Patents

Literature

64results about How to "Reduce destructive effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

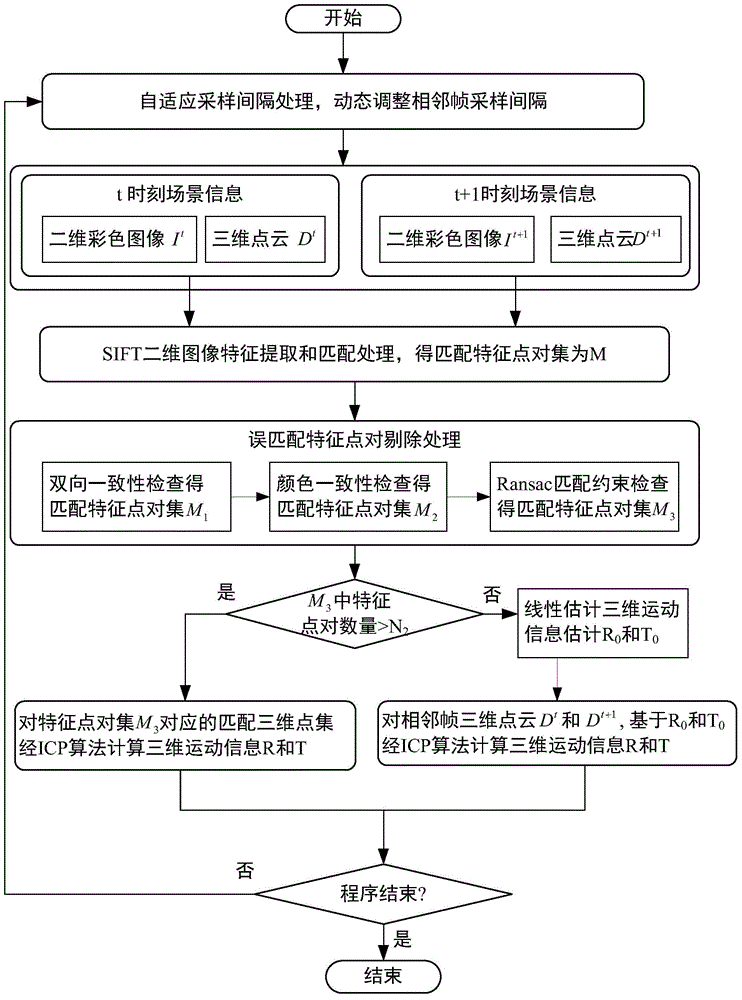

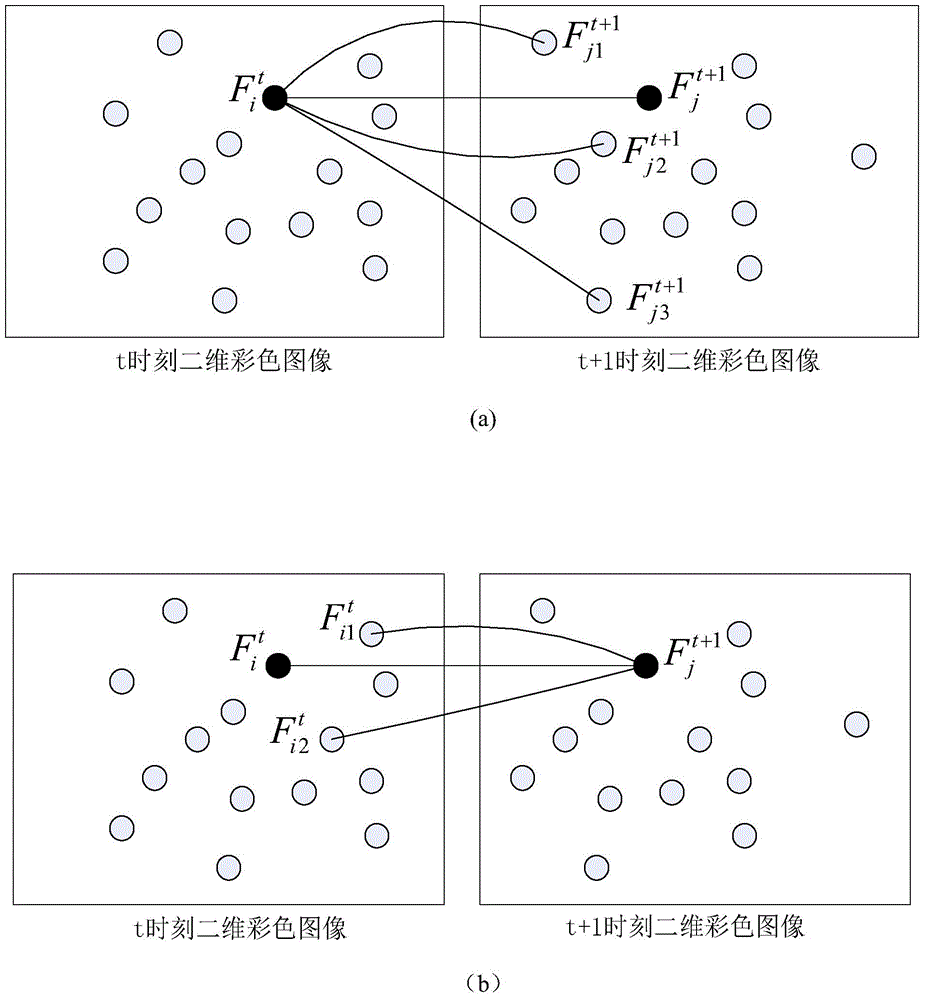

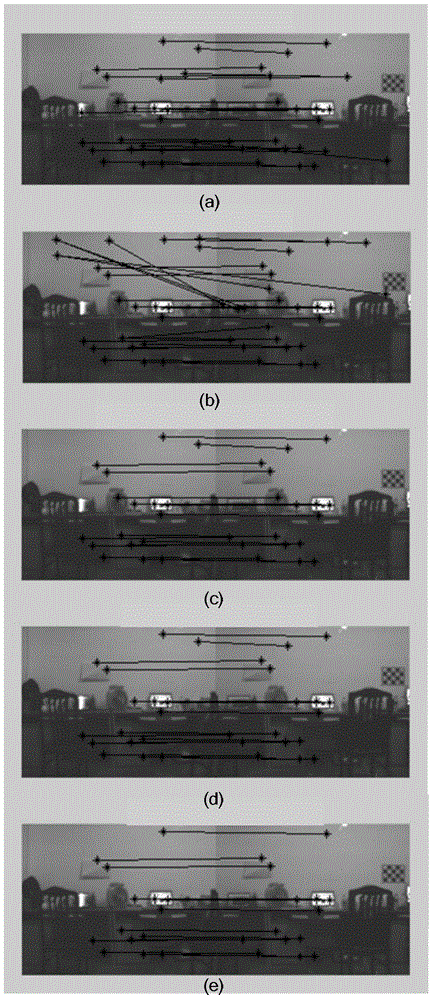

Motion estimation method based on image features and three-dimensional information of three-dimensional visual system

InactiveCN103559711AEasy accessSmall amount of calculationImage analysisThree dimensional motionImaging Feature

The invention discloses a motion estimation method based on image features and three-dimensional information of a three-dimensional visual system. The method includes the first step of obtaining two-dimensional image information and space three-dimensional information corresponding to two-dimensional image pixels in real time on the basis of the three-dimensional visual system, the second step of controlling collection intervals between adjacent frames through the adoption of an adjacent frame sampling interval self-adaptive regulation method and automatically regulating the sampling intervals of the t+1 moment relative to the t moment according to the dot pair number of the effective matching image features between the frame at the t-1moment and the frame at the t moment, and the third step of synthesizing two-dimensional scene image features and three-dimensional point cloud information and carrying out three-dimensional motion estimation according to the matching point pair number of the current two-dimensional image features of the adjacent frames to obtain high-precision three-dimensional motion estimation. Through the method, on the basis of satisfying accuracy and reliability of the three-dimensional estimation, the calculated amount is effectively reduced, and the method has the advantages of being less in calculated amount, small in limitation to an application scene and the like.

Owner:余洪山

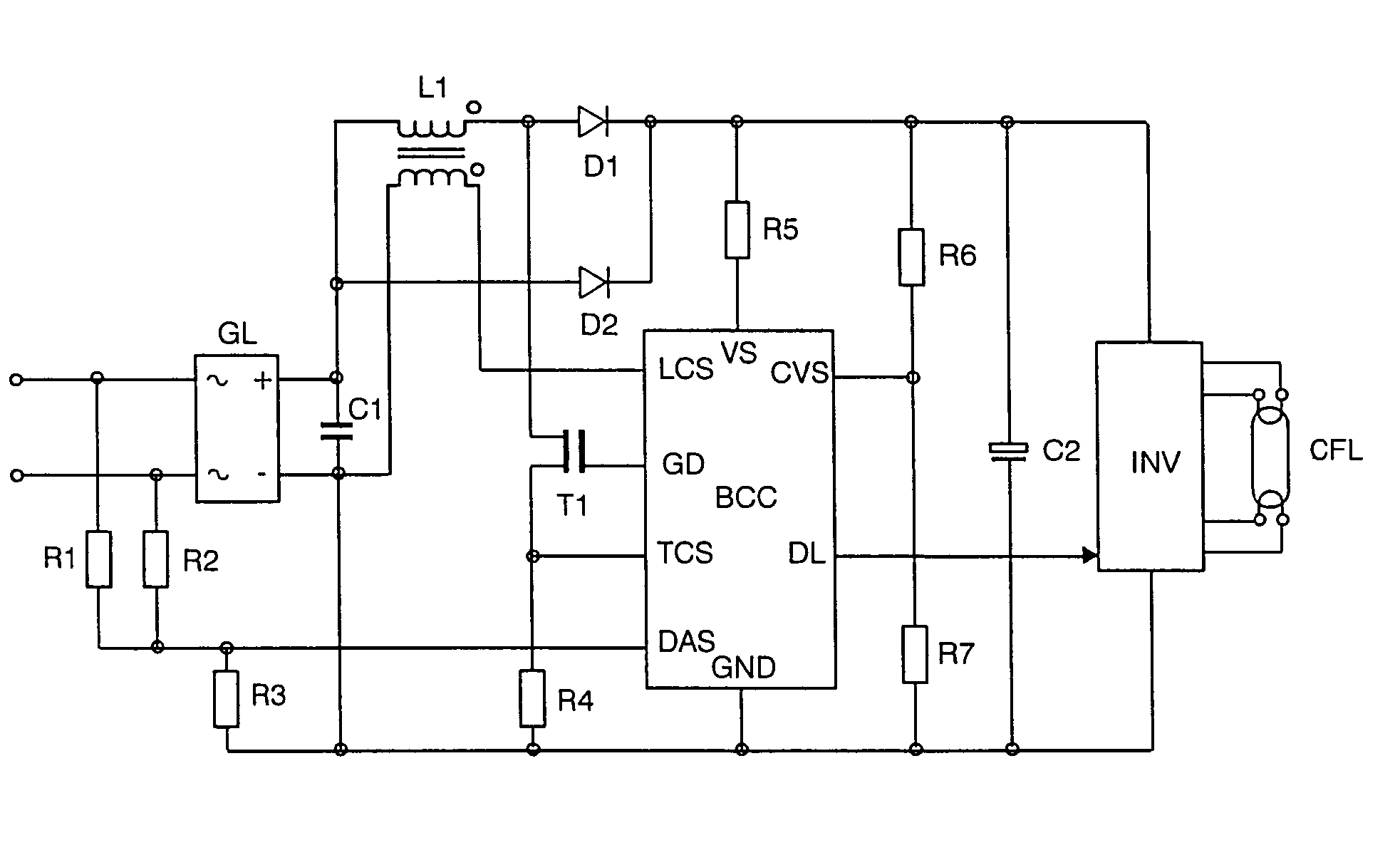

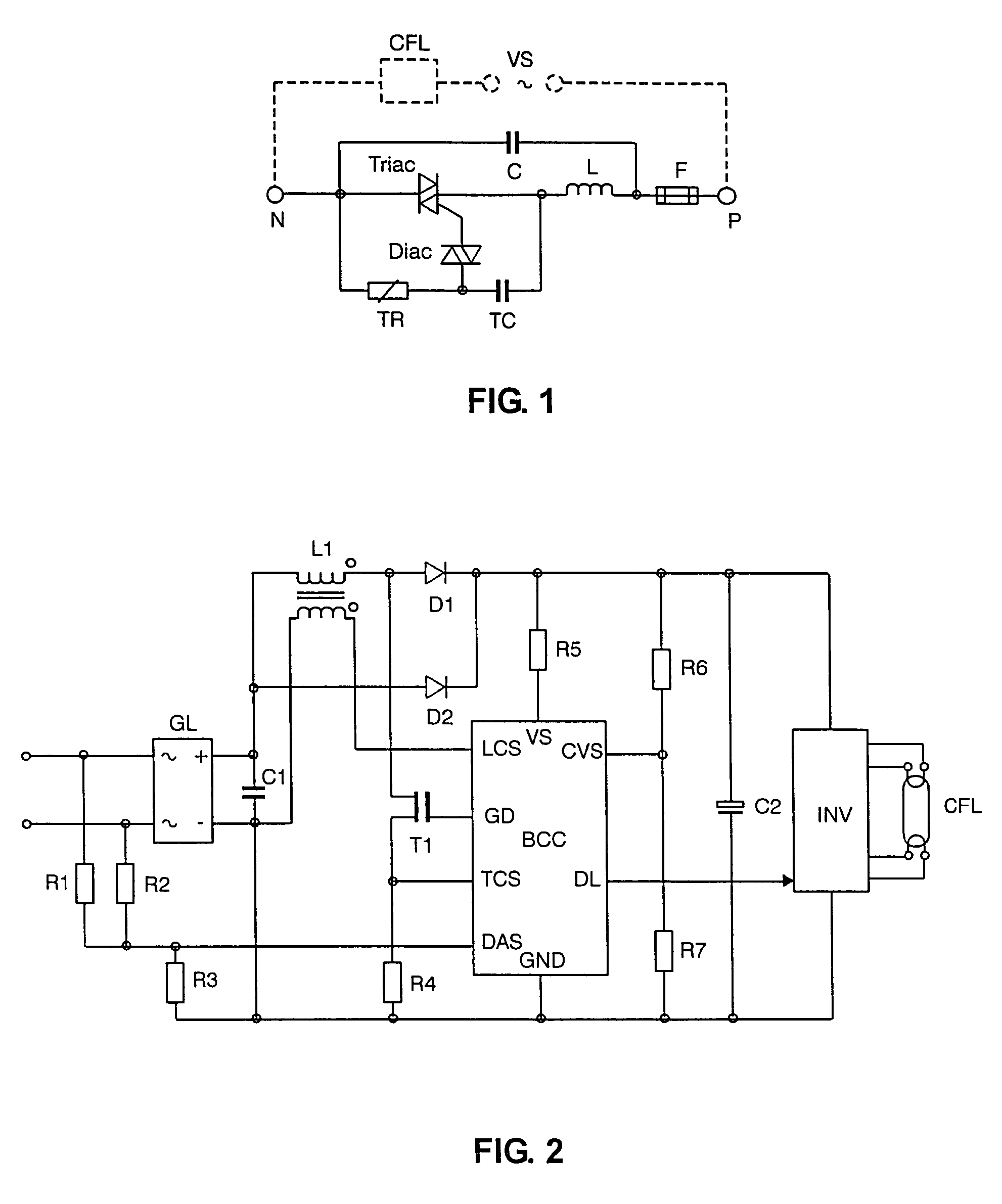

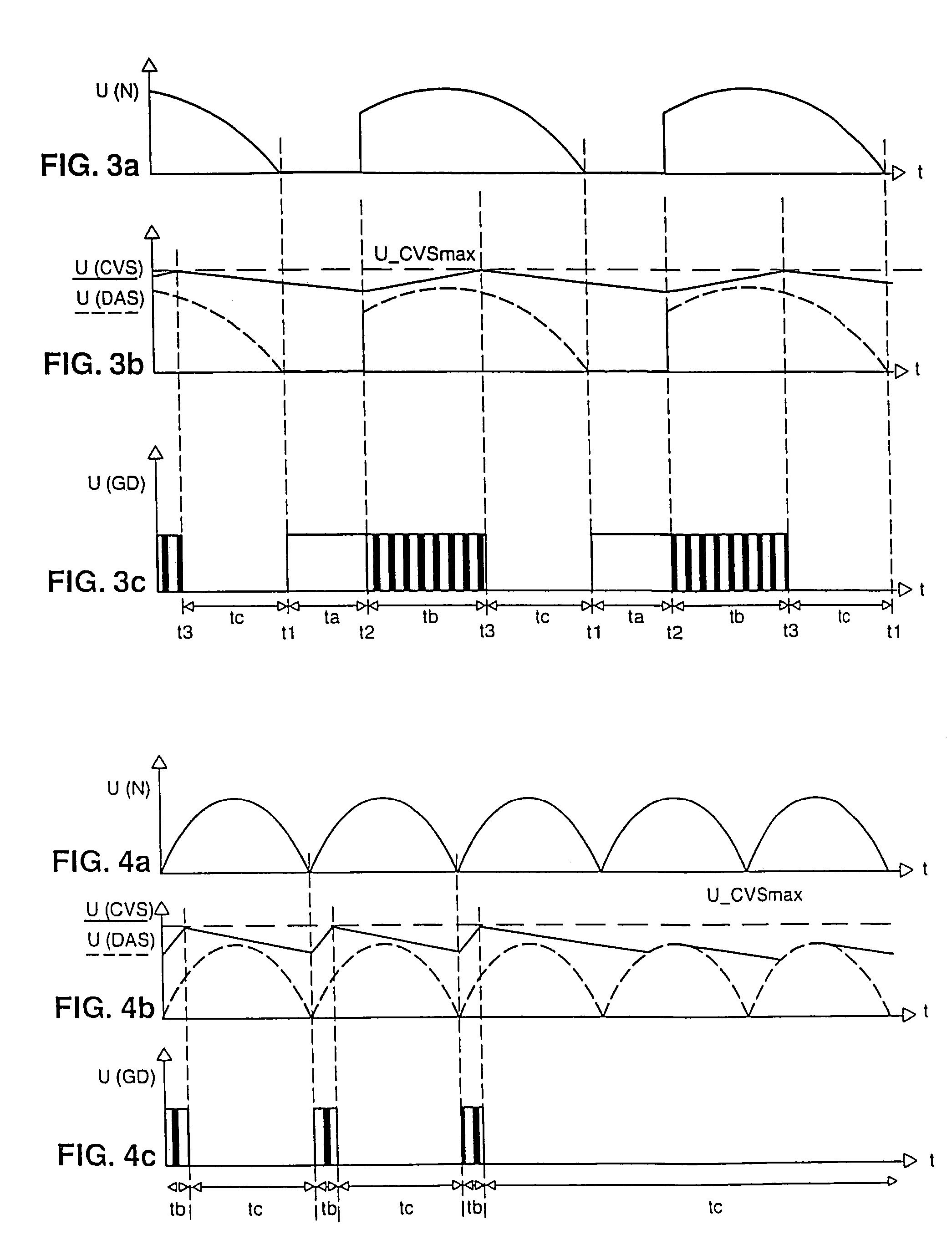

Method for varying the power consumption of capacitive loads

ActiveUS7132802B2Avoid Overvoltage ProblemsLife of lamp can be influencedAc-dc conversion without reversalConversion with intermediate conversion to dcDimmerCapacitor

Method for varying the power consumption of capacitive loads, in particular compact fluorescent lamps which are operated using a phase-gating dimmer by a converter (step-up converter). According to the invention, in the case of a nonconducting dimmer (i.e. no system power supply to the load), the switch (T1) in the converter (step-up converter) is closed. In the case of a conducting dimmer (i.e. when a system voltage is applied to the load), the step-up converter operation takes place until a predetermined maximum voltage is reached across the smoothing capacitor of the load.

Owner:ABL IP HLDG

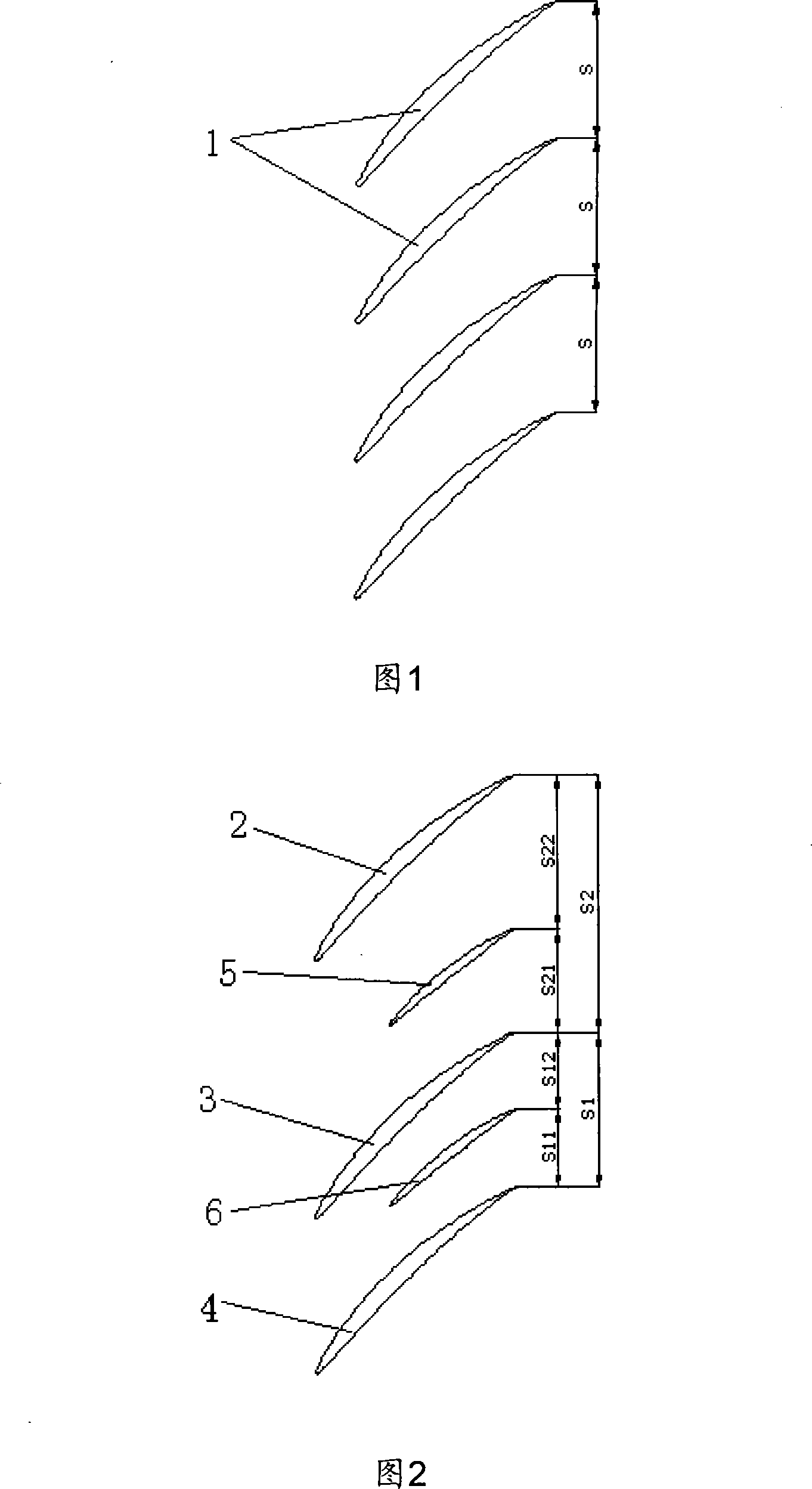

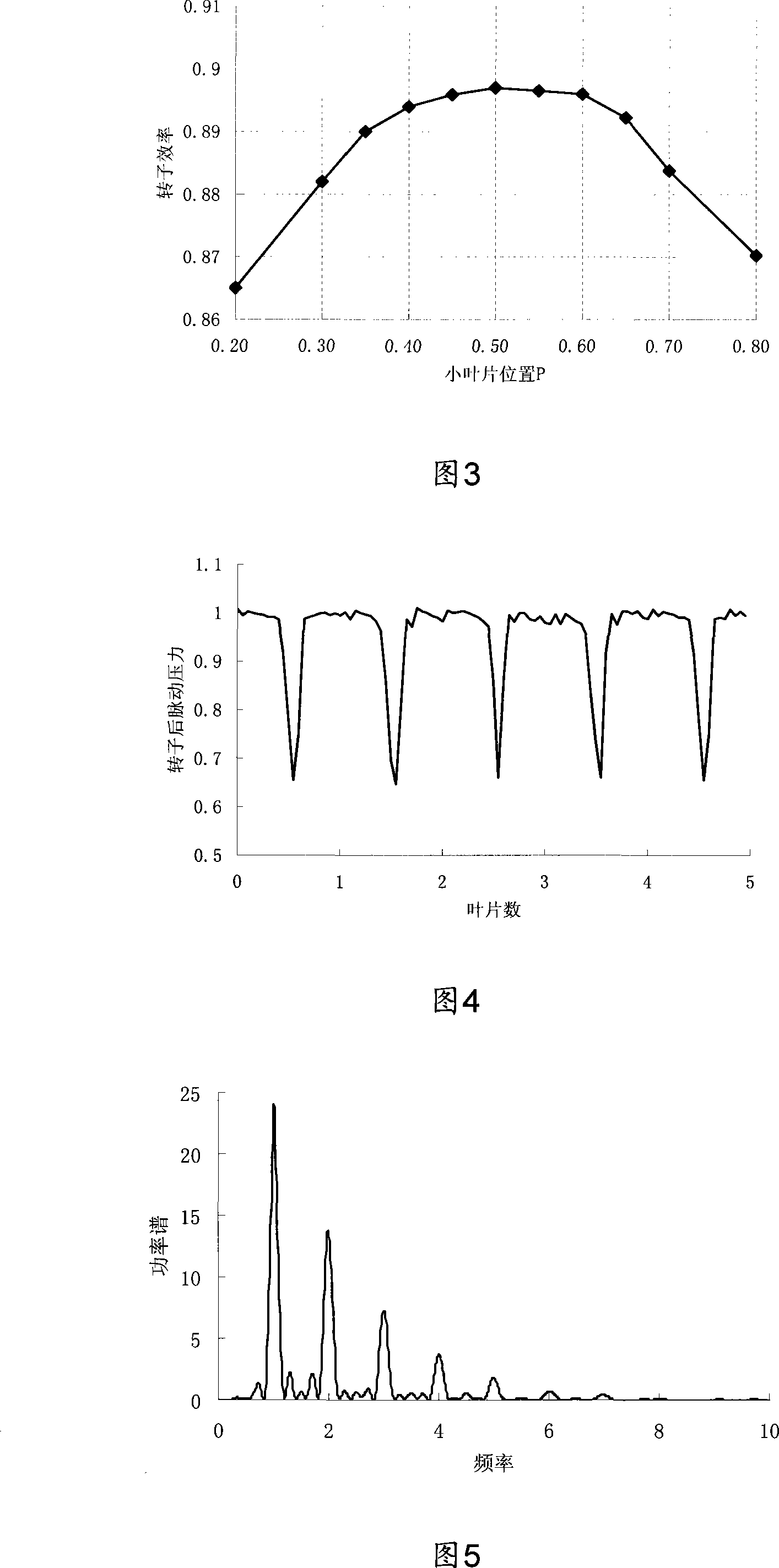

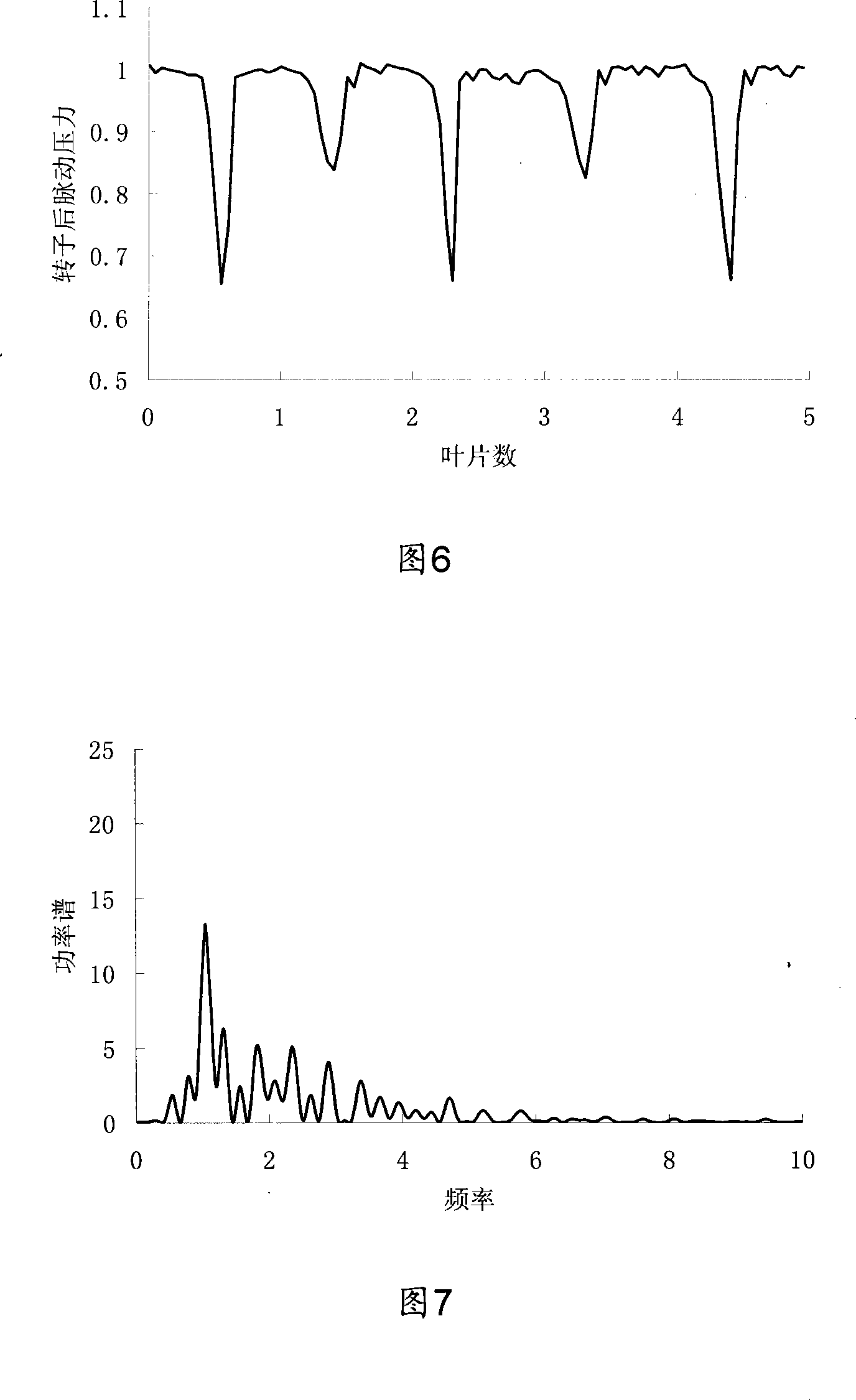

Big and small impeller vane impeller with non-homogeneously distributed blades along circumference and compressor machine

The invention discloses a compressor and an impeller with big and small blades unevenly distributed along circumferential direction; wherein, the big blade of the impeller with big and small blades is unevenly distributed along circumferential direction, and the variation value of the distance in circumferential direction is equal to or less than ten percents. The invention is characterized in that: a small blade is arranged between the adjacent two big blades; the distance in circumferential direction between the small blade and the big blade near the side of the pressure surface of the small blade is equal to twenty-five percents to seventy percents of the distance in circumferential direction between the adjacent big blades. The invention has the advantages that when the rotor of the compressor is the impeller with big and small blades, the exciting force imposed on the downstream stator by the wake of the rotor blade is not periodical strictly, and the destructive influence of the downstream stator is less.

