Stainless steel base water electrolysis catalytic electrode and manufacturing method thereof

A catalytic electrode, stainless steel technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of not being able to use as a catalyst for total water splitting, poor performance of electrocatalytic hydrogen evolution, etc., and achieve excellent stability, optimized performance, and strong nanostructure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

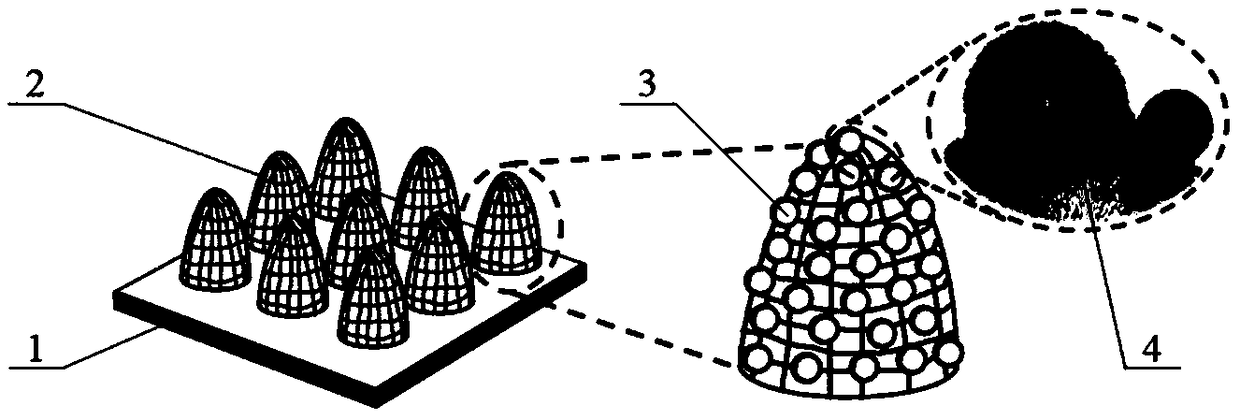

[0031] Concrete preparation method of the present invention comprises the steps:

[0032] 1) Using a high-energy-density pulsed laser to ablate the surface of the stainless steel substrate, and scanning according to a vertical intersection path to form a three-dimensional micro-protrusion array, the high-energy-density pulsed laser can be a femtosecond, picosecond or nanosecond laser; The ablation path It is a vertical cross scanning method, the scanning distance is 20-200μm, and the scanning speed is 100-2000mm / s.

