Flying saucer type photovoltaic cell panel cleaner and cleaning method thereof

A technology of photovoltaic panels and cleaners, applied in the field of remote cleaning, which can solve problems such as inability to clean panels, large equipment maintenance, and complex systems, and achieve the effects of overcoming the limitations of cleaning areas, stable flight systems, and high feedback efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

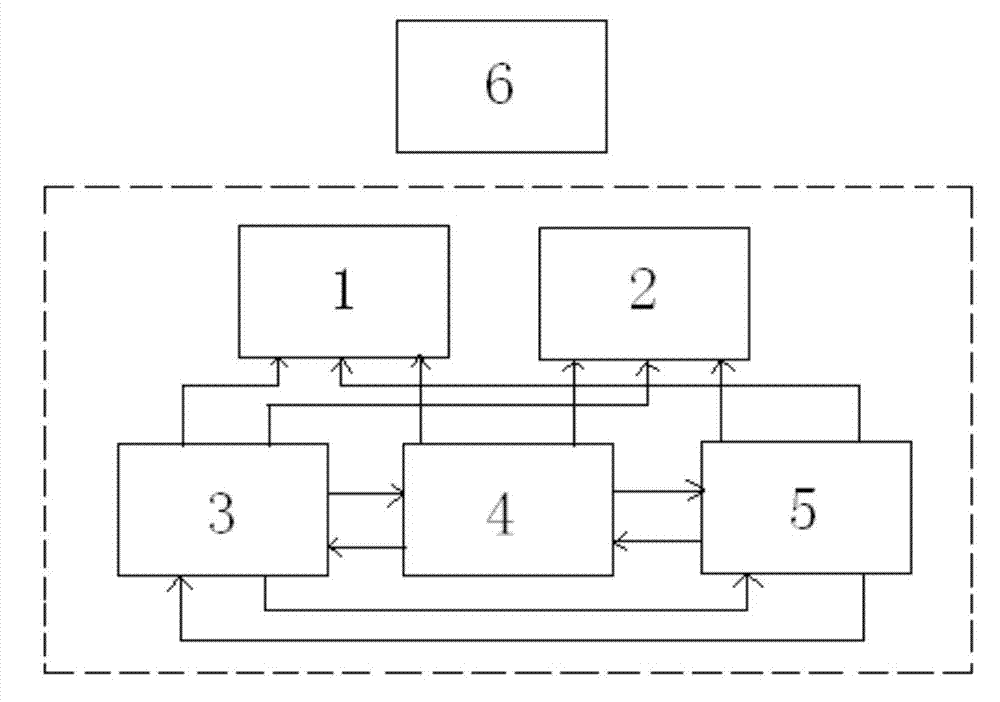

[0046] A kind of flying saucer type photovoltaic panel cleaner of the present invention, as figure 1 As shown, it includes a cleaning system 2 , a power supply system 3 and a control system 4 , and is characterized in that it also includes a flight system 1 , a communication system 5 and a remote control system 6 .