Owner:BEIHANG UNIV +1

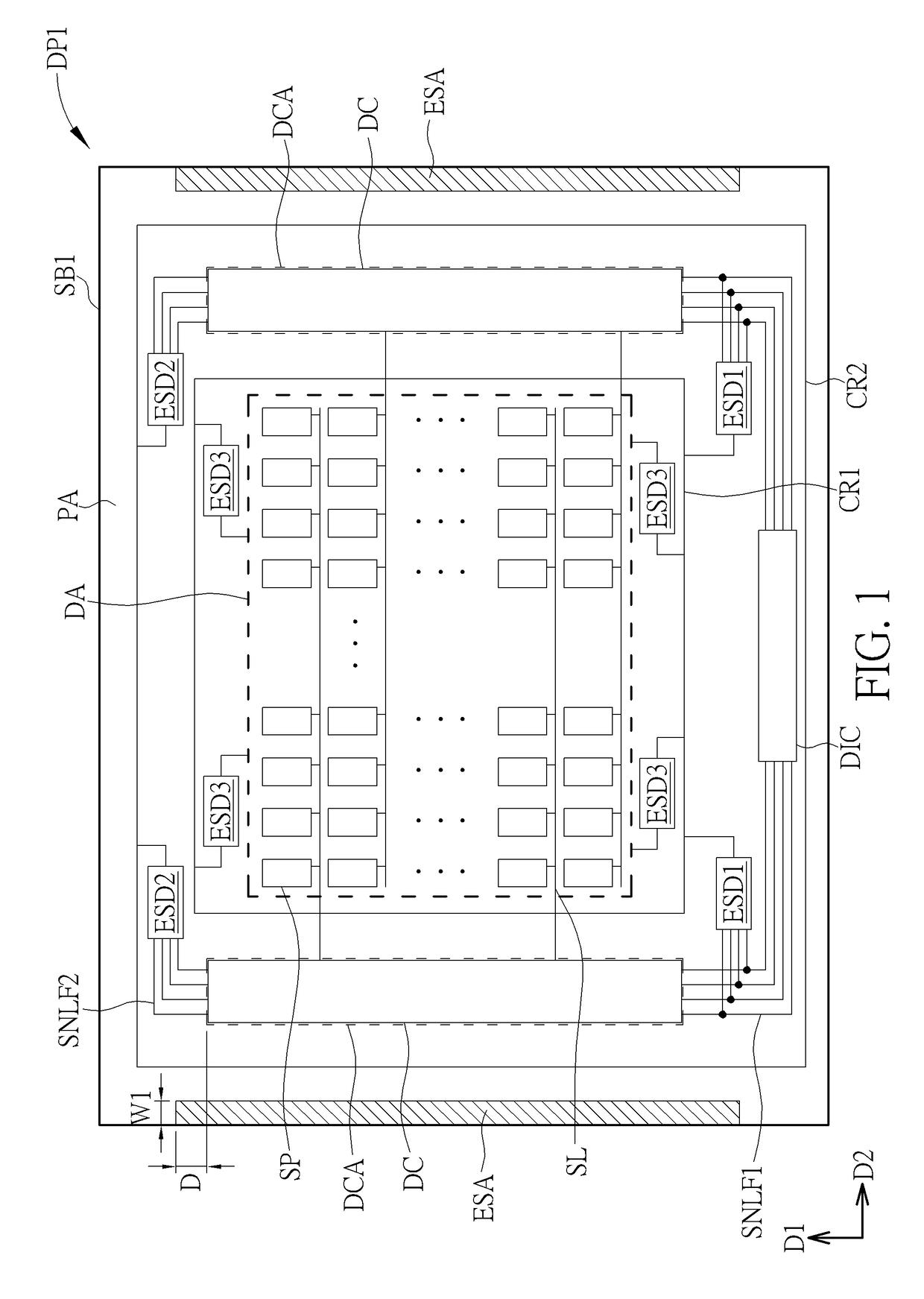

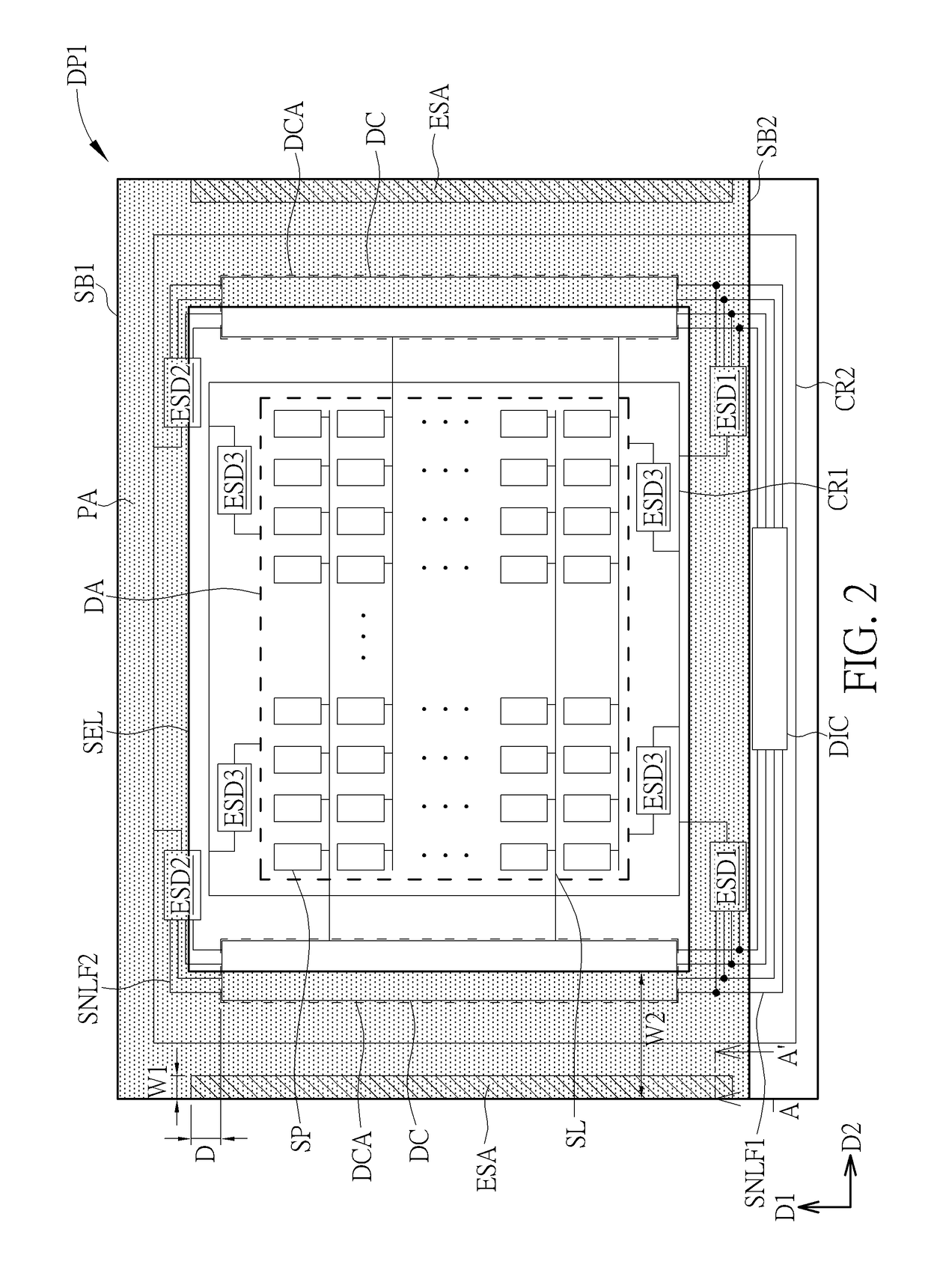

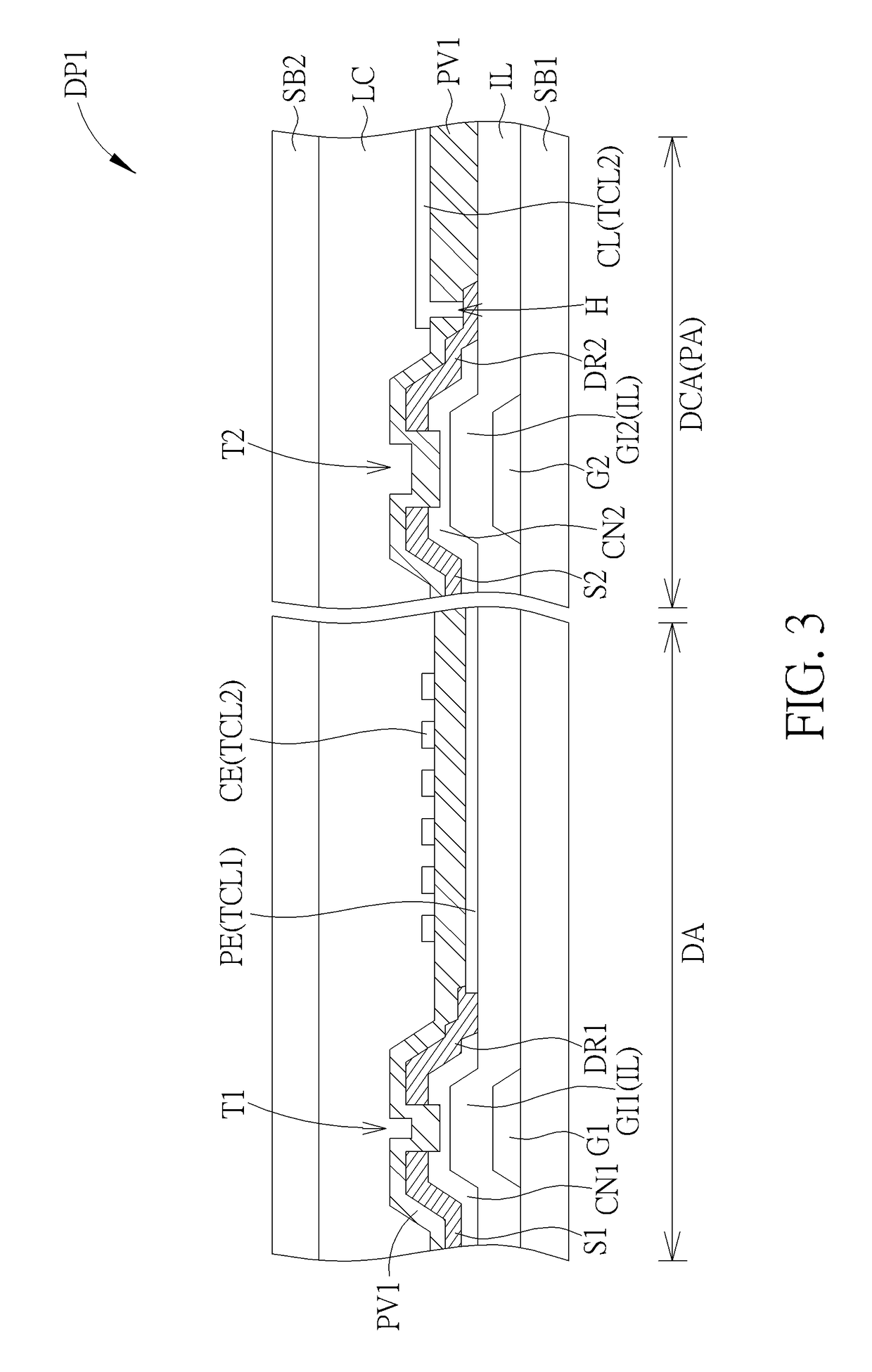

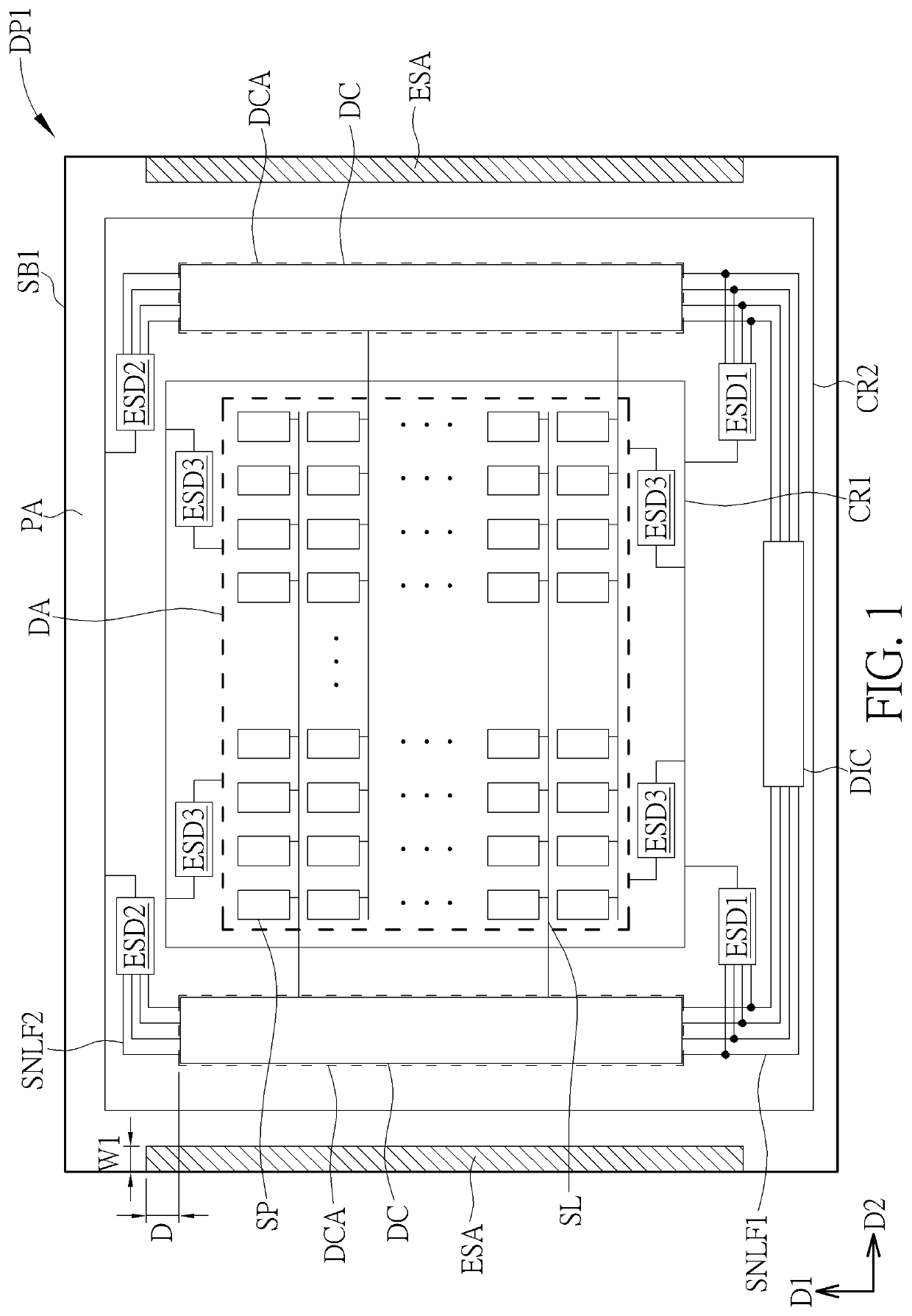

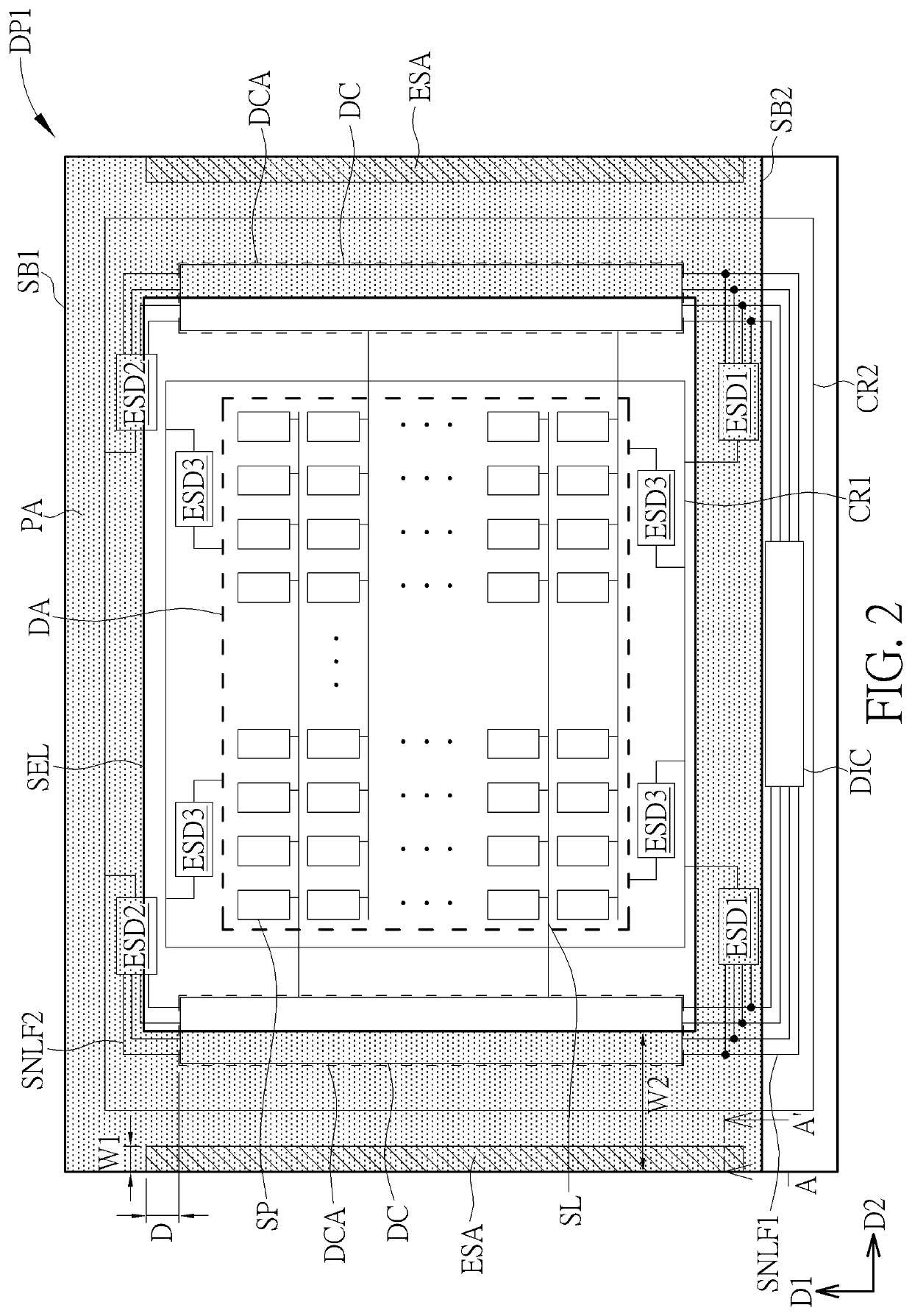

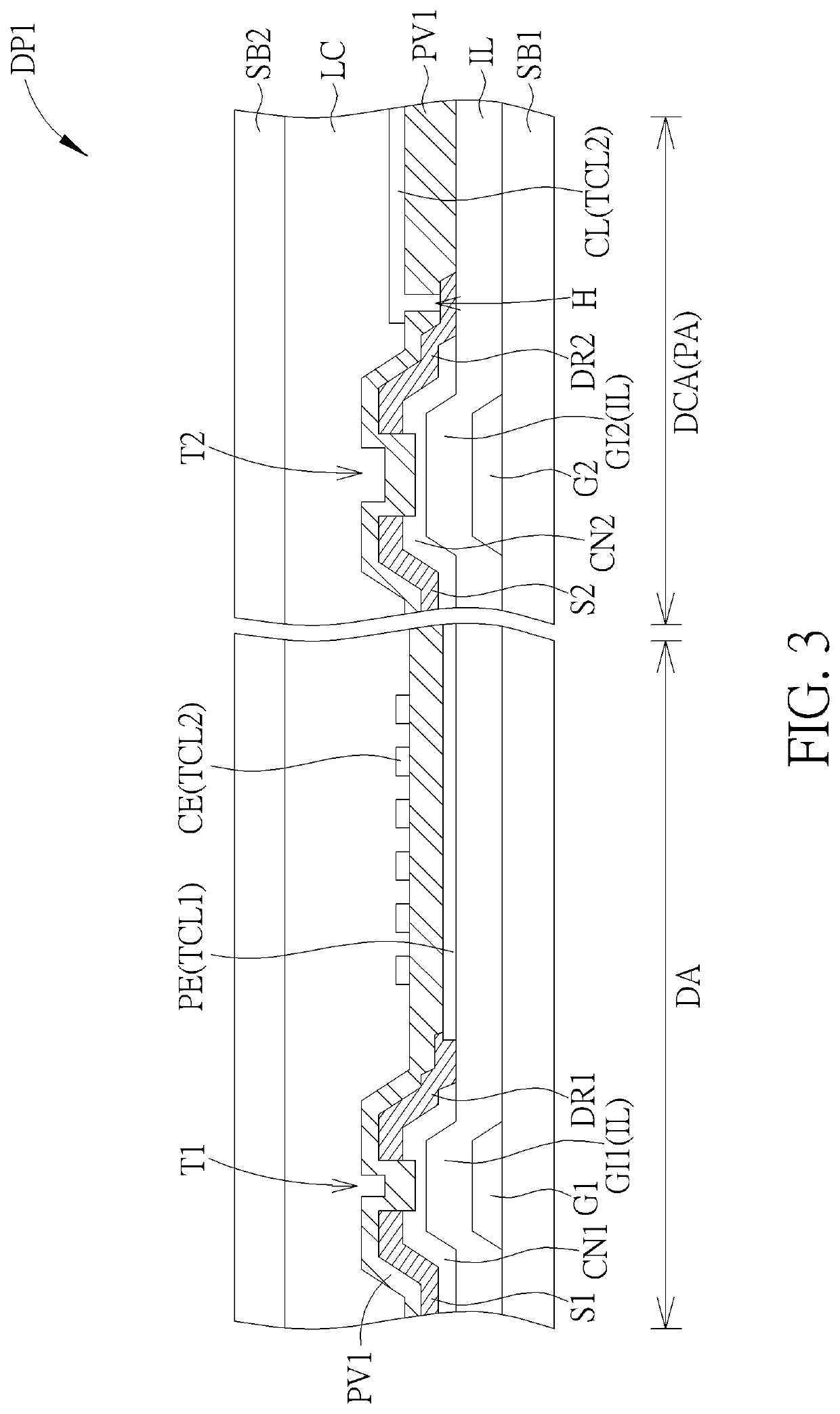

Thin film transistor substrate and display device

ActiveUS20190067218A1Avoid it happening againReduce static chargeSemiconductor/solid-state device detailsSolid-state devicesEngineeringScan line

A thin film transistor substrate having a display region and a peripheral region, and the thin film transistor substrate includes a first substrate, scan lines, data lines, an insulating layer, first thin film transistors, at least one passivation layer and at least one gate driving circuit. The first substrate has an electrostatic protection area and a driving circuit area, and the electrostatic protection area and the driving circuit area are situated in the peripheral region. The scan lines, the data lines and the first thin film transistors are disposed in the display region. The insulating layer includes a gate insulator of the first thin film transistor, and the passivation layer is disposed on the insulating layer. The gate driving circuit is disposed in the driving circuit area. At least one of the passivation layer and the insulating layer are not disposed in the electrostatic protection area.

