Fe-doped Ni-MOF nanosheet as well as preparation method and application thereof

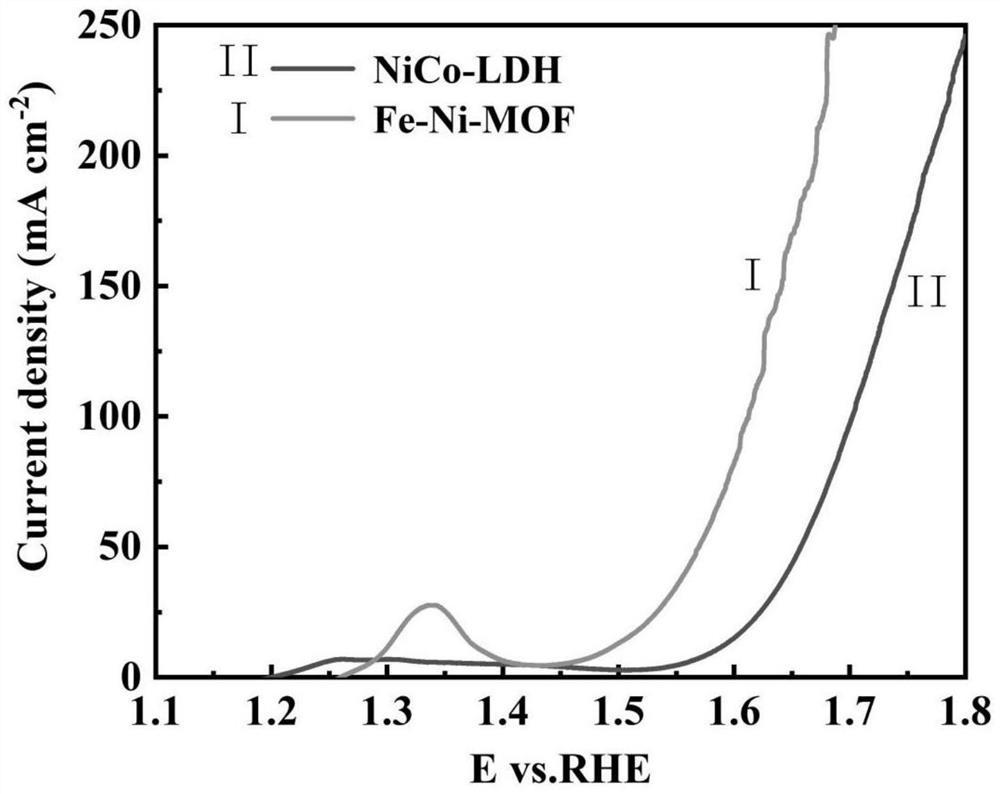

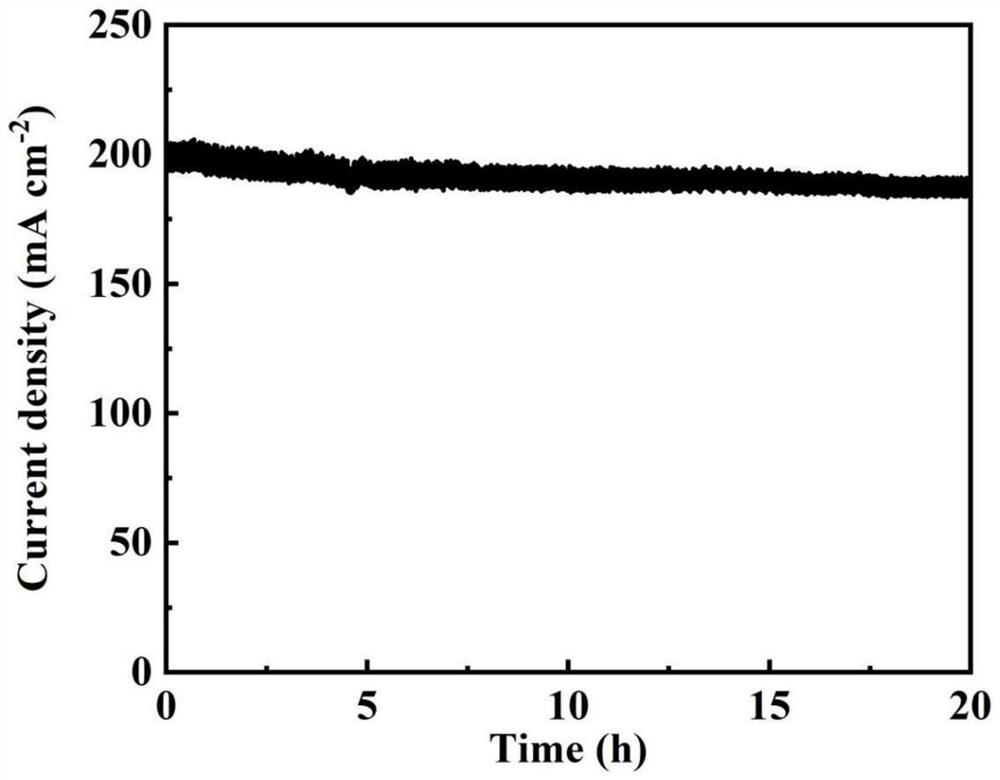

A nanosheet, soluble technology, applied in electrodes, electrical components, electrolysis process, etc., can solve the problems of hindering electrocatalytic performance and poor electrical conductivity of MOFs, and achieve the effect of excellent electrocatalytic performance, improved oxygen evolution performance, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

