Pneumatic Control For A Vacuum Toilet

A vacuum, toilet technology, applied in water supply installations, electrical components, flushing equipment with water tanks, etc., can solve problems such as wrong control, use no longer feasible, and interference of vacuum toilet flushing control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

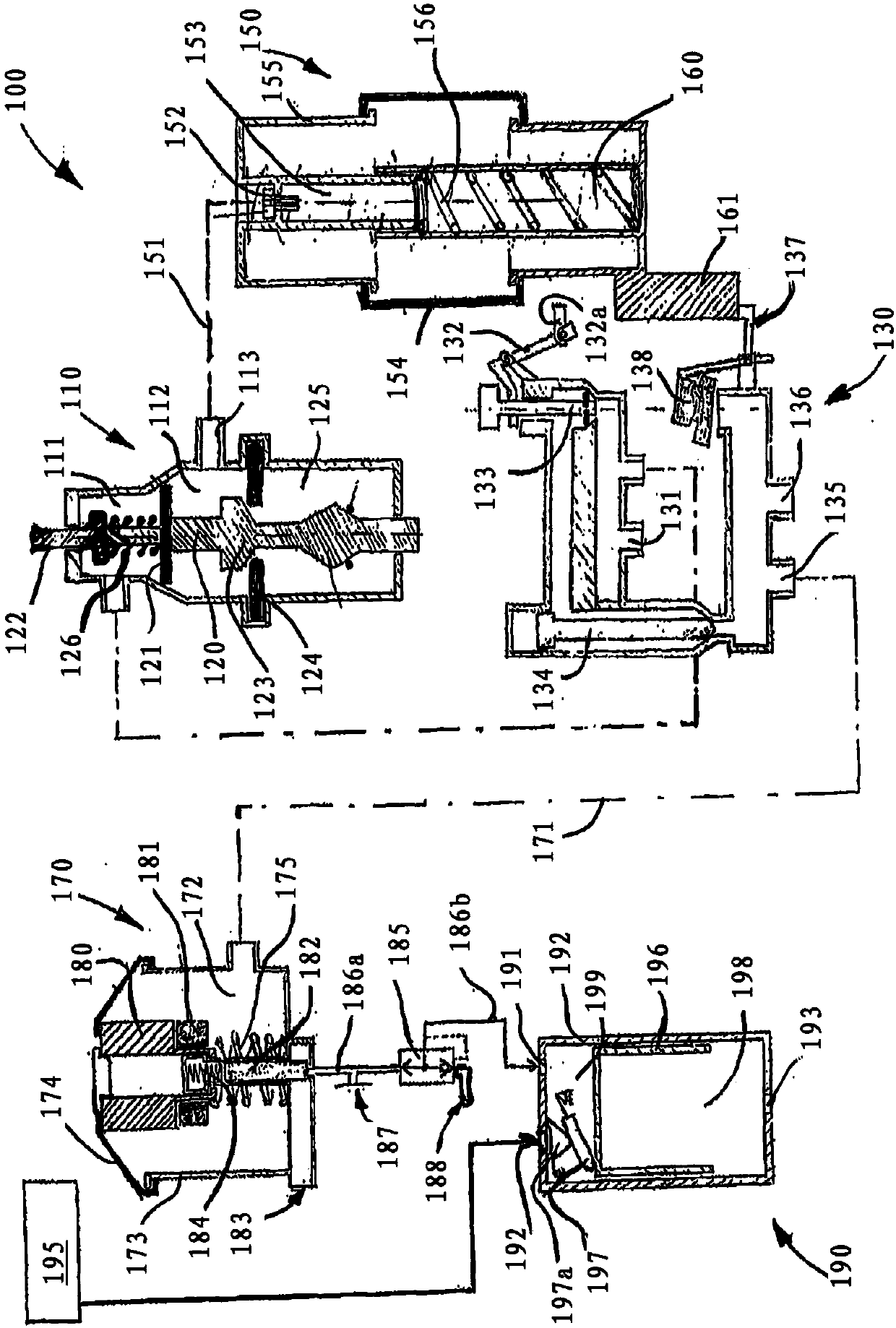

