Machine tool

A machine tool and chip technology, applied in the field of machine tools with movable nozzles, can solve the problems of control, inability to flush chips, and inability to change nozzle orientation, etc., to achieve efficient flushing and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

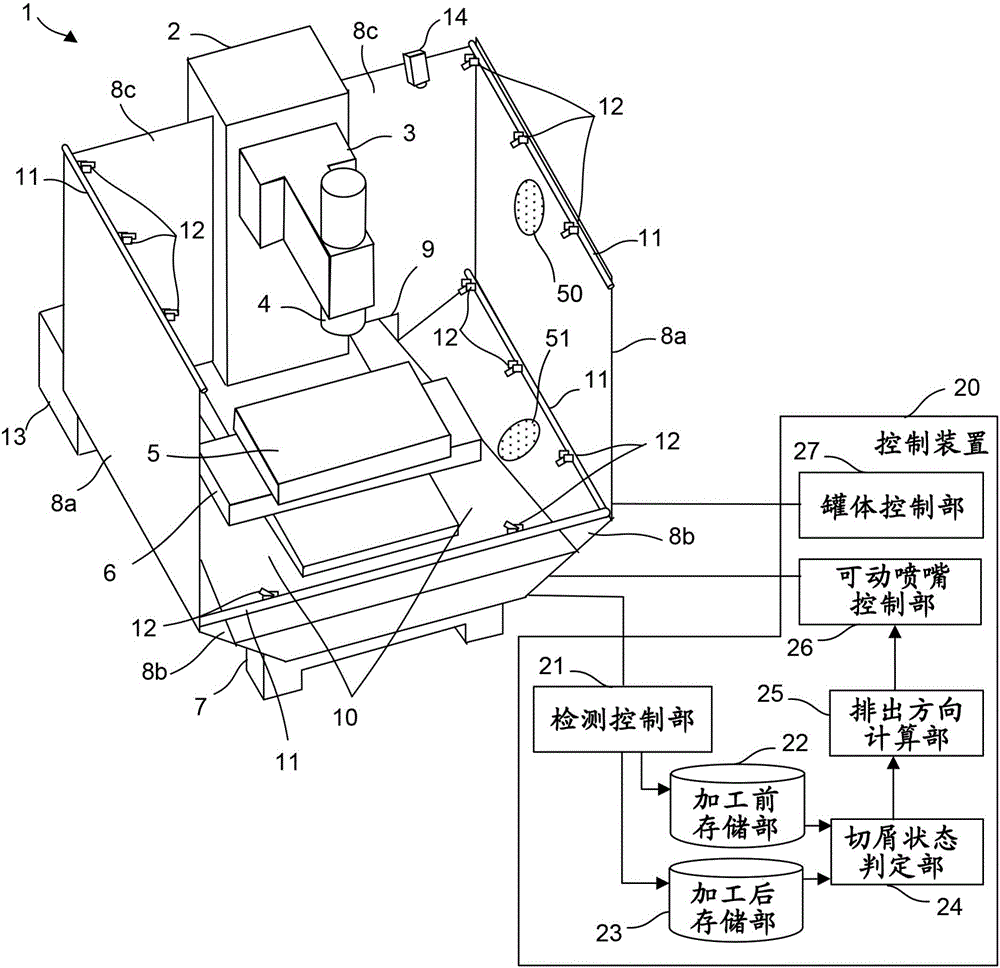

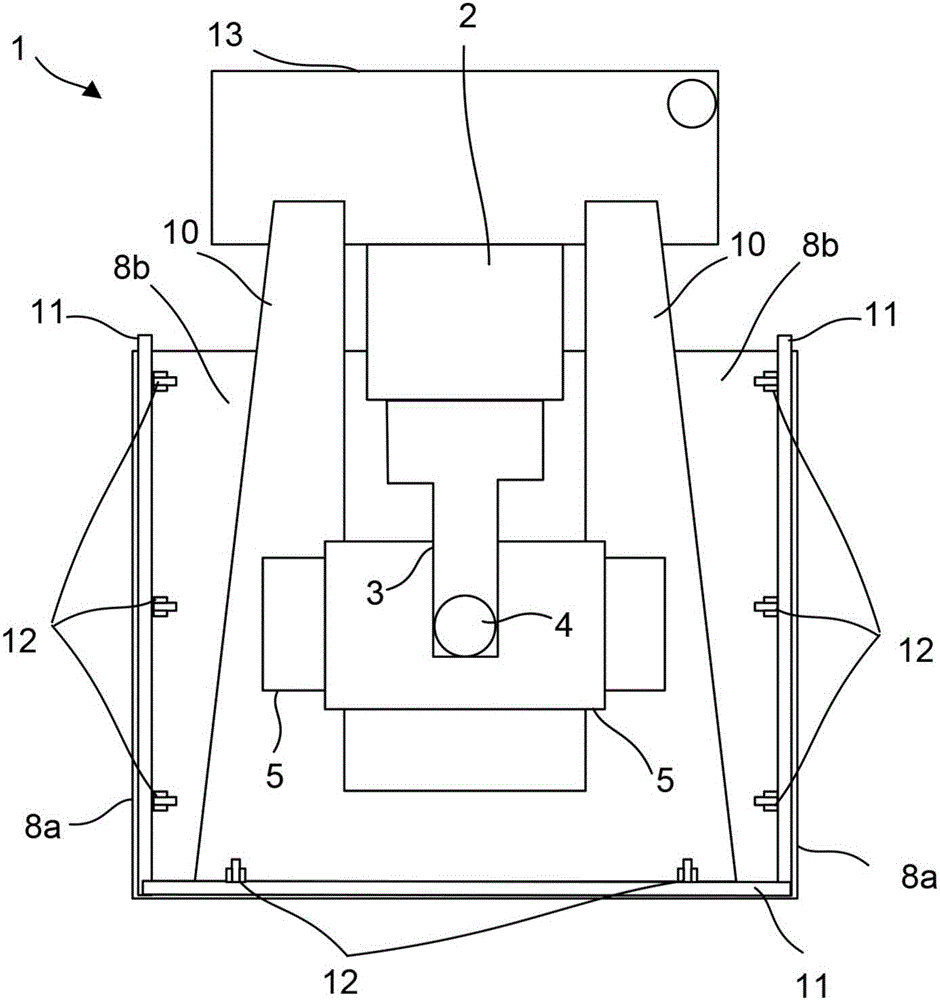

[0023] use Figure 1A as well as Figure 1B A brief configuration of a machine tool according to an embodiment of the present invention will be described.

[0024] The machine tool 1 includes a table 5 movably provided via a saddle 6 , and a spindle 4 attached to a spindle head 3 supported by a column 2 . The table 5 and the spindle 4 are provided