Owner:HANNSTAR DISPLAY CORPORATION

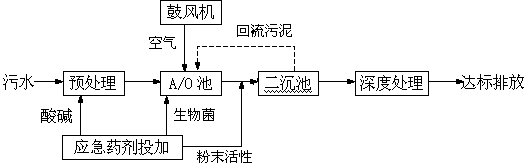

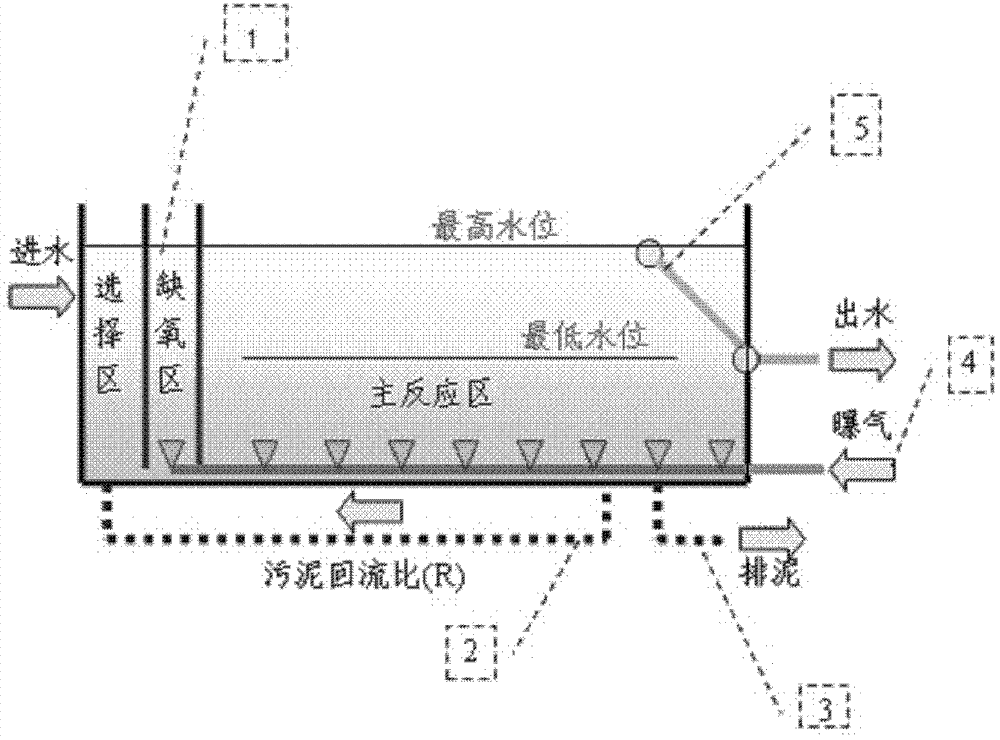

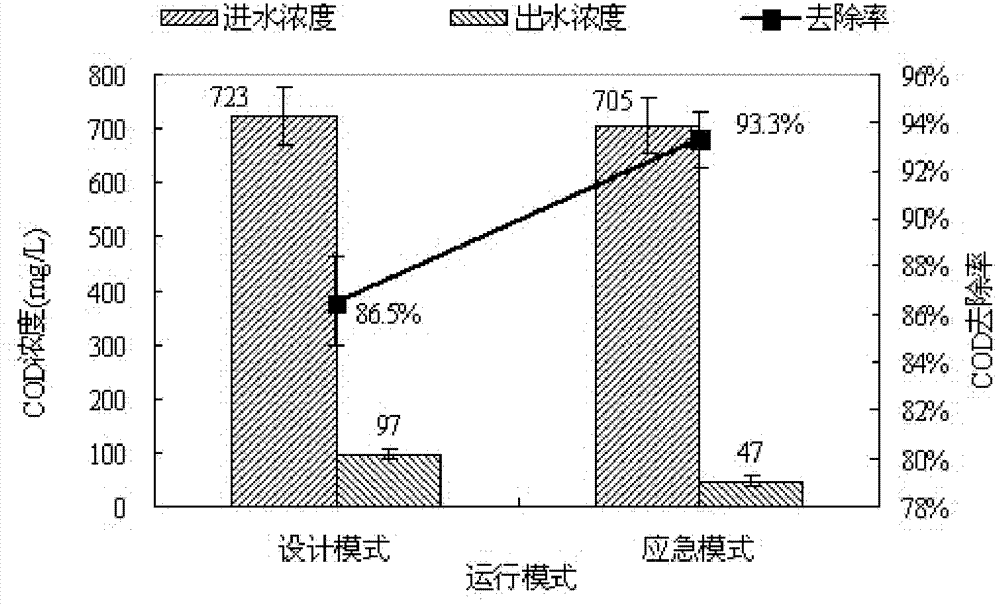

Emergency control method for sewage treatment system for treating abnormal influent/effluent quality

InactiveCN103864194ALess investmentImproved resistance to shock loadsTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentTreatment effectEngineering

The invention relates to an emergency control method for a sewage treatment system for treating abnormal influent / effluent quality. The emergency control method comprises the steps of firstly, judging weather a sewage treatment plant is impacted by abnormal influent; secondly, judging weather an effluent quality index belongs to abnormal effluent; if detecting to find abnormal influent within a certain period of time, regulating an operation condition according to different exceeding conditions; if detecting to find abnormal effluent within a certain period of time, starting up emergency agent addition to improve the treatment effect in time. The method is realized according to the overall regulation thinking that the impact of influent impact to the sewage treatment system is reduced through regulating process control parameters when abnormal influent of a sewage plant appears, and the system function is restored in time through adding an emergency agent when abnormal influent of the sewage plant appears; in addition, the real-time control for front feed and back feed is realized by sufficiently utilizing online monitored data. The method is low in investment and capable of effectively handling the influent impact load, rapidly improving and restoring a system treatment effect, exerting the treatment capability of a sewage treatment facility to the maximum extent and increasing the rate of reaching the standard.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI

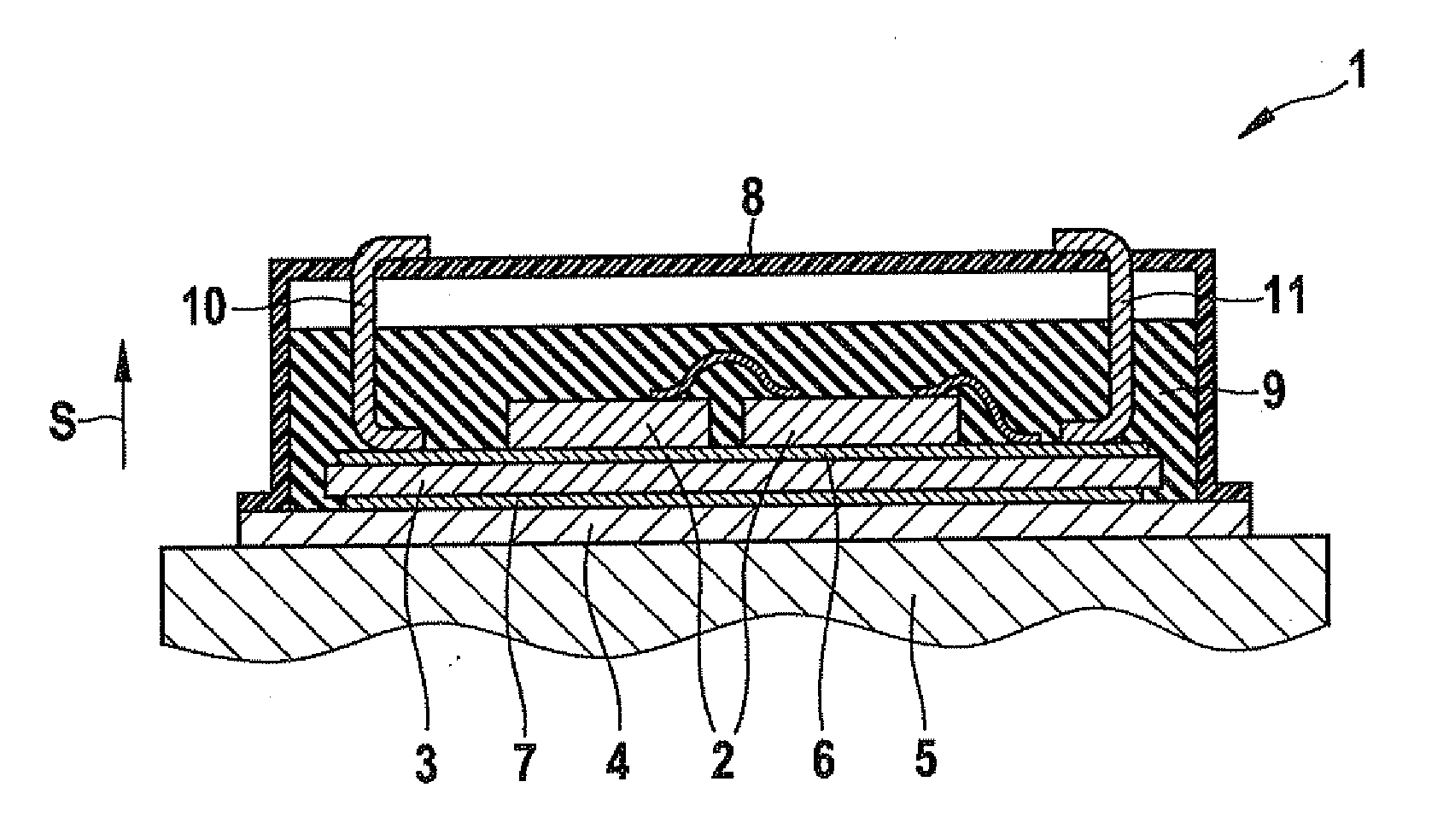

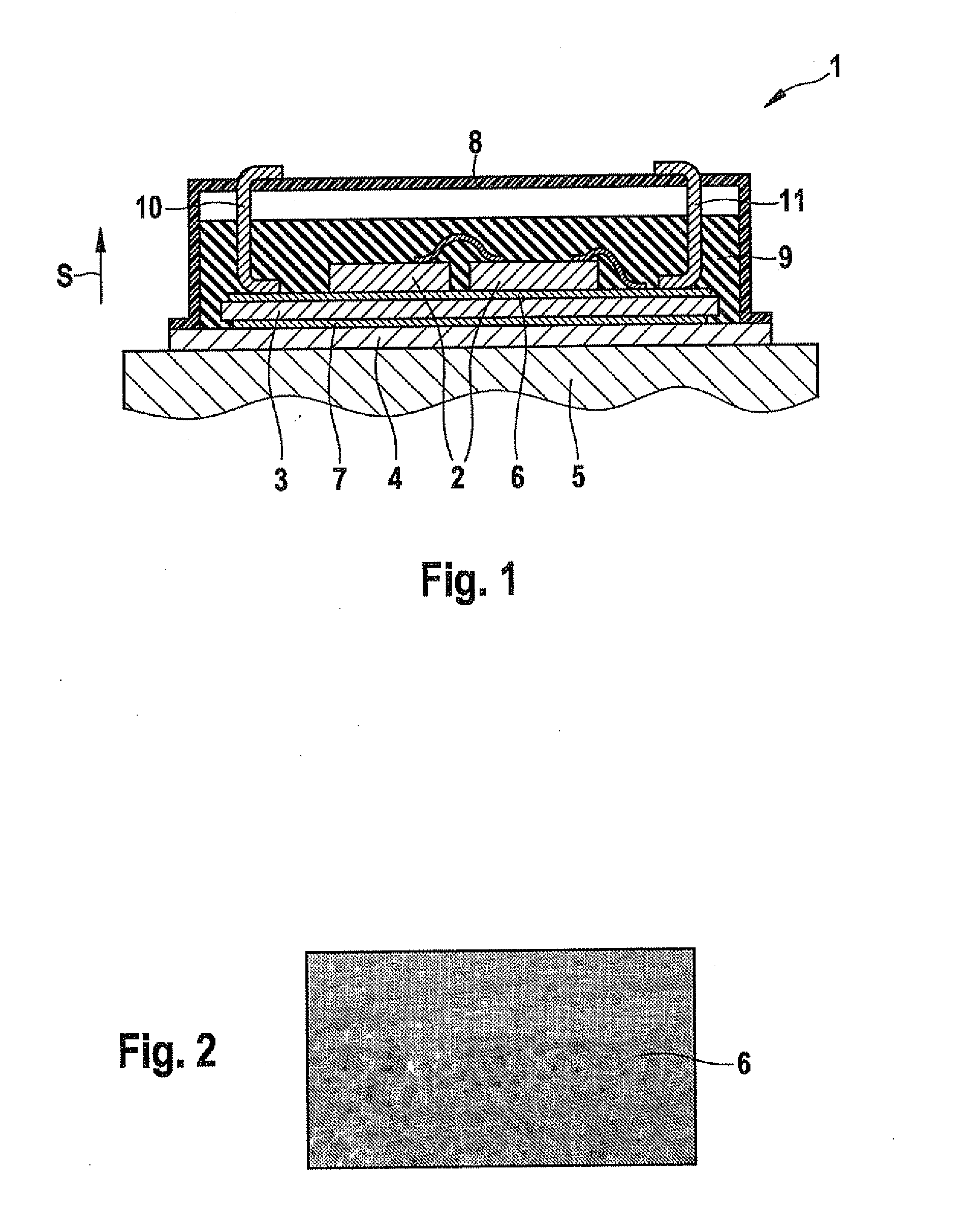

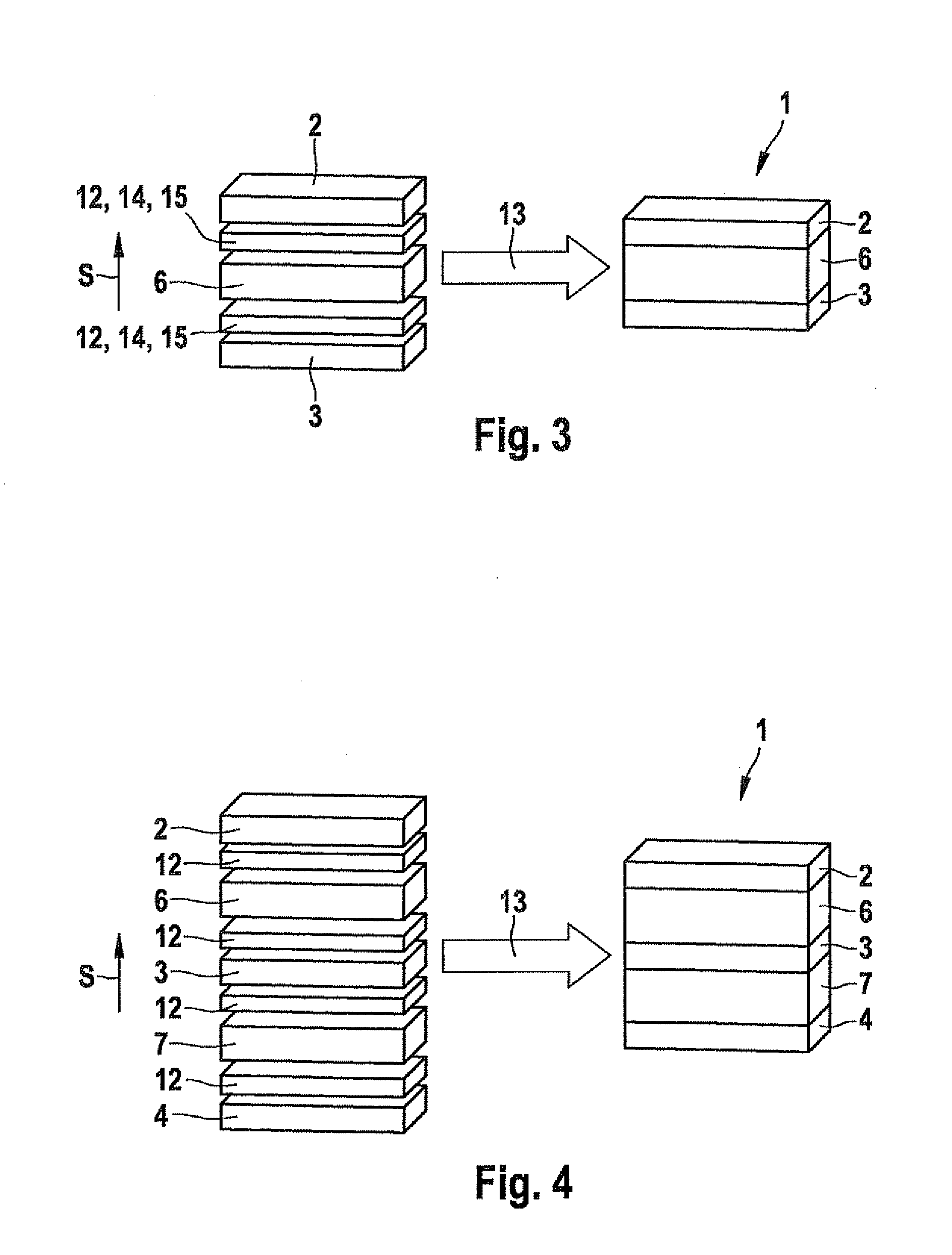

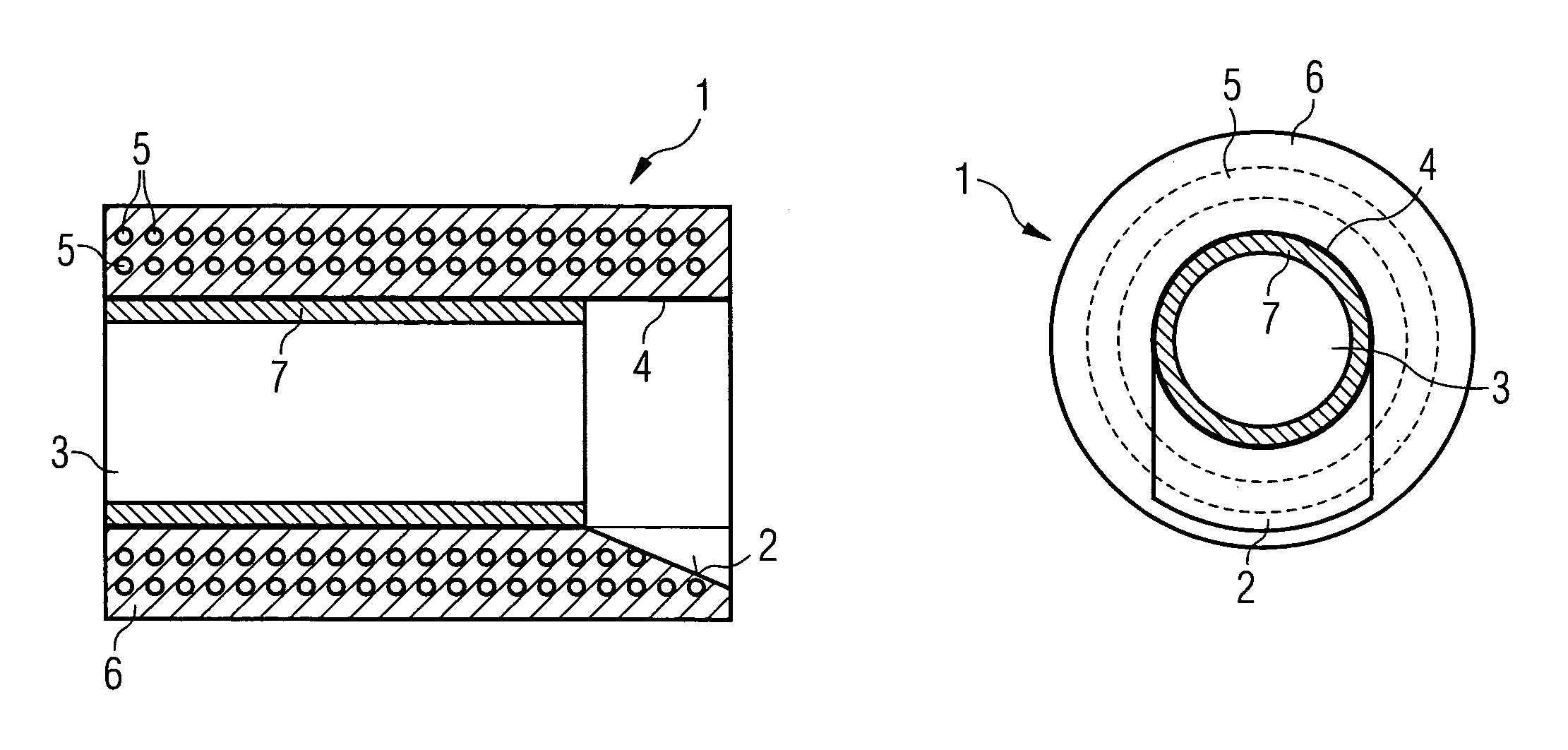

Electrical or electronic composite component and method for producing an electrical or electronic composite component

InactiveUS20110304985A1Low costProducibleSemiconductor/solid-state device detailsSolid-state devicesMechanical engineeringMaterials science

An electrical or electronic composite component is described as having a first joining partner and at least one second joining partner. According to the present system, it is provided that a sintered compact having open porosity is accommodated between the first and the second joining partner, the sintered compact is connected fixedly to the first and to the second joining partner.

Owner:ROBERT BOSCH GMBH

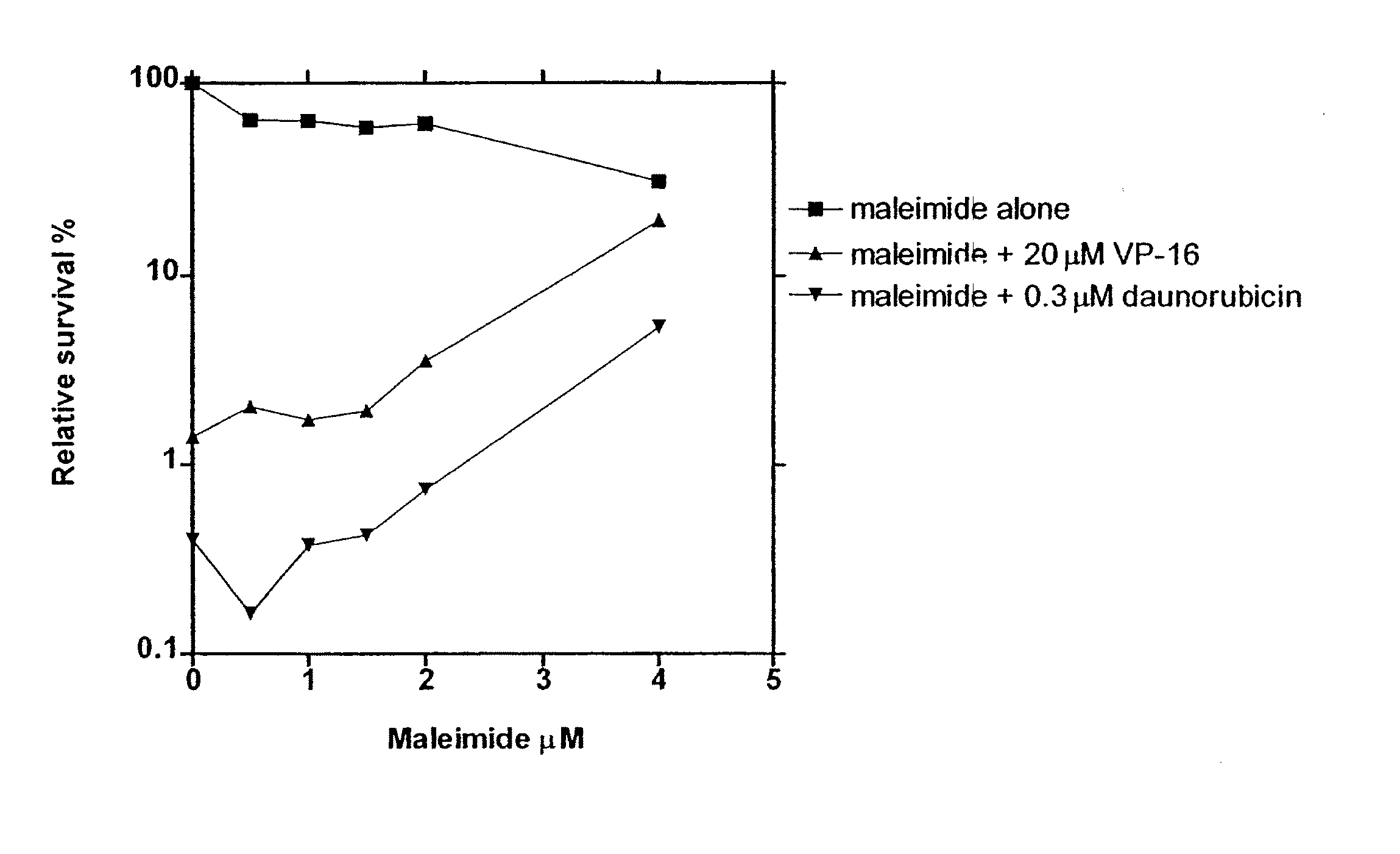

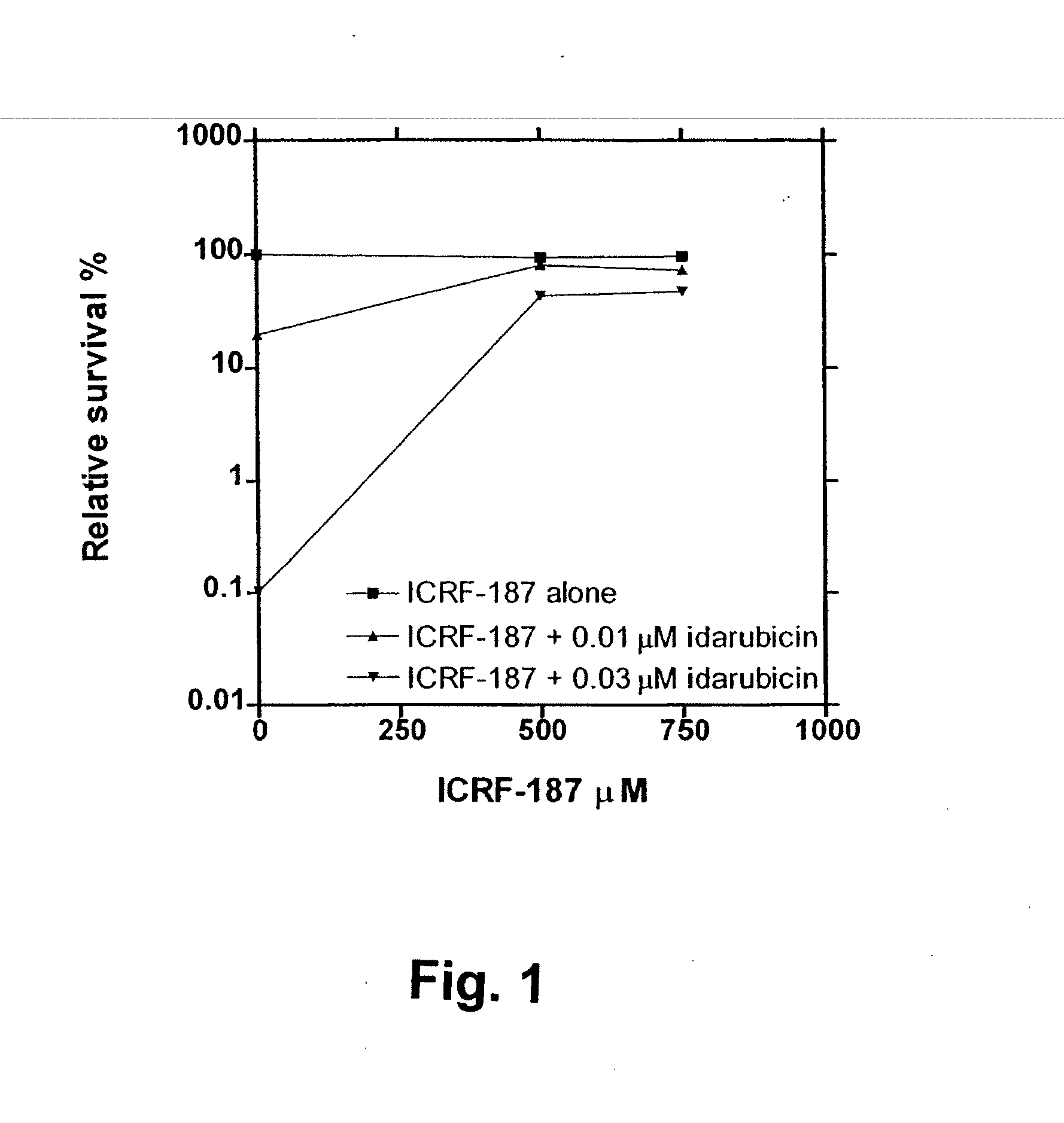

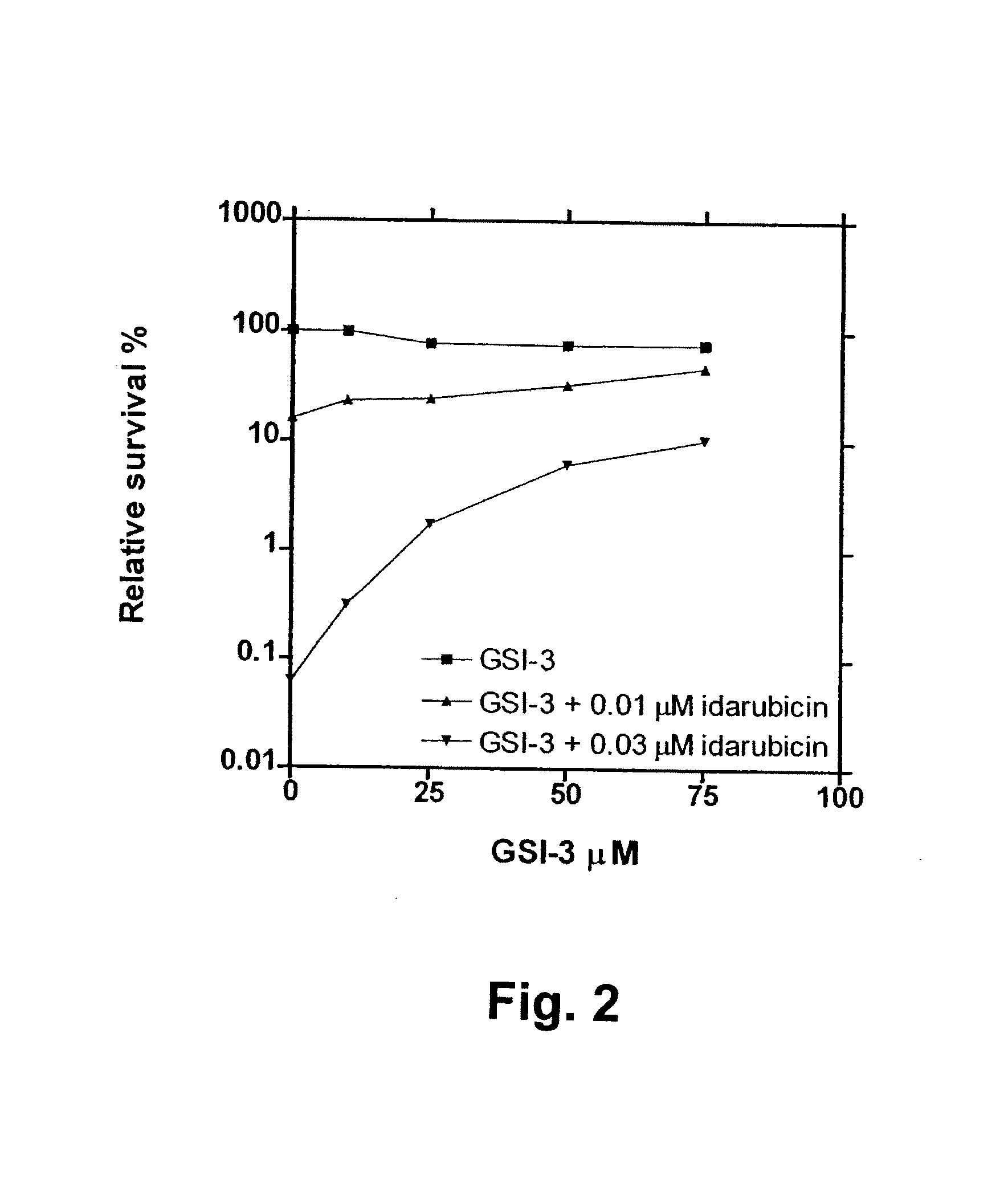

Succinimide and maleimide derivatives and their use as topoisomerase ii catalytic inhibitors

InactiveUS20070196360A1Improve therapeutic indexEliminate side effectsOrganic active ingredientsOrganic chemistryDNA underwindingTopoisomerase-II Inhibitor

Maleimide and succinimide derivatives were found to be effective topoisomerase II catalytic inhibitors. Due to this property, the maleimide and succinimide derivatives were investigated for their use as cytostatic agents and thus in the treatment of cancer. The compounds of the invention can be used in combination treatments with other cytostatic agents, such as topoisomerase II poisons. The maleimide and succinimide derivatives, due to their effective topoisomerase II catalytic inhibitory activity, are also useful as extravasation agents, such as upon administration of a topoisomerase II poison.