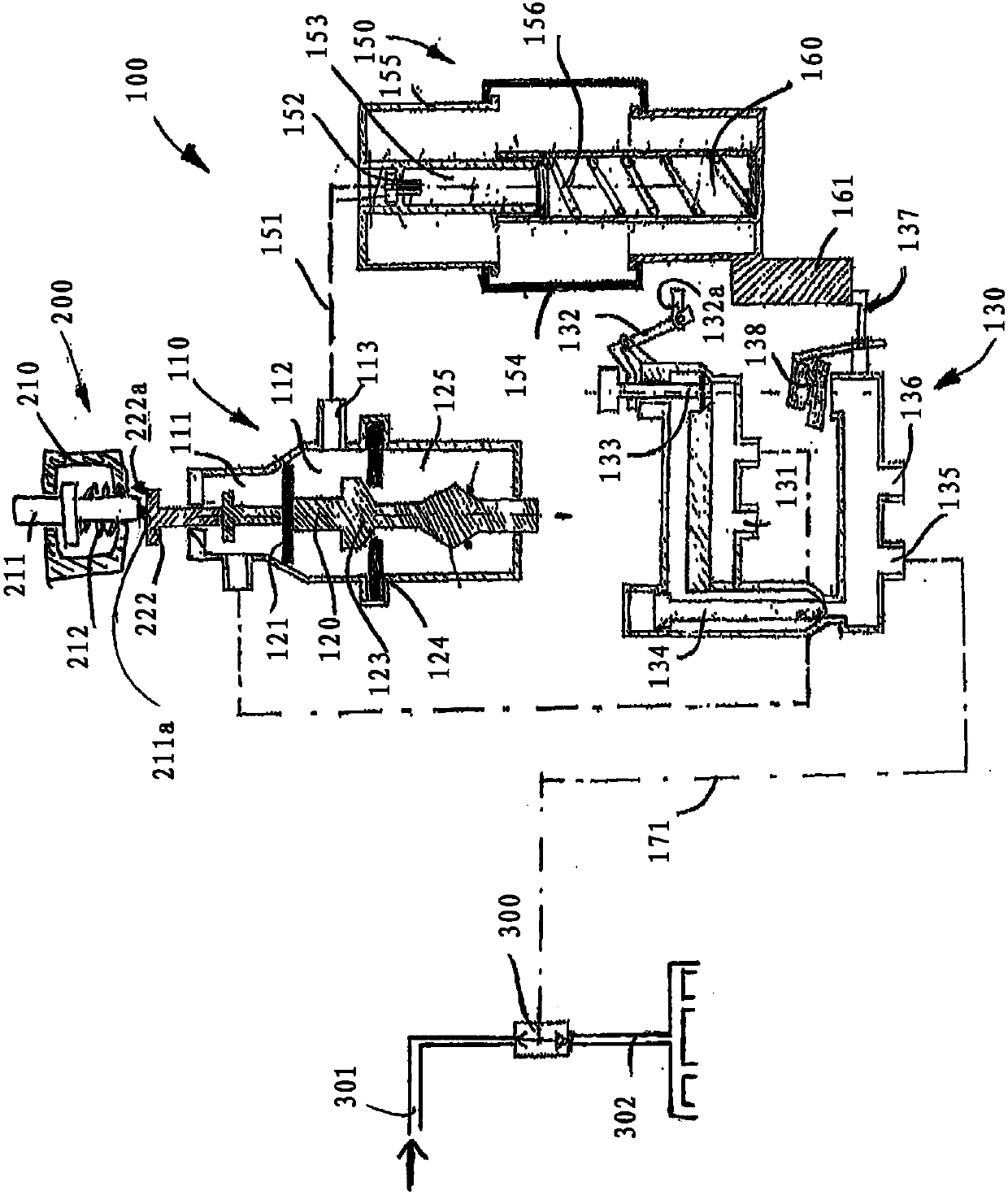

[0055] The drawing shows a control unit 100 comprising an actuating unit 110 , a distribution valve unit 130 and an actuating coupling unit 150 . Furthermore, the flushing control device 170 is a component of the illustrated embodiment of the control device according to the invention. The flushing control device 170 controls the flushing water unit 190 .

