Solid-free anti-salt cleaning type well cementation spacer fluid and preparation method thereof

A clean, solid-free technology, applied in the field of oil drilling, which can solve the problems of influence, increased fluid friction in the mixing section, and increased pump pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

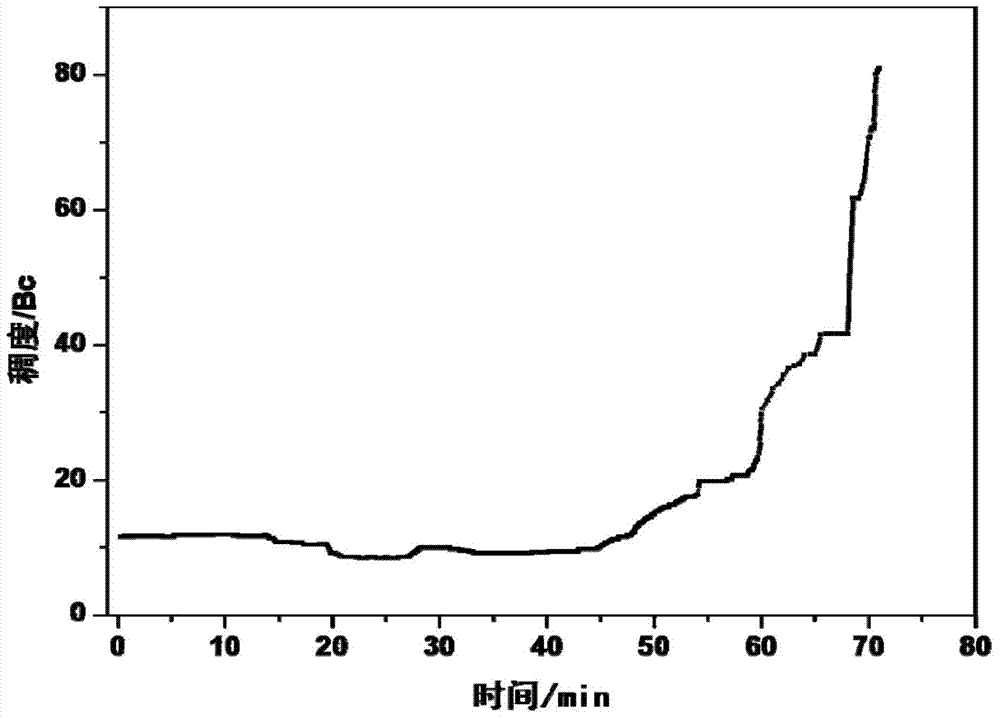

Embodiment 1

[0036] Add 53 parts by weight of sodium formate to 100 parts by weight of clear water, stir to dissolve, add 0.75 parts by weight of disodium edetate, stir and dissolve; add 0.4 parts by weight of xanthan gum and 3 parts by weight of 2-acrylamide-2- Methylpropanesulfonic acid fluid loss reducer; after dissolving, add 6 parts by weight of OP-10 and 2 parts by weight of sodium dodecylbenzenesulfonate, stir for 55-65 minutes, then add 0.2 parts by weight of sodium hydroxide, and finally Add 0.1 parts by weight of tributyl ester, and stir evenly to obtain the solid-phase-free, salt-resistant, clean cementing spacer fluid.

