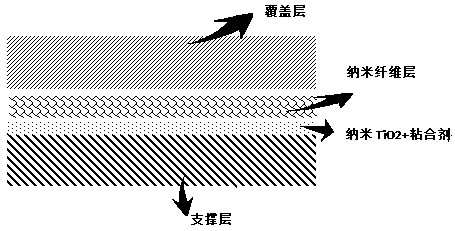

Preparation method of sandwich type anti-microbial composite nanometer filtering material for scavenging formaldehyde with high efficiency and low resistance

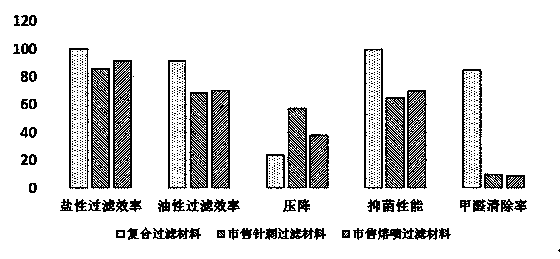

A sandwich-type, nano-filtration technology, applied in the field of materials, can solve the problems of application limitations, increase the difficulty of fiber technology, and the mechanical properties of nano-filtration materials cannot meet the requirements, etc., to achieve easy interception, excellent antibacterial performance, and excellent formaldehyde removal performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Prepare nanoparticle binding solution: weigh 5g of polyethylene glycol, add water to 100g, heat to dissolve and stir evenly for binding solution, add 3g of nanometer titanium dioxide particles and add a small amount of water to ultrasonically dissolve to form nanoparticle solution, and then sticky The mixing solution and the nanoparticle solution are mixed and stirred evenly to obtain a nanoparticle binding solution with a nanoparticle mass fraction of 3wt%;

[0033] (2) Spraying nanoparticles: Spray the nanoparticle bonding solution obtained in (1) on a PET melt-blown non-woven fabric support with a Japanese Meiji A-100 spray gun (caliber 0.5-2.0mm, working pressure 5Mpa, working temperature 110°C) The surface of the material, or spray it several times with a spray gun to form a uniform film, and dry it under a tungsten lamp for later use;

[0034] (3) Preparation of spinning solution: weigh 14g of polyvinylidene fluoride (PVDF) particles, and use a mixed solvent o...

Embodiment 2

[0046] (1) Prepare nanoparticle binding solution: weigh 5g of polyethylene glycol, add water to 100g, heat to dissolve and stir evenly for binding solution, add 3g of nanometer titanium dioxide particles and add a small amount of water to ultrasonically dissolve to form nanoparticle solution, and then sticky The mixing solution and the nanoparticle solution are mixed and stirred evenly to obtain a nanoparticle binding solution with a nanoparticle mass fraction of 3wt%;

[0047] (2) Spraying nanoparticles: Spray the nanoparticle bonding solution obtained in (1) on a PET melt-blown non-woven fabric support with a Japanese Meiji A-100 spray gun (caliber 0.5-2.0mm, working pressure 5Mpa, working temperature 110°C) The surface of the material, or spray it several times with a spray gun to form a uniform film, and dry it under a tungsten lamp for later use;

[0048] (3) Preparation of spinning solution: Weigh 14g of polylactic acid (PLA) particles, use chloroform to make up to 100g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com