Washing method of cooking equipment

A technology of cooking equipment and crushing chamber, which is applied in beverage preparation devices, household utensils, applications, etc., can solve the problems of wasting water and poor cleaning effect, and achieve the effect of small cleaning area, water saving and large cleaning area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

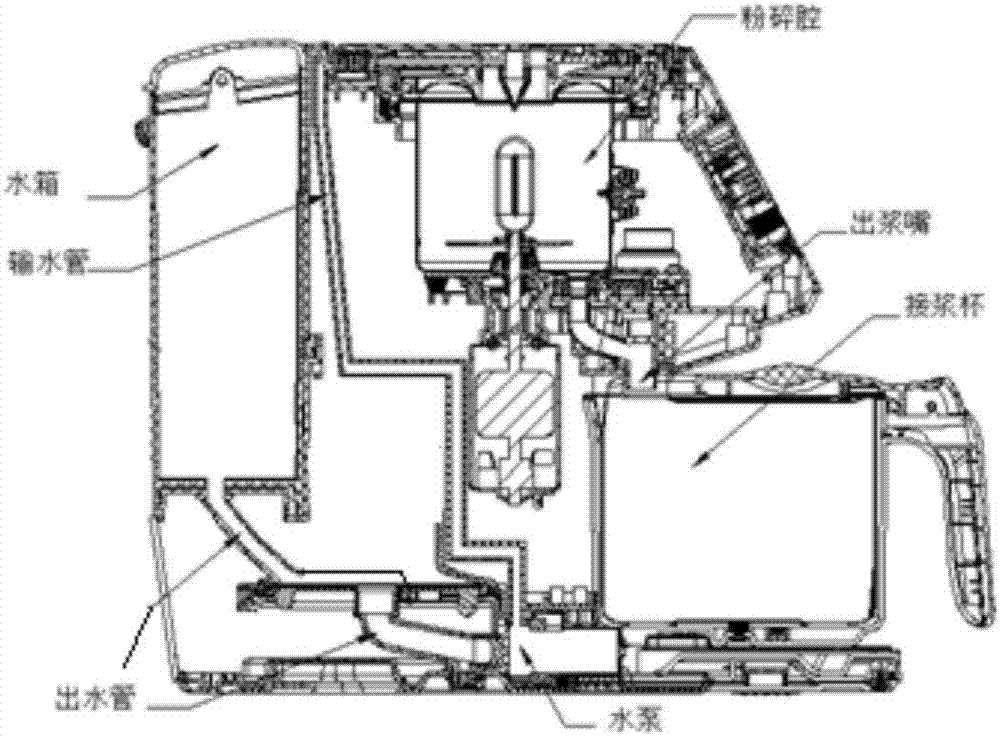

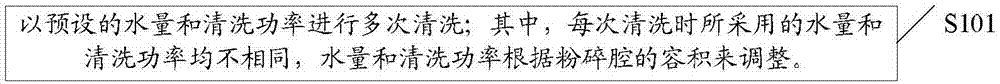

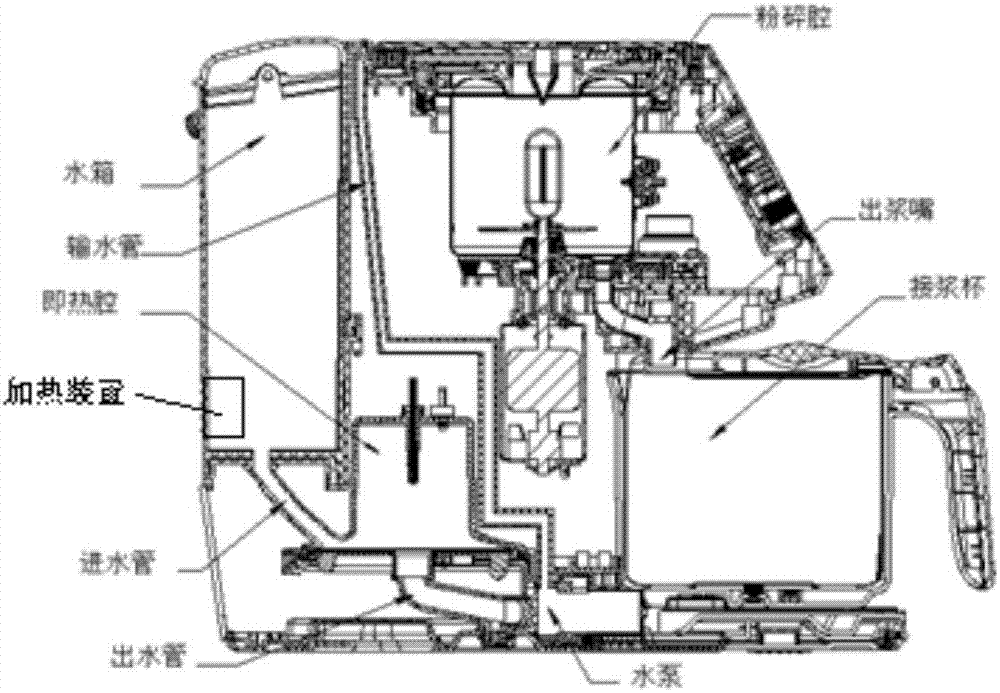

[0033] A cleaning method for cooking equipment, such as figure 1 As shown, the cooking equipment may include: a grinding chamber, a water tank, a water pump, a water outlet pipe connecting the water tank and the water pump, and a water delivery pipe connecting the grinding chamber and the water pump. The water pipe is sent to the crushing chamber to clean the crushing chamber, such as figure 2 As shown, the specific cleaning scheme may include S101: Perform multiple cleanings with a preset water volume and cleaning power; wherein, the water volume and cleaning power used for each cleaning are different, and the water volume and cleaning power are determined according to the volume of the crushing chamber. Adjustment.

[0034] In the embodiment of the present invention, the cooking equipment may include a soybean milk machine, such as figure 1 In the schematic diagram of the structural embodiment shown, the water pump extracts the water in the water tank through the water ou...

Embodiment 2

[0052] The difference between Embodiment 2 and the apparatus in Embodiment 2 is that the amount of water and cleaning power are adjusted according to the volume of the slurry during the last pulverization.