Owner:TOPOTARGET AS

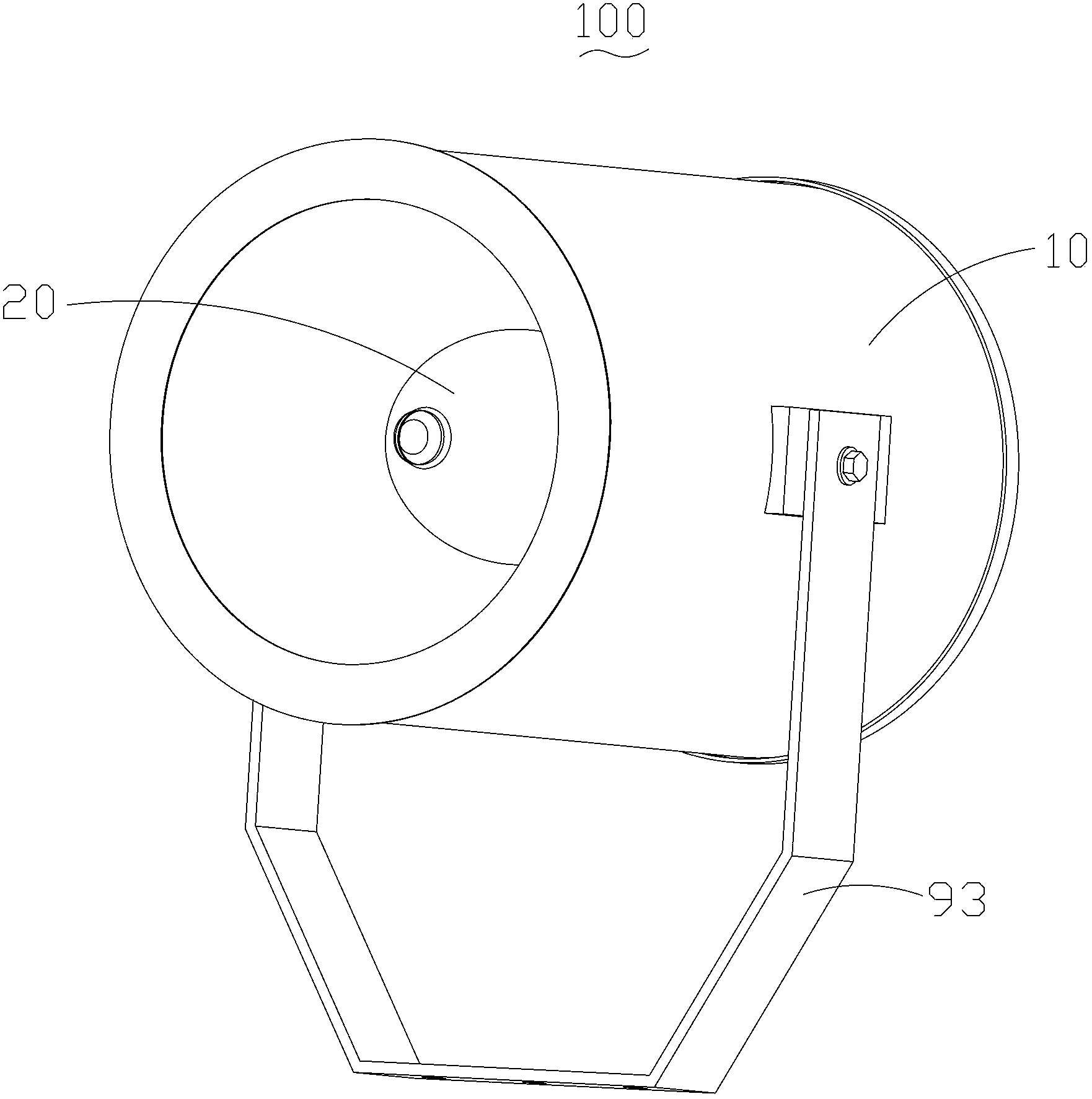

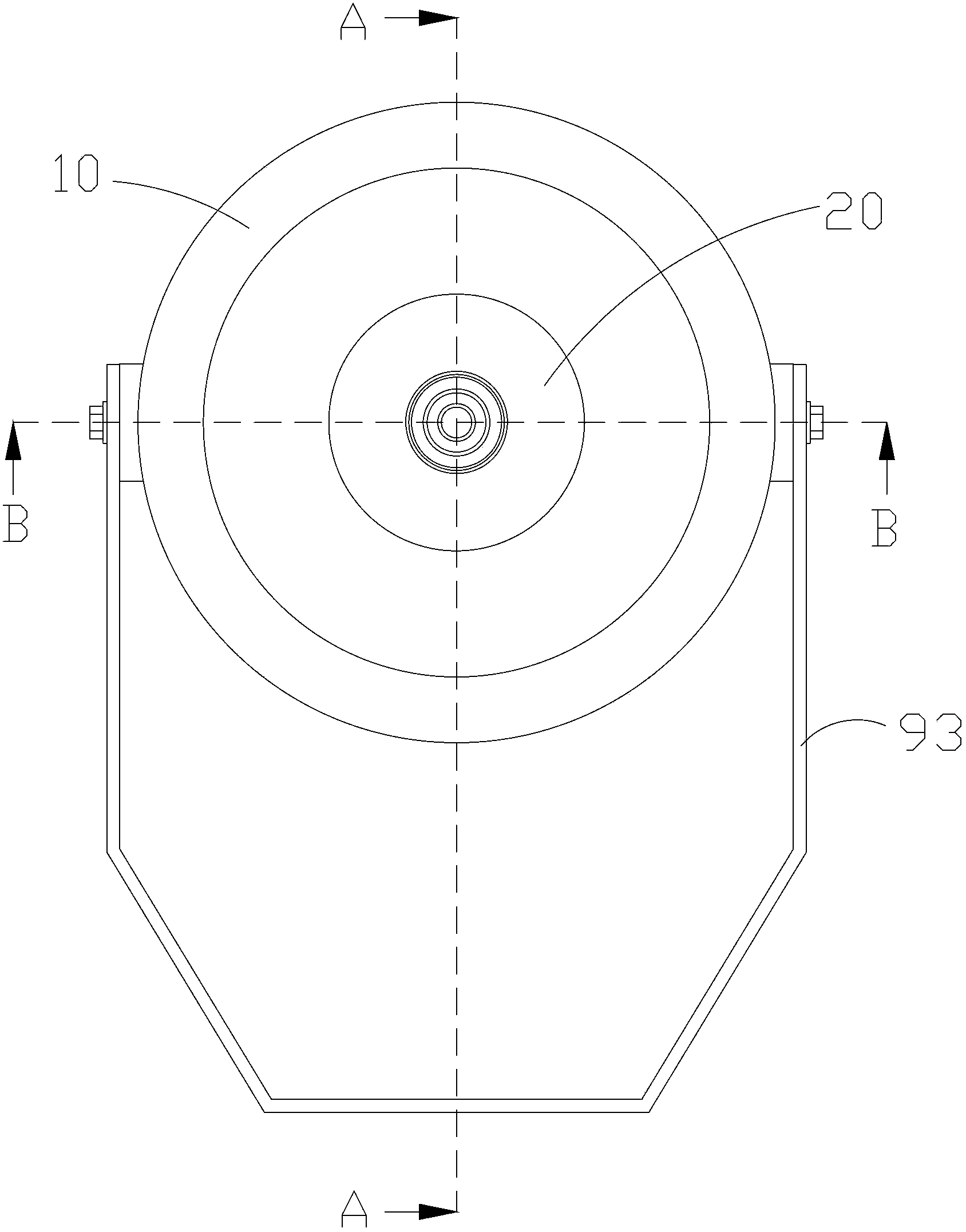

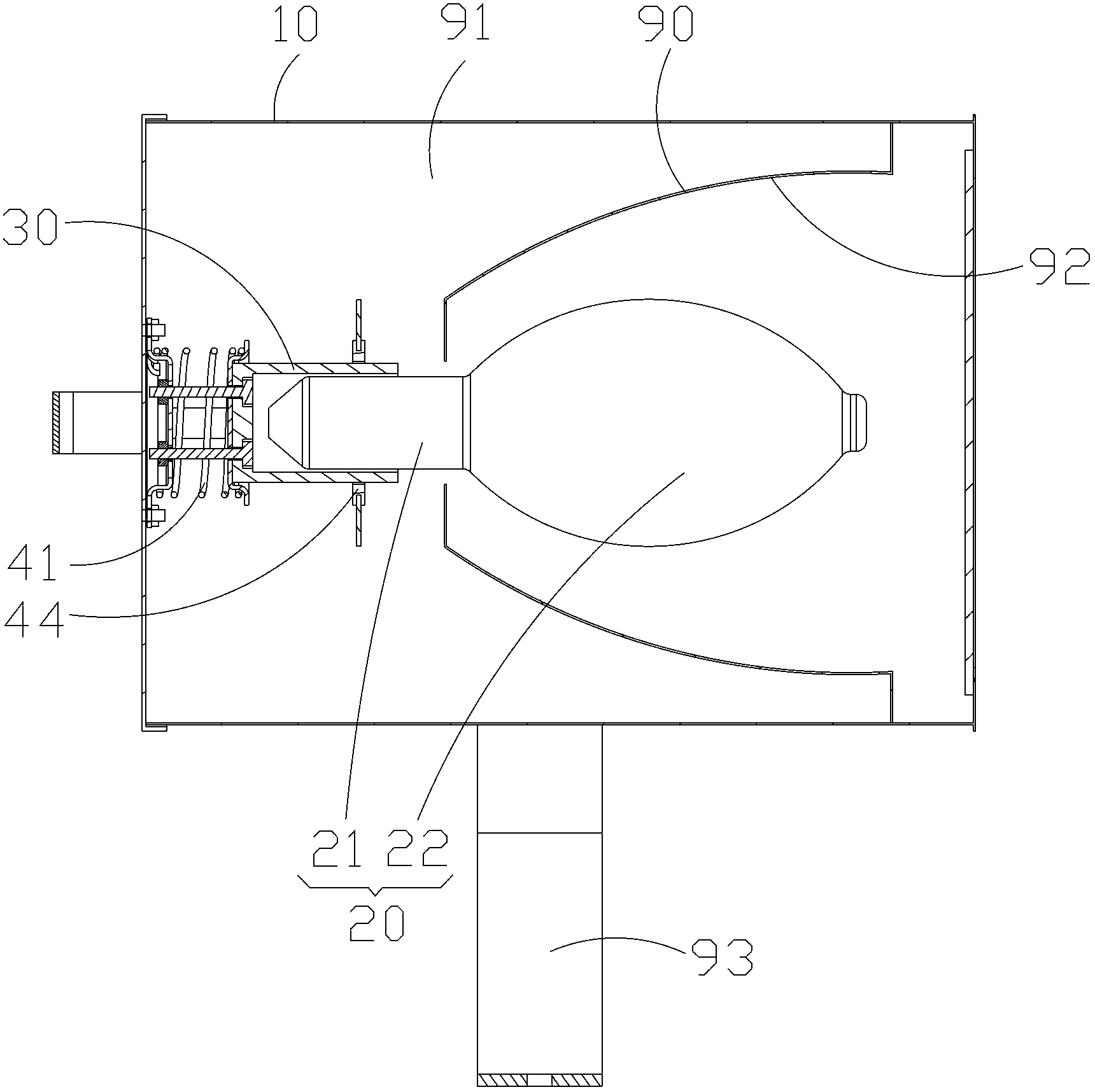

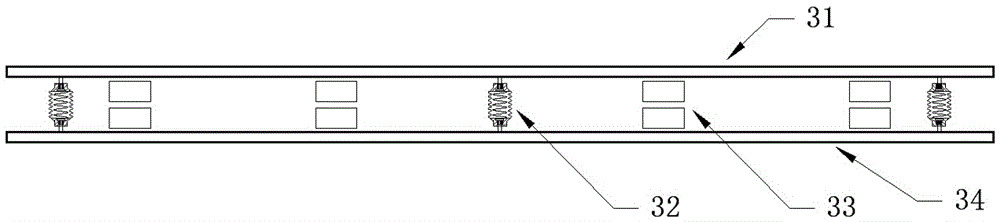

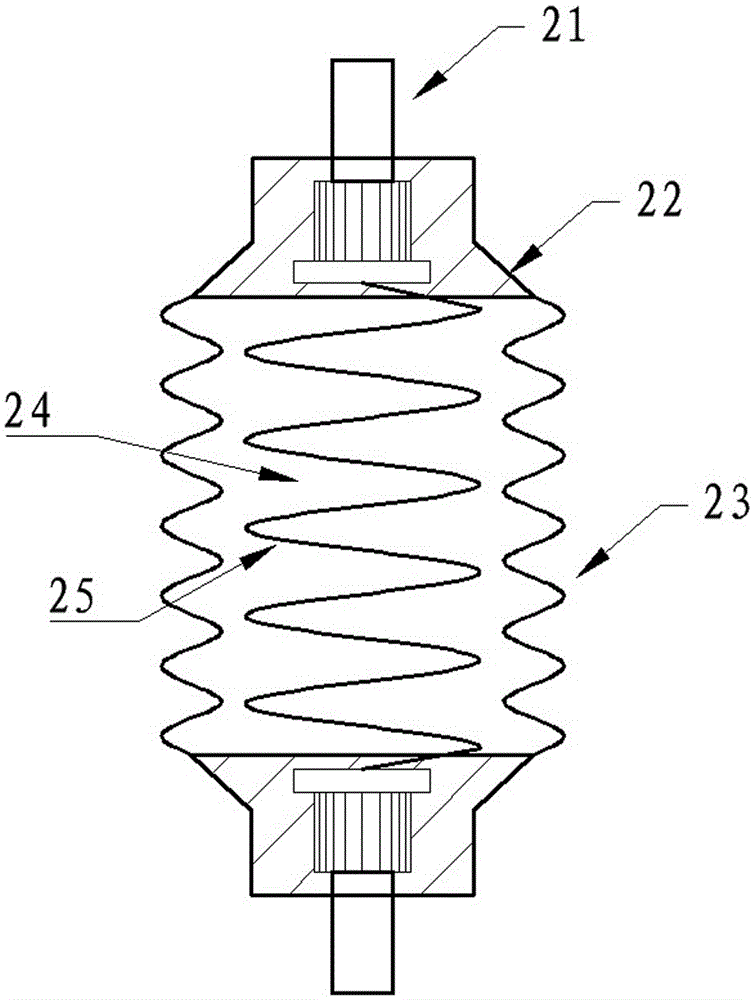

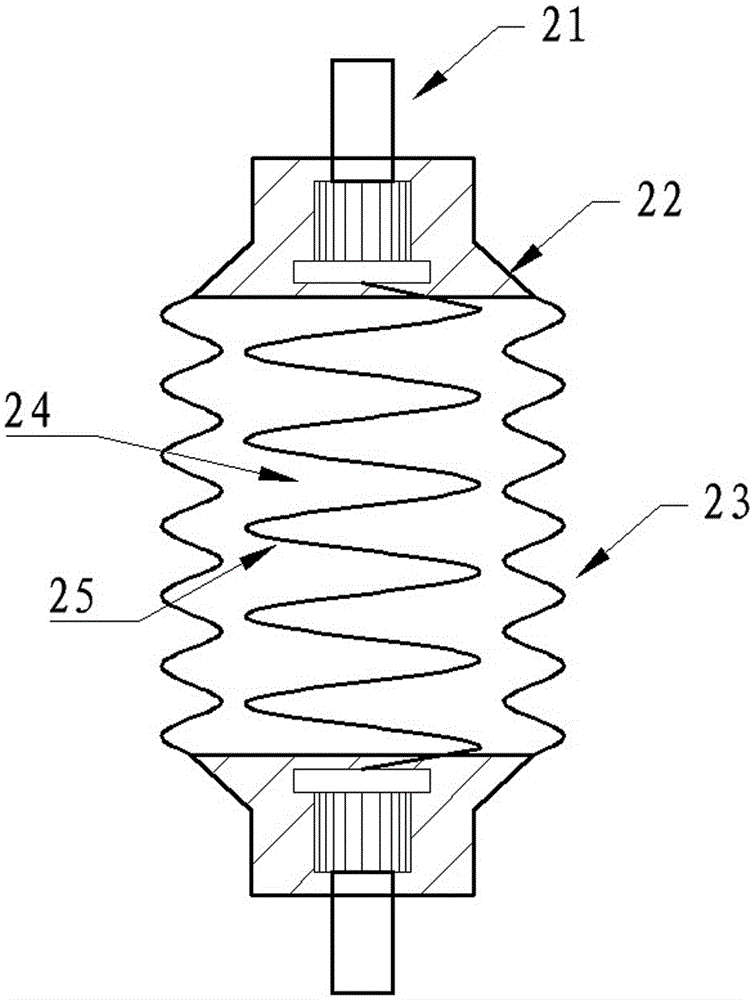

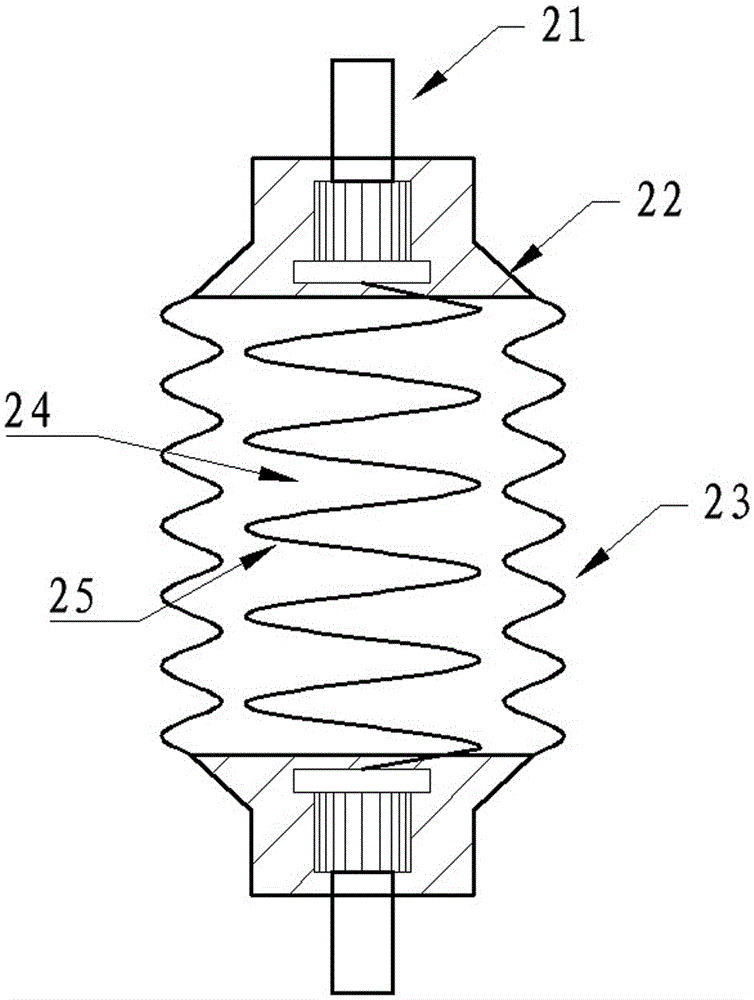

Damping lamp and damping lamp base

ActiveCN103453480AReduce destructive effectsExtend your lifeLighting support devicesProtective devices for lightingLamp shellEngineering

The invention provides a damping lamp base comprising a base body and a damping device connected to the base body. The damping device comprises a damping element disposed between the bottom of the base body and a lamp shell, a limit plate for sleeving the outside of the base body, a support, and an elastic hoop, wherein the support which supports the limit plate is used for fixing the limit plate on the lamp shell, and the elastic hoop for sleeving the outside of the base body is located between the limit plate and the outer surface of the base body. The invention further provides a damping lamp comprising the lamp shell, the damping lamp base installed inside the lamp shell, and a light source installed inside a base body of the damping lamp base. The damping element and the elastic hoop allow the base body and the light source to suffer less destructive influence of external vibration; the base body and the light source are protected; external vibration is reduced to the range acceptable to the base body and the light source; luminous effect of the lamp is improved, and the service lives of the base body and the light source are prolonged.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

