Sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine and barrel-cleaning control method thereof

A technology for a mildew-proof cleaning bucket and a control method, which is applied to the control device of a washing machine, other washing machines, washing machines with containers, etc., can solve the problems of insufficient cleaning ability of the upper half of the inner and outer buckets, and the chemical sterilization effect of ozone water is not utilized. Achieve the effect of quickly and effectively killing bacteria and viruses, reasonable program settings, and less water and electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

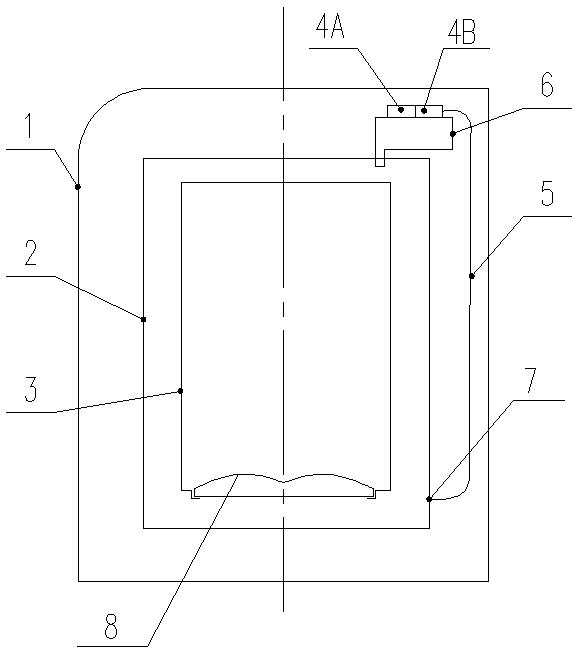

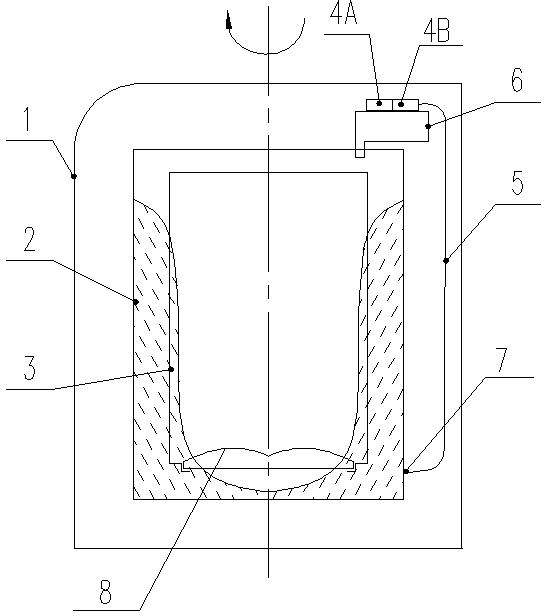

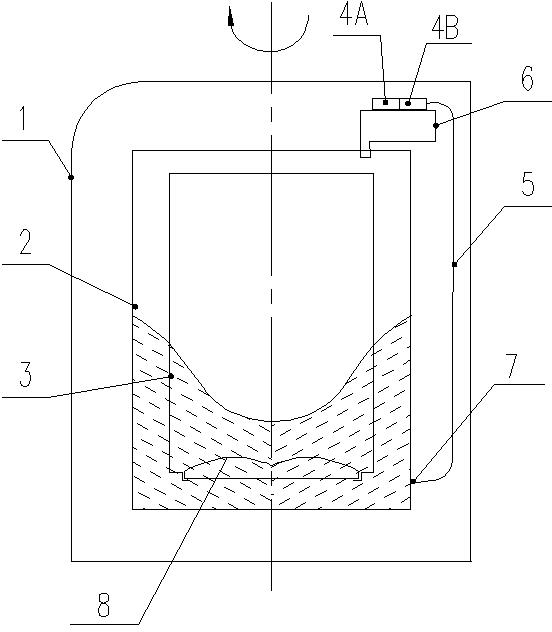

[0041] Such as figure 1 As shown, the sterilization, disinfection, and mildew-proof cleaning tub washing machine of the present invention includes a housing 1. The housing 1 is provided with an outer water storage barrel 2, and the outer barrel 2 is provided with a washing inner barrel 3, and the housing 1 is provided with a water inlet box 6 , Drain valve, clutch, the program controller used to control the working state of the washing machine and the power supply part, the water inlet box 6 is equipped with an inlet valve, and the program controller has a built-in time controller (program controller and its time controller, power supply part, drain valve , The clutch and the water inlet valve are prior art, not shown), the bottom of the inner barrel 3 is provided with a pulsator 8. An ozone generating device is installed on the water inlet box 6, and the outlet end of the ozone generating device is communicated with the bottom of the side wall of the outer barrel 2 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com