[0053] Optionally, the method further includes: adjusting the amount of water and cleaning power according to the volume of the slurry during the last pulverization.

[0054] In the embodiment of the present invention, if the amount of water and the cleaning power are adjusted according to the volume of the slurry during the last pulverization, the amount of water and the cleaning power can be determined according to the volume of the slurry. Because the change of the volume of the slurry causes the change of the cleaning area, the volume of the slurry is large. The cleaning area is large, and the cleaning area is small if the slurry volume is small. This scheme can predict the actual cleaning area according to the actual slurry volume, and configure the water volume and cl...

Embodiment 3

[0058] Embodiment 3 is a specific embodiment of Embodiment 1 and Embodiment 2.

[0059] Optionally, the volume V of the grinding chamber may include: 500-2000ml; the rated power P of the motor of the cooking device may include: 10000-20000 rpm.

[0060] Optionally, V=800ml, P=15000 rpm, a=1 / 4, b=1 / 2, c=1 / 3, d=1 / 2.

[0061] In the embodiment of the present invention, the first water injection volume satisfies V1=1 / 4V=200ml, the second water injection volume V2 satisfies V2=1 / 2V=400ml, P1 is 1 / 3P=5000 rpm, and P2 is 1 / 2P=7500 rpm, too little water can not clean the edge of the crushing cup in place, first inject 200ml of water, stir with 5000 rpm motor power, basically can make the water stir to the upper edge of the crushing cup, clean to Most of the crushing cup remains; inject 400ml of water for the second time, and at the same time increase the motor power to 7500 rpm, which can increase the washing water to all parts of the crushing chamber to ensure the washing of the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com