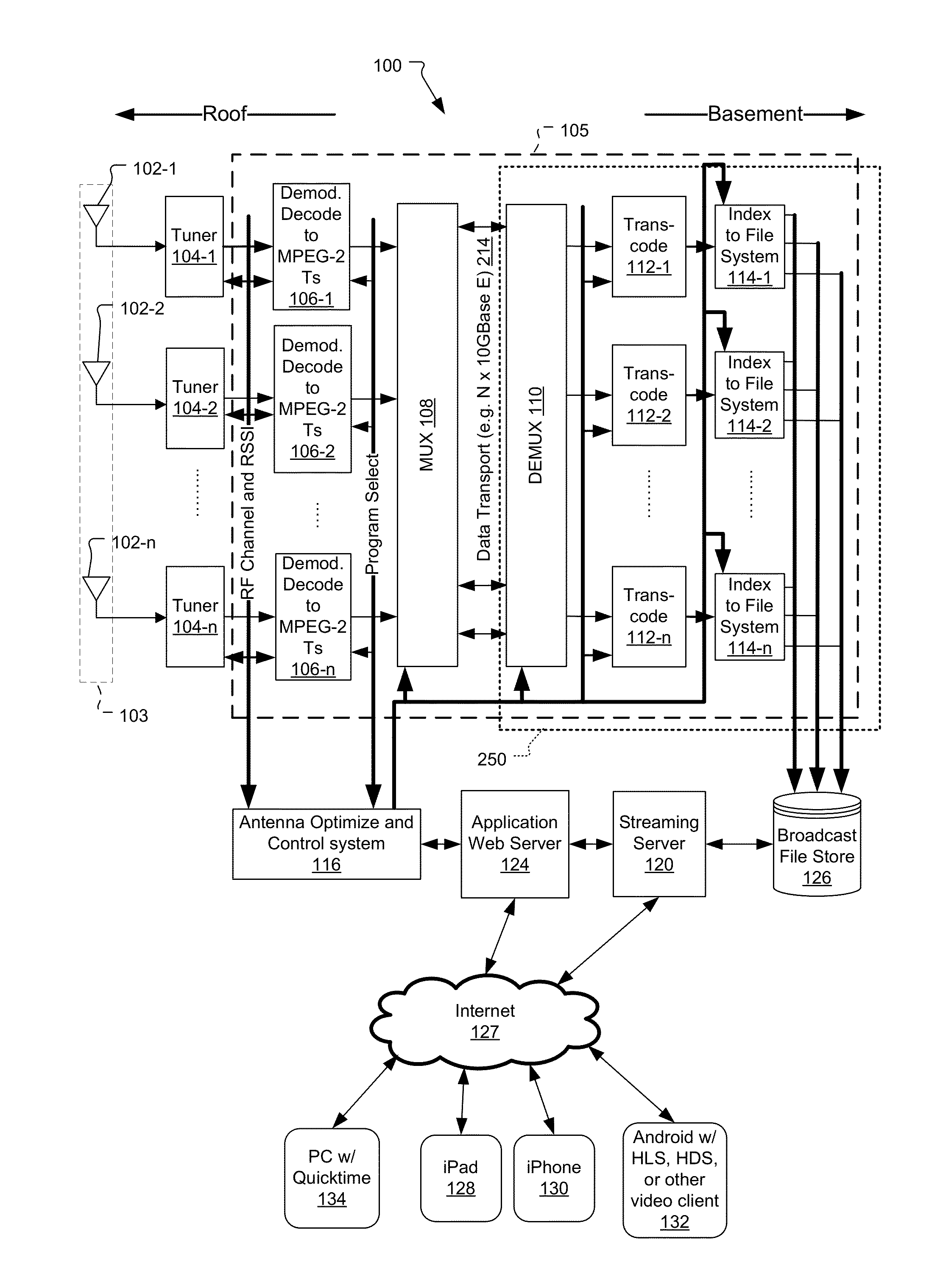

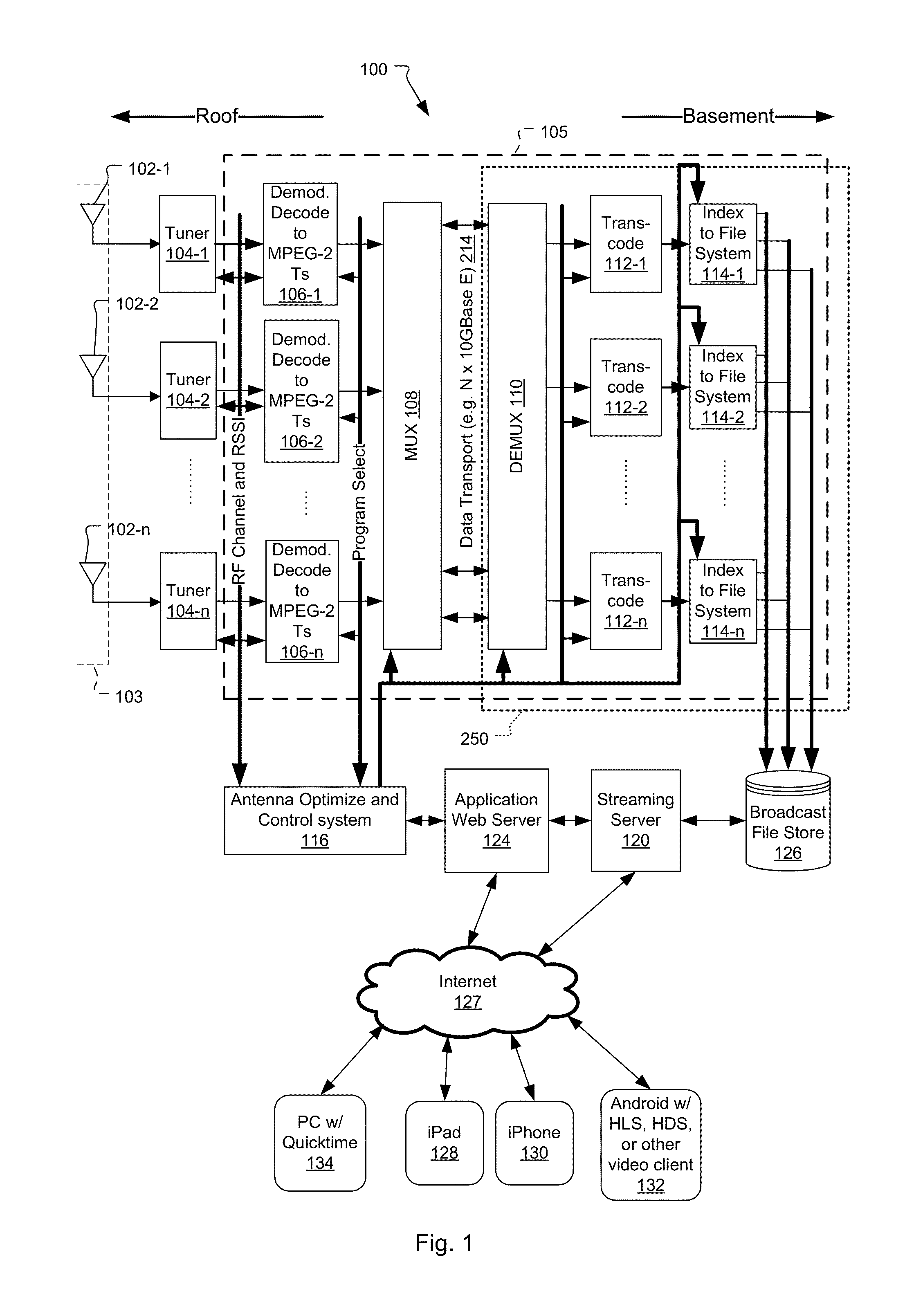

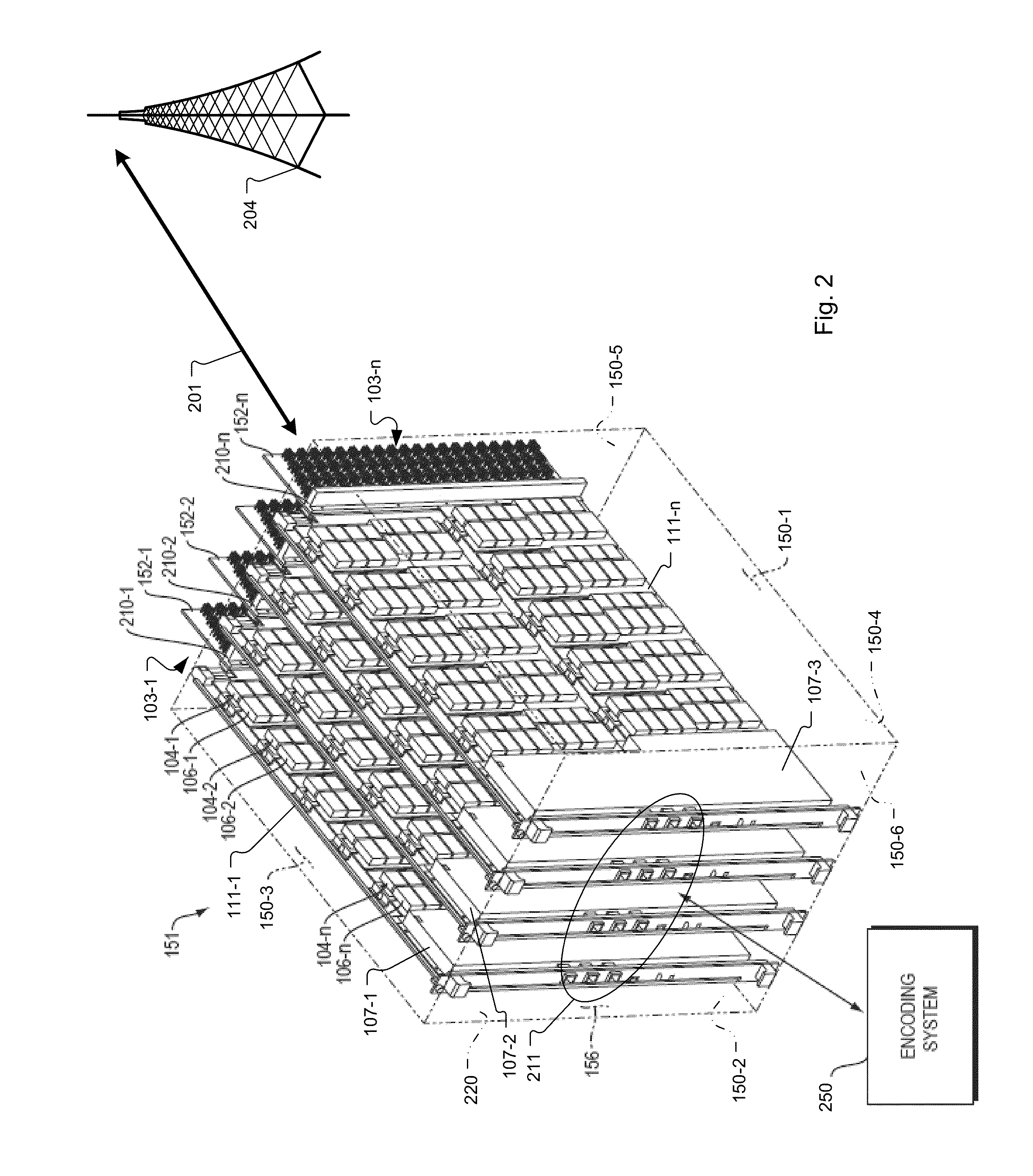

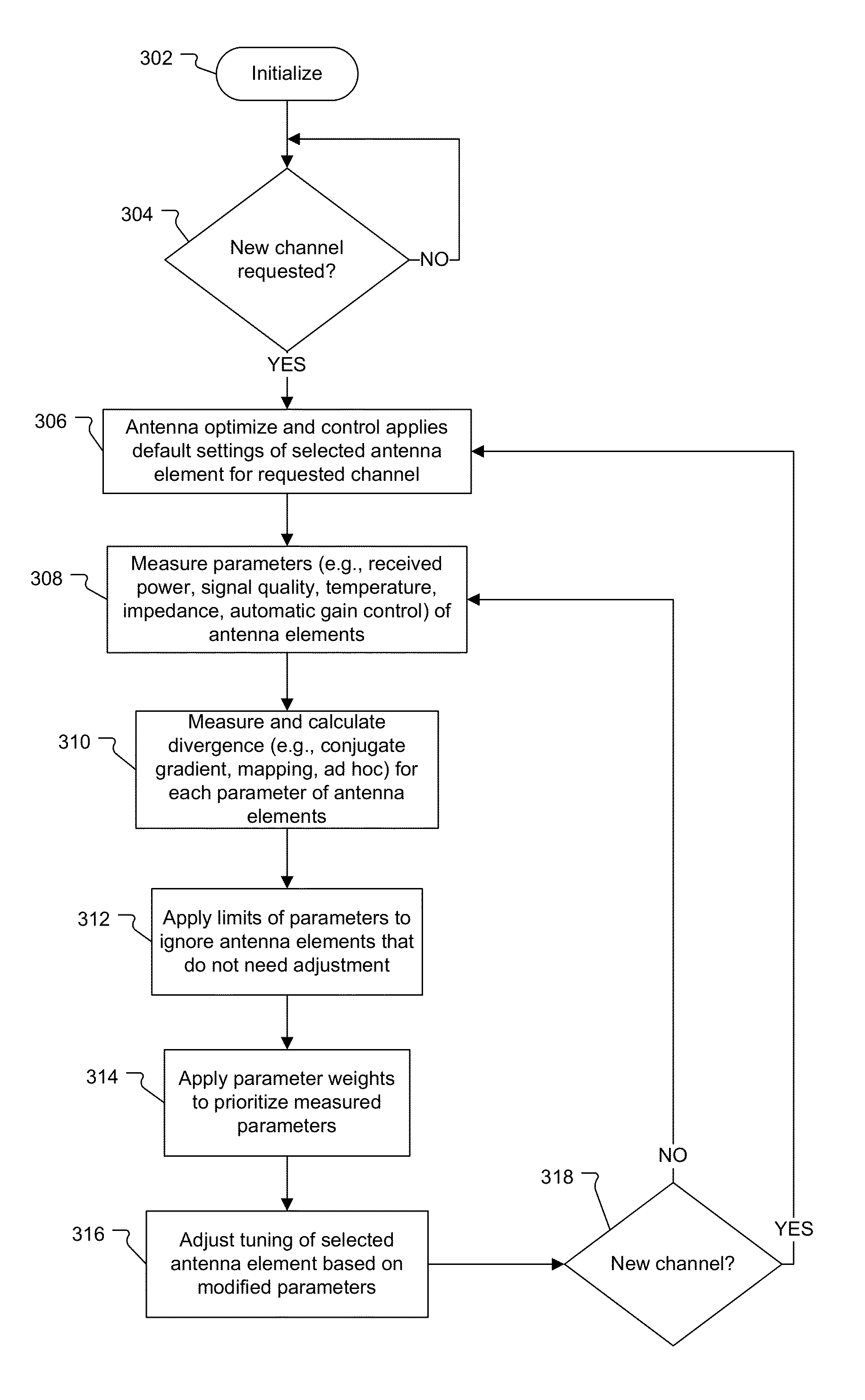

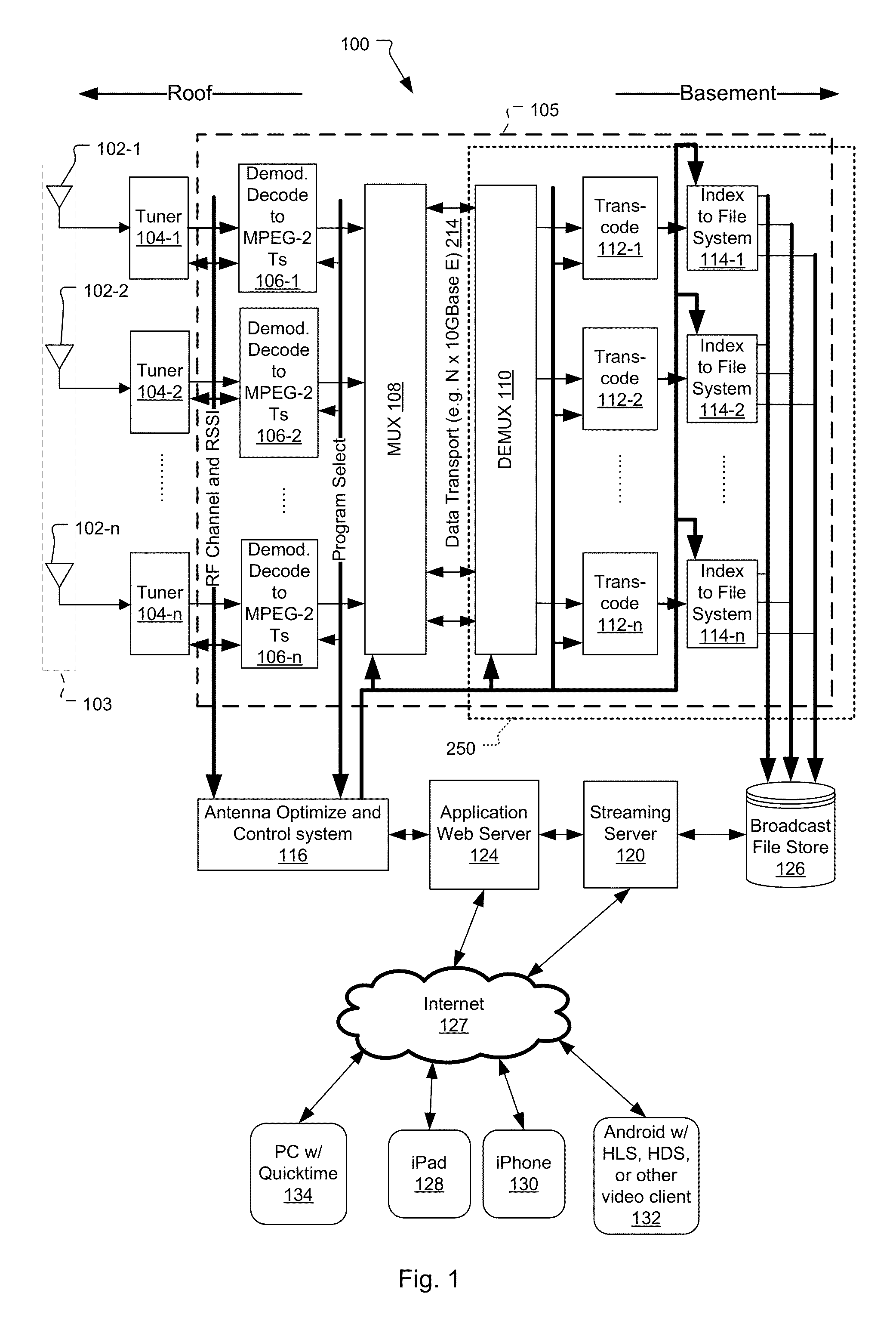

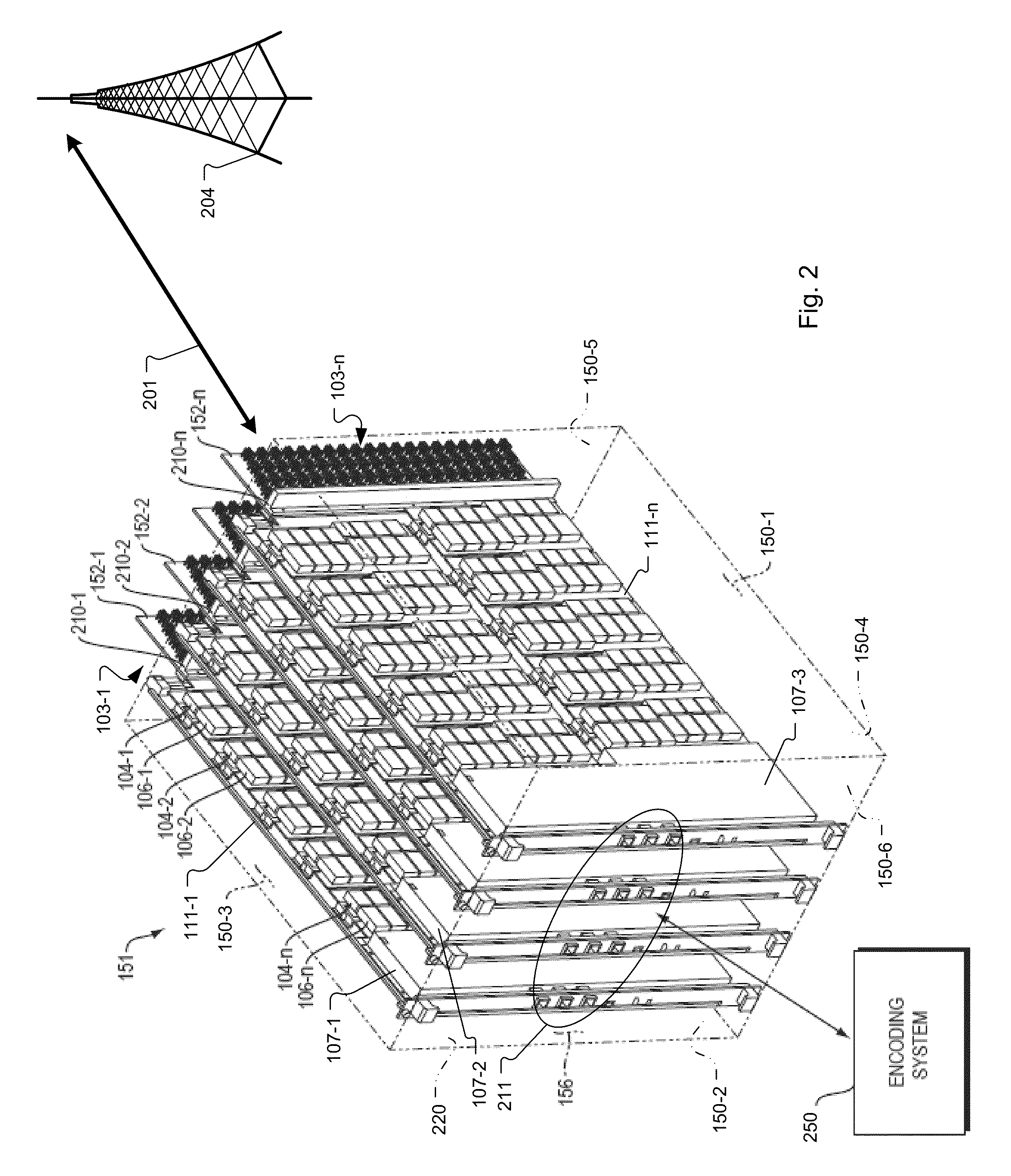

Dynamic Tuning in Dense Arrays of Electrically Small Elements

ActiveUS20140038535A1Minimize couplingEasy to receiveDiscontinuous tuningTelevision system detailsSignal qualityCoupling

The purpose of dynamically tuning in dense arrays is to improve power received and signal quality. In traditional phased array the inherent design procedure is to design for good matching over the frequency and scan angle of operation. Typically this is done in the overall design based on a priori knowledge of the frequency, relative phasing and amplitude distribution of all the elements. With this a priori knowledge the design can be done based on known mutual coupling.

Owner:CHARTER COMM OPERATING LLC

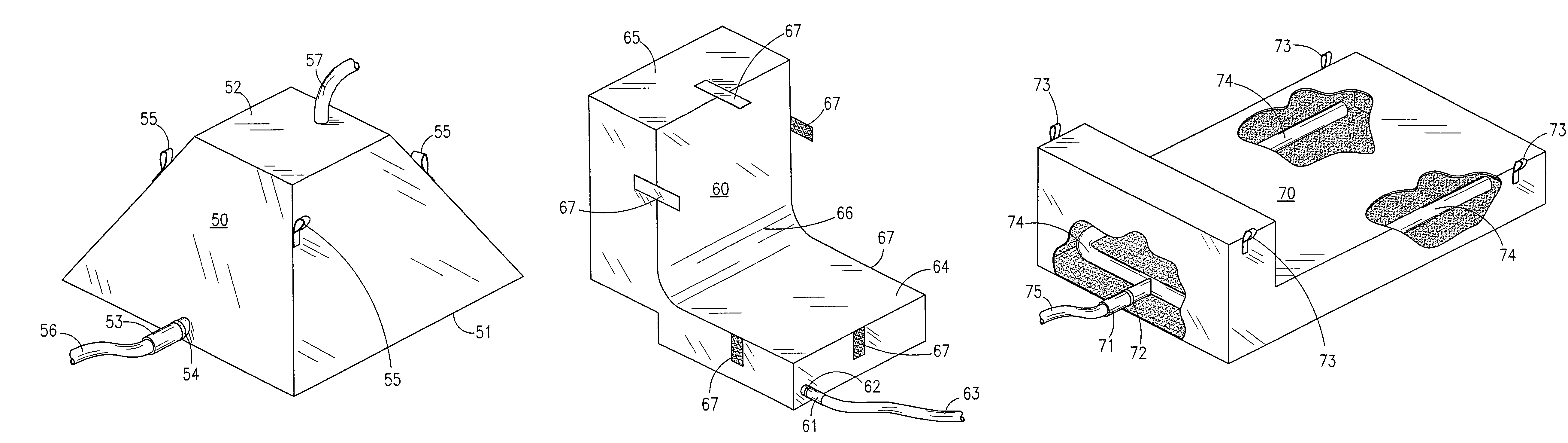

Apparatus and method for blast suppression

InactiveUS7313994B1Reduce destructive effectsHinders its propagationAmmunitionBlastingCombustionEngineering

An improved method of blast suppression involves forming a foam barrier in proximity to a bomb or other suspicious device. The foam is maintained in position by a containment structure which is inflated and kept in an inflated state by the foam used to form such barrier. Various containment structures and methods are disclosed for suppression of compression waves and combustion effects caused by an explosive event.

Owner:BURNER FIRE CONTROL

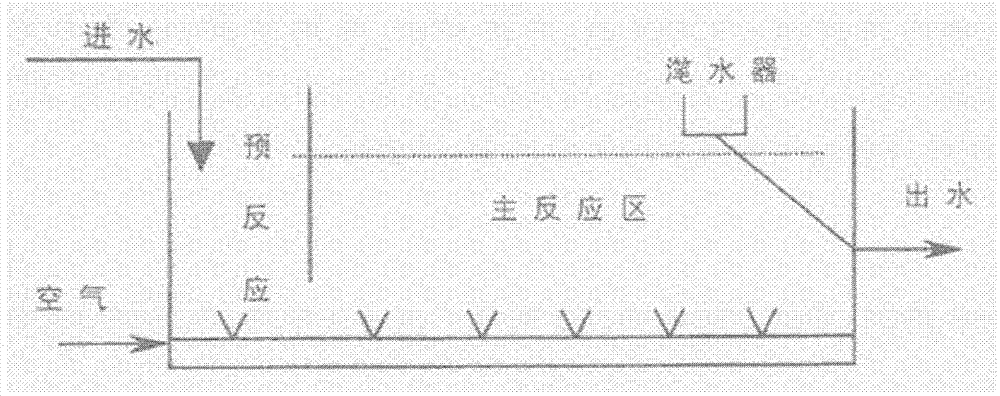

Emergency regulation method for treating water quality impact of abnormal inlet water by using CASS (cyclic activated sludge system) process

InactiveCN102815788APracticalImprove buffering effectTreatment with aerobic and anaerobic processesSludgeWater quality

The invention provides an emergency regulation method for treating water quality impact of abnormal inlet water by using a CASS (cyclic activated sludge system) process. The emergency regulation method comprises the following steps: determining whether a CASS reaction tank is about to be impacted by the abnormal inlet water according to on-line detection of a total water inlet installed on a CASS process sewage treatment plant; if detecting that the abnormal inlet water enters the CASS reaction tank in a certain time interval, adjusting the CASS reaction tank in or about to enter the water inlet stage to realize the lowest water filling ratio (f) and the highest sludge return ratio (R) according to the water inlet flow so as to create the maximum buffering capacity; controlling time allocation and corresponding dissolved oxygen concentration levels of four stages of water inlet, aeration, sediment and water decantation of the CASS reaction tank in or about to enter the water inlet stage in an operation cycle according to the water quality characteristics of the abnormal inlet water; and if the circumstances are normal, operating according to a normal mode. By utilizing the emergency regulation method, a CASS process operation method is regulated, equipment does not need to be changed, and the emergency regulation method has the characteristic of practicability.

Owner:CHONGQING UNIV +1

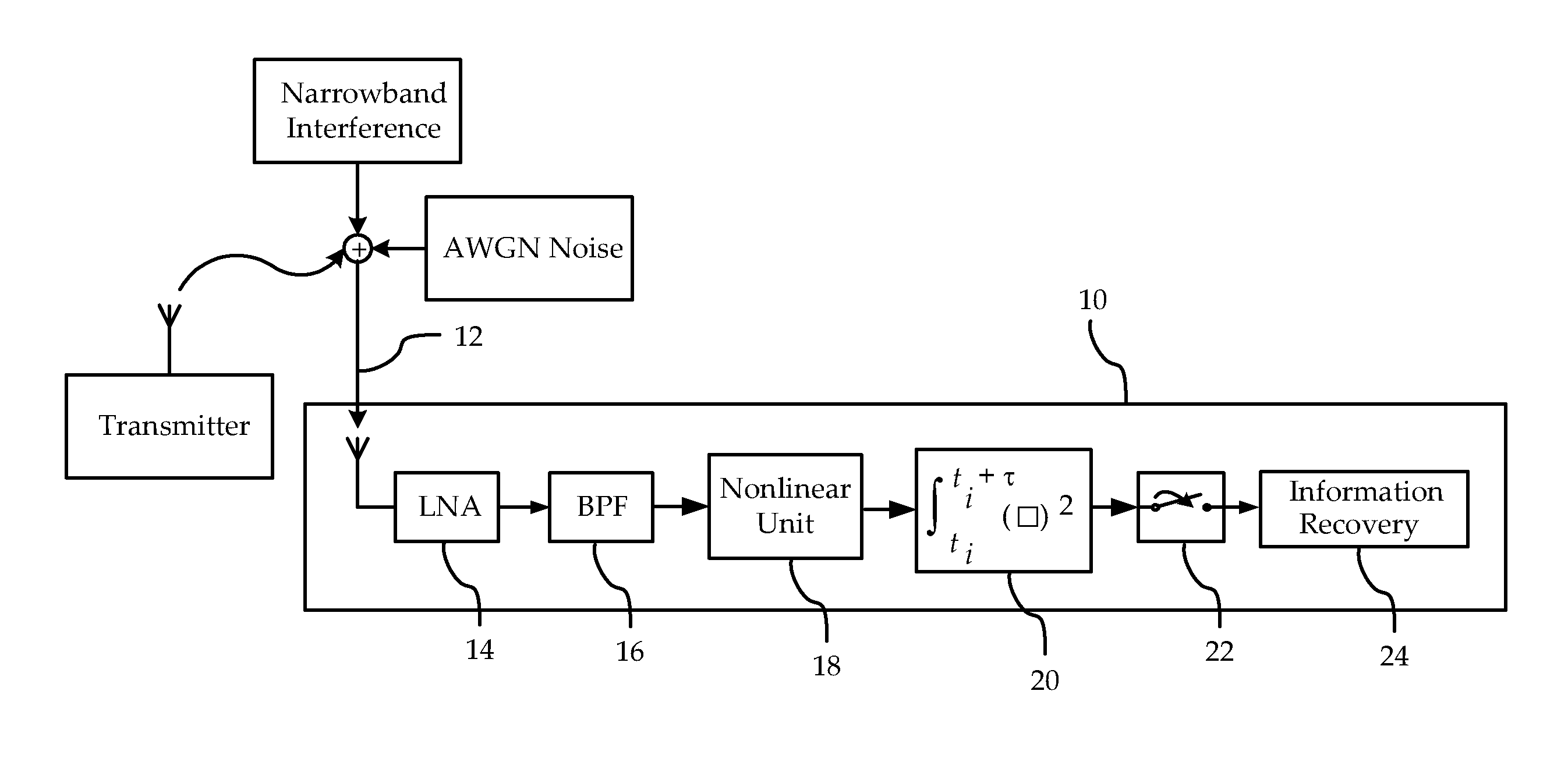

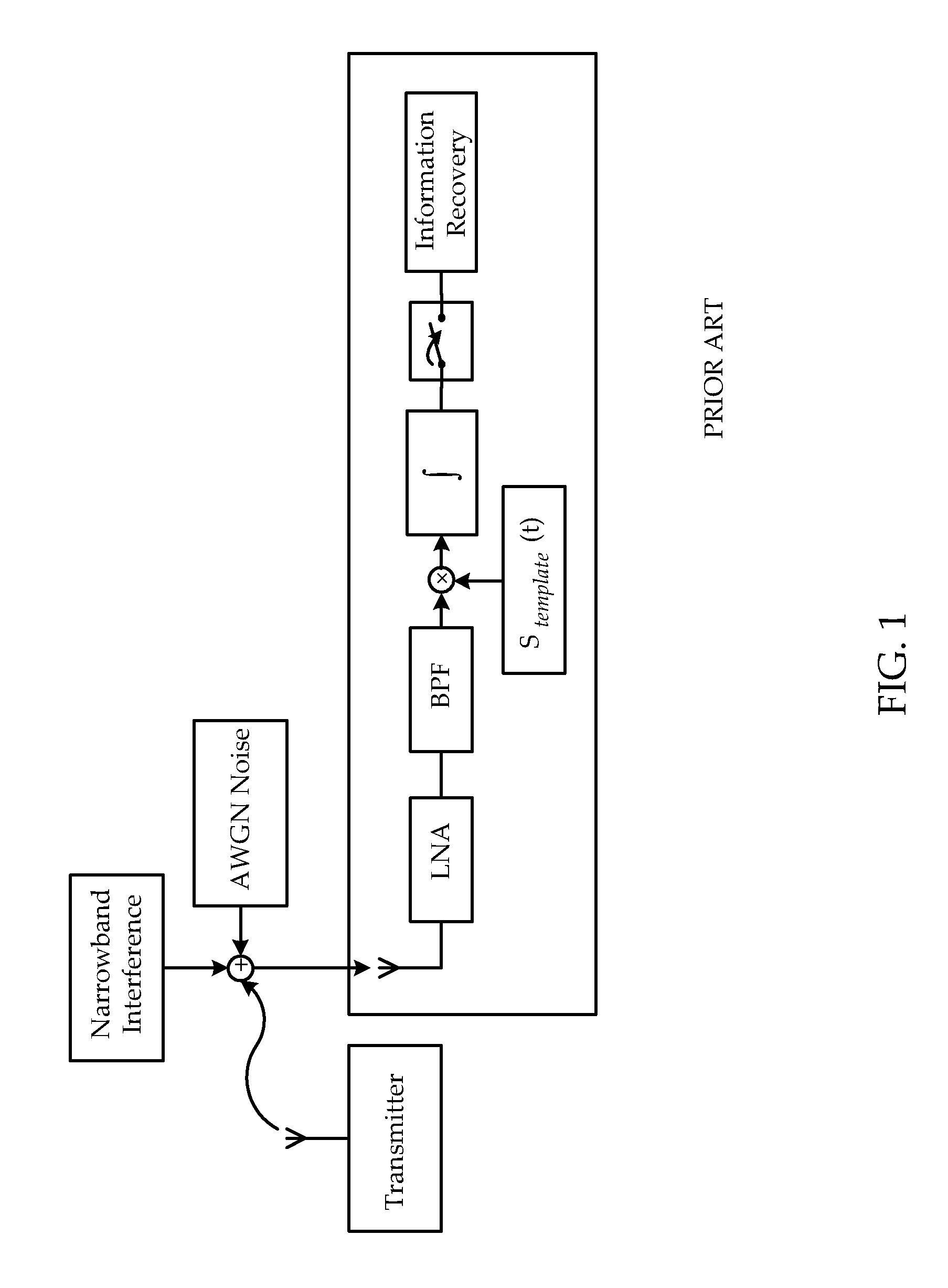

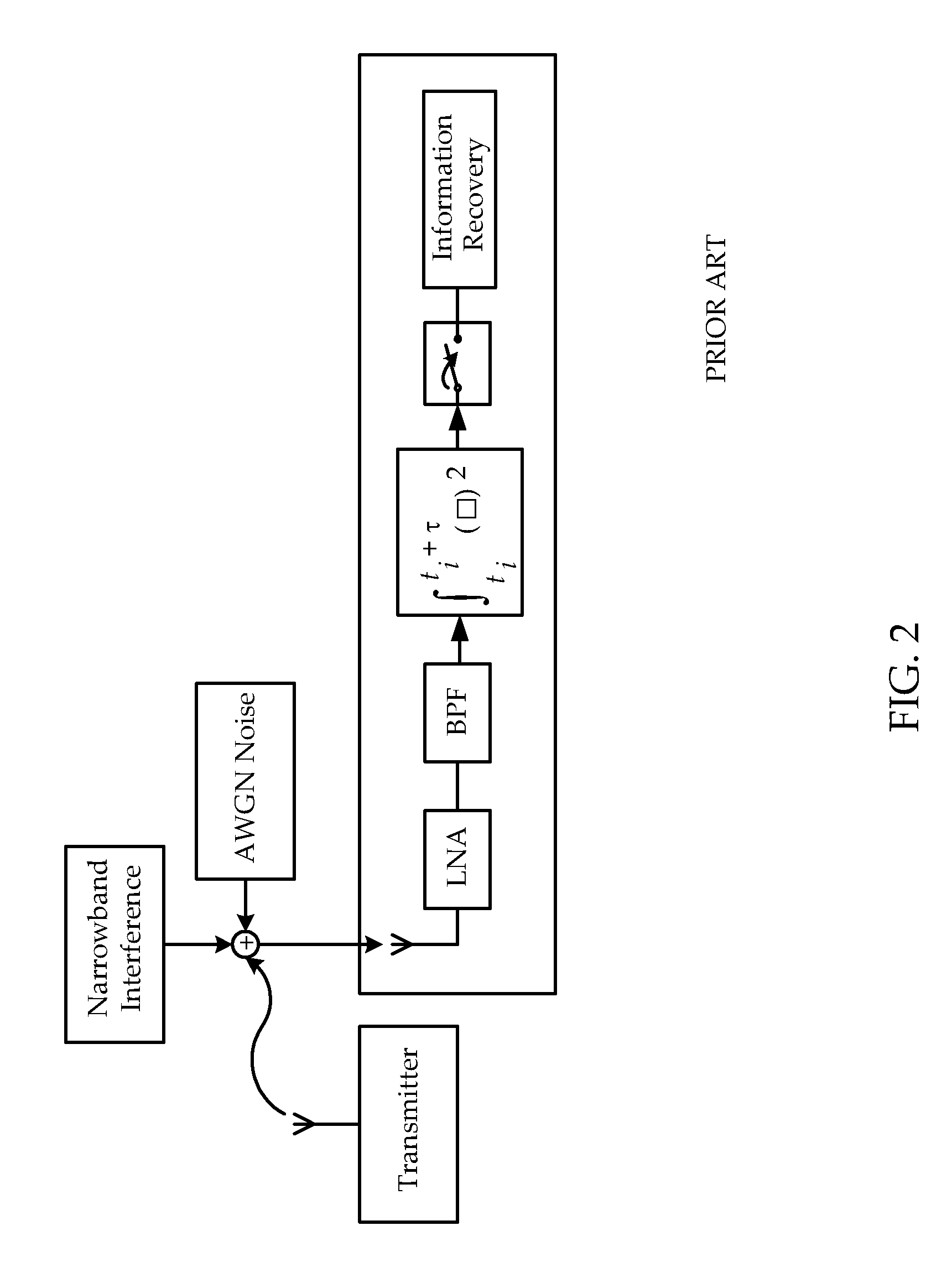

Nonlinear signal processing method and apparatus for pulsed-based ultra-wideband system

InactiveUS20130058381A1Reduce of narrowband interferenceReduce noise energyTransmissionUltra-widebandInterference ratio

A method and apparatus are provided for processing a received pulsed-based ultra-wideband (UWB) signal before the signal is demodulated by an energy detection based receiver. A nonlinear signal processing unit contains one or multiple subunits, and each subunit consists of a nonlinear device and a filter. The nonlinear devices can be any devices that can shift signal, noise, and interference spectra in a nonlinear fashion, and include but are not limited to square law devices and Teager-Kaiser operators. By applying the nonlinear signal processing unit on the received UWB signal, a major part of the energy of noise and narrowband interferences is shifted to specific frequency ranges and then removed by the appropriate filter(s) in the nonlinear signal processing unit. Thus, the signal-to-noise-plus-interference ratio (SNIR) of the received UWB signal can be improved.

