Preparation method and application of grapefruit pulp peel based porous carbon material

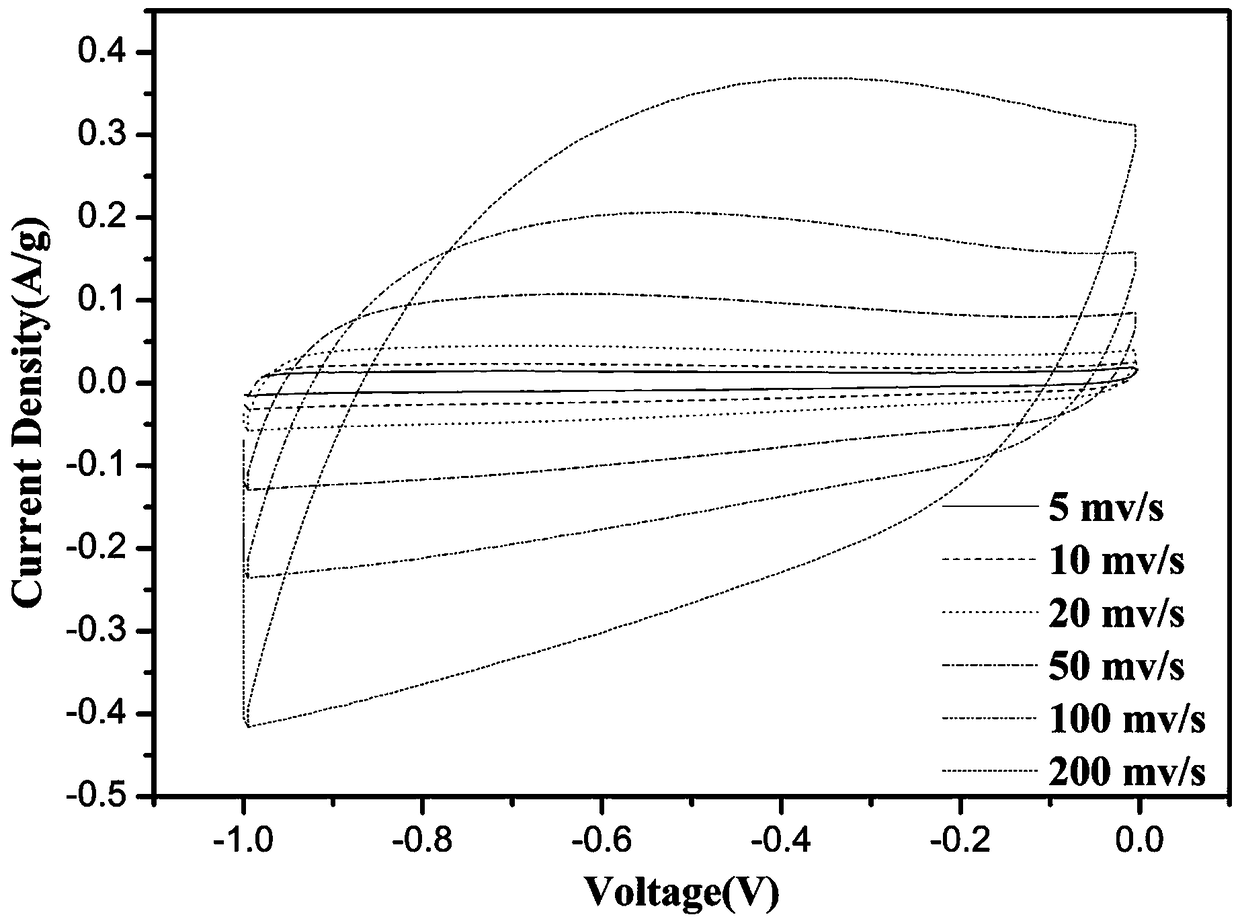

A technology of porous carbon materials and pomelo pulp, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem of low specific capacitance of porous carbon materials, achieve good electrochemical performance and stability, realize effective utilization, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Step 1) Low-temperature carbonization of pomelo pulp skin, peel off the white thin skin wrapped on pomelo pulp, wash, cut into strips, dry in a blast drying oven at 85°C, and then dry the dried pomelo The pulp skin was calcined in a muffle furnace, the reaction temperature was 300°C, the reaction time was 2h, and the heating rate was 3°C / min to generate a carbon precursor;

