Patents

Literature

629results about How to "Effective flushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

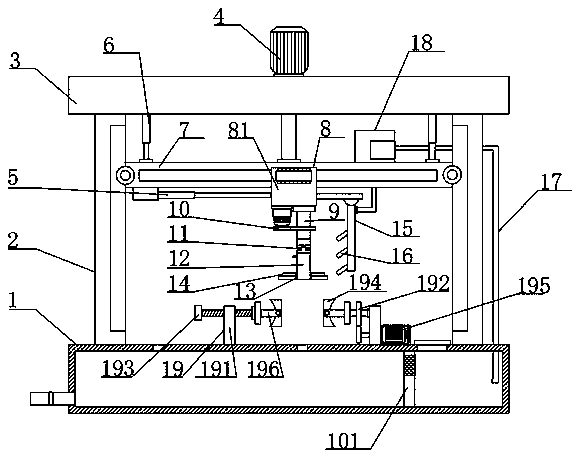

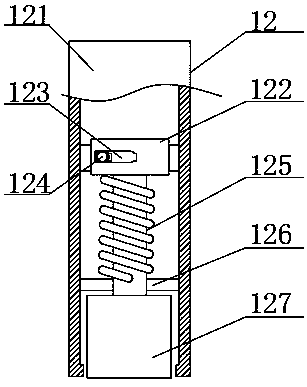

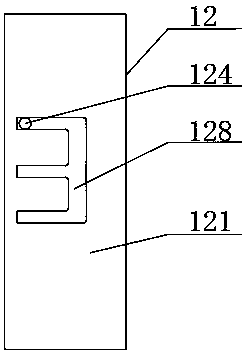

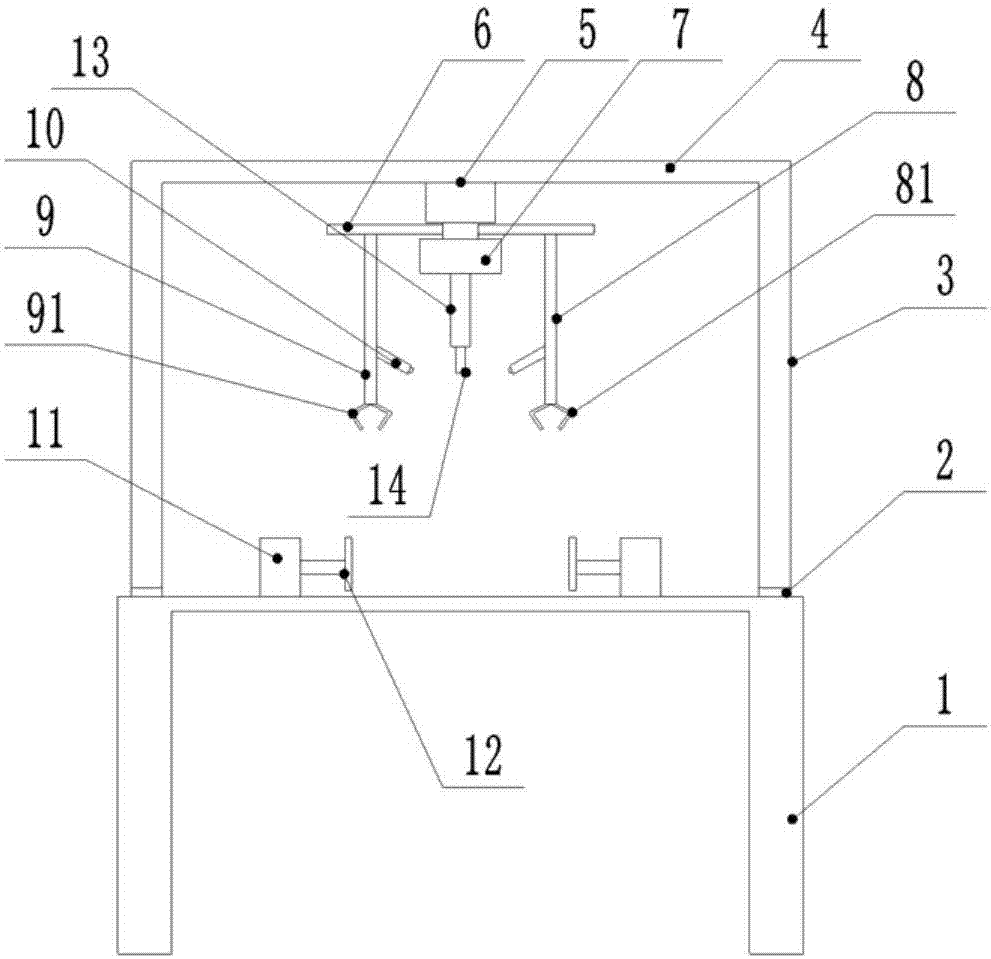

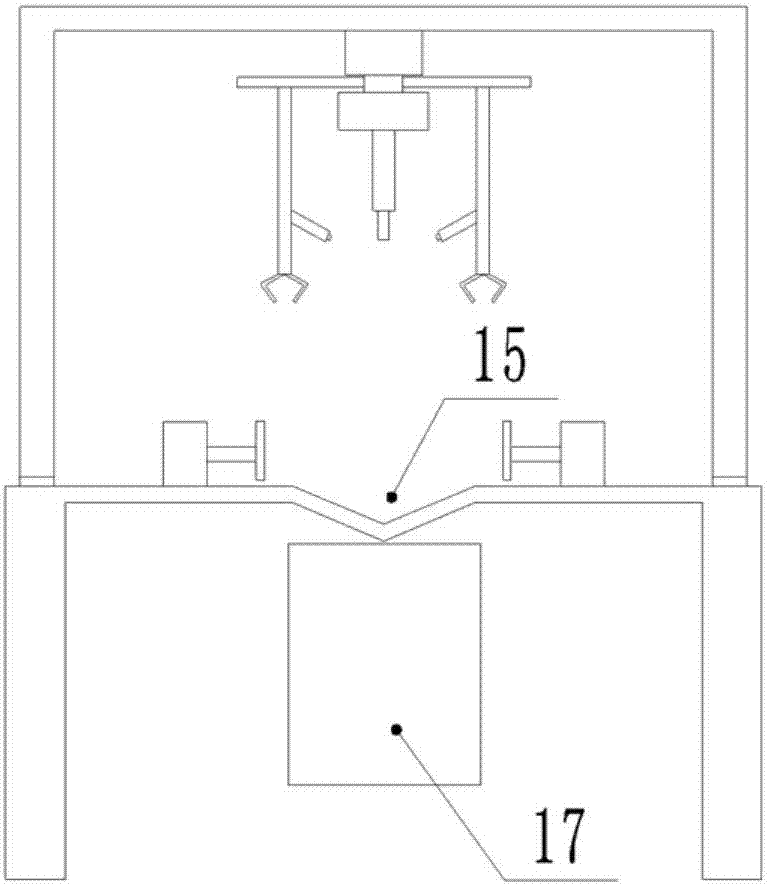

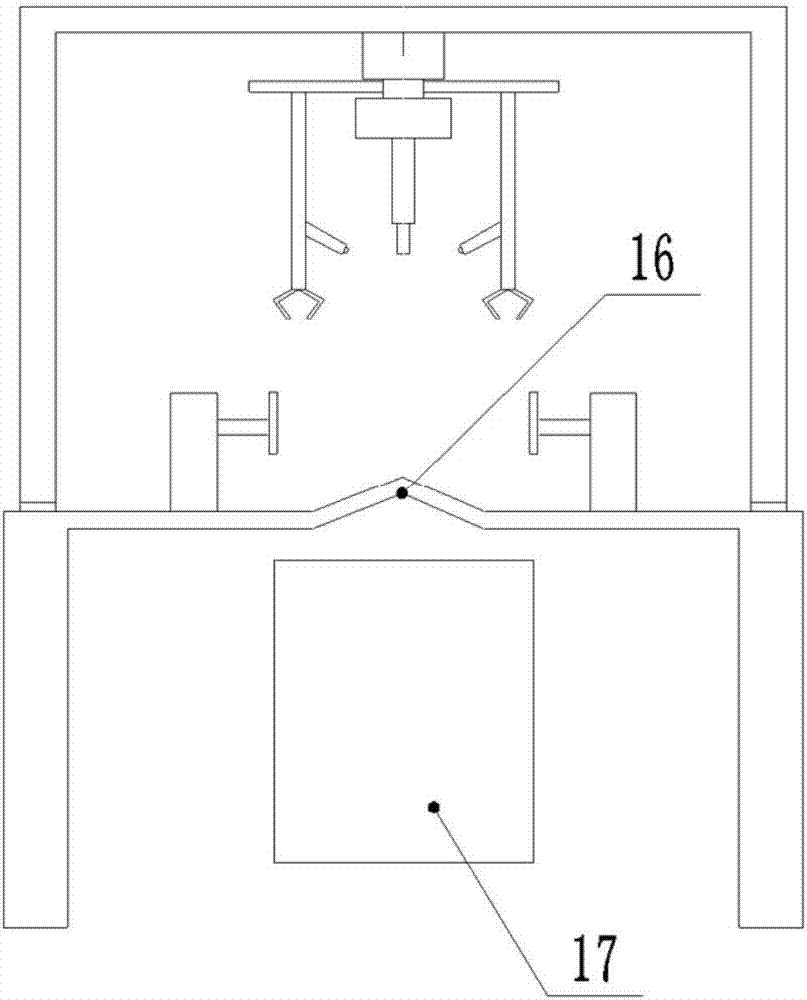

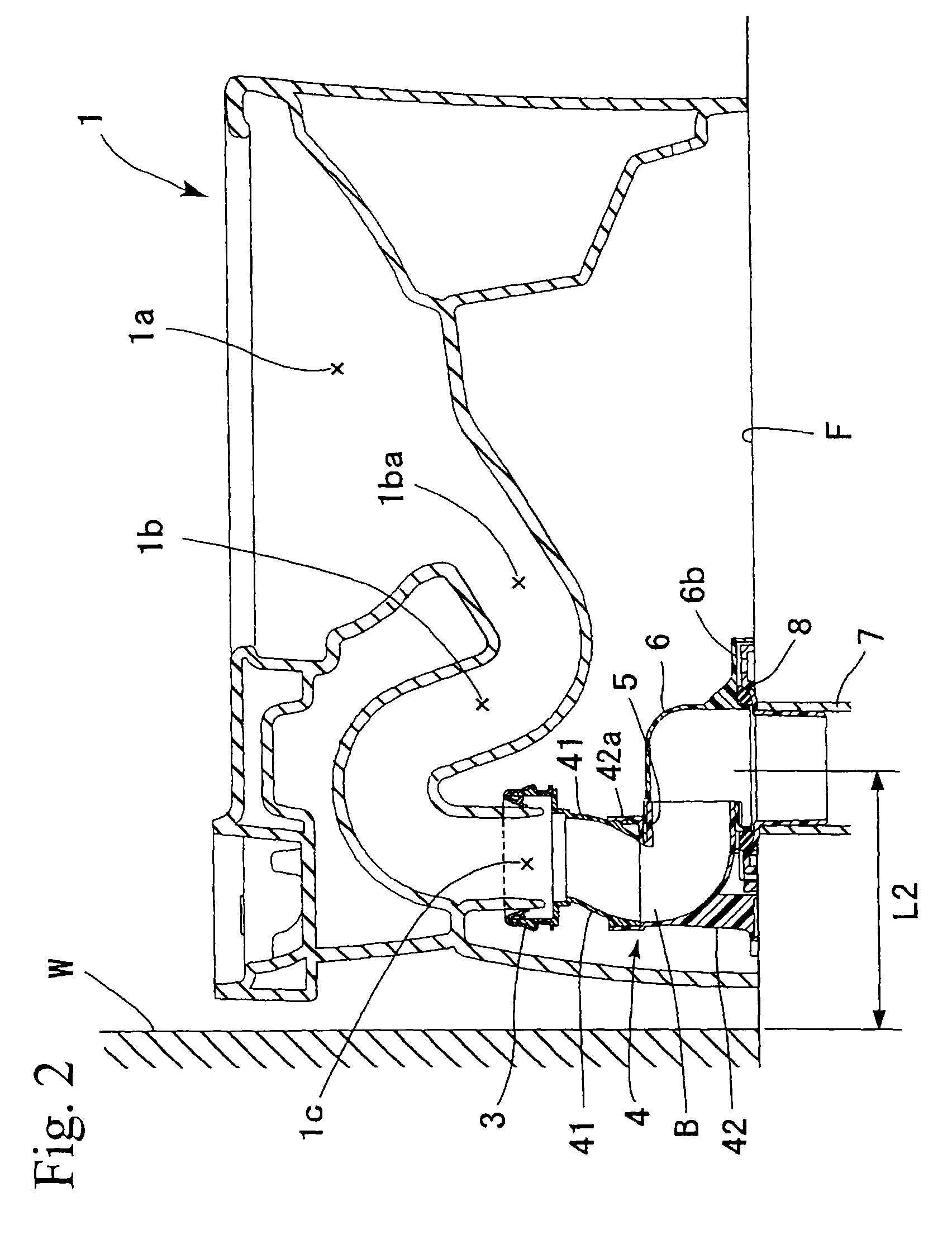

Automatic grinding machine for industrial machinery and grinding method

InactiveCN108789087AIncrease flexibilityImprove stabilityGrinding carriagesGrinding drivesHydraulic cylinderCoupling

The invention discloses an automatic grinding machine for industrial machinery and a grinding method. The automatic grinding machine comprises a base box body, wherein left and right sides of the topof the base box body are symmetrically equipped with stand columns; a top plate is arranged on the tops of the two groups of the stand columns; the outer wall of a bearing rod is movably equipped witha slide assembly; the bottom of the slide assembly is sequentially equipped with a grinding motor and a rotary rod from left to right; the bottom of the rotary rod is equipped with a universal shaftcoupler; the top of the base box body is equipped with a fixed clamp; and the right side of the top of the base bottom box is spliced with a water conveying hose I. The grinding machine for industrialmachinery is high in flexibility and is good in stability; a hydraulic cylinder drives the bearing rod to lift through a pushing rod, so that a grinding disc in grinding can lift; and an electric telescopic pole extends and shortens to drive the slide assembly to move left and right, so that the grinding disc in grinding can move left and right, and therefore, the automatic grinding machine has relatively high flexibility, and improves grinding working efficiency.

Owner:CHENGDU PUJIANG KEXIAN TECH

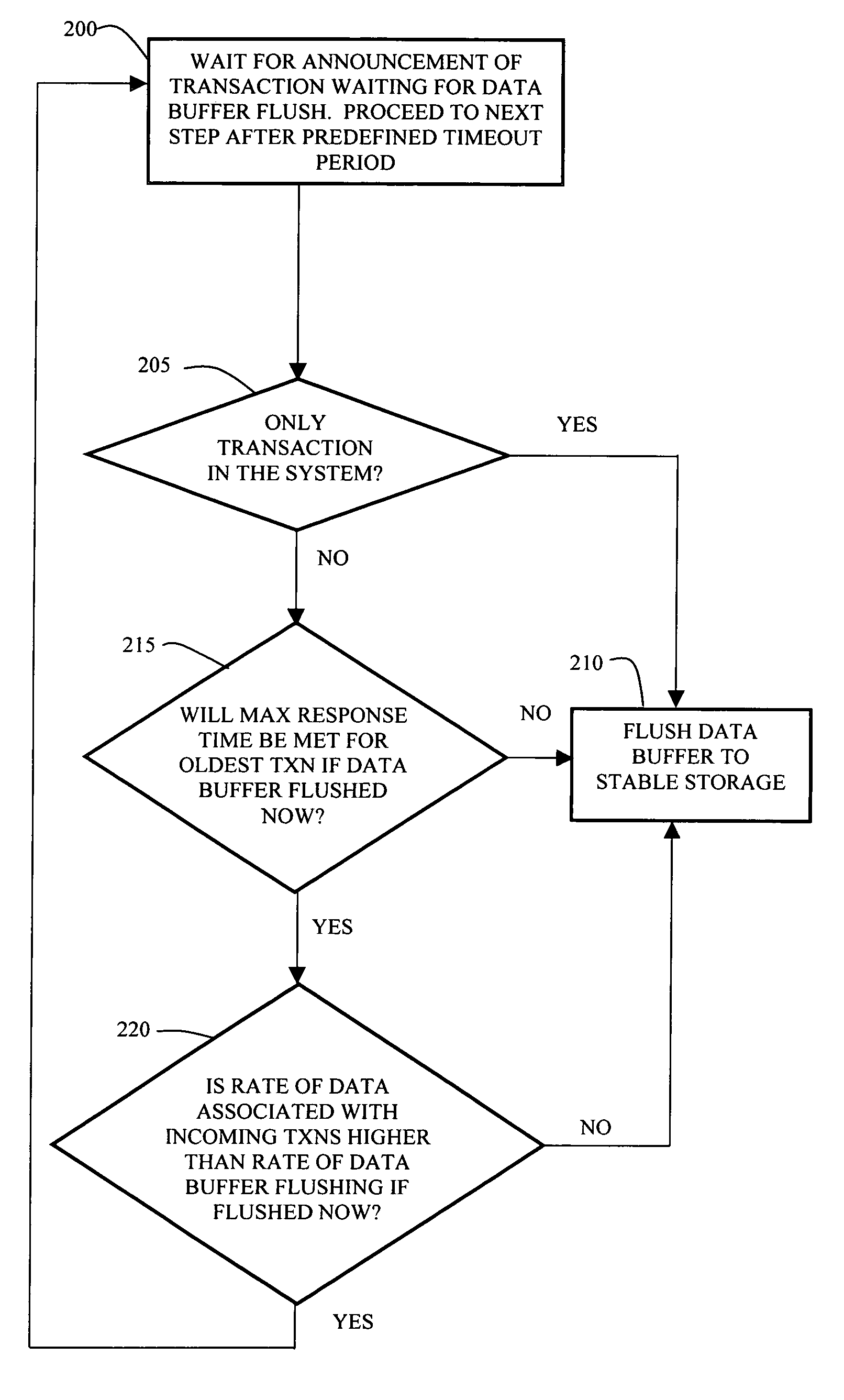

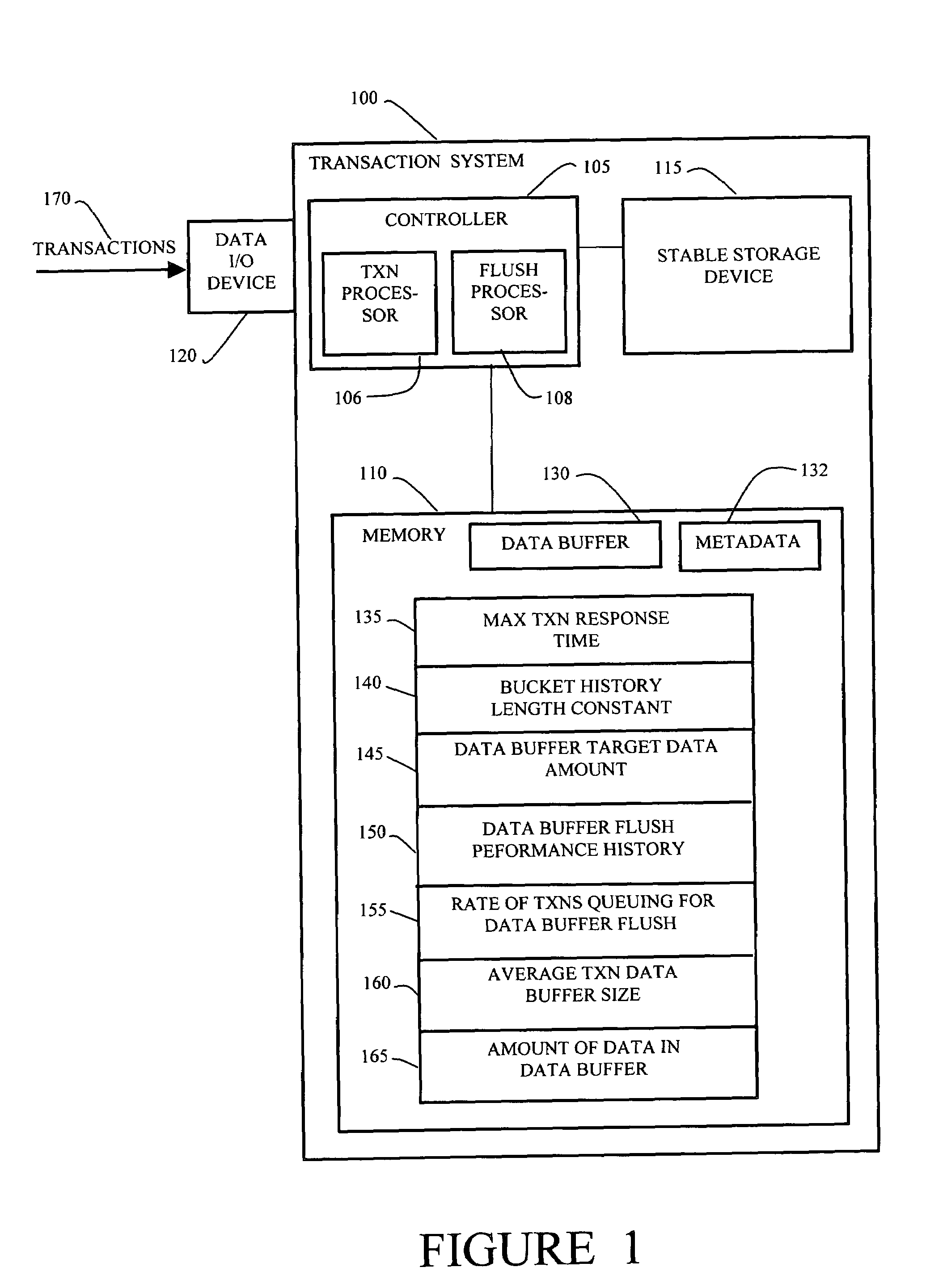

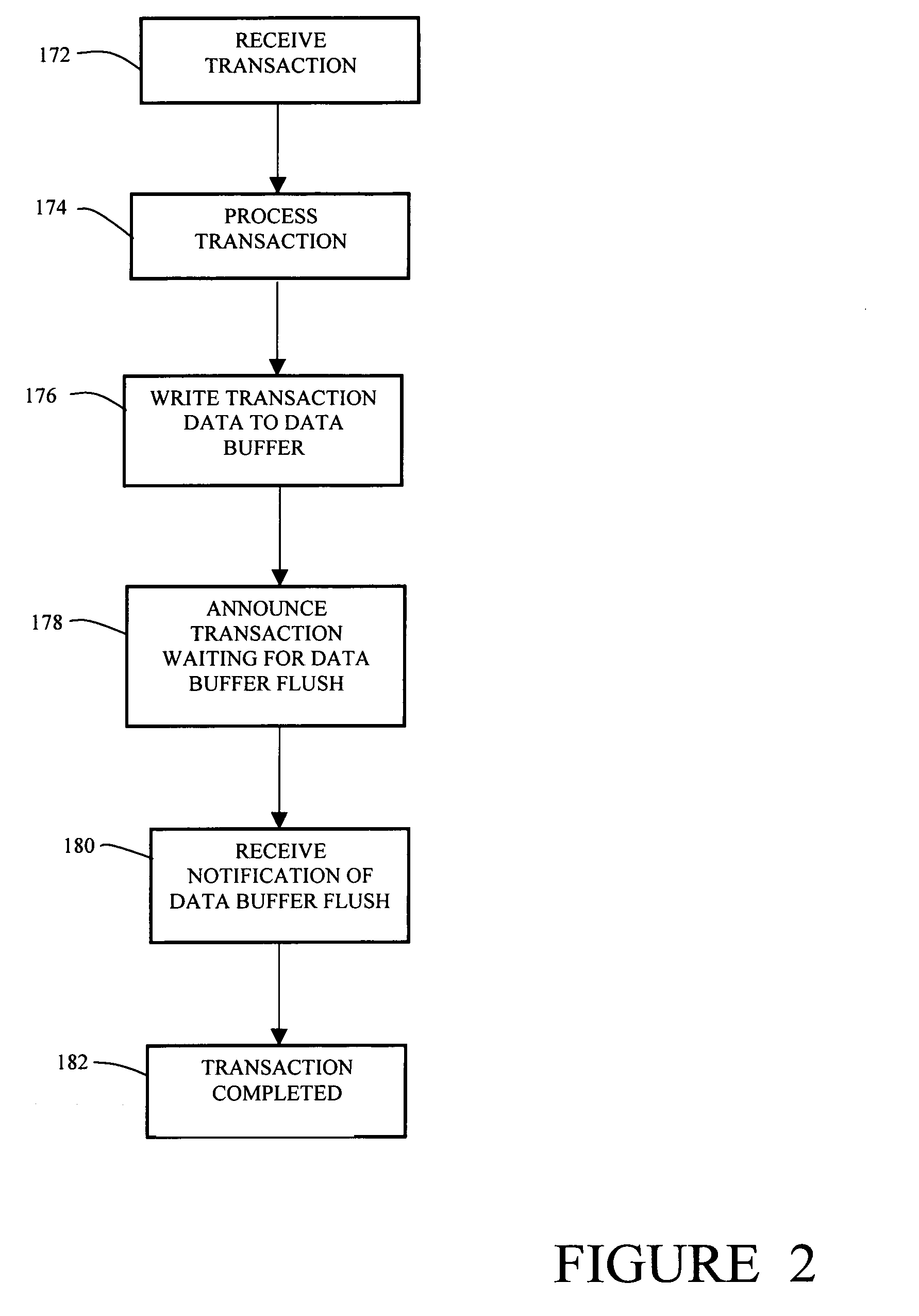

Method and apparatus for self-tuning transaction batching

InactiveUS7165129B1Improve responseImprove throughputMemory architecture accessing/allocationSpecial data processing applicationsSelf-tuningPeak value

In a transaction system, a dynamic batching process enables efficient flushing of data in a data buffer to a stable storage device. The transaction system uses constant values and dynamic values and a system performance history to adjust the rate of flushing data and also to adjust the amount of data flushed in each flush operation. The transaction system is able to respond to both spikes in rate of received transactions as well as more gradual changes in the rate of received transactions and to automatically adapt to stable storage device performance variations.

