Process and device for simulated moving bed separation with a reduced number of large diameter valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

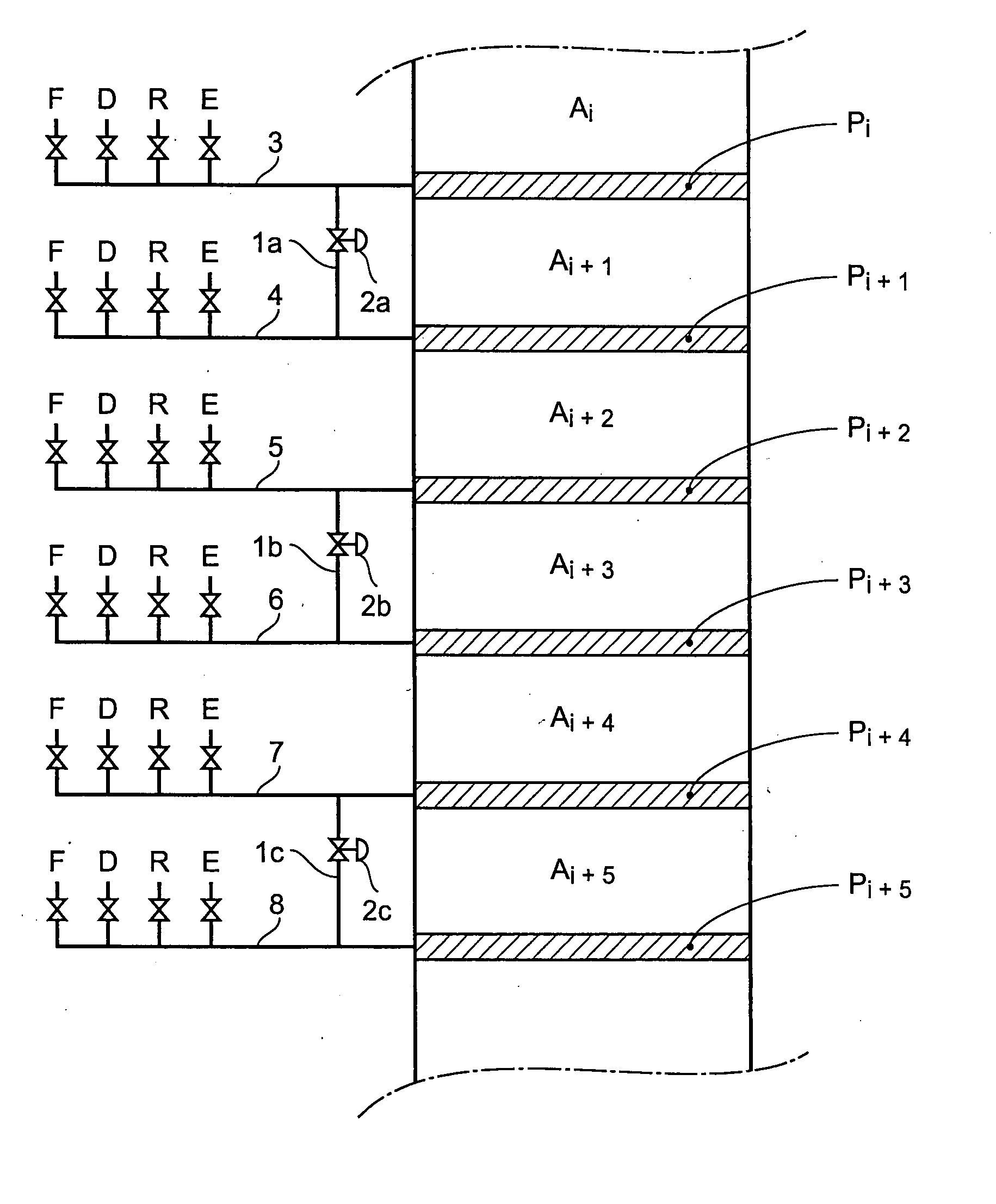

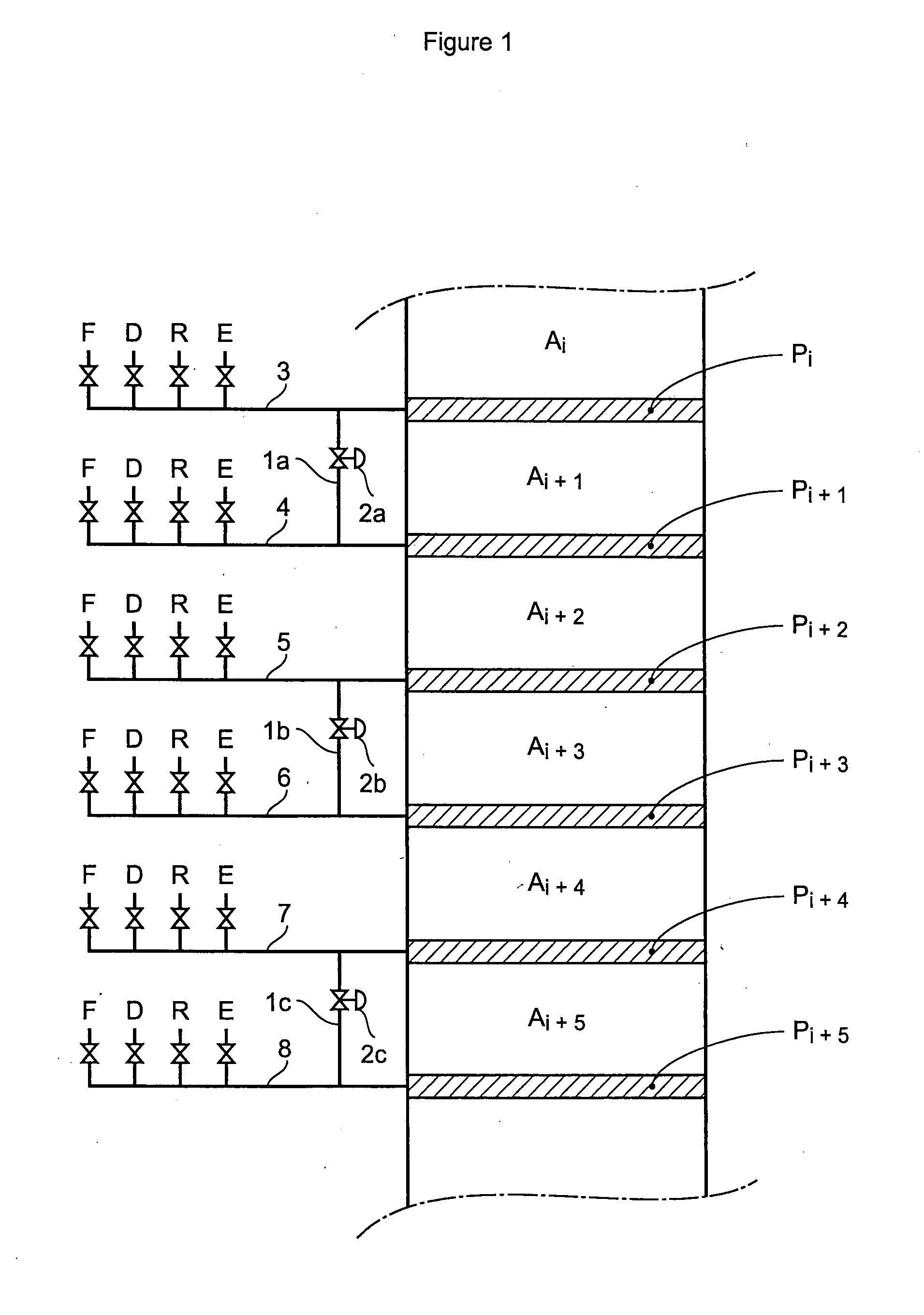

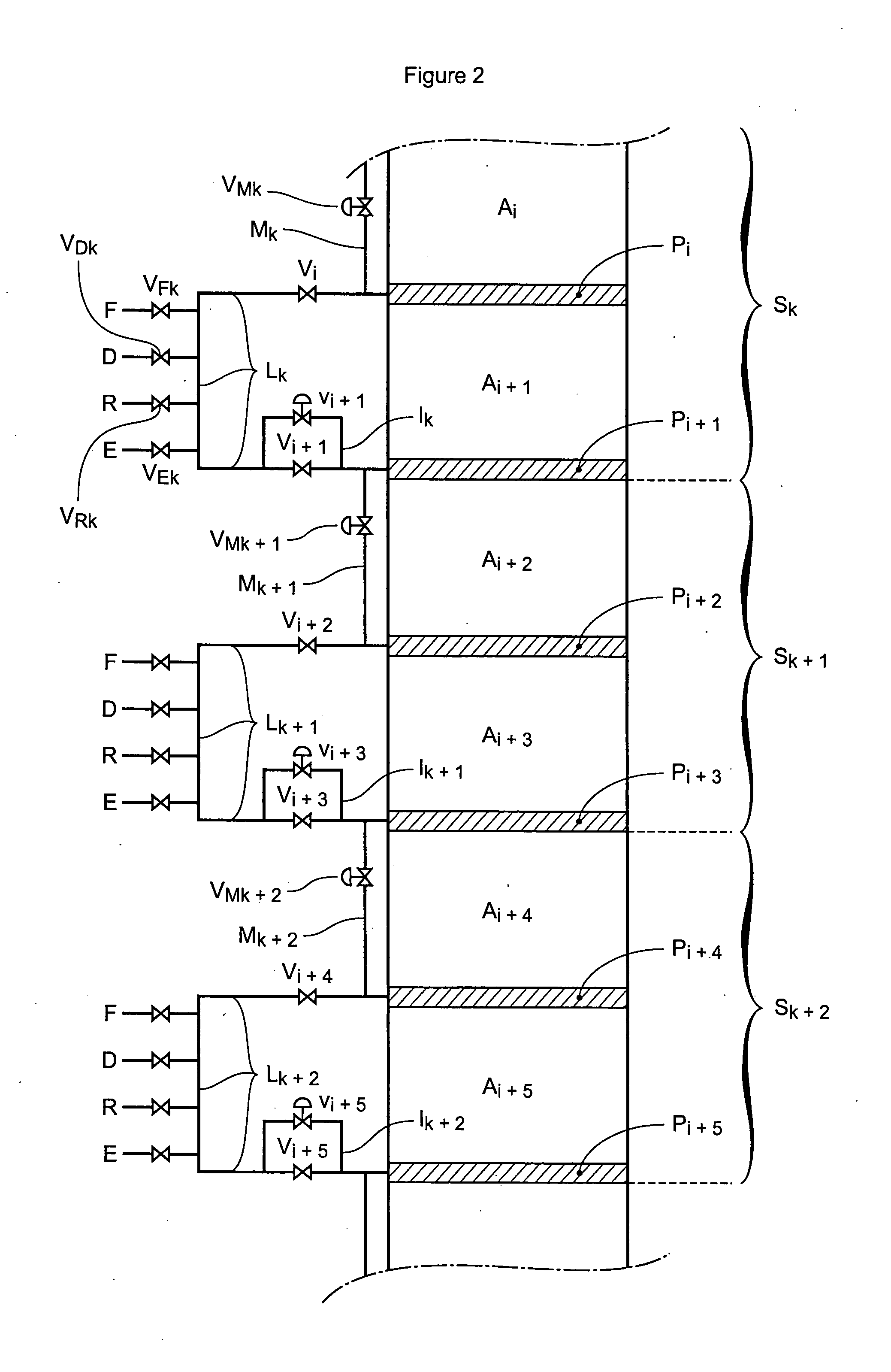

[0043]The invention will be better understood from the following description made with reference to FIG. 1 (prior art) and FIGS. 2 and 3 (device of the invention).

[0044]To accomplish one of the aims cited above, the invention thus proposes a device which can separate at least one compound from a mixture comprising said compound by simulated moving bed adsorption, comprising:

[0045]at least one column comprising a plurality of adsorbant beds Ai separated by distributor / extractor plates Pi for sequential supply and extraction of at least two supply fluids: a feed F and a desorbant D, and at least two withdrawal fluids: a raffinate R and an extract E, Pi being disposed between the bed Ai and the immediately lower bed Ai+1;

[0046]the device also comprising at least one feed network F-Net, a desorbant network D-Net, a raffinate network R-Net and an extract network E-Net, each of said networks being connected to the column via a plurality of lines comprising controlled two-way isolating val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com