Owner:CHEN ZHIZHANG +2

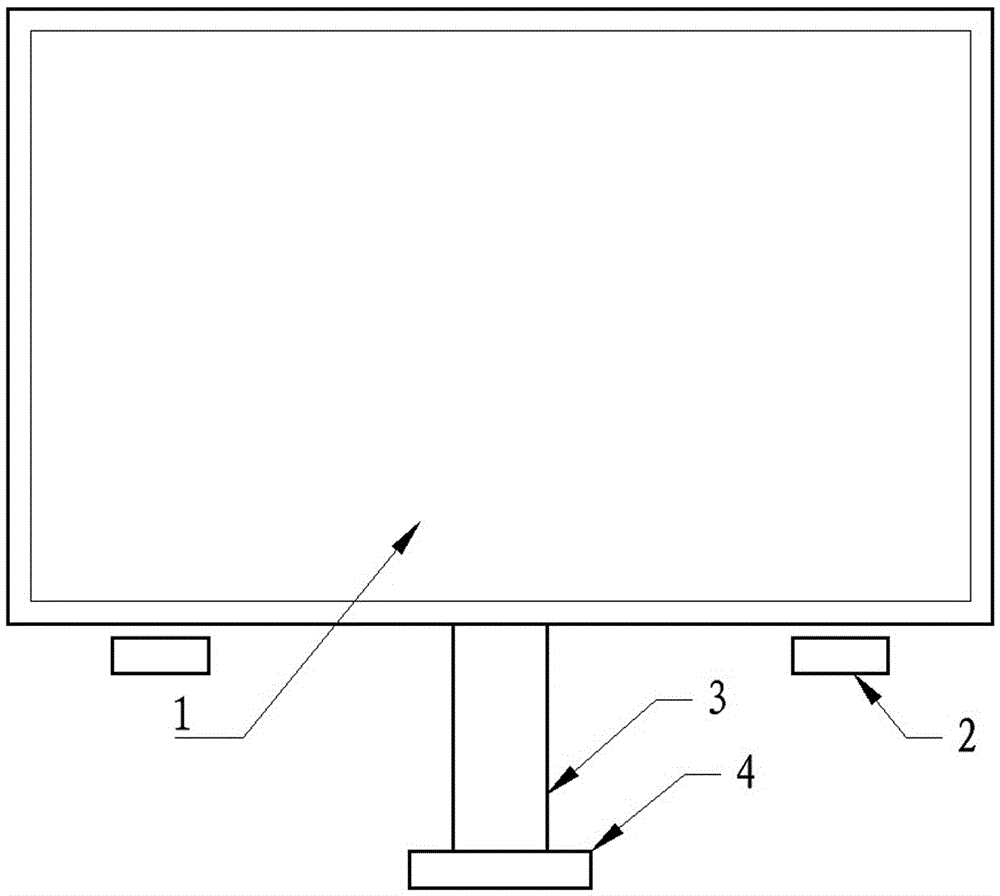

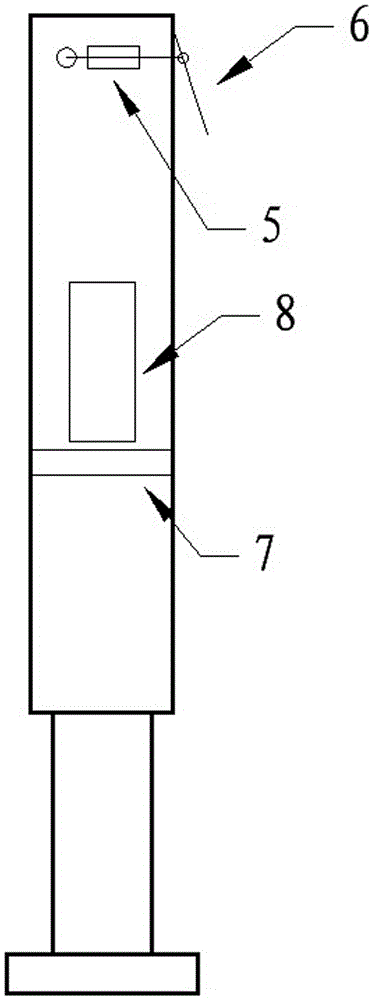

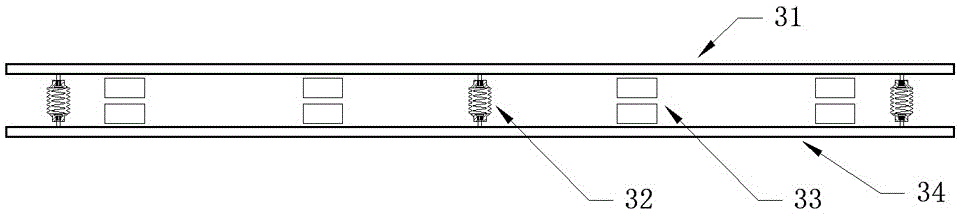

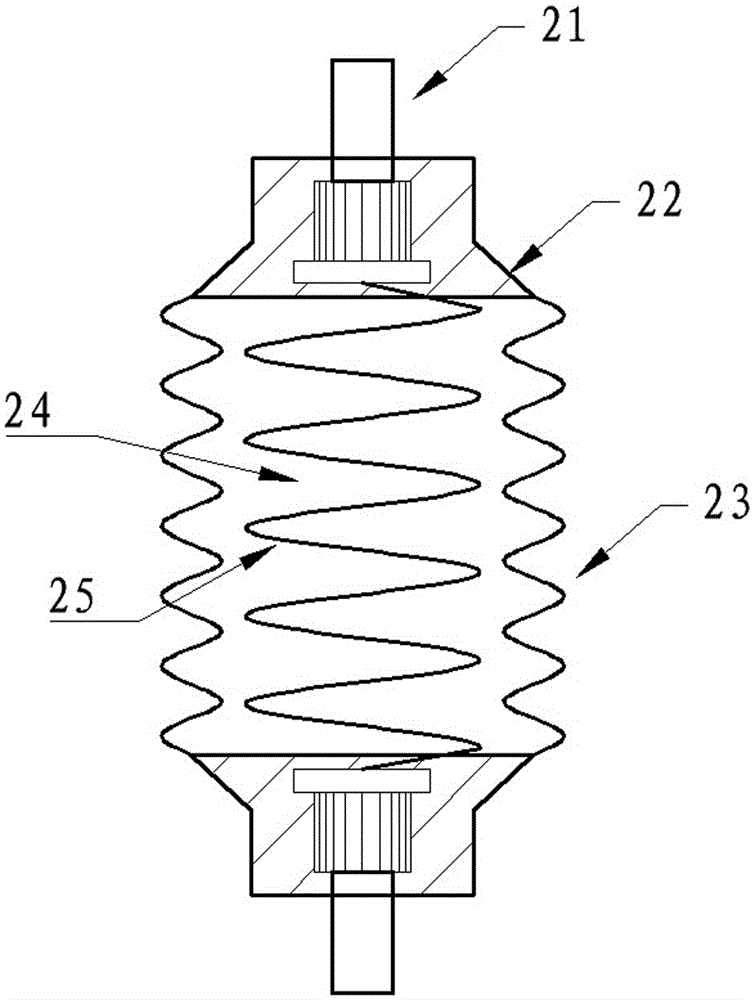

Large-scale damping electronic display screen with dehumidifier and temperature control air door

ActiveCN106228908AReduce destructive effectsEliminate vibration and shockNon-rotating vibration suppressionIdentification meansAutomatic controlSine wave

The invention discloses a large-scale damping electronic display screen with a dehumidifier and a temperature control air door. An air door on a lateral surface of a display screen is controlled by a sine wave thermal expander and is used for automatically controlling the opening degree and discharging heat according to the temperature variation; the dehumidifier is firmly integrated and fixed on a platform board of a damping platform; a base plate of the damping platform is connected with a lower frame of the large screen; the normal work of the display screen is ensured by damping; a plurality of magnets are arranged between the platform board of the damping platform and the base plate; a proper gap is reserved between the upper and lower magnets; the same magnetic poles can repel each other; the platform board of the damping platform and the base plate are in threaded shaft connection through the sine wave damper; a spring is arranged between the platform board of the damping platform and the base plate; the two ends are connected with a threaded shaft base disc; the threaded shaft is integrally cast with a rubber substrate through a knurling part connecting base disc; damping oil under a certain pressure is filled in an airtight chamber formed by a sine wave outline cylinder and the two end parts. The large-scale damping electronic display screen is simple in structure, practical and low in running cost. Excellent guarantee is supplied for the continuous stable work of the large-scale damping electronic display screen.

