Fluorine and nitrogen co-doped three-dimensional graphene material and one-step carbonization preparation method thereof

A graphene and co-doping technology, applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of not having the characteristics of graphene, complex process, toxicity, etc., achieving easy industrialization and simple process. , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A fluorine, nitrogen co-doped three-dimensional graphene material and a one-step carbonization preparation method thereof, the specific preparation method is as follows:

[0060] Step 1, mixing of raw materials, weighing 3.0 g of melamine powder and 4.5 g of polytetrafluoroethylene powder in a mass ratio of 1:1.5, mixing and manual grinding in a mortar to obtain a uniform powder sample;

[0061] Step 2, one-step carbonization method, put the uniform powder sample obtained in step 1 into a quartz boat, put it into a tube furnace, and raise the temperature from room temperature to 700°C at a heating rate of 5°C / min under a nitrogen atmosphere Carry out carbonization, heat preservation carbonization time is 2.0h, obtain fluorine, nitrogen co-doped three-dimensional graphene material after cooling.

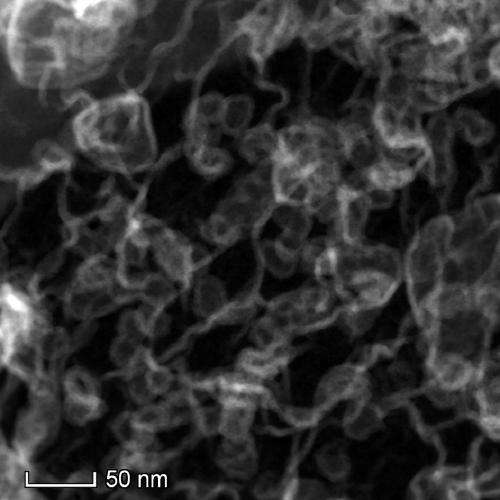

[0062] The fluorine, nitrogen co-doped three-dimensional graphene material prepared in embodiment 1 is tested by transmission scanning electron microscope, and the results are ...

Embodiment 2

[0069] In order to reflect the influence of carbonization temperature on the specific surface area of the material of the present invention, examples of different carbonization temperatures are given.

[0070] A fluorine, nitrogen co-doped three-dimensional graphene material and a one-step carbonization preparation method thereof, the steps not particularly specified in the specific steps are the same as the preparation method described in Example 1, the difference is that the step 2 is heated to Carbonization is carried out at 800°C, that is, the carbonization temperature is 800°C.

