Preparation and applications of nitrogen doped porous active carbon material

A technology of porous activated carbon and nitrogen doping, which is applied in the manufacture of hybrid/electric double layer capacitors, inorganic chemistry, non-metallic elements, etc., can solve the problems of low specific surface area and low specific capacitance of porous carbon materials, and achieve easy industrialization , Convenient control, simple effect of design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

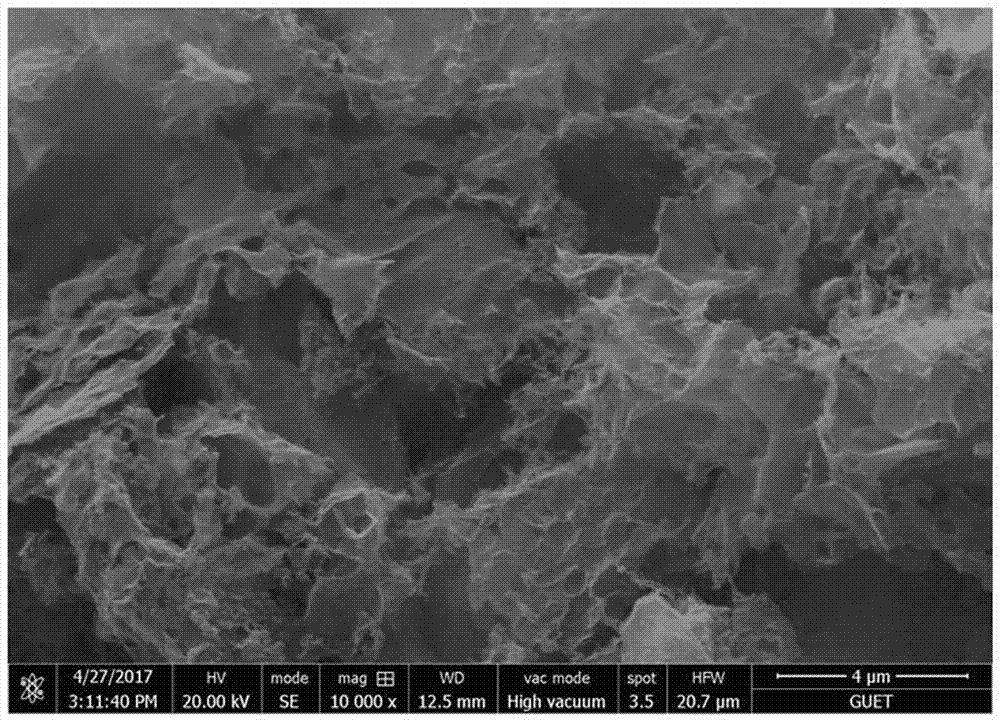

[0036] Preparation of a nitrogen-doped porous activated carbon material

[0037] In step (1), the raw iron leaves are washed with water to remove surface dust, and then dried in a blast drying oven at 80°C, and then the dried iron leaves are broken into strip-shaped leaf fragments, which are calcined in a muffle furnace for reaction The temperature is 300°C, the reaction time is 2h, and the heating rate is 3°C / min to generate a carbon precursor;

[0038] In step (2), soak 1g of carbon precursor, 2g of urea and 2g of potassium hydroxide in 30ml of deionized water at the same time. The sample was put into a tube furnace and calcined under the protection of nitrogen. The reaction temperature was 700°C, the reaction time was 2h, and the heating rate was 3°C / min to obtain a nitrogen-doped porous activated carbon material;

[0039] In step (3), the above-mentioned nitrogen-doped porous activated carbon material is soaked in 1M HCl solution, then filtered and washed with distilled w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com