Method for comprehensively utilizing ginger straw

A technology of ginger straw and straw, which is applied in the direction of chemical instruments and methods, carbon compounds, carbon preparation/purification, etc., can solve the problems of complex steps of porous activated carbon, large amount of chemical reagents, etc., achieve high utilization value and improve electrochemical performance , easy to realize the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of the above-mentioned porous carbon electrode is also within the protection scope of the present disclosure. The mixing method of waste ginger straw-based porous carbon, binder and conductive agent uses the current common method: including preparing the mixed slurry of ginger straw-based porous carbon, binder and conductive additive through pulping and spreading the slurry evenly on the The method on the current collector and the method of heating and pressing the uniformly mixed ginger straw-based porous carbon, binder and conductive additive mixed active material.

[0062] The current collector used in the present disclosure includes copper foil, aluminum foil, nickel mesh, stainless steel foil, etc. that have been widely used at present.

[0063] The fifth embodiment of the present disclosure is a method for comprehensively utilizing ginger straw, including the above-mentioned preparation method of ginger straw-based porous carbon, after the p...

Embodiment 1

[0070] A comprehensive utilization and preparation method of ginger straw, comprising the following steps:

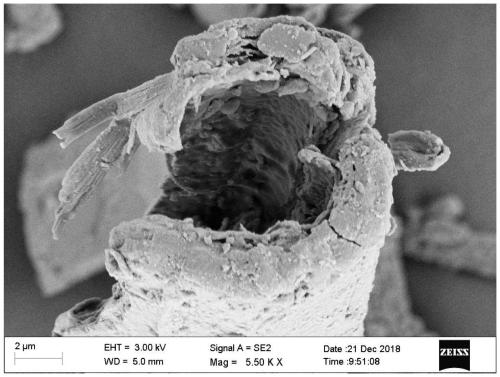

[0071] Step 1, ginger stalk raw material (such as figure 2 Shown) rinse with clean water to remove impurities such as soil, then cut into 3cm-long segments, then squeeze with a juicer, and collect the squeezed juice and slag separately.

[0072] Step 2: filter the ginger straw juice obtained in step 1 with qualitative filter paper, remove the insoluble particles therein to obtain a transparent liquid, then let it stand until obvious layers are separated, and then remove the water layer to separate the upper oil layer to obtain ginger straw crude oil.