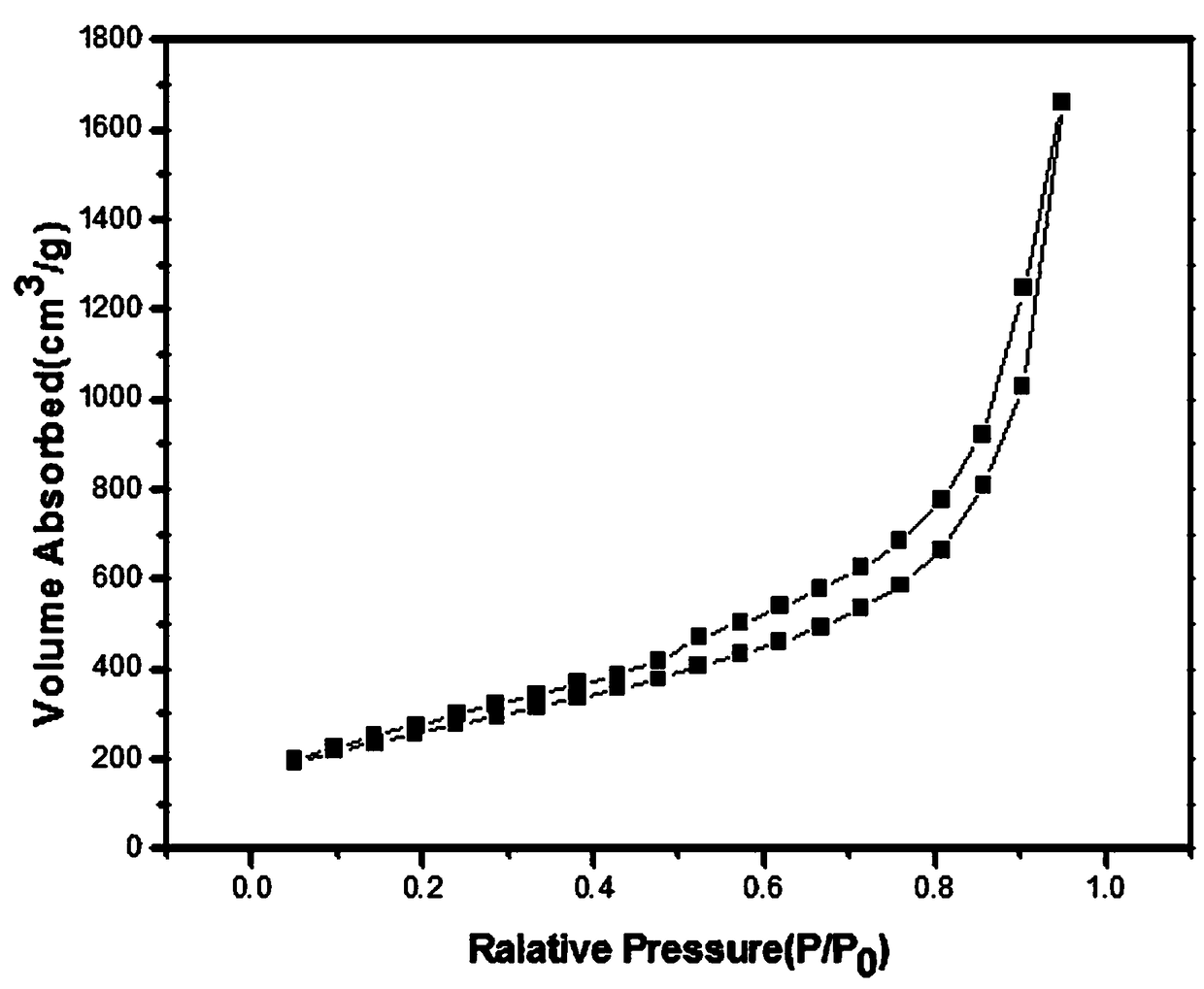

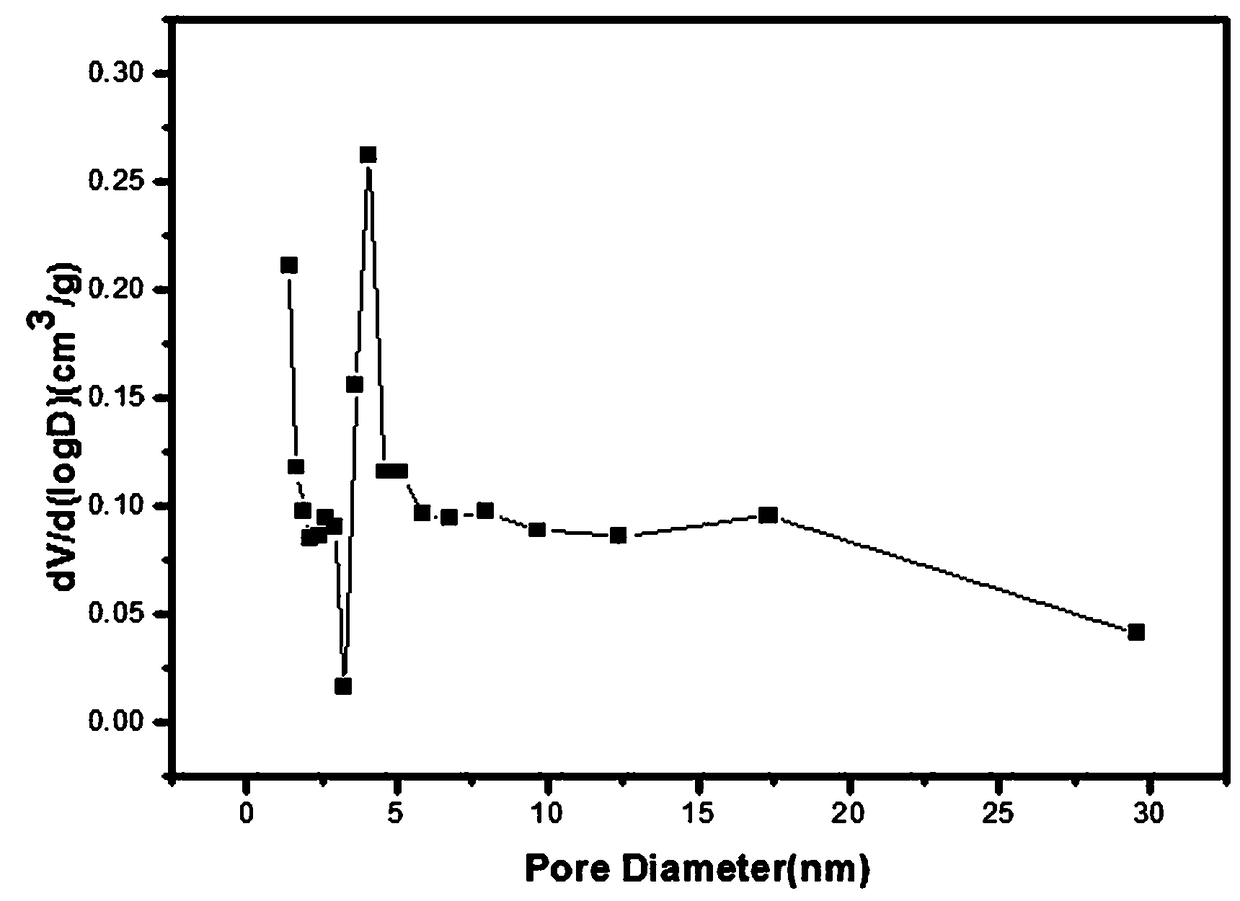

[0071] The fluorine, nitrogen co-doped three-dimensional graphene material prepared in embodiment 2 is tested through isotherm adsorption curve and pore size distribution, the result is as follows Figure 7 and 8 As shown, the results show that the specific surface area of fluorine and nitrogen co-doped three-dimensional graphene material is 284 m 2 g -1 , with a total pore volume of 0.79...

Embodiment 3

[0073] In order to reflect the influence of carbonization temperature on the specific surface area of the material of the present invention, examples of different carbonization temperatures are given.

[0074] A fluorine, nitrogen co-doped three-dimensional graphene material and a one-step carbonization preparation method thereof, the steps not particularly specified in the specific steps are the same as the preparation method described in Example 1, the difference is that the step 2 is heated to Carbonization is carried out at 600°C, that is, the carbonization temperature is 600°C.

[0075] The fluorine and nitrogen co-doped three-dimensional graphene material prepared in embodiment 3 are tested through isotherm adsorption curve and pore size distribution, and the results are as follows: Figure 9 and 10 As shown, the results show that the specific surface area of the 3D graphene material co-doped with fluorine and nitrogen is 60 m 2 g -1 , with a total pore volume of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com