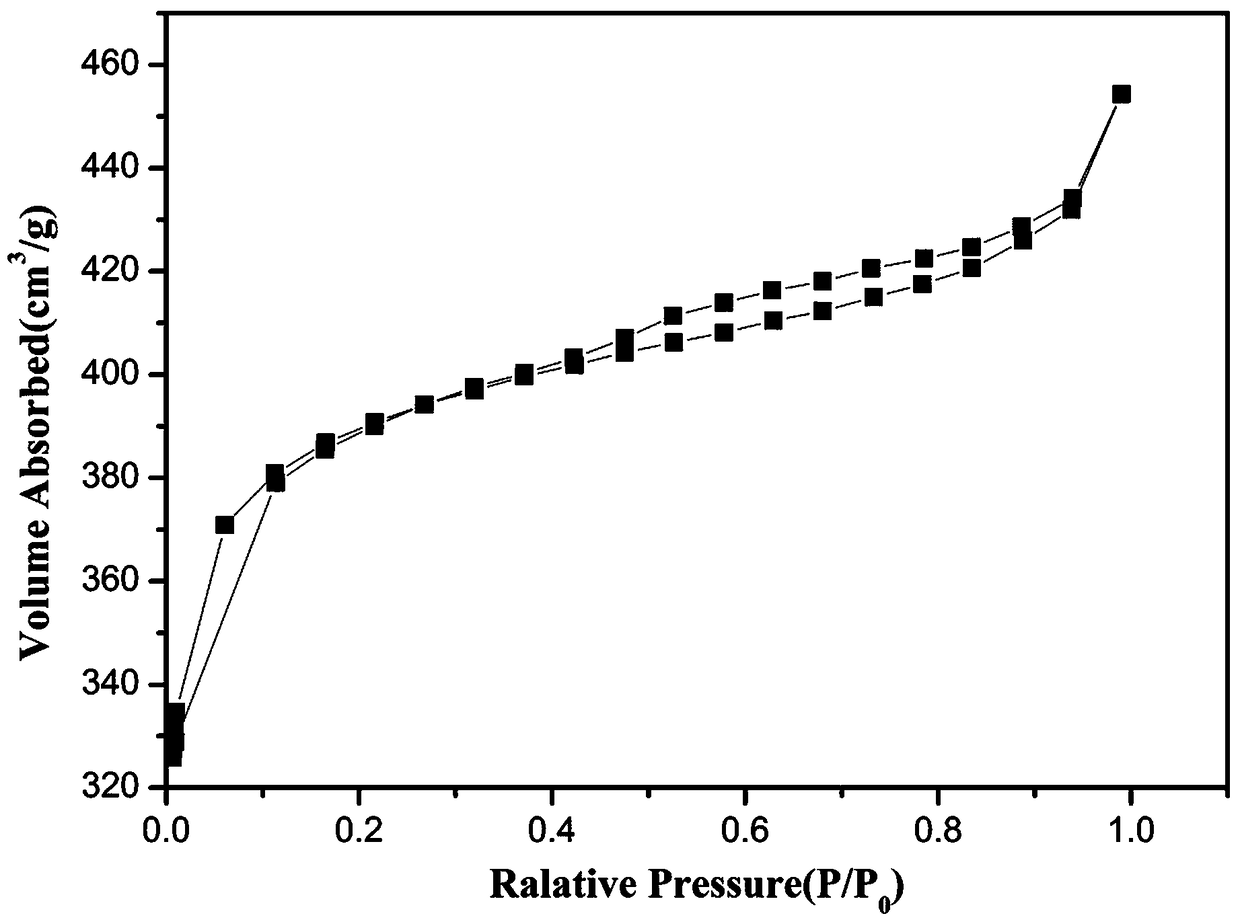

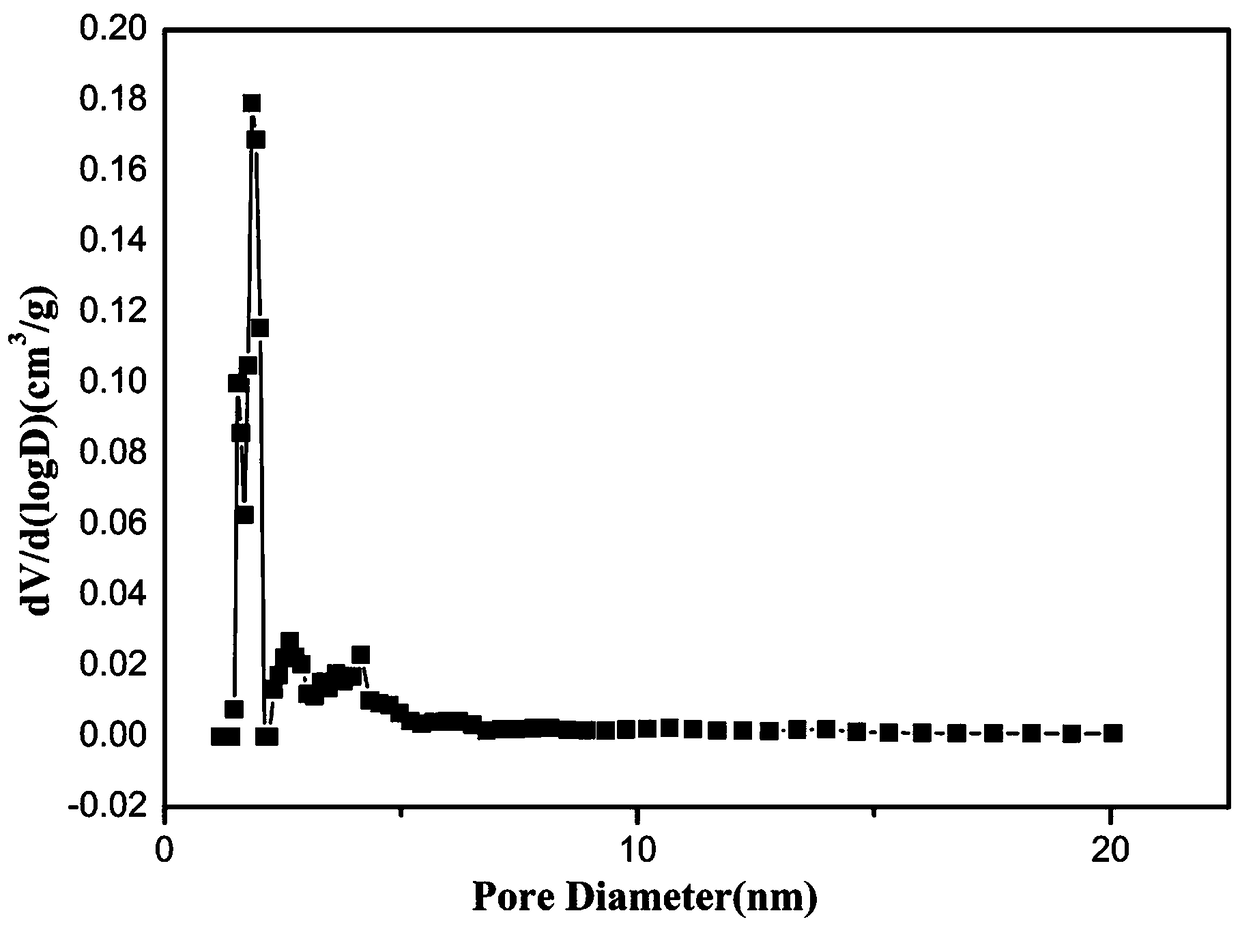

[0032] Step 2) Activation of pomelo peel-based porous carbon materials. Soak 1g of carbon precursor and 2g of potassium hydroxide in 30ml of deionized water at the same time, stir magnetically for 5h at room temperature, and then dry in a blast drying oven. The dried sample was put into a tube furnace and calcined under the protection of nitrogen. The reaction temperature was 700°C, the reaction time was 2h, and the heating rate was 3°C / min to obtain a pomelo peel-based porous carbon material;

[0033] Step 3) Post-processing of the pomelo peel-based porous carbon material, soaking the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com