Method and system utilizing external steam for start debugging of new-built supercritical unit

A supercritical unit and external steam technology, which is applied to steam engine installations, engine starting, engine components, etc., can solve problems such as inability to flexibly adjust steam parameters, inability to meet trial operation conditions, and repeated start and stop of equipment, reducing the need for The effect of solid particle erosion, avoiding dry burning and overheating, and avoiding coordination difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

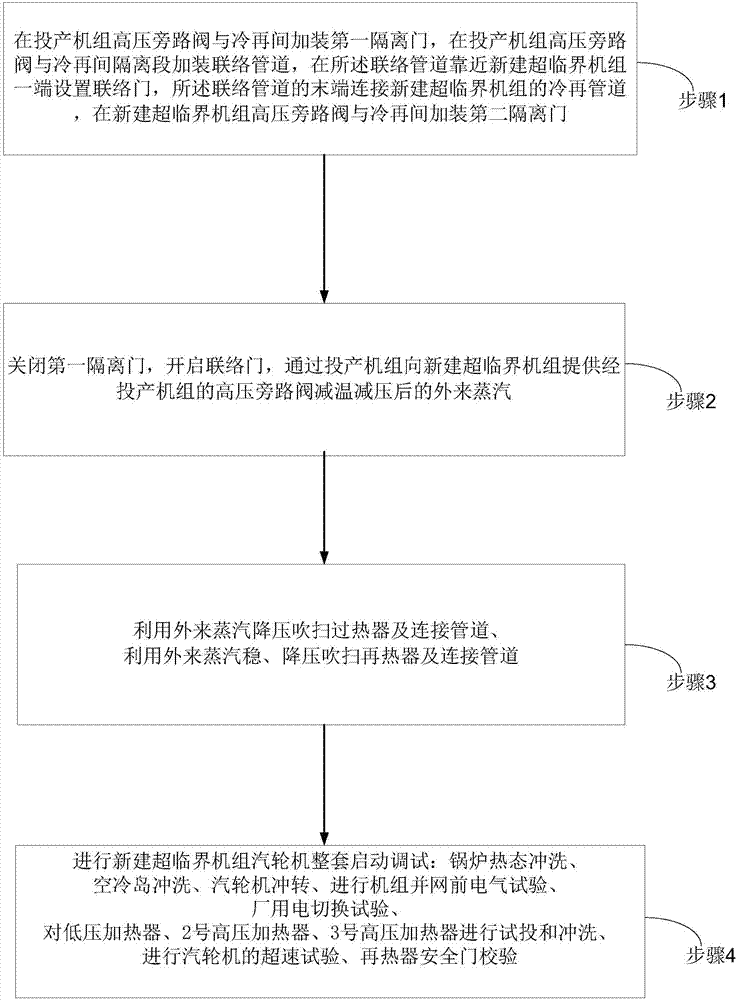

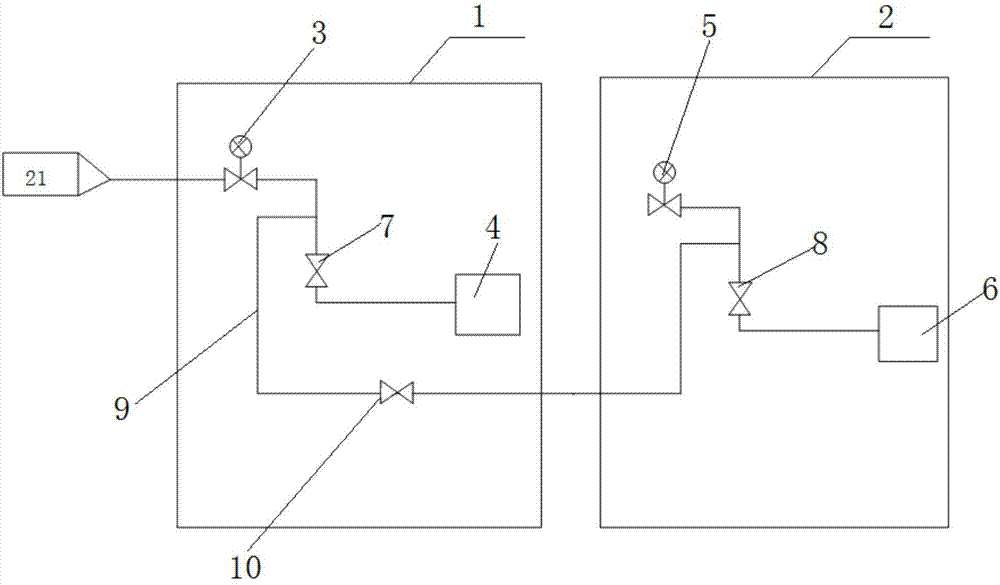

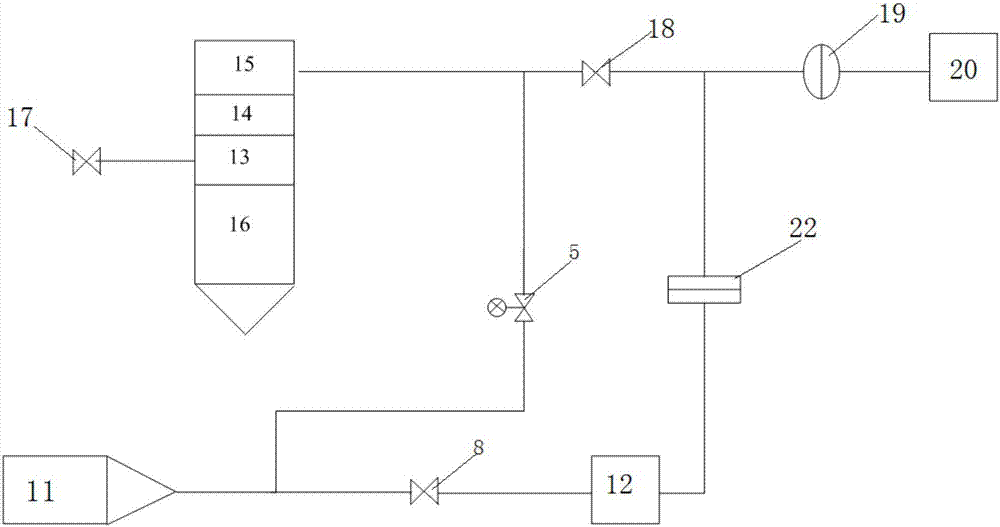

[0061] The present invention will be further described below in conjunction with the accompanying drawings.

[0062] This embodiment provides a system for using external steam to start and debug a newly built supercritical unit, including an external steam supply system and a newly built supercritical unit blowpipe system, wherein, such as figure 2 As shown, the external steam supply system is used to provide external steam to the newly built supercritical unit, including the commissioned unit 1 and the newly built supercritical unit 2, the commissioned unit includes the commissioned unit high pressure bypass valve 3 and the commissioned unit cold reheating unit 4, the newly built The supercritical unit includes the newly-built supercritical unit high-pressure bypass valve 5 and the newly-built supercritical unit cold reheater 6; The first isolation door 7 is set on the top, so that when the steam is supplied through the high-pressure bypass valve of the production unit, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com