Owner:CISCO TECH INC

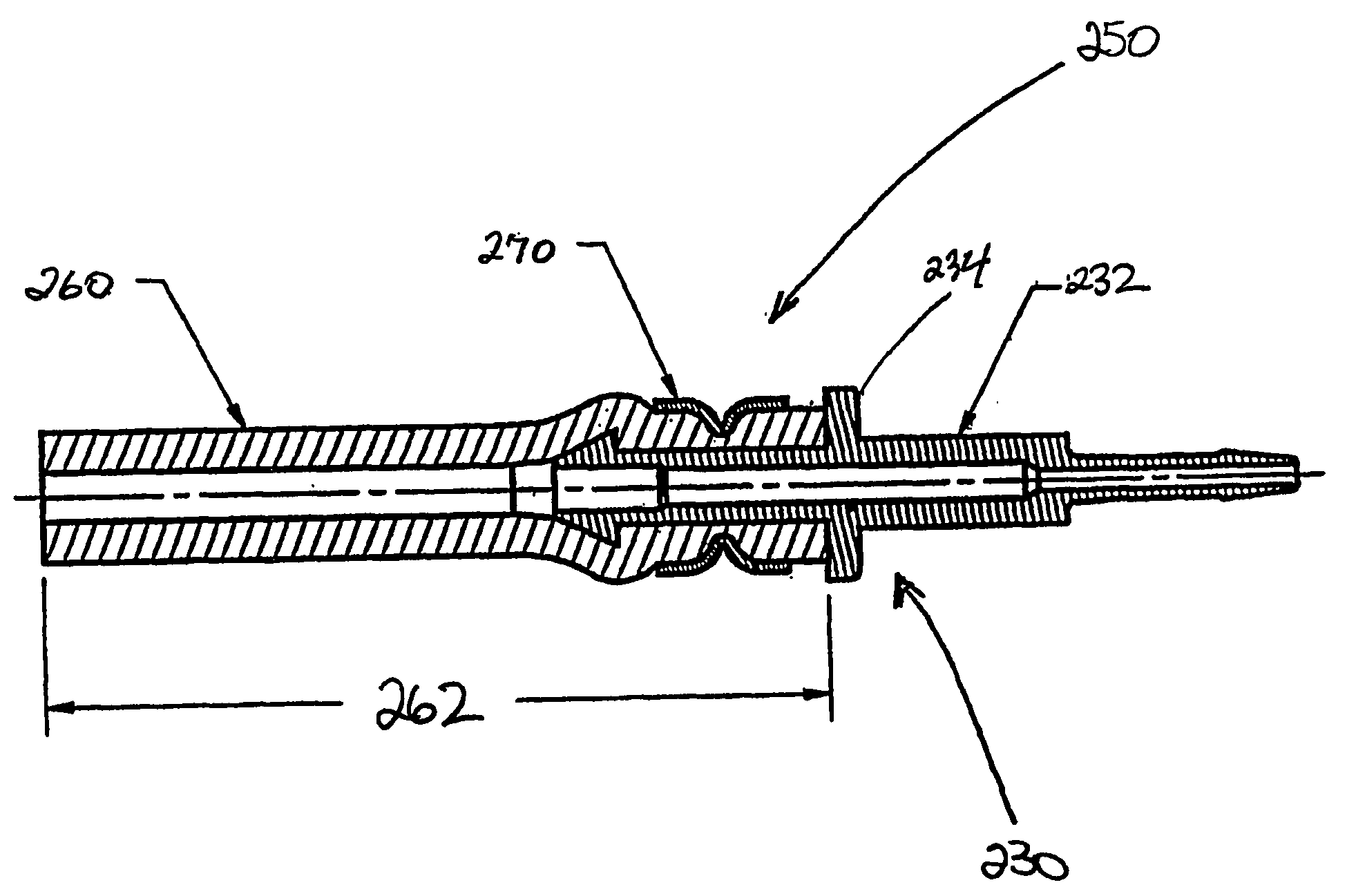

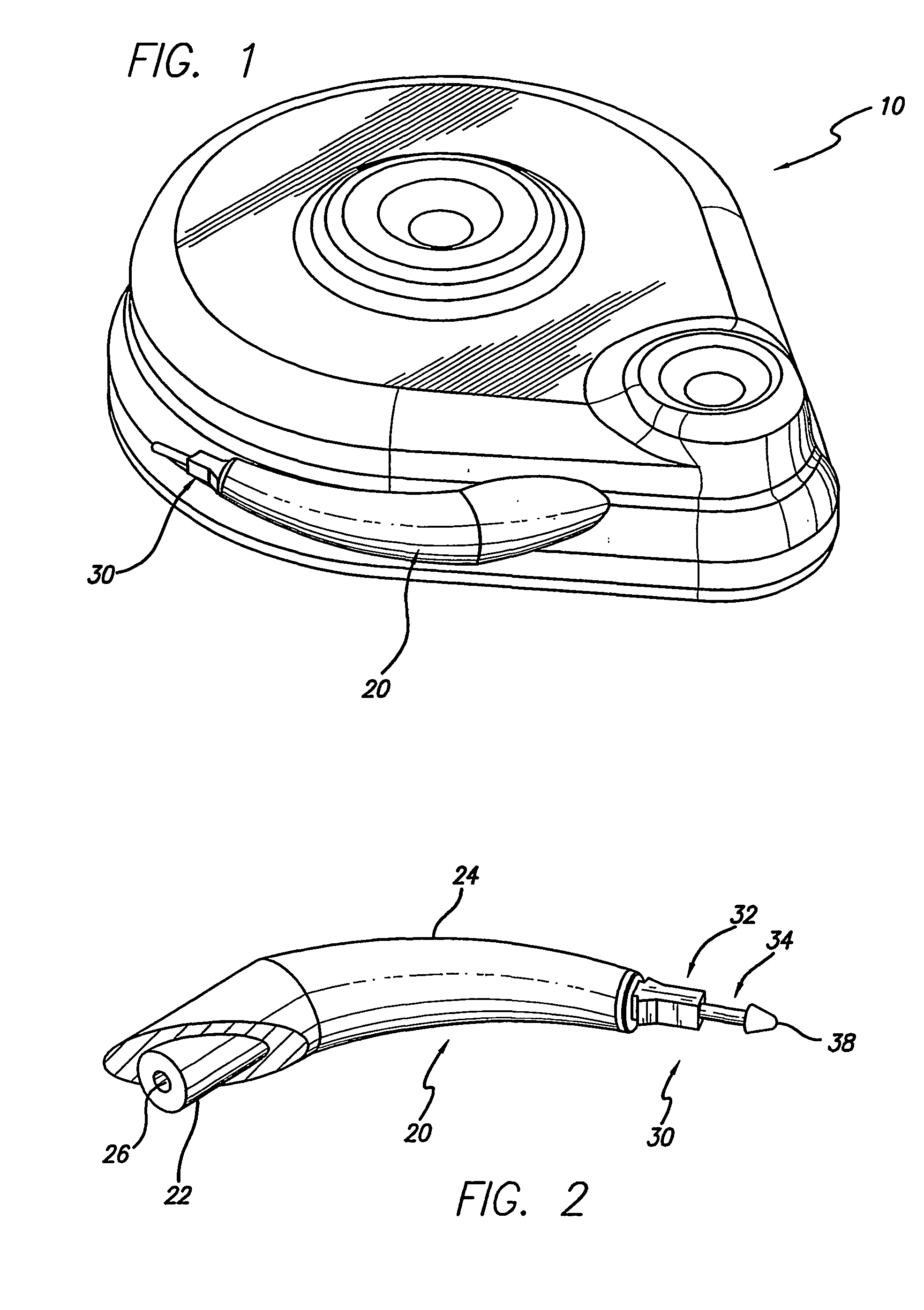

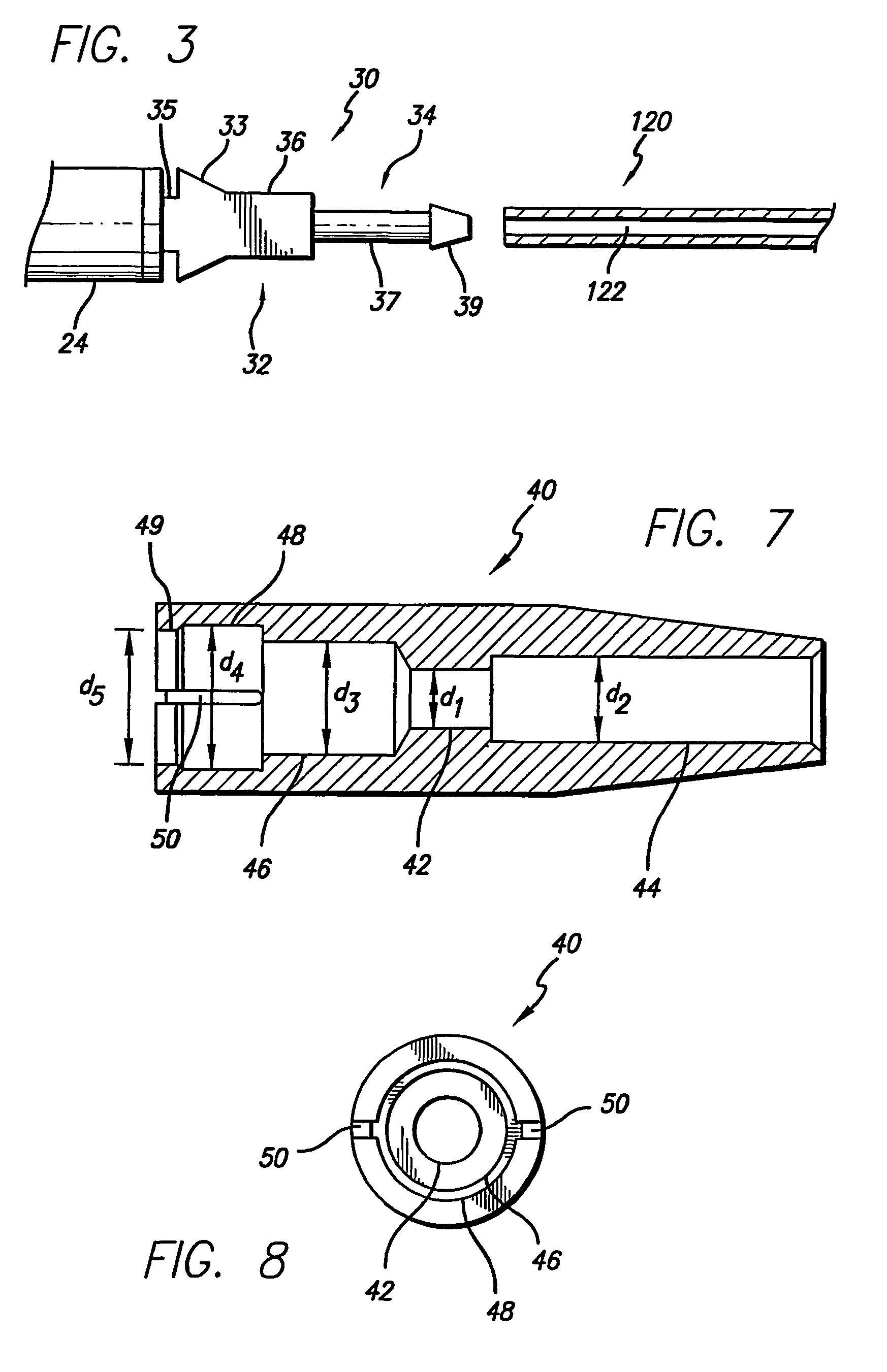

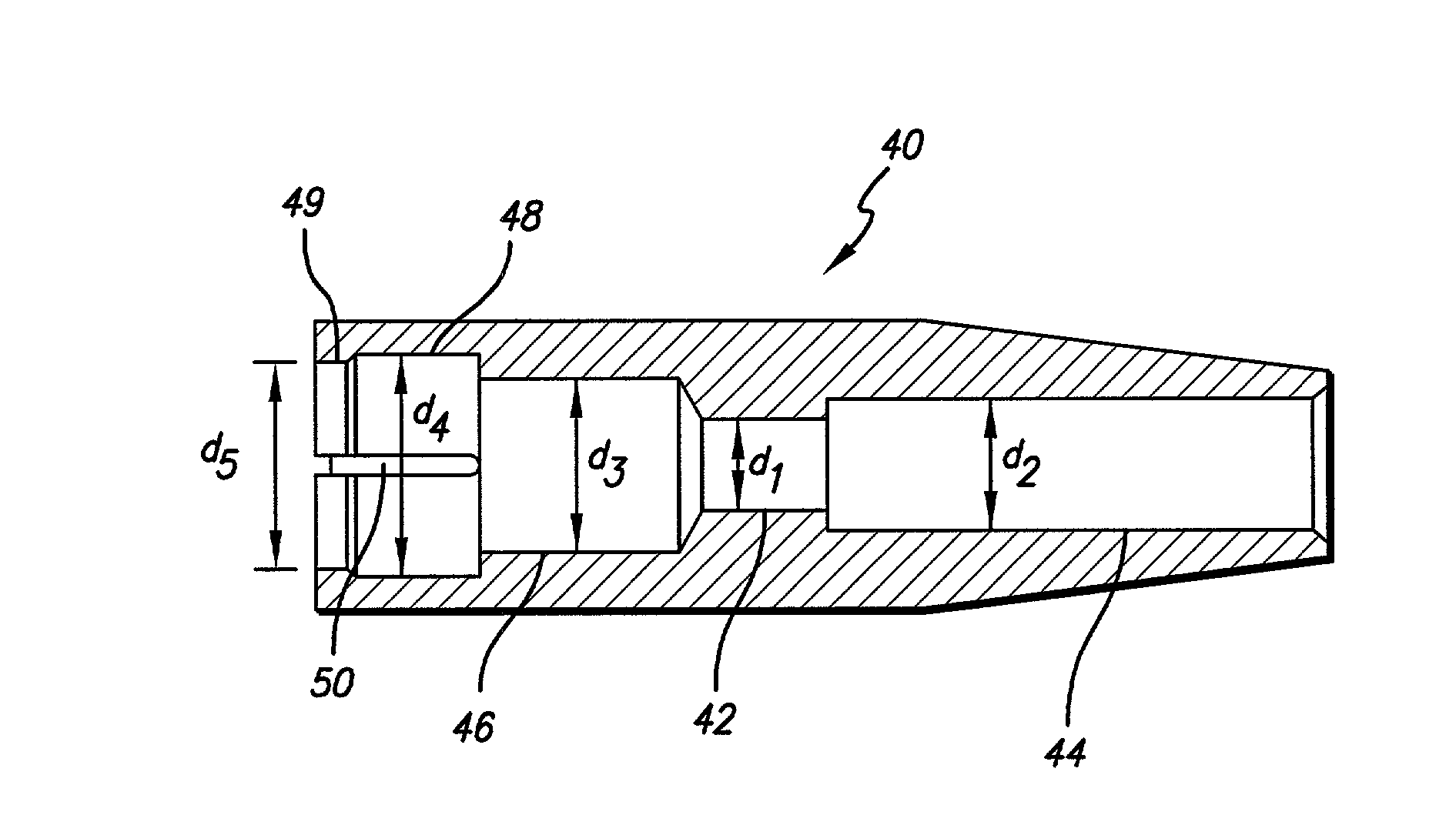

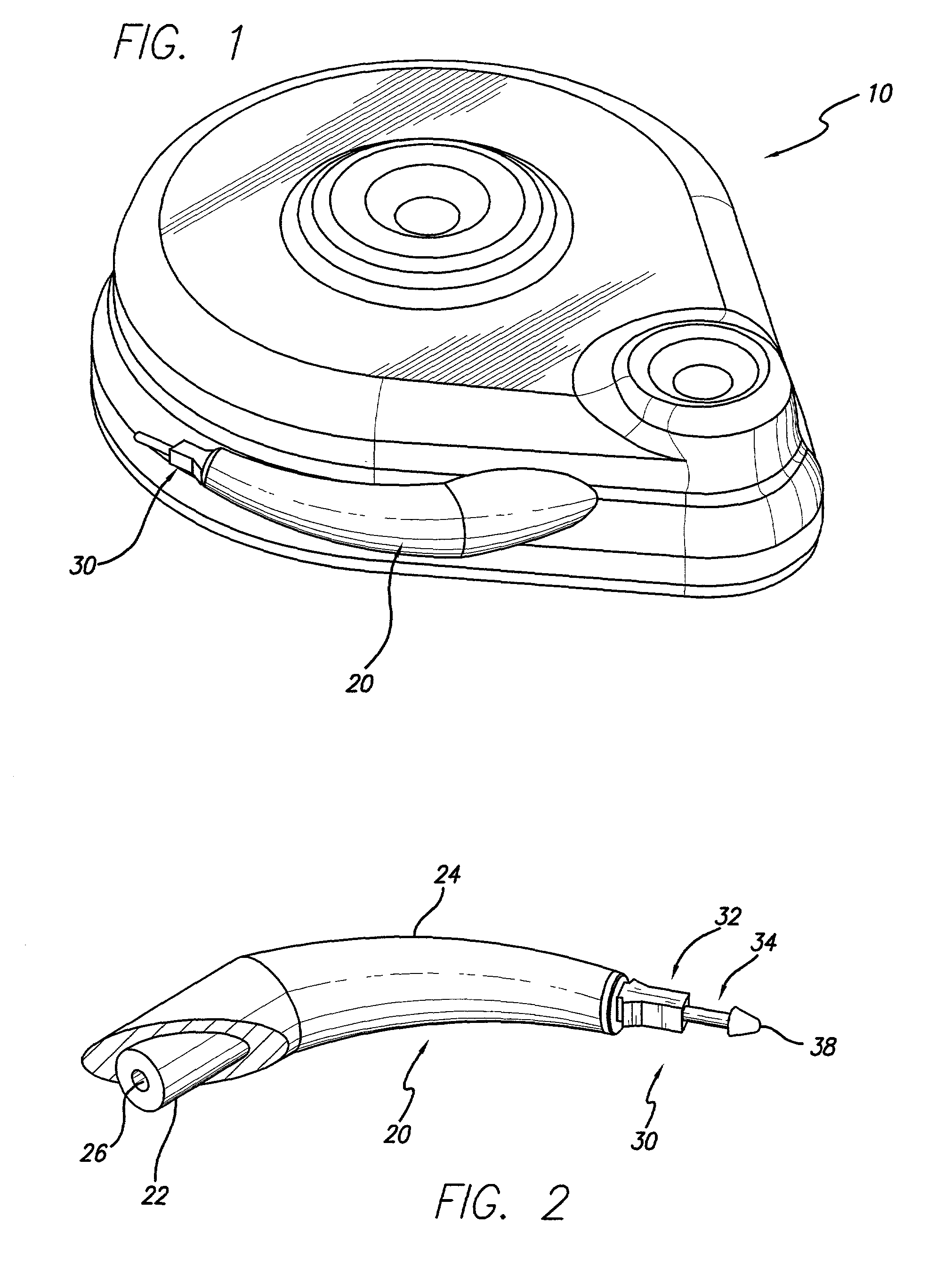

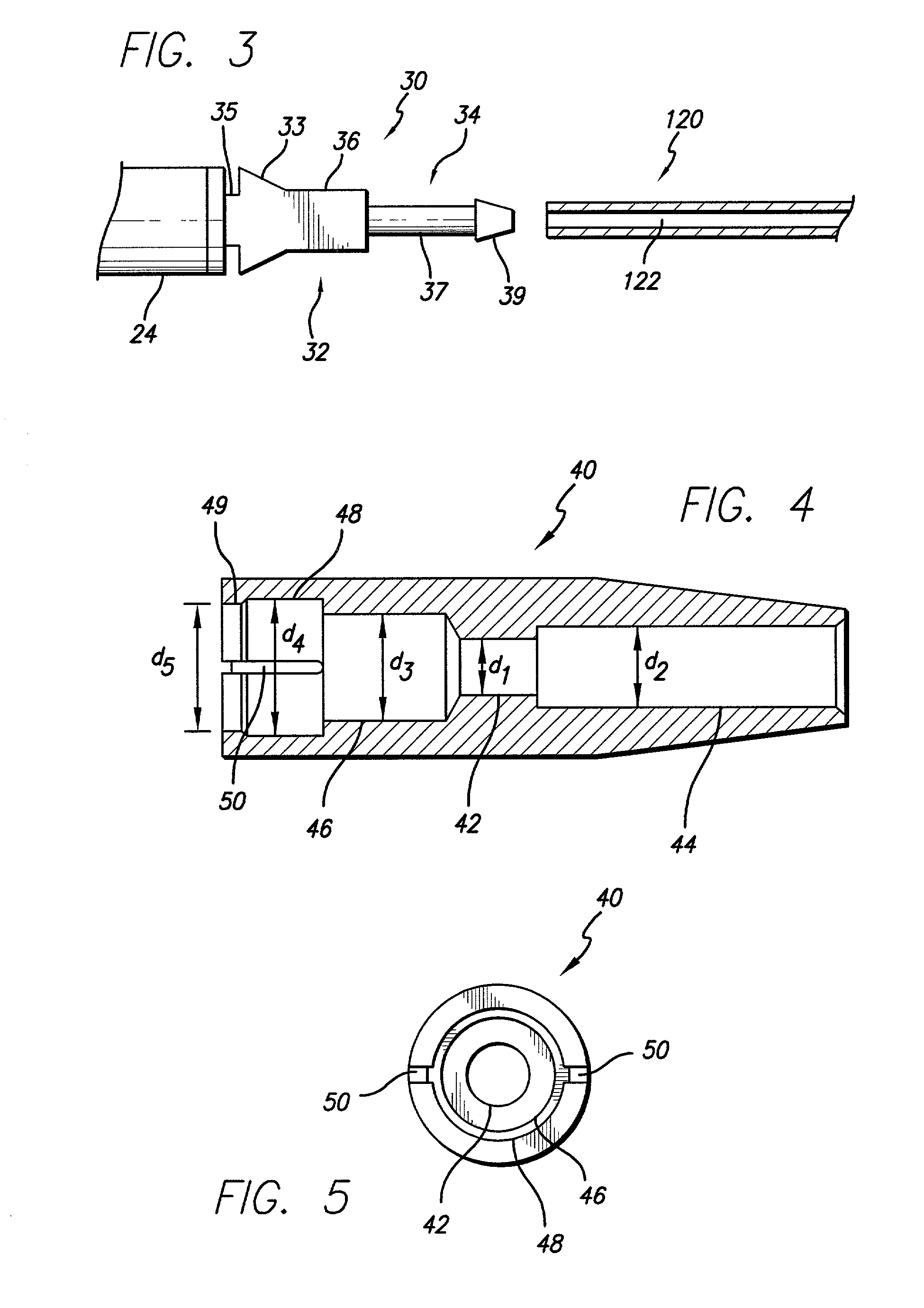

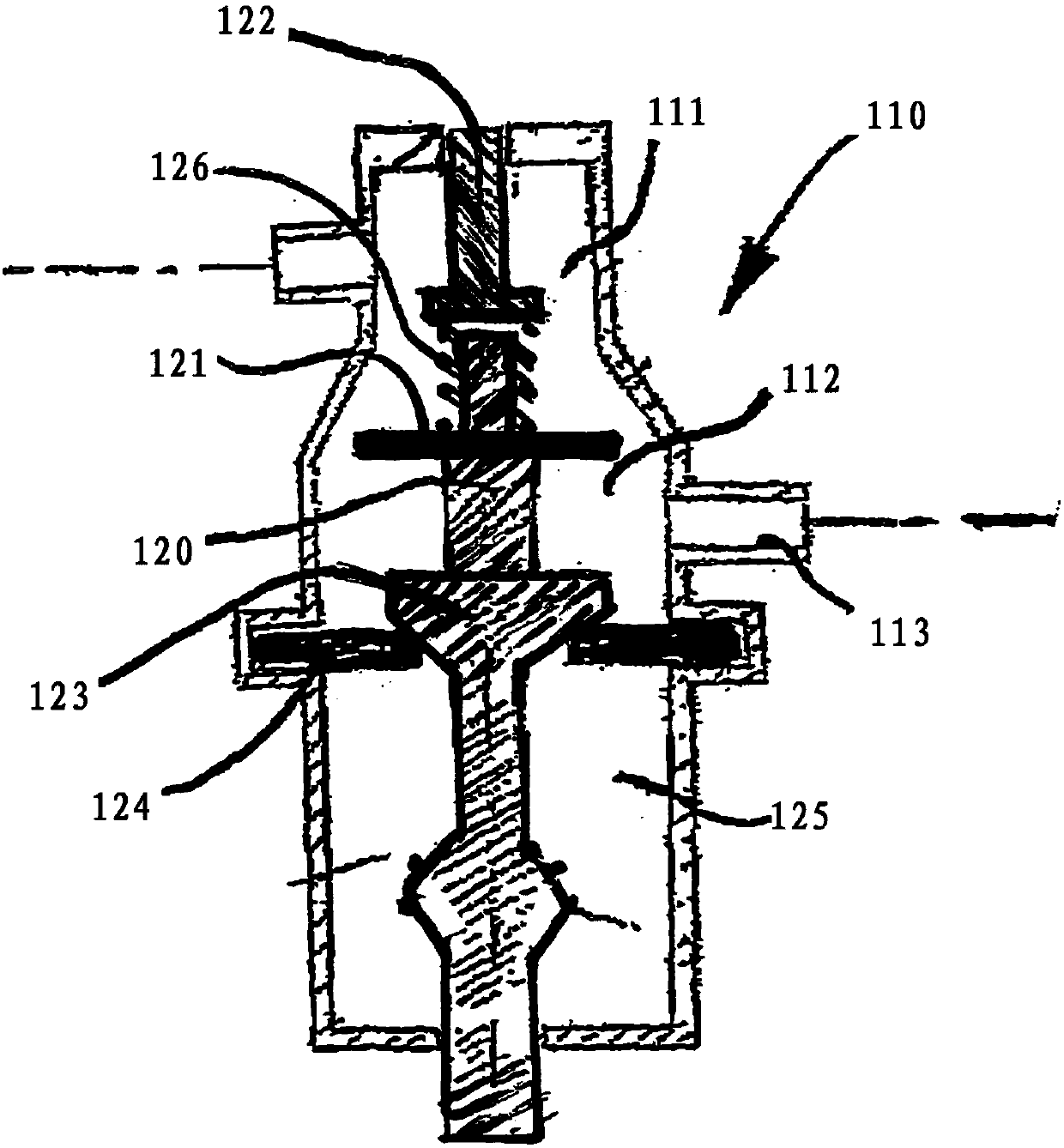

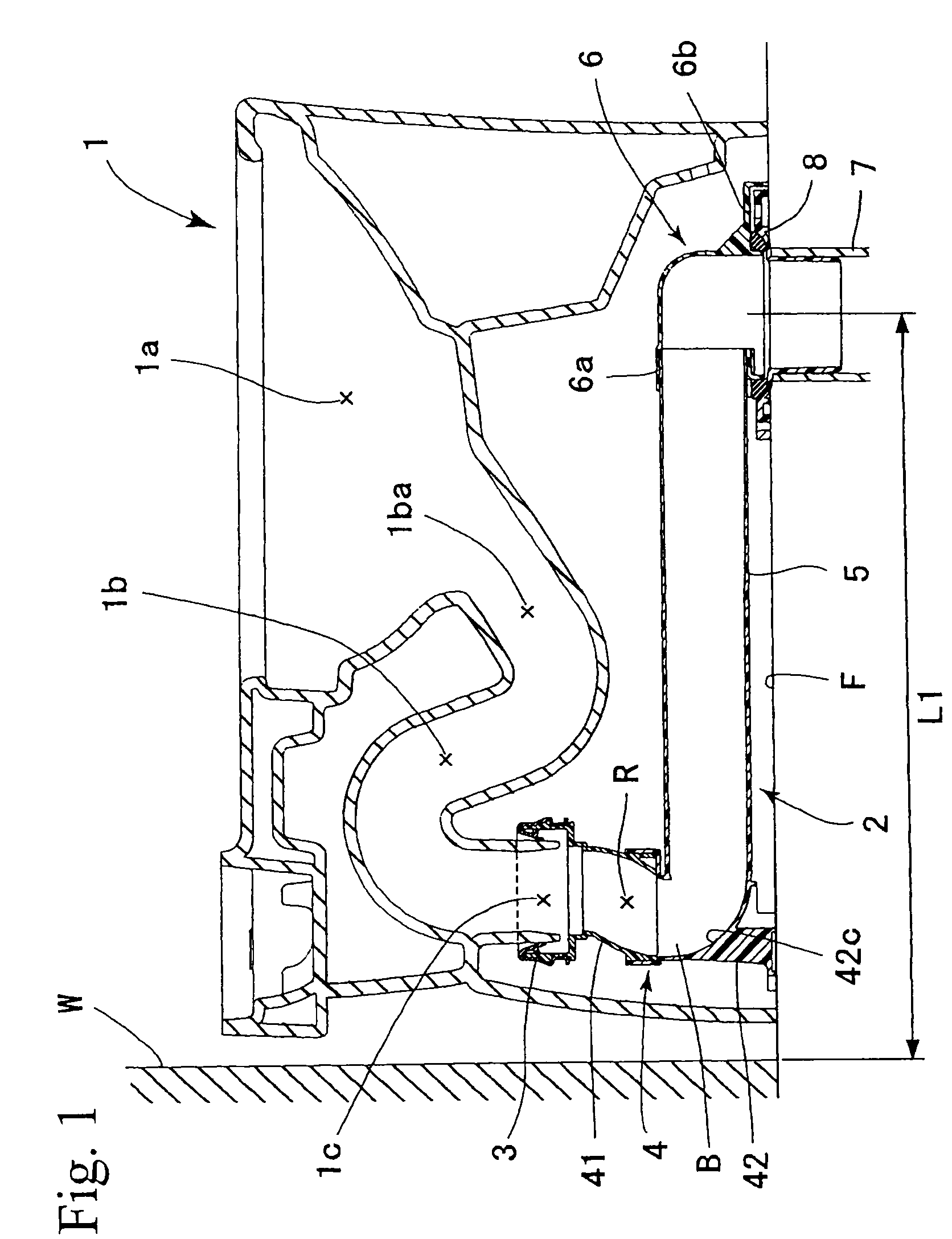

Connector for catheter attachment to an implantable pump

InactiveUS20050242579A1Effective flushingSecure and safe and effective mannerPressure infusionCatheterHydrophilic coatingCatheter device

A catheter system for locking a catheter to an implantable pump and for effectively flushing a catheter after implantation within a body. A locking component comprises an extension boot and catheter lock that together fluidly connect the catheter to the pump in a secure, safe and effective manner. A catheter component comprises a design having kink-resistant walls and a unique tip. A flushing component comprises a hub and stylet combination characterized by a hydrophilic coating on the stylet and a flush through hub to allow flushing of the stylet while inside the catheter.

Owner:INSET TECH

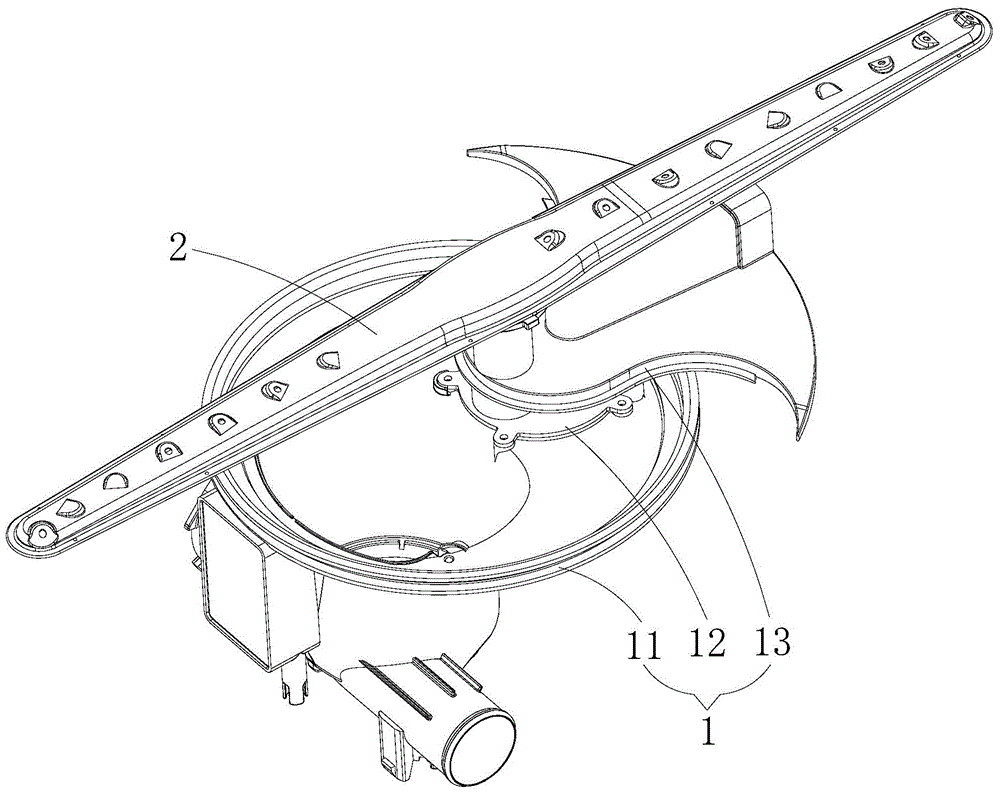

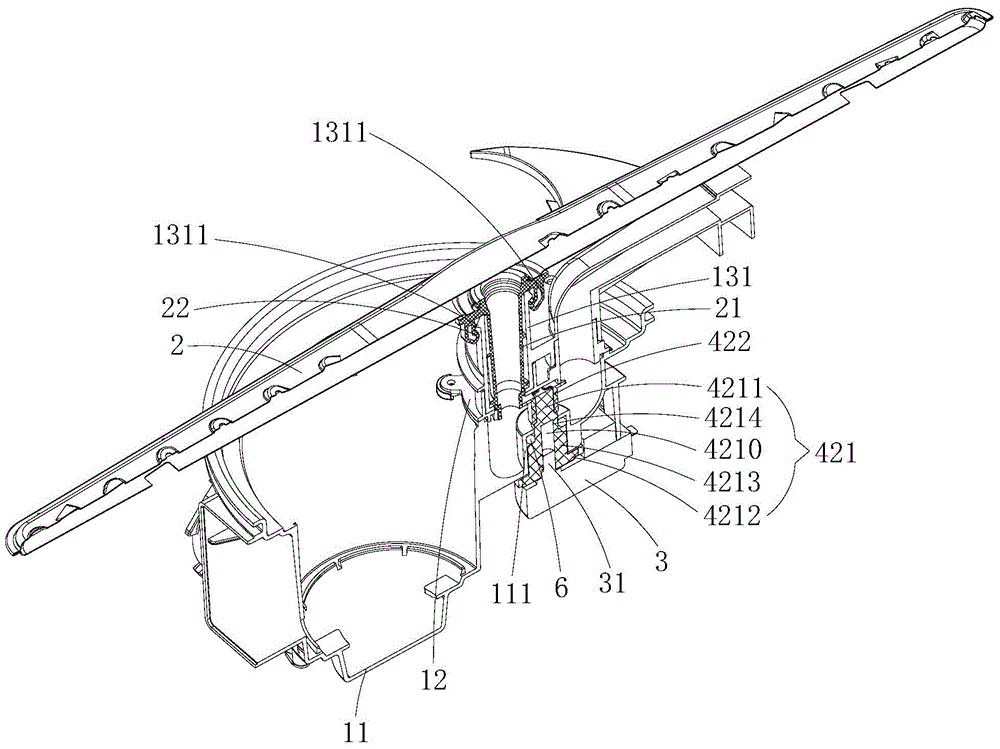

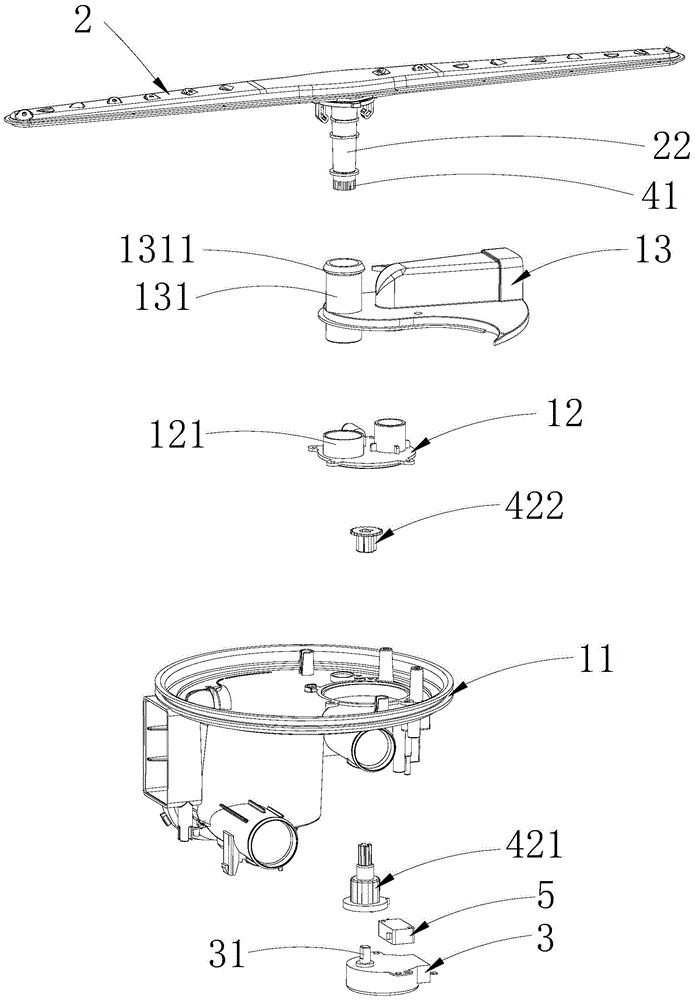

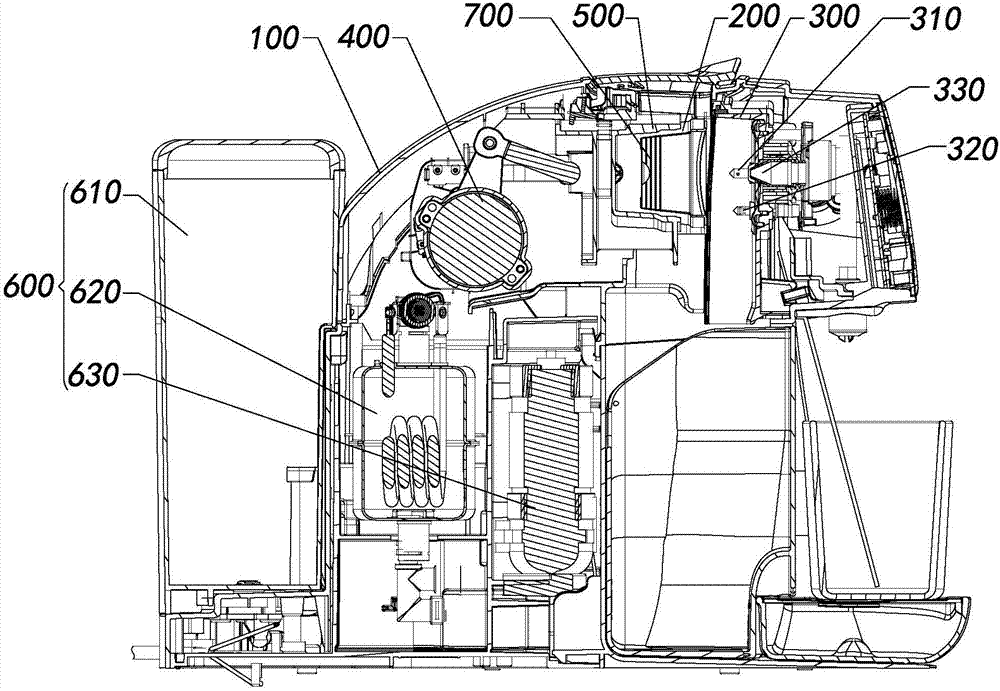

Spraying arm device and dish washing machine

ActiveCN104523208AGuaranteed stabilityImprove controllabilityTableware washing/rinsing machine detailsWater resourcesEngineering

The invention is applicable to the field of dish washing machines and discloses a spraying arm device and a dish washing machine. The spraying arm device comprises a spraying arm base assembly, a motor, a transmission structure and a spraying arm installed on the spraying arm base assembly, wherein a water cavity is formed in the spraying arm base assembly, a first connection pipe is arranged on the spraying arm in a protruding mode, penetrates through the spraying arm assembly and is communicated with the water cavity, the motor is installed on the spraying arm base assembly, and the transmission structure is connected between the first connection pipe and the motor in a transmission mode. Due to the fact that the motor and the transmission structure are matched to drive the spraying arm to rotate, the controllability of the rotational movement of the spraying arm is achieved, the spraying arm can stop at a certain position to perform reinforced washing by controlling starting and stop of the motor in the washing process, tableware which is high in fouling degree and difficult to clean can be subjected to independent prolonged washing, the washing efficiency and the washing effect of the tableware are improved, and electric energy and water resources can be saved easily; meanwhile, due to the fact that driving of the motor is stable, stability of rotation of the spraying arm is guaranteed.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Implantable pump connector for catheter attachment

InactiveUS7452354B2Effective flushingSecure and safe and effective mannerPressure infusionCatheterHydrophilic coatingCatheter device

Owner:FLO(ABC) LLC

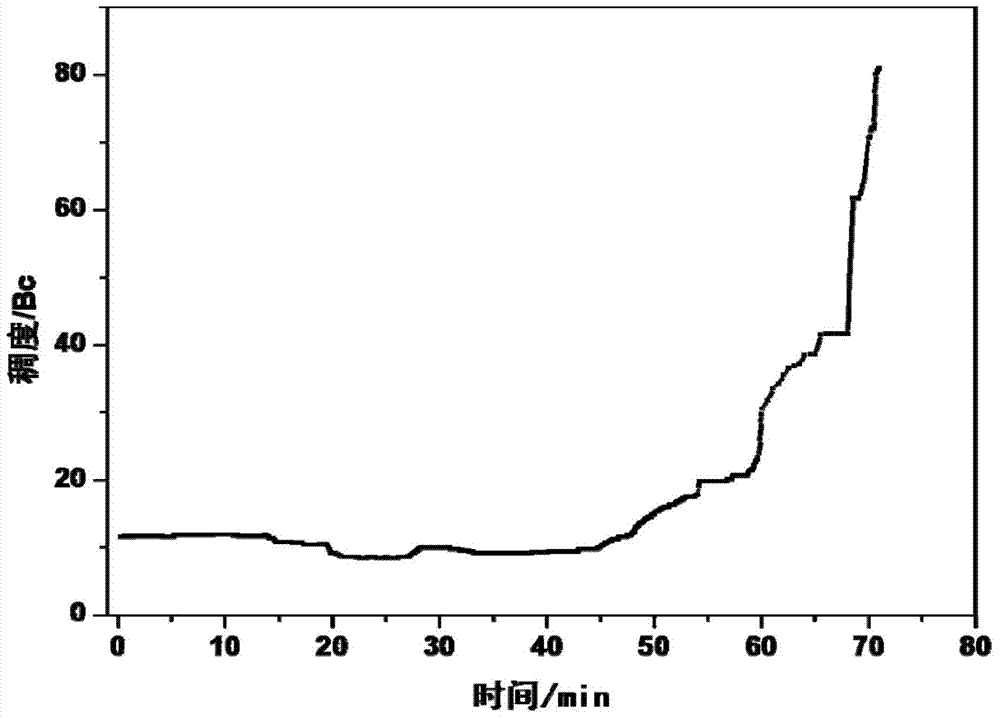

Solid-free anti-salt cleaning type well cementation spacer fluid and preparation method thereof

InactiveCN103756653AGood settlement stabilityImprove bonding qualityDrilling compositionSludge cakeEthylenediamine

The invention discloses a solid-free anti-salt cleaning type well cementation spacer fluid and a preparation method thereof. The spacer is prepared from the following components in parts by weight: 100 parts of water, 20-350 parts of soluble weighting agent, 0.1-1.0 part of additive, 0.2-0.5 part of thickening agent, 0.5-3.0 parts of fluid loss agent, 5-10 parts of non-ionic surfactant, 1.5-2.5 parts of anionic surfactant, 0.1-0.3 part of pH adjusting agent and 0.1-0.5 part of defoaming agent, wherein the additive is sodium tripolyphosphate, ethylenediamine tetraacetic acid disodium or ethylenediamine tetraacetic acid sodium. The solid-free anti-salt cleaning type well cementation spacer fluid is free of solid phase, so that virtual thick sludge cake cannot be formed on a well wall, the function of effectively spacing a drilling liquid from cement slurry is achieved, and meanwhile the well cementation is improved. In the preparation process, the substances are added to reaction in different batches, so that the operation method is simple.