on a bed 7 . The table 5 is provided movably by a saddle 6 , and a workpiece to be processed is fixed on the table 5 . A tool for machining the workpiece can be attached to the spindle 4 .

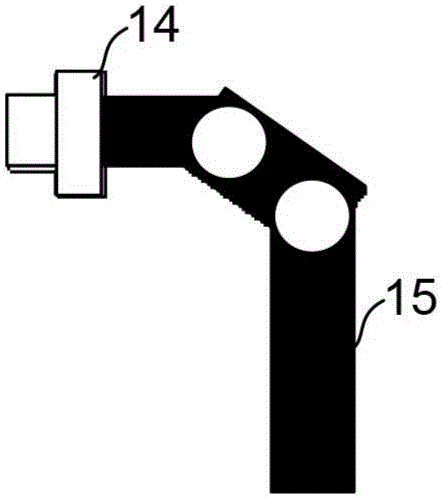

[0025] The entire machining area of the machine tool 1 where workpieces are machined is covered with covers 8 (side covers 8 a , bottom covers 8 b , and rear covers 8 c ) that prevent chips and cutting fluid generated during machining from scattering around. In addition, in the machine tool 1, pipes 11 are arranged from the outside of the cover 8 to the inside of the cover 8, and a plurality of nozzles whose discharge directions can be change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com