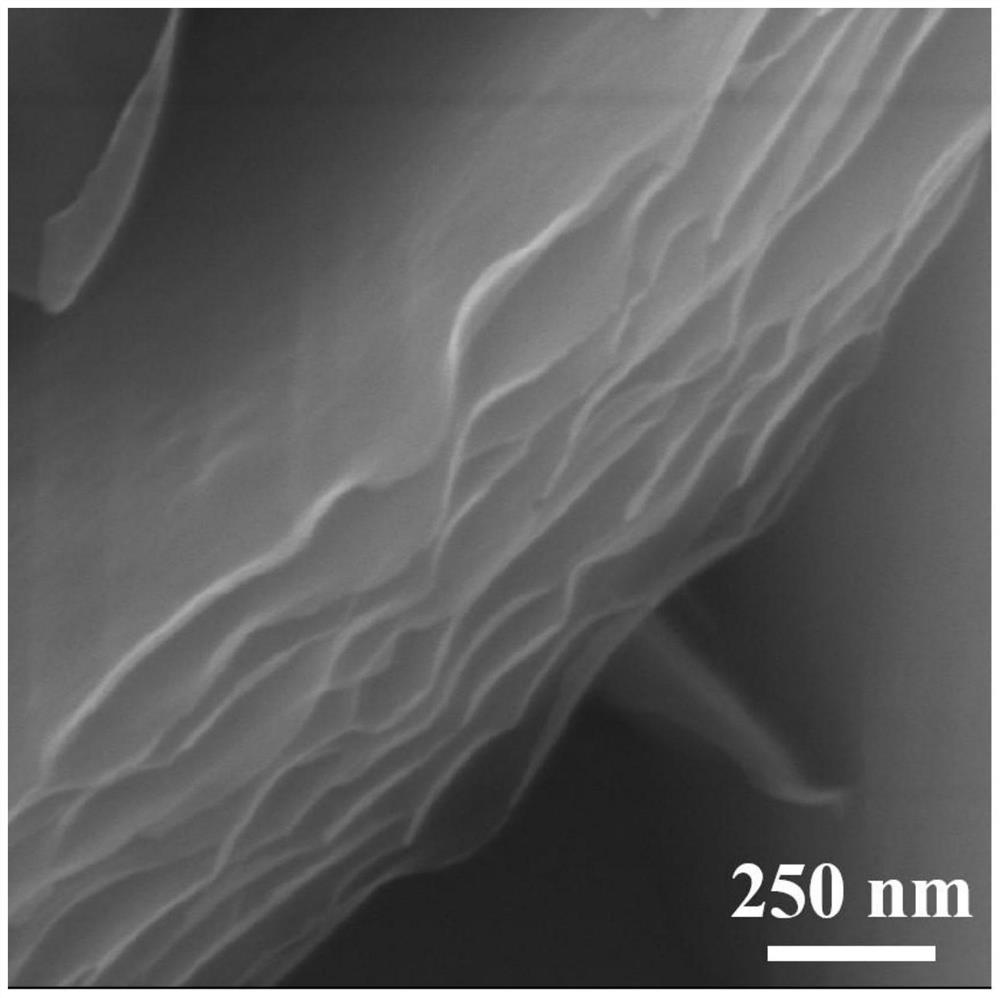

[0042] A preparation method of Fe-doped Ni-MOF nanosheets, comprising the following steps:

[0043] S1. Precursor NiCo-LDH nanosheets prepared by hydrothermal method

[0044] S1.1, the Co(NO 3 ) 2 ·6H2 O (0.08g, 0.275mmol), Ni (NO 3 ) 2 ·6H 2 O (0.04g, 0.1375mmol), hexamethylenetetramine (HMT, 0.234g) were dissolved in 12mL of ethylene glycol aqueous solution (the volume ratio of ethylene glycol to deionized water was 1:5), and stirred until a uniform solution to obtain solution A;

[0045] S1.2. Place nickel foam in hydrochloric acid solution and ultrasonically clean it for 20 minutes; then ultrasonically clean it with water for 4 times, each cleaning time is 5 minutes; finally use ethanol to ultrasonically clean it for 5 minutes to obtain pretreated nickel foam; among them, hydrochloric acid solution It is obtained by mixing hydrochloric acid with a mass concentration of 37% and water at a volume ratio of 1:3;

[0046] S1.3. Put a piece of S1.2 pretreated foamed nicke...

Embodiment 2

[0052] A preparation method of Fe-doped Ni-MOF nanosheets, comprising the following steps:

[0053] S1. Precursor NiCo-LDH nanosheets prepared by hydrothermal method

[0054] S1.1, the Co(NO 3 ) 2 ·6H 2 O (0.08g, 0.275mmol), Ni (NO 3 ) 2 ·6H 2 O (0.04g, 0.1375mmol), hexamethylenetetramine (HMT, 0.234g) were dissolved in 12mL of ethylene glycol aqueous solution (the volume ratio of ethylene glycol to deionized water was 1:5), and stirred until a uniform solution to obtain solution A;