Owner:CNPC BOHAI DRILLING ENG

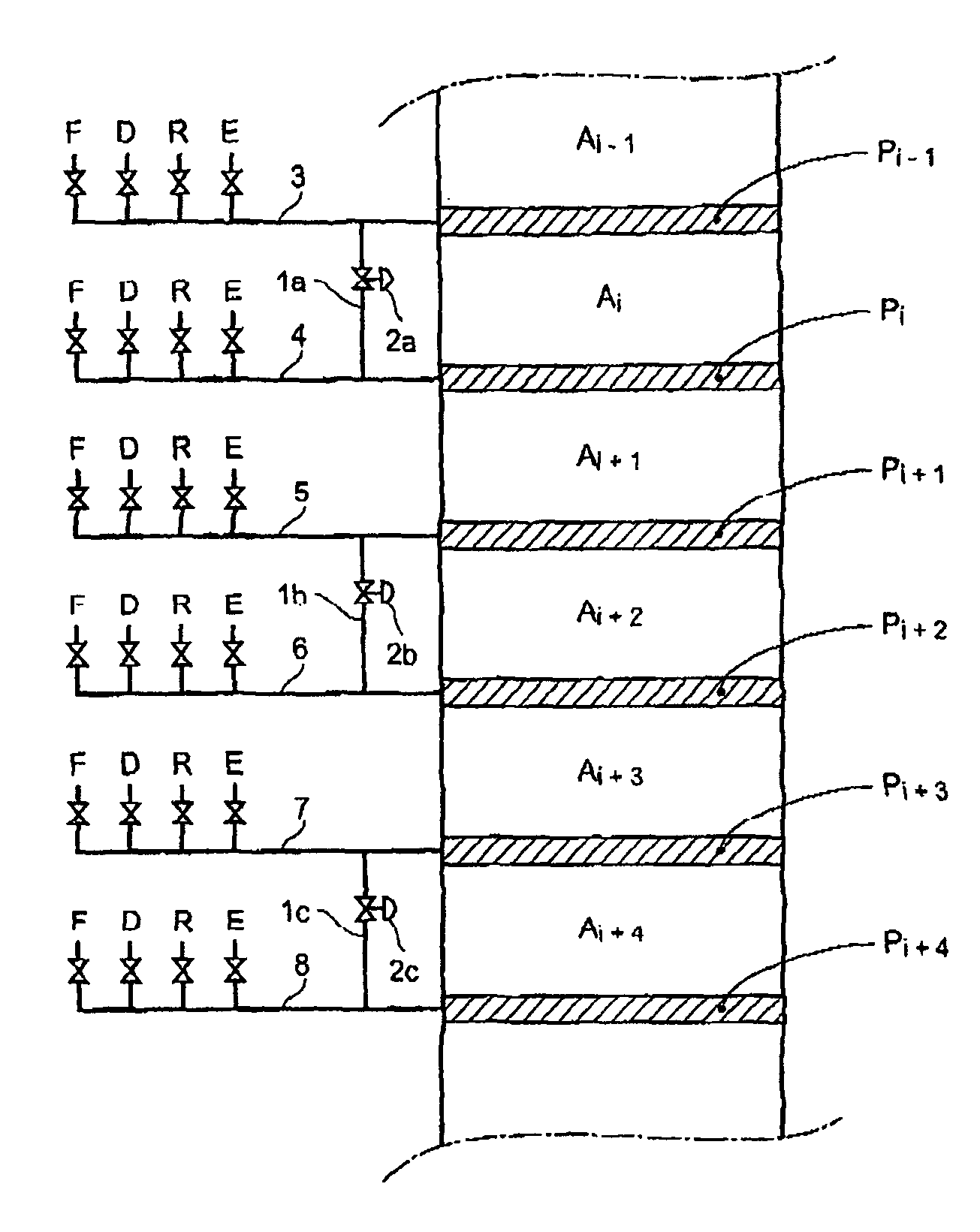

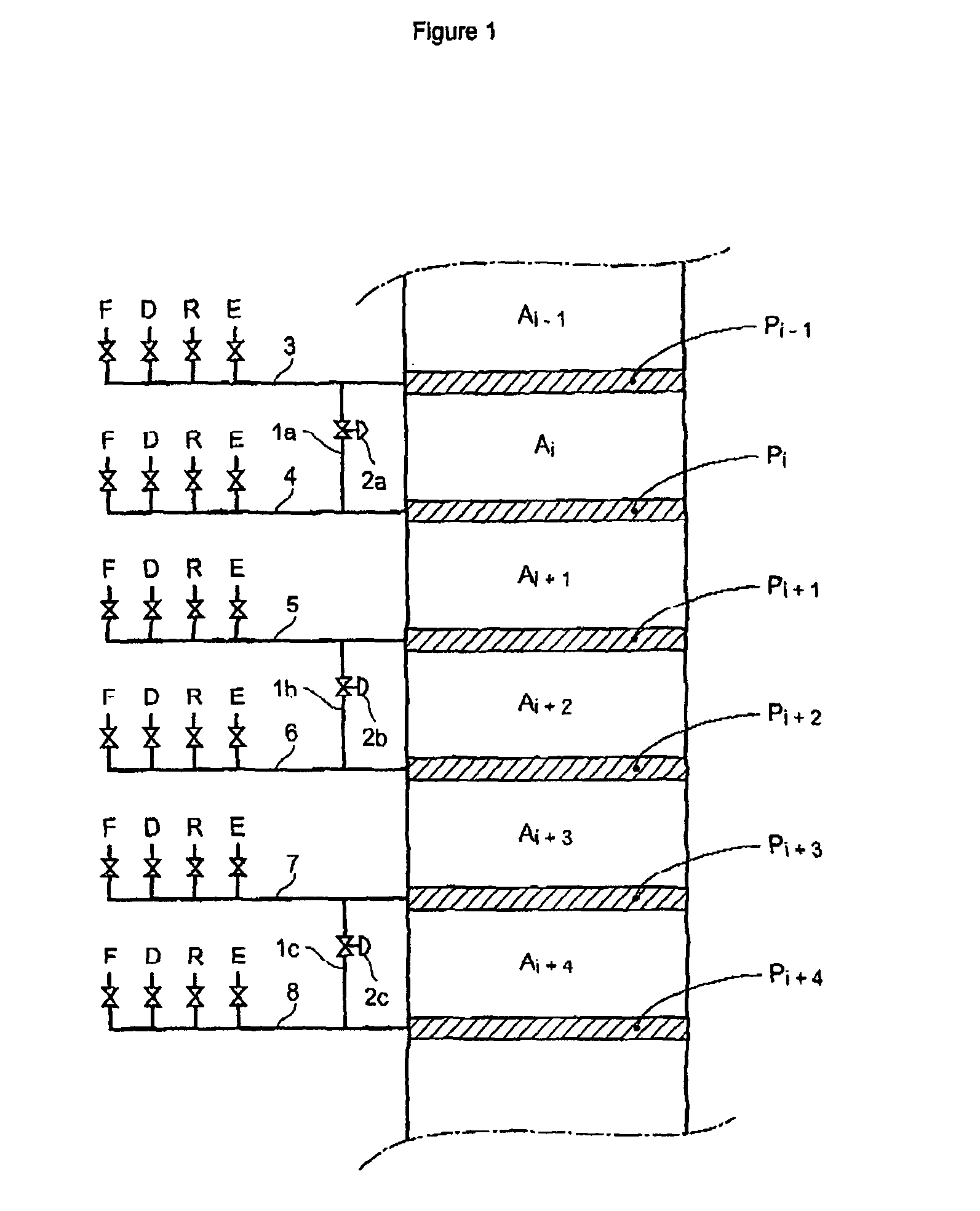

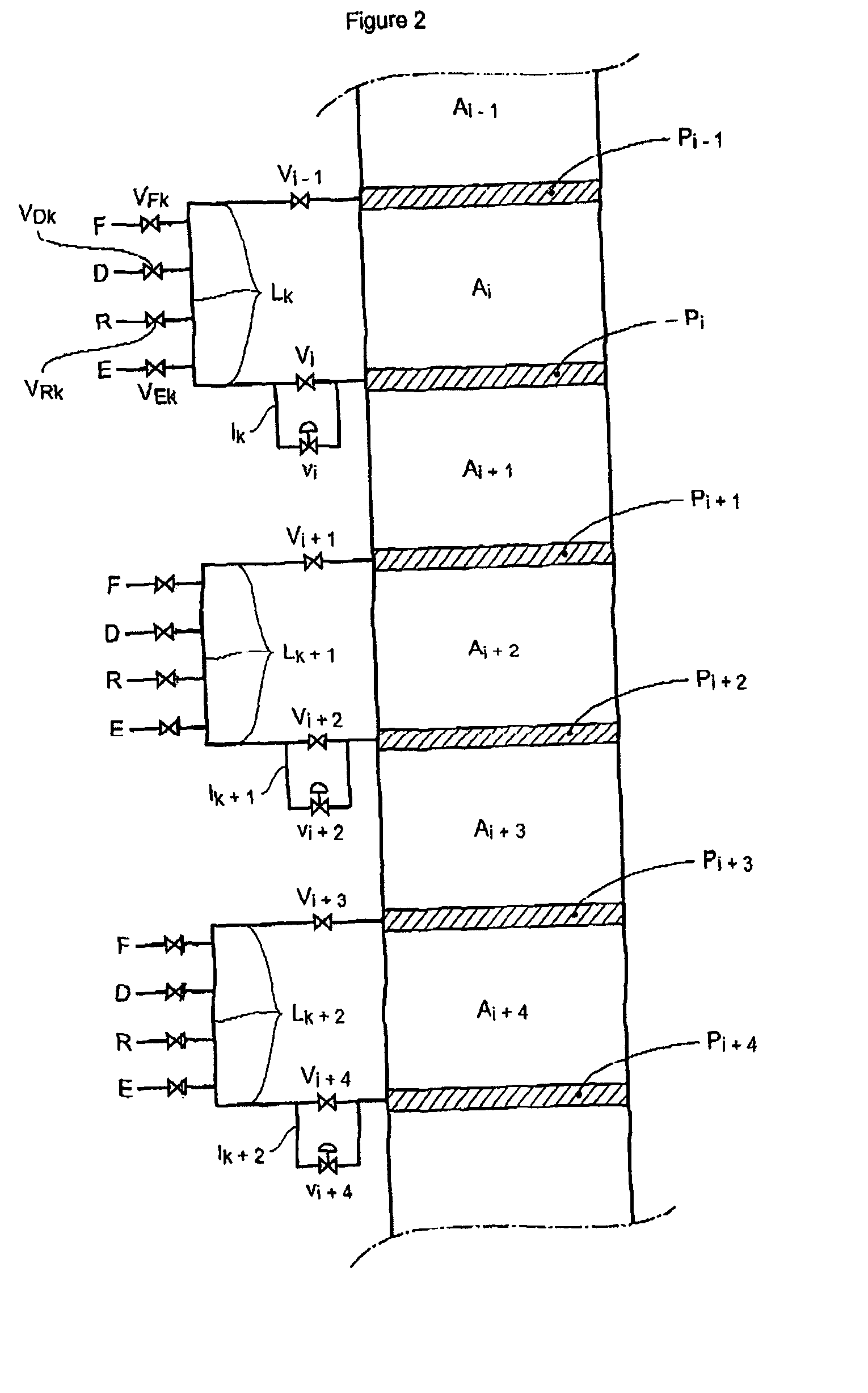

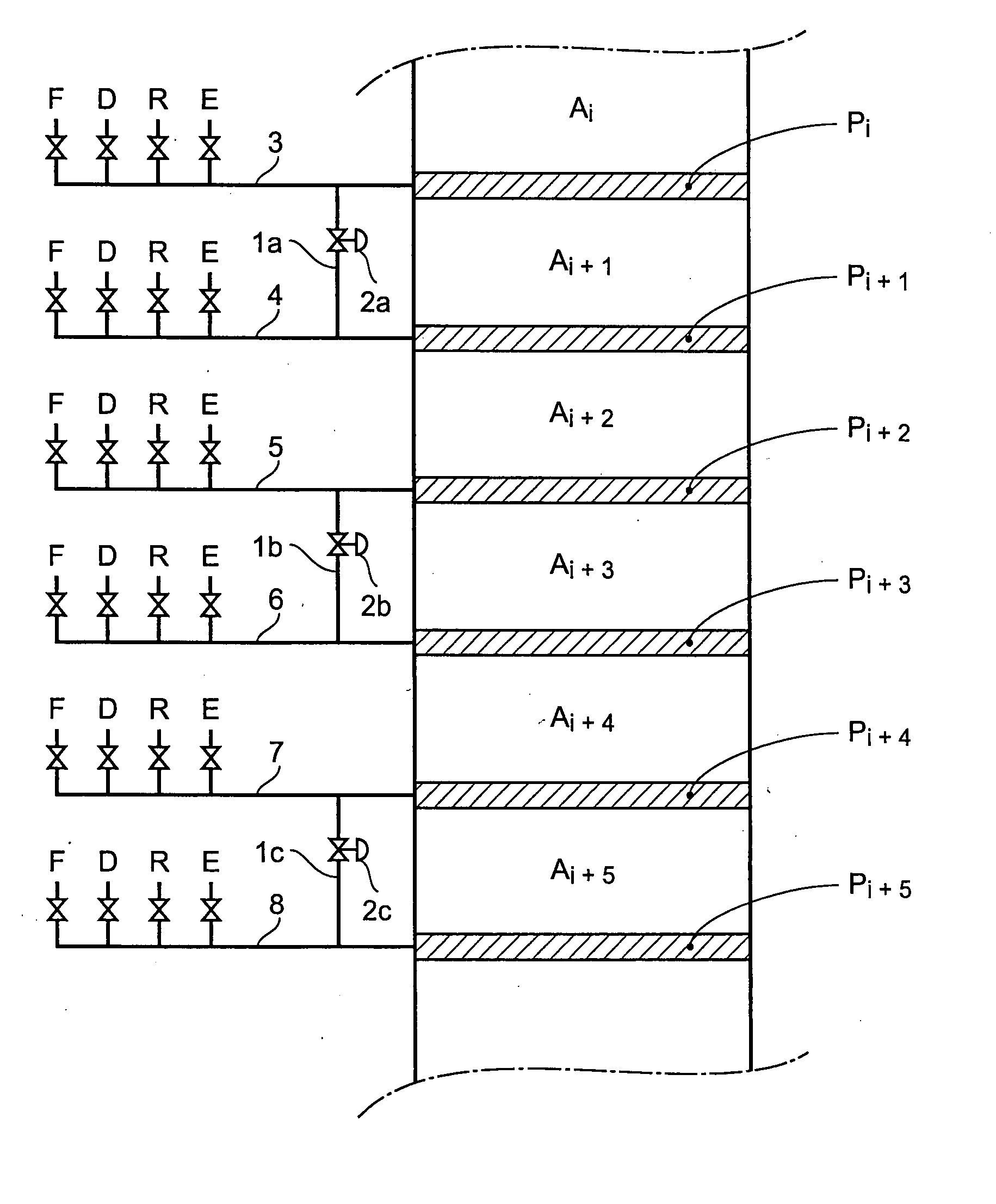

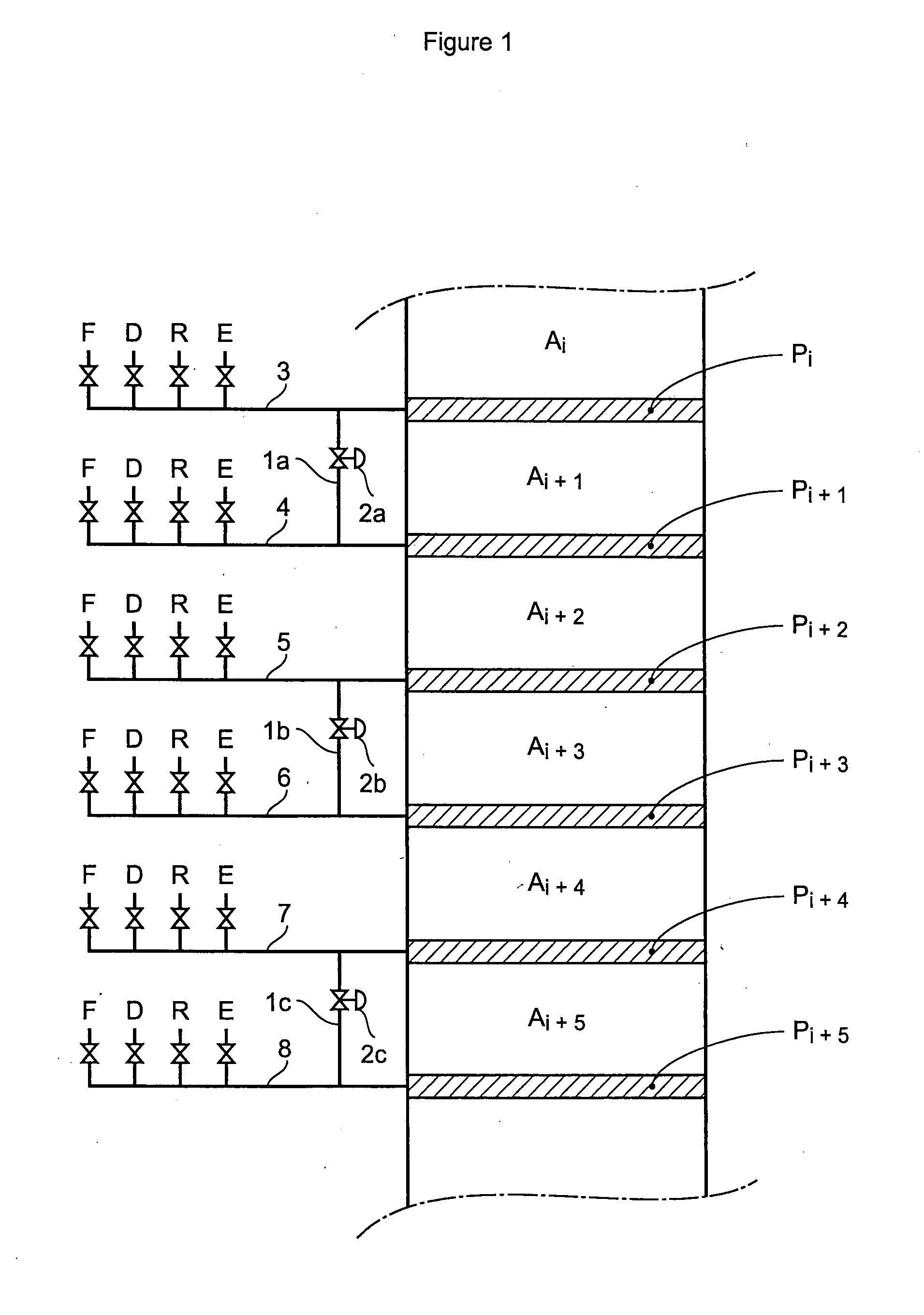

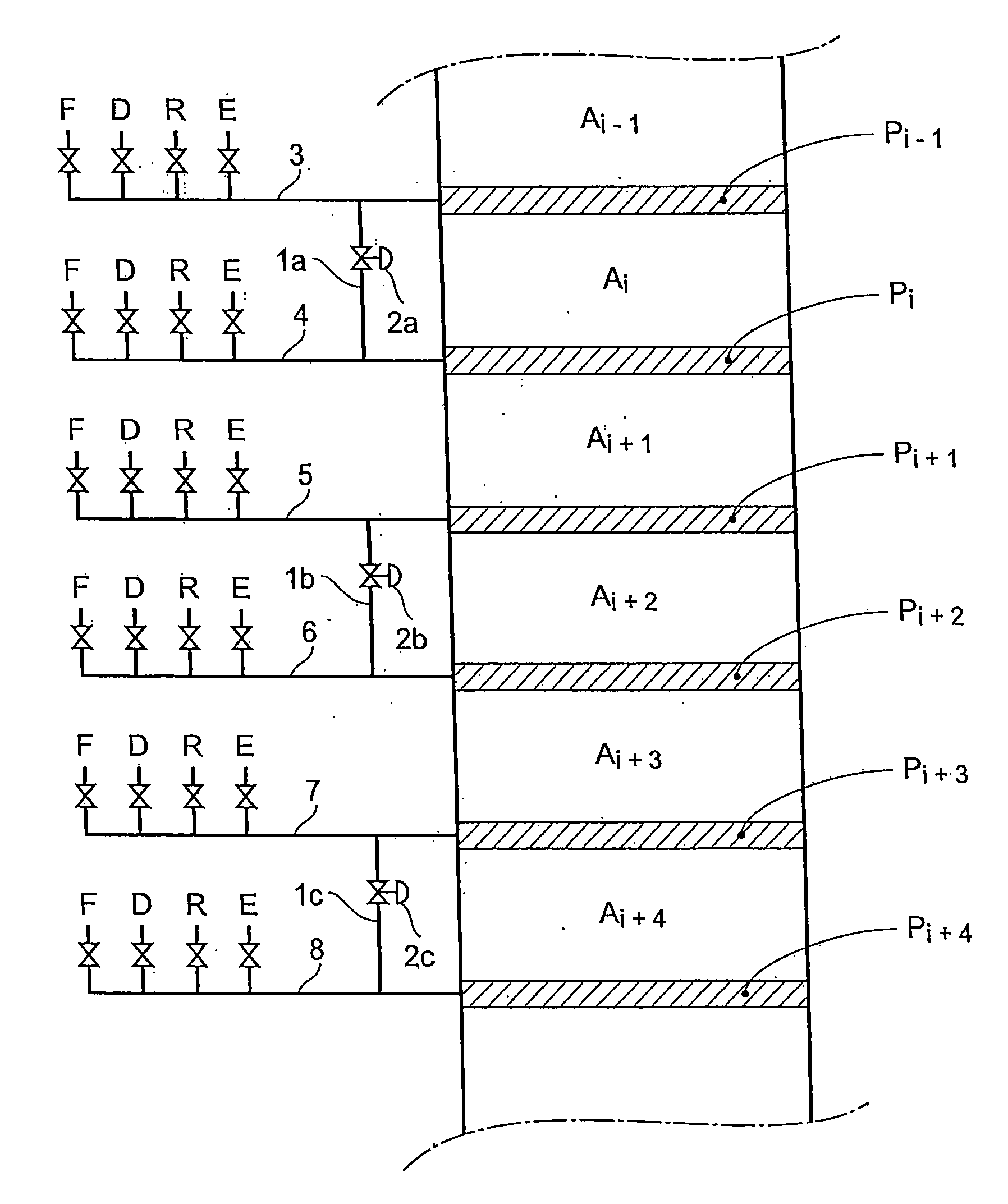

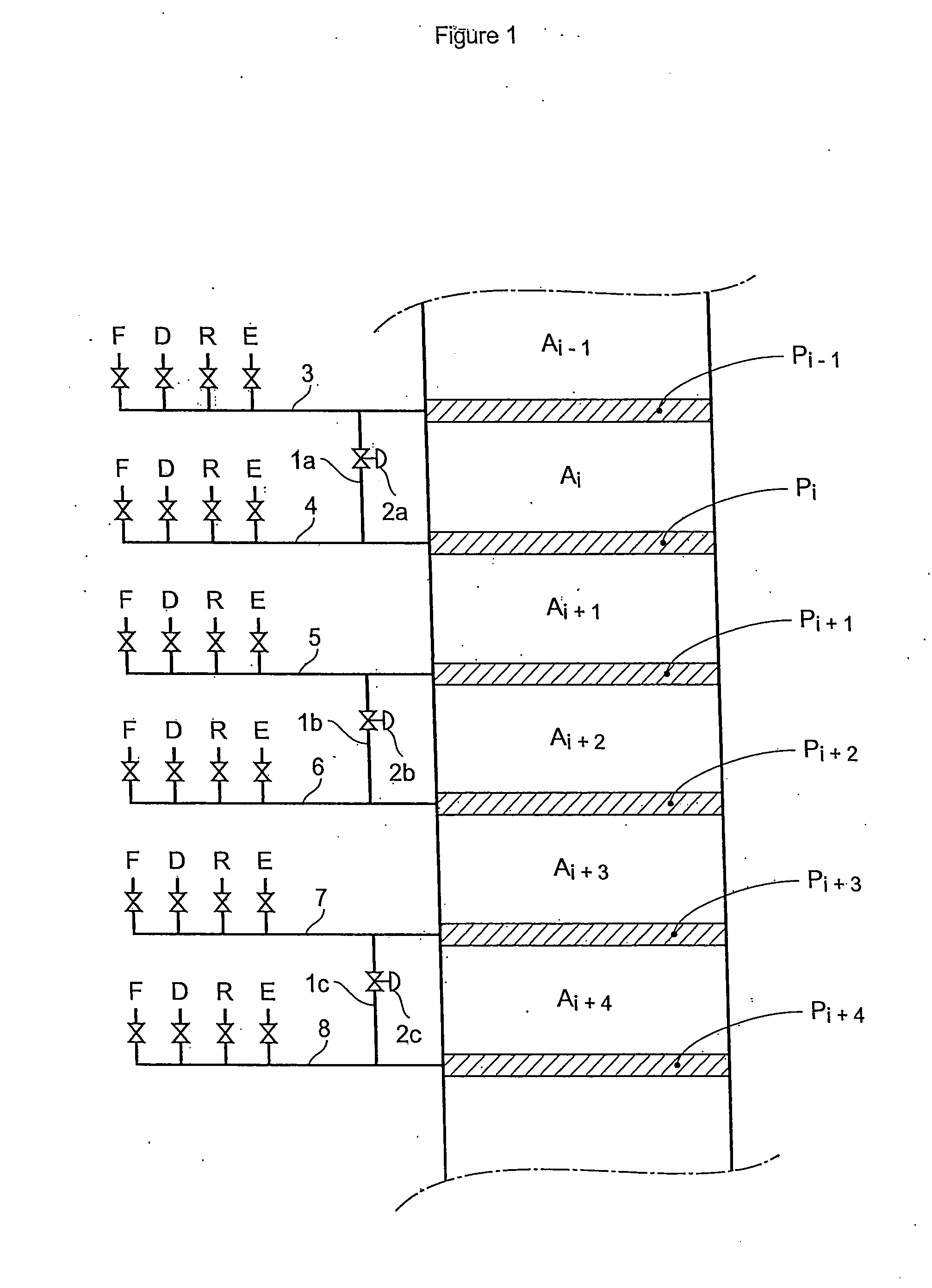

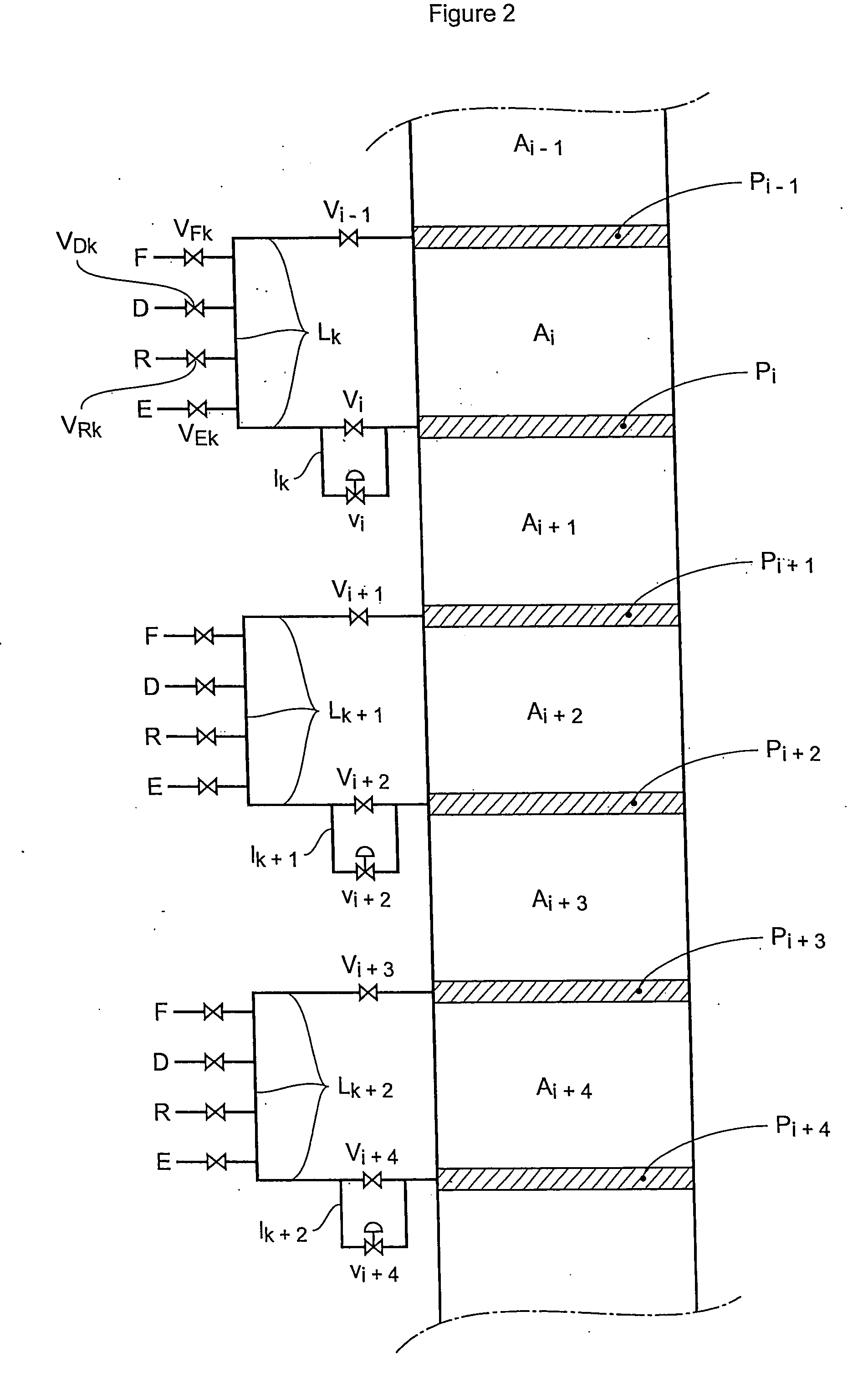

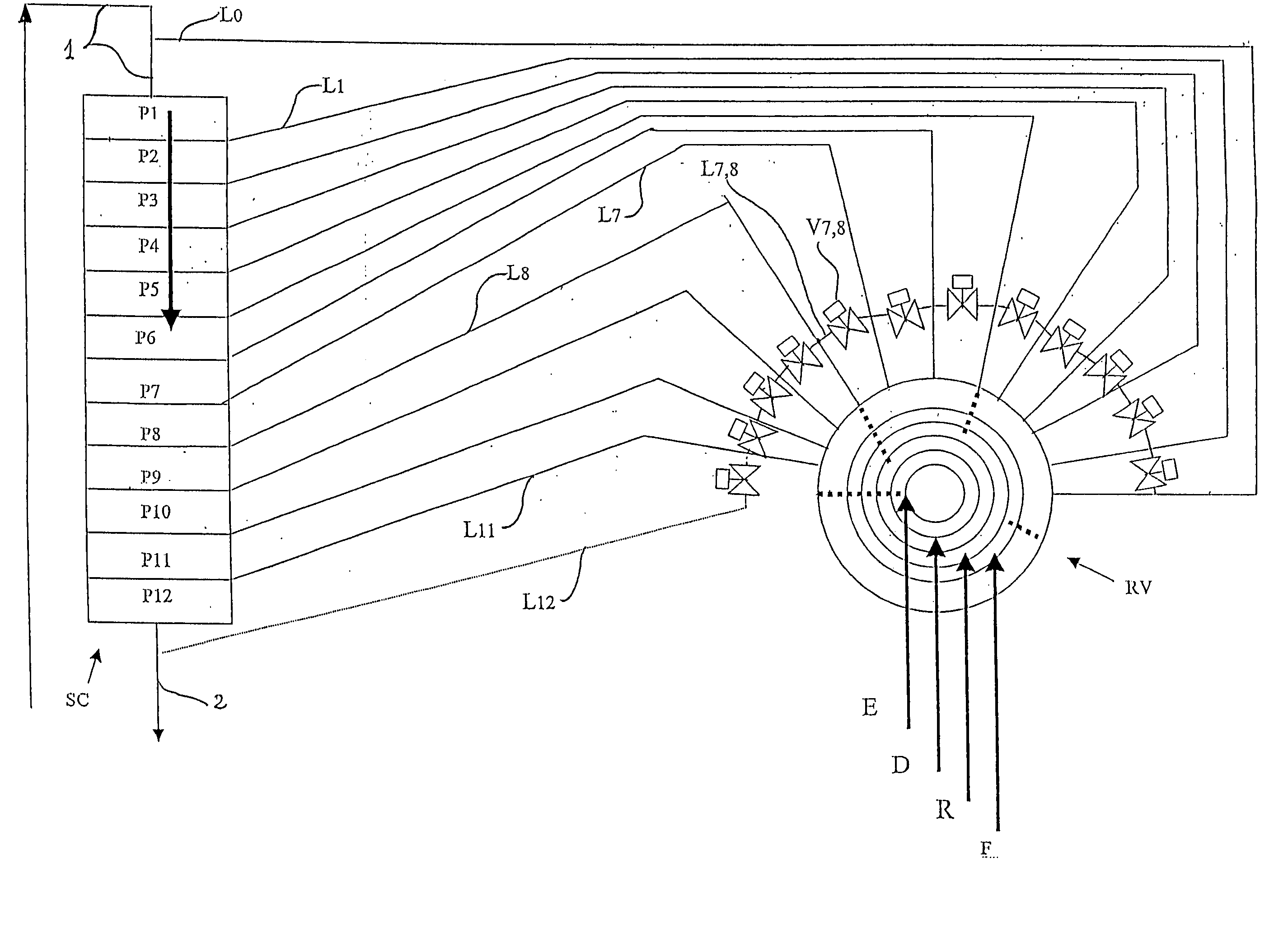

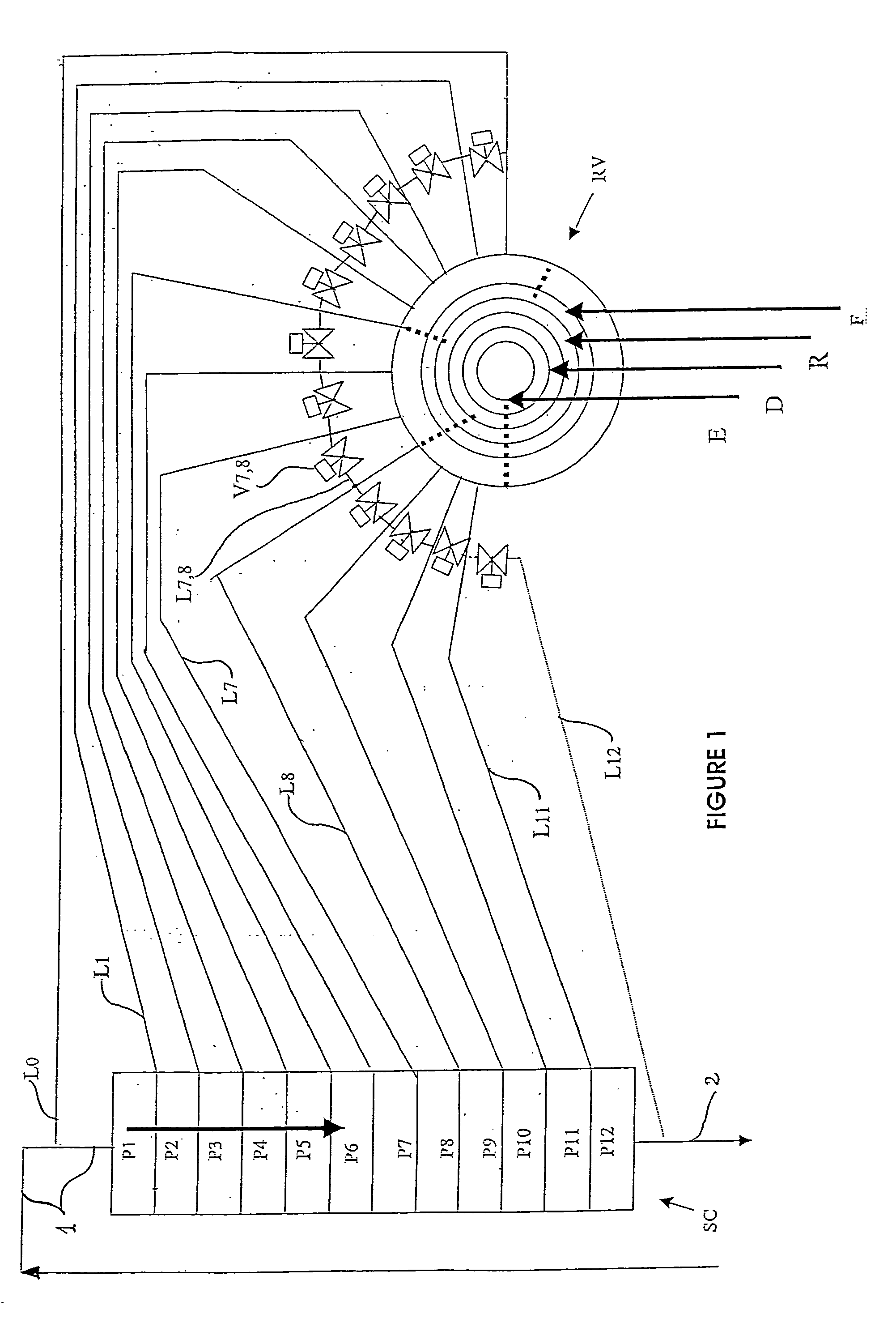

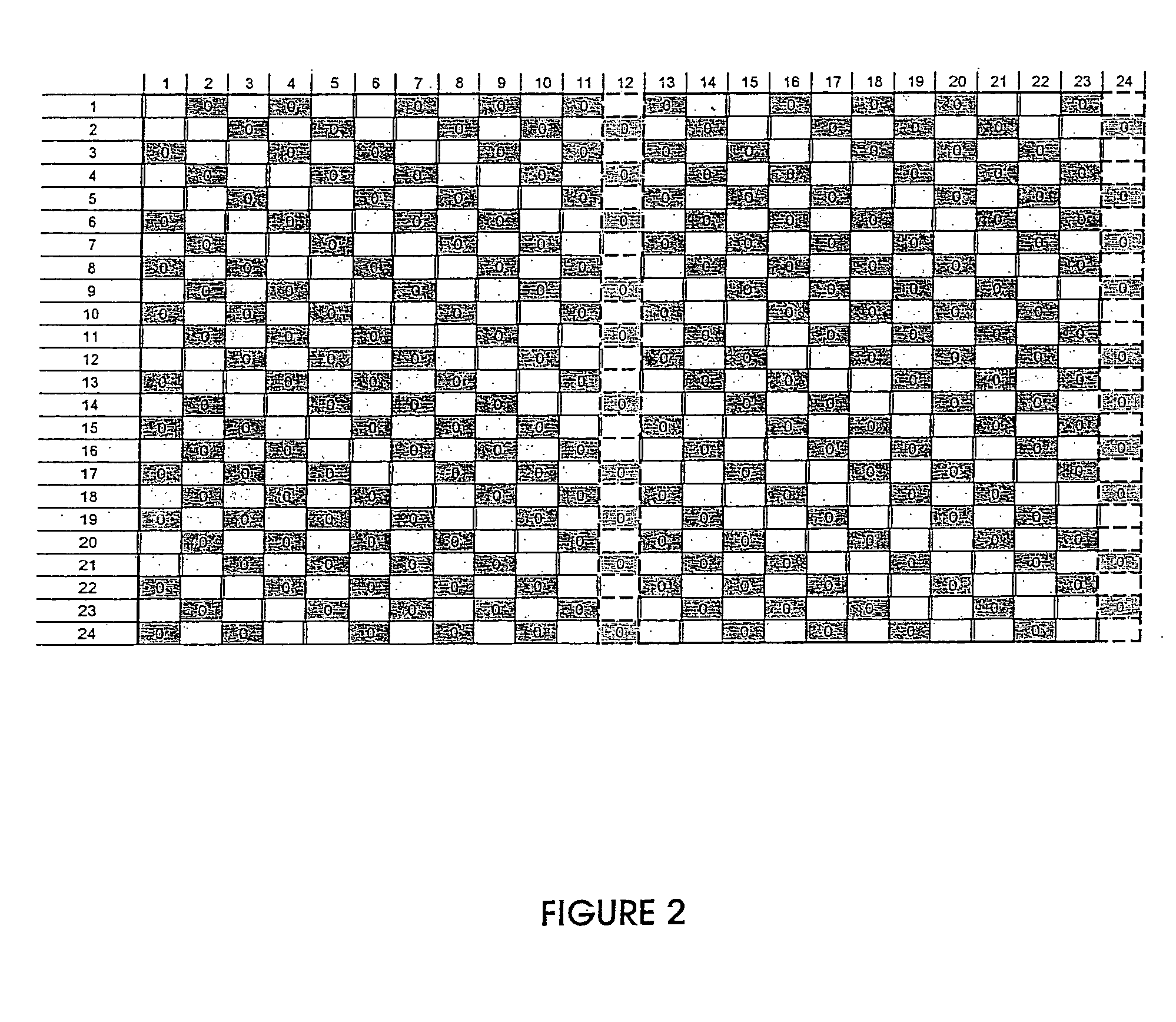

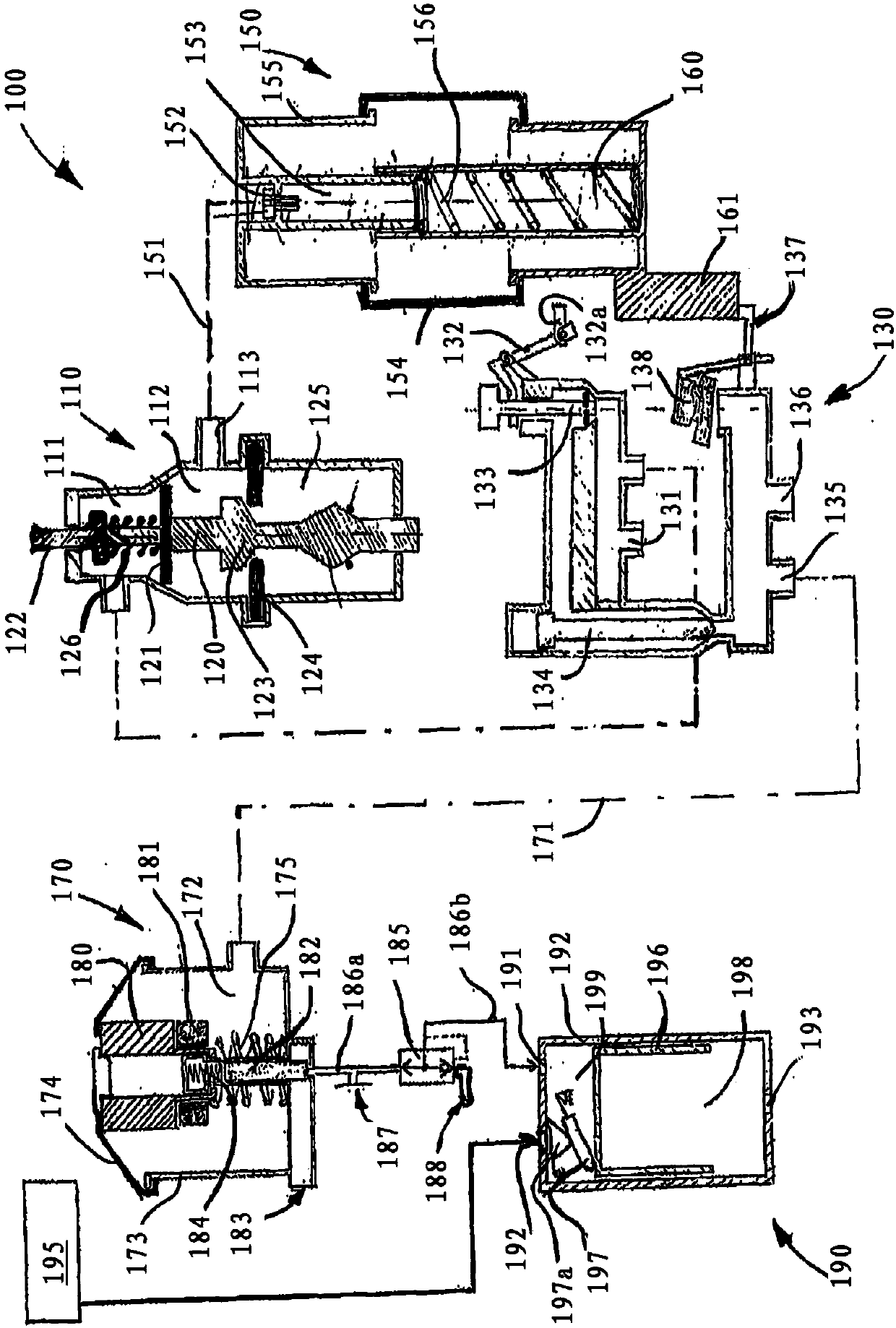

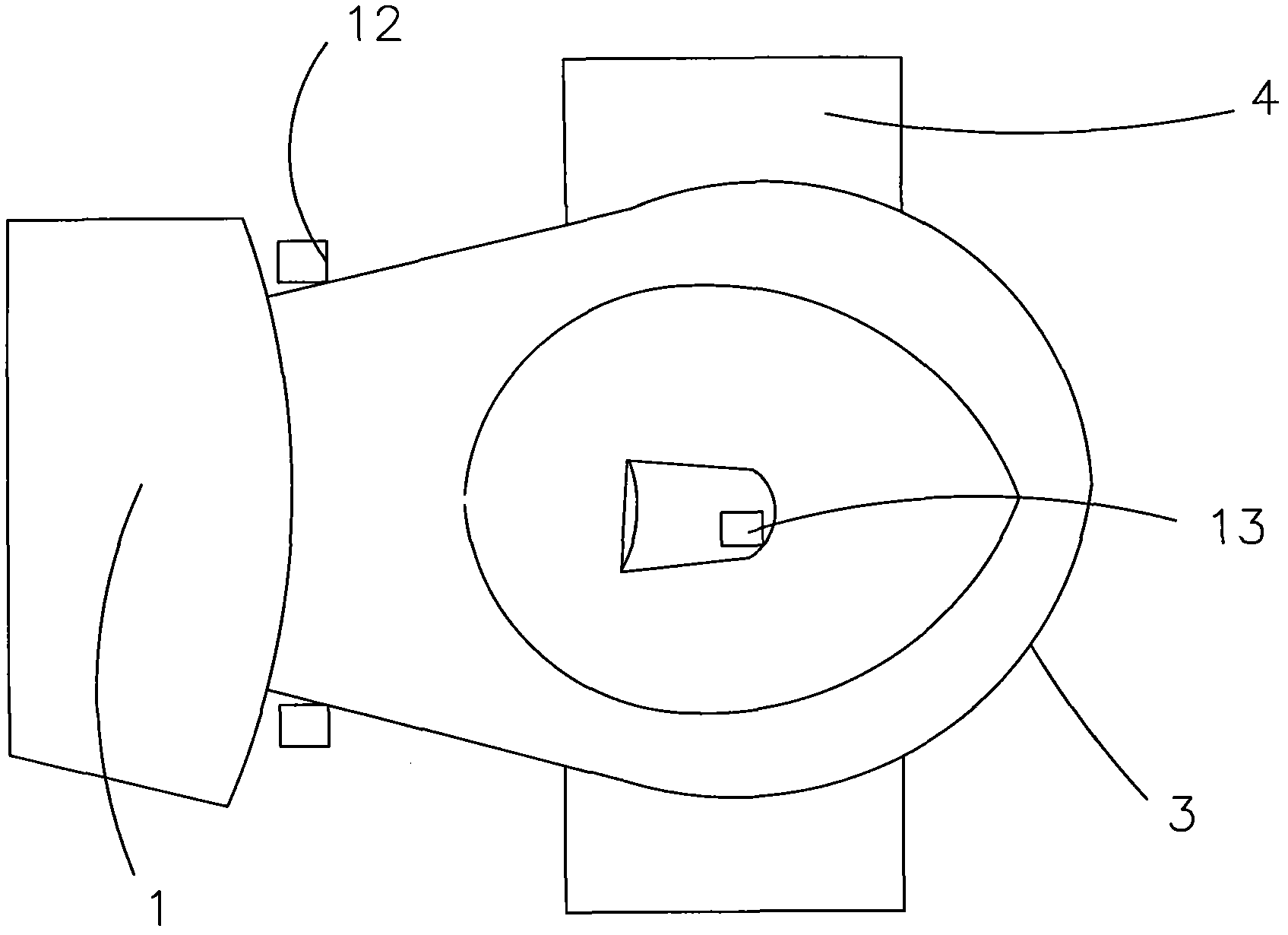

Process and device for simulated moving bed separation with a reduced number of valves and lines

InactiveUS20080237132A1Reduce in quantityReduce disadvantagesComponent separationIon-exchanger regenerationSimulated moving bedMeta-xylene

The invention concerns a simulated moving bed adsorption separation device comprising a limited number of valves. According to the invention, the device comprises a column with a plurality of sectors Sk with 2 superimposed plates Pi with a single distribution network, each sector Sk comprising an external principal bypass line Lk connected to each plate Pi of Sk via a plate valve Vi. Each line Lk comprises a flow limitation means and is connected to each of the fluid networks via a single valve.Further, the connectors of lines Lk onto the column are offset by at most 20° inside Sk to limit the volume of lines Lk, and are offset by a mean angle in the range 70° to 110° between two neighbouring sectors Sk and Sk+1 so as not to weaken the column mechanically. The