Embodiment 2

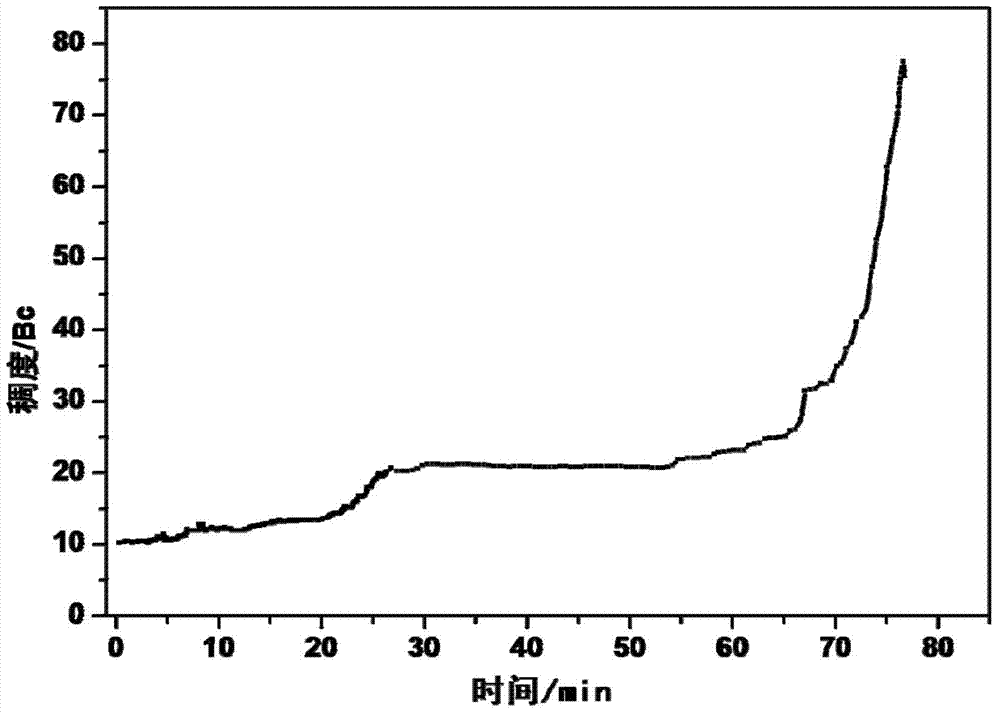

[0038] Add 183 parts by weight of sodium formate and potassium formate to 100 parts by weight of clear water, wherein the mass ratio of sodium formate and potassium formate is 8:2, add 0.9 parts by weight of auxiliary agent disodium edetate after stirring and dissolving; add 0.2 Parts by weight of xanthan gum and 1 part by weight of sulfonated lignite; after dissolving, add 7.5 parts by weight of Tween-80 and 1.5 parts of sodium dodecylsulfonate, stir for 50 to 65 minutes, and then add 0.1 part by weight of potassium hydroxide, Finally, add 0.1 parts by weight of tributyl phosphate and stir evenly to obtain a density of 1.45g / cm 3 Solid-free salt-free cleaning cementing spacer fluid.

Embodiment 3

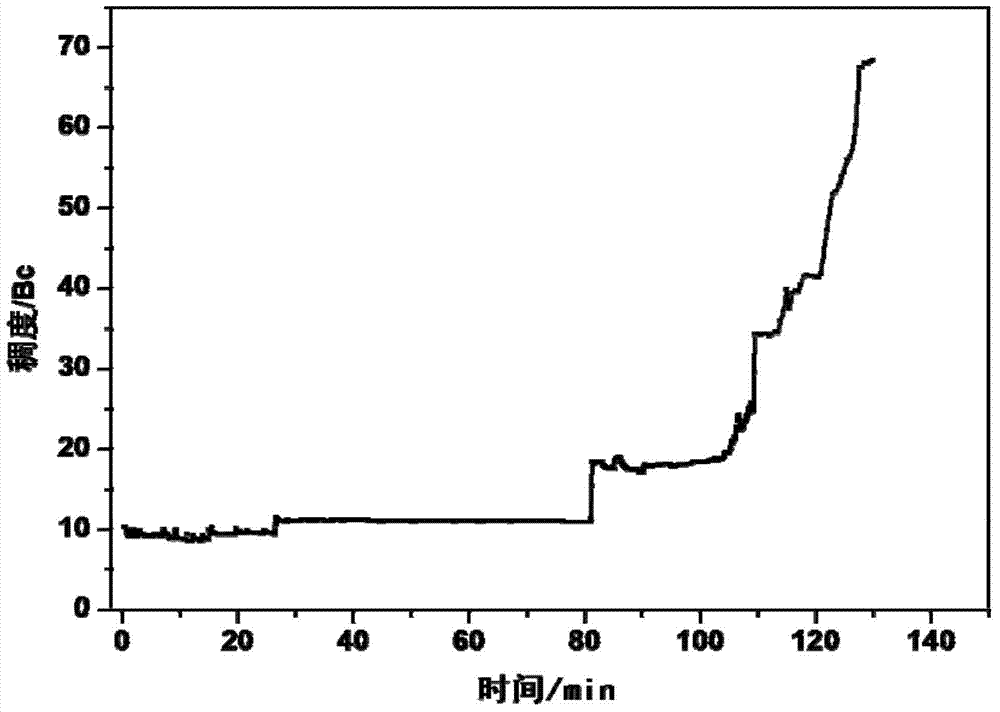

[0040] Add 350 parts by weight of a mixture of sodium formate and potassium acetate to 100 parts by weight of clear water, wherein the mass ratio of sodium formate and potassium acetate is 2:8; stir and dissolve and add 0.5 parts by weight of auxiliary agent sodium edetate, stir and dissolve; add 0.3 parts by weight of high-viscosity polyanionic cellulose and 3 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid fluid loss reducer; after dissolving, add 8 parts by weight of Tween 40 and 2.5 parts by weight of dodecylbenzene Sodium sulfonate, stirred for 55-65 minutes, then added 0.1 parts by weight of sodium hydroxide, and finally added 0.1 parts by weight of tributyl phosphate, stirred evenly to obtain a density of 1.60 g / cm 3 The solid-free anti-salt cleaning type cementing spacer fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com