Owner:JISHOU UNIVERSITY

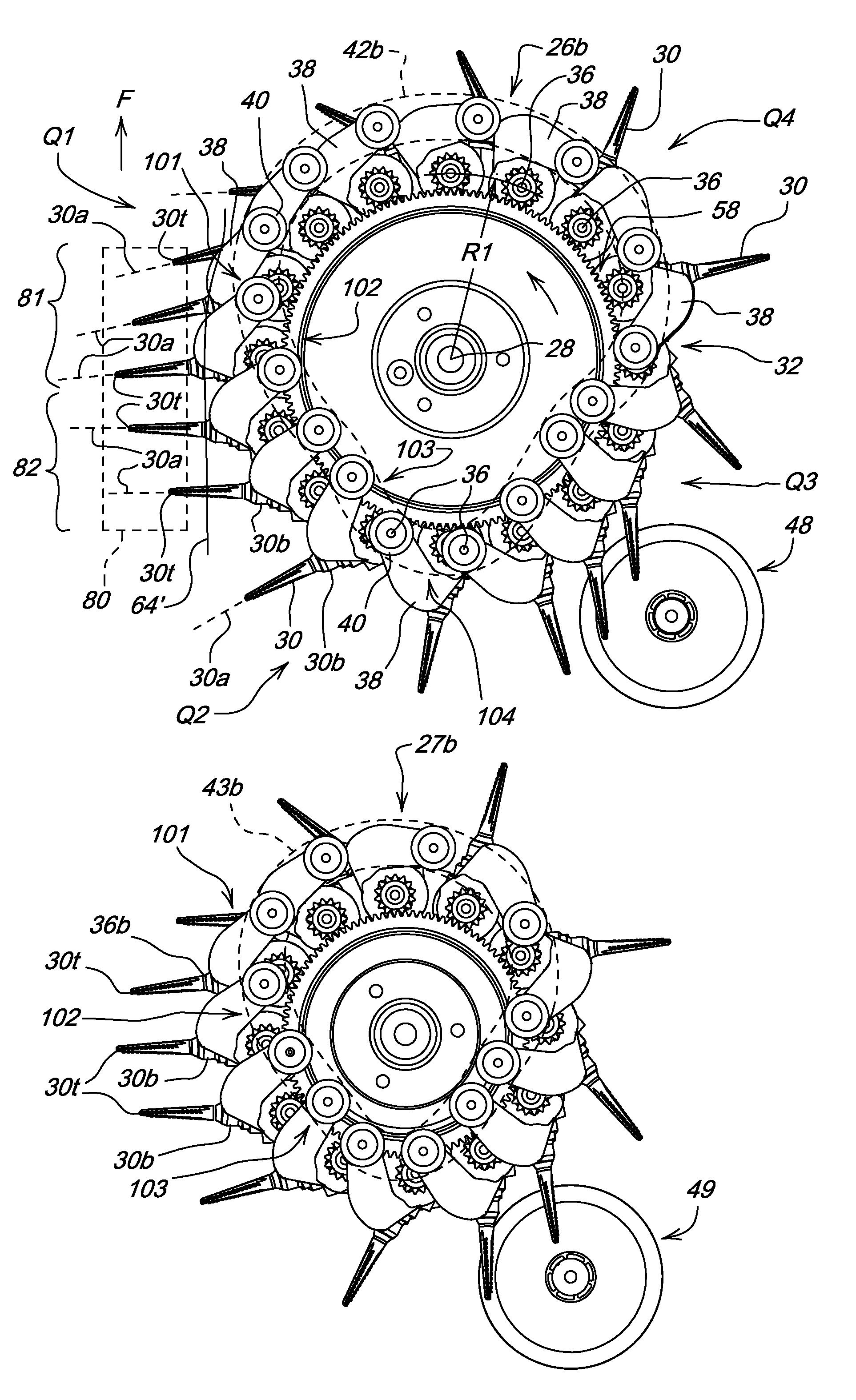

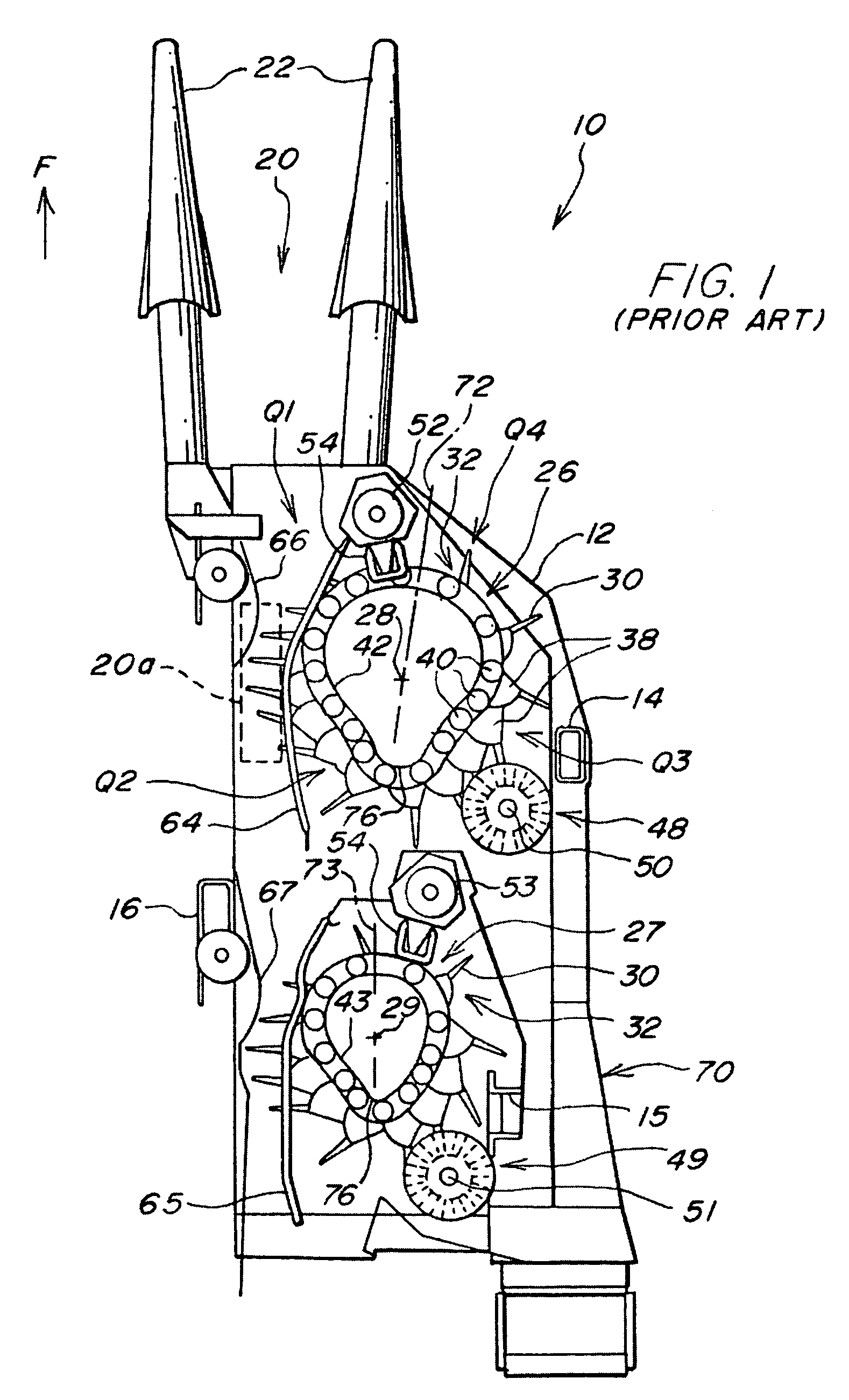

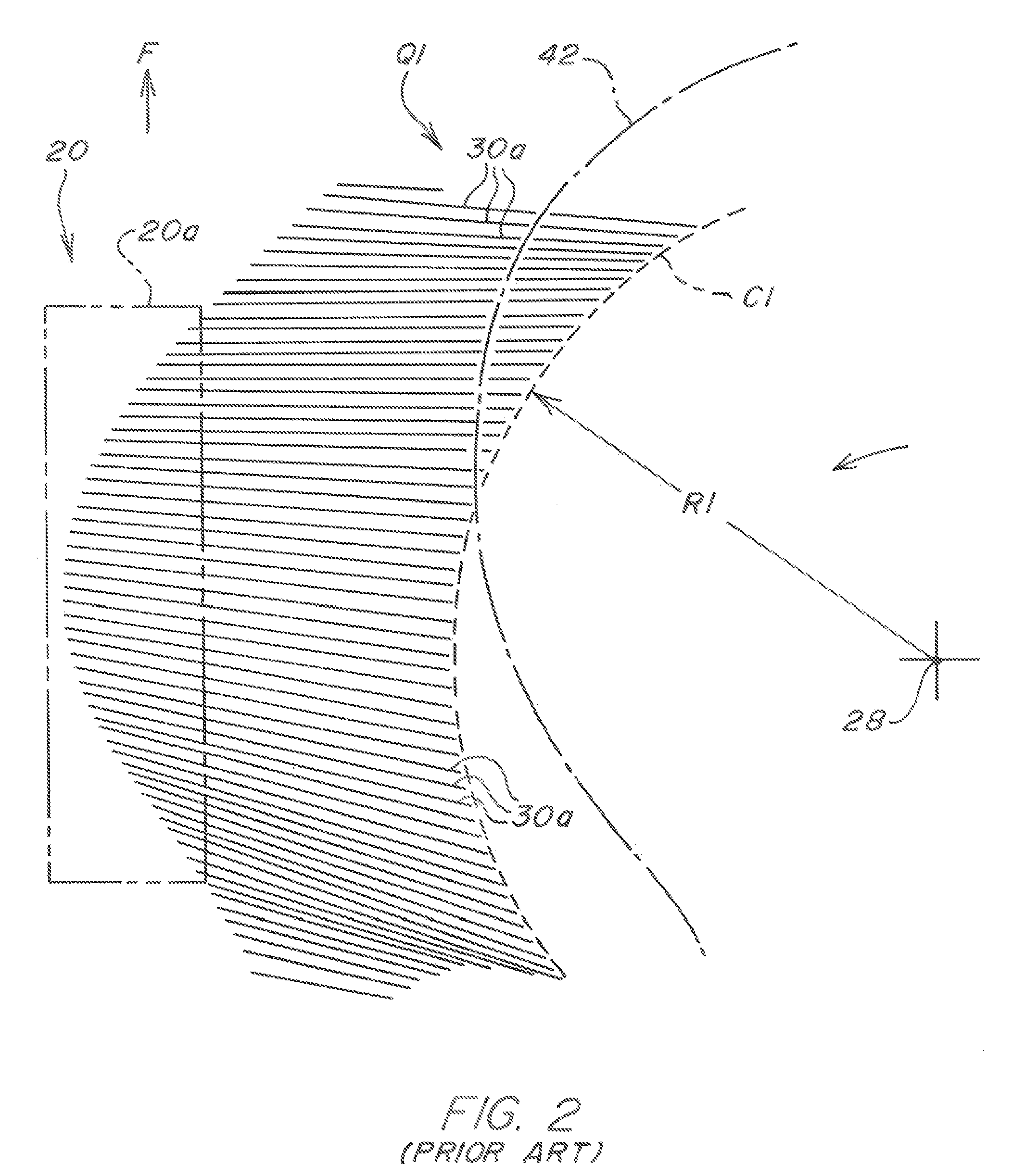

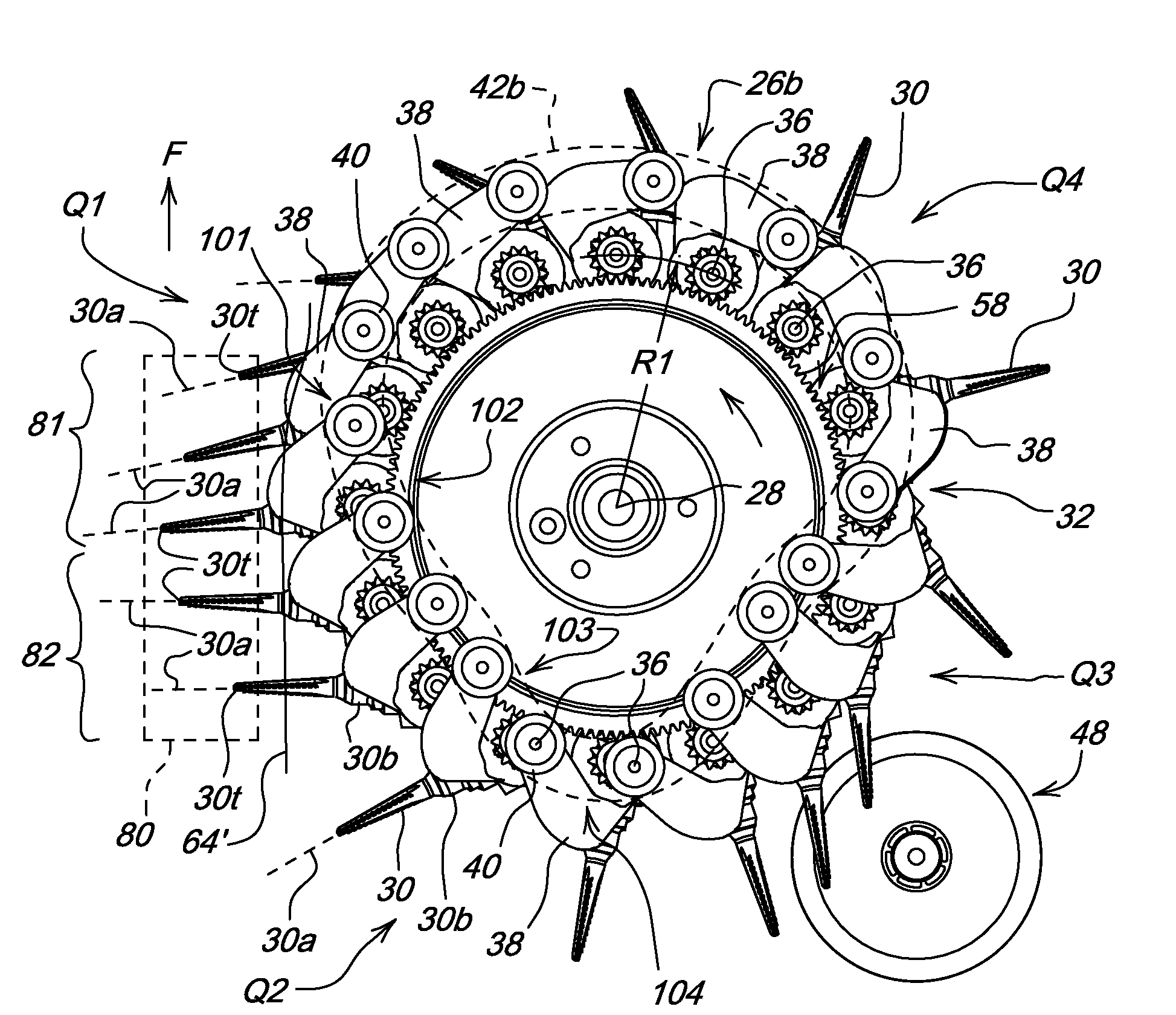

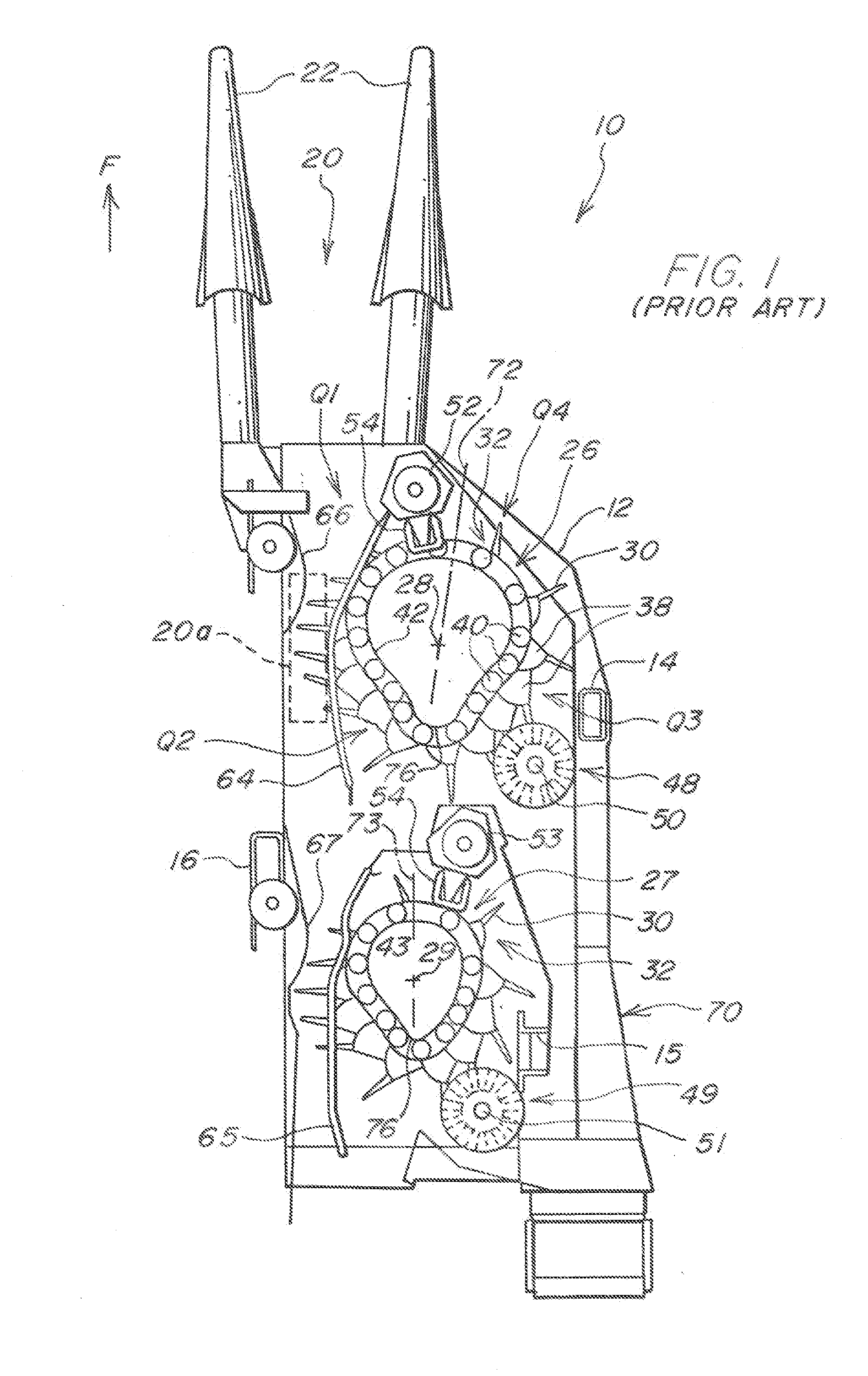

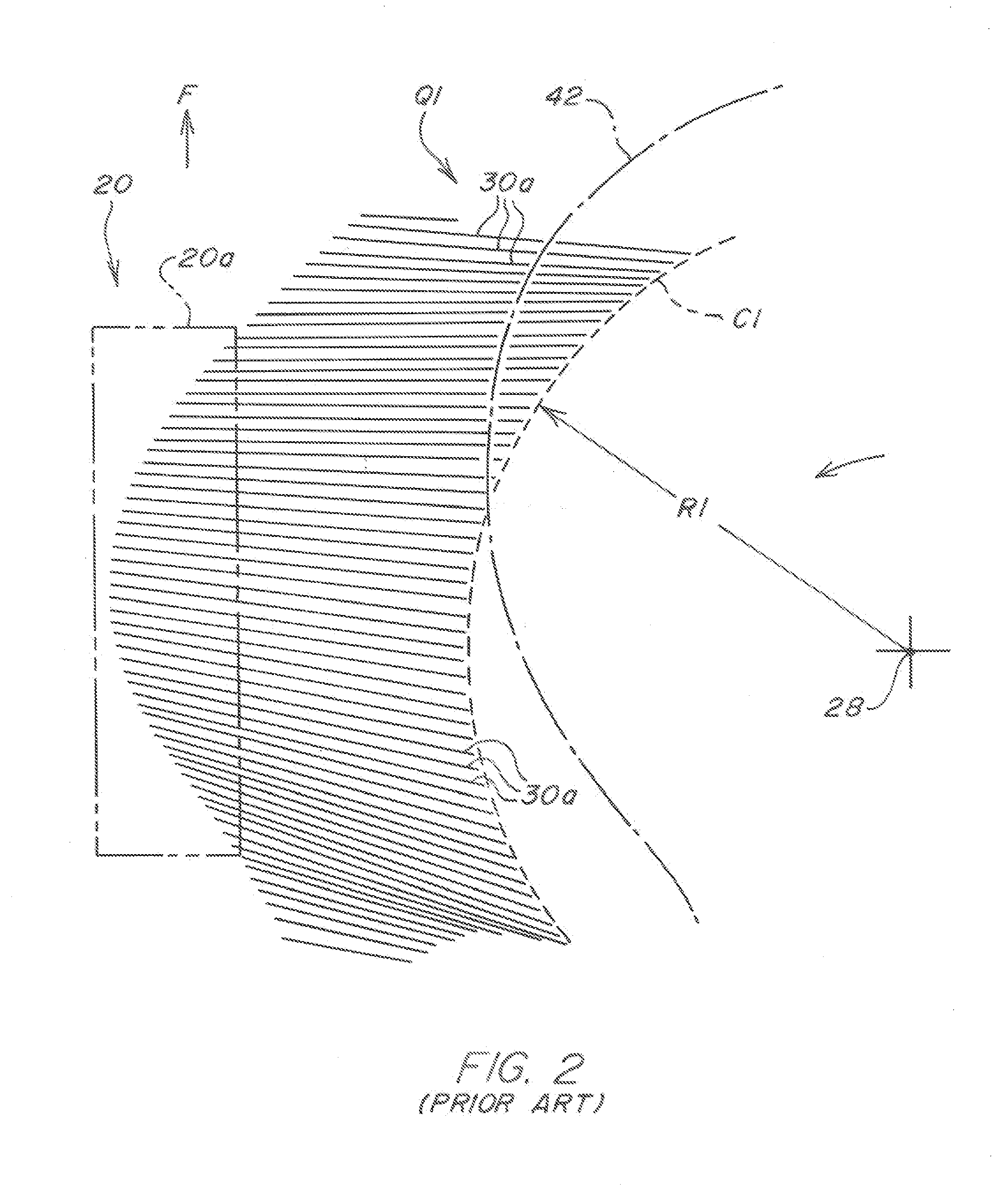

High speed cotton picker drum

ActiveUS7614208B2Reduce destructive effectsWithout loss of picking efficiencyPicking devicesEngineeringCam

To reduce destructive effects of cotton picker high speed drum rotation, rearward spindle tip motion is adjusted in part by angularly positioning the spindles in the picking zone with an improved cam track arrangement. The cam rotates the picker bar about the upright axis of the bar to vary the speed of the spindle tip in the picking zone and allow a higher drum speed. In a first portion of the picking zone the spindle tips are closer together than the spindle bases at the picker bar. The spindle tip spacing in a second portion of the picking zone is approximately equal to spindle base spacing in the extremities. The resulting spindle tip movement facilitates higher cotton picker vehicle ground speed without picking efficiency loss or additional damage to the cotton plants.

Owner:DEERE & CO

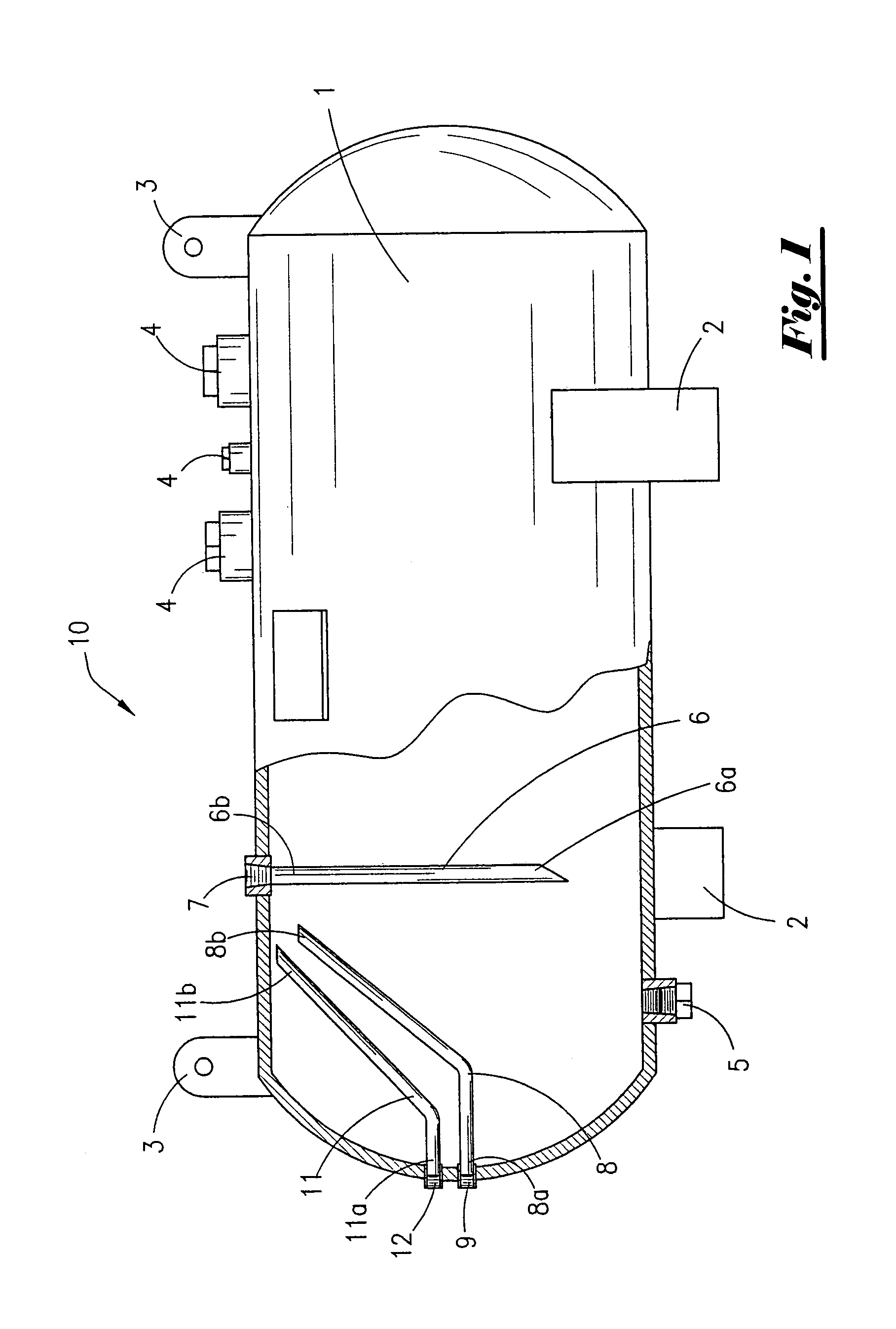

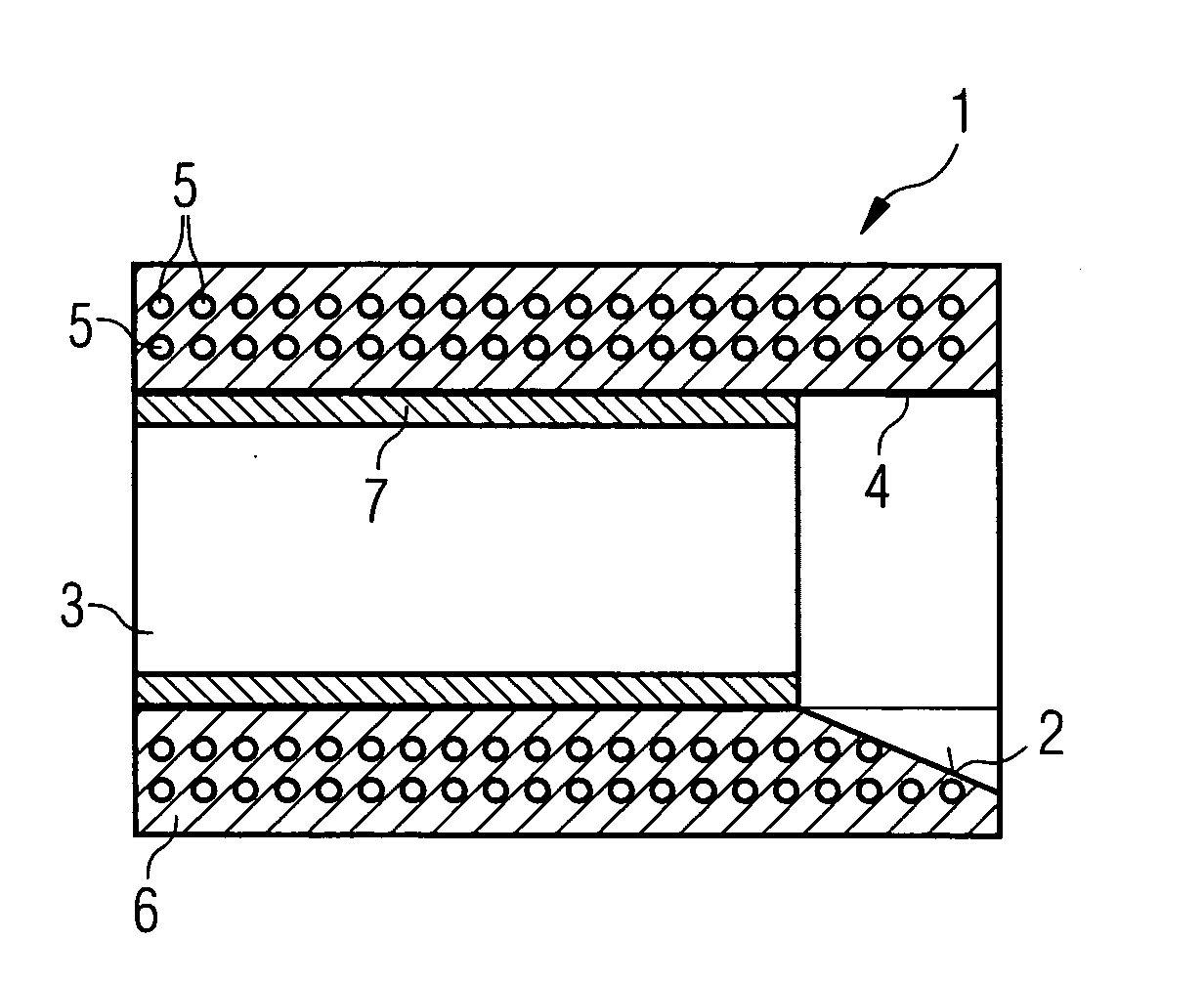

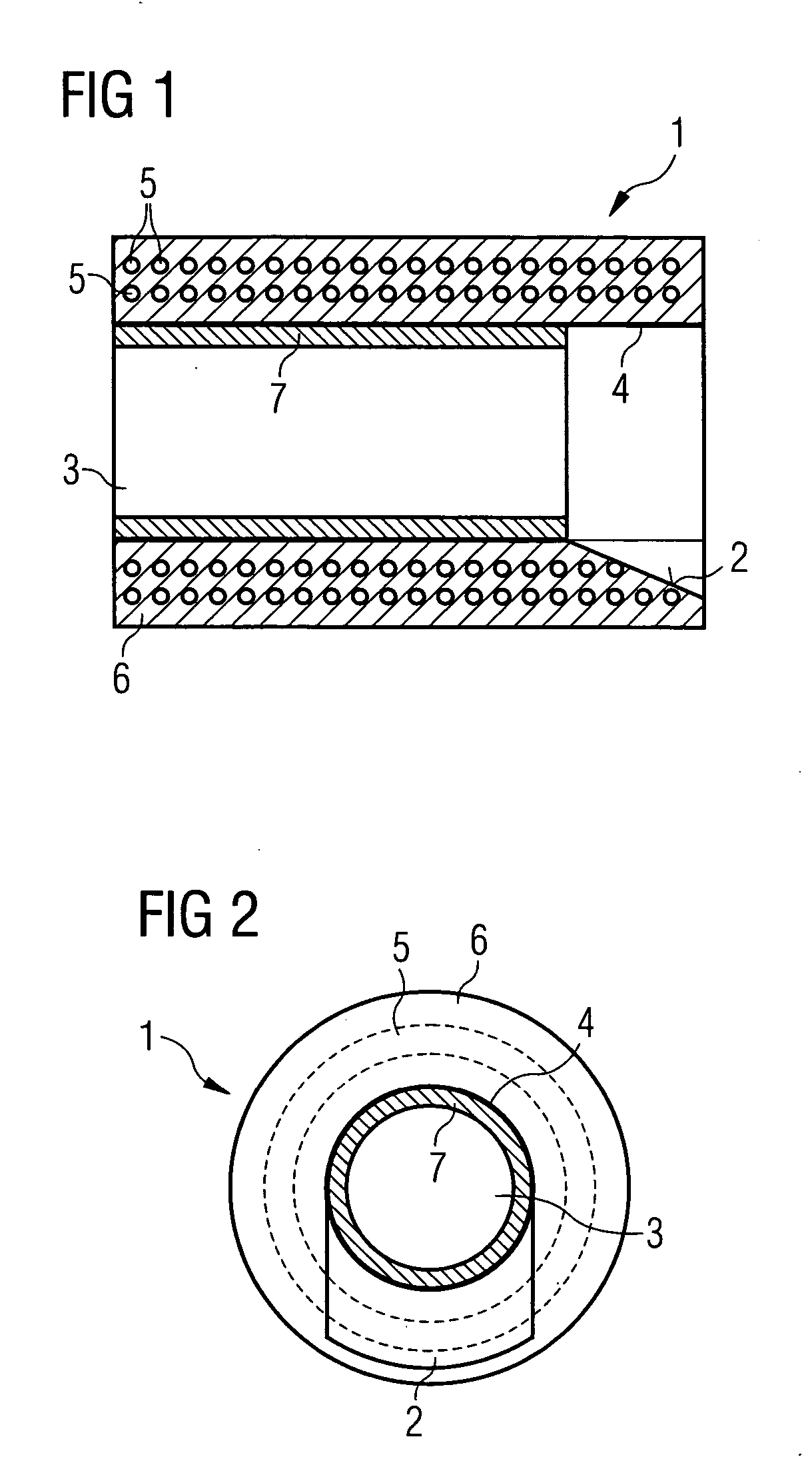

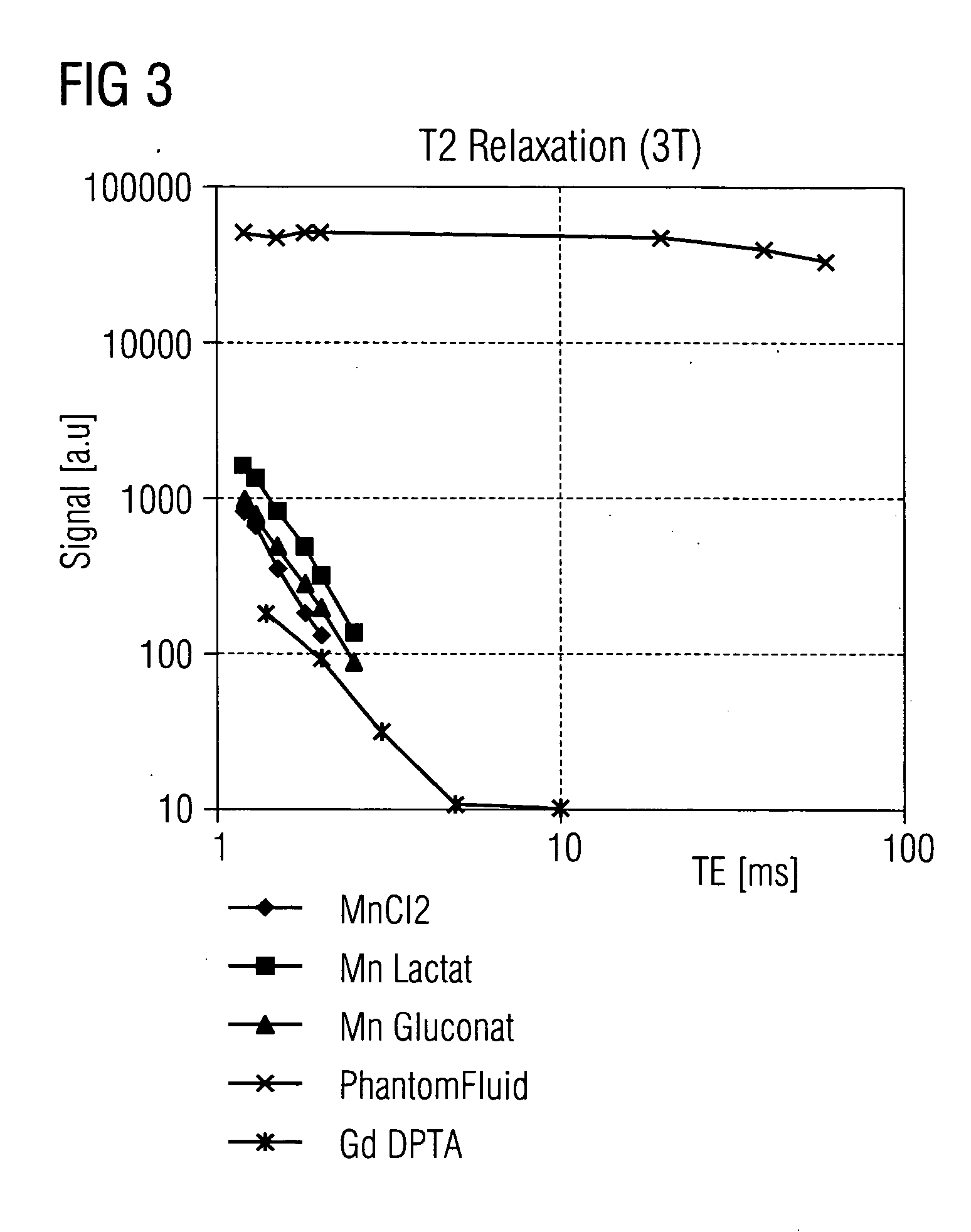

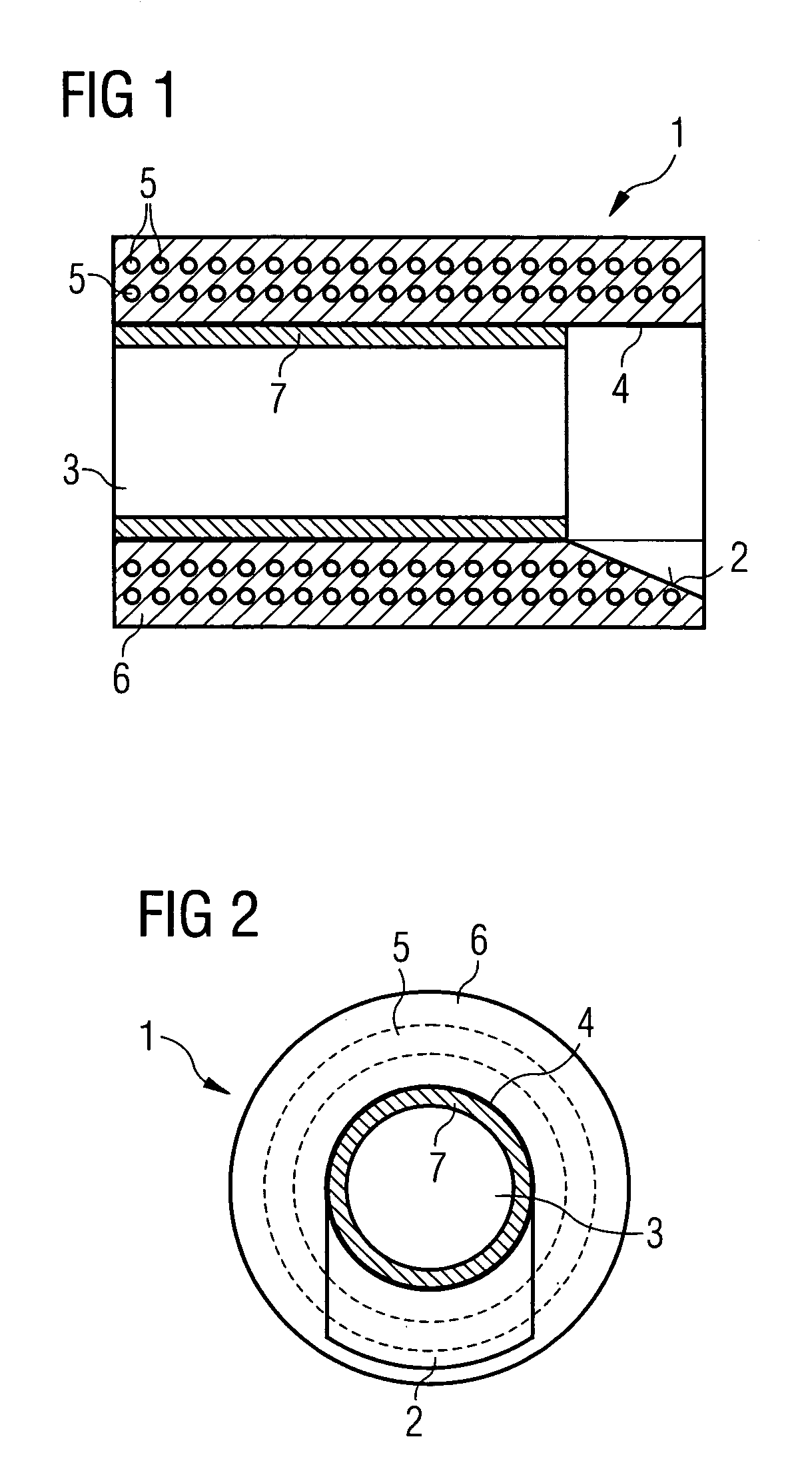

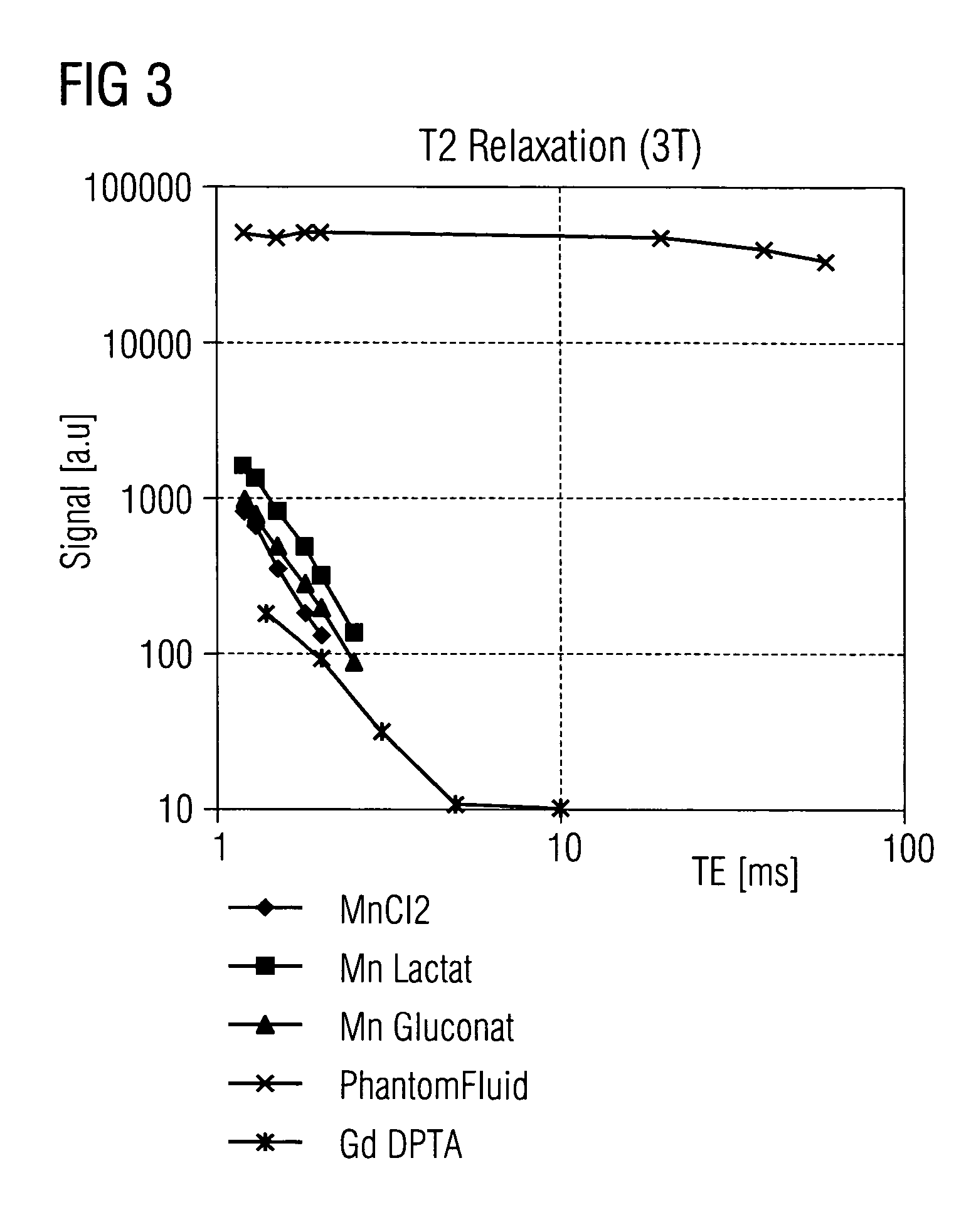

Water-soluble paramagnetic substance for reducing the relaxation time of a coolant and corresponding method

InactiveUS20050123480A1Reduce destructive effectsSuppress interferenceSamplingLighting and heating apparatusResonanceWater soluble

Use of a water-soluble paramagnetic substance to reduce the relaxation time of a coolant and corresponding method The invention relates to the use of a water-soluble paramagnetic substance, in particular a magnetic resonance contrast medium, to reduce the magnetic resonance relaxation time of a coolant for magnetic resonance systems. Furthermore the invention relates to a corresponding method for reducing the magnetic resonance relaxation time of a coolant.

