Garbage drum screen with self-cleaning function and cleaning device thereof

A technology of cleaning device and trommel screen, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of inconvenient cleaning, achieve high washing efficiency, save resources, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

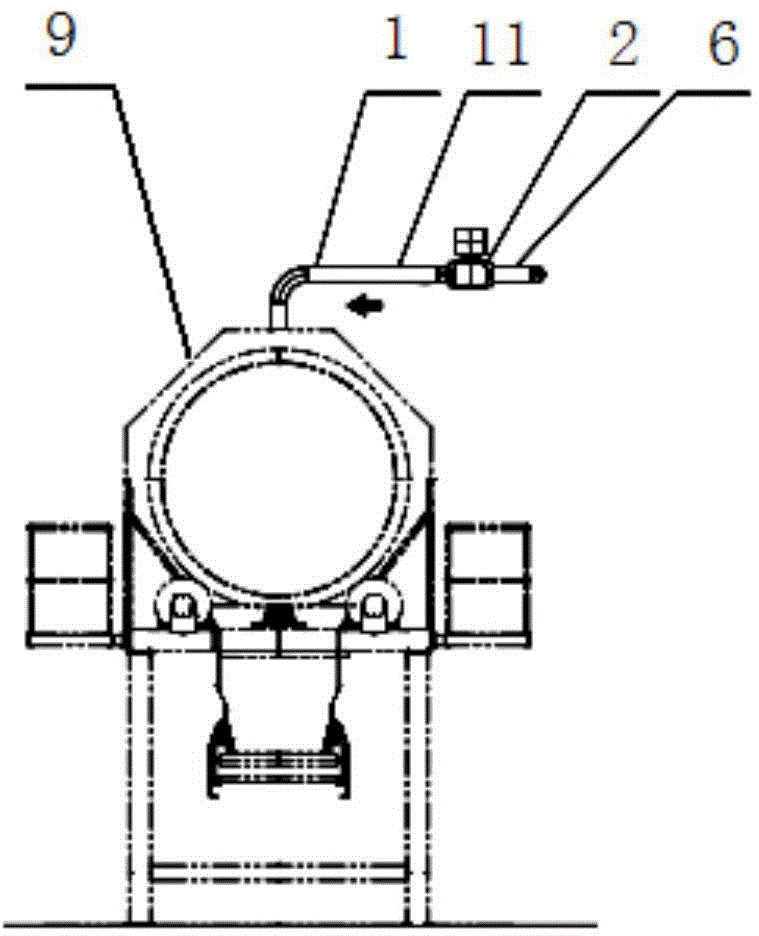

[0042] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

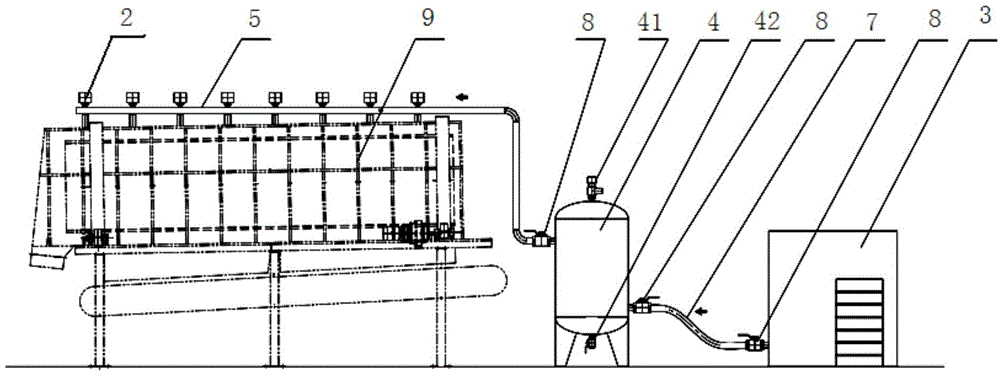

[0043] Such as figure 1 and figure 2 As shown, the garbage drum screen cleaning device provided by the present invention may include an air compressor 3, a pipeline and a control device for controlling the on-off of the pipeline.

[0044] Specifically, the air compressor 3 is used to pressurize the gas flowing through it to form high-pressure gas. The air compressor 3 can select a variety of suitable compressors according to needs; gas, such as air, is usually selected as a safer inert gas. In this embodiment, the air compressor 3 is selected as a screw air compressor.

[0045] The pipeline of the present invention can be made of a variety of suitable materials, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com