plates preferably comprise panels DMEi,j with parallel segments the direction of which varies from plate to plate or per group of 2 plates.The invention also concerns a separation process using said device, in particular to separate para-xylene or meta-xylene from an aromatic C8 cut.

Owner:INST FR DU PETROLE

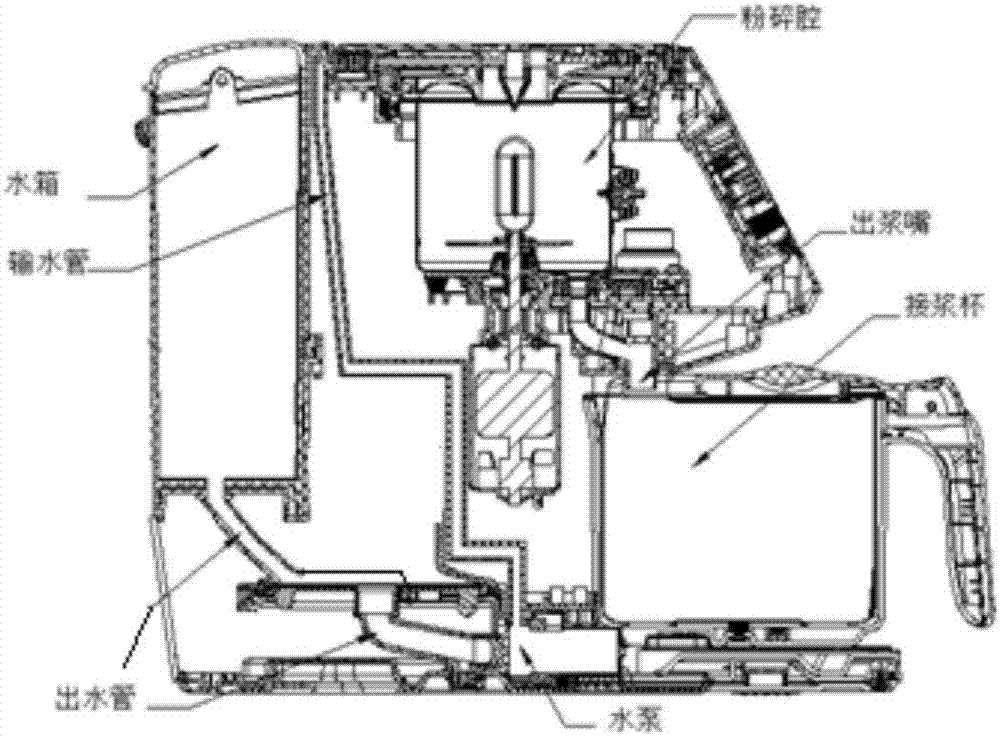

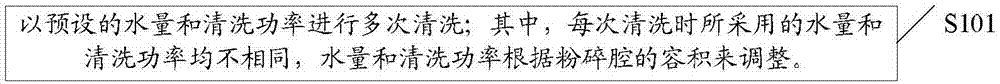

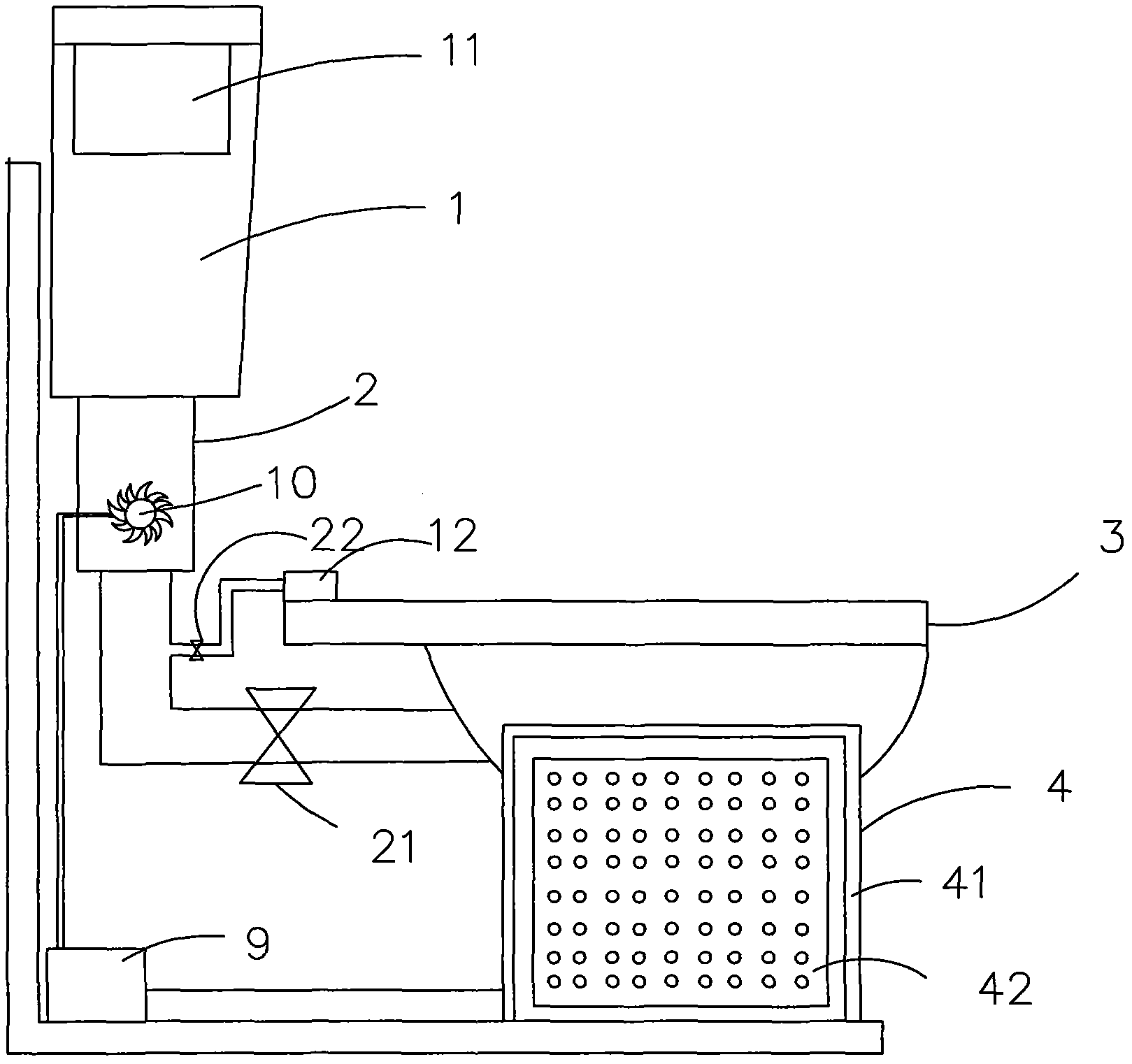

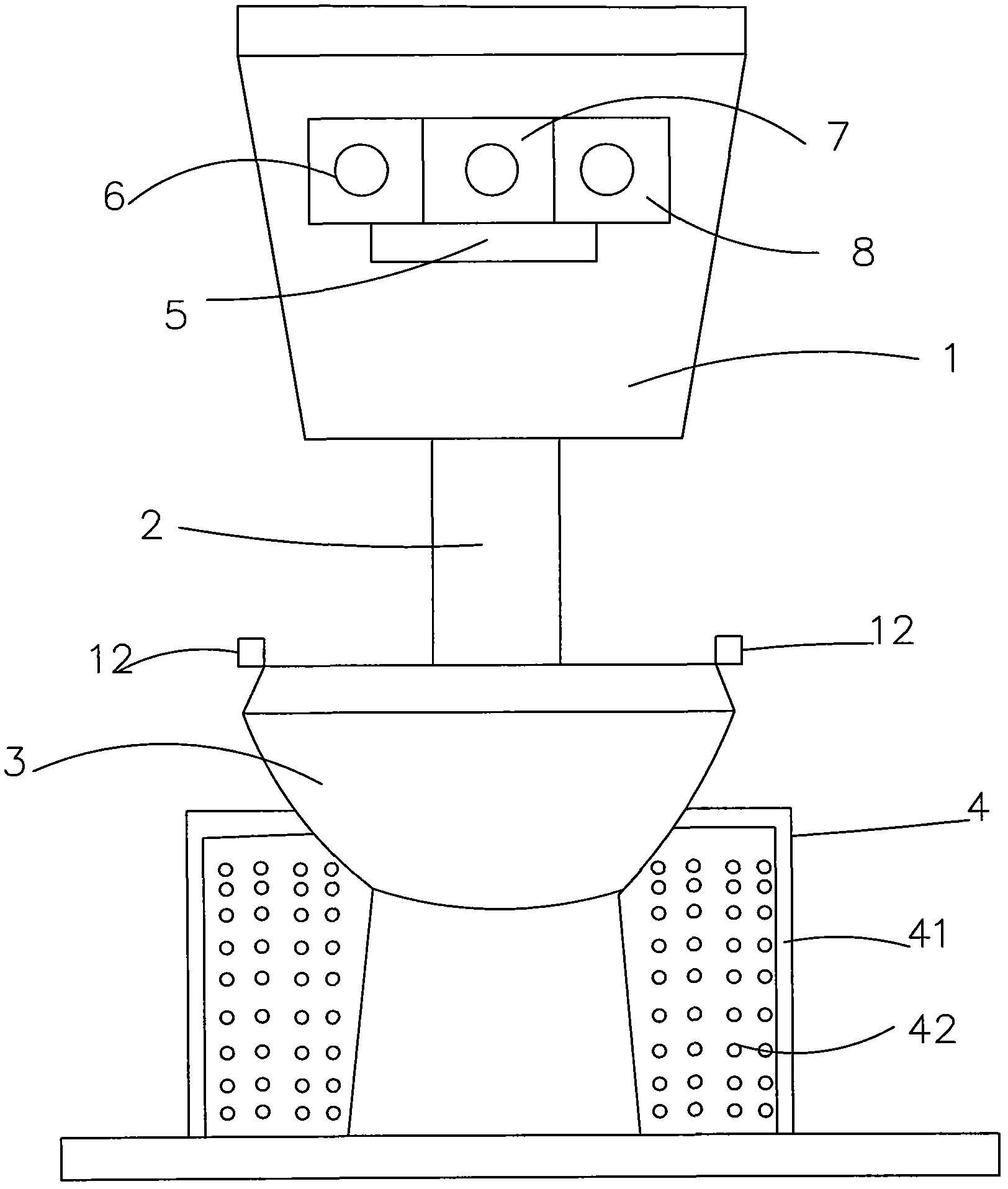

Washing method of cooking equipment

PendingCN107184104AEasy to cleanGuaranteed cleaning effectBeverage vesselsWater deliveryWaste management

The embodiment of the invention discloses a washing method of cooking equipment. The cooking equipment comprises a smashing cavity, a water tank, a water pump, a water outlet pipe connected with the water tank and the water pump and a water delivery pipe connected with the smashing cavity and the water pump, the water pump pumps water in the water tank through the water outlet pipe, and the pumped water is delivered into the smashing cavity through the water delivery pipe to wash the smashing cavity. The method comprises the step of conducting washing many times with the preset water capacity and washing efficiency, wherein the water capacity and the washing power adopted in each time of washing are both different, and the water capacity and the washing power are adjusted according to the volume of the smashing cavity. According to the washing method of the cooking equipment, an ideal washing effect can be achieved by using a small amount of water.

Owner:JOYOUNG CO LTD

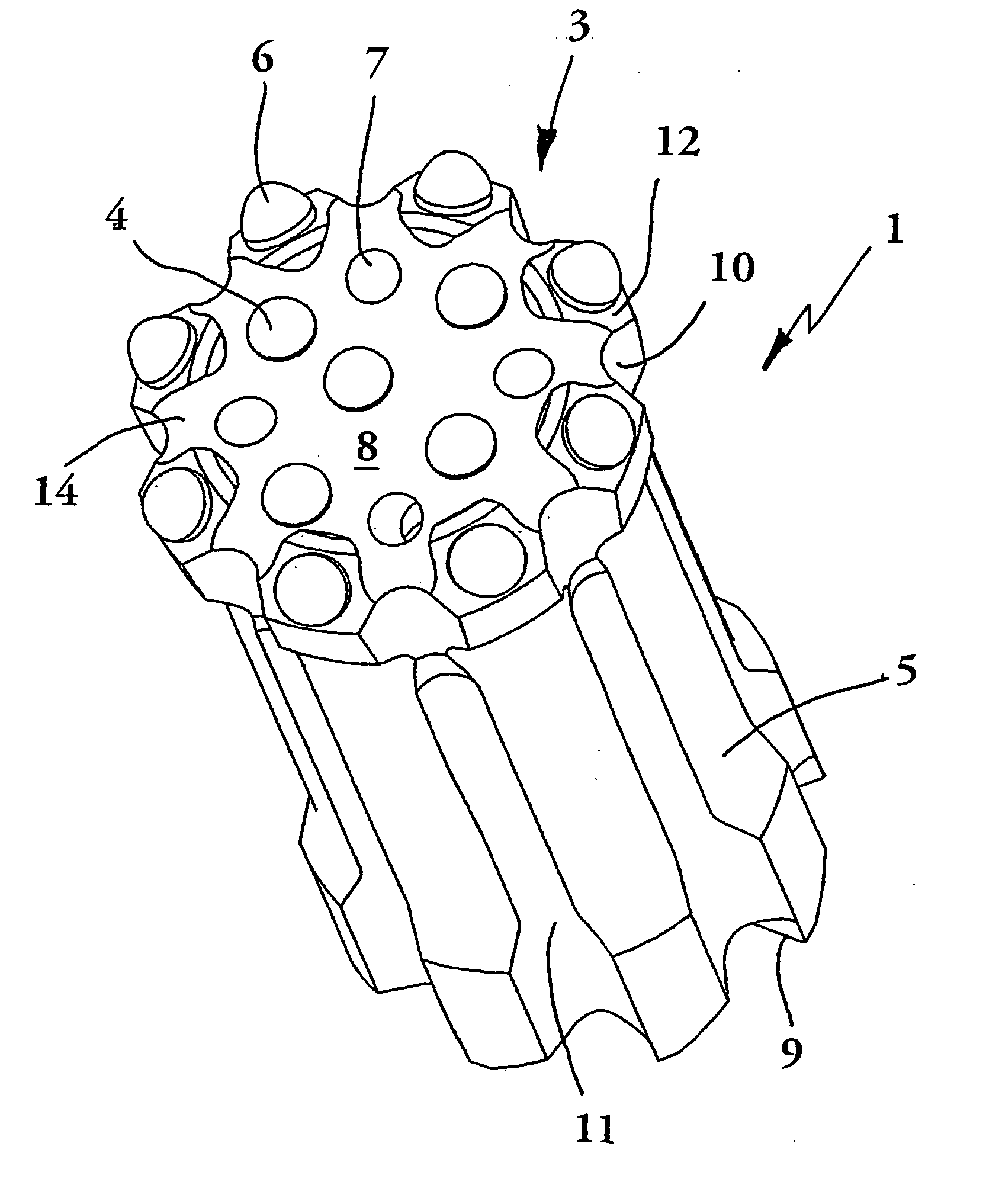

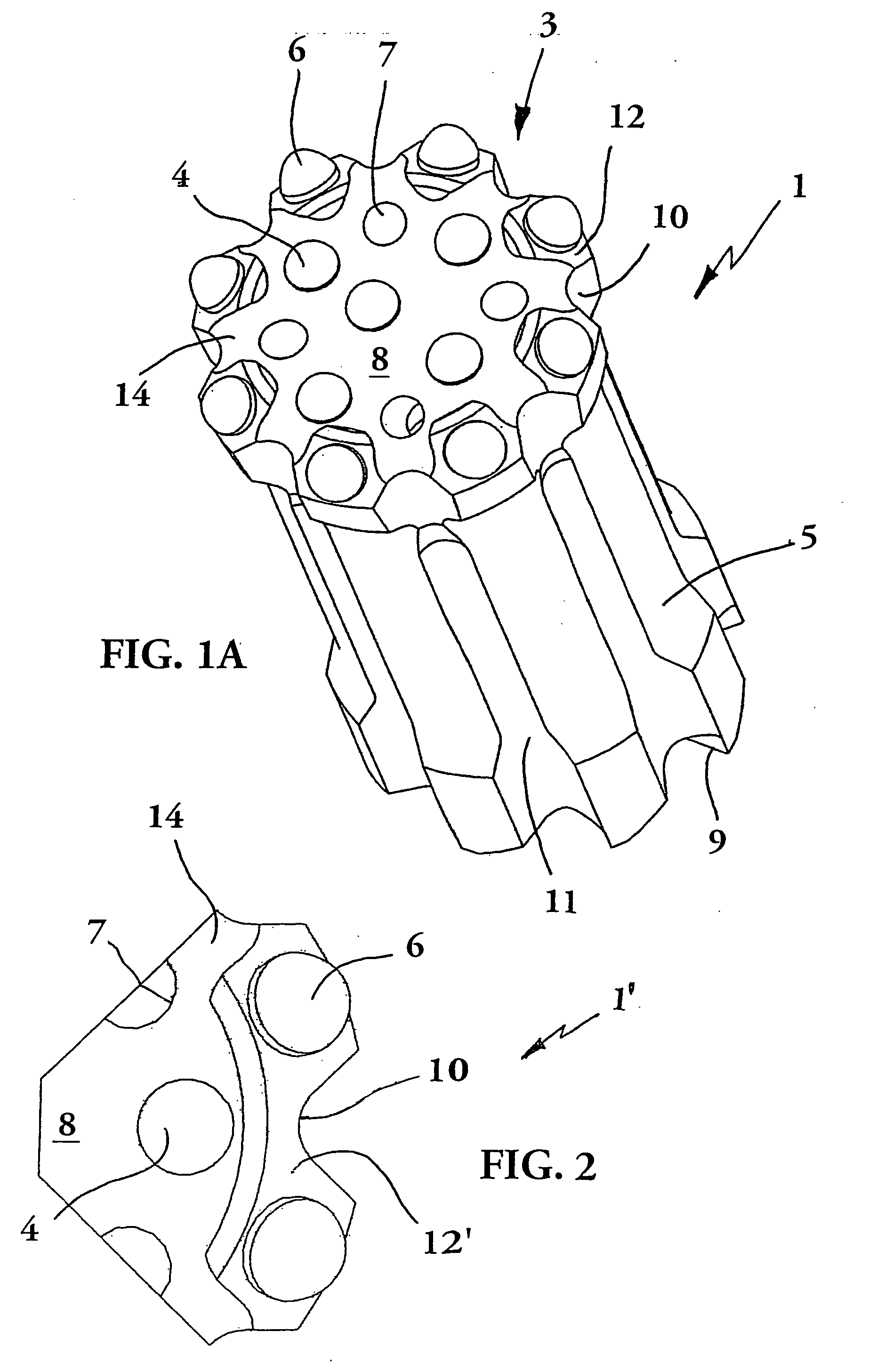

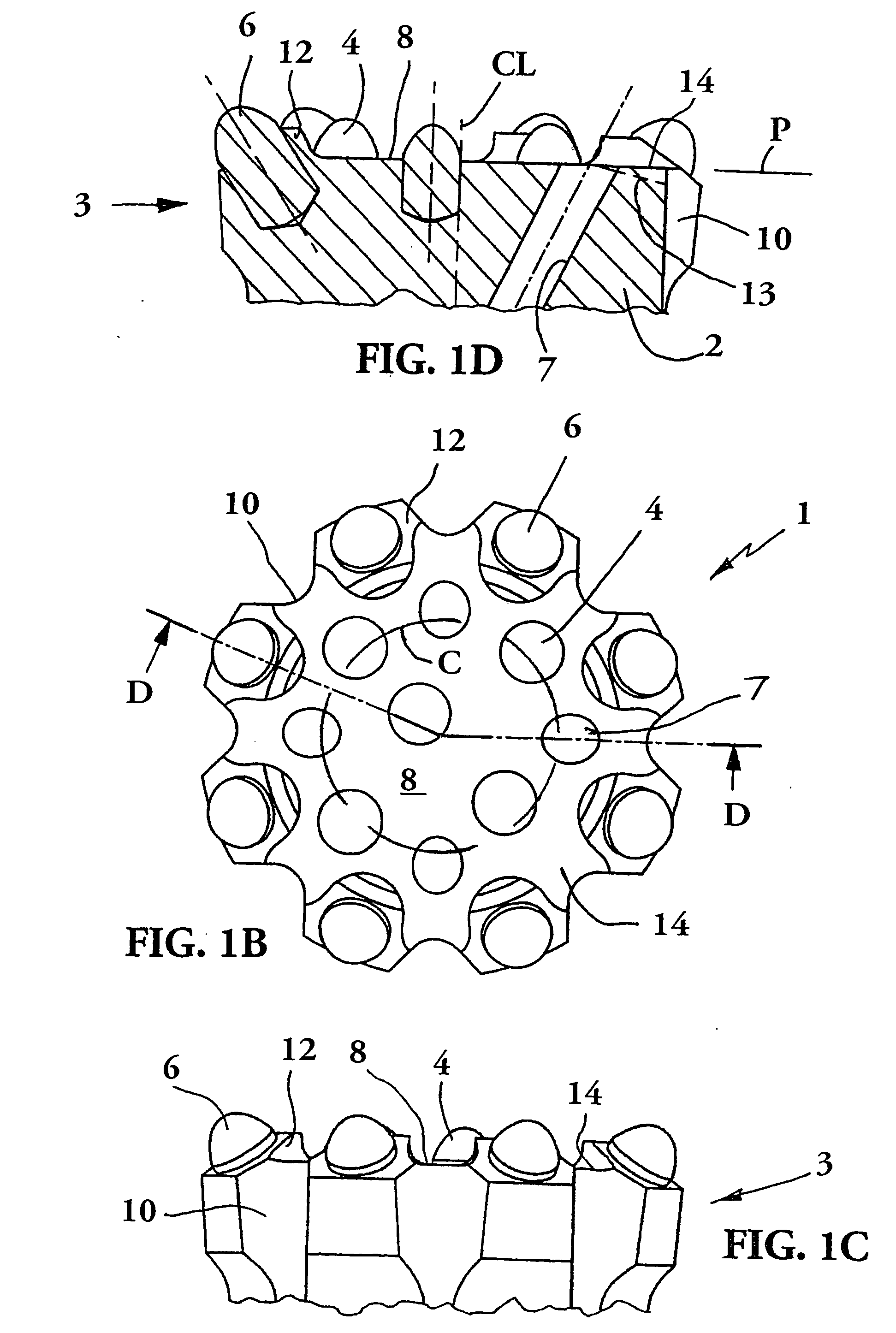

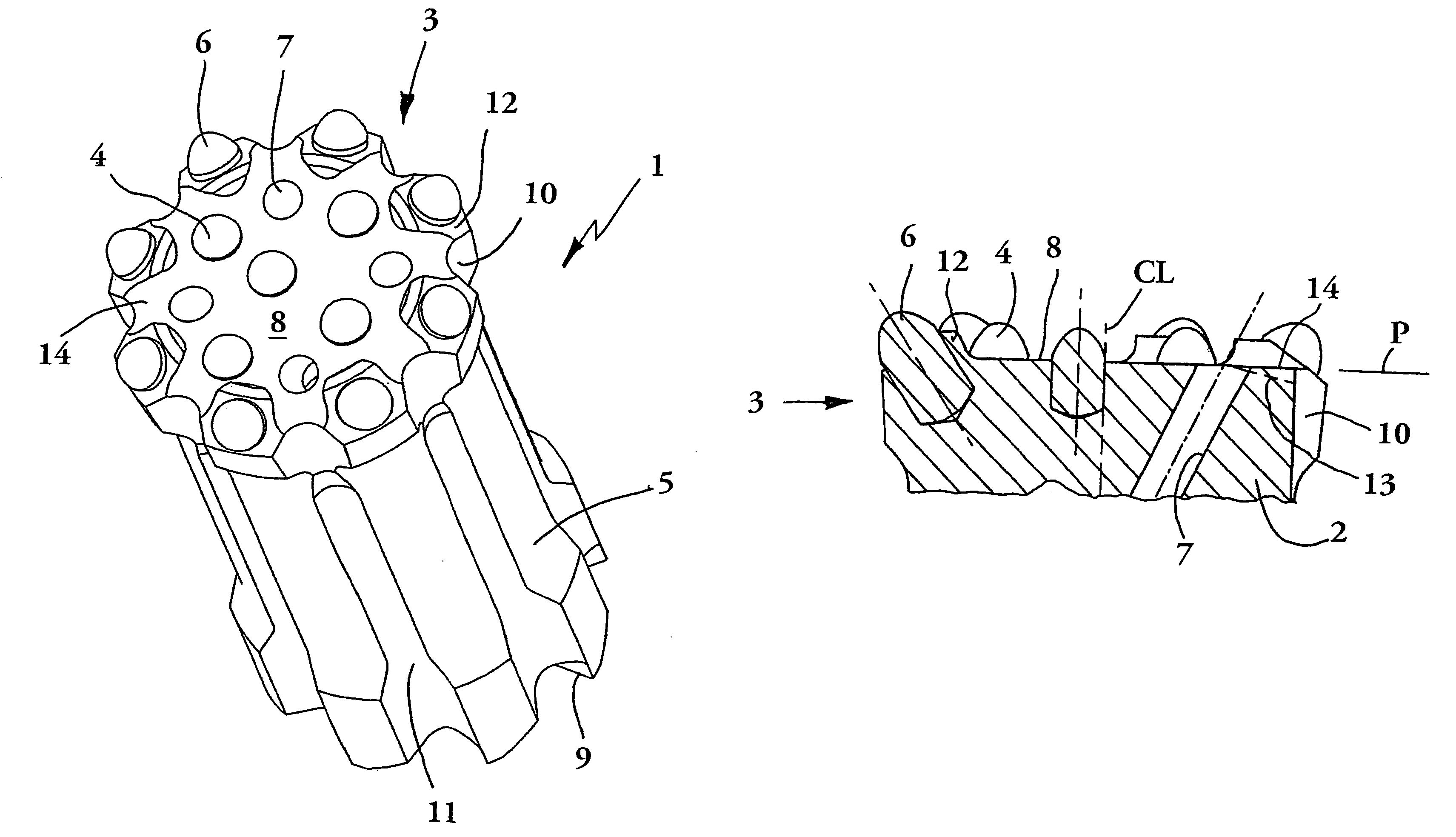

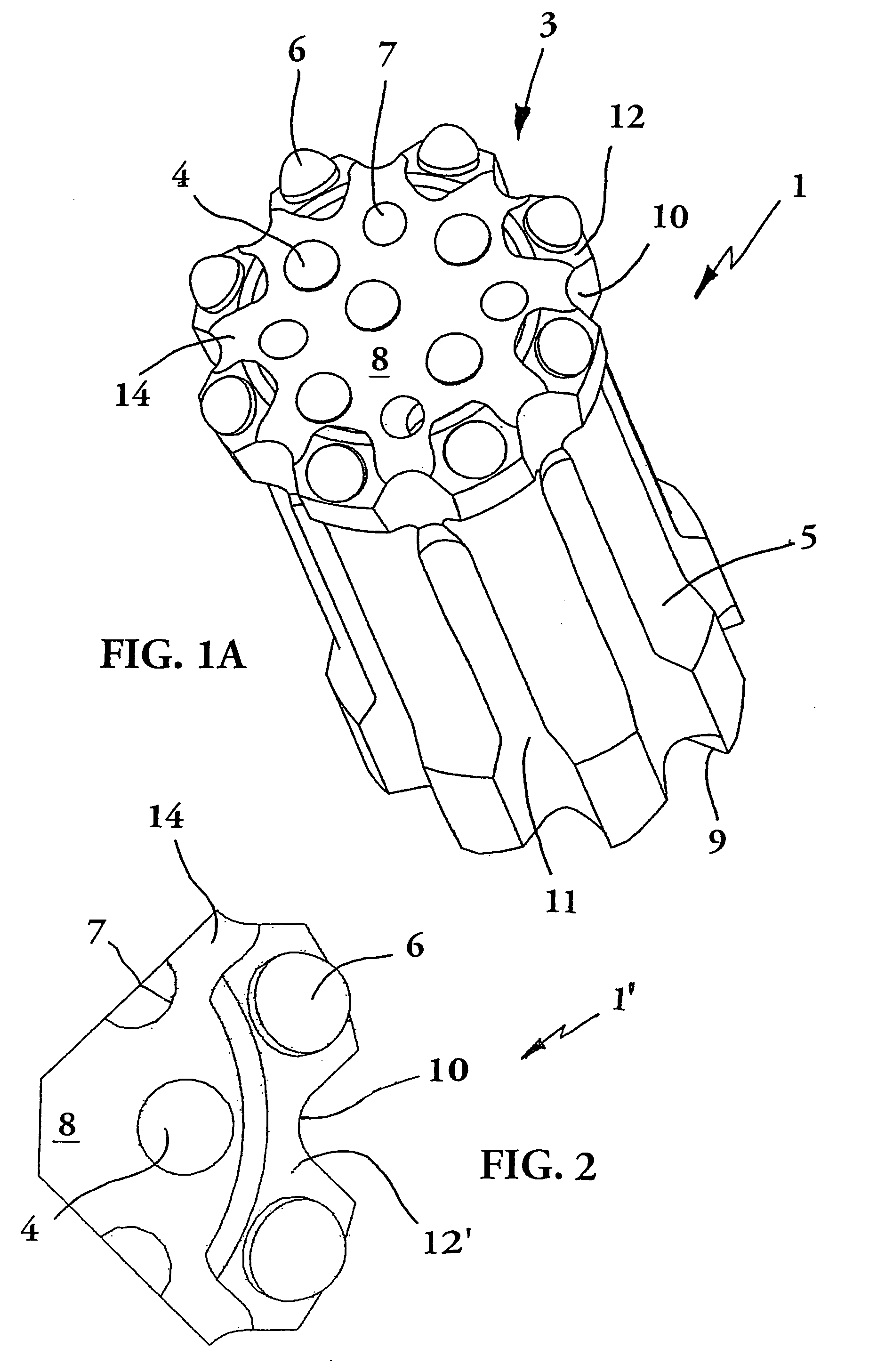

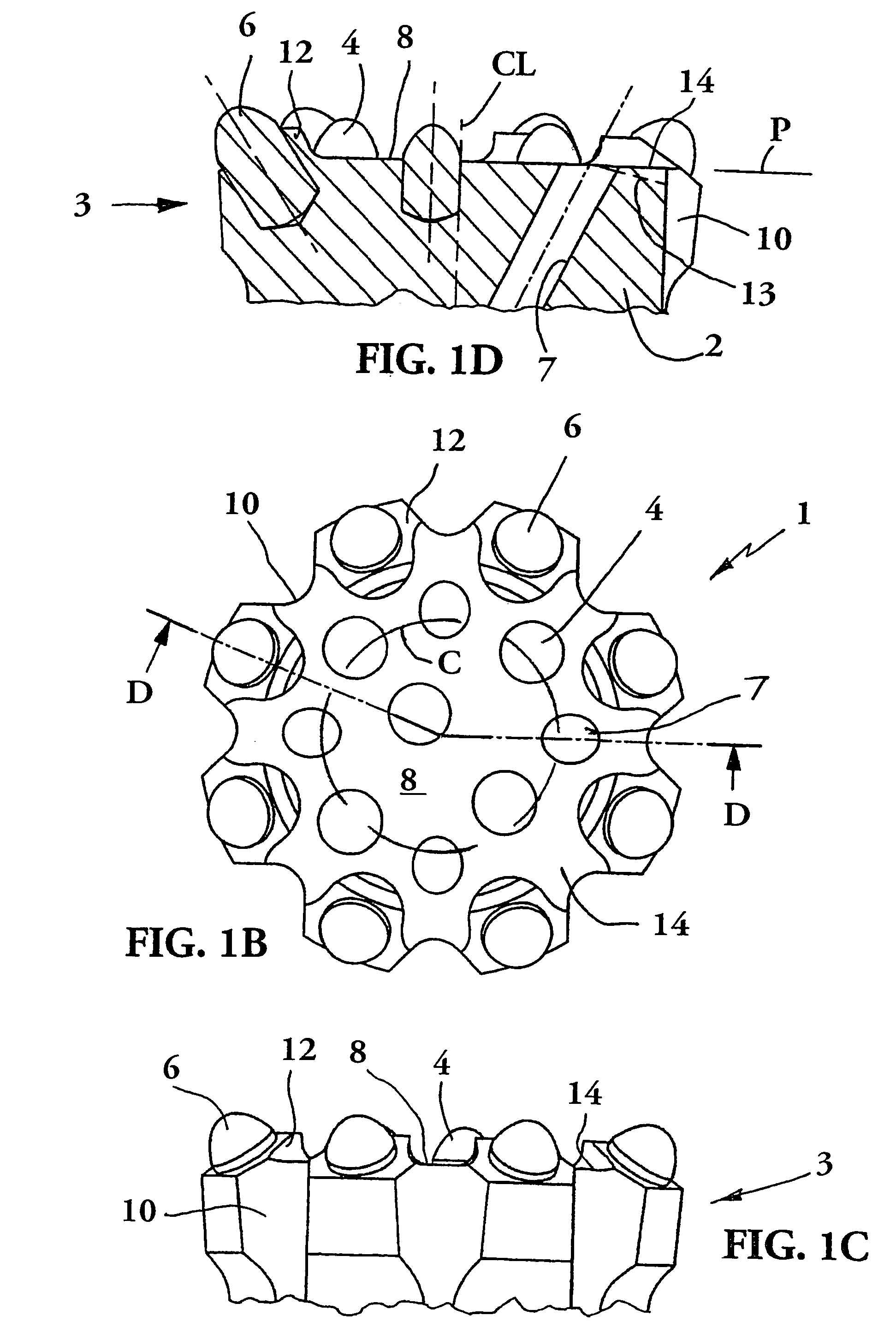

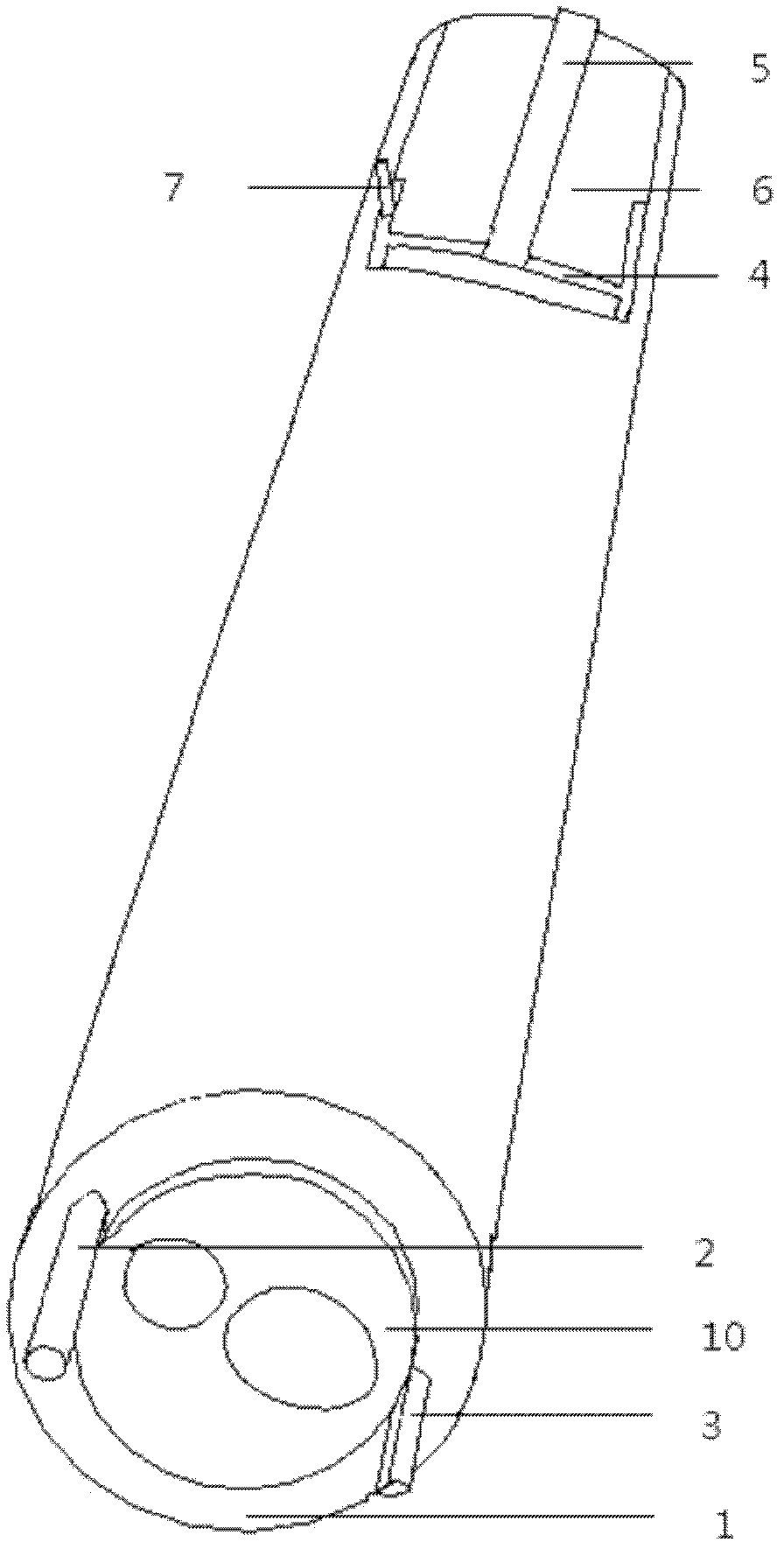

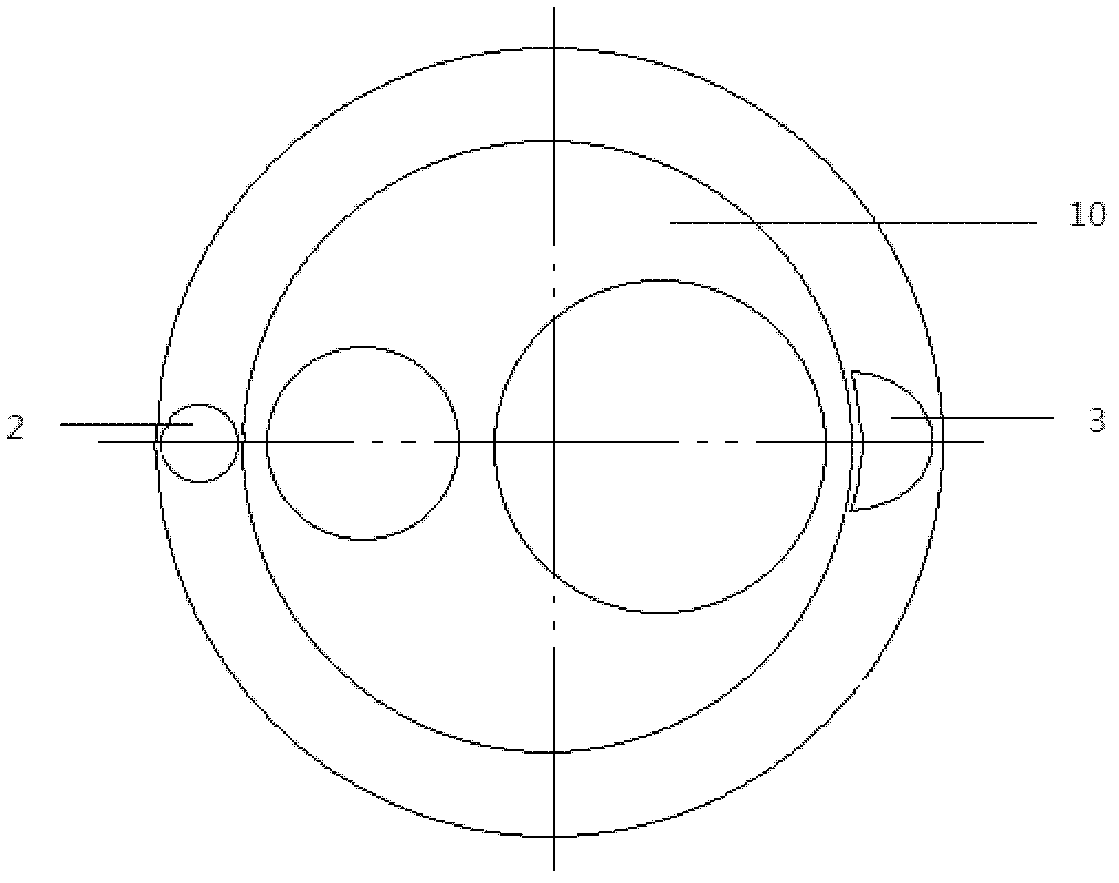

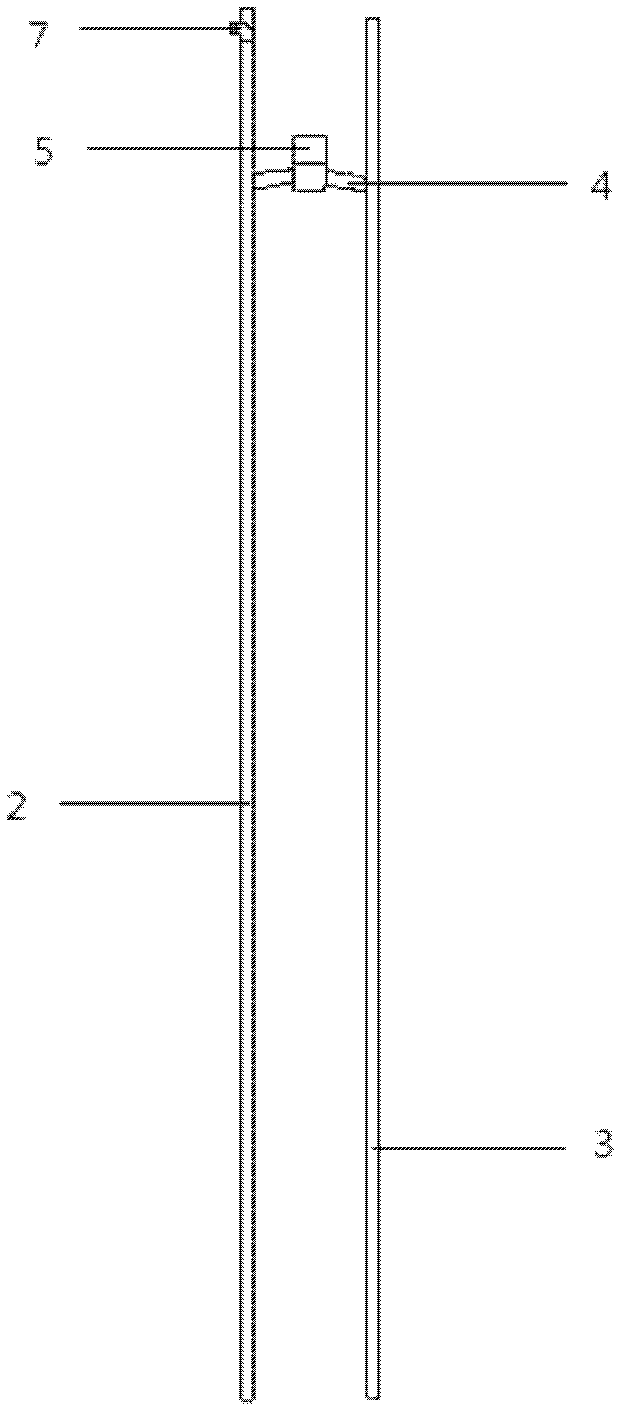

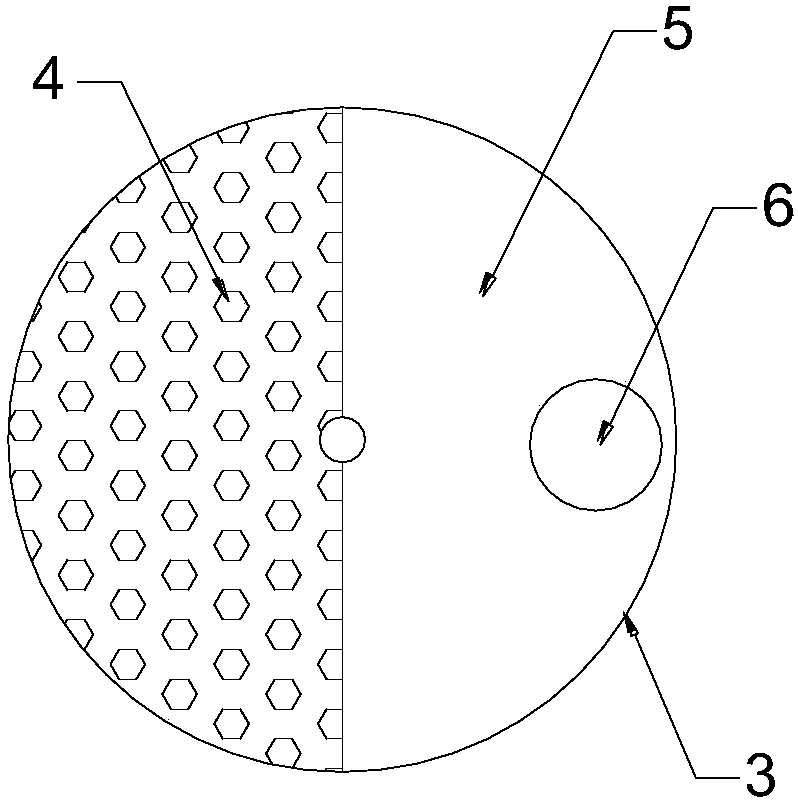

Rock drill bit having outer and inner rock-crushing buttons

InactiveUS20060060389A1Extended service lifeGood removal effectDrill bitsConstructionsEngineeringDrill bit

A rock drill bit for percussive drilling includes a front face which has radially outer and inner portions. Fluid channels are disposed in the head portion in communication with the inner portion of the front face. The inner portion of the front face carries a plurality of front buttons. The outer portion comprises circumferentially spaced steel portions which are axially raised relative to the inner portion. Each raised portion carries one or two peripheral buttons located radially outwardly of an imaginary circle which intersects at least two of the front buttons and at least two of the flushing channels. The imaginary circle is arranged coaxially relative to the center axis.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