Owner:SIEMENS HEALTHCARE GMBH

Battery heat dissipation structure, battery cluster heat dissipation structure, heat dissipation system and heat dissipation method

PendingCN113809433AAchieve directional flowSmooth circulationSecondary cellsThermodynamicsElectrical battery

The invention belongs to the technical field of heat dissipation of energy storage systems, and discloses a battery heat dissipation structure, a battery cluster heat dissipation structure, a heat dissipation system and a heat dissipation method. The battery heat dissipation structure comprises an air inlet formed in one side wall of a battery module and an air outlet formed in the other side wall of the battery module, wherein one-way valves are arranged at the air inlet and the air outlet correspondingly, an exhaust pipeline is arranged on one side of the battery module, the air outlet is communicated with the exhaust pipeline, and a fan is arranged at the top of the exhaust pipeline. According to the invention, directional air flow of the module is realized, large-scale air flow in an area is avoided, the heat dissipation efficiency is improved, normal heat dissipation during battery operation is not influenced, and the problem that flue gas of battery thermal runaway is diffused to other connected modules is avoided.

Owner:CHINA ELECTRIC POWER RES INST +2

Dynamic tuning in dense arrays of electrically small elements

ActiveUS9118304B2Minimize couplingEasy to receiveTelevision system detailsDiscontinuous tuningSignal qualityRelative phase

Owner:CHARTER COMM OPERATING LLC

Thin film transistor substrate and display device

ActiveUS10700020B2Reduce impactReduce destructive effectsSemiconductor/solid-state device detailsSolid-state devicesScan lineDisplay device

A thin film transistor substrate having a display region and a peripheral region, and the thin film transistor substrate includes a first substrate, scan lines, data lines, an insulating layer, first thin film transistors, at least one passivation layer and at least one gate driving circuit. The first substrate has an electrostatic protection area and a driving circuit area, and the electrostatic protection area and the driving circuit area are situated in the peripheral region. The scan lines, the data lines and the first thin film transistors are disposed in the display region. The insulating layer includes a gate insulator of the first thin film transistor, and the passivation layer is disposed on the insulating layer. The gate driving circuit is disposed in the driving circuit area. At least one of the passivation layer and the insulating layer are not disposed in the electrostatic protection area.

Owner:HANNSTAR DISPLAY CORPORATION

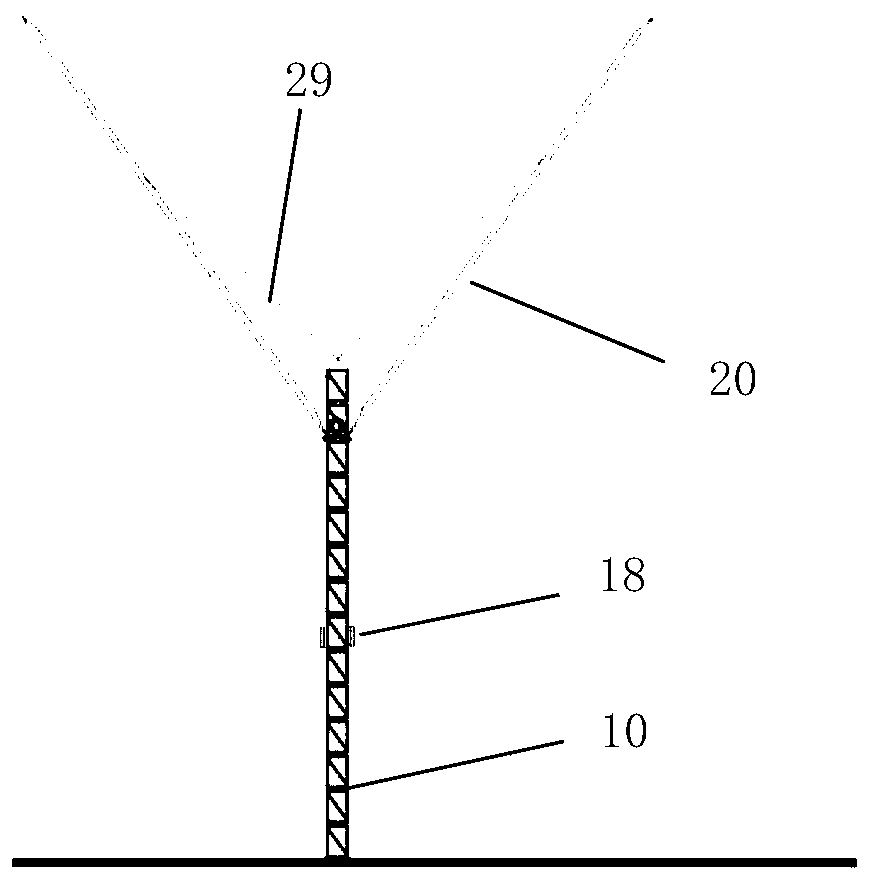

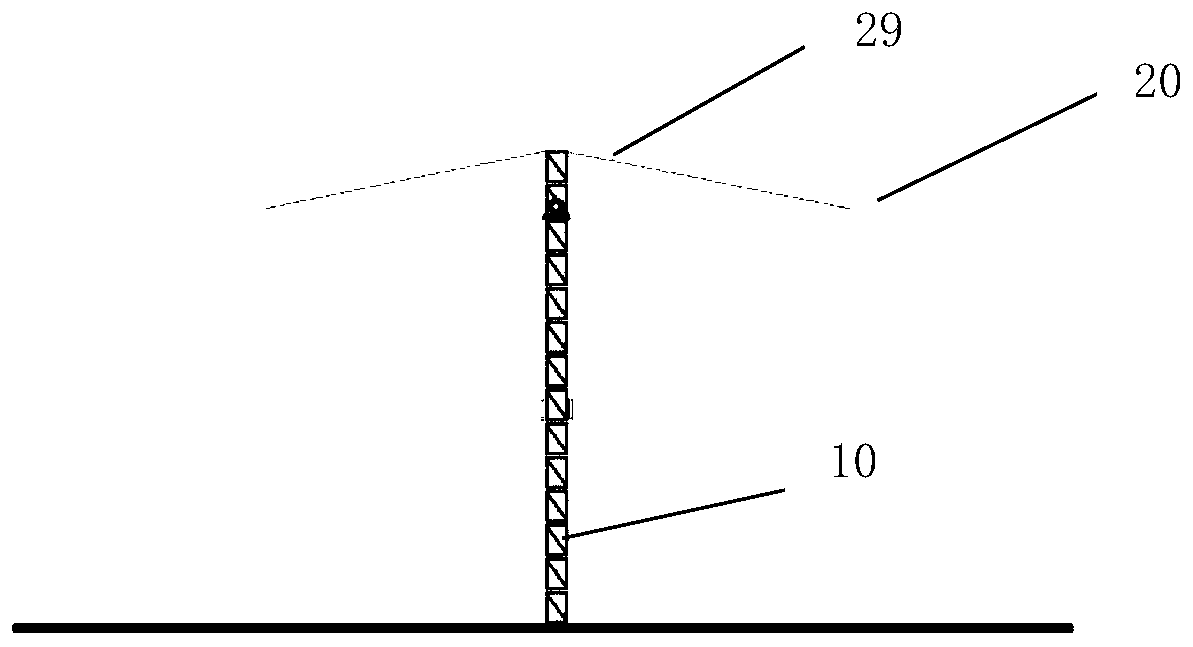

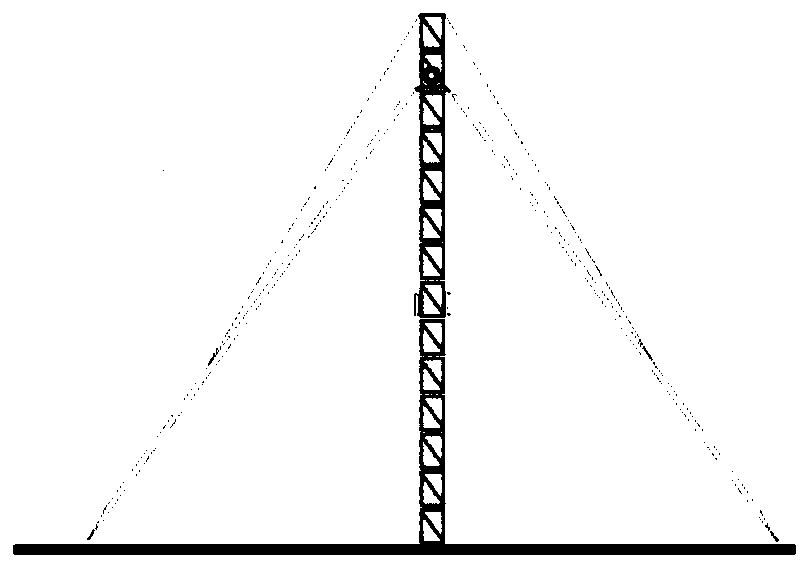

Steel structure wind-resistant tower-type parachuting training device

PendingCN111547249AReduce riskShorten the lengthParachutes training apparatusWinding mechanismsEmergency rescueTower crane

The invention relates to a steel structure wind-resistant tower-type parachuting training device which comprises a main tower and at least one tower arm connected with the side edge of the main tower,and the main tower and the tower arm are both of a frame-shaped steel structure. The tower arms are evenly distributed on the periphery of the main tower. The tower crane further comprises a tractionmechanism arranged on the tower arm, and the traction mechanism is arranged at the front end of the tower arm. The traction mechanism comprises a traction rope, and the traction rope is directly andvertically led out downwards. Both the main tower and the tower arm adopt steel structures, and have the characteristics of high strength and good wind resistance. The tower arm and the main tower areconnected through the hinge, and the tower arm can be put down to the ground in severe weather, so that destructive influence of the severe weather on the structures of the main tower and the tower arm is reduced. The traction mechanism is directly arranged at the front end of the tower arm, structures such as pulleys are omitted, and safety and no accident are achieved. And the weather adaptability of the parachuting tower and the parachuting safety are improved by arranging the rotating part. And the arranged blower can avoid collision accidents. And an emergency rescue channel can be established by the arranged emergency rescue rope bag when a fault occurs.

Owner:许多 +1

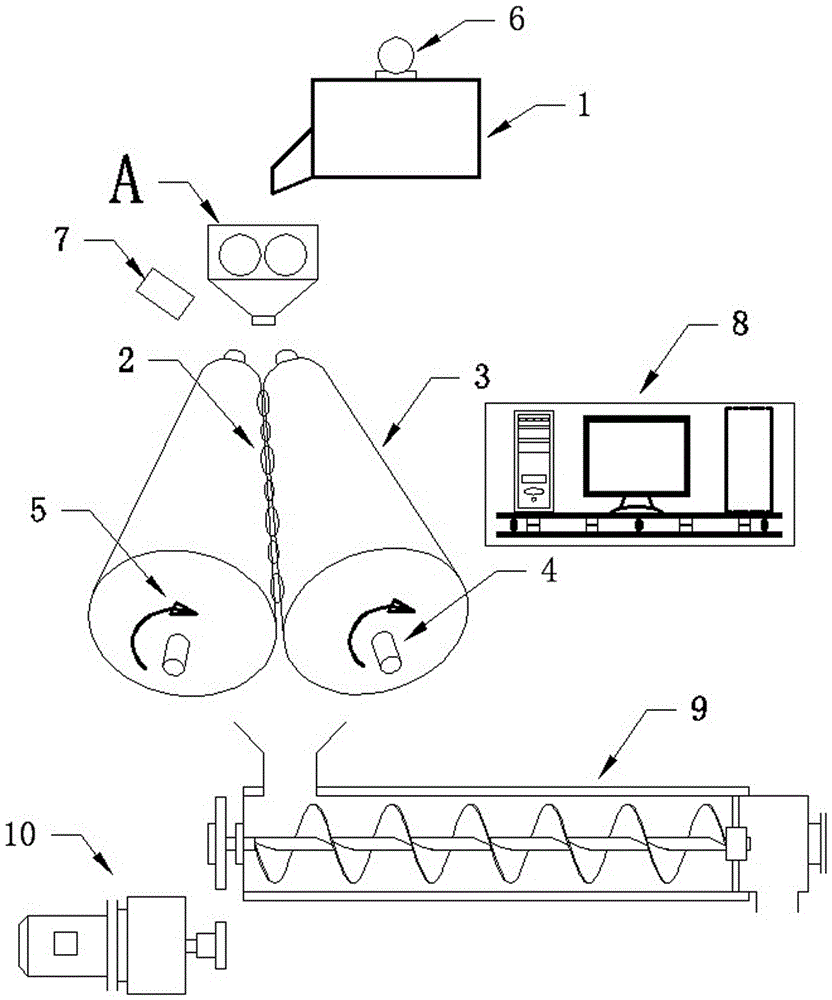

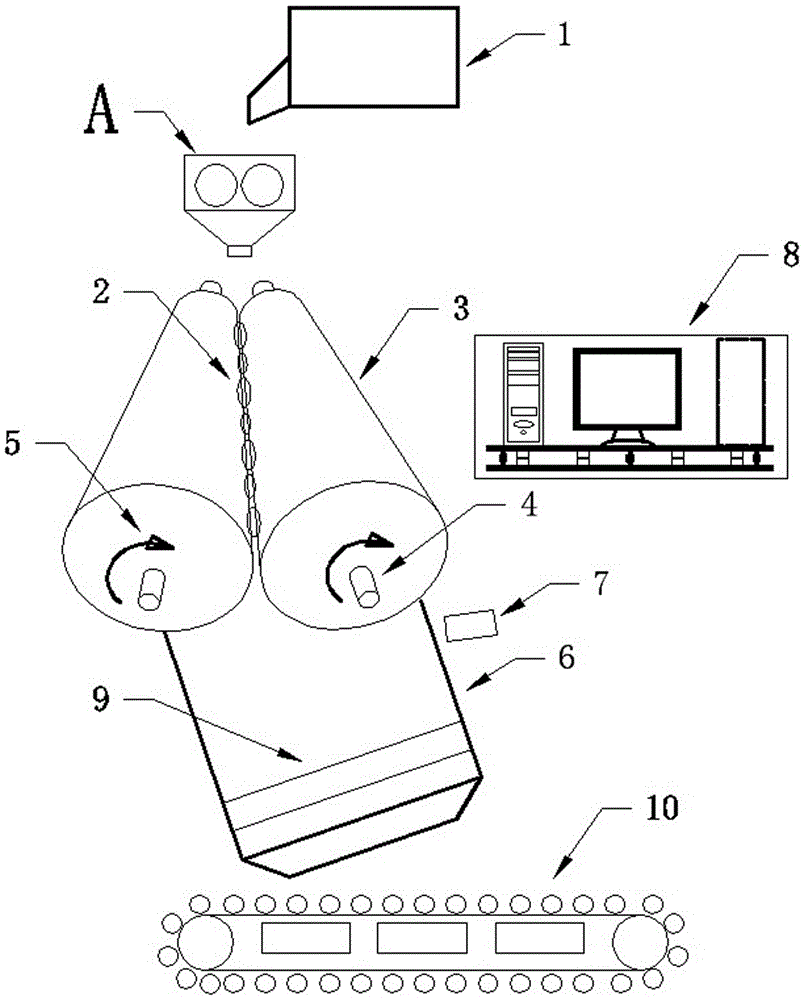

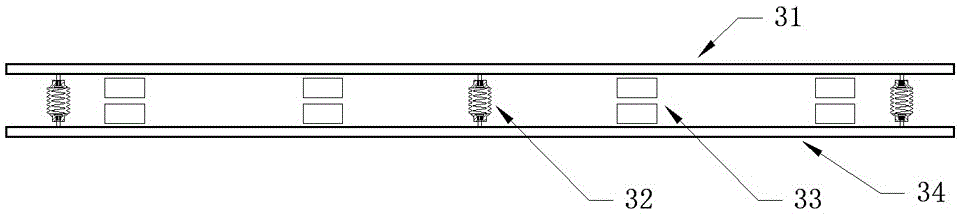

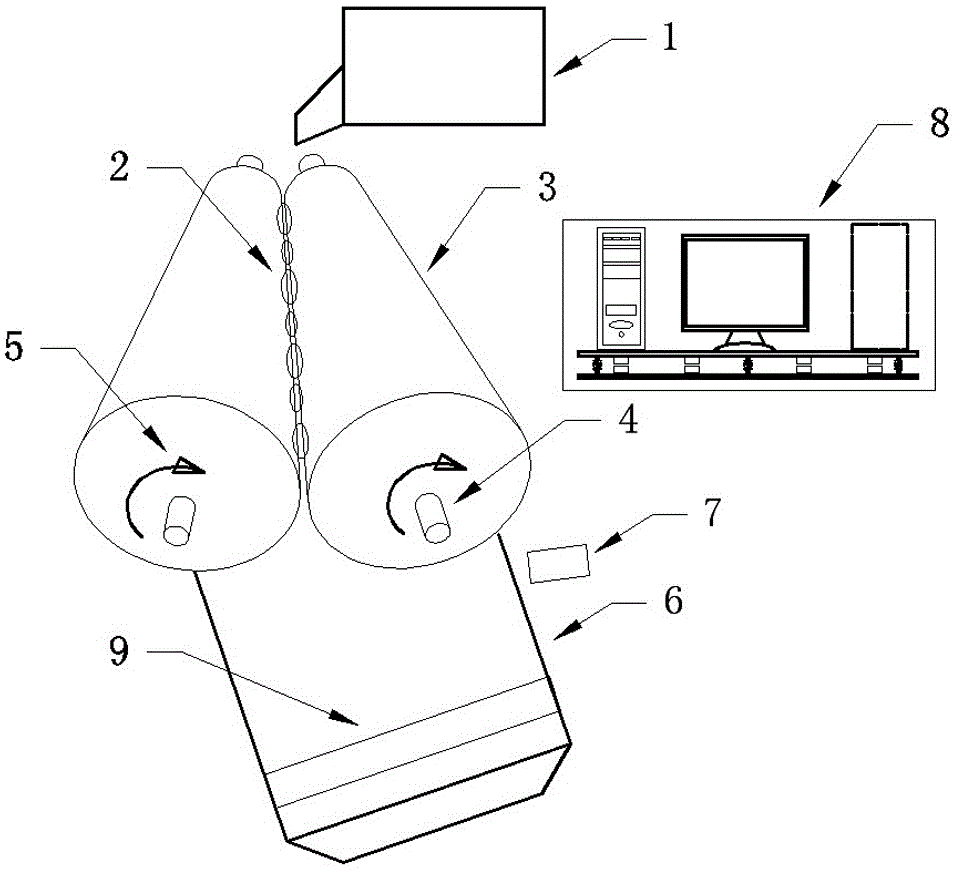

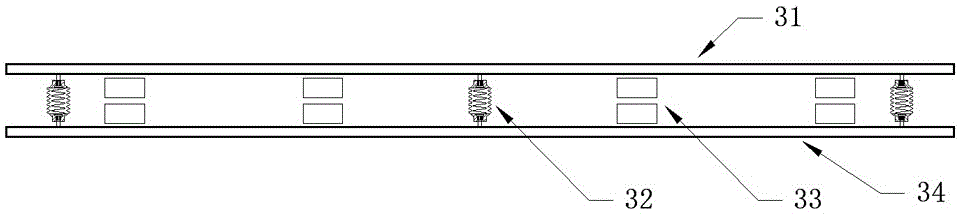

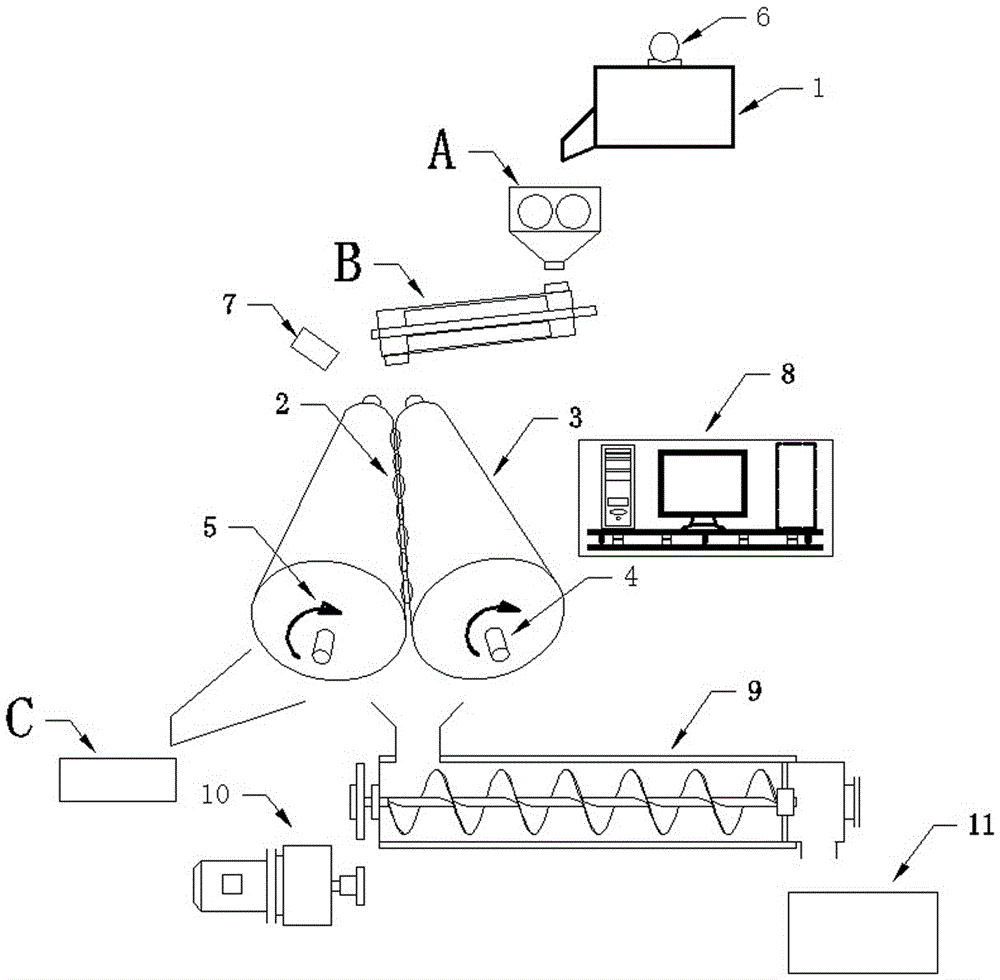

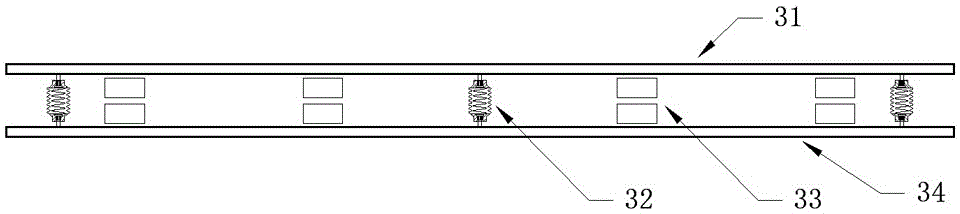

Screw-conveying-taper-rotating-drum computer monitoring feeding walnut-pulp removing machine

InactiveCN106465950AExpends energy rapidlyReduce destructive effectsHuskingHullingVibration attenuationComputer monitoring

The invention discloses a screw-conveying-taper-rotating-drum computer monitoring feeding walnut-pulp removing machine. A V-shaped pulp removing chamber is formed by an interval between two taper rotating drums which are arranged side by side and rotate in the same direction, a camera is arranged on a discharging opening in a roll differential twisting machine and used for providing feeding signals for a computer, the computer controls the rotating speed of a vibration motor to guarantee even best feeding, when walnuts fall into a V-shaped cavity between the two taper rotating drums, walnuts can gradually and linearly rotate in a speed-up mode under the effects of the gravity and the friction force of the two taper rotating drums and move towards the large ends of the two taper rotating drums, the line speed can be higher and higher, the walnuts centrifugally rotate in the extruding-completely-free state and the friction-damage-free state, and therefore it is achieved that centrifugal force is combined with the brushing effect of a soft brush to remove pulp. According to the original thinking of the screw-conveying-taper-rotating-drum computer monitoring feeding walnut-pulp removing machine, walnut-centrifuging-brushing pulp removing is carried out through the taper rotating drums implanted with fiber hair, pulp is thoroughly removed and completely free of damage; damping, buffering and vibration energy removing can be achieved through a sine-wave damping vibration attenuation device, and the service life of the device can be prolonged.

Owner:JISHOU UNIVERSITY

Taper rotary drum type walnut pulp removing and grading device with rotating speed monitored by computer

InactiveCN106108048AReduce destructive effectsEliminate vibration and shockHuskingHullingElectric machinerySine wave

The invention discloses a taper rotary drum type walnut pulp removing and grading device with the rotating speed monitored by a computer. A V-shaped pulp removing chamber is formed by the gap between two taper rotary drums which are arranged side by side and rotate in the same direction, a camera is arranged on one side of the taper rotary drums to provide feeding signals for the computer, and the computer controls the rotating speed of a vibrating motor to ensure uniform and optimal feeding. When falling into the V-shaped cavity between the two taper rotary drums, walnuts can rotate in a linear speed gradually-increasing mode and move towards the large ends of the taper rotary drums under the action of gravity and the friction force of the two taper rotary drums, the linear speed can become higher and higher, the walnuts can rotate centrifugally in a completely squeezing-free and friction-damage-free state, and thus the effects of pulp removing and grading through the combination of centrifugal force and the brushing action of a soft brush can be achieved. According to the device, by adopting the creative thought of removing pulp of the walnuts in a centrifuging and brushing mode through the taper rotary drums with fiber bristles implanted, the pulp is thoroughly removed in a completely damage-free mode; a sine wave damping shock absorber is beneficial to absorbing shock, achieving buffering and eliminating vibration energy, and thus the service life of the device can be easily prolonged.

Owner:JISHOU UNIVERSITY

Water-soluble paramagnetic substance reducing the relaxation time of the coolant in an MRI system

InactiveUS7557577B2Reduce destructive effectsSuppress interferenceNMR/MRI constrast preparationsGroup 3/13 element organic compoundsResonanceWater soluble

The invention relates to the use of a water-soluble paramagnetic substance, in particular a magnetic resonance contrast medium, to reduce the magnetic resonance relaxation time of a coolant for magnetic resonance systems. Furthermore the invention relates to a corresponding method for reducing the magnetic resonance relaxation time of a coolant.

Owner:SIEMENS HEALTHCARE GMBH

Slide-plate brushing buffer taper drum type computer speed-monitoring kiwi fruit fuzz removing device

InactiveCN106360776AReduce destructive effectsEliminate vibration and shockFood treatmentSine waveKiwi fruit

The invention discloses a slide-plate brushing buffer taper drum type computer speed-monitoring kiwi fruit fuzz removing device. The space between two taper drums arranged side by side forms a V-shaped fuzz removing chamber; a computer ensures that fuzz on the surface of kiwi fruits is optimally and uniformly removed by controlling the speed of the drum, accelerates to enhance the fuzz removing ability when fuzz residues are detected, and decelerates to avoid damage when fuzz is removed completely; when the kiwi fruits fall into the V-shaped chamber between the two taper drums, the kiwi fruits gradually and linearly accelerate to rotate under action of gravity and friction force of the two taper drums, and move to large ends of the taper drums; the linear speed becomes increasingly higher, so the kiwi fruits are centrifugally rotated without extrusion or frictional damage, so as to realize fuzz removal through combining centrifugal force with brushing effect of a soft brush. The invention originally creates an idea of using the taper drums implanted with fiber hair for centrifugally brushing the kiwi fruits to remove the fuzz, so as to completely remove the fuzz without damage; a sine wave damping shock absorber is beneficial for damping, buffering and eliminating the vibration energy, and is beneficial for improving the service life of the device.

Owner:JISHOU UNIVERSITY

High speed cotton picker drum

ActiveUS20090000261A1Reduce destructive effectsWithout loss of picking efficiencyPicking devicesEngineeringCam

To reduce destructive effects of cotton picker high speed drum rotation, rearward spindle tip motion is adjusted in part by angularly positioning the spindles in the picking zone with an improved cam track arrangement. The cam rotates the picker bar about the upright axis of the bar to vary the speed of the spindle tip in the picking zone and allow a higher drum speed. In a first portion of the picking zone the spindle tips are closer together than the spindle bases at the picker bar. The spindle tip spacing in a second portion of the picking zone is approximately equal to spindle base spacing in the extremities. The resulting spindle tip movement facilitates higher cotton picker vehicle ground speed without picking efficiency loss or additional damage to the cotton plants.

Owner:DEERE & