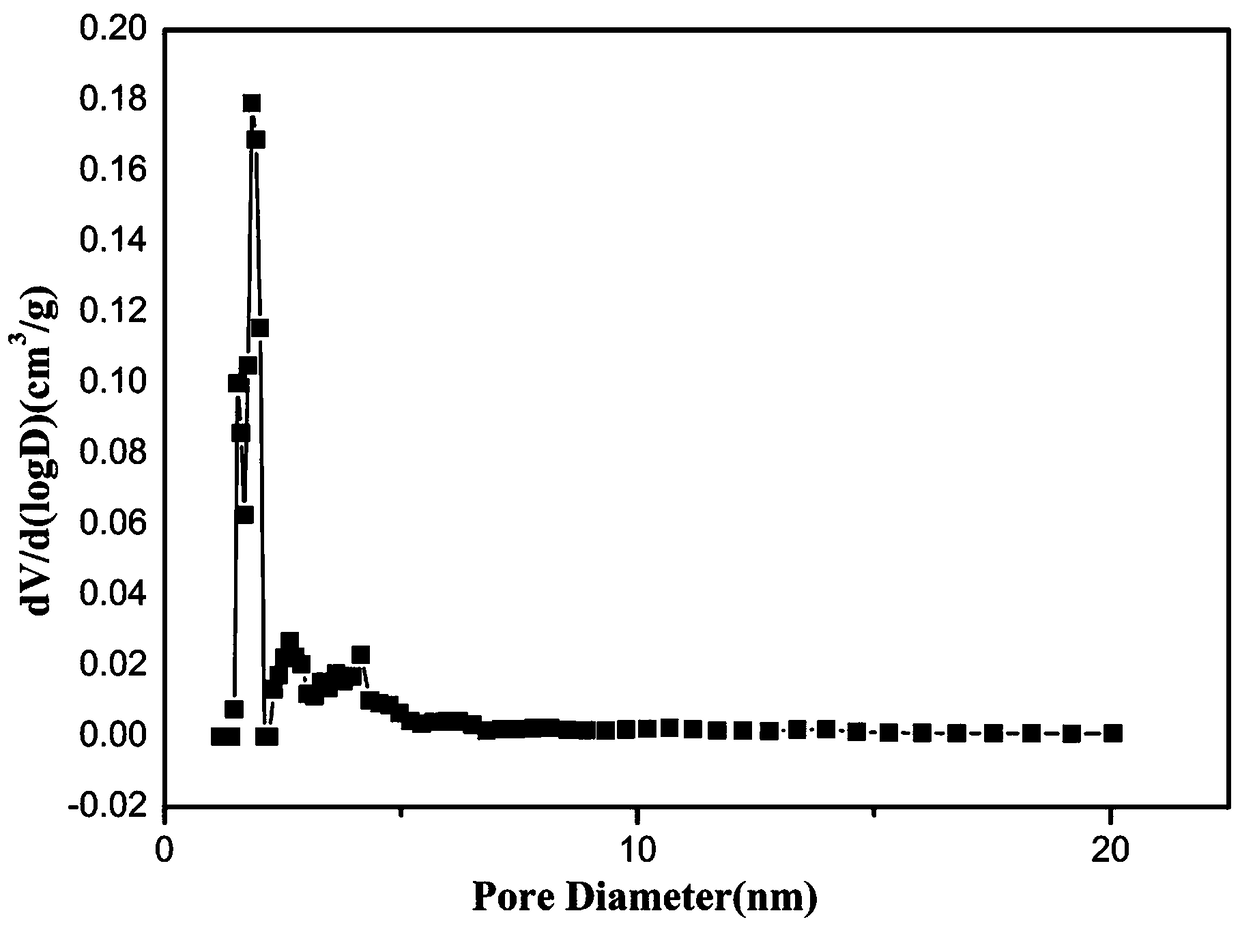

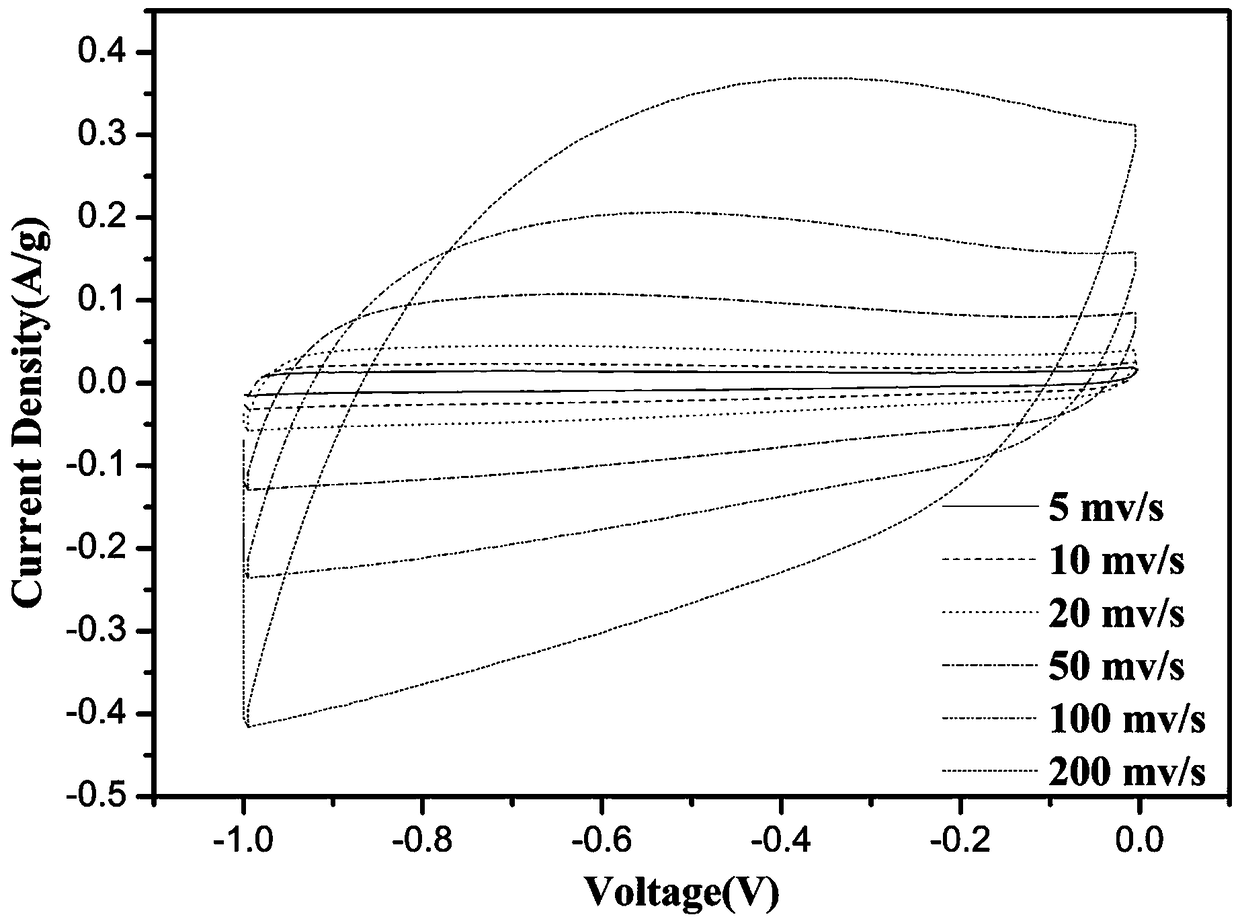

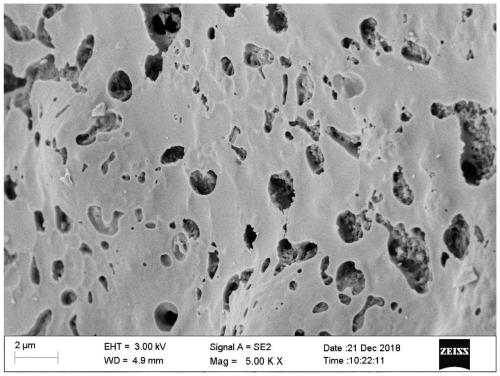

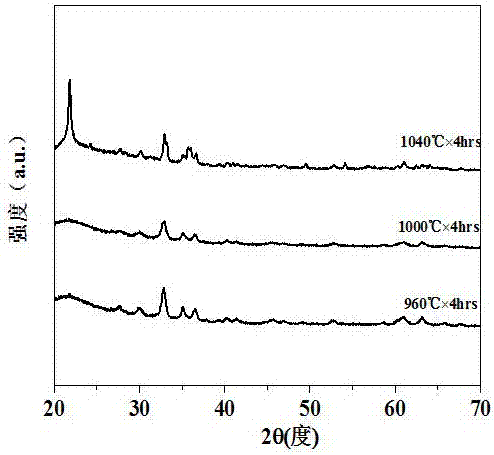

Preparation and applications of nitrogen doped porous active carbon material

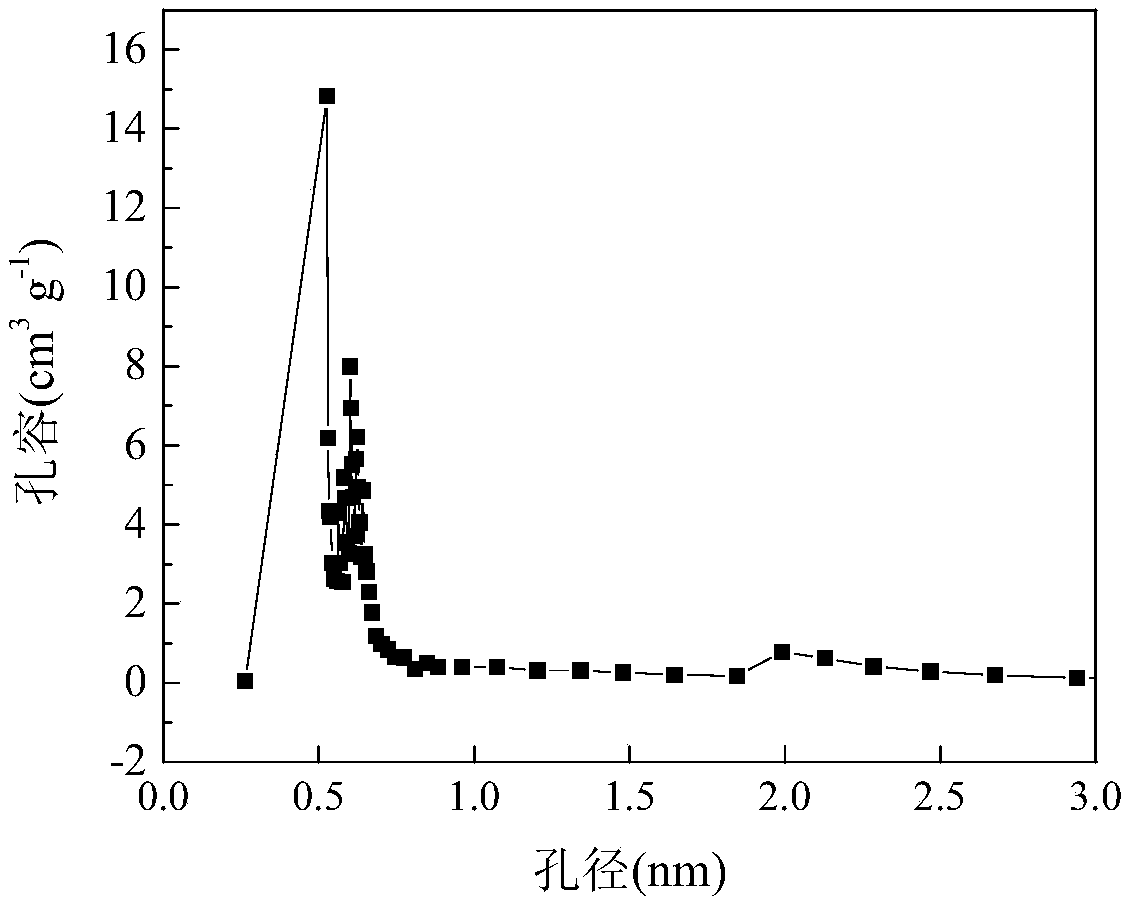

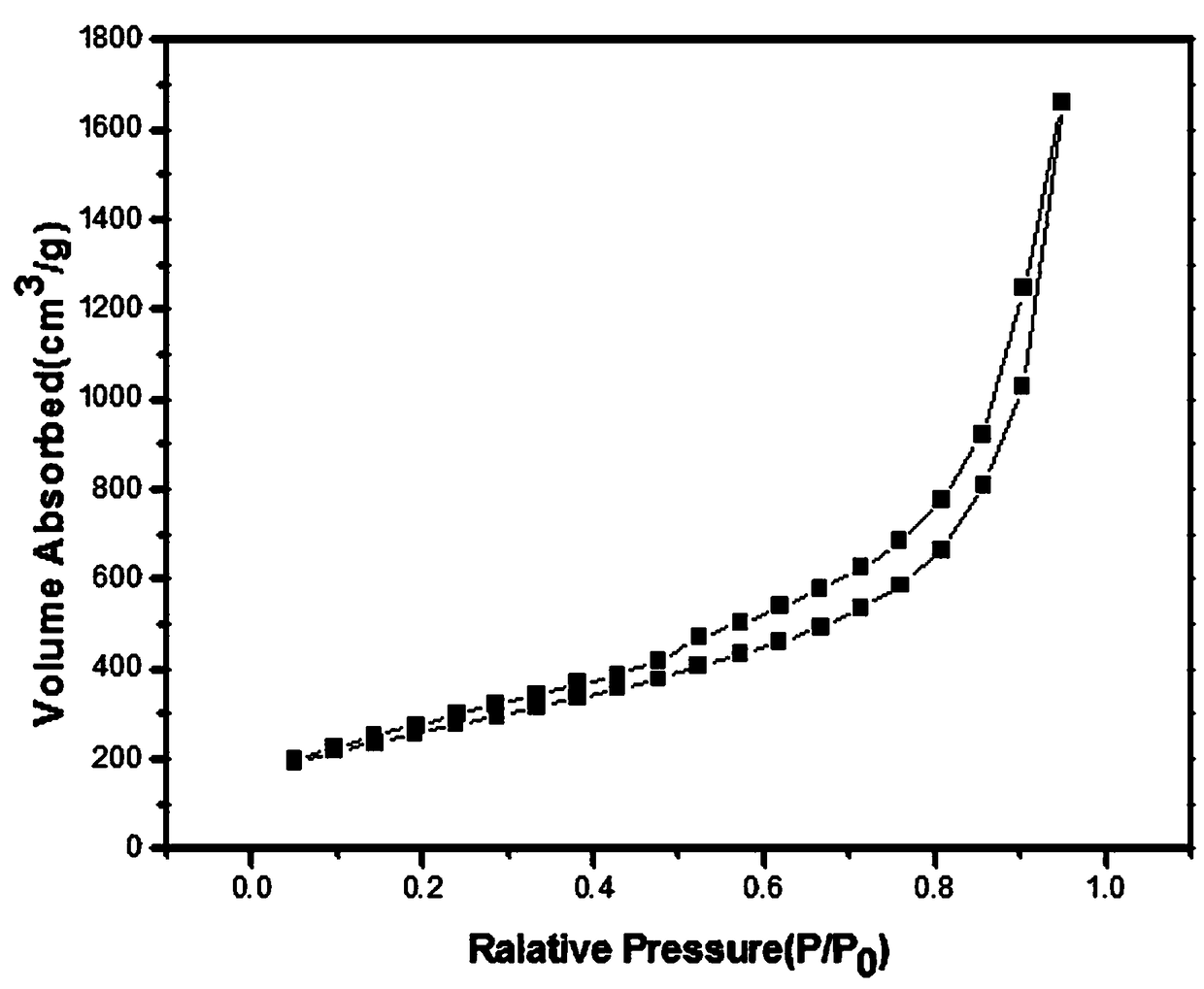

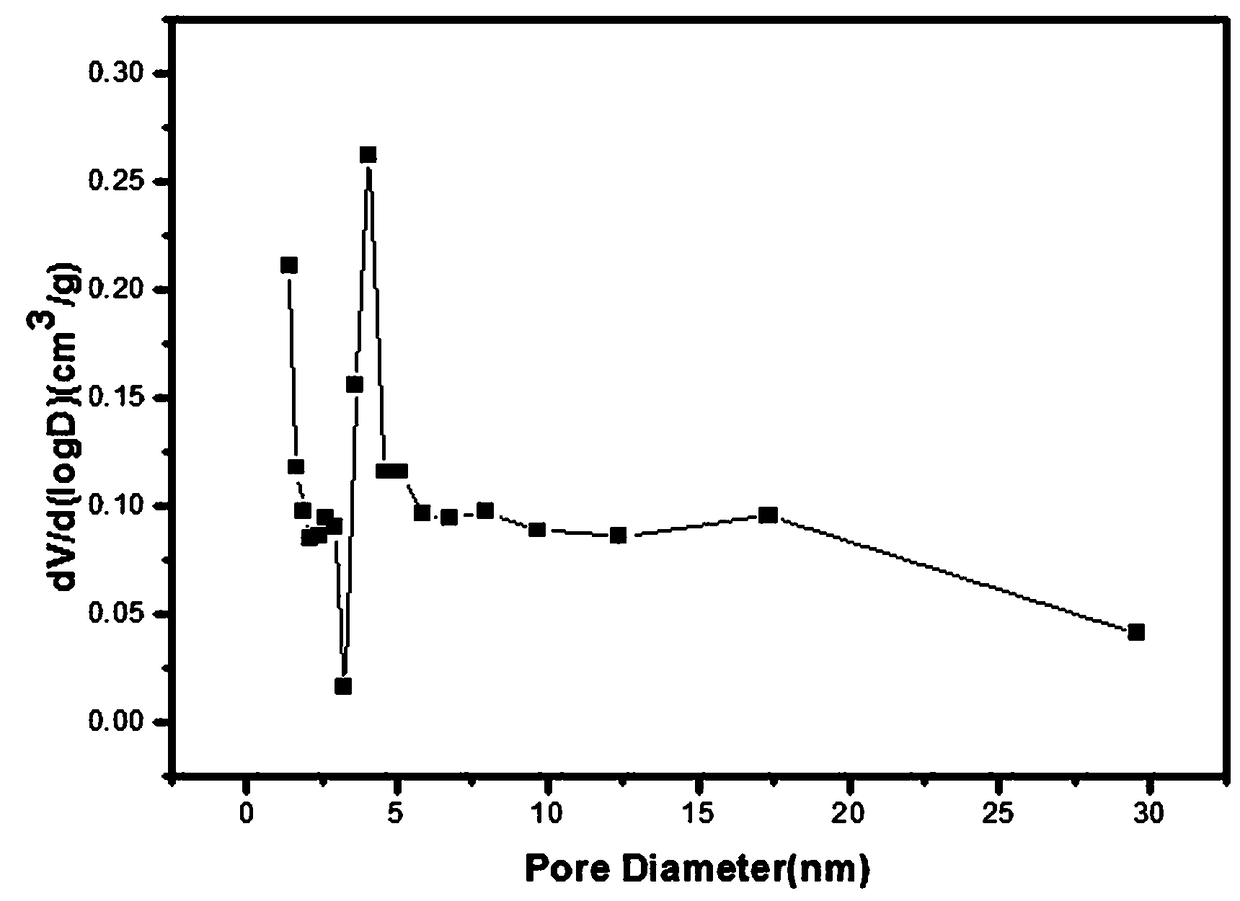

InactiveCN107128918ASimple design processLow activation temperatureCarbon compoundsHybrid capacitor electrodesCapacitanceNitrogen doped

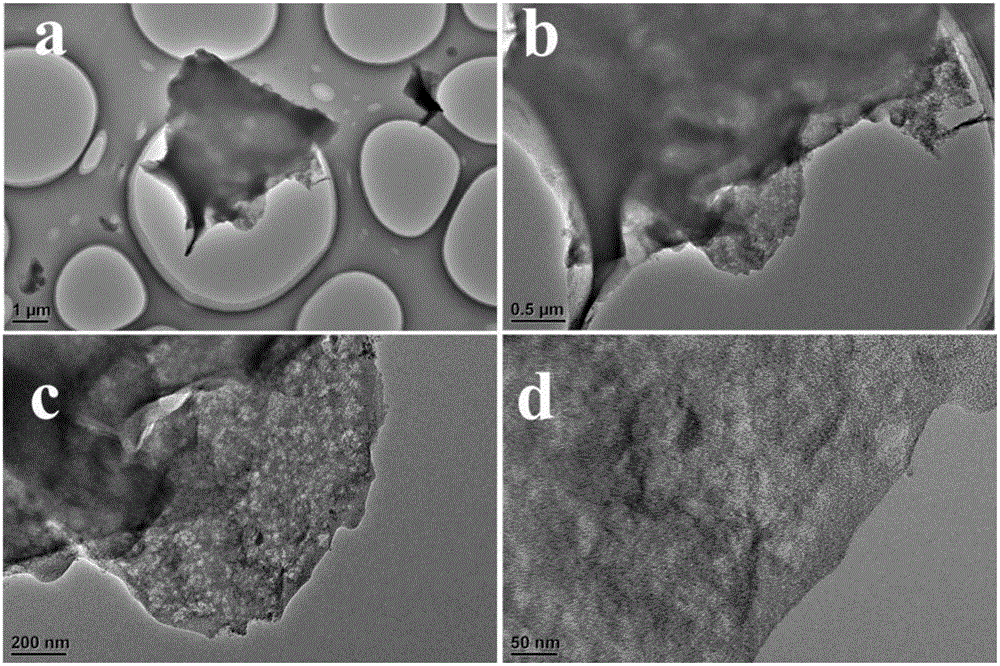

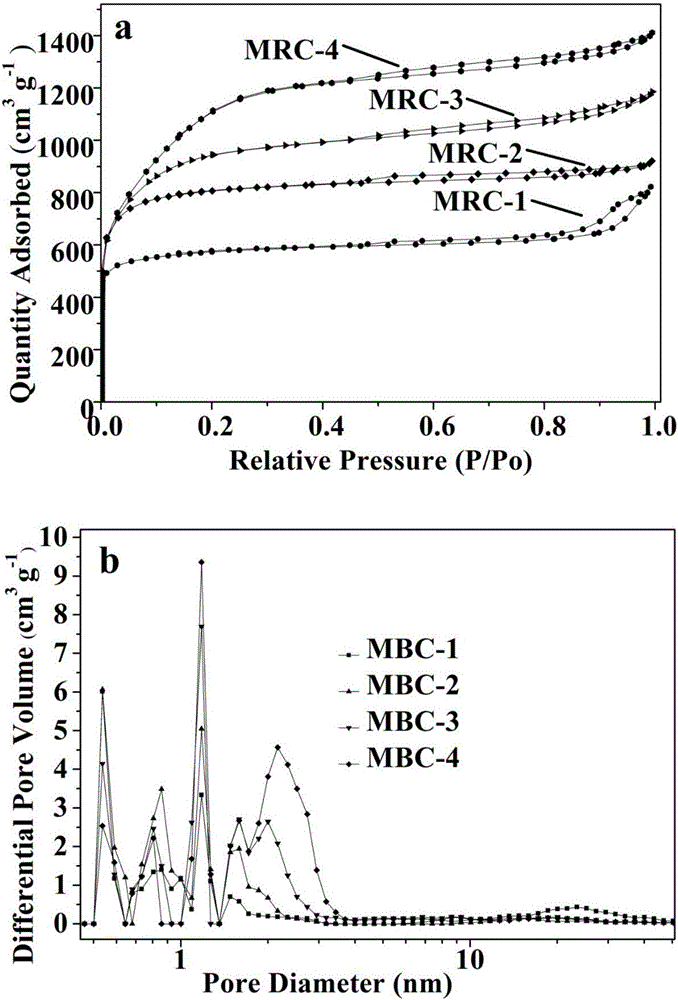

The invention discloses a nitrogen doped porous active carbon material, which is prepared by burning a carbon precursor prepared from sago cycas, a nitrogen source, and an alkaline inorganic substance. The specific surface of the material is in a range of 1136 to 2628 m<2> / g, and the average aperture is in a range of 1.17 to 2.11 nm. The preparation method comprises the following steps: step one, washing the leaves of sago cycas by water, drying the leaves, grinding the leaves, and burning the leaves to obtain a carbon precursor; step two, mixing the carbon precursor, the nitrogen source, and the alkaline inorganic substance, soaking, drying, burning, and carrying out activation to obtain a nitrogen doped porous active carbon material; and step three, soaking the nitrogen doped porous active carbon material in an acid solution, washing, filtering, drying, and grinding to obtain the final nitrogen doped porous active carbon material. When the material is used as the electrode material of a super capacitor, and if the current density is 1 A g<-1>, the specific capacitance is in a range of 266 to 351 F g<-1>. Leaves of sago cycas are taken as the raw materials, the application range is enlarged; and the material has a wide application prospect in the fields of porous materials and super capacitor.

Owner:GUILIN UNIV OF ELECTRONIC TECH

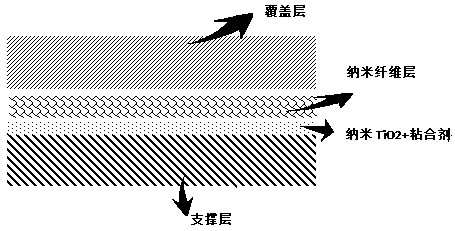

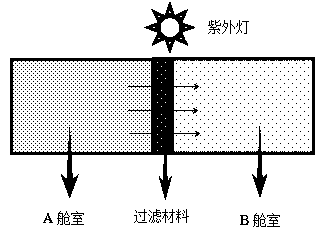

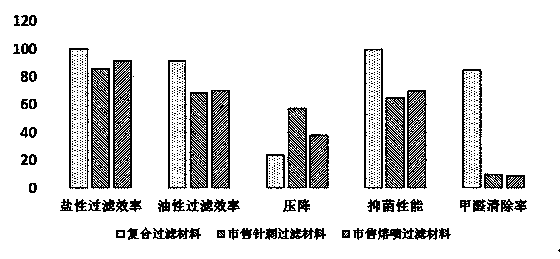

Preparation method of sandwich type anti-microbial composite nanometer filtering material for scavenging formaldehyde with high efficiency and low resistance

InactiveCN108097066AEasy to prepareSimple design processSemi-permeable membranesMembranesHigh resistanceNanoparticle

The invention discloses a preparation method of a sandwich type anti-microbial composite nanometer filtering material for scavenging formaldehyde with high efficiency and low resistance, and the method comprises the following steps: a nanoparticle bonding solution is prepared; nanoparticles are coated; spinning liquid is prepared; a nanometer fibrous layer is formed by electrostatic spinning; a covering layer is attached on the nanometer fibrous layer, in order to form a three-dimensional multidimensional sandwich structure which is composed of a supporting layer containing nanoparticles, thenanometer fibrous layer and the covering layer. The method has simple design technology, and the material has high filtering efficiency and low air resistance for PM 2.5; the material has small pressure drop and can dedust, so that the problems of low efficiency and high resistance of traditional air cleaning materials are overcome; the product is advantageous in that the material can precipitateharmful PM2.5, formaldehyde and a plurality of substances which are harmful for human bodies in indoor space or newly finished rooms in a short period of time, and the like; and at the same time, theproduct has excellent antibacterial properties and formaldehyde scavenging performance.

Owner:惠州德赛信息科技有限公司 +2

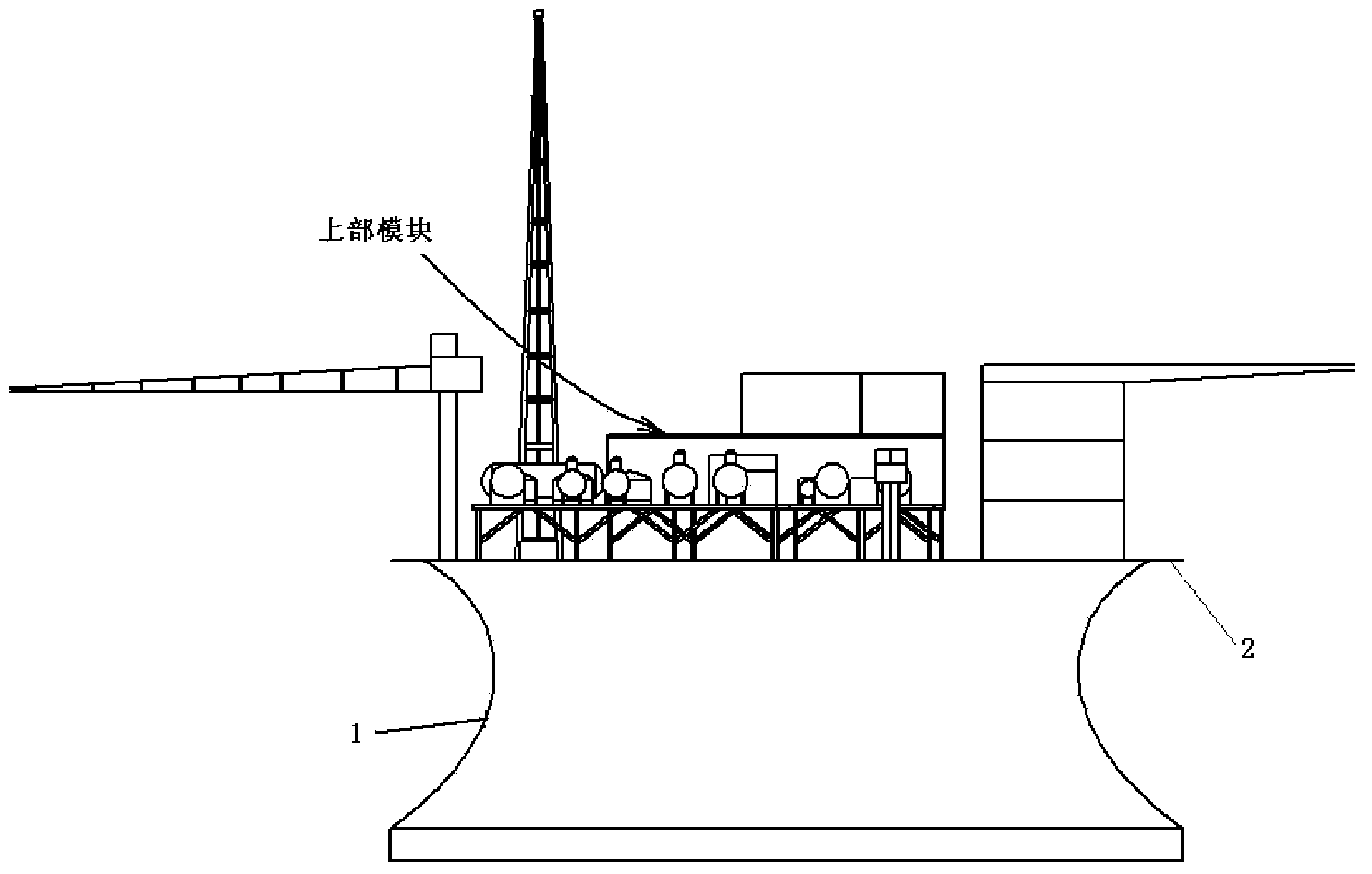

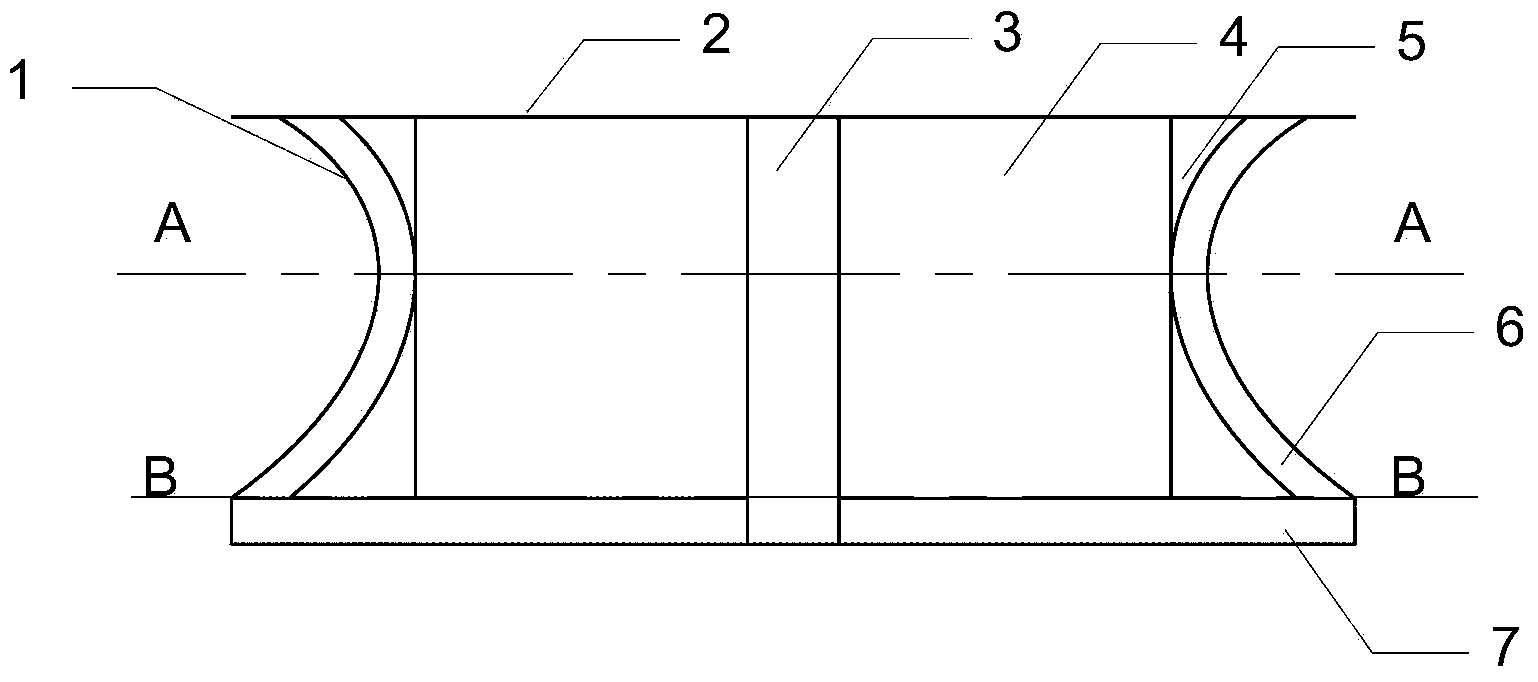

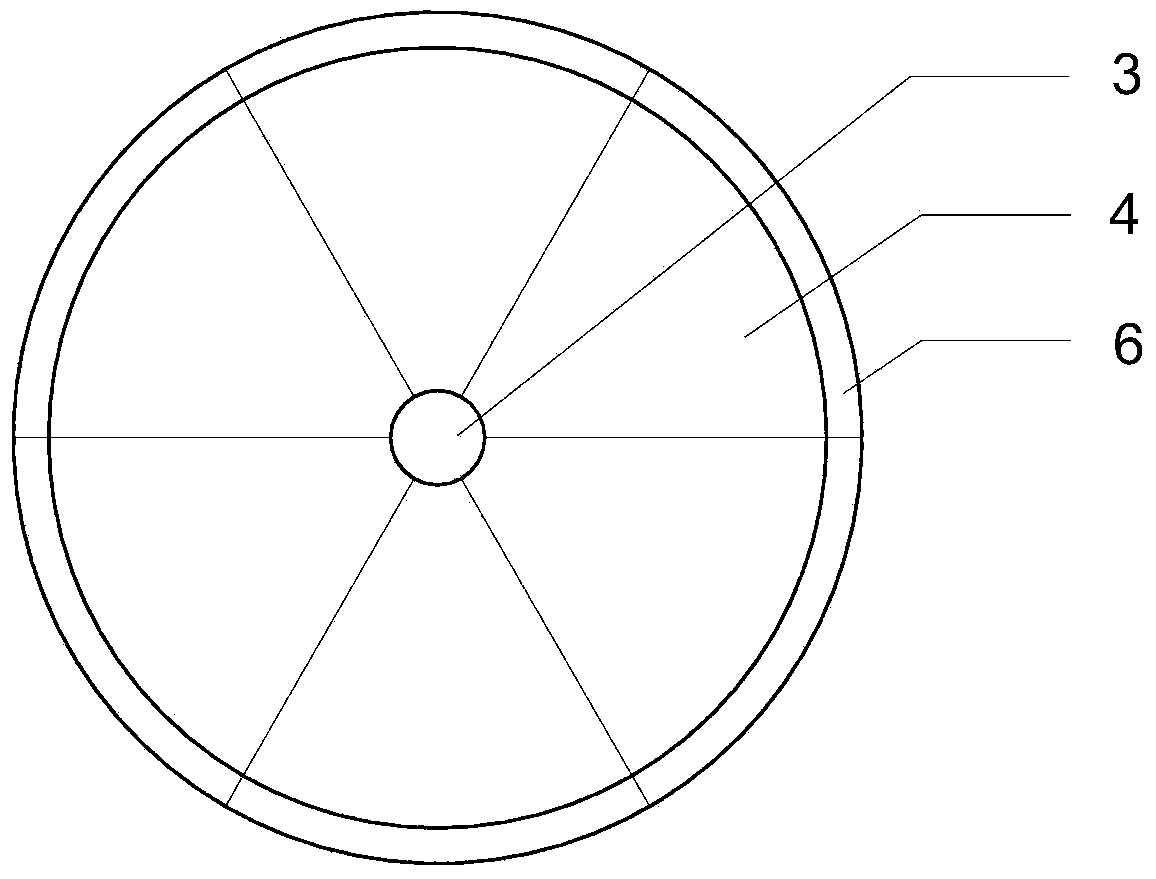

Double-curved-surface floating type production oil storage platform

InactiveCN103895828AImprove stabilityIncrease the usable areaFloating buildingsHyperboloidMarine engineering

The invention discloses a double-curved-surface floating type production oil storage platform. The platform comprises a floating body and a production deck. The vertical section of the floating body is of a uniparted hyperboloid shape or a rotary uniparted hyperboloid shape. A cylindrical central cabin is disposed in the middle of the floating body and along the axial direction of the floating body. An annular oil storage canine is disposed along the outer wall of the central cabin. The production deck is disposed on the upper end face of the floating body and provided with an oil-gas processing module, a water injection module, a water processing module, a power supply and distribution module, an auxiliary production module and a living building module. The platform has the advantages that the inherent defects of ship FPSO are overcome, the advantages of convenient moving and repeated using of traditional FPSO are inherited, stability and hydrodynamic performance of the platform are further improved, oil storage efficiency and bearing capacity are increased, building difficulty and cost are lowered, and a novel device is provided for efficient development of offshore oil fields.

Owner:SINOPEC PETROLEUM ENG DESIGN

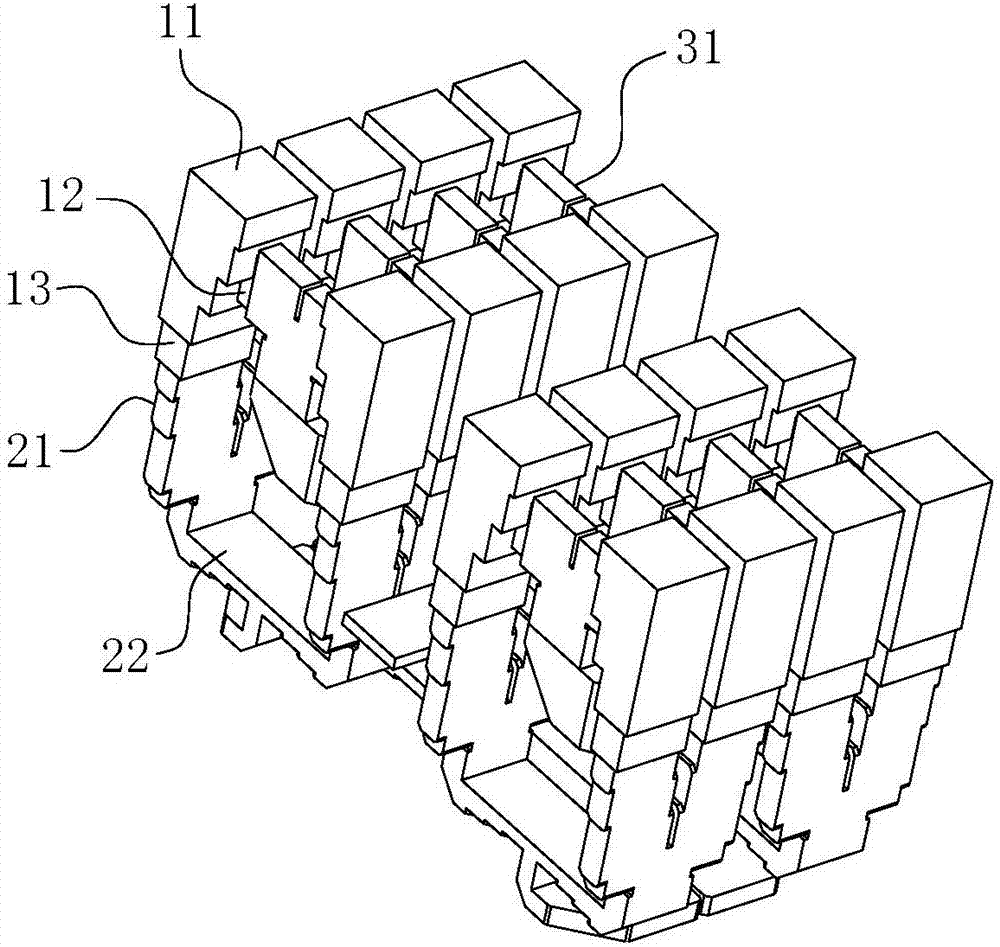

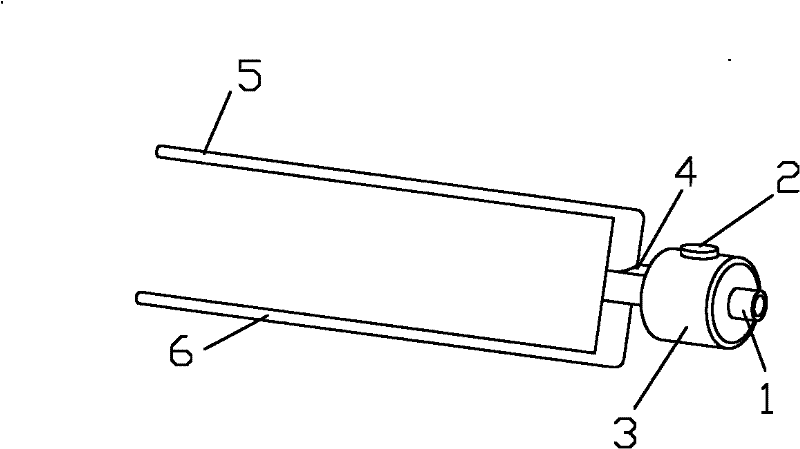

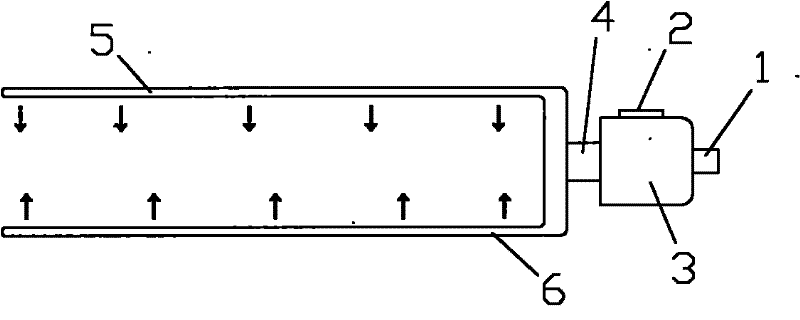

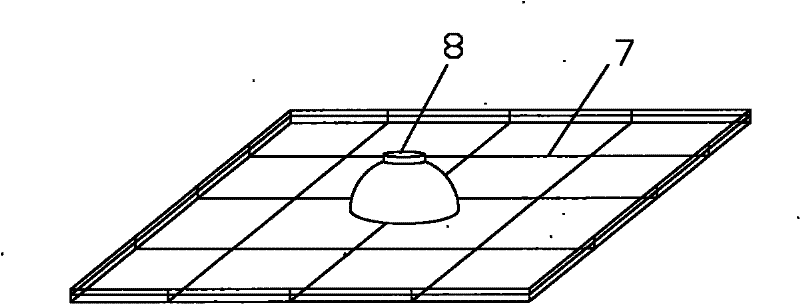

Dual-polarized wideband flat array antenna feed network

InactiveCN106877004AThe overall structure is compactReduce volumeAntennas earthing switches associationLinear waveguide fed arraysPhysicsWideband

The invention belongs to the technical field of design and manufacture of waveguide antennas, and in particular relates to a dual-polarized broadband flat panel array antenna feeding network. The feed network includes polarization separators, and the polarization separators form a basic array distribution of four rows and four columns; the vertical polarization unit includes a first vertical polarization power splitter, a second vertical polarization power splitter, a third a vertical polarization power divider and a fourth vertical polarization power divider; the horizontal polarization unit includes a first horizontal polarization power divider, a second horizontal polarization power divider, a third horizontal polarization power divider and a fourth horizontal polarization power divider Horizontal polarized power splitter; there is a waveguide arm between the two adjacent first vertical polarized power splitters on the second row and the third row for the two input ports of the fourth horizontal polarized power splitter to pass through The gap; the output port of the fourth horizontal polarization power splitter is located in the reserved area between the third row and the fourth row of polarization splitters. The invention has the advantages of compact structure, wide bandwidth and low profile, and can be used as a feed network for broadband dual-polarization antennas.

Owner:ANHUI SUN CREATE ELECTRONICS

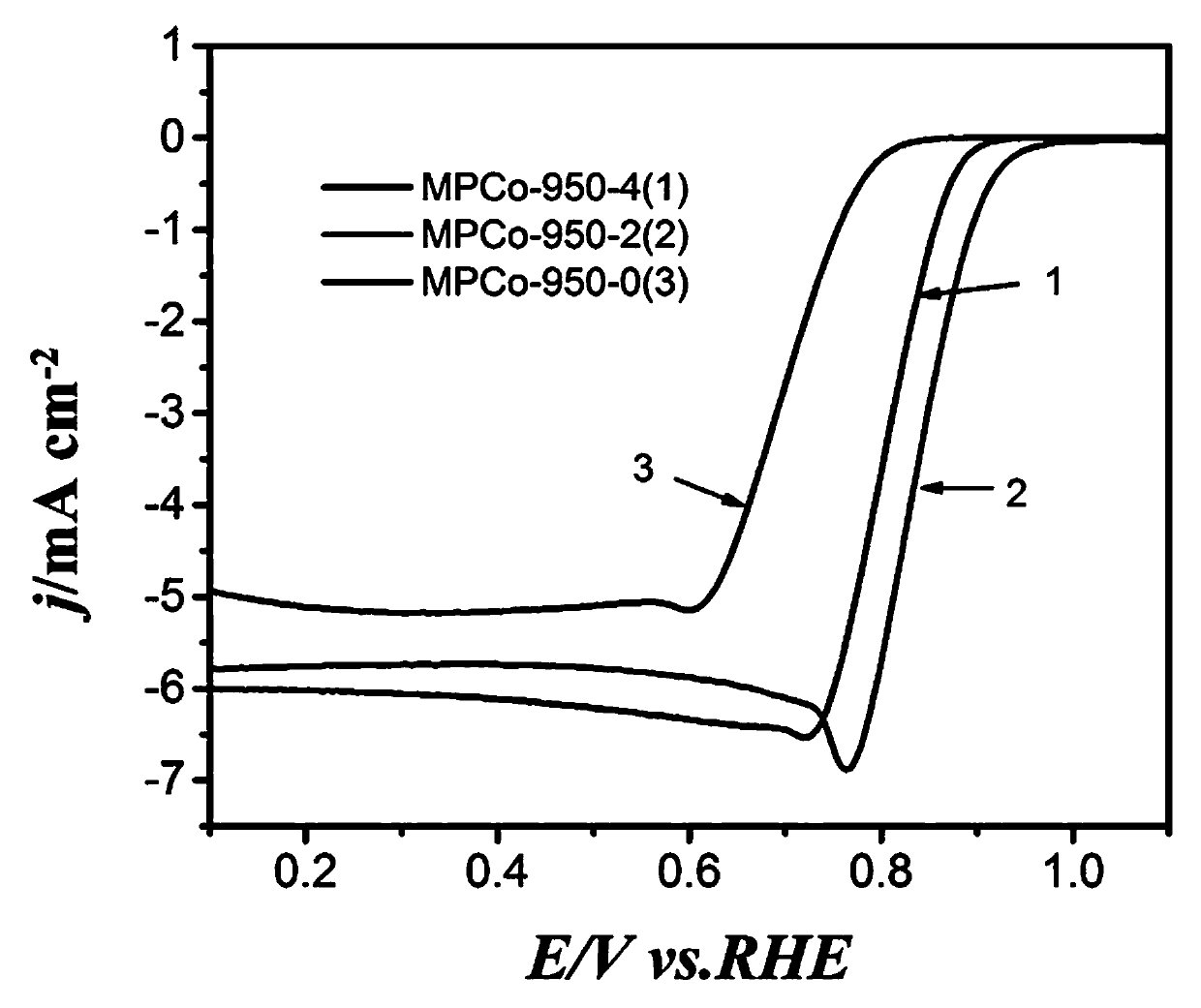

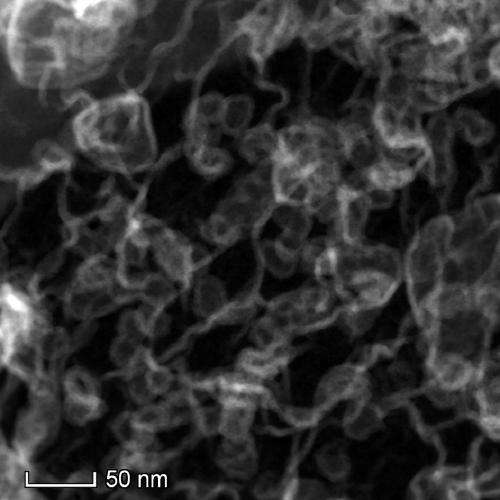

Carbon material with nitrogen, fluorine and transition metal co-doped graphene structure and one-step carbonization preparation method thereof

ActiveCN110148762ASimple design processEasy to operateCell electrodesCvd graphenePolytetrafluoroethylene

The invention provides a carbon material with a nitrogen, fluorine and transition metal co-doped graphene structure. Melamine, polytetrafluoroethylene and a metal salt are taken as raw materials for mixing and uniform grinding to prepare and obtain a nitrogen, fluorine and transition metal co-doped carbon material by employing a one-step carbonization method. The carbon material shows a graphene or graphene-like structure; the nitrogen, fluorine and metal elements are uniformly distributed, and the carbon material has excellent oxygen reduction and oxygen evolution performances. The one-step carbonization preparation method comprises the following steps of: 1) mixing of the raw materials; and 2) one-step carbonization method. The carbon material provided by the invention has excellent oxygen reduction and oxygen evolution performances. Besides, the excellent oxygen reduction and oxygen evolution performances of the material can be improved through regulation of the synergistic effect among the nitrogen, the fluorine and transition metal. The one-step carbonization method is good in repeatability, simple in process and easy to operate. The carbon material has wide application prospects in the fuel cell and metal-air cell electrode catalysis and the direction of functional carbon materials.

Owner:GUILIN UNIV OF ELECTRONIC TECH

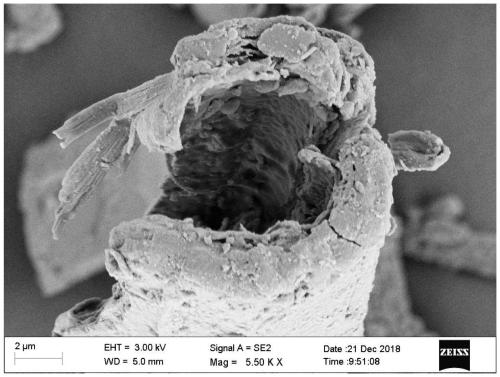

Preparation method and application of grapefruit pulp peel based porous carbon material

InactiveCN108584947ASimple design processLow activation temperatureCarbon compoundsHybrid capacitor electrodesCapacitancePorous carbon

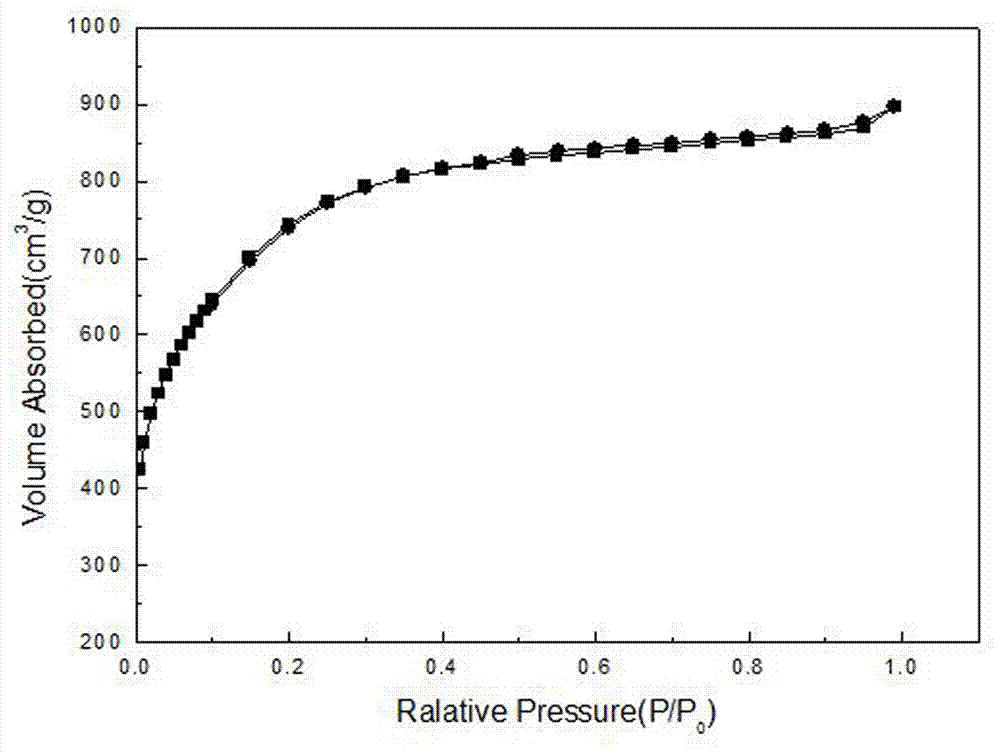

The invention discloses a porous carbon material prepared from grapefruit pulp peel, namely by using grapefruit pulp peel to prepare carbon precursor, using alkaline inorganic matter for treatment andcalcining. Specific surface area of the porous carbon material ranges from 972m2 g-1 to 1598m2 g-1, and average pore diameter distribution ranges from 1.76nm to 1.89nm. The preparation method includes following steps: 1), carbonizing grapefruit pulp peel at low temperature; 2), activating the grapefruit pulp peel based porous carbon material; 3), post-treating the grapefruit pulp peel based porous carbon material. When the porous carbon material is applied as a supercapacitor electrode material, Specific capacitance value ranges from 117F g-1 to 315F g-1 when current density is 0.5A g-1. Thegrapefruit pulp peel is used as a carbon source, so that application field of biological materials is expanded; the porous carbon material has extensive application prospect in the field of porous materials and supercapacitors.

Owner:GUILIN UNIV OF ELECTRONIC TECH

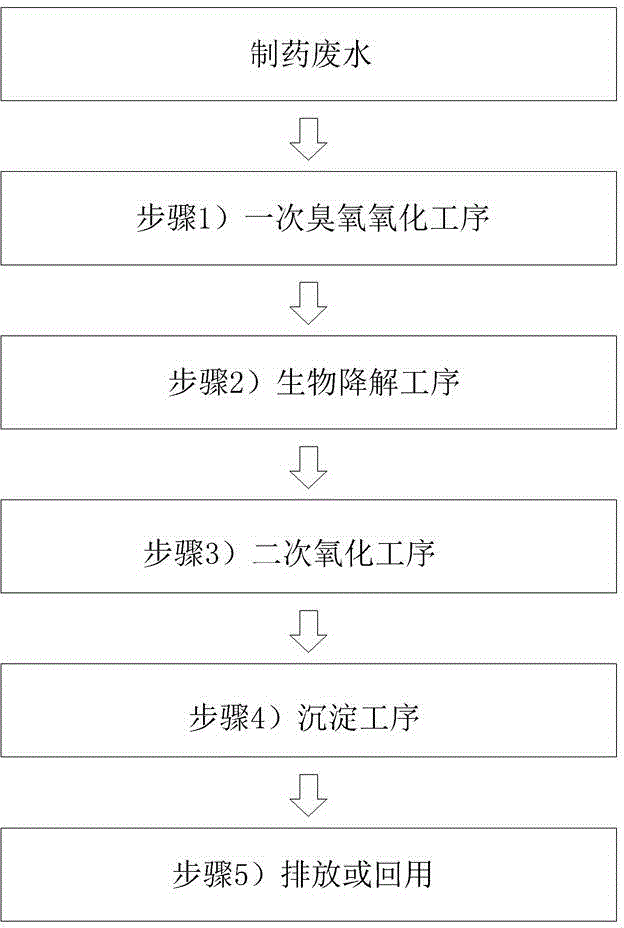

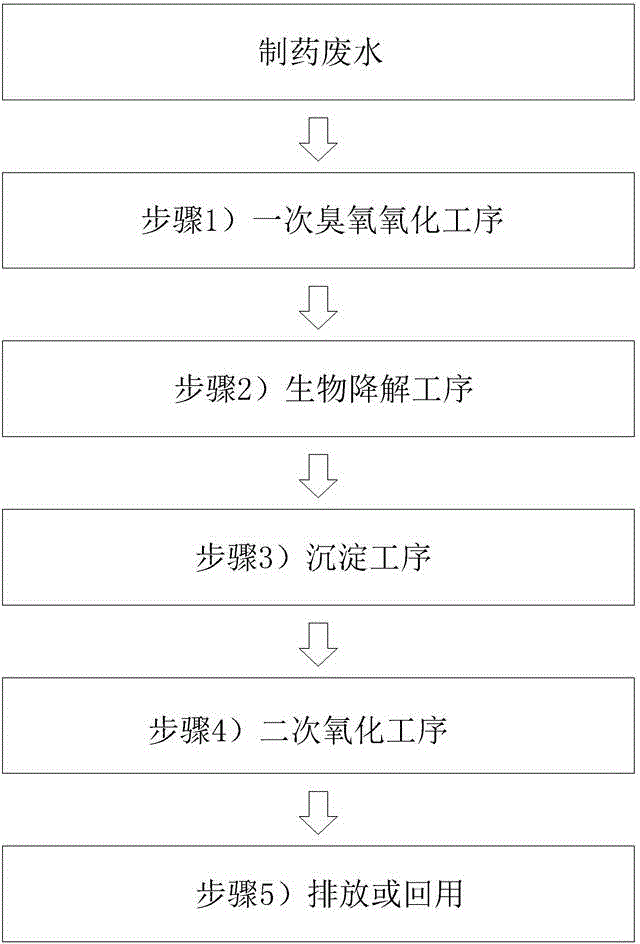

Pharmaceutical wastewater treatment method

InactiveCN104556586ASimple design processEasy to operateWater/sewage treatment by irradiationWater treatment compoundsWastewaterAntibiotic Y

The invention discloses a pharmaceutical wastewater treatment method. The pharmaceutical wastewater treatment method comprises the following steps: firstly carrying out primary ozonation on pharmaceutical wastewater, treating toxins like antibiotics, then carrying out biochemical degradation by virtue of biological bacteria, then carrying out secondary oxidation on the biochemically degraded wastewater, killing biological bacteria and other toxic and harmful bacteria, finally carrying out sedimentation treatment, and directly discharging the pharmaceutical wastewater up to the standard or recycling the pharmaceutical wastewater into a production process by virtue of recycling equipment. The pharmaceutical wastewater treatment method has the advantages that ozone is adopted as an oxidizing agent and is discharged out in a gas form after oxidation is completed, no residue or pollution is produced, and no adverse impact is produced to follow-up treatment. meanwhile, a design working procedure is simple, flow operation is easy, and the treated wastewater can meet the standard emission requirement, so that the pharmaceutical wastewater treatment method is good and is a development direction of the pharmaceutical wastewater treatment in future.

Owner:何学文

Method for preparing porous carbon material from allyl wastes and application

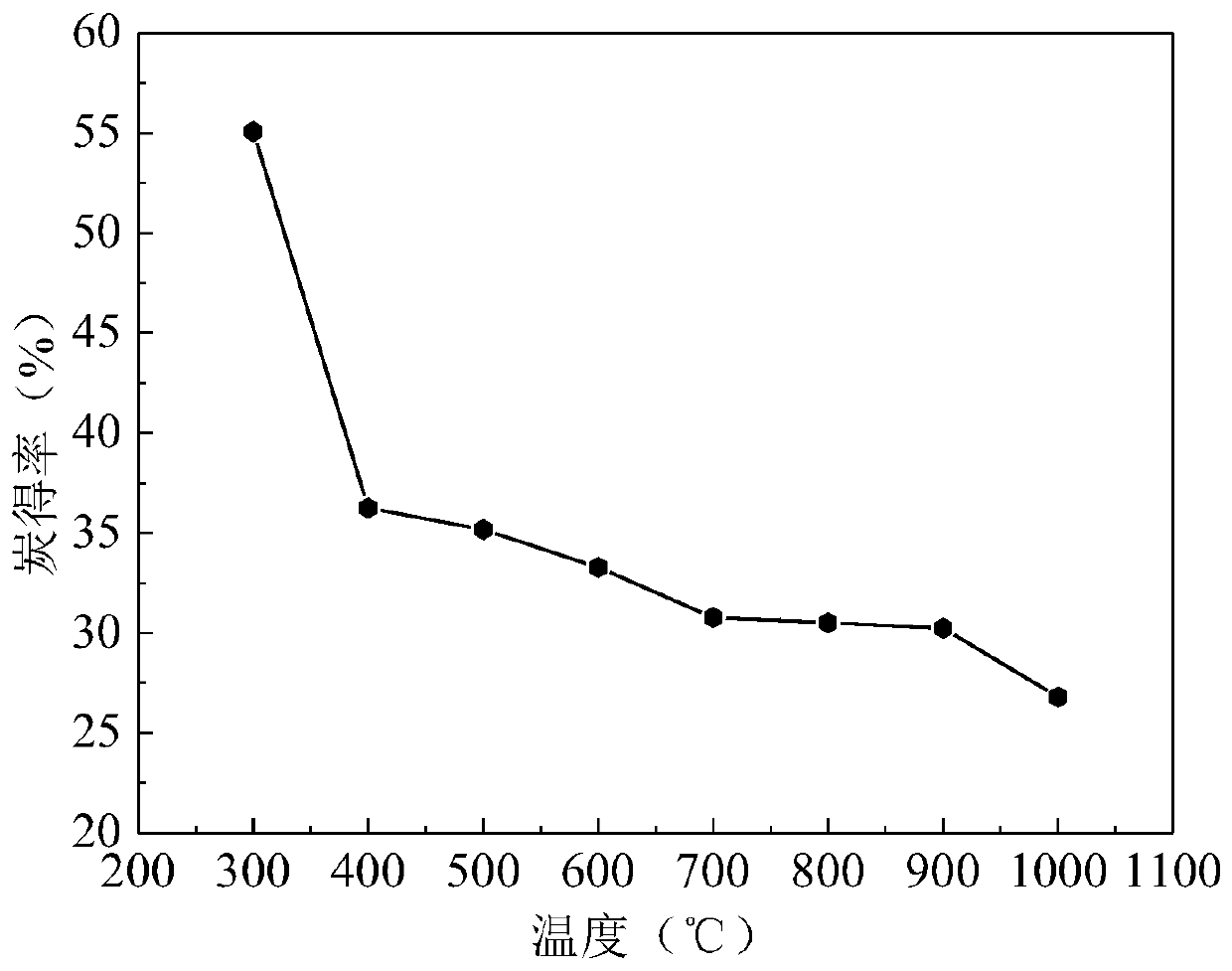

ActiveCN108557819ALow ashImprove wettabilityCarbon compoundsHybrid capacitor electrodesPorous carbonHeating temperature

The invention discloses a method for preparing a porous carbon material from allyl wastes and application. The preparation method comprises the following steps: S1, heating and carbonizing the allyl wastes in an inert atmosphere, wherein the carbonizing temperature is 400-800 DEG C, and the carbonizing time is 80-150 min; S2, carrying out acid pickling on the product prepared in step S1, and washing the product until the product is neutral; S3, dipping the product prepared in step S2 in a chemical activating agent; and S4, heating and activating the product prepared in step S3, wherein the heating temperature is 700-900 DEG C, and the time is 60-140 min; and carrying out acid pickling, washing and drying to obtain an allyl waste porous carbon electrode material. The method is high in professional applicability, a design process is simple, and industrialization is easy to realize. While the porous carbon material is prepared, the allyl wastes are utilized at high quality, and an obtained porous carbon super-capacitor is excellent in performance.

Owner:SHANDONG UNIV

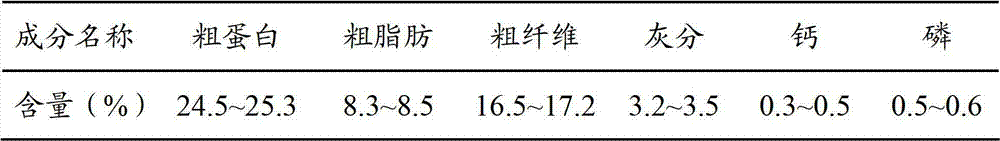

Nutritive feed and preparation method thereof

InactiveCN102860413ASimple design processLess capital to buildFood processingAnimal feeding stuffRoom temperatureSterile water

The invention relates to a nutritive feed prepared by mixing bagasse and brewer's grain and a preparation method of the nutritive feed. The preparation method comprises the following steps of: taking sawdust, sterilizing, adding sterile water, inoculating irpex lacteus according to the weight part proportion of the sawdust to the irpex lacteus of 1:1*10<-5>-3*10<-5>, culturing for 15h-18h under room temperature to obtain a strain; mixing the bagasse with the brewer's grain according to the weight part proportion of 1:(1.5-1.8), adding the strain, fermenting for 15h-18h at room temperature, then adding a bacterium liquid containing nitrobacteria, continuously fermenting for 9h-10h; and after the fermenting is ended, freezing and drying to obtain the nutritive feed. The preparation method is simple in designed process, is little in construction cost, is easy to operate, and is suitable for small farms and retail farmers; meanwhile, the waste of the sugar industry and the brewing industry is recycled without polluting the environment; and the prepared feed is rich in nutrition and can better improve the intestinal tract digestive system of livestocks.

Owner:GUANGZHOU YOURUI BIOSCI

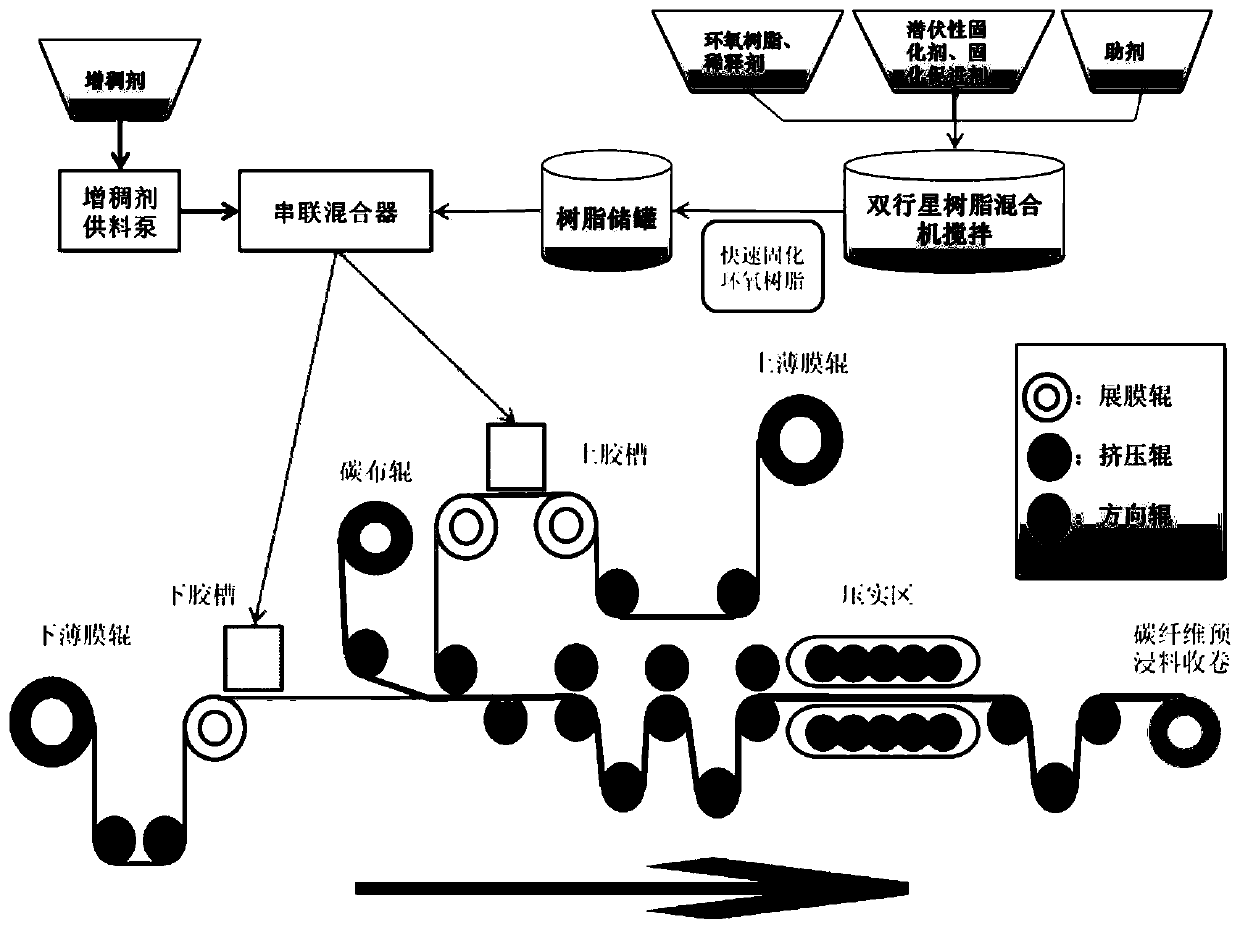

Epoxy chopped carbon fiber felt prepreg for rapid prototyping and production process thereof

The invention discloses an epoxy chopped carbon fiber felt prepreg for rapid prototyping and a production process thereof, and relates to the field of resin-based composites. The epoxy carbon fiber felt prepreg comprises the following components in percentage by weight: 20-45% of chopped carbon fiber felt, and 55-80% of an epoxy resin composition which can be quickly thickened. The epoxy resin composition which can be quickly thickened comprises rapidly cured epoxy resin and an epoxy thickener containing amino reactive hydrogen, the invention further discloses a production process of the epoxychopped carbon fiber felt prepreg for rapid prototyping. The epoxy carbon felt prepreg is good in mechanical property, is a quasi-isotropic material, is simple in structural design and paving process, can be quickly formed by mould pressing at 140-160 DEG C for 3-10 minutes, and can realize low-cost batch production of carbon fiber composite material parts.

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

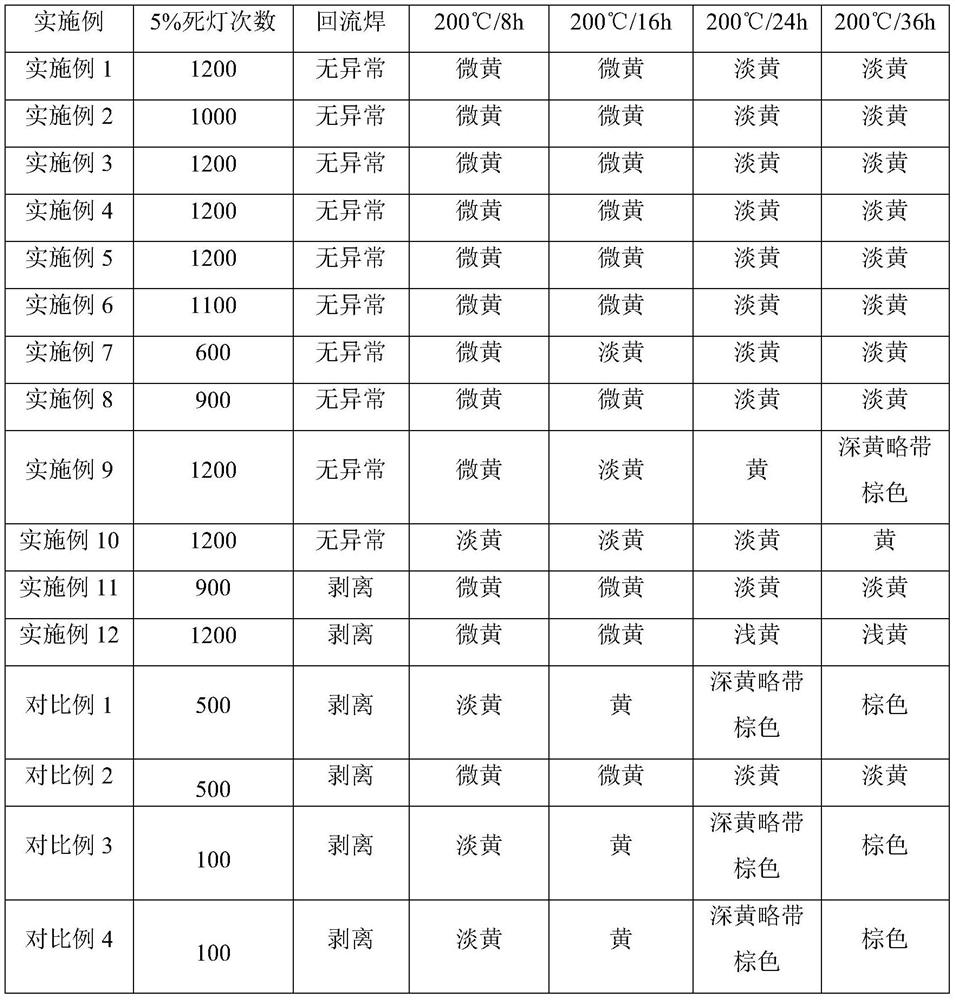

Packaging adhesive for LED, use method and application thereof

ActiveCN111826105AEasy to synthesizePerformance free adjustmentNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesUv absorbancePolymer science

The invention discloses a packaging adhesive for LED, a use method and application thereof. The packaging adhesive for LED comprises a component A and a component B. The component A comprises epoxy resin, an antioxidant and optional color paste. The component B comprises a curing agent, a hydroxyl-terminated polyurethane prepolymer, polyol, an accelerant and an optional ultraviolet absorbent. Thepackaging adhesive for LED disclosed by the invention has good cold and hot impact resistance and humidity and heat resistance.

Owner:BEIJING KMT TECH

Tableware cleaning machine

InactiveCN102440744AQuick washEasy to cleanTableware washing/rinsing machine detailsEngineeringMechanical engineering

A tableware cleaning machine comprises a bowl cleaning cavity, a tableware rack and a spraying device. The tableware rack is placed in the bowl cleaning cavity, and the spraying device comprises a spraying arm. The tableware cleaning machine is characterized in that the tableware rack is a flat-bottom type tableware rack with fences on the periphery and a plane at the bottom, the spraying device is a translation type spraying device, and the spraying arm of the spraying device is perpendicular to a certain side surface of the bowl cleaning cavity and works in a translation manner. Compared with an existing dish washing machine, the tableware cleaning machine in the technical scheme not only is better in cleaning effect and faster in cleaning speed, but also is simpler in structure and easier in operation, and cost of products and service cost are lower.

Owner:刘勇

Fluorine and nitrogen co-doped three-dimensional graphene material and one-step carbonization preparation method thereof

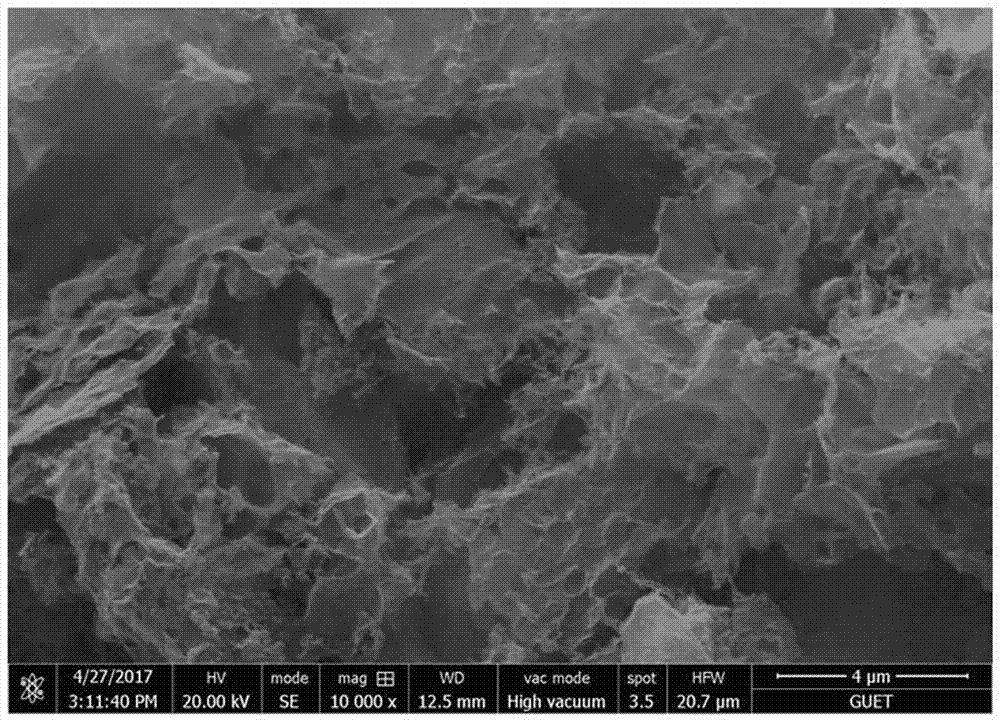

The invention discloses a fluorine and nitrogen co-doped three-dimensional graphene material. The fluorine and nitrogen co-doped three-dimensional graphene material is prepared by taking polytetrafluoroethylene and melamine as precursors through mixing and uniformly grinding and carrying out a one-step carbonization method; fluorine and nitrogen elements of three-dimensional graphene are uniformlydistributed; the specific surface area is 1200 to 1400m<2>g<-1> and the total pore volume is 2.5 to 2.9cm<3>g<-1>; the specific surface area of the material can be greatly regulated and controlled tobe 50 to 1600m<2>g<-1> through changing the carbonization temperature and the total pore volume is regulated and controlled to be 0.2 to 3.2cm<3>g<-1>. The one-step carbonization preparation method comprises the following steps: 1, mixing the raw materials; 2, carrying out a one-step carbonization method. Three-dimensional graphene grids in the material are uniform, and the fluorine and nitrogenelements are uniformly distributed; the repeatability is good and the carbonization temperature is moderate; the material is synthesized through one-step carbonization and a technology is simple and easy to operate. The material has a wide application prospect in the field of super-capacitors and a carbon functional material.

Owner:GUILIN UNIV OF ELECTRONIC TECH

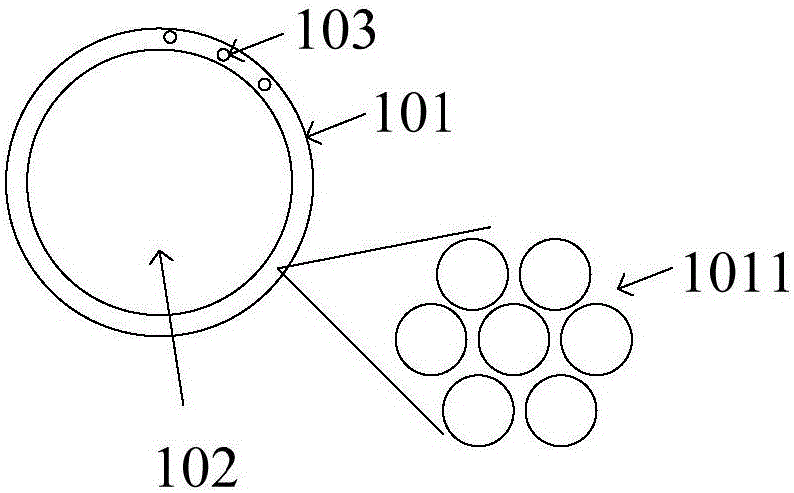

Fingerprint identification button device and mobile terminal

InactiveCN106101311ASimple design processMaximize utilizationElectric light circuit arrangementDigital data authenticationKey pressingComputer terminal

The invention provides a fingerprint identification button device and a mobile terminal. The fingerprint identification button device comprises a metal ring, a fingerprint identification chip and luminescent parts, wherein the luminescent parts are arranged in the lower side of the metal ring, the metal ring is provided with a preset amount of through holes so that light generated by the luminescent parts can transmit through the through holes, the size of the metal ring is adapted to that of the fingerprint identification chip, and the metal ring sleeves the fingerprint identification chip. According to the invention, a display screen can be utilized to the largest degree, and design technology of the mobile terminal is simplified.

Owner:VIVO MOBILE COMM CO LTD

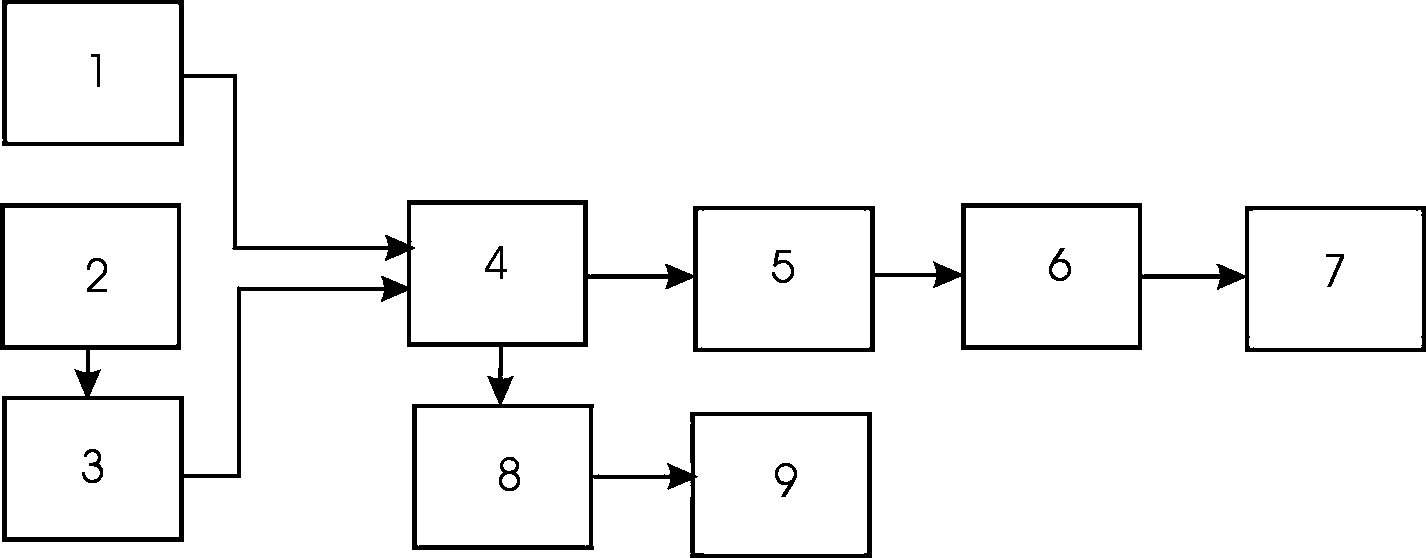

Method for comprehensively utilizing ginger straw

ActiveCN110203926AImprove use valueSimple design processHybrid capacitor electrodesCarbon preparation/purificationPorous carbonAcid washing

The present invention provides a method for comprehensively utilizing ginger straw. The method comprises: washing ginger straw, pressing, and separately collecting the juice and the residue after thepressing treatment; separating the oil from the obtained ginger straw juice through standing or by using a centrifuge to obtain a ginger straw crude oil; drying the obtained ginger straw residue, placing in a closed furnace hearth, introducing a protective gas, and heating to carbonize so as to obtain ginger straw charcoal; and carrying out acid washing on the obtained ginger straw charcoal, carrying out water washing to achieve a neutral state, and drying to obtain the ginger straw-based porous carbon, wherein the temperatures of the acid washing and the water washing respectively are 70-90 DEG C. According to the present invention, with the method, the high value utilization of ginger straw waste is achieved, the preparation process is simple, the chemical reagent consumption is less, and the waste utilization rate is high.

Owner:SHANDONG UNIV

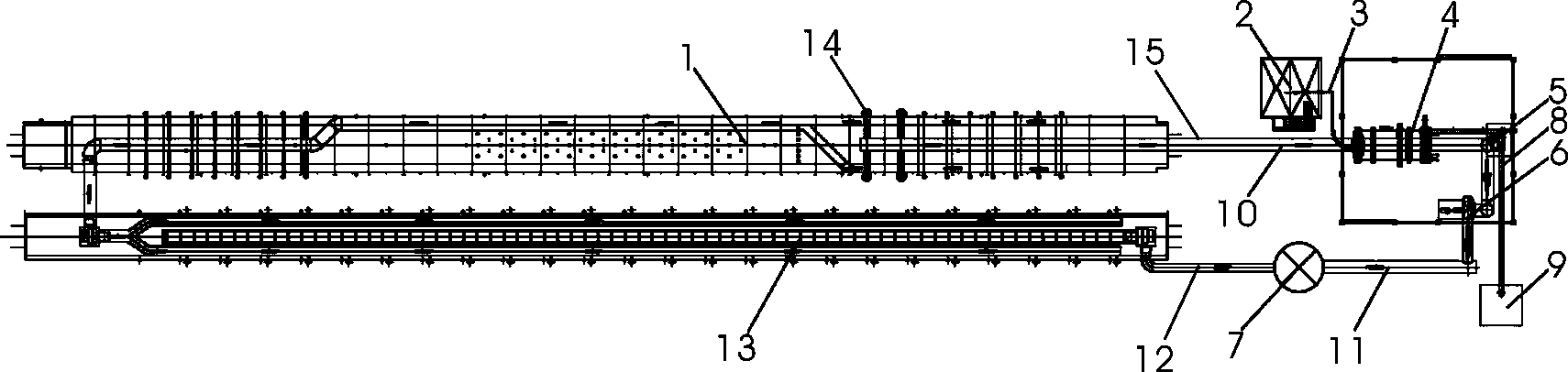

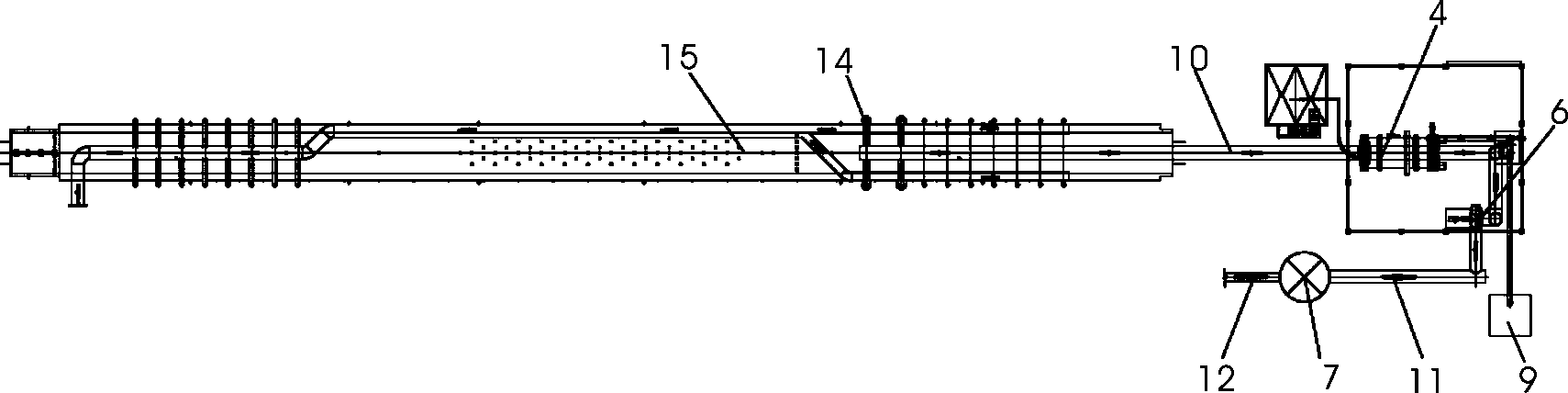

Process for producing brick by waste heat drying sludge from sintered brick production line tunnel kiln

InactiveCN104315844ARealize comprehensive utilizationEfficient use ofFurnace typesWaste heat treatmentTunnel kilnBrick

The invention discloses a process for producing a brick by waste heat drying sludge from a sintered brick production line tunnel kiln, and the sintered brick production line tunnel kiln includes waste heat from a cooling section of a roasting kiln, a wet sewage sludge bin, a mud conveying pipe, a sludge drying machine, a cyclone dust collector, an induced draft fan, a desulfurizing tower, a spiral conveyer, a dry sludge bin, an air intake pipeline, air exhaust pipelines of sulfurizing and desulfurizing towers in a drying workshop, air exhaust pipelines of sulfurizing and desulfurizing towers in a drying kiln, a drying kiln, an auxiliary heat waste extracting air pipe and a main heat waste extracting air pipe. The wet sludge is conveyed into the wet sewage sludge bin after being gathered, a mud conveying pipe arranged in the wet sewage sludge bin is connected with the sludge dryer, at the same time, the waste heat from the cooling section of the roasting kiln is led into the sludge dryer through the air intake pipeline. The center of the upper part of the roasting kiln is provided with the main heat waste extracting air pipe, both sides of the upper part of the roasting kiln are provided with the auxiliary heat waste extracting air pipe, the roasting kiln and the drying kiln are in parallel arranged, the cyclone dust collector is provided with the induced draft fan, the spiral conveyer is connected with the dry sludge bin, and the induced draft fan is connected with the desulfurizing tower. The process is simple, low in investment, high in reliability and convenient to operate.

Owner:郭金良

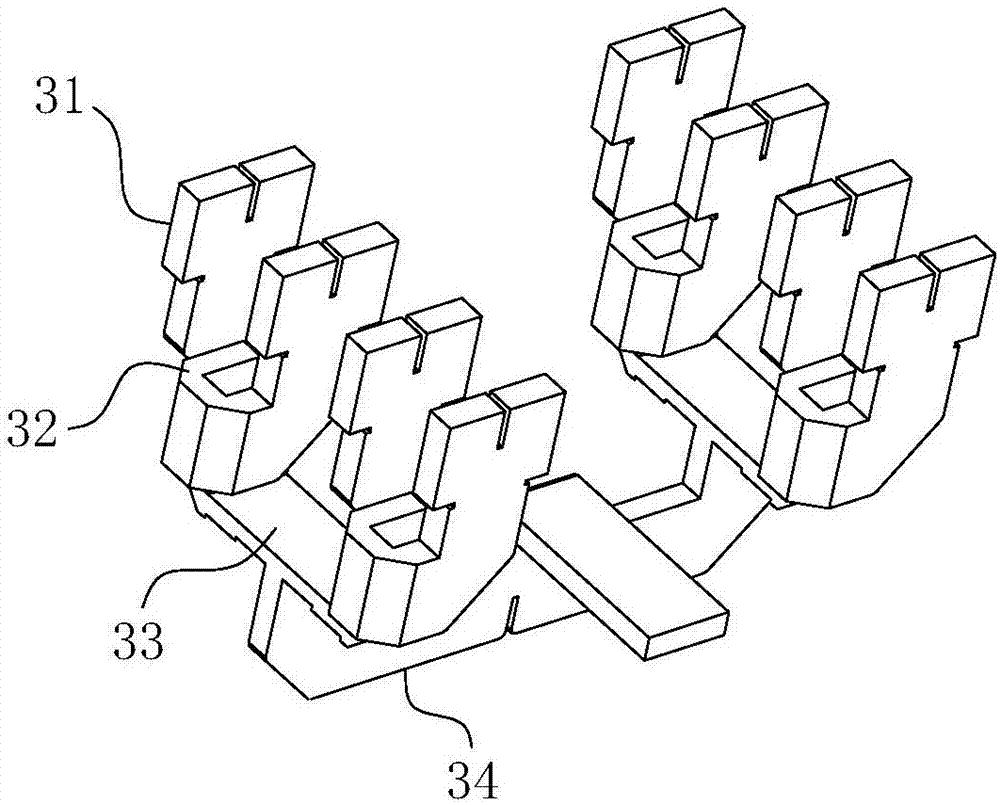

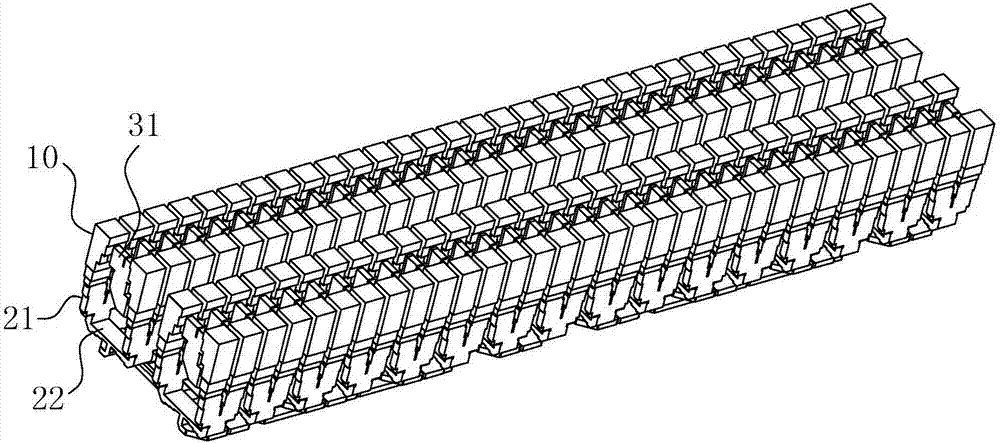

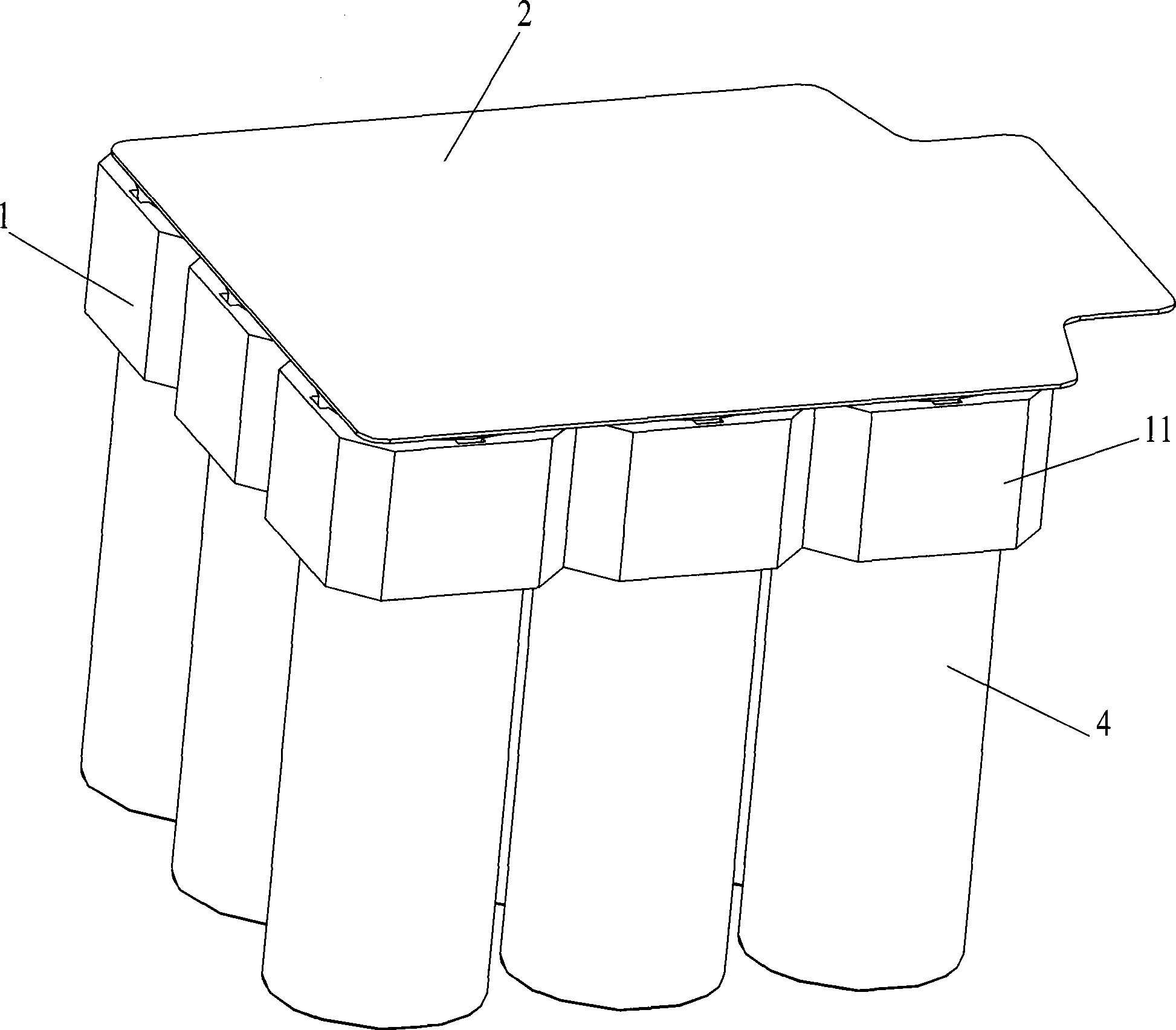

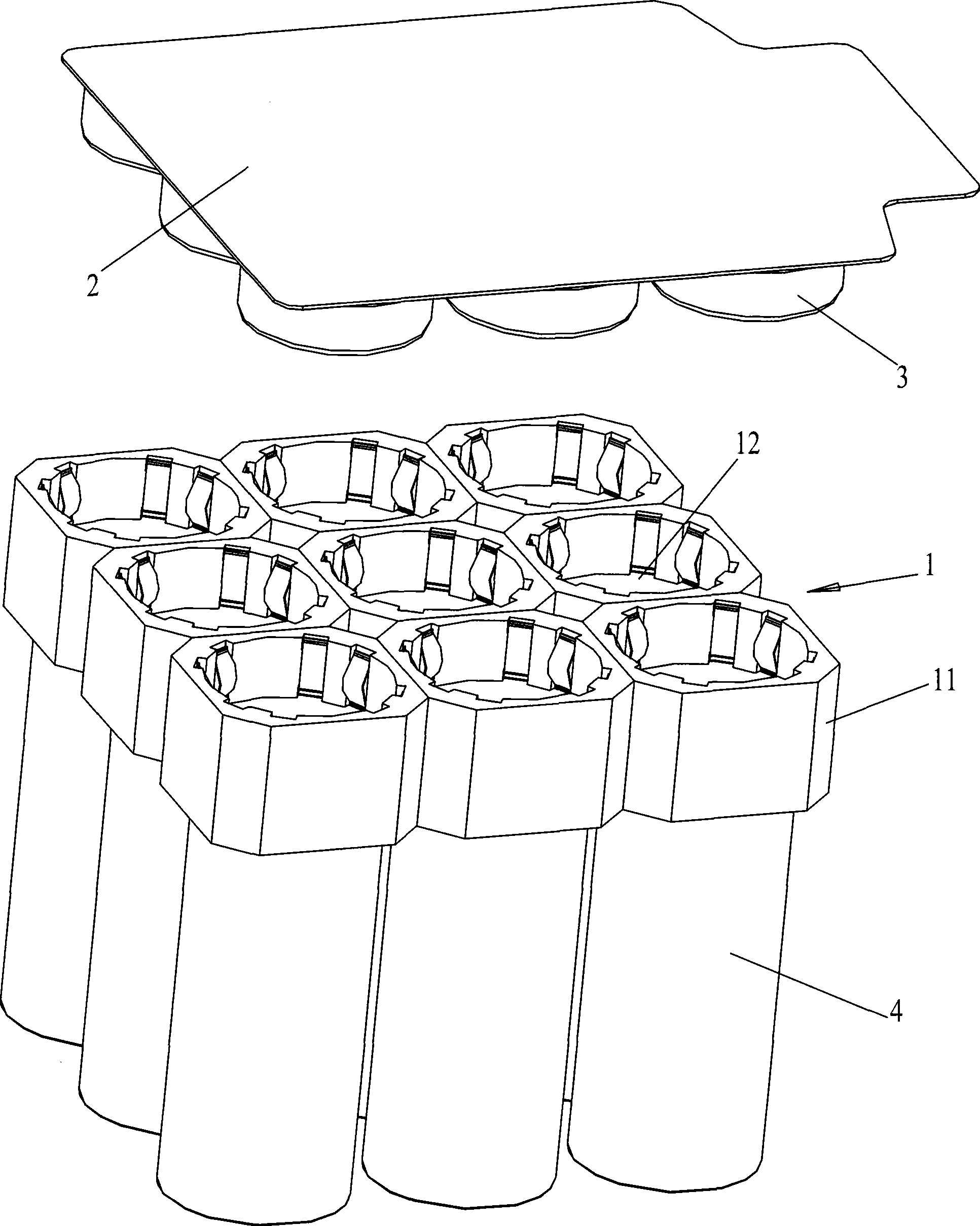

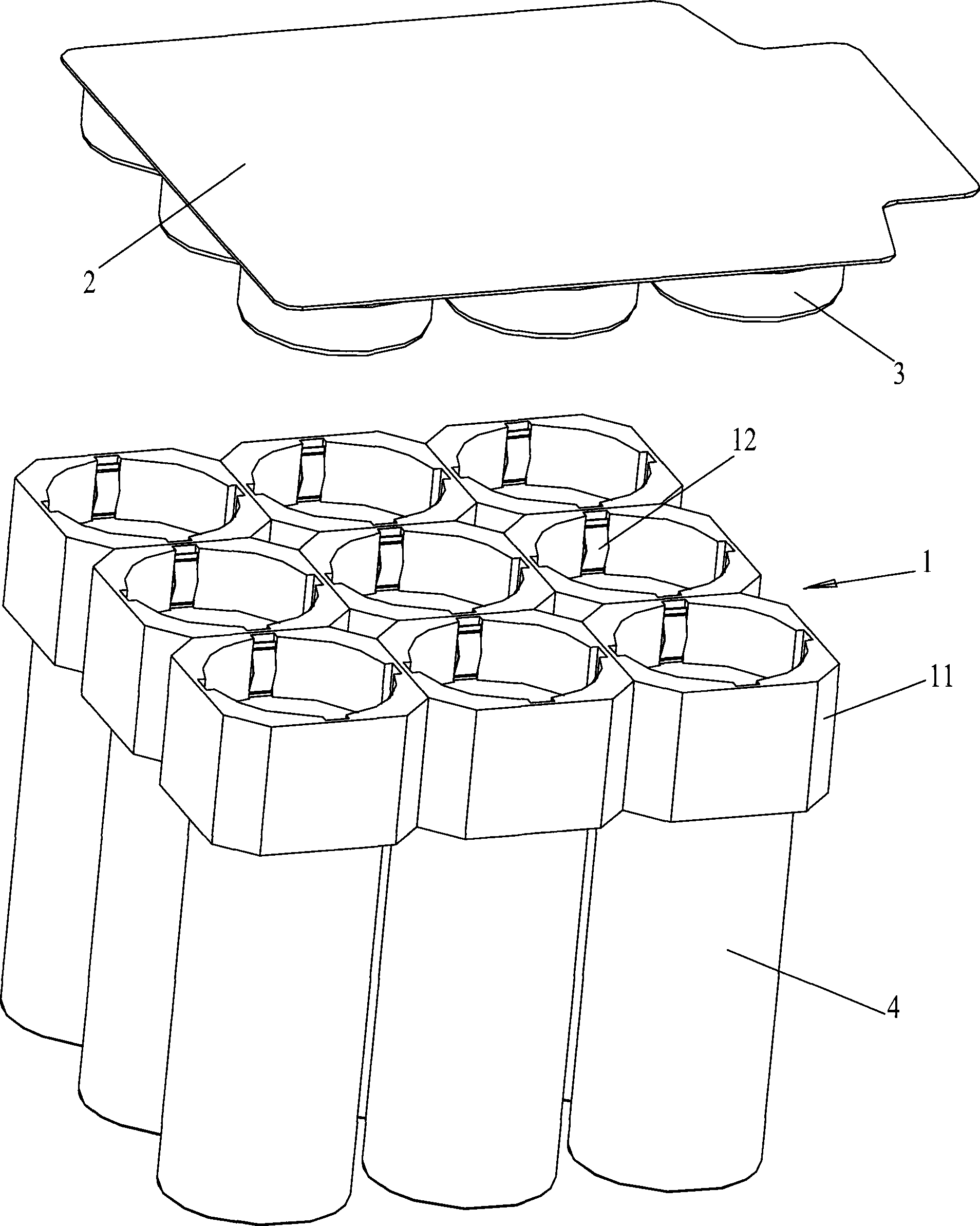

Combined connection apparatus of battery

InactiveCN101499521ACombined process is simpleEasy to disassembleCell component detailsEngineeringWelding process

The invention discloses a combined connection device for batteries, which comprises a plurality of batteries and connecting parts which are respectively connected with the ends of each battery. The connection device also comprises a plurality of conductive connection units and conductive parts; wherein, the number of the conductive connection units is equal to that of the batteries; the conductive parts are electrically connected with the conductive connection units; and the conductive connection units correspond to the batteries one by one and are electrically connected to the connecting parts. The invention replaces the welding process in the battery combination, simplifies the battery combination process, facilitates the disassembly of one battery, and also ensures the reliability of the battery combination.

Owner:CENS ENERGY TECH

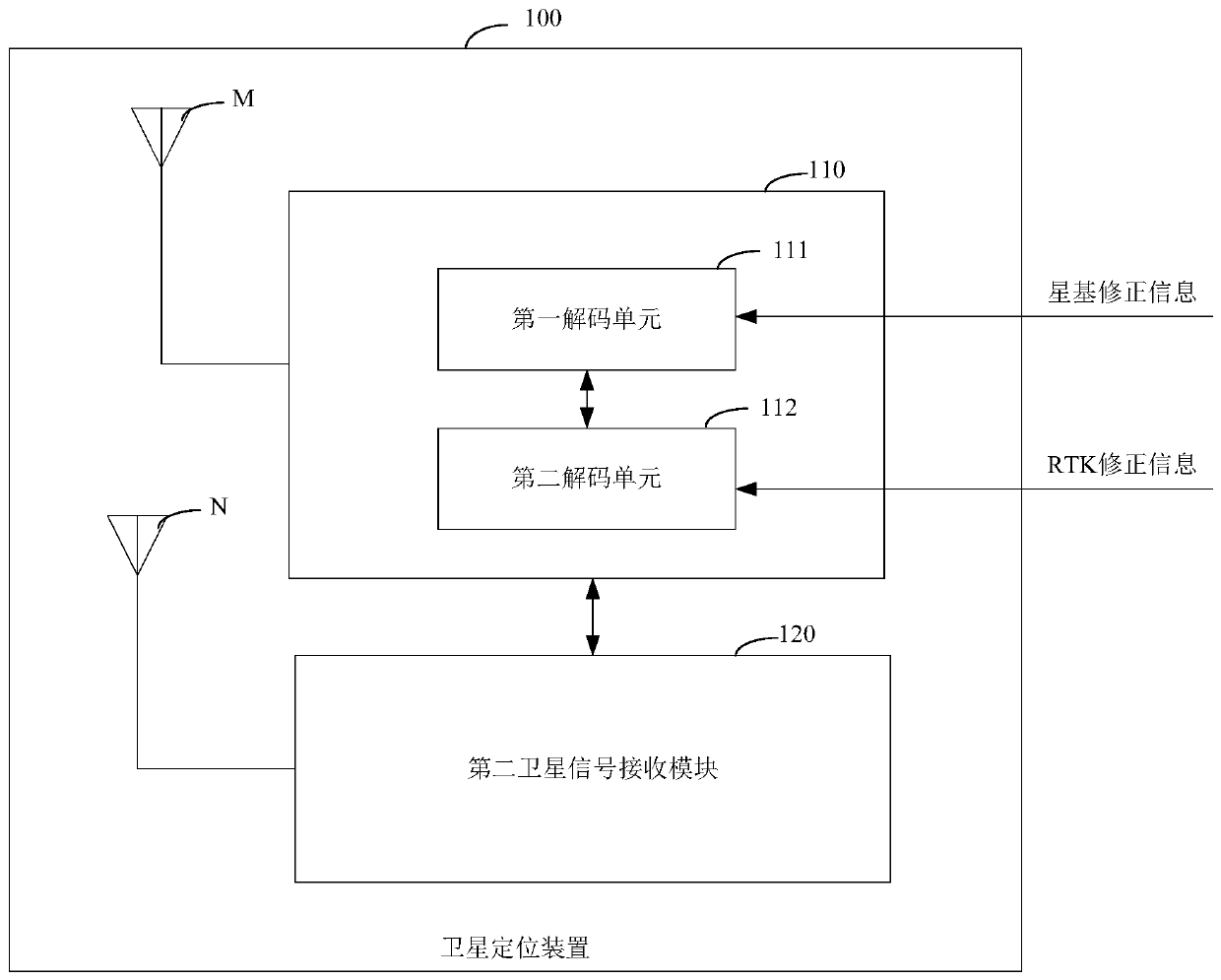

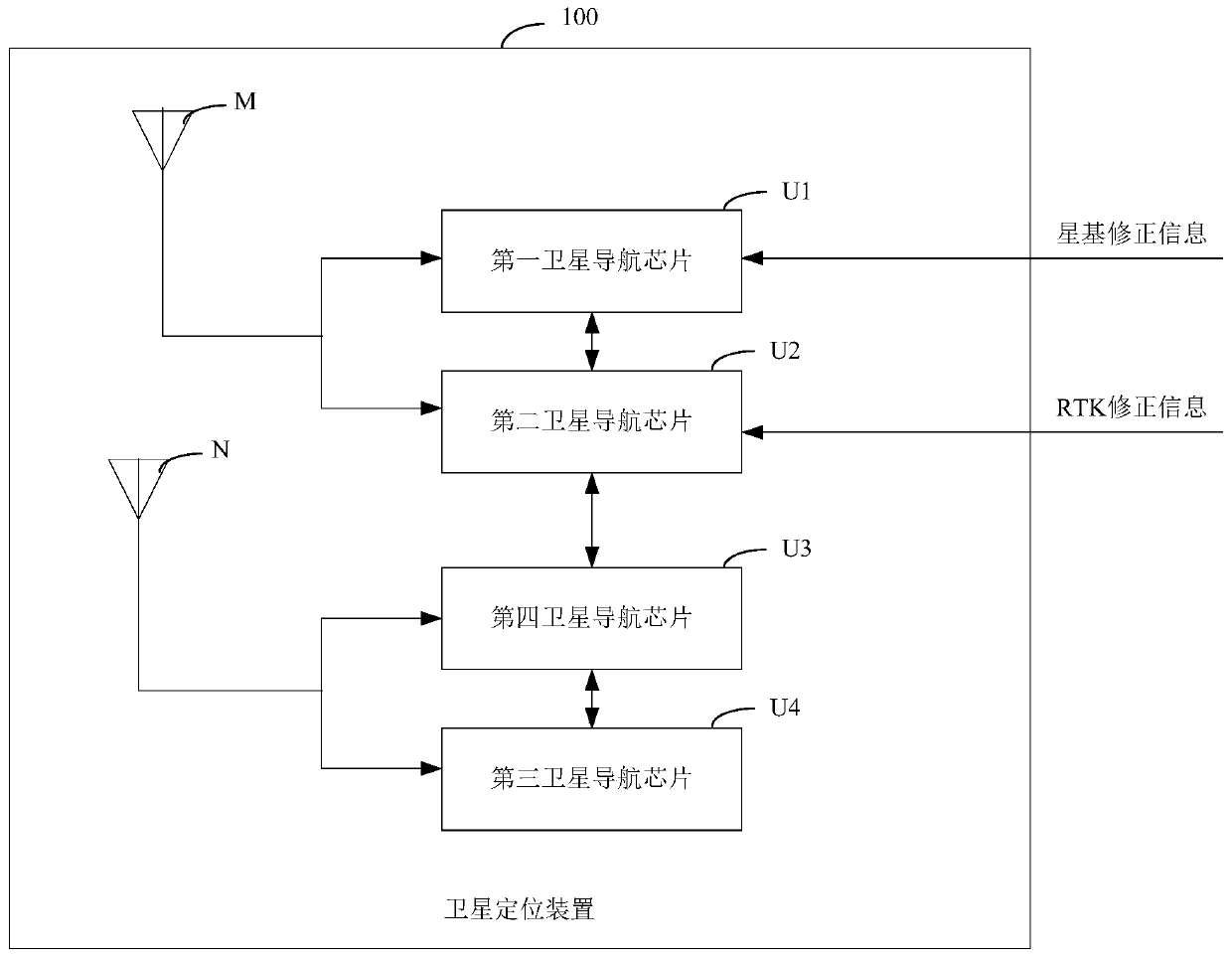

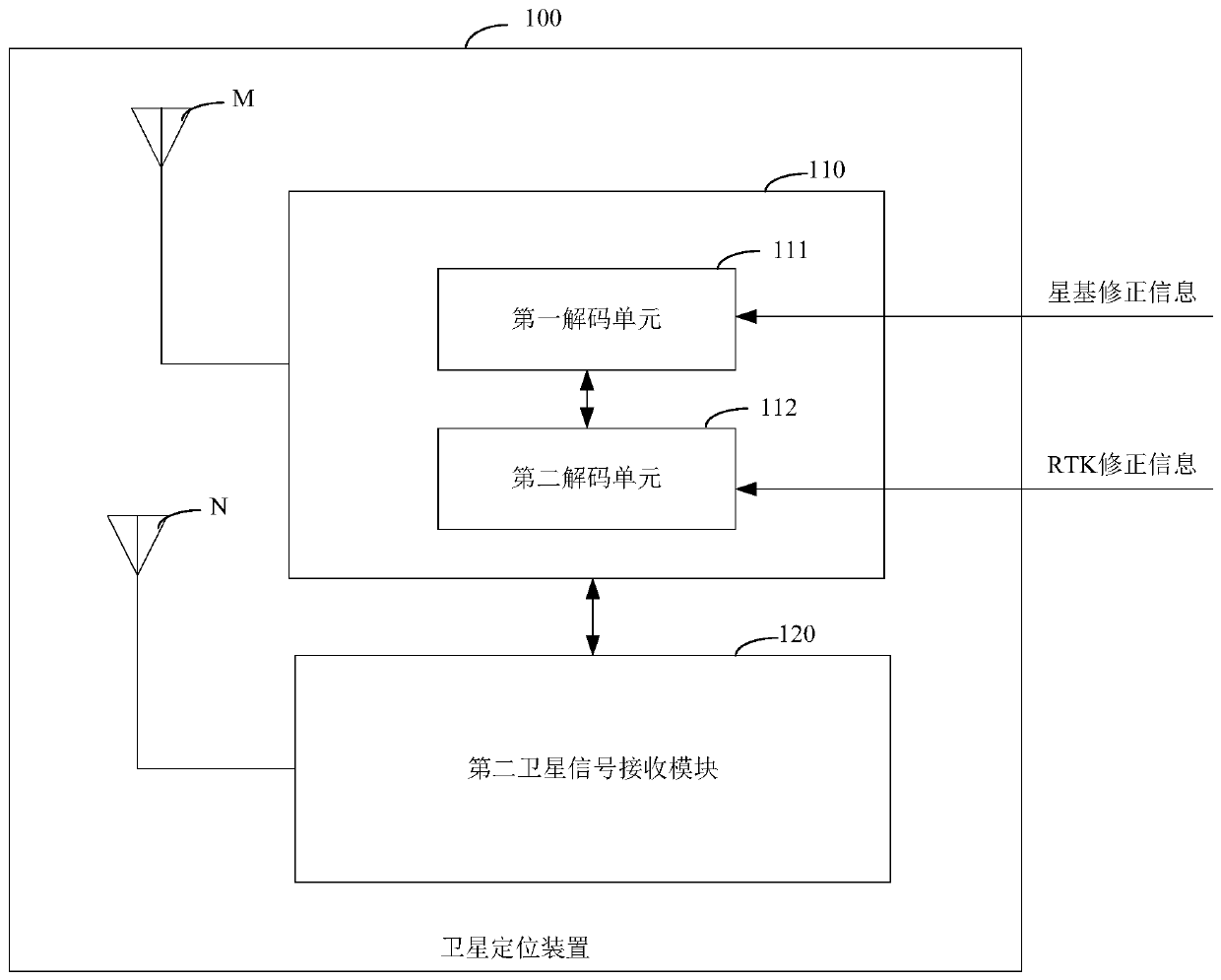

Satellite positioning device, satellite signal receiver and terminal device

The invention is applicable to the technical field of satellite navigation, and particularly relates to a satellite positioning device, a satellite signal receiver and a terminal device. The satellitepositioning device comprises a first satellite signal receiving module, a second satellite signal receiving module, a first antenna and a second antenna. The first satellite signal receiving module receives a first satellite signal with a first preset frequency and a second satellite signal with a second preset frequency through the first antenna. The second satellite signal receiving module receives a third satellite signal and a fourth satellite signal through a second antenna. Satellite signals are processed and positioned through different satellite signal receiving modules. The satellite-based correction information and the RTK correction information are respectively decoded based on different decoding units. According to the satellite positioning device, the data processing and positioning functions of the universal navigation chip can be fully utilized, the design process of a satellite signal receiver can be simplified, the implementation cost can be reduced, and high-precision positioning can be realized through the satellite positioning device formed by combining a plurality of universal navigation chip sets.

Owner:TECHTOTOP MICROELECTRONICS +1

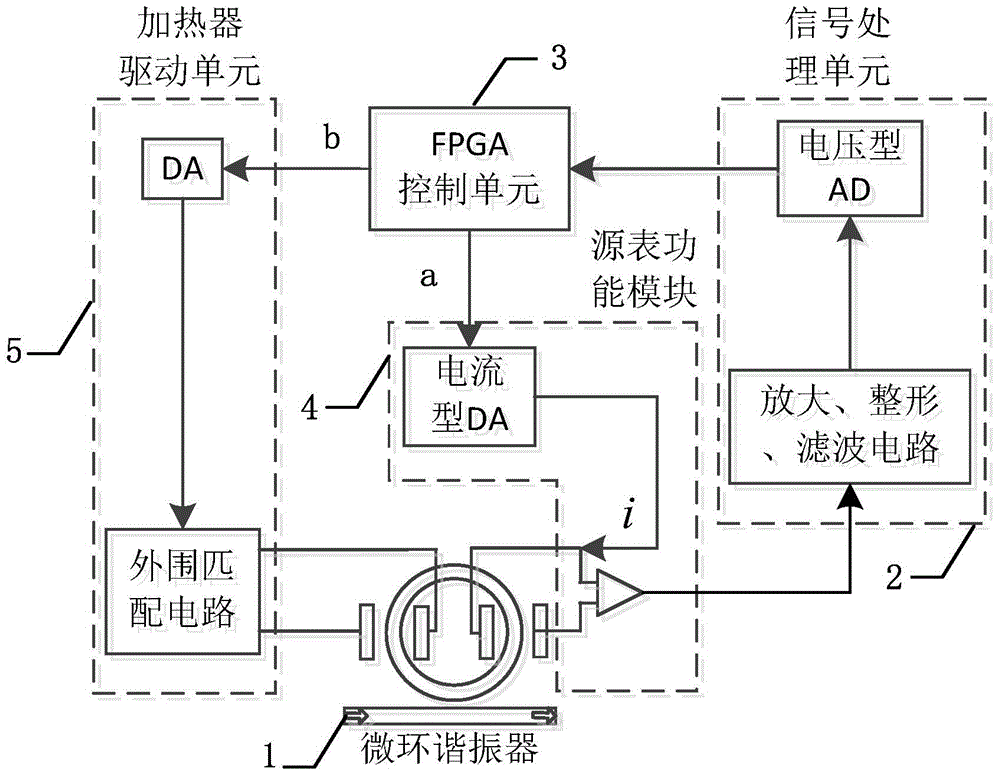

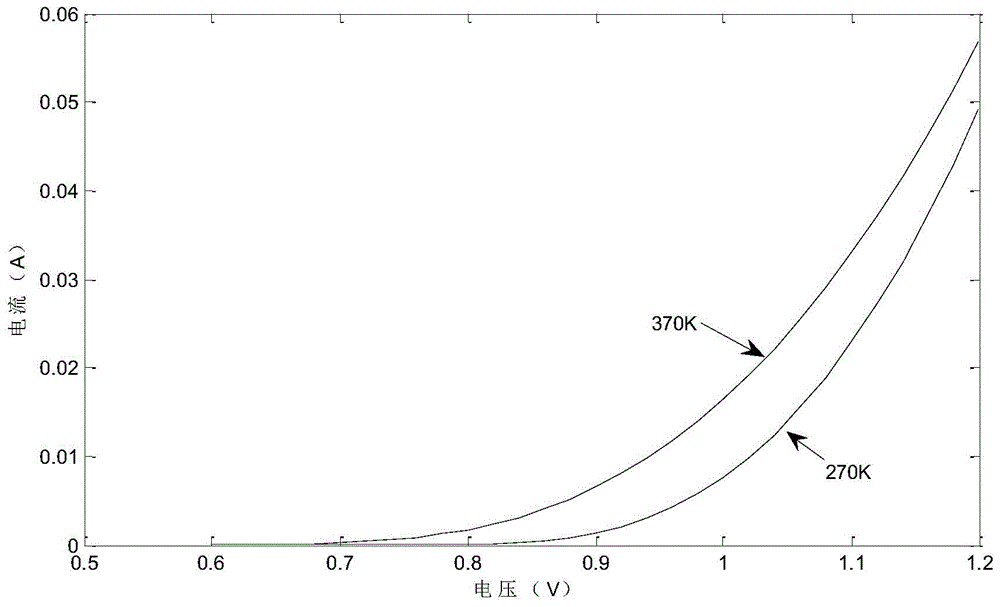

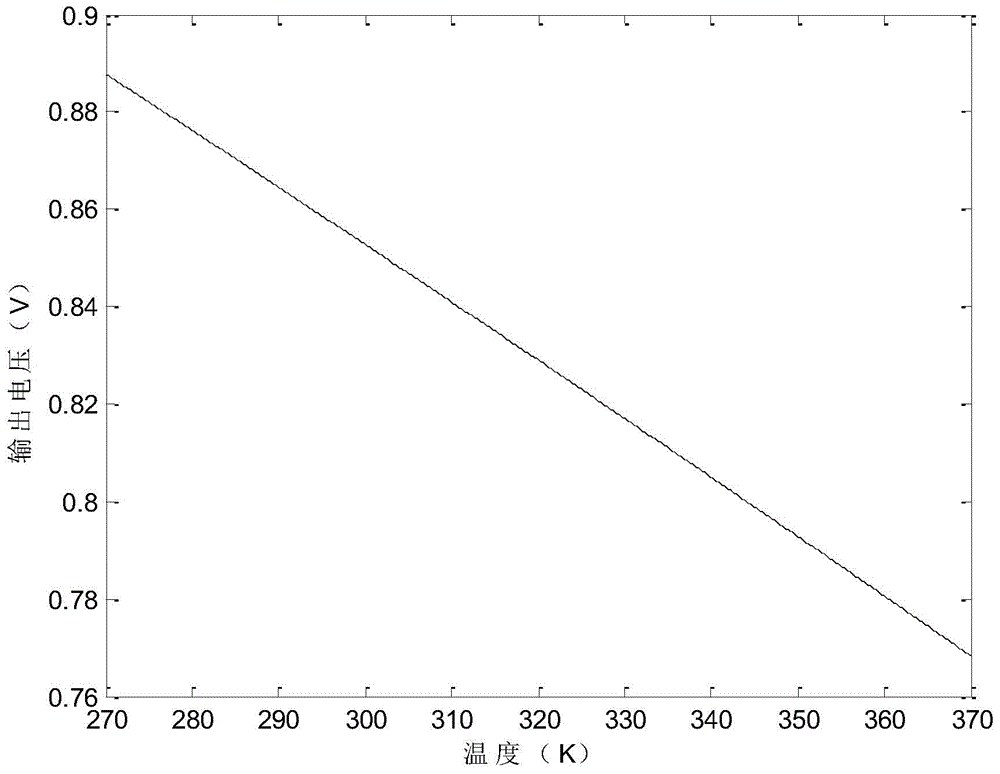

Device for stabilizing spectrum of micro-ring resonator

ActiveCN103955247ASimple design processEasy to operateCoupling light guidesLight controlEngineeringOptical communication

The invention discloses a device for stabilizing a spectrum of a micro-ring resonator. After a current is input into a PIN junction of the micro-ring resonator, a voltage driving signal used for stabilizing the spectrum of the micro-ring resonator is generated by detecting the variation, caused by temperature changes of the micro-ring resonator, of the voltages at the two ends of the PIN junction of the micro-ring resonator and processing the voltage vibration through a signal processing unit and an FPGA control unit, and therefore the device has the advantages of being simple in design process and easy to operate. In practical configuration, the PIN junction detects working temperatures of all micro-ring switches in real time, the problem that positioning can not be conducted due to the fact that the number of micro-rings is large is solved, no additional functional devices are needed, the device has the advantages of being high in temperature detection speed and low in cost, and the device can meet the requirements of a current optical communication system for high-speed development.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

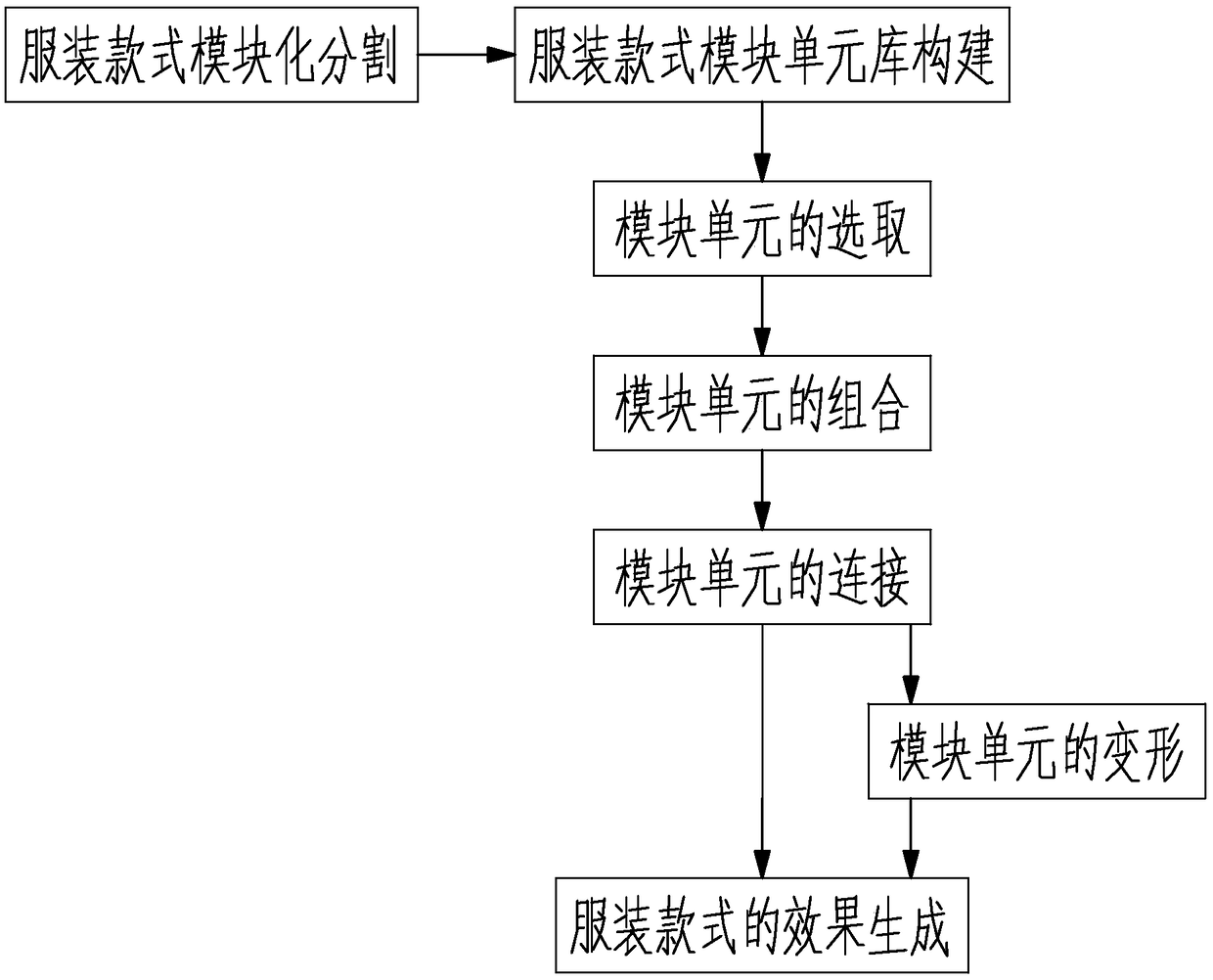

A garment module replacement style splicing method

PendingCN109241687AMeet individual needsAchieve the purpose of interaction designDesign optimisation/simulationSpecial data processing applicationsConsumer demandComputer engineering

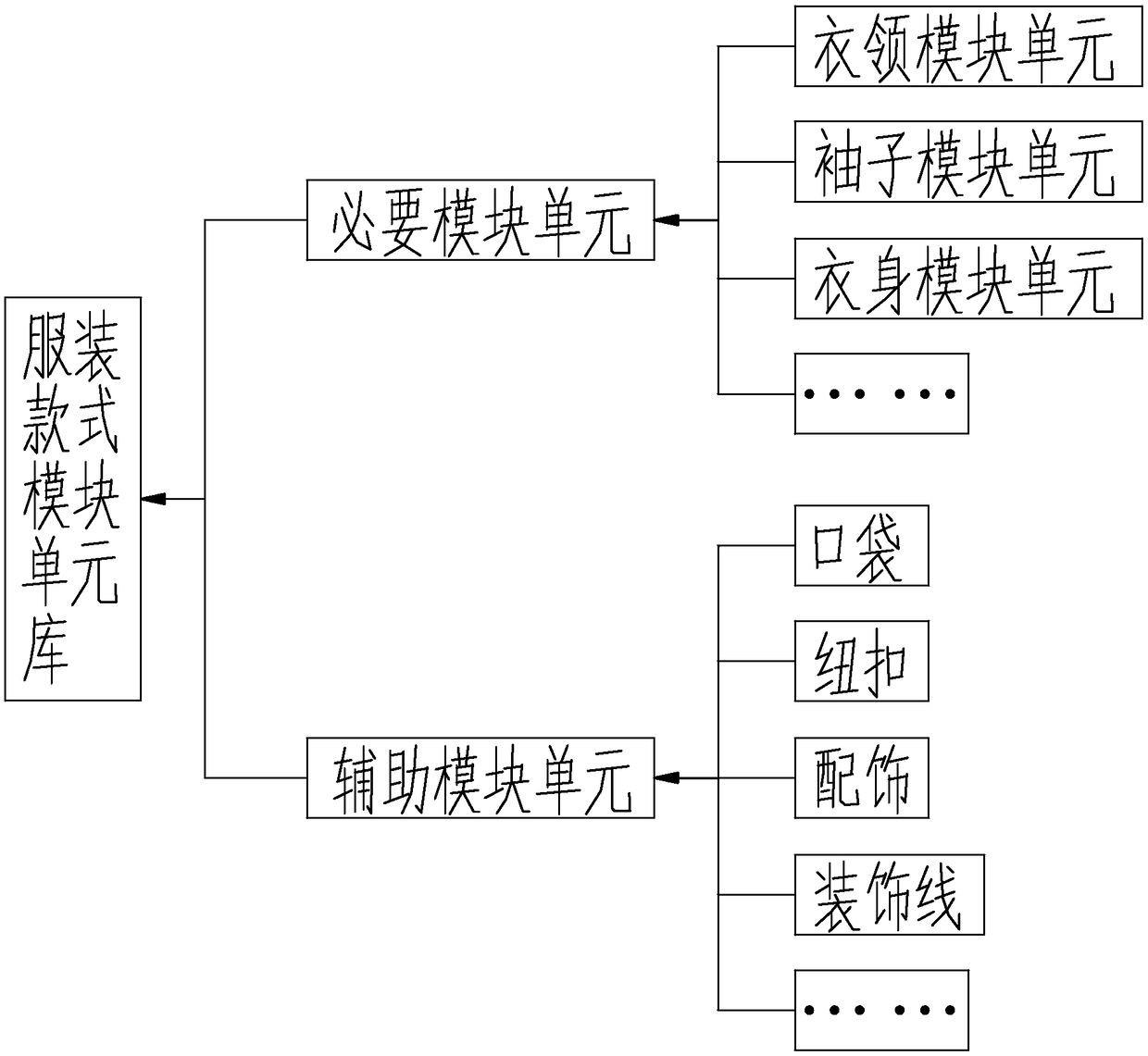

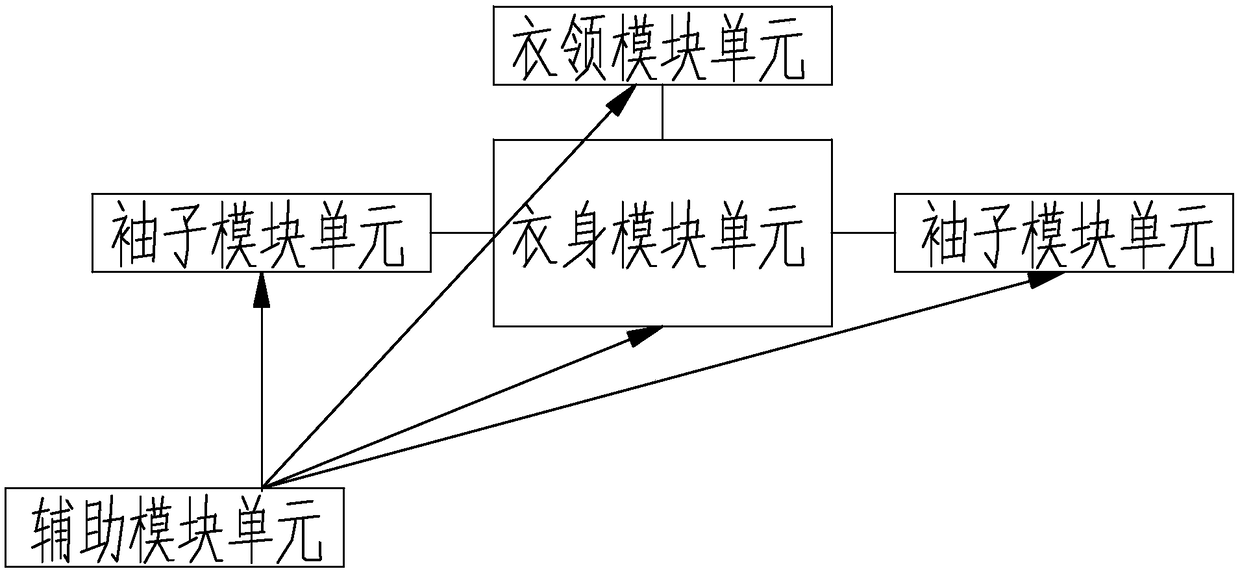

The invention discloses a garment module replacement style splicing method, which mainly comprises four contents, namely, the construction of garment style module unit library, the combination, splicing and deformation of style module units, so as to realize the rapid generation of garment style. This method firstly divides different kinds of garment styles into modules, and then constructs different parts of the garment styles module unit library. On the basis of the module unit library, different module units are selected from the necessary module units and auxiliary module units to realizethe different changes of clothing styles. After the combination relationship of the module units is determined, the module units are connected with each other by the way of interface. After the initial garment style splicing, according to consumer demand, the garment style module unit deformation is realized, mainly by the module unit internal deformation and joint deformation.

Owner:ZHEJIANG SCI-TECH UNIV

Voice coil motor

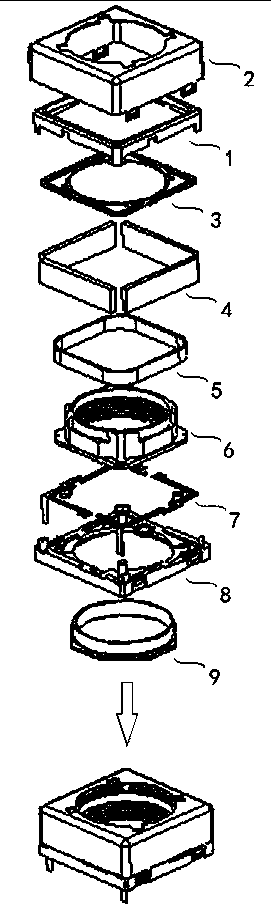

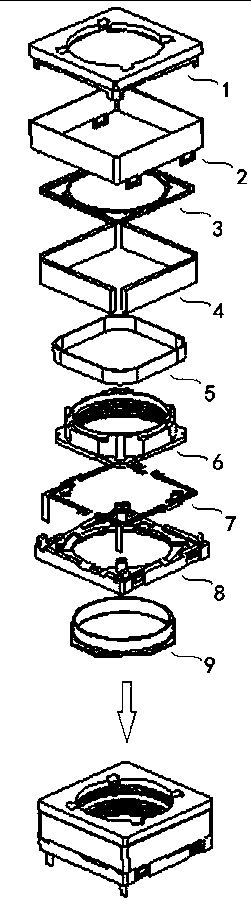

InactiveCN103353662ASimple design processSimplify the assembly processDynamo-electric machinesMountingsOblique angleVoice coil

The invention discloses a voice coil motor. The motor comprises a top cover, a shield, a coil, a magnet, springs, a lens mount, a base and a stopper, wherein the coil is noncircular, and has four corners each formed by a quadrant with an arbitrary radius; an even number of snap grooves are arranged on side walls of a lower edge of the shield, and a plurality of projections with oblique angles are arranged on side edges of the base; and a fixed connection structure of the shield and the base is formed by the snap grooves and the projections. The voice coil motor provided by the invention has the advantages of simplicity in design and assembly, and overcomes the defects of large number of components and complex structure of the conventional voice coil motor, achieving excellent performance in quality improvement.

