Cleaning method of flying saucer type photovoltaic cell panel cleaner

A technology for photovoltaic panels and cleaners, applied in the field of remote control cleaning, can solve the problems of inability to clean the panels, large equipment maintenance, complex systems, etc., to overcome the limitations of the cleaning area, the flight system is stable, and the feedback efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

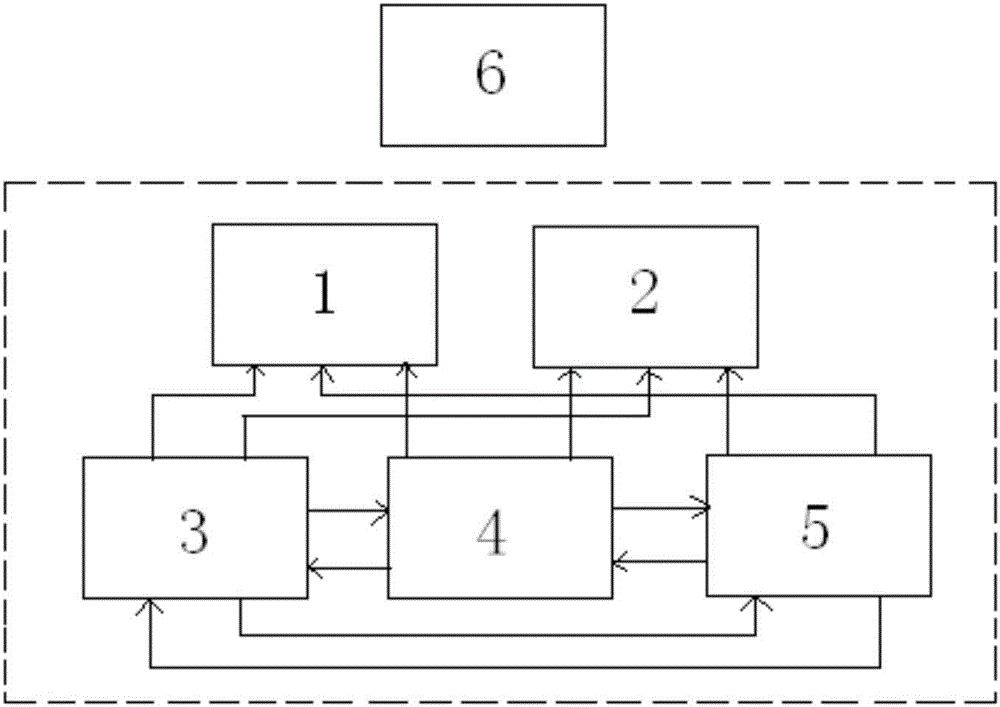

[0069] A flying saucer type photovoltaic cell panel cleaner of the present invention, such as figure 1 As shown, it includes a cleaning system 2, a power supply system 3 and a control system 4, and is characterized in that it also includes a flight system 1, a communication system 5 and a remote control system 6.