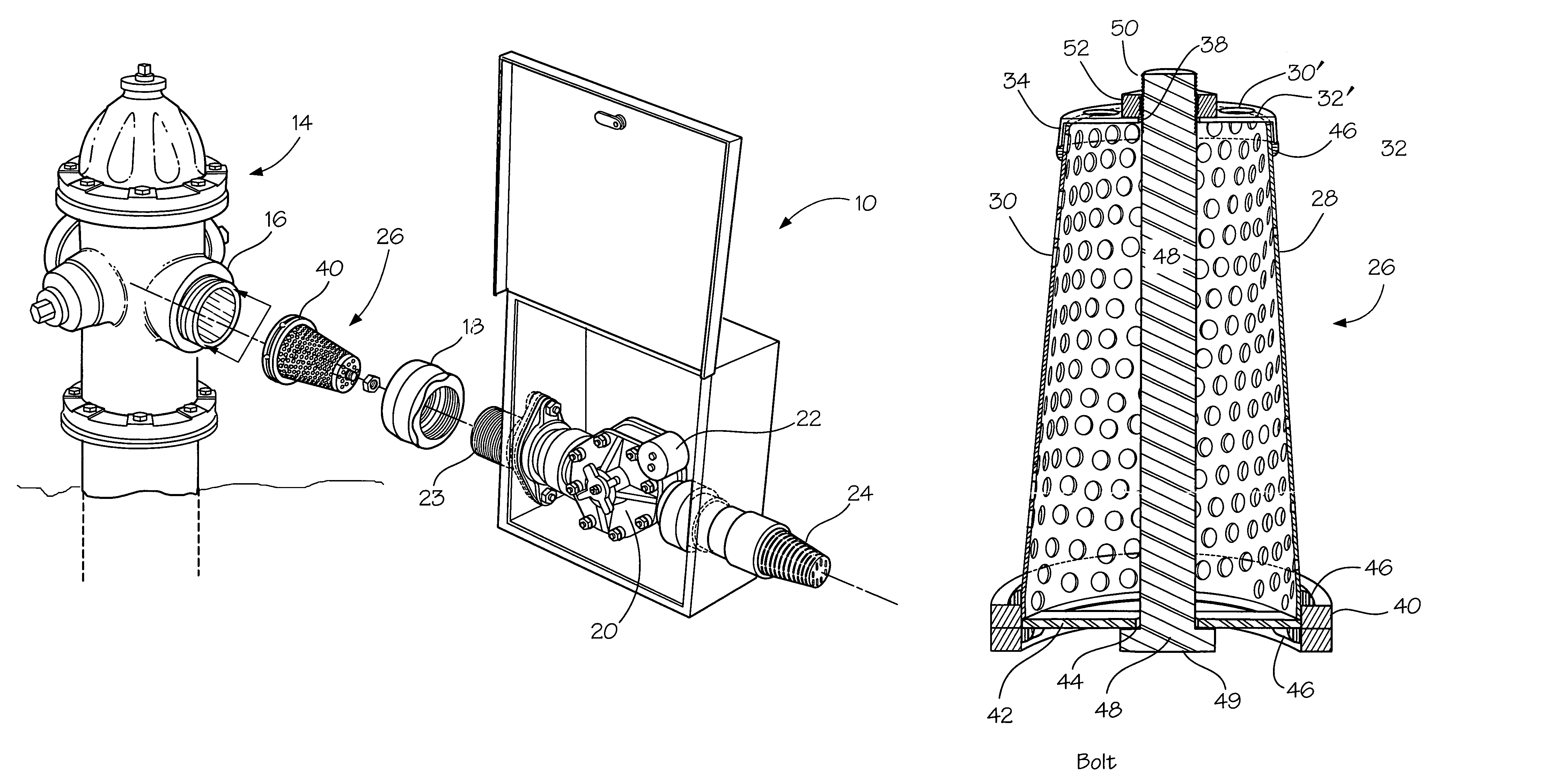

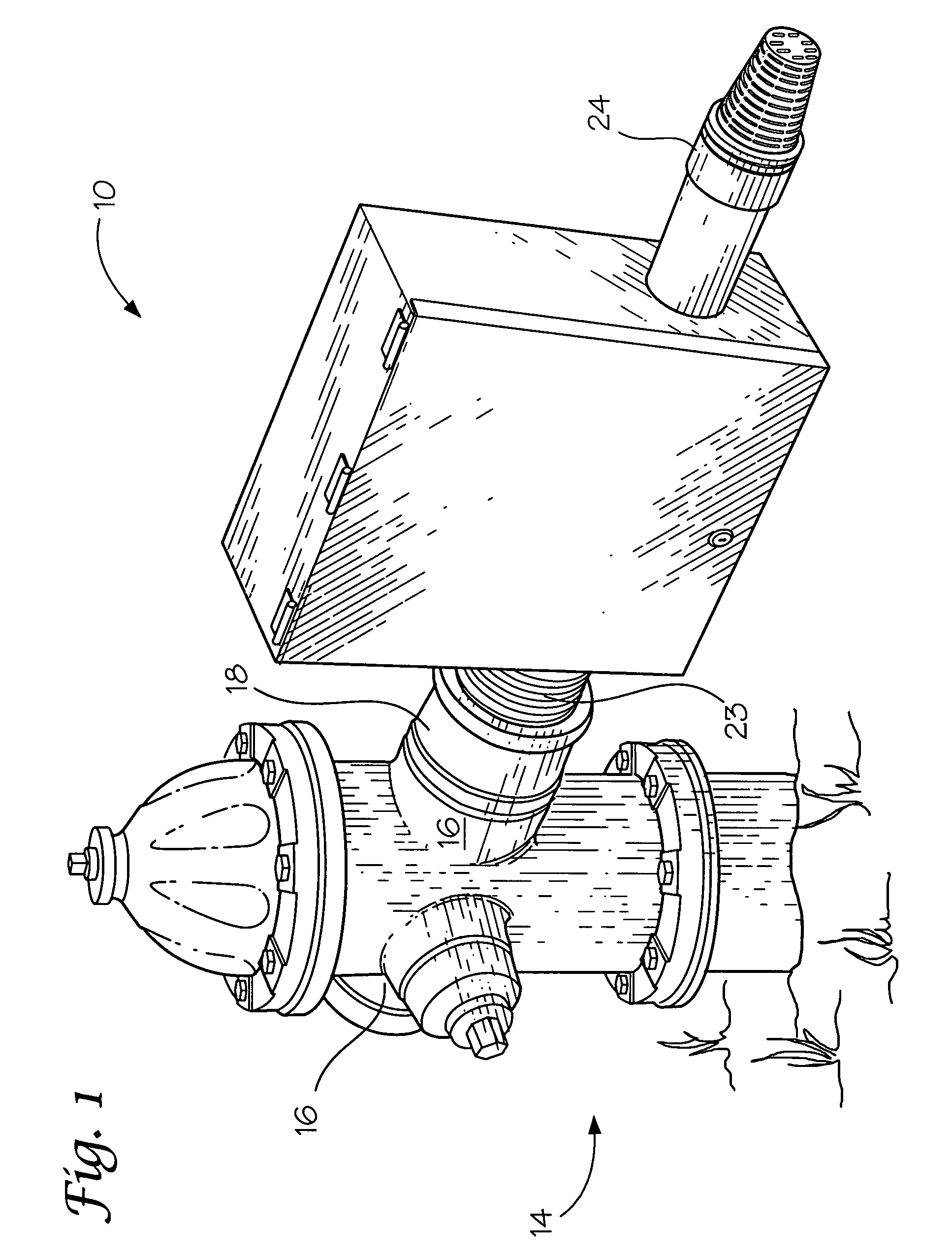

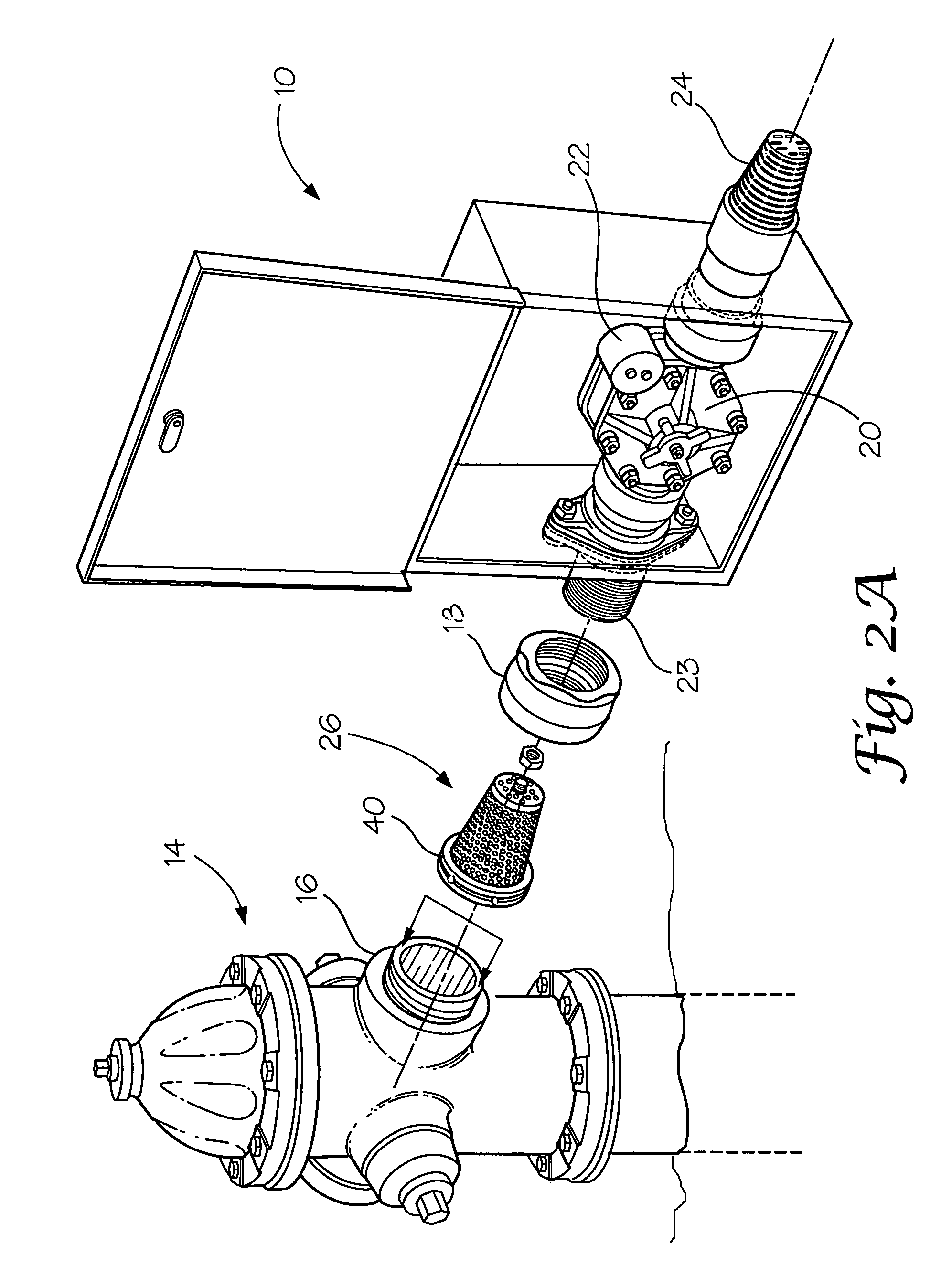

System for straining water

InactiveUS7473359B1Easy to assembleEasy to removeHollow article cleaningMembrane filtersEngineeringControl unit

A water straining system for use in a flushing arrangement for a water delivery system. The flushing arrangement is connected to a main line of the water delivery system and includes a discharge valve controlled by an automatic valve control unit. A filter is positioned in the pipeline of the flushing arrangement between the main line and the automatic valve control. The filter acts to prevent debris in the main line from entering the discharge valve where it could become stuck preventing closure of the discharge valve.

Owner:BARRETT II F MADISON

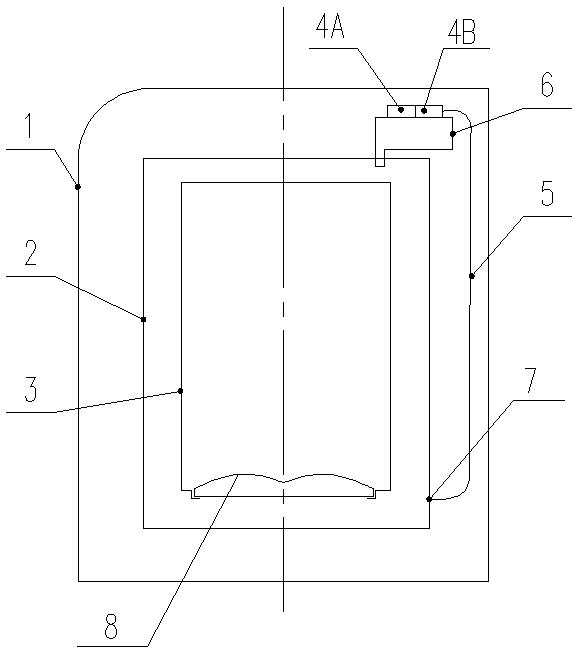

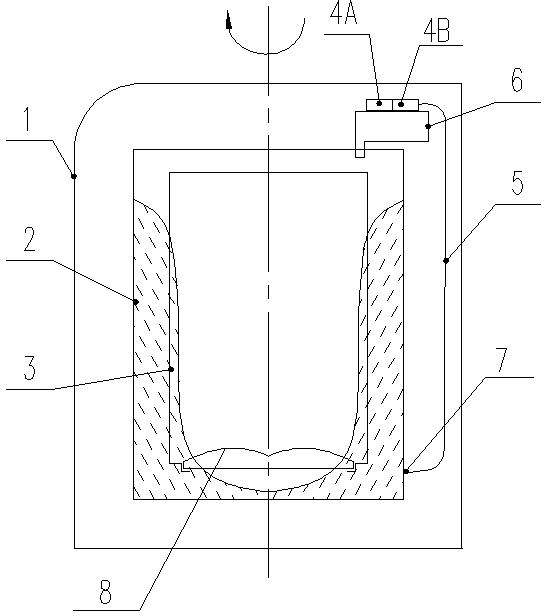

Sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine and barrel-cleaning control method thereof

InactiveCN102628205AAvoid depositionEnsure normal dischargeOther washing machinesControl devices for washing apparatusImpellerInlet valve

The invention discloses a sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine which comprises a shell, wherein an external water-storing barrel and an internal washing barrel are arranged in the shell; a water inlet box, a draining valve, a clutch, a program controller and a power supply part are arranged in the shell; a water inlet valve is arranged on the water inlet box; an ozone generating device is mounted on the water inlet box; an air outlet end of the ozone generating device is communicated with the bottom of a side wall of the external barrel through an ozone pipeline; the ozone generating device is connected with the program controller and the power supply part; and the draining valve and the clutch are respectively arranged and are respectively controlled by the program controller. The invention also discloses a barrel-cleaning control method of the washing machine. The sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine is simple in structure and convenient in use; the internal barrel, the external barrel, the space between the internal and external barrels and the space under an impeller are cleaned and are sterilized and disinfected by using ozone; when water is discharged, the impeller is started to rotate positively and negatively by the washing machine so as to prevent line scraps and dirt in water from depositing at the bottom of the external barrel and internal barrel and on the impeller; the discharging of the line scraps and dirt is ensured; and the barrel-cleaning function is achieved.

Owner:HENAN XINFEI ELECTRICAL EQUIP

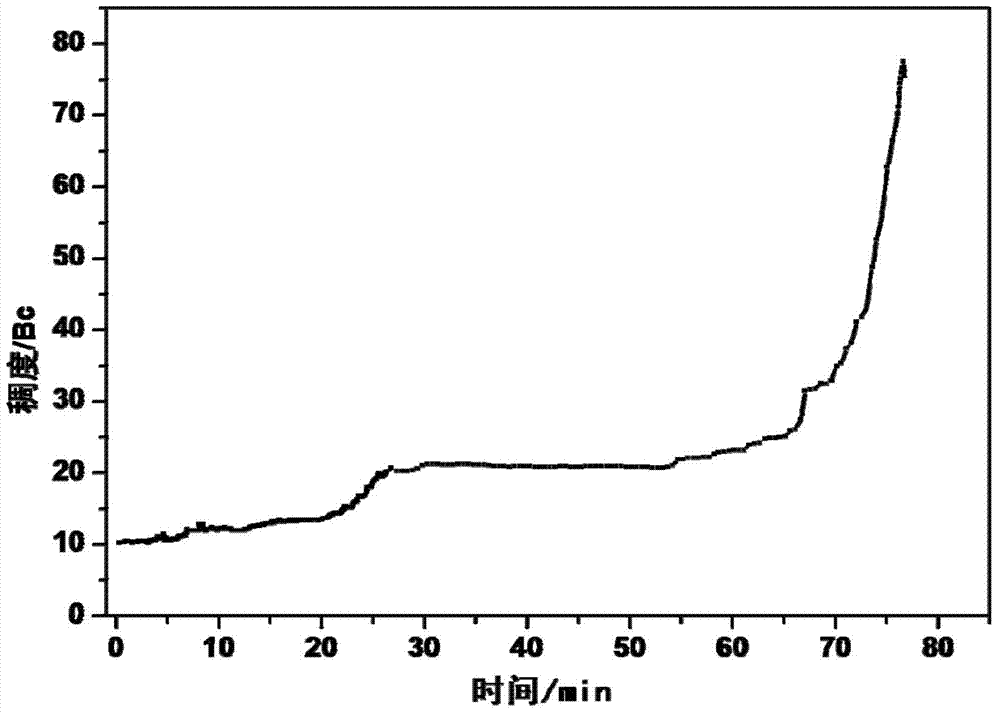

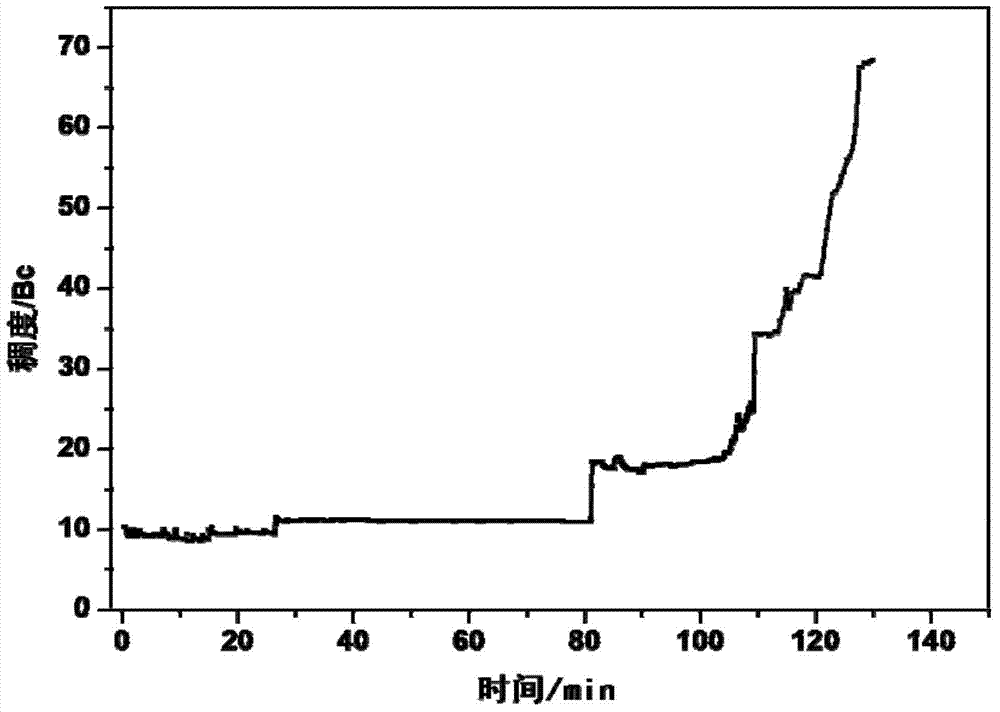

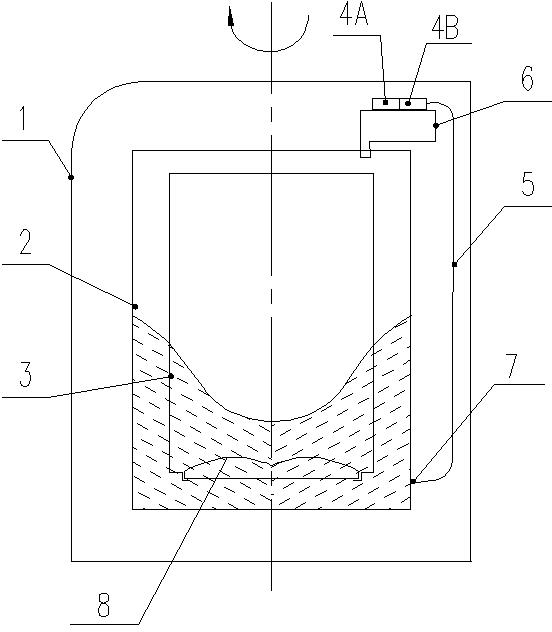

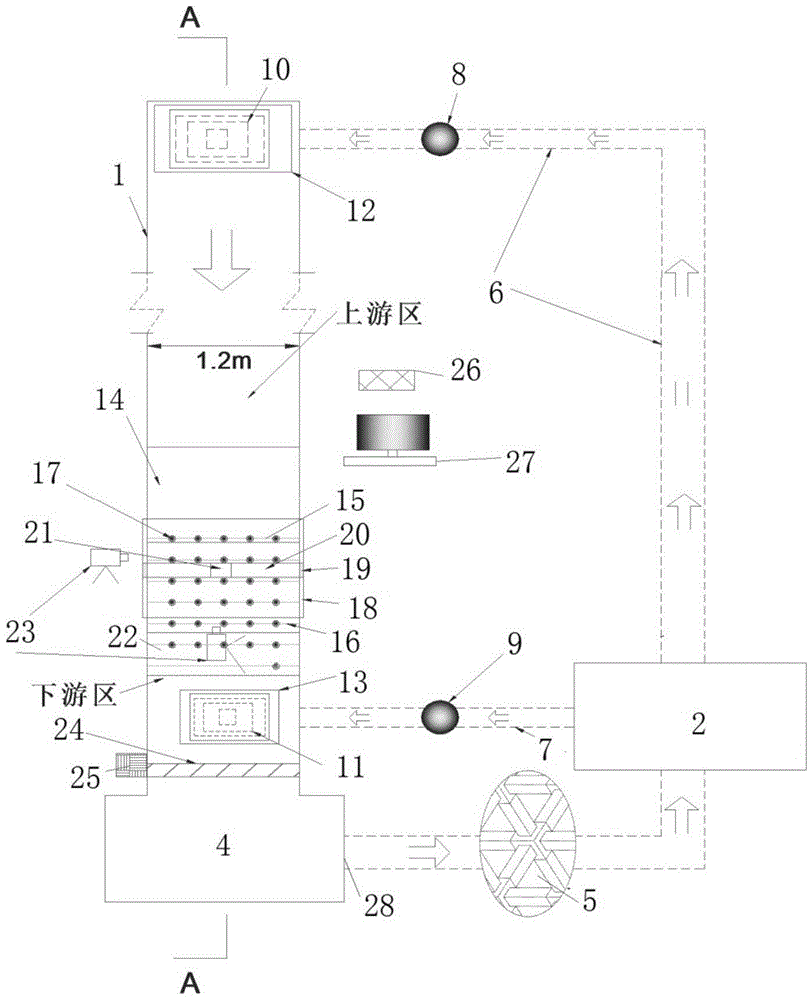

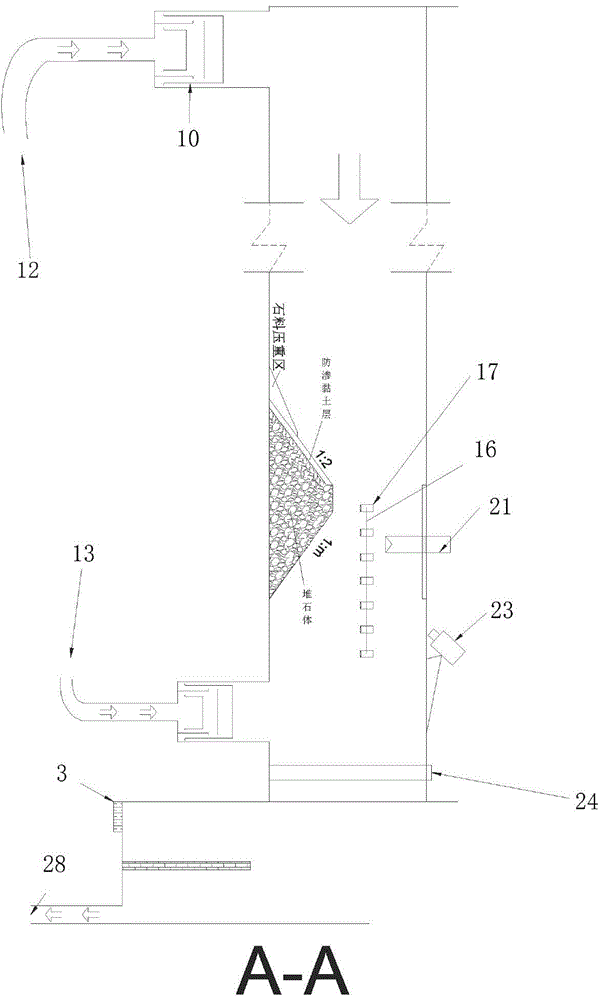

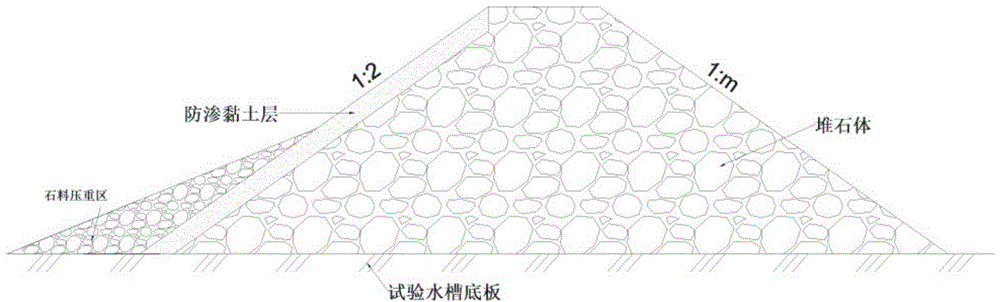

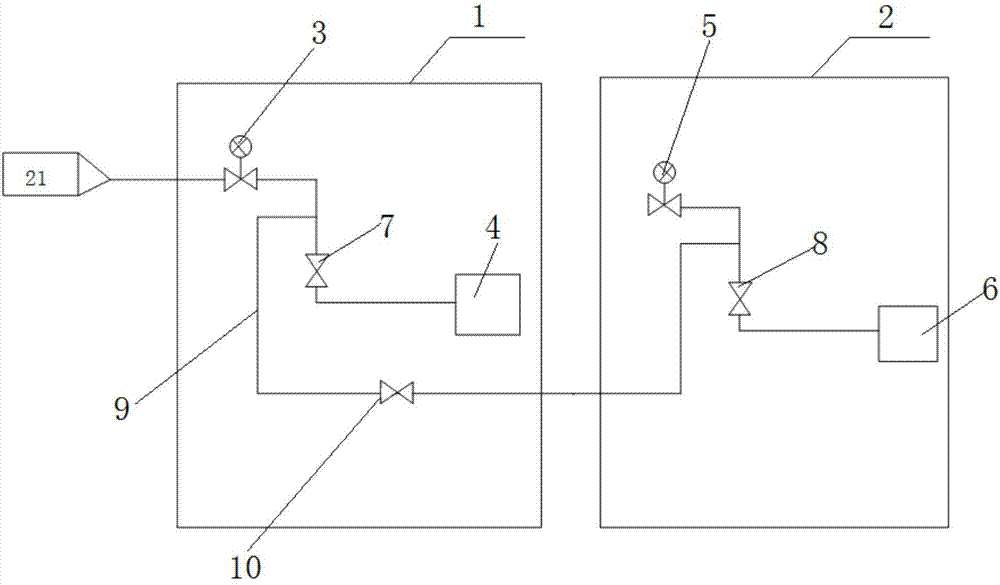

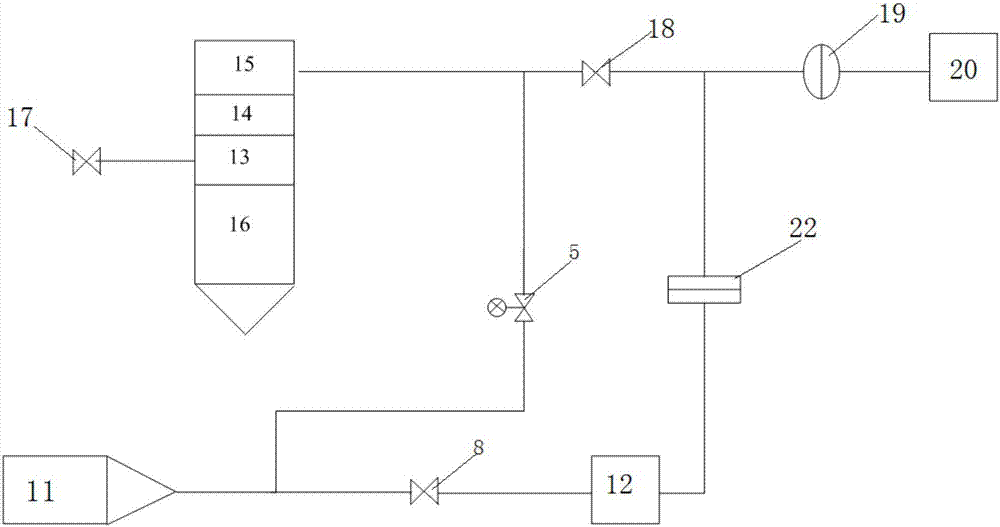

Rockfill scouring simulation experiment device and experimental data acquisition method

InactiveCN104792945AAvoid operabilityAvoid Low Data Acquisition RatesMaterial analysisComputer control systemData acquisition

The invention discloses a rockfill scouring simulation experiment device and an experimental data acquisition method. The device comprises a glass water tank, a water circulation unit, a water control unit, a rockfill testing unit, a data acquisition unit, a sample acquisition unit and a central dataset unit, wherein the water circulation unit is communicated with the glass water tank; the water control unit is arranged in a water outlet of the water circulation unit and is used for accurately controlling the flow and the water level; the rockfill testing unit is arranged at a downstream end of the glass water tank; a computer control system is connected with the water control unit, the data acquisition unit, the sample acquisition unit and the central dataset unit; the data acquisition unit is used for acquiring experimental parameters; the sample acquisition unit is used for acquiring relevant samples of the rockfill, and the acquired data are stored in the central dataset unit. According to the rockfill scouring simulation experiment device, the discrimination of the rockfill dam burst development path and mechanism is facilitated, and the risk development mechanism is determined, so that the basic evidence is provided for safety assessment of engineering.