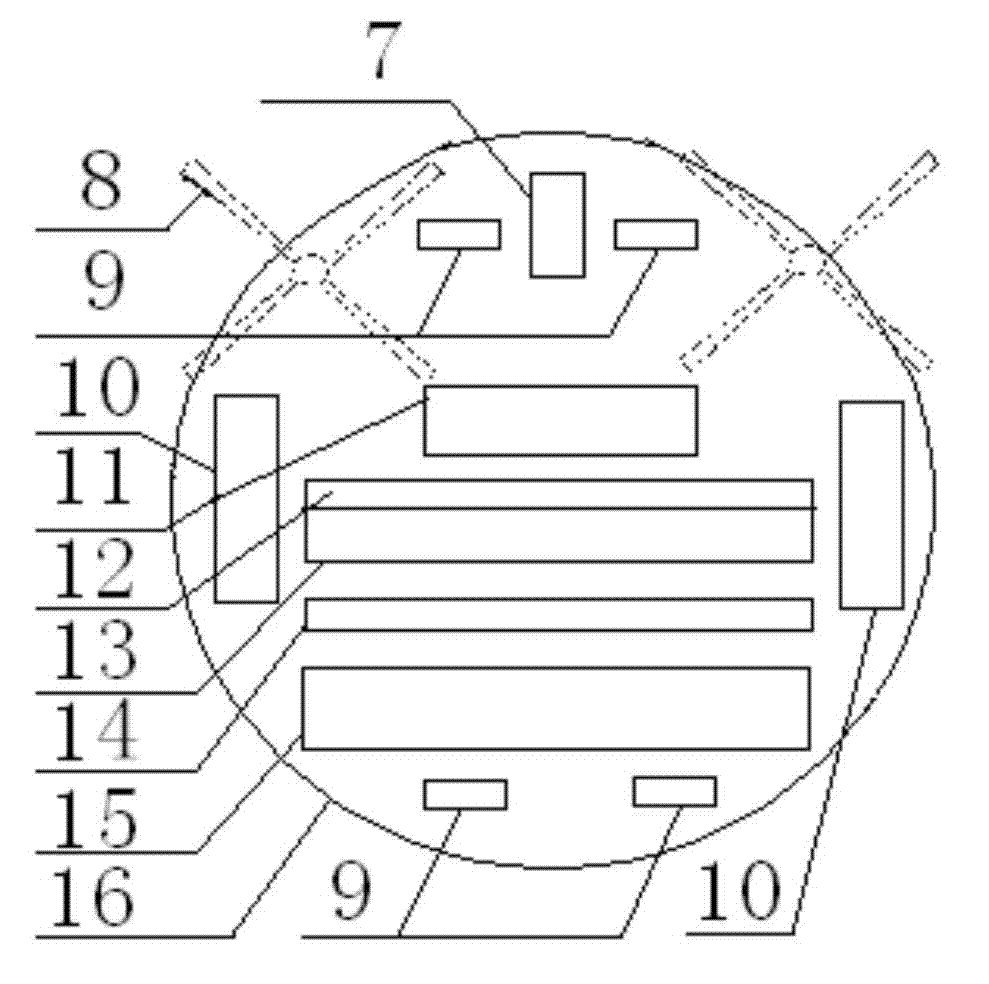

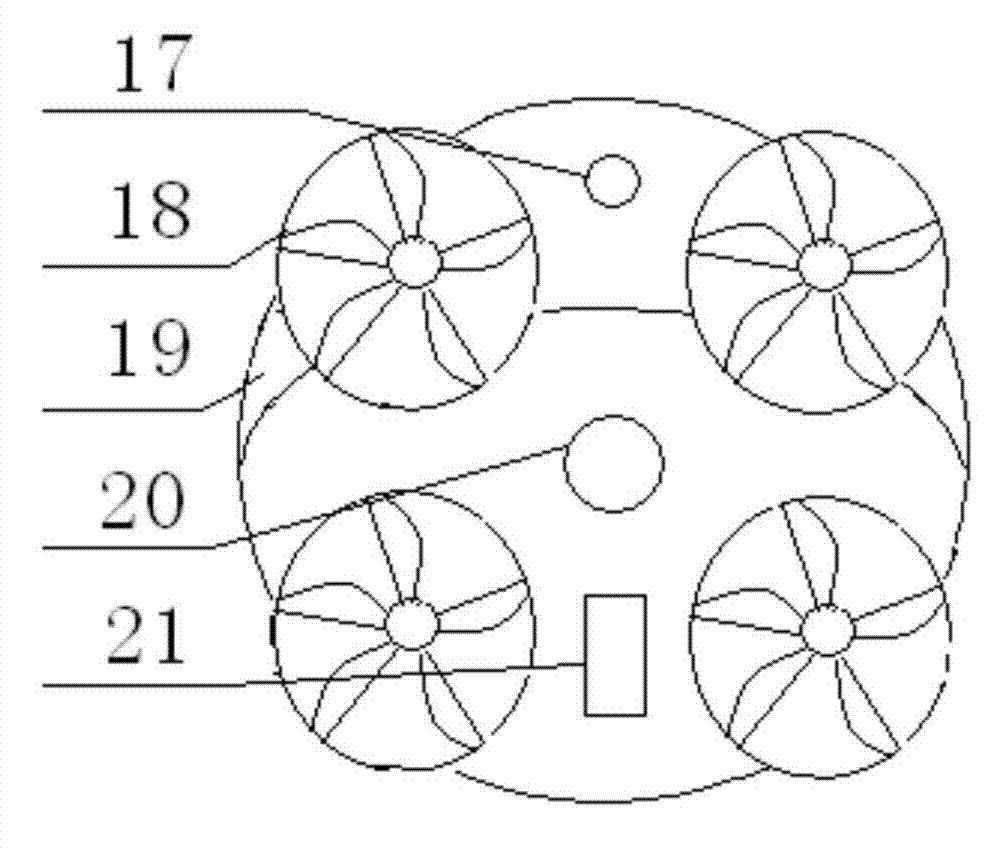

[0047] The flight system 1, the cleaning system 2, the power system 3, the control system 4 and the communication system 5 form a control and execution mechanism, that is, a washer host, and the washer host is a disc structure, also known as a disc structure. Such as figure 2 As shown, the cleaning system 2 is composed of two parts, one part is composed of the power supply system 3, the control system 4, the communication system 5 and the control system 4 arranged in the disc structure to form the power and control part; the other part is arranged in the cleaning system. Cleaning tools on the site of system 2, i.e. corner brush 8, squeegee 12, sweeping brush 13,...

Embodiment 2

[0092] In this embodiment, a flying saucer-type photovoltaic cell panel cleaner is selected to remotely clean the five roof photovoltaic cell assemblies of the building where it is located. The cleaner can be released from any floor of the building.

[0093] The user uses the remote control to operate, the operation mode adopts the manual remote control flight mode with buttons and touch, and the operation mode combined with automatic cleaning, and sets the cleaning path from top to bottom, from left to right and cleaning for 2 minutes each by suction, sweeping and wiping Way. The specific operation is as follows:

[0094] (1) Press the second right button and the first right button of the automatic cleaning mode button 34 of the remote control, and the cleaner performs the automatic cleaning function and the automatic flight function to the next target;

[0095] (2) Press the start / stop flight button of the remote control button 29 and the return button by the original fligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com