Owner:YIXING GUIXIN MAGNETOELECTRIC HI TECH

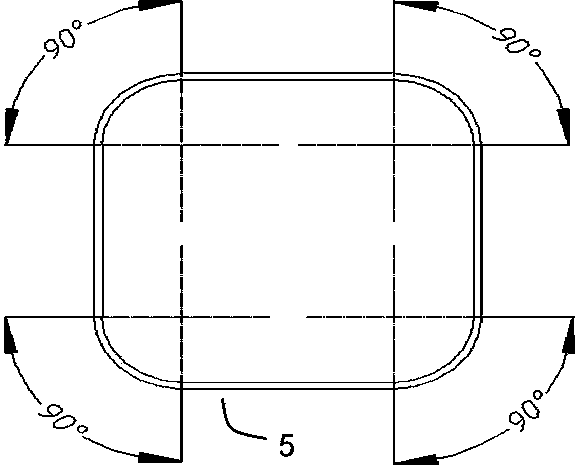

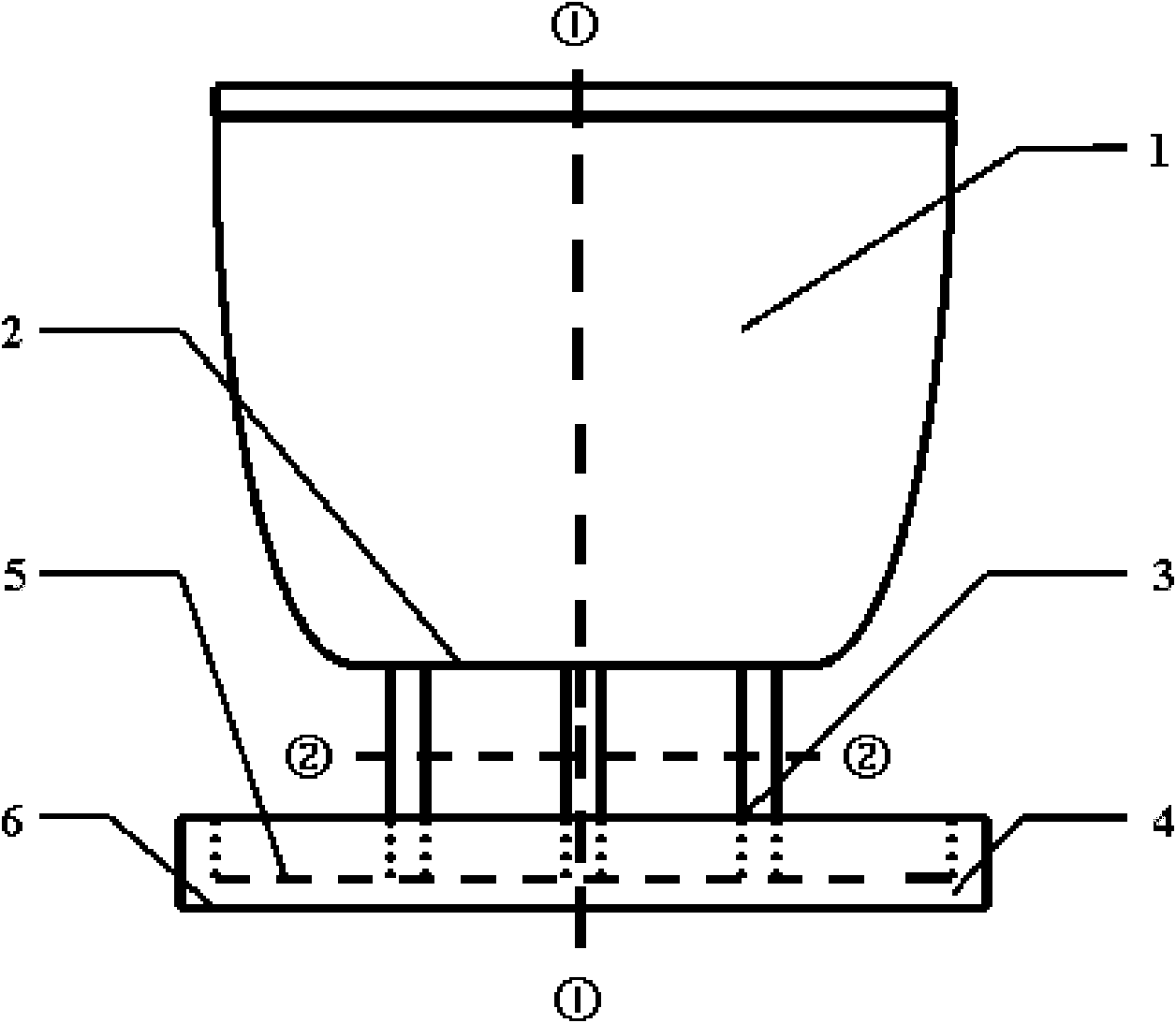

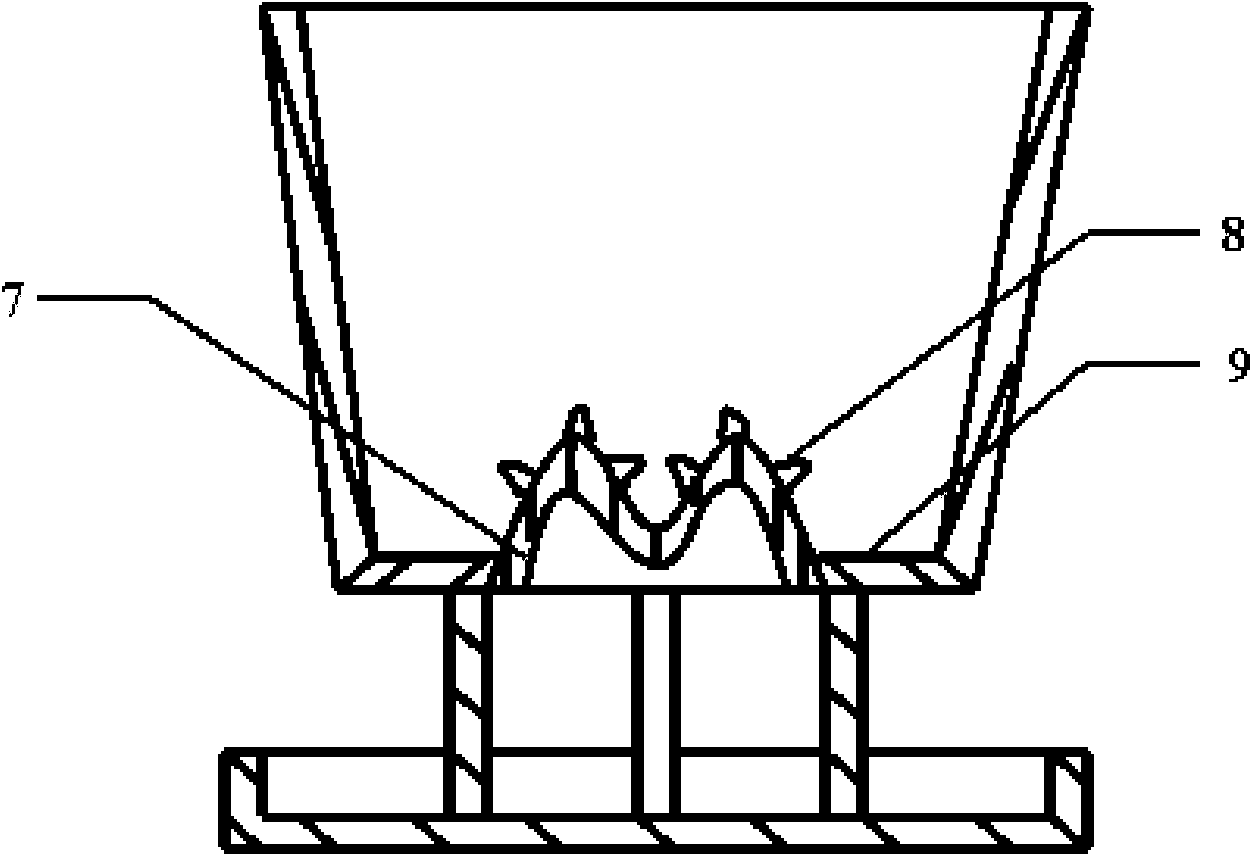

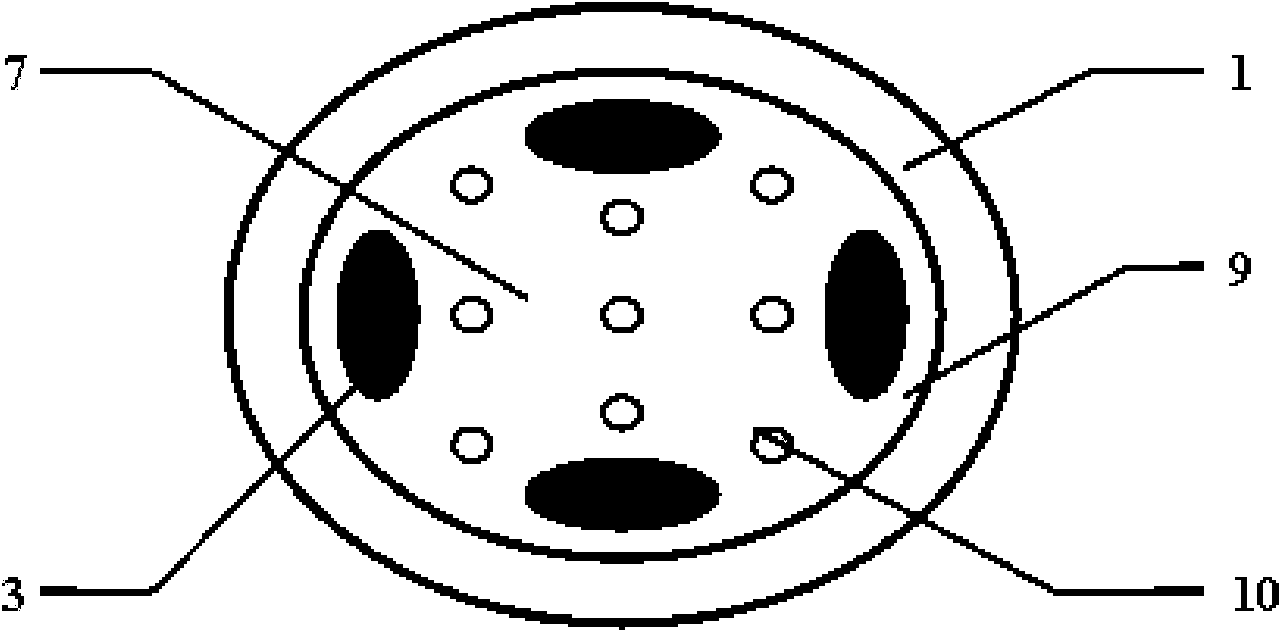

Dual-layer flowerpot for conserving water and soil

InactiveCN102144506AImprove adhesionGuaranteed breathabilityReceptacle cultivationSoil scienceFlowerpot

The invention discloses a dual-layer flowerpot for conserving water and soil, comprising an upper flowerpot body and a lower flowerpot body; a granular protrudent wave surface is arranged at the center of the bottom surface of the upper flowerpot body; a plurality of draining holes are distributed on the wave surface; therefore the structure design of the dual-layer flowerpot solves the problems that soil and fertilizer are lost with the water during the using of the traditional flowerpot and ensures the ventilation property of soil. A plurality of connection supports are uniformly arranged between the upper flowerpot body and the lower flowerpot body for supporting and stabilizing the upper flowerpot body, and the bottom of the lower flowerpot body is not provided with a small hole, therefore, the problem of the water and soil overflowing is avoided and no tray is needed any more. If the flowerpot is used for cultivating flowers, the waste of chemical fertilizer is greatly reduced, the cultivation cost is saved, the cultivation environment is improved; furthermore, the flowerpot is convenient for removing and suspending.

Owner:陈文 +1

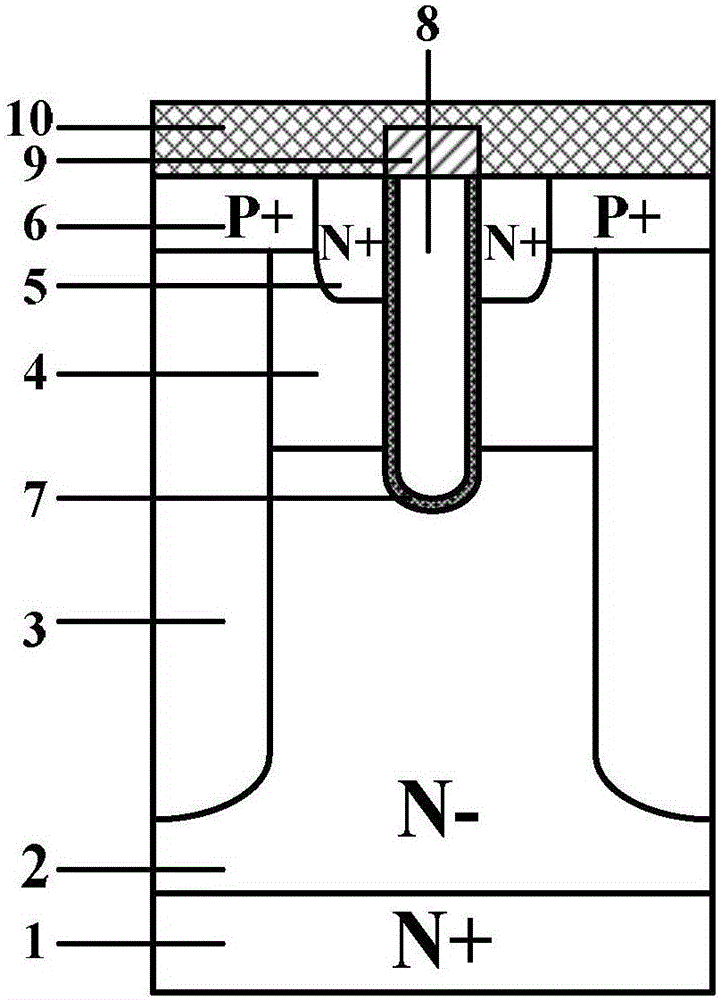

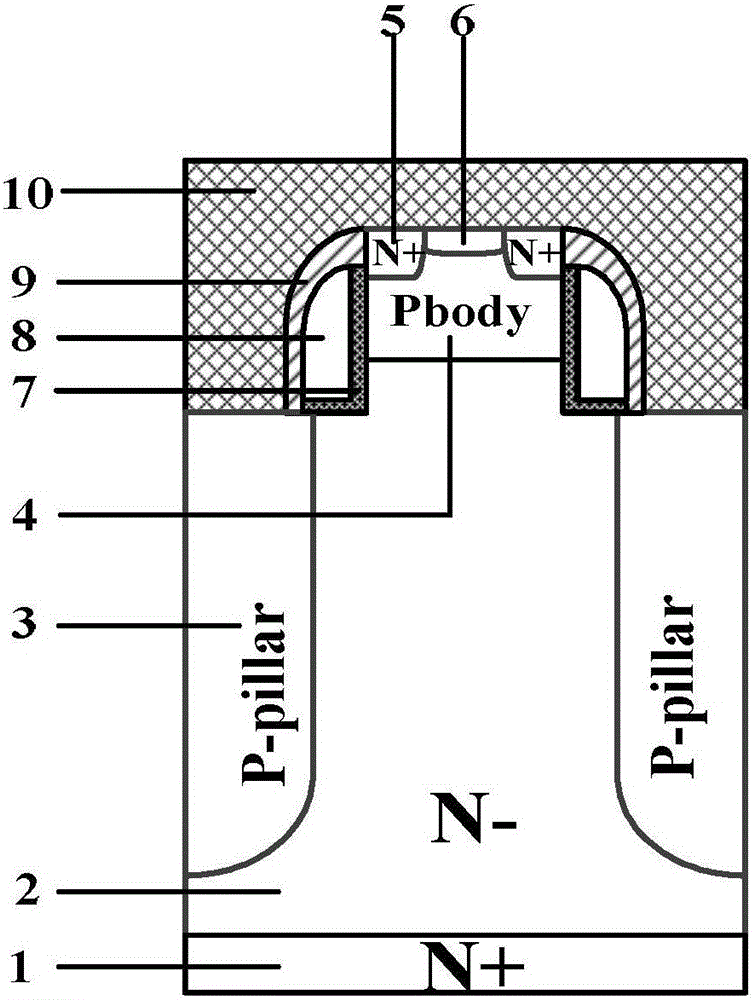

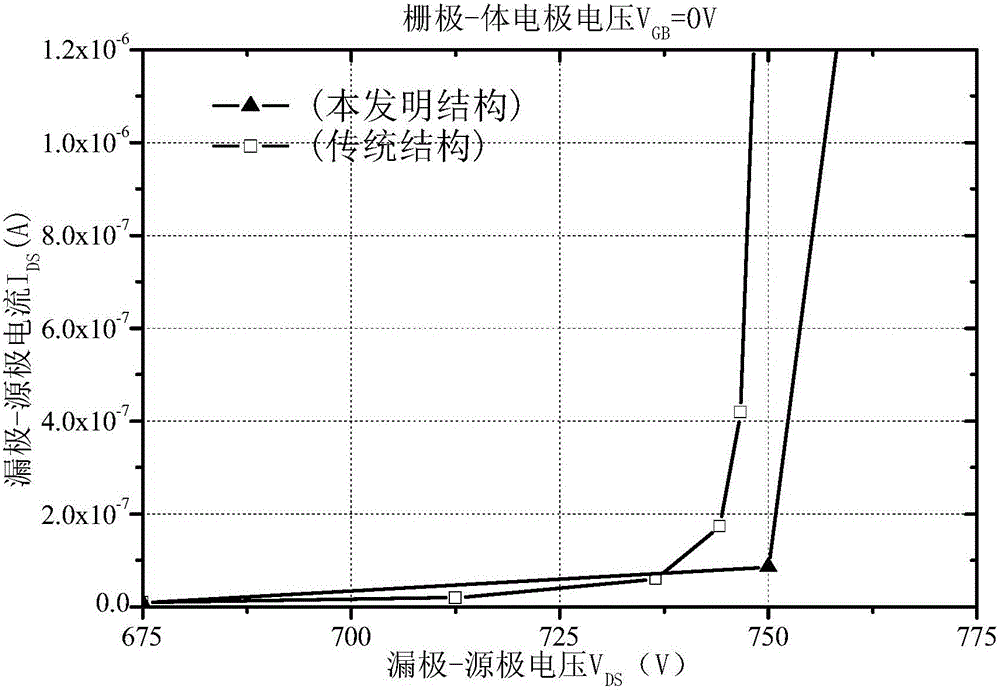

Fin type fast recovery super-junction power semiconductor transistor and preparation method thereof

ActiveCN106024910AInhibit onPrevent inflowFinal product manufactureSemiconductor/solid-state device manufacturingPolysilicon gateBody region

The invention discloses a fin type fast recovery super-junction power semiconductor transistor and a preparation method thereof. The fin type fast recovery super-junction power semiconductor transistor comprises an N-type substrate, wherein an N-type epitaxial layer is arranged on the N-type substrate; second columnar P-type body regions are arranged in the N-type epitaxial layer; a first P-type body region is arranged on the top of the N-type epitaxial layer, and the first P-type body region is positioned between the two second columnar P-type body regions; the surface of the N-type epitaxial layer is provided with an N-type heavily-doped source region and a P-type heavily-doped semiconductor contact region; the N-type heavily-doped source region, the P-type heavily-doped semiconductor contact region and the second P-type body region are connected with source electrode metals; polysilicon gates are arranged on two sides of the first P-type body region respectively; the second columnar P-type body regions are terminated at the lower surfaces of the polysilicon gates, and the second columnar P-type body regions are lower than the first P-type body region; gate oxide layers are arranged between the polysilicon gates and the first P-type body region, the N-type epitaxial layer and the second P-type body regions; insulated layers are arranged between the polysilicon gates and the source electrode metals; and the gate oxide layers enable the first P-type body region and the second P-type body regions to be separated from each other.

Owner:SOUTHEAST UNIV

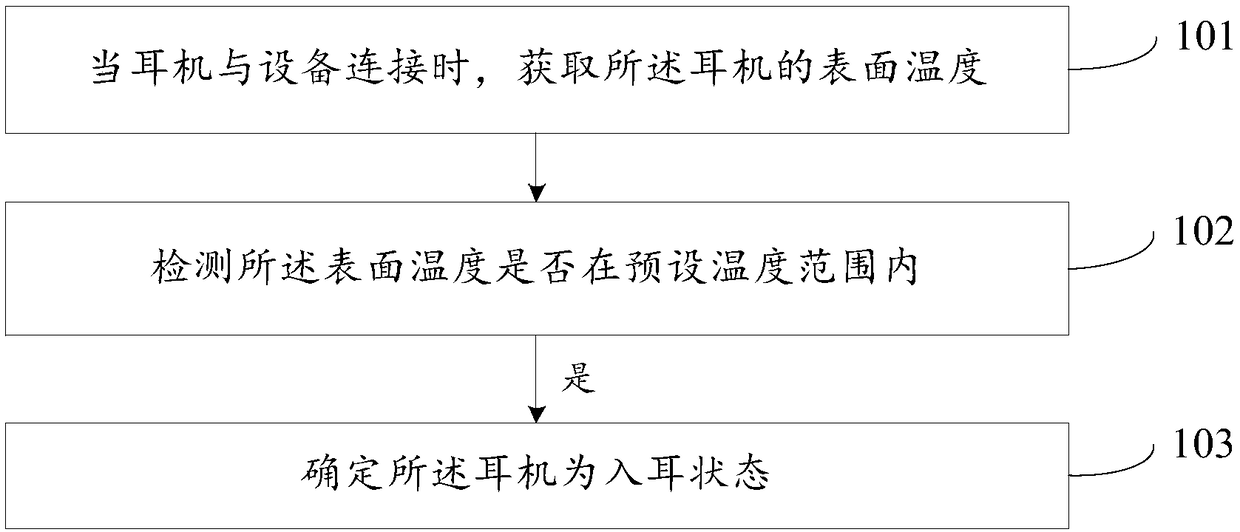

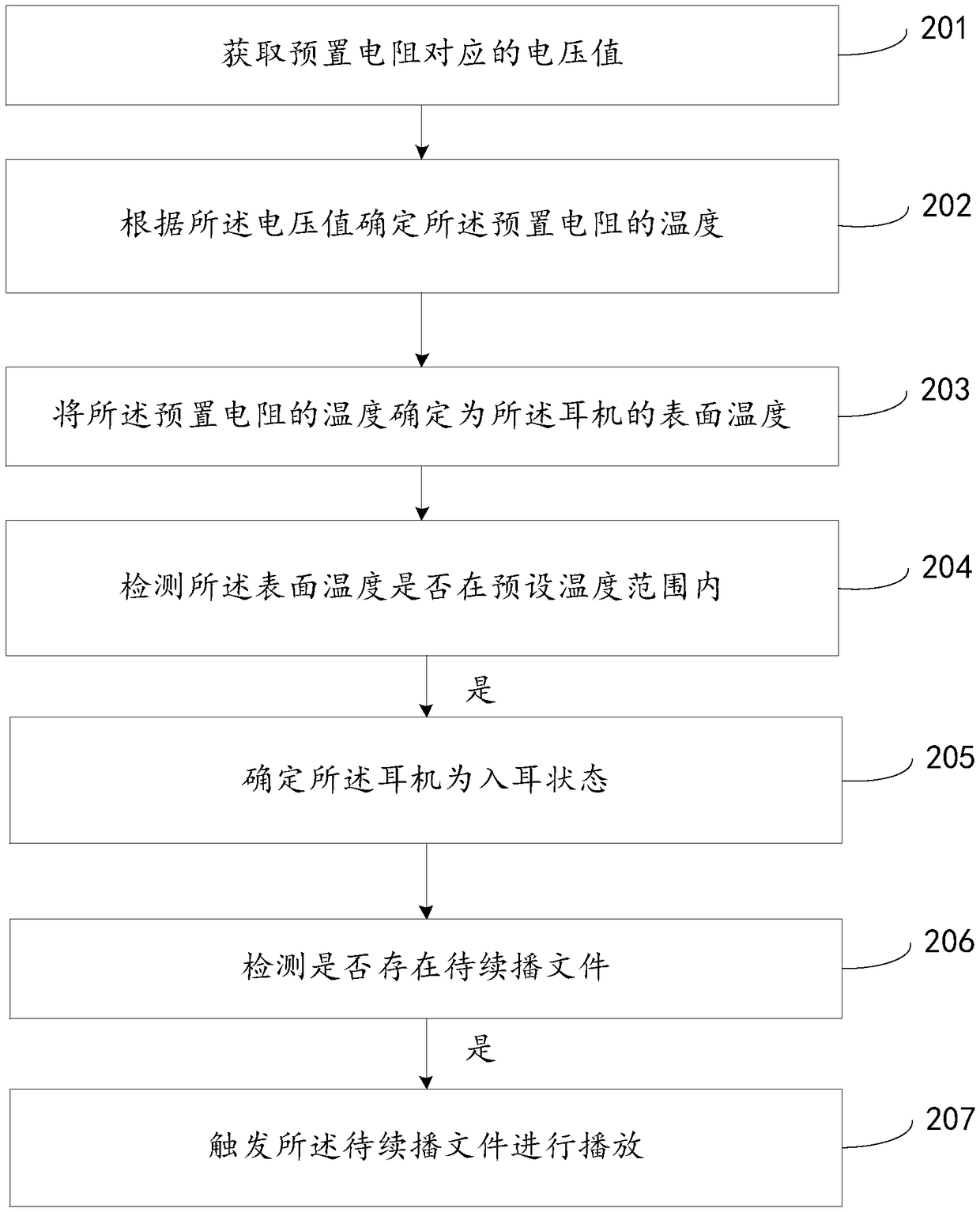

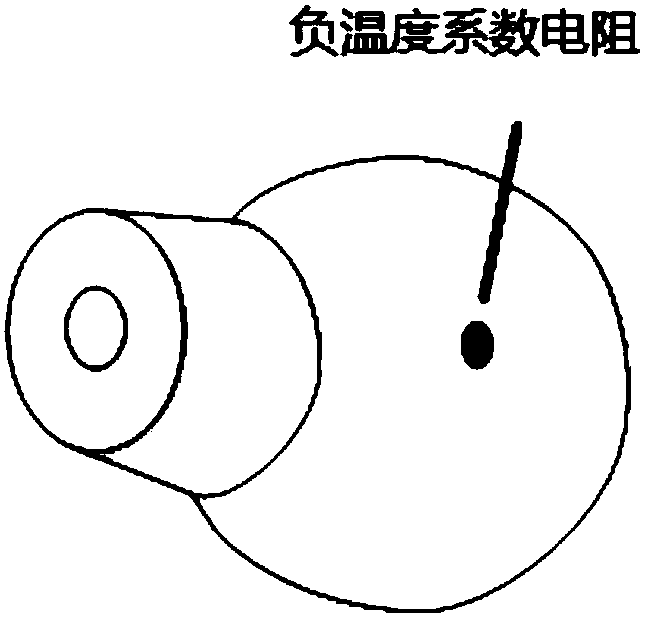

Method and device for detecting in-ear state of earphone

InactiveCN108882095ASimple design processLow costIntra aural earpiecesEarpiece/earphone manufacture/assemblyEngineeringProcess design

The embodiments of the invention disclose a method and device for detecting the in-ear state of an earphone and belong to the terminal application technical field. The invention mainly aims to solve the problems of complicated process design and high cost during the earphone in-ear state detection by means of arraigning an induction area in the earphone. According to the technical schemes of the present invention, when the earphone is connected with a device, the surface temperature of the earphone is acquired; whether the surface temperature is within a preset temperature range can be detected, wherein the preset temperature range is used to identify the body temperature of a human; if the surface temperature is within the preset temperature range, it is determined that the earphone is inan in-ear state.