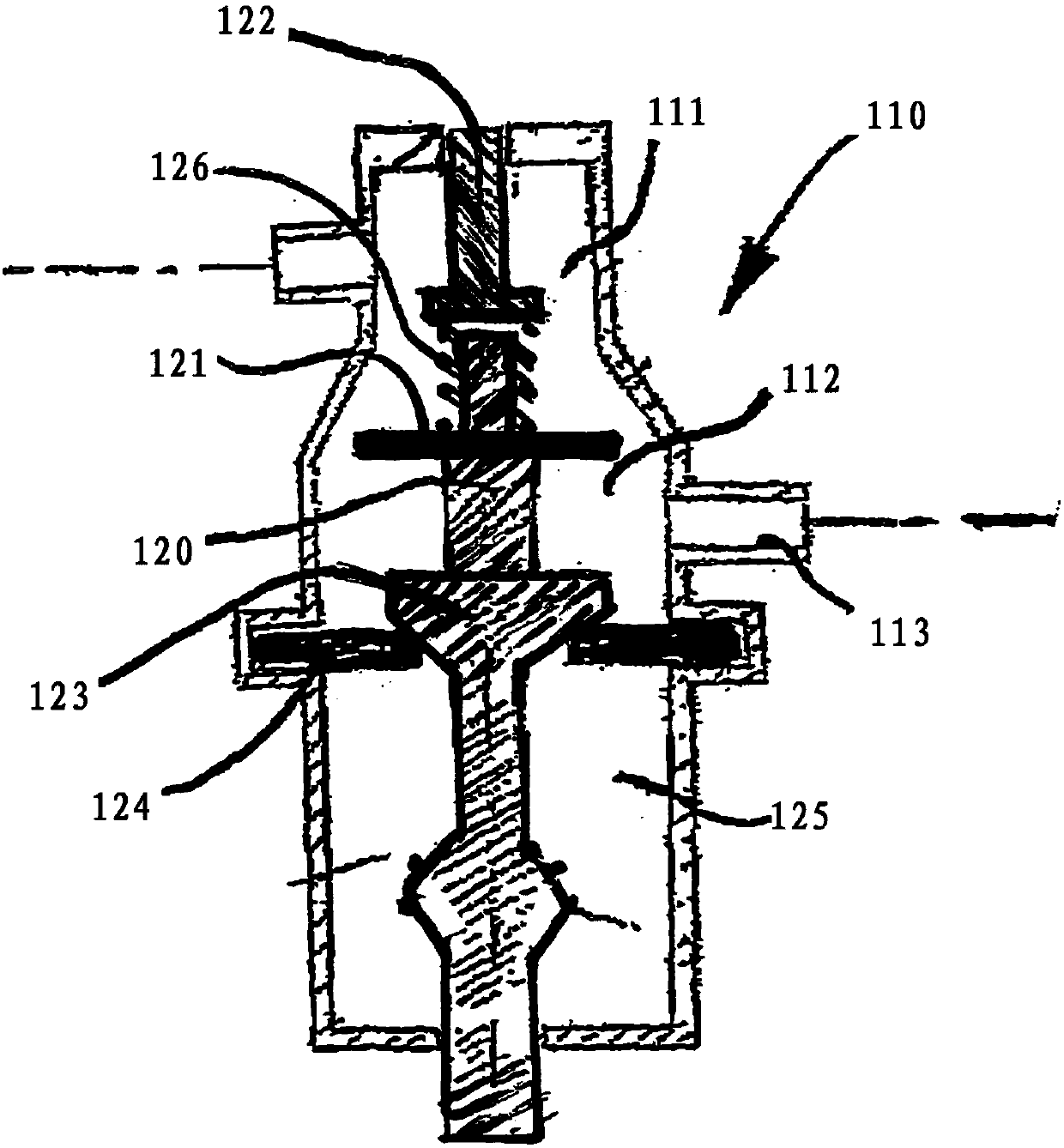

[0056] The power supply of the control device according to the invention takes place via a vacuum connection 131 at the distribution valve unit 130 . The vacuum connection 131 is permanently connected to the negative pressure chamber 111 of the operating unit 110 via the distribution valve unit. The vacuum chamber 111 is sealed from the intermediate chamber 112 of the actuating unit by a sealing element 121 which is arranged on the plunger 120 .

[0057] The punch carries at its upper end a button 122 which can be pressed by the user. By actuating this button, the seal between the negative pressure chamber 111 and the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com