[0055] S1.2. Place nickel foam in hydrochloric acid solution and ultrasonically clean it for 20 minutes; then ultrasonically clean it with water for 4 times, each cleaning time is 5 minutes; finally use ethanol to ultrasonically clean it for 5 minutes to obtain pretreated nickel foam; among them, hydrochloric acid solution It is obtained by mixing hydrochloric acid with a mass concentration of 37% and water at a volume ratio of 1:3;

[0056] S1.3. Put a piece of S1.2 pretreated foamed nic...

Embodiment 3

[0062] A preparation method of Fe-doped Ni-MOF nanosheets, comprising the following steps:

[0063] S1. Precursor NiCo-LDH nanosheets prepared by hydrothermal method

[0064] S1.1, the Co(NO 3 ) 2 ·6H 2 O (0.08g, 0.275mmol), Ni (NO 3 ) 2 ·6H 2 O (0.04g, 0.1375mmol), hexamethylenetetramine (HMT, 0.24g) were dissolved in 12mL of ethylene glycol aqueous solution (the volume ratio of ethylene glycol to deionized water was 1:5), and stirred until a uniform solution to obtain solution A;

[0065] S1.2. Place nickel foam in hydrochloric acid solution and ultrasonically clean it for 20 minutes; then ultrasonically clean it with water for 4 times, each cleaning time is 5 minutes; finally use ethanol to ultrasonically clean it for 5 minutes to obtain pretreated nickel foam; among them, hydrochloric acid solution It is obtained by mixing hydrochloric acid with a mass concentration of 37% and water at a volume ratio of 1:3;

[0066] S1.3. Put a piece of S1.2 pretreated foamed nick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com