Owner:MOBVOI INFORMATION TECH CO LTD

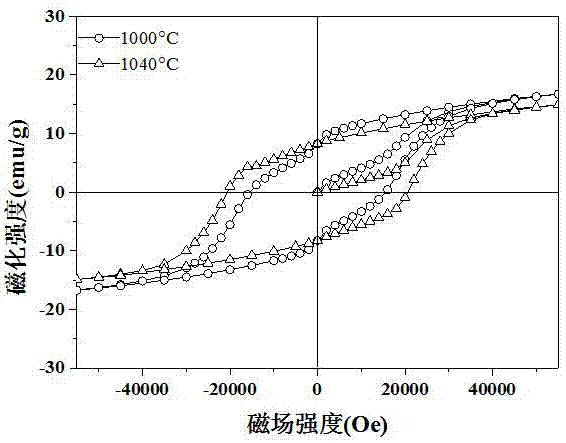

Method for induced-growing Epsilon-ferric oxide nano-rod by lead ions

ActiveCN107364898ASynthetic strongMaintain growth-inducing effectNanotechnologyFerric oxidesLead nitrateProcess design

The invention discloses a method for induced-growing an Epsilon-ferric oxide nano-rod by lead ions, and belongs to the technical field of the novel nano permanent magnet material preparation. The method comprises the following steps: mixing lead nitrate, iron nitrate nonahydrate and water, and preparing mixed metal solution; mixing normal octane, cetyl trimethyl ammonium bromide and normal butanol, and preparing suspension liquid; mixing the suspension liquid with ammonium hydroxide and the mixed metal solution, and preparing two types of reversed-phase microemulsion; mixing two types of the reversed-phase microemulsion and executing the first time of the reaction, and adding tetraethoxysilane to execute the second time of the reaction after the first time of the reaction until the ending, to obtain a precursor, heating the precursor to obtain the powder-like Epsilon-ferric oxide nano-rod. The method is a technology method for stably synthesizing the Epsilon-ferric oxide nano-rod within the wider temperature range, is capable of providing the foundation for the synthesis of a lot of the Epsilon-ferric oxide nano permanent magnets, and providing the excellent reference for the synthetic process design of a similar nano metastable state material.

Owner:YANGZHOU UNIV

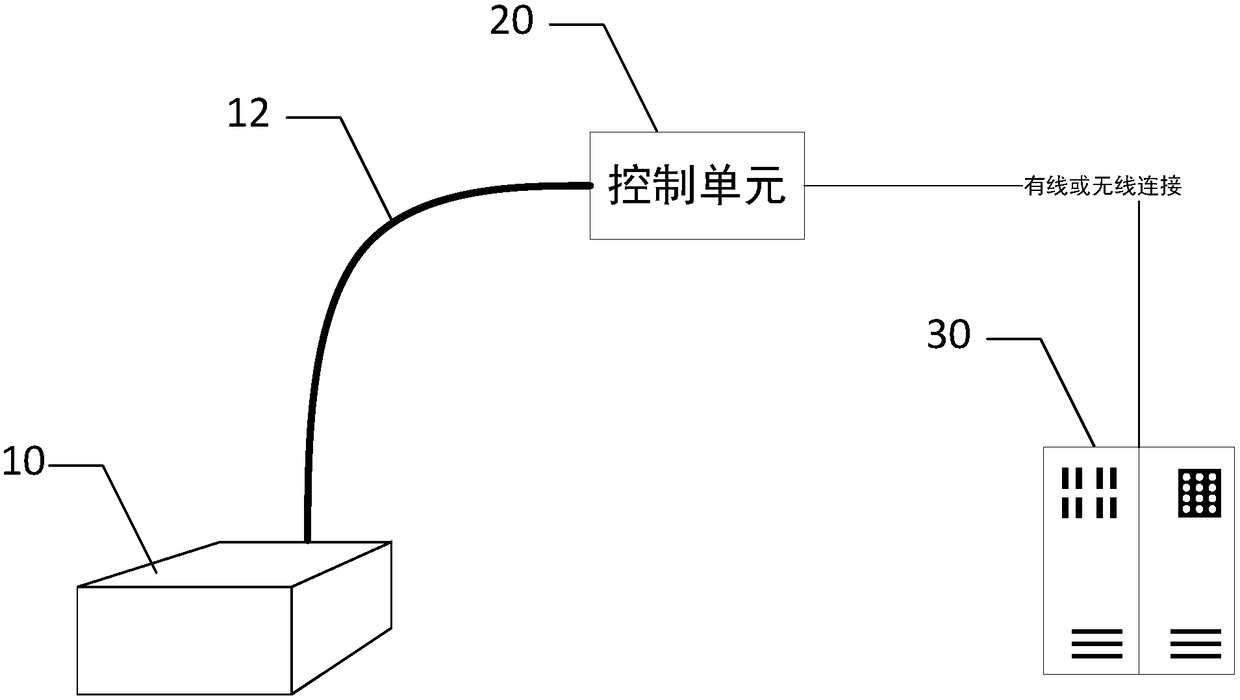

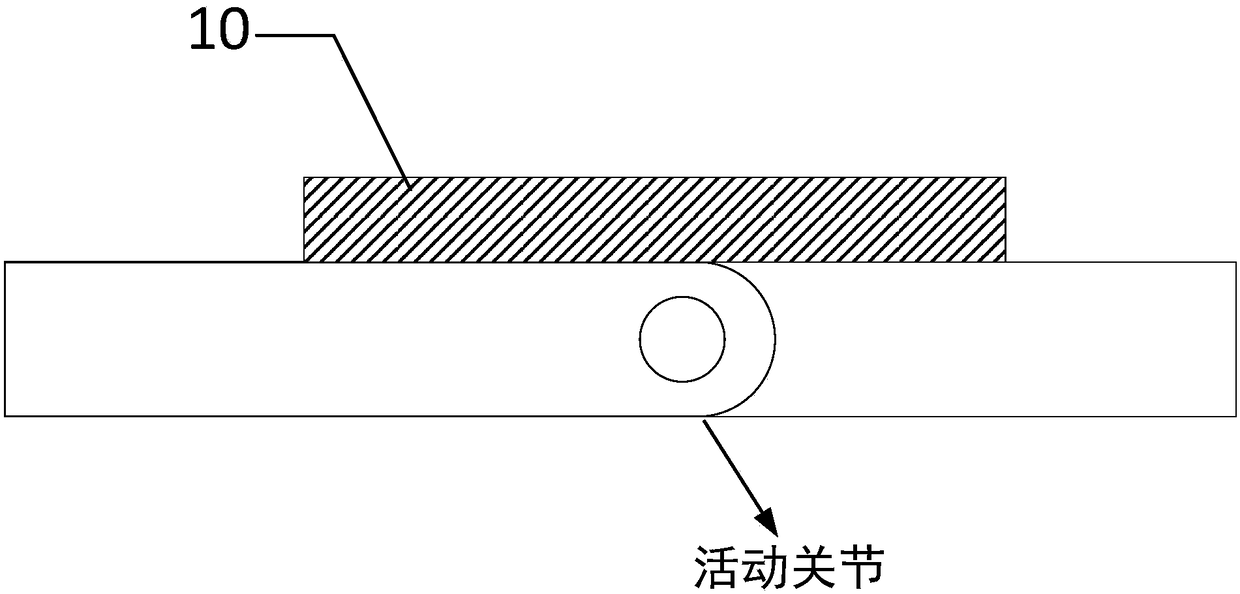

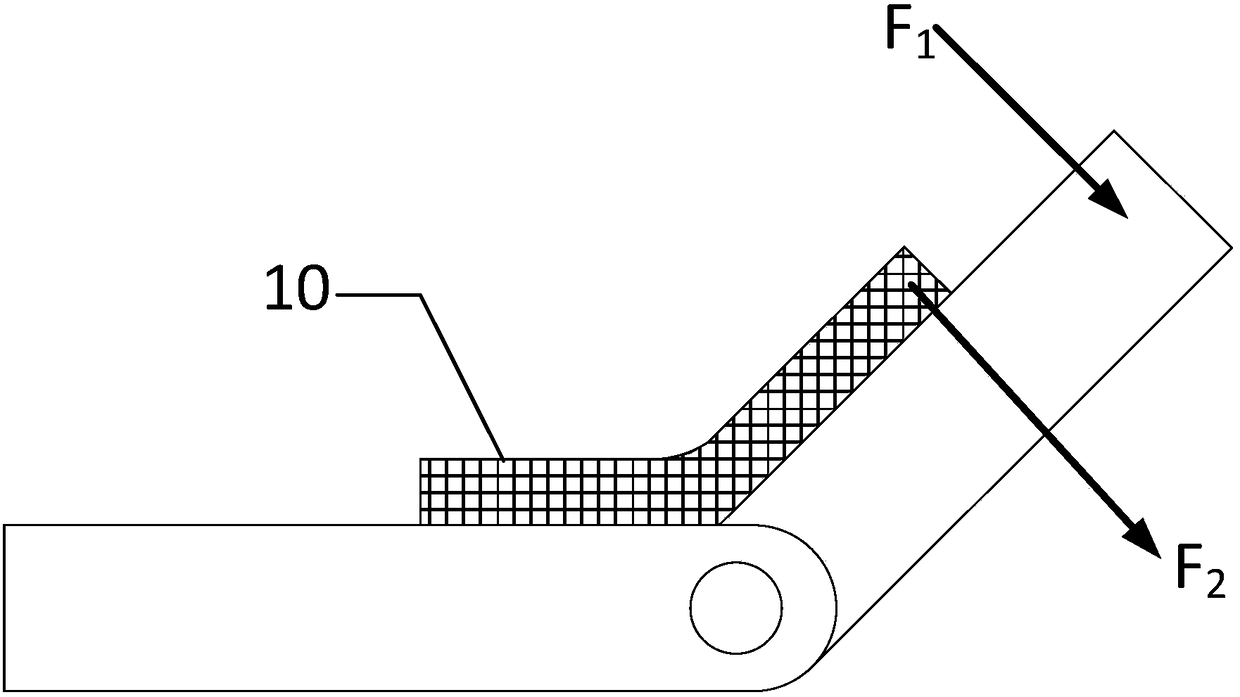

Mechanical feedback device and method and virtual reality interaction attachment control method

ActiveCN108693956AGood authenticitySimple design processInput/output for user-computer interactionGraph readingFluid pressureProcess design

Embodiments of the invention disclose a mechanical feedback device. The device comprises an induction sac and a control unit, wherein the induction sac is used for filling a fluid medium; the induction sac filled with the fluid medium generates tensile force to carry out force feedback after deformation; the control unit is connected with the induction sac through a first conduit; the control unitis used for detecting fluid pressure parameters of the fluid medium in the first conduit and feeding back the fluid pressure parameters to an external controller; and the control units is further used for filling and releasing the induction sab according to a control instruction sent by the external controller. According to the method and device, force feedback is carried out through a manner offilling the fluid medium by using the induction sac, so that the process design is simpler; and the induction sac is a flexible component, so that the third dimension brought to the VR users is stronger.

Owner:TENCENT TECH (SHENZHEN) CO LTD

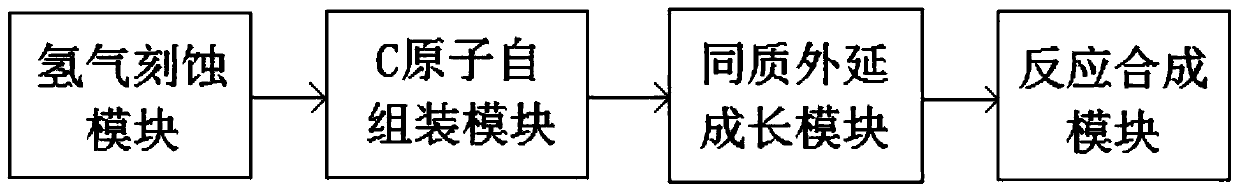

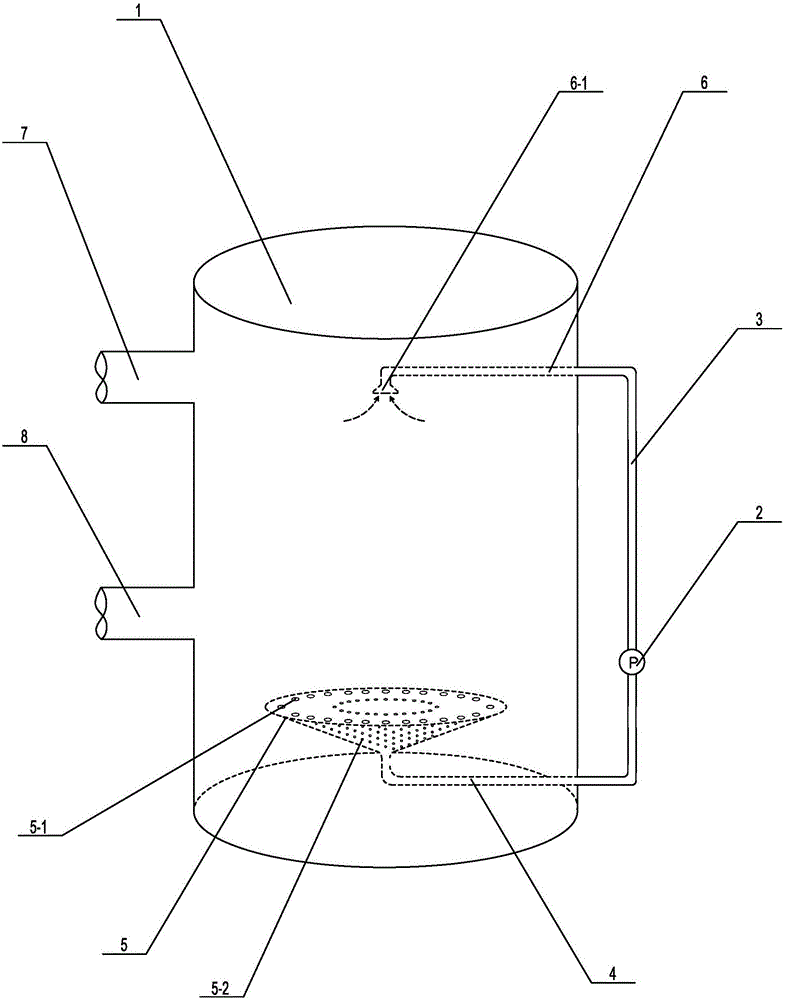

Graphene semiconductor preparation device and method

InactiveCN111410191AQuality improvementImprove uniformityGrapheneSemiconductor materialsHydrogen etching

The invention discloses a graphene semiconductor preparation device and method, and the method comprises the following steps: I, providing a SiC substrate, and etching the SiC substrate through hydrogen; II, heating the SiC substrate slice in an argon atmosphere; III, forming a hexagonal honeycomb-shaped graphene film in an ultrahigh vacuum environment; and IV, forming the graphene semiconductor composite material. A graphene semiconductor preparation device comprises a hydrogen etching module; a C atom self-assembly module; a homoepitaxy growth module; reaction synthesis module. According tothe method, large-area and high-quality graphene can be obtained, and the obtained graphene has good uniformity and has good compatibility with a current integrated circuit technology; and meanwhile,by utilizing the advantages of the semiconductor material and the characteristics of the graphene, the preparation of the graphene and the compounding of the graphene and the semiconductor material are simultaneously carried out, and the applicability is wide.

Owner:山东华达新材料有限公司

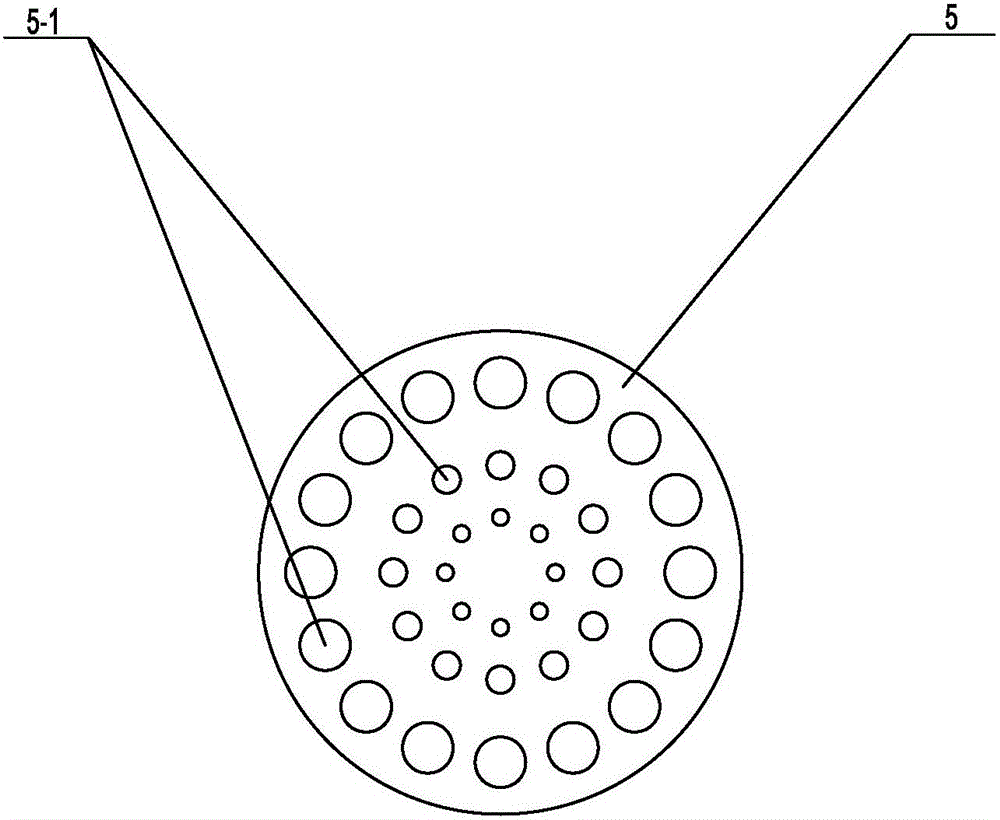

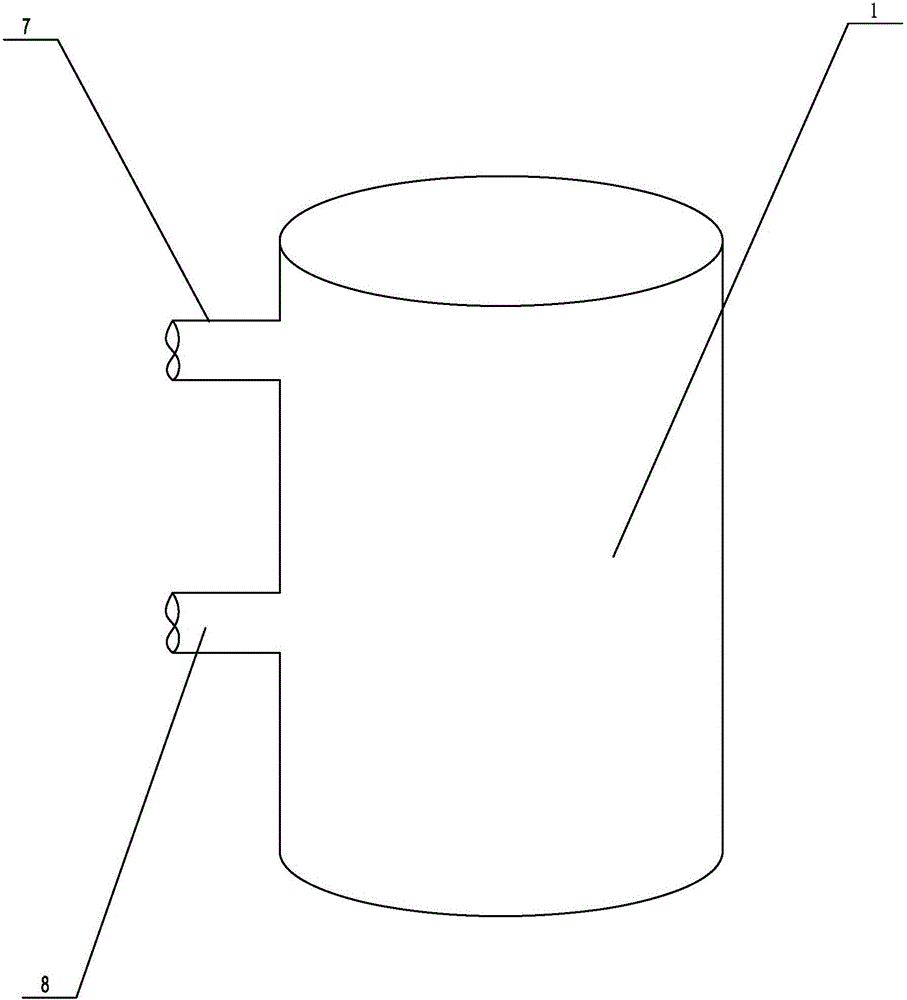

Surging type oil mixing device

ActiveCN105771719AImprove mixing uniformityThe quality and technical indicators are consistentFlow mixersTransportation and packagingOil qualityMechanical engineering

The invention discloses a surging type oil mixing device. The surging type oil mixing device comprises a tank body, wherein a conveying pipe is arranged at the exterior of the tank body and is connected with a special crude oil conveying pump; one end of the conveying pipe is connected with a spraying pipe which extends into the lower end of the interior of the tank body; a conical spraying body is arranged at the tail end of the spraying pipe; the round surface of the spraying body faces upwards, and a plurality of spraying holes are formed in the spraying body; the other end of the conveying pipe is connected with a suction pipe which extends into the upper end of the interior of the tank body; the tail end of the suction pipe is provided with a horn-shaped suction opening. The surging type oil mixing device has the advantages that the structure is simple, the design and installation technology is simple and convenient, and the manufacturing is easy; by utilizing the surging type, the oil in the tank can do highly turbulence movements under the action of spraying effect, such as upward and downward surging and turning, the mixing uniformity is high, and the oil quality in the tank is uniform; the sealing property is good, the safety is high, the practicality is good, and the like; the surging type oil mixing device is suitable for widely popularizing.

Owner:QINZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com