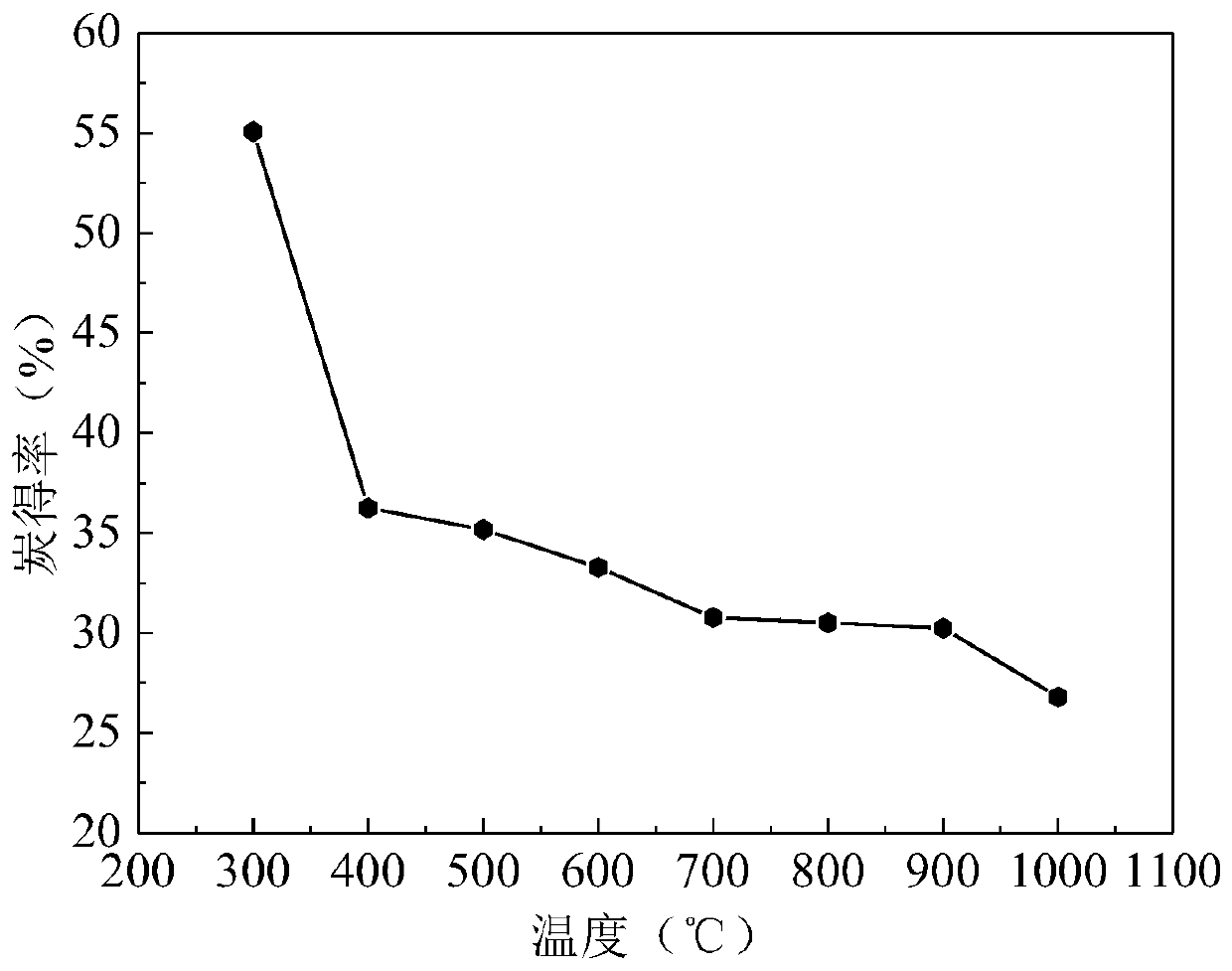

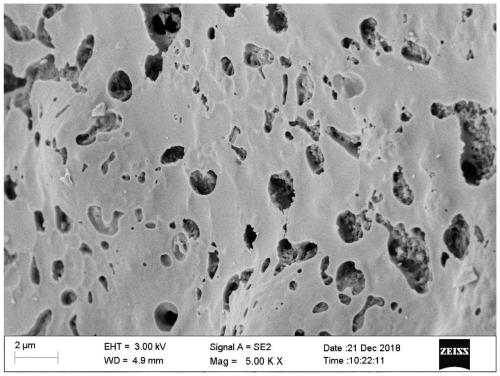

[0073] Step 3, drying the obtained ginger straw residue at 105° C. for 24 hours, crushing, and passing through an 80-mesh sieve. Then place it in a tube furnace for carbonization at 700°C for 2h, the protective gas is nitrogen, and the flow rate is 1L / min. The heating rate was 5°C / min.

[0074] Step 4, place the produ...

Embodiment 2

[0077] A comprehensive utilization and preparation method of ginger straw, comprising the following steps:

[0078] Step 1: Rinse the raw material of ginger stalks with clean water to remove impurities such as soil, then cut them into 2cm-long sections, then press them with a juice extractor, and collect the juice and slag obtained from the pressing.

[0079] Step 2: filter the ginger straw juice obtained in step 1 with qualitative filter paper, remove the insoluble particles therein to obtain a transparent liquid, then let it stand until obvious layers are separated, and then remove the water layer to separate the upper oil layer to obtain ginger straw crude oil.

[0080] Step 3, drying the obtained ginger straw residue at 105° C. for 24 hours, crushing, and passing through a 120-mesh sieve. Then place it in a tube furnace for carbonization at 500°C for 2h, the protective gas is nitrogen, and the flow rate is 1.5L / min. The heating rate is 10°C / min.

[0081] Step 4: Place th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com