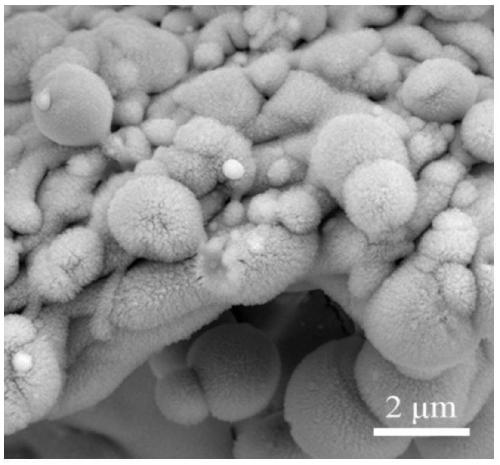

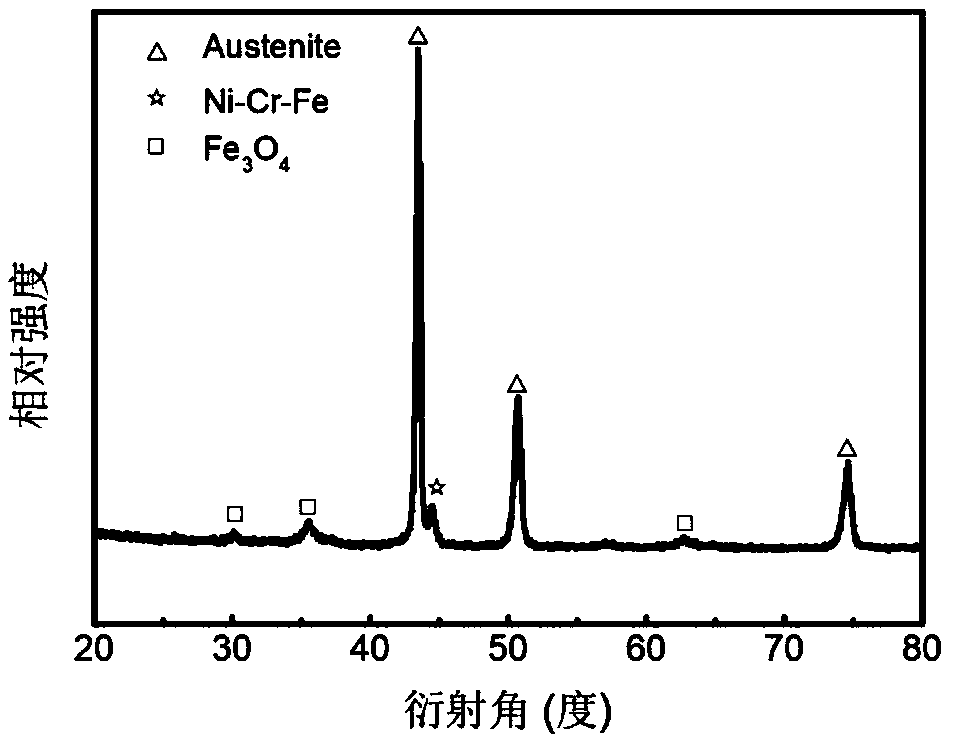

[0033] 2) Using nanosecond pulsed laser to irradiate the surface of the stainless steel substrate with convex arrays in the atmospheric environment, and also scan according to the vertical cross path, The scanning distance is 10-100μm, and the scanning speed is 20-1000mm / s; The microspheres and the oxide nano-velvet structure covering the surface of the raised array are ablated to form a three-dimensional self-supporting micro-nano composite multi-level struct...

Embodiment 1

[0036] Embodiment 1: In the two-step ablation process, the first step uses a femtosecond laser to ablate, and the second step uses a nanosecond laser to prepare an electrolytic water catalytic electrode, including the following steps:

[0037] 1) Cut the stainless steel sheet to a size of 10×20×0.3mm 3 The small piece of substrate, tear off the protective film;

[0038] 2) The femtosecond laser is used to perform the first ablation on the surface of the stainless steel substrate, wherein the laser wavelength is 1030nm, the pulse width is 800fs, the pulse repetition frequency is 200kHz, the average power is 20W, the scanning path is vertical cross lines, and the scanning distance is 100μm , the scanning speed is 2000mm / s;

[0039] 3) The second ablation is performed with a nano-laser, wherein the laser wavelength is 1030nm, the pulse width is 10ns, the pulse repetition frequency is 60kHz, the average power is 20W, the scanning path is vertical crossing lines, the scanning dist...

Embodiment 2

[0041] Embodiment 2: Two-step ablation adopts nanosecond laser to prepare electrolytic water catalytic electrode, including the following steps:

[0042] 1) Cut the stainless steel sheet to a size of 10×20×0.3mm 3 A small piece of substrate, tear off the protective film.

[0043] 2) Use a nanosecond laser to perform the first ablation on the surface of the stainless steel substrate, where the laser wavelength is 1030nm, the pulse width is 500ns, the pulse repetition frequency is 90kHz, the average power is 36W, the scanning path is vertical cross lines, and the scanning distance is 70μm , the scanning speed is 1000mm / s.

[0044] 3) The second ablation is performed with a nano-laser, wherein the laser wavelength is 1030nm, the pulse width is 800ns, the pulse repetition frequency is 100kHz, the average power is 50W, the scanning path is vertical cross lines, the scanning distance is 30μm, and the scanning speed is 1000mm / s. Then the sample was ultrasonically cleaned in anhyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com