Owner:WUHAN UNIV

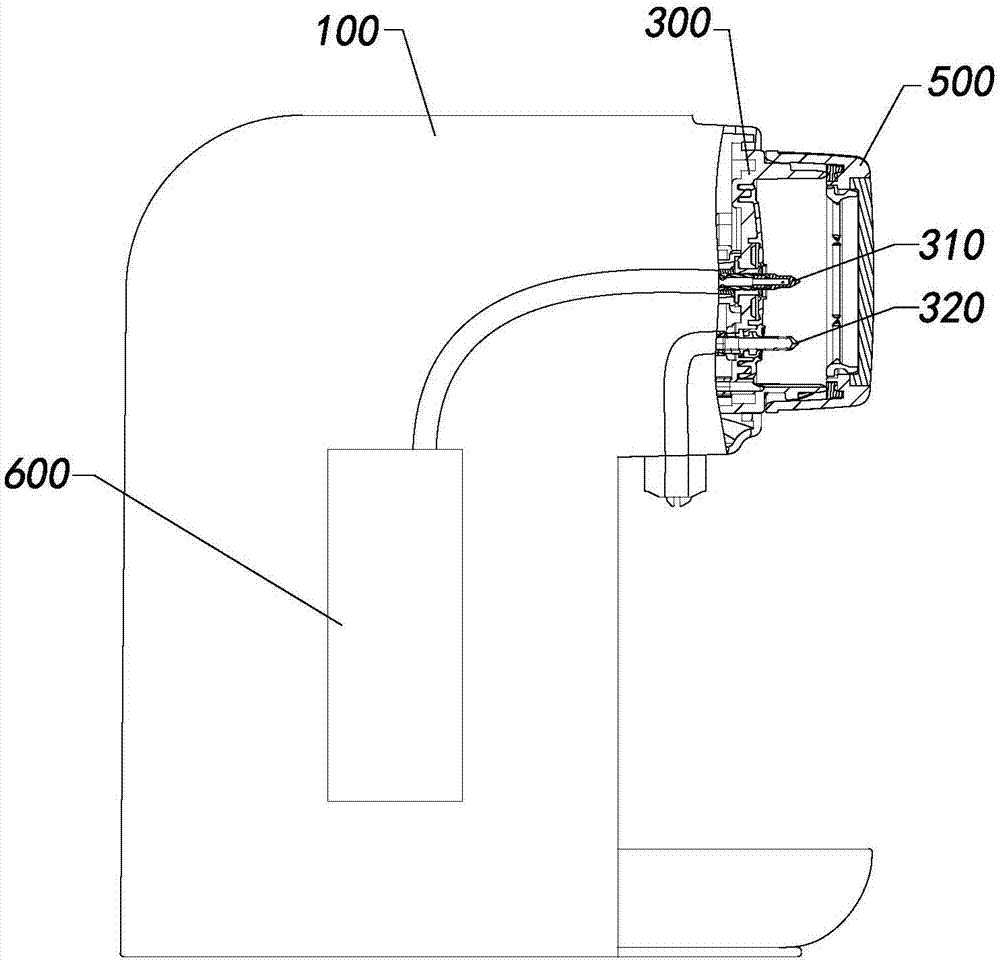

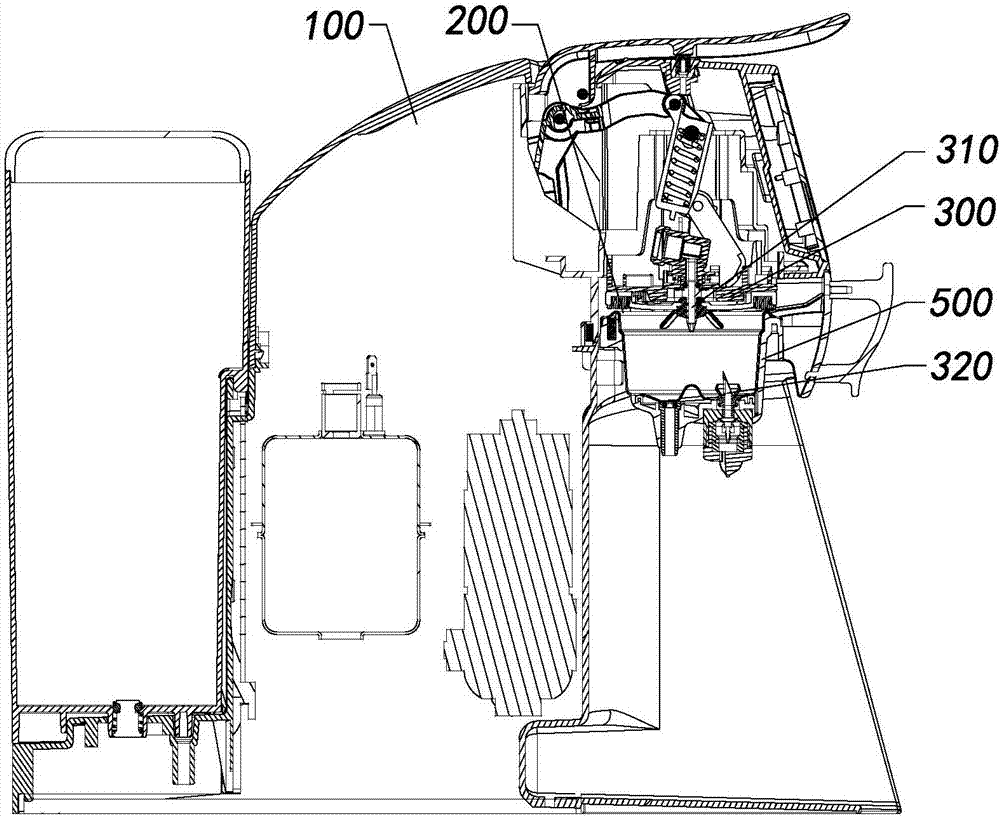

Method for cleaning capsule beverage dispenser

The invention discloses a method for cleaning a capsule beverage dispenser, and belongs to the technical field of beverage preparation. The problems that wasting of water is caused in the cleaning process of an existing capsule beverage dispenser and the cleaning effect is poor are solved. The capsule beverage dispenser comprises a machine base with a brewing cavity, a liquid feeding mechanism, an input module and a control module. The control module controls the capsule beverage dispenser to be cleaned according to signals of the input module. The cleaning method includes a first cleaning stage and a second cleaning stage capable of being selected to be executed. The first cleaning stage at least includes a first washing step in which the liquid feeding mechanism leads liquid into the brewing cavity at a first power P1 for cleaning. The second cleaning stage at least includes a second washing step in which the liquid feeding mechanism leads liquid into the brewing cavity at a second power P2 for cleaning. The rated power of the liquid feeding mechanism is PE1, and P1<P2<=PE1. The method disclosed by the embodiment of the invention is used for cleaning the capsule beverage dispenser. The capsule beverage dispenser can be a capsule coffee maker, a capsule soybean milk machine and the like.

Owner:杭州易杯食品科技有限公司

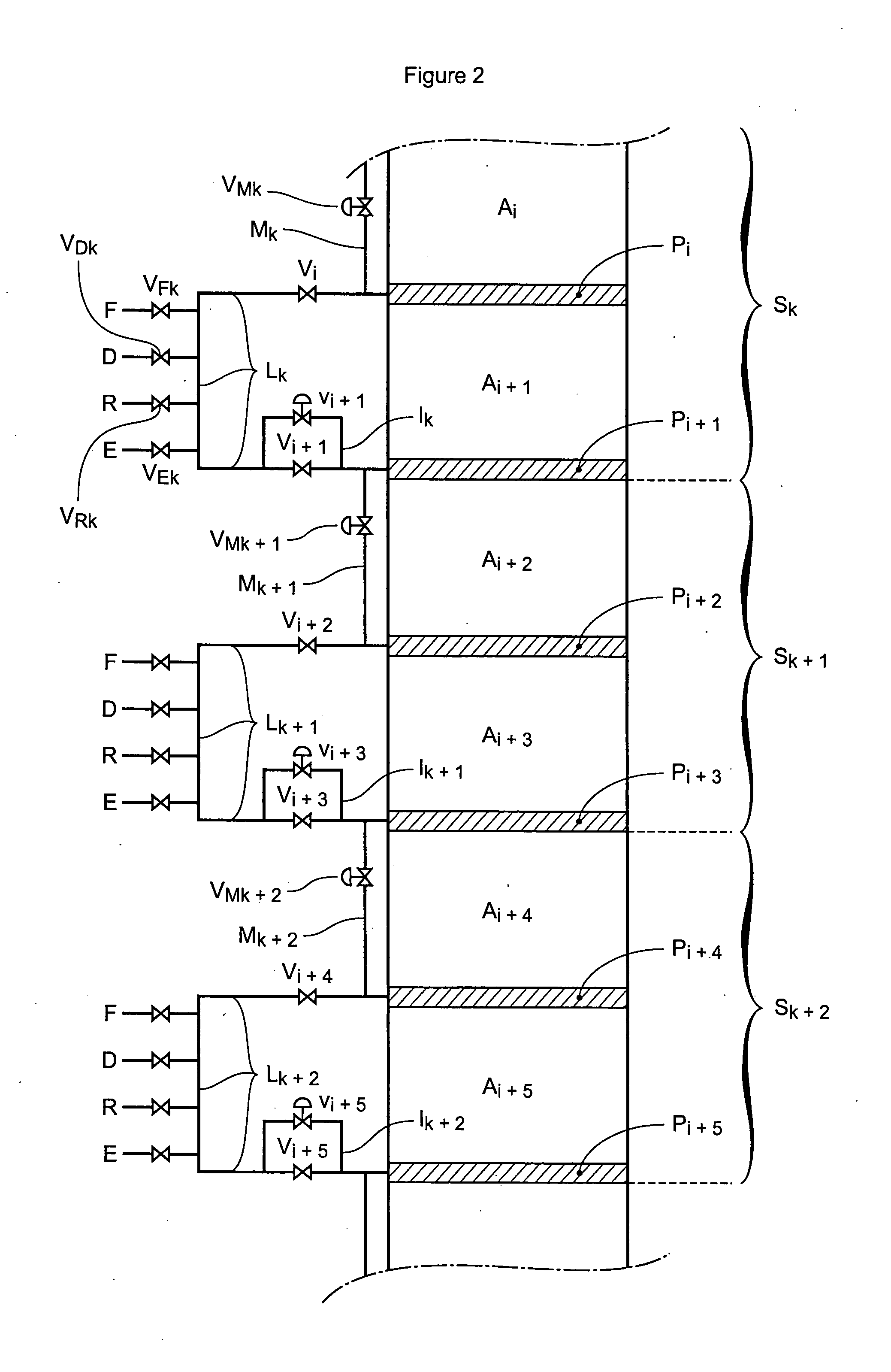

Process and device for simulated moving bed separation with a reduced number of large diameter valves

InactiveUS20080121586A1Control flowLow costIon-exchange process apparatusComponent separationSimulated moving bedEngineering

The invention concerns a simulated moving bed (SMB) separation device and process comprising a column, beds Ai of adsorbent separated by plates Pi with a single distribution and extraction network for fluids, in particular feed F, desorbant D, raffinate R and extract E, and a plurality of two-way valves for distribution of said fluids, said valves being limited in number and in particular with dimensions that are smaller than in the prior art. According to the invention, the column is divided into a plurality of sectors Sk with 2 superimposed plates, each sector Sk comprising an external principal bypass line Lk connected to each plate Pi of Sk via a large diameter plate valve Vi and an external secondary bypass line Mk comprising a small diameter valve VMk connected to the adjacent sector Sk−1. Each line Lk comprises a flow limitation means, and is connected to each of the fluid networks F, D, R, E via a single large diameter valve for sequential supply or withdrawal of the corresponding fluid F, D, R or E to or from the sector Sk under consideration.

Owner:INST FR DU PETROLE

Insulating liquid for injecting cement in oil well

The invention relates to an isolating liquid used in oil well cementing, comprising fresh water, suspension agent, thinner agent and aggravation agent. The invention is characterized in that: the suspension agent is made from hydroxy ethyl cellulose, carboxymethyl cellulose, xanthan and na-bentonite; the thinner agent is made from sodium lignosulphonate, sodium dodecyl benzene sulfonate and alkyl phenol polyoxyethylene ether; the aggravation agent is made from barite, fly ash, limestone and slag. When preparing the isolating liquid, the suspension agent is dissolved in water for one hour, thereafter thinner agent is added. Before cementing, the aggravation agent is added into the solution and mixed evenly. The isolating liquid is characterized by low viscosity, good rheological performance, slow critical velocity and being easy to form turbulent flow, so as to effectively substitute and wash mud, prevent forming mixed slurry of cement slurry and mud. Meanwhile, the invention can be compatible with ordinary cement slurry and mud system, thus diluting and improving cement slurry rheological performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Process and device for simulated moving bed seperation with a reduced number of valves

InactiveUS20080041788A1Reduce in quantityReduce disadvantagesIon-exchange process apparatusGas treatmentIsolation valveLine tubing

The invention concerns a simulated moving bed (SMB) separation device comprising a column, beds Ai of adsorbent separated by plates Pi with a single distribution and extraction network for fluids, in particular feed F, desorbant D, raffinate R and extract E, and a plurality of two-way valves for distribution of said fluids, said valves being limited in number compared with the prior art. According to the invention, the column is divided into a plurality of sectors Sk with 2 or 3 superimposed plates, each sector Sk comprising an external bypass line Lk connected to each plate Pi of Sk via a connector comprising a plate valve Vi. Each line Lk comprises a controlled means for limiting its internal flow, and is connected to each of the fluid networks F, D, R, E via a single line comprising a single controlled two-way isolation valve to supply for sequential supply or withdrawal of the corresponding fluid F, D, R or E towards or from the sector Sk under consideration. The invention also concerns a separation process using said device or the use of said device for the separation of para-xylene or meta-xylene from an aromatic C8 cut.

Owner:INST FR DU PETROLE

Simulated moving bed separation process and device

InactiveUS20050269268A1Effective flushingAvoid recyclingIon-exchanger regenerationMaterial analysis by optical meansSimulated moving bedRotary valve

A simulated moving bed separation device is described, comprising at least one column, beds of adsorbent arranged in this column, trays Pi with a chamber Ci for distribution and extraction of fluids, a multi-way rotary valve for the distribution of the fluids feeding or leaving said trays, and junction lines Li between this valve and said trays. The device according to the invention also comprises a plurality of bypass lines Li,i+1 between adjacent lines, these bypasses being outside the multi-way rotary valve and situated in proximity to this valve, for the circulation of rinsing liquids with a small or zero concentration gradient. The invention makes it possible to use all types of distribution and extraction trays and all types of adsorbent loading, whilst preserving a high level of product purity. Application to the separation process in particular of paraxylene or metaxylene from a C8 aromatic charge.

Owner:INST FR DU PETROLE

Rock drill bit having outer and inner rock-crushing buttons

InactiveUS7296641B2Extended service lifeGood removal effectDrill bitsConstructionsEngineeringMechanical engineering

A rock drill bit for percussive drilling includes a front face which has radially outer and inner portions. Fluid channels are disposed in the head portion in communication with the inner portion of the front face. The inner portion of the front face carries a plurality of front buttons. The outer portion comprises circumferentially spaced steel portions which are axially raised relative to the inner portion. Each raised portion carries one or two peripheral buttons located radially outwardly of an imaginary circle which intersects at least two of the front buttons and at least two of the flushing channels. The imaginary circle is arranged coaxially relative to the center axis.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Machine part drilling device

InactiveCN107999805AEasy to clamp and fixEasy to rinseWork clamping meansMetal working apparatusMachine partsBiochemical engineering

The invention belongs to the technical field of drilling equipment, and particularly discloses a machine part drilling device. The device comprises a rack, a guide rail is arranged on the rack, a supporting frame is arranged on the guide rail in a sliding connection manner, a cross beam connected with a telescopic device is arranged on the supporting frame, a motor is arranged on the telescopic device, a drill bit is arranged at the output end of the motor, and the device is characterized in that a transverse rod is arranged on the telescopic device, a first supporting rod and a second supporting rod are arranged on the transverse rod, and are hinged with a first clamp and a second clamp correspondingly, two opposite air cylinders are arranged in the middle of the rack, a clamping plate isarranged on piston rods of the air cylinders, and a first spraying head and a second spraying head connected with a water pipe are arranged in the middle of the first supporting rod and the middle ofthe second supporting rod. The device is mainly used for machine part drilling, and the problem that after drilling, sweeps easily remain in holes is solved.

Owner:宁波德深机械设备有限公司

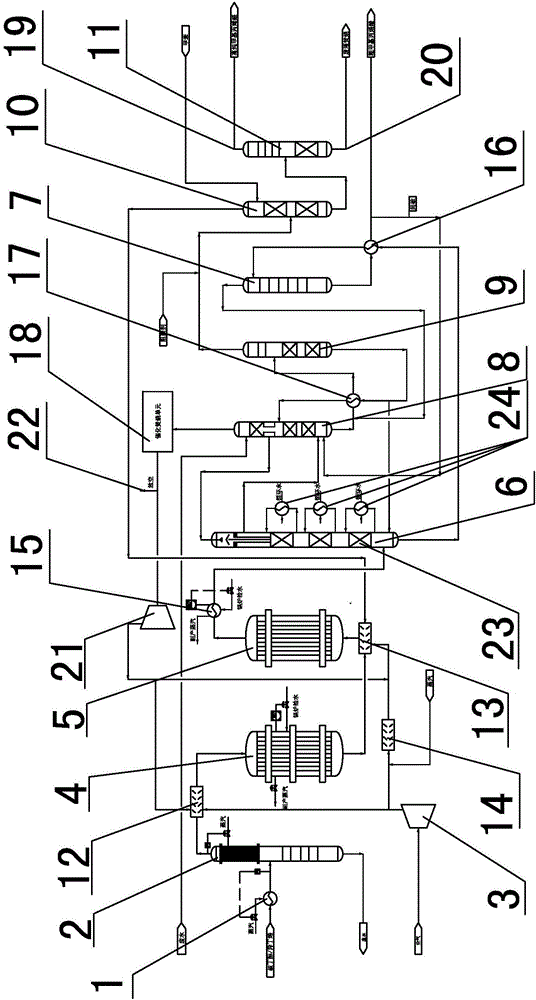

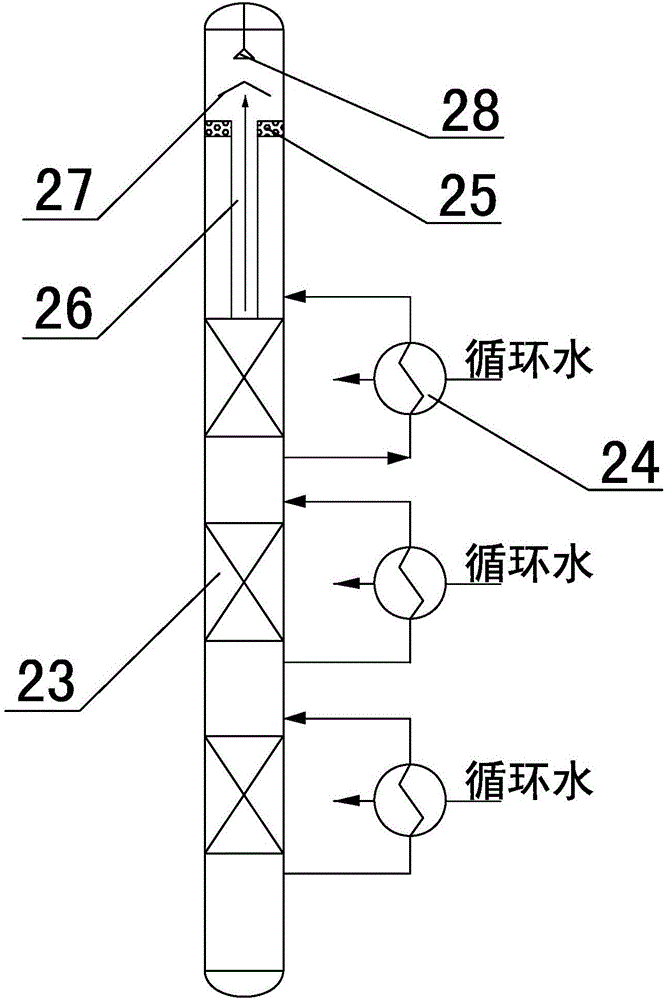

System and method for simultaneously producing methacrylic acid and methacrolein

ActiveCN106631759AGuaranteed conversion rateGuaranteed pressureOrganic compound preparationChemical industryFixed bedAcid washing

The invention discloses a method and system for simultaneously producing methacrylic acid and methacrolein. The system comprises a raw material feed preheater, a raw material vaporizing tower, a first oxidation reactor, a second oxidation reactor, a rapid cooling / acid washing coupled tower, a methacrolein stripping tower, a methacrolein absorption tower, a methacrolein recovery tower, a methacrolein light component removal tower and a methacrolein heavy component removal tower. The method comprises the following steps: preheating and vaporizing a raw material tert-butyl alcohol or isobutylene; then mixing with air and water; feeding to a catalyst-filled fixed-bed reactor; performing oxidation reaction to generate methacrylic acid and methacrolein; and performing effective rapid cooling, absorption and rectification to finally obtain 99%wt methacrolein and 30%wt crude methacrylic acid. The method and system have the advantages that the reaction conversion rate is high, the unreacted raw material can be effectively recovered, impurities and solid particles are removed, and high-purity methacrylic acid and methacrolein are produced.

Owner:齐翔华利新材料有限公司

Method for building ecological littoral zone in buffer area

ActiveCN104429529ARestore diversityIncrease diversityWater resource protectionStream regulationFluvialWater level

The invention discloses a method for building an ecological littoral zone in a buffer area. The method comprises building of gabions, a low pond, multiple ponds and a retention canal. The method comprises the following specific steps: (1) a gabion area is built, wherein the gabions are built between a normal water level of a river and a level of a flood occurring every two years, and emergent aquatic plants are planted in gaps between the gabions; (2) the low pond is built, wherein a low area which is 20cm lower than the gabion area and 20cm lower than foundations of the multiple ponds is built between the level of the flood occurring every two years and the level of a flood occurring every twenty years; (3) a multi-pond system is built, wherein two rows of pond systems are built in the low pond area, substrate improvement is conducted, submerged plants are closely planted in the ponds, and the emergent aquatic plants are planted on the foundations and the circumferences of the ponds; (4) the retention canal is built, wherein the retention canal is built along the outside of the level of the flood occurring every twenty years. The method effectively solves the ecological problems that a surface source of a gentle slope area of the river is severely polluted, landscapes are poor, the biodiversity is reduced and water and soil loss occurs, and offers a feasible and efficient ecological restoration measure for recovery and reconstruction of a hydro-fluctuation belt.

Owner:HUAQIAO UNIVERSITY +1

Laparoscope lens washing-drying device

InactiveCN102578999AShorten operation timeAvoid cross infectionLaproscopesEndoscopesEngineeringControl switch

A laparoscope lens washing-drying device comprises a sleeve, a washing tube, a drying component, a connecting piece and a handle, wherein the nominal dimensions of the inner diameter of the sleeve and the outer diameter of the laparoscope are the same and the sleeve and the laparoscope are in movable fit, two through holes used for mounting the washing tube and the drying component are arranged in the wall of the sleeve, an arc groove is arranged at the rear end of the sleeve, a flushing liquor outlet is arranged on the side wall at the front end of the flushing tube, a flushing liquor control switch is arranged on the side wall at the rear end of the flushing tube, the drying component is a pipe fitting provided with a water sucking sponge, an opening for introducing the flushing liquor into the water sucking sponge is arranged on the side wall at the front end of the pipe fitting, the front end of the flushing tube is inserted in the through hole for mounting the flushing tube on the wall of the sleeve, the front end of the pipe fitting provided with the water sucking sponge is inserted in the through hole for mounting the drying component on the wall of the sleeve, one end of the connecting piece is connected with the rear end part section of the flushing tube, the other end of the connecting piece is connected with the rear end part section of the pipe fitting provided with the water sucking sponge, and the handle is arranged on the connecting piece.

Owner:SICHUAN UNIV

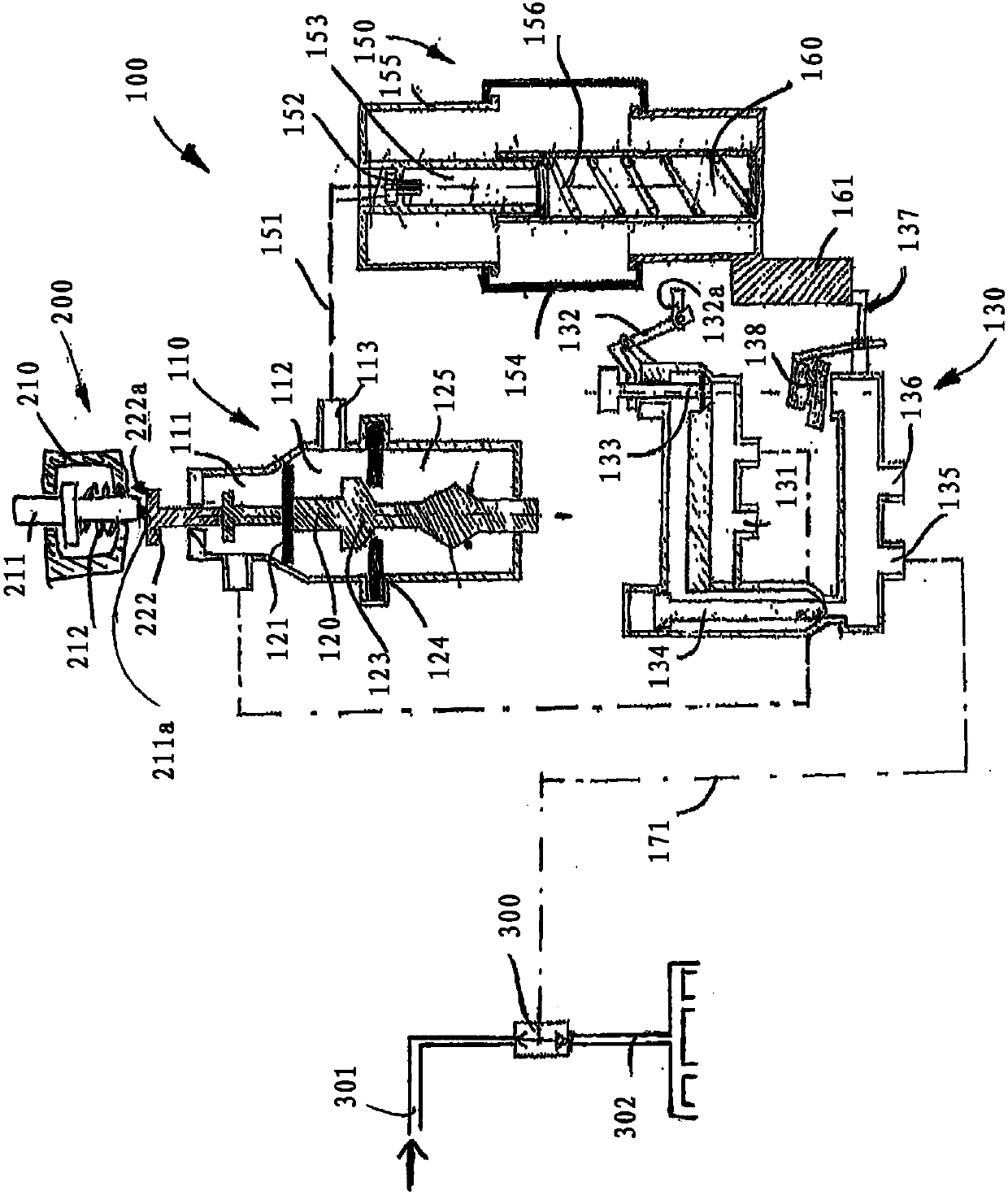

Pneumatic Control For A Vacuum Toilet

InactiveCN107896499AOperation executionCouplingFlushing devicesElectric switchesKey pressingEngineering

The invention relates to a controller for a vacuum toilet, comprising a control unit (100) with an actuating unit with an actuating element to be manually actuated by user. The actuating element has acontact surface (222a) and an actuation surface (211a) of a push-button key (211) opposite the contact surface (222a), said push-button key being spring-loaded in an initial position and being movable out of said initial position into a trigger position by actuating a press button. In the trigger position, the actuation surface (211a) is in contact with the contact surface (222a), and the actuating element is actuated by the push-button key (211).

Owner:EVAC GMBH

Multifunctional squatting toilet capable of emitting light and cleaning dirt

ActiveCN102337757AExtended service lifeConserve waterWater closetsElectric circuit arrangementsImpellerWater storage tank

The invention provides a multifunctional squatting toilet capable of emitting light and cleaning dirt, which comprises a water storage tank, a toilet body connected with water storage tank through a water flushing pipeline and a toilet cover pivoted on the toilet body, wherein both sides of the toilet body are respectively and symmetrically provided with a squatting platform, and the side wall ofthe squatting platform passes through a transparent layer covered light emitting assembly; the light emitting assembly is connected with a processor, and the processor is also connected with a luminance sensor, a sound sensor and a human body sensor; the light emitting assembly is also connected with a generator, and the generator is connected with a rotating impeller arranged in the water flushing pipeline; the water flushing pipeline is connected with the toilet body through an automatic valve, and the automatic valve is connected with the processor; a pressure packet is arranged in the water flushing pipeline; and the water flushing pipeline is also connected with at least to sprinkling heads through hand valves, and the sprinkling heads are symmetrically distributed on both sides of the toilet body, and the direction of the arrangement positions of the sprinkling heads is corresponding to the front leading platform face of the toilet body. A user can freely control the multifunctional squatting toilet to emit light, and dirt on the platform face of the toilet body can be cleaned conveniently.

Owner:NANTONG HONGCI PHARMA

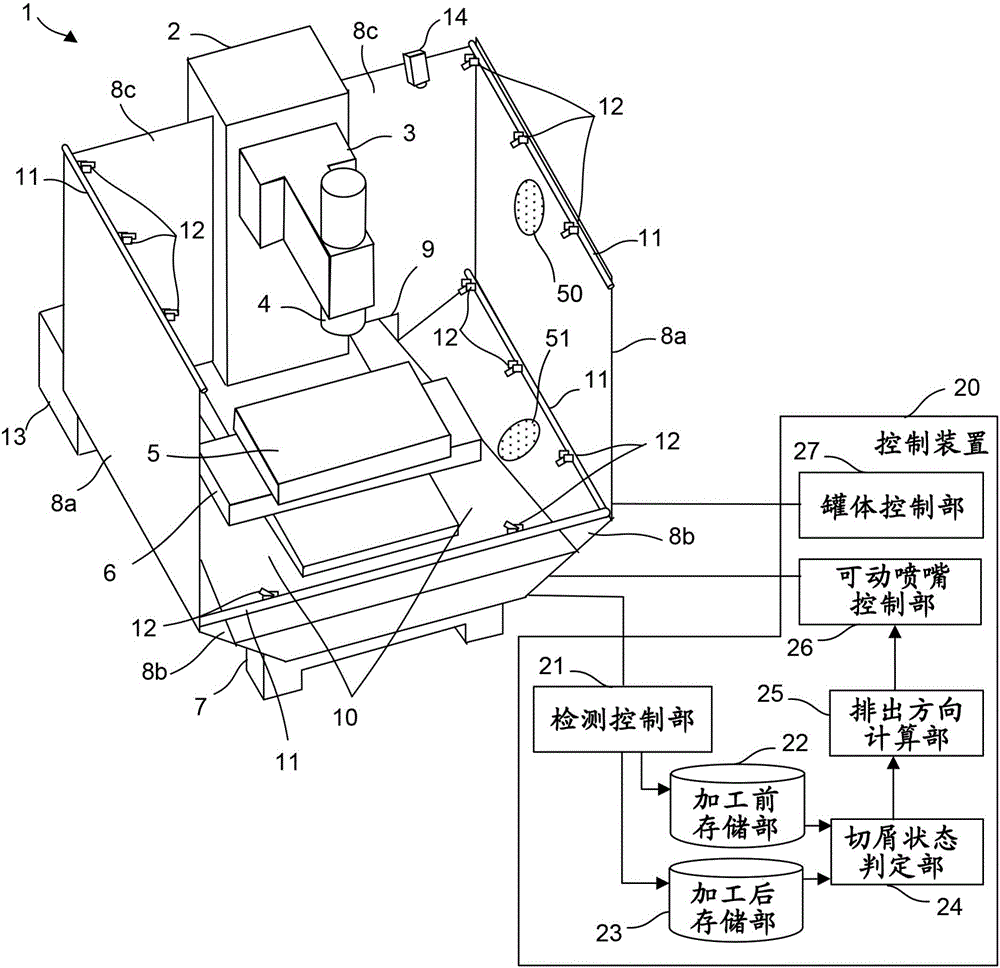

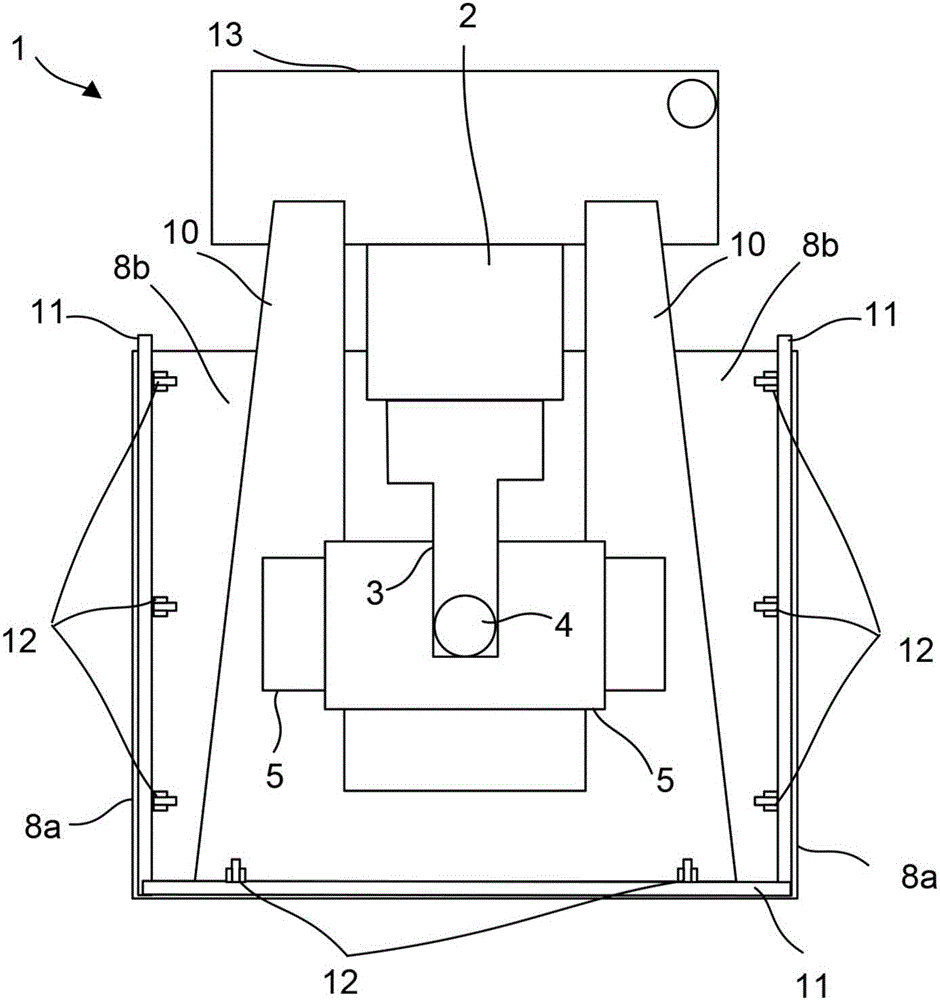

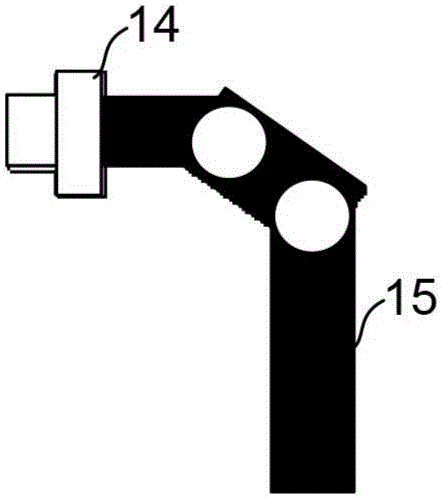

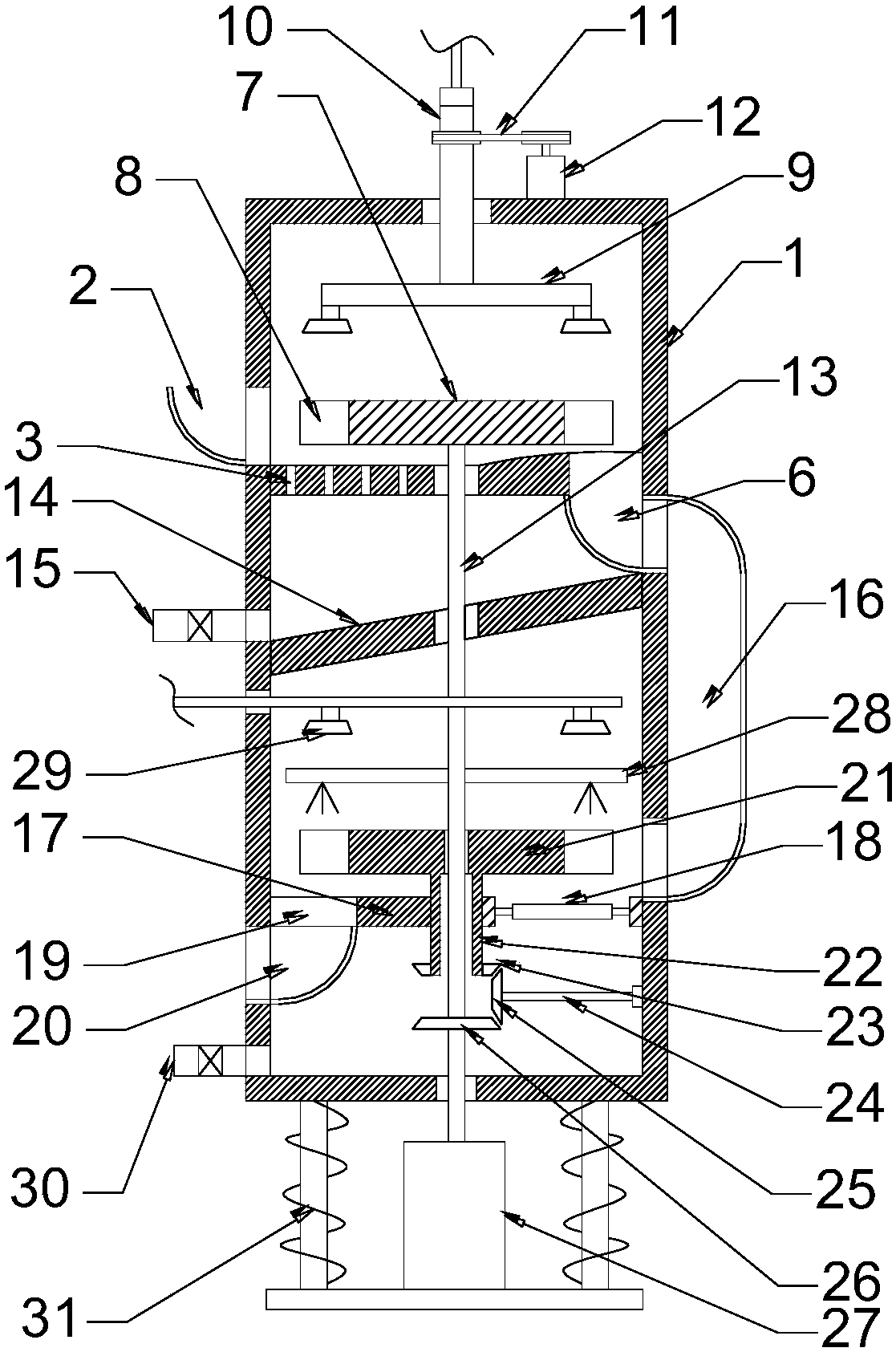

Machine tool

ActiveCN106736825AEffective flushingReduce power consumptionFouling preventionSpraying apparatusMachine toolIndustrial engineering

A machine tool has a cover that prevents chips generated by machining and cutting fluid from scattering around and a plurality of movable nozzles with liquid discharge directions thereof being movable so as to wash out chips that have adhered to or accumulated on an inner surface of the cover. The machine tool is capable of changing a discharge direction of each of the movable nozzles individually. The machine tool compares the state of the inside of the cover before start of machining with the state of the inside of the cover after chips are generated to determine an adhesion or accumulation state of chips. The machine tool thus calculates the liquid discharge direction to wash out chips from the movable nozzles based on a result of the determination.

Owner:FANUC LTD

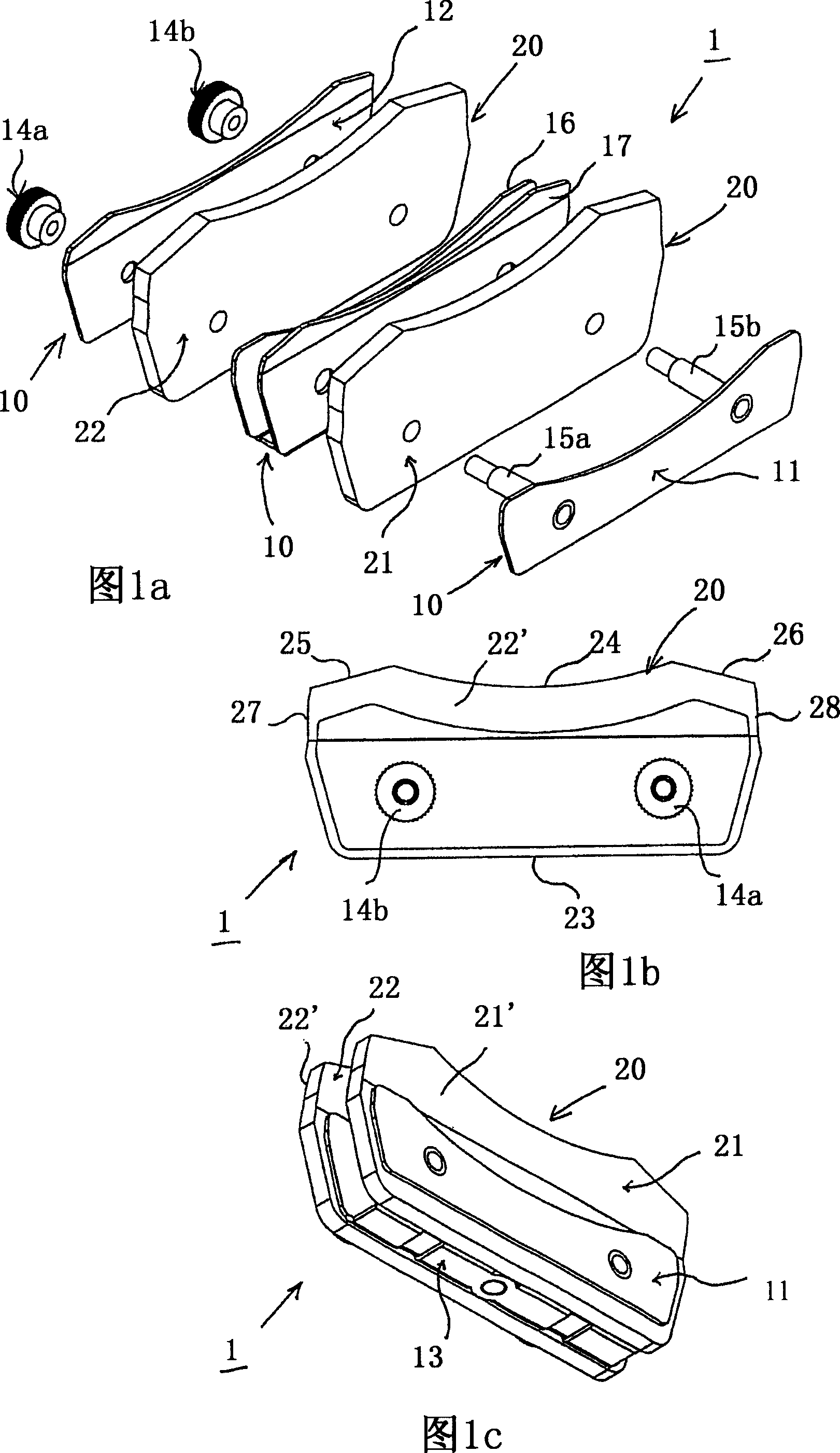

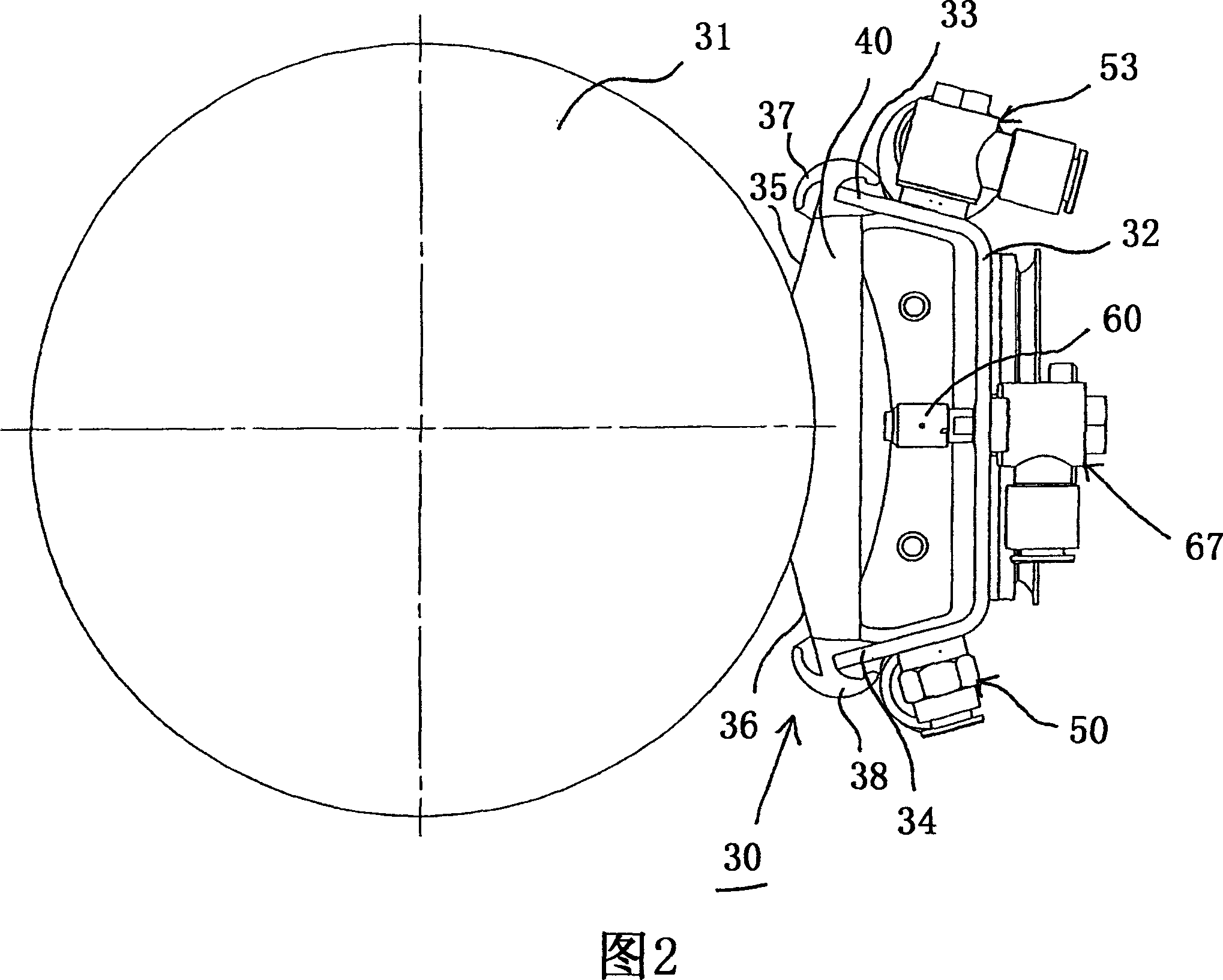

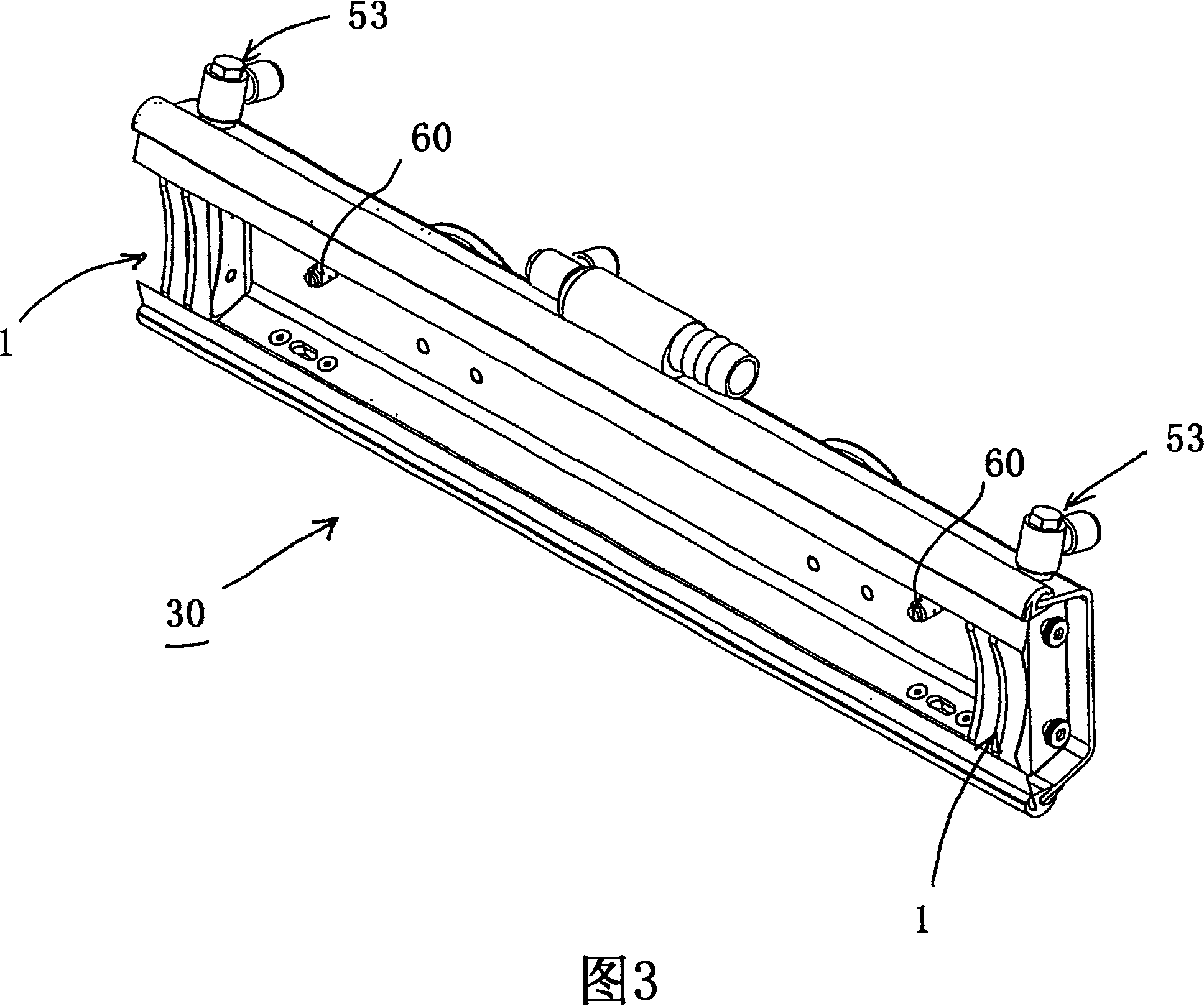

Device and method for chambered doctor blade

InactiveCN1950207AEliminate lossWon't dry outRotary intaglio printing pressPrinting press partsAdhesiveLacquer

Device in a chambered doctor blade for printing units, which chambered doctor blade is arranged for applying ink, lacquer, adhesive or the like to a rotatable cylinder in the printing unit, comprising an elongate frame, which frame is arranged parallel to and outside the cylinder and on which are mounted two parallel, projecting and from each other separated doctor blades, also disposed parallel to the cylinder and arranged in operative position, to be resiliently and wipingly applied against the cylinder, where the doctor blades, when in said operating position, together with the surface of the frame facing the cylinder, the envelope surface of the cylinder together with two sealing means, are arranged to define an elongated chamber containing medium which is intended to be applied on the rotating cylinder, wherein sealing means (20) comprising a first and a second part (21, 22) forming a space there between extending in the axial direction of the cylinder (31) in which an inlet (51) of at least one drainage channel (50) is provided for diverting of to the space leaking medium. The invention further relates to an additional device in a chambered doctor blade (30), and a method for sealing a chambered doctor blade (30).

Owner:AKEBOOSE INT AB

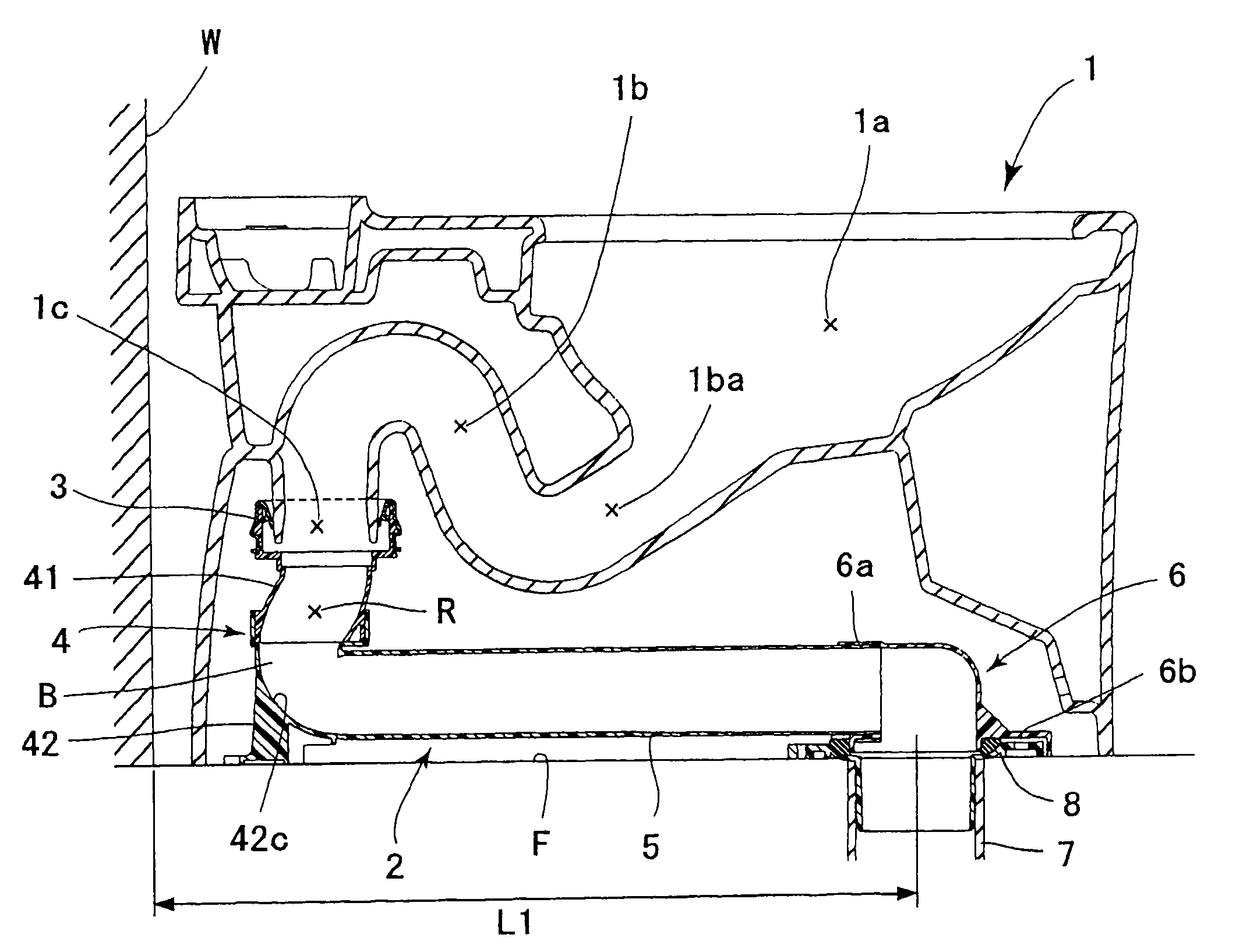

Drain socket

In a drain socket for a toilet stool includes a vertical pipe including an upper end connected with the discharge port of the toilet stool, an adjustable pipe extending substantially horizontally from the lower end of the vertical pipe and a connecting pipe between the adjustable pipe and a drain of a toilet. The vertical pipe has a bend causing the vertical pipe to have at its lower end an axis displaced longitudinally and rearward of the toilet stool from an axis at the upper end to define an eccentrically curved flow path. The flow path includes a part located near the bend and formed by increasing a transverse dimension of a longitudinal front end thereof with respect to the toilet stool so that the part has such a noncircular cross section in which a front portion of the section has a larger area than a rear portion of the cross section.

Owner:LIXIL CORP

Vertical multilayer potato cleaning device

InactiveCN107752063AImprove flushing effectImprove scrubbing effectFood treatmentEngineeringWater spray

The invention discloses a vertical multilayer potato cleaning device. The device comprises a casing, wherein a feeding pipe is arranged at the upper end of the left side of the casing, and a first carrying disc is arranged in the casing and located on the right side of the feeding pipe; a first rotating disc is arranged above the first carrying disc and a rotating water spray pipe is arranged above the first rotating disc; a mud guide plate is arranged below the first carrying disc and an annular water spray pipe is arranged below the mud guide plate; a brush plate is arranged below the annular water spray pipe and a second rotating disc is arranged below the brush plate. Potatoes are rotationally washed by the aid of the rotating discs and the rotating water spray pipe, so that the washing effect is improved. The device can efficiently and thoroughly brush potatoes by the aid of the second carrying disc provided with a freely rotating roller, a reversely rotating second rotating discand the brush plate, so that the brushing effect and efficiency are improved. Automatic discharging is realized by the aid of the rotating discs and a discharging channel, and the washing efficiency is improved.

Owner:李小春

Garbage drum screen with self-cleaning function and cleaning device thereof

InactiveCN104889058AWith self-cleaning functionImprove flushing efficiencySievingScreeningEngineeringHigh pressure

The invention relates to the garbage sorting equipment design, in particular to a garbage drum screen with a self-cleaning function and a cleaning device of the garbage drum screen. The cleaning device of the garbage drum screen comprises an air compressor, a first branch pipe and a control device, wherein the air compressor is used for pressurizing gas which flows through the air compressor, and therefore high-pressure gas can be formed; the inlet end of the first branch pipe is communicated with the outlet end of the air compressor, the outlet end of the first branch pipe penetrates through a shell of the garbage drum screen to stretch into the garbage drum screen, and the first branch pipe is used for spraying the high-pressure gas flowing out of the air compressor to screen meshes of a screen plate of the garbage drum screen; the control device is used for controlling connection and disconnection of the first branch pipe. According to the cleaning device of the garbage drum screen, the high-pressure gas which is compressed through the air compressor is guided into the garbage drum screen through the first branch pipe, and therefore the screen meshes of the screen plate can be flushed and smoothened; in addition, the flushing time of the first branch pipe can be selected through the control device, and therefore the flushing efficiency can be higher, and resources are saved.

Owner:HUNAN VARY TECH

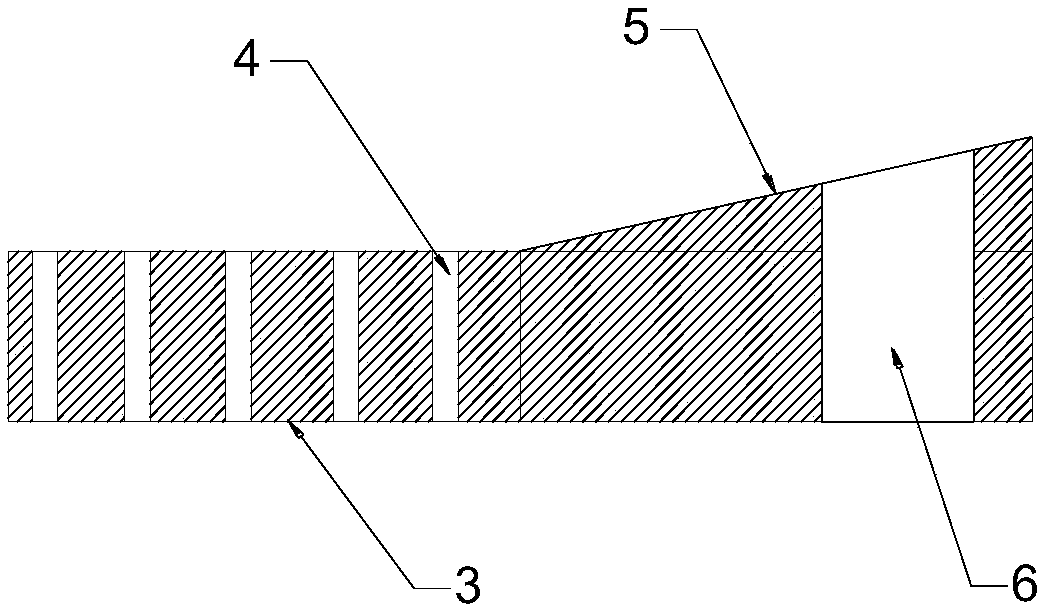

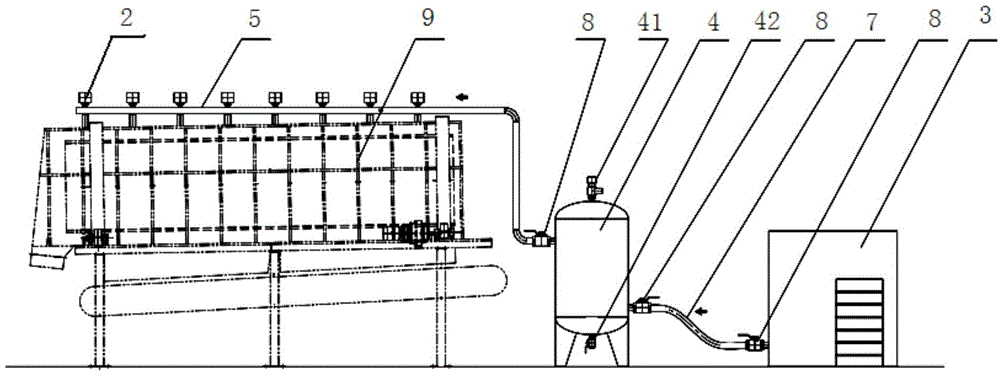

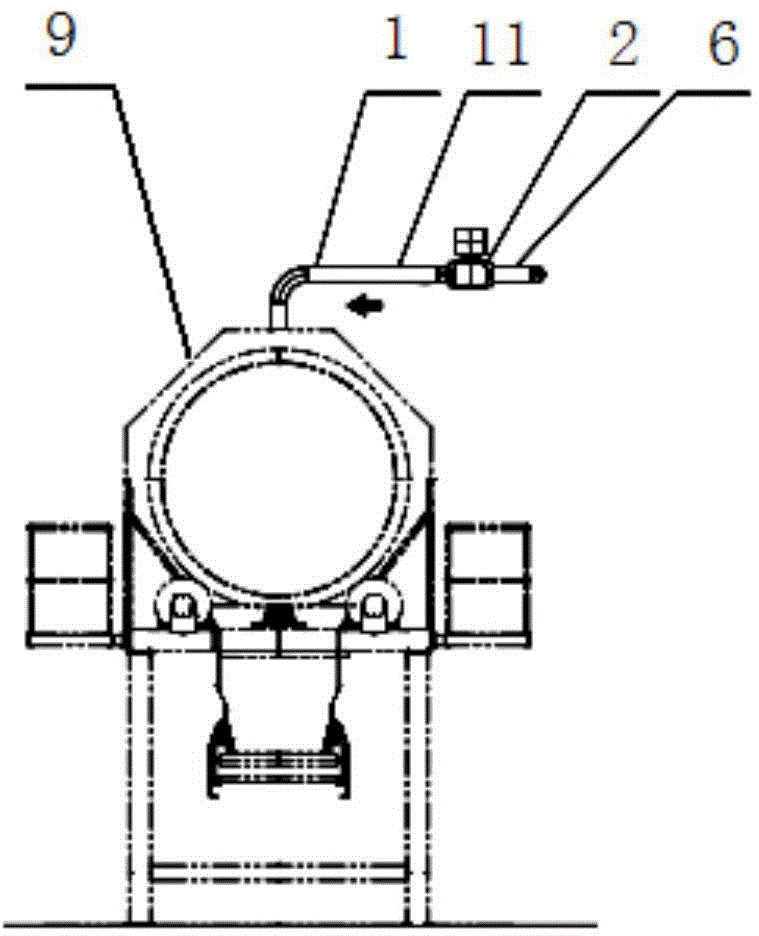

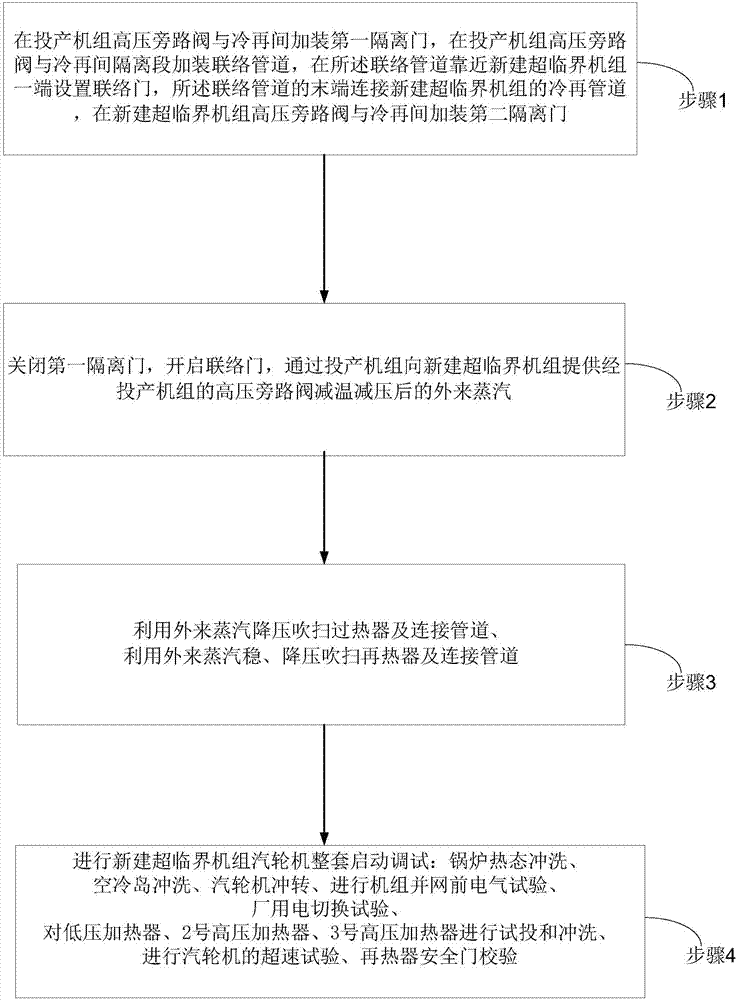

Method and system utilizing external steam for start debugging of new-built supercritical unit

InactiveCN107120149AReduce startImprove efficiencyEngine startersSteam engine plantsSuperheaterEngineering

The invention discloses a method and a system utilizing external steam for start debugging of a new-built supercritical unit. The method comprises steps as follows: a first isolation gate is additionally mounted between a high-pressure bypass valve I and a reheat cooling section I of a production unit, a communication pipeline is additionally mounted at an isolation section between the high-pressure bypass valve I and the reheat cooling section I of the production unit, a communication gate is arranged on the communication pipeline, and a second isolation gate is additionally mounted between a high-pressure bypass valve II and a reheat cooling section II of the new-built supercritical unit; the first isolation gate is closed, the communication gate is opened, and external steam after temperature and pressure reduction is supplied to the new-built supercritical unit by the high-pressure bypass valve I of production unit; a superheater and a connecting pipeline are purged under the reduced pressure by means of the external steam, and a reheater and a connecting pipeline are purged under stable pressure and reduced pressure by means of the external steam; overall start debugging of a turbine of the new-built supercritical unit is performed. Under the condition that a boiler of the new-built unit is not ignited, steam purging of the units and overall start debugging work of the no-load test operation stage are completed by the aid of the external steam provided by the production unit, so that the ignition times of the boiler in the supercritical unit and time of operation in a non-economic area are reduced.

Owner:SHANDONG ZHONGSHI YITONG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com