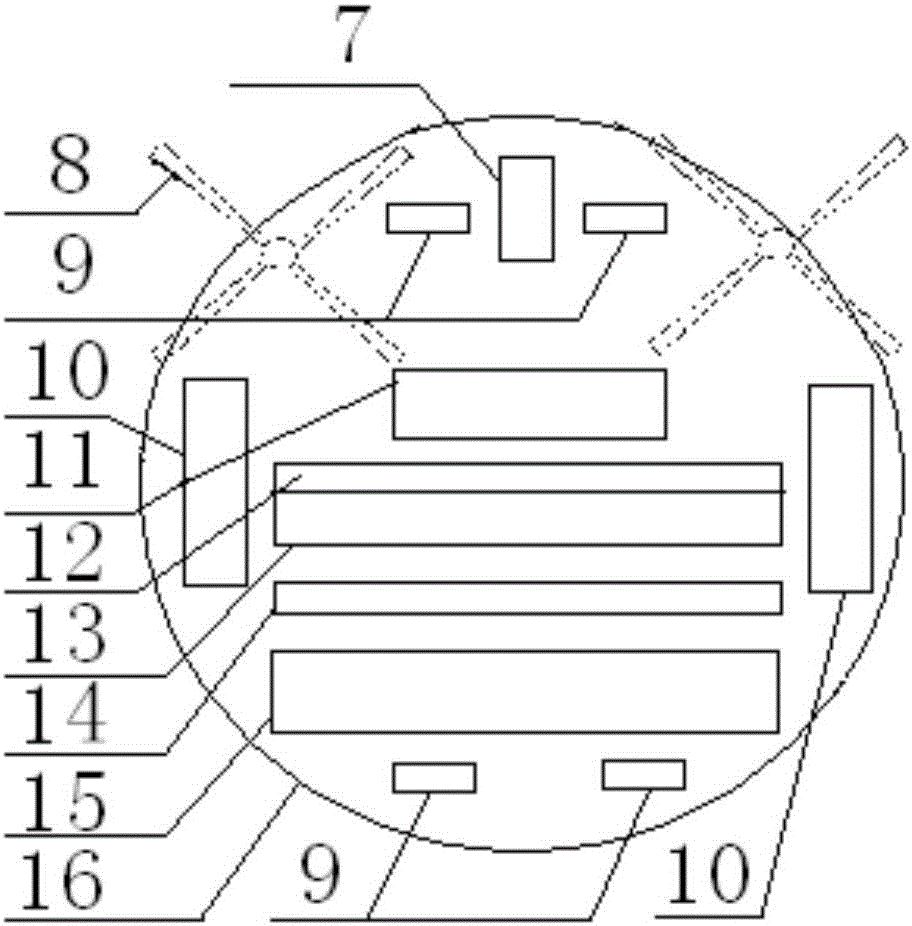

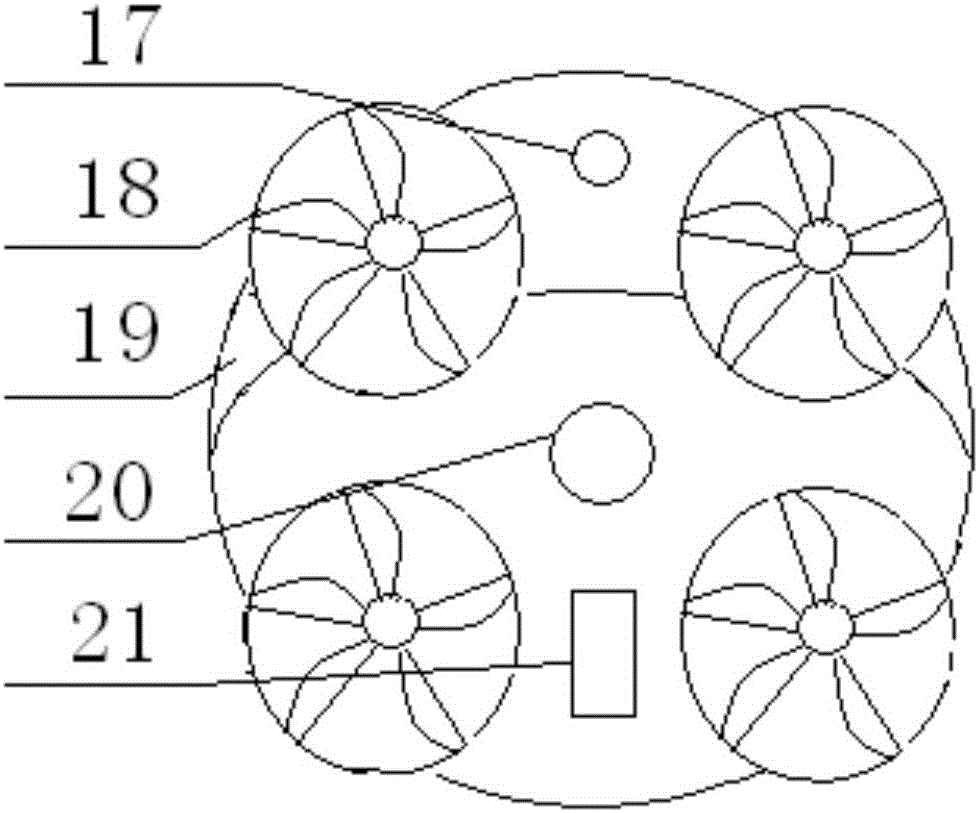

[0070] The flight system 1, cleaning system 2, power supply system 3, control system 4 and communication system 5 form a control and execution mechanism, namely the main body of the washer. The main body of the washer is a disc structure, also called a disc structure. like figure 2 As shown, the cleaning system 2 consists of two parts, one part consists of the power supply system 3, the control system 4 and the communication system 5 arranged in the disc structure, and the control system 4 to form the power and control part; the other part is arranged in the cleaning system. The cleaning tools on the site of the system 2, namely the corner brush 8, the squeegee 12...

Embodiment 2

[0086] There are various operating methods for the washer to control cleaning, the specific types are as follows:

[0087] The washer can perform remote real-time manual remote control, as well as remote partial automatic control and fully automatic control. Its automatic control covers intelligent control. The operator can use the automatic cleaning mode button 34 on the remote control panel to set the washer according to actual needs. The automatic control mode is activated and the automatic or semi-automatic control algorithm in the control system 4 is activated and applied to perform partial automatic control and full automatic control of the flight process and cleaning process of the washer. The control modes are:

[0088] (1) Press the left button of the automatic cleaning mode button 34, and the cleaning device automatically flies to the target;

[0089] (2) Press the second left button of the automatic cleaning mode button 34, and the cleaning device performs automatic r...

Embodiment 3

[0104] Embodiment 3 is basically the same as Embodiment 1, and also includes that the cleaning device can carry out intelligent voice remote control, which is composed of the intelligent voice hardware module and remote control software program arranged in the cleaning device host and the voice use buttons 31 and voice buttons on the remote control panel. The interactive terminal 30 is composed; after pressing the voice use button 31, after sending out a command voice to the voice interactive terminal 30, through the communication system 5, the cleaner host receives the voice command, and then it will immediately respond to execution; when the cleaner host When there is a problem at the operating site, it will also automatically report to the operator by voice through the communication system 5; if the voice use button 31 is not pressed, the intelligent voice remote control function disappears. The host can only report to the operator with data and text through the communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com