Tableware cleaning machine

A technology for a tableware washing machine and a tableware rack, which is applied in the field of kitchen cleaning, can solve the problems of complex design structure, high maintenance rate, deep concavity, etc., and achieves the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

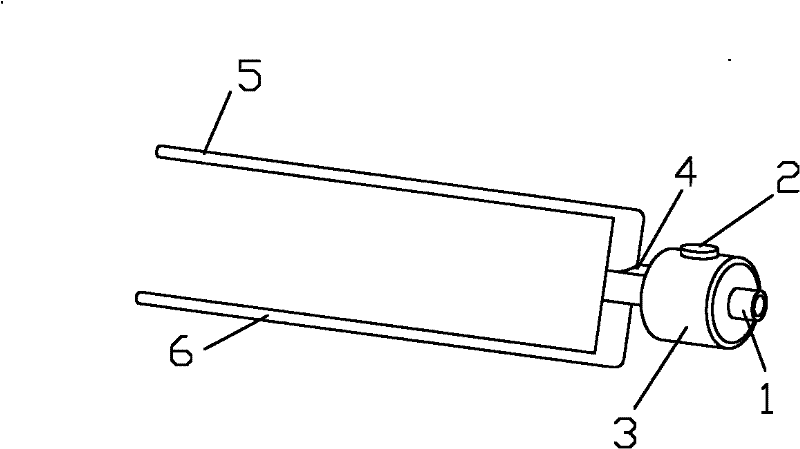

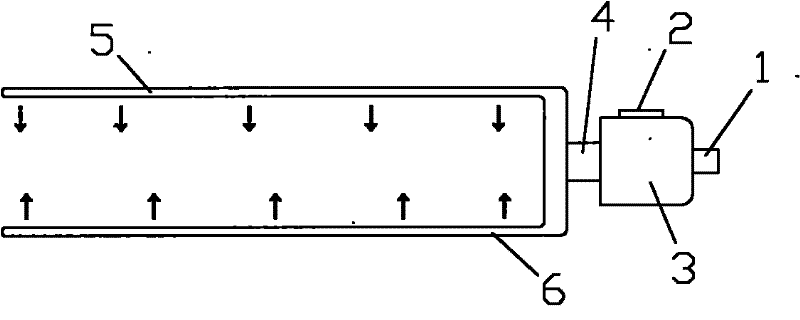

[0052] Tableware washing machine with tuning fork spray device structure (designed according to three-layer tableware rack, manual type), see Figure 1 to Figure 8 .

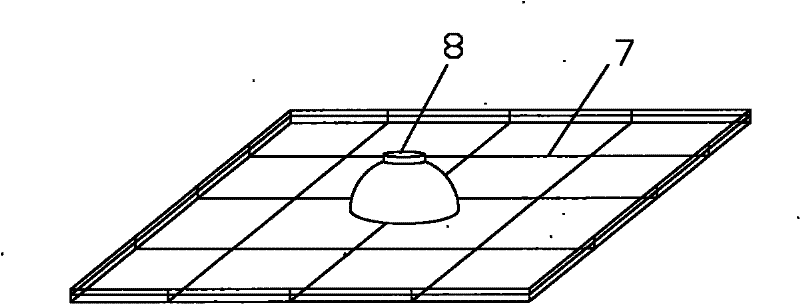

[0053] Design the sprinkler as a tuning fork structure, see figure 1 , figure 2shown. The bottom of the tableware rack 7 is designed into a plane structure, and the height of the surrounding bars can block the outer sliding of the tableware, preferably 2-5cm, see image 3 . On the right side wall of the dishwashing chamber 10, a guide opening 12 shaped like an "E" is opened; on the left sidewall of the dishwashing chamber 10, a three-layer tableware rack support bar 9 is installed, see Figure 4 . The tableware rack 7 is placed on the tableware rack support bar 9; the tuning fork type spray device ( figure 1 ) on the dishwashing cavity (see Figure 5 ), requirements: the spray handle 3 is outside the right side wall of the dishwashing cavity, the spray neck 4 is in the "E"-shaped guide port 12, and the s...

Embodiment 2

[0063] Dishwashing machine with single-arm spray device structure (designed according to three-layer tableware rack, manual type), see Figure 11 to Figure 13 .

[0064] Design the spraying device as a single-arm structure, see Figure 11 shown. The bottom of the cutlery rack 7 is designed into a plane structure, and the height of the hurdles around it is preferably 2-5cm, see image 3 . Open a guide opening 17 shaped like a "bow" on the right side wall of the dishwashing cavity; install a three-layer tableware rack support bar on the left side wall inside the dishwashing cavity; place the tableware rack on the tableware rack support bar on, see Figure 12 . With reference to Embodiment 1, the single-arm spray device can be easily installed on the dishwashing cavity, which will not be repeated here.

[0065] The main difference between this embodiment and embodiment 1 is that there are two spray arms in embodiment 1 (upper spray arm 5 and lower spray arm 6), while there ...

Embodiment 3

[0068] Dishwashing machine (manual type) with multi-arm spray device structure, see Figure 14 to Figure 16 .

[0069] Design the sprinkler as a multi-arm structure, see Figure 14 shown. Design the bottom of the tableware rack as a flat structure, and the height of the surrounding fences is preferably 2-5cm, see image 3 . On the right side wall of the dishwashing cavity, open a guide port 19 shaped like a "one"; install a three-layer tableware rack support bar on the left side wall inside the dishwashing cavity; place the tableware rack on the tableware rack support bar on, see Figure 15 , Figure 16 . With reference to Embodiment 1, the multi-arm spray device can be easily installed on the dishwashing cavity, which will not be repeated here.

[0070] The tableware cleaning device of this embodiment is very simple to operate when cleaning tableware. Theoretically speaking, since the multi-arm spray arms 18 correspond to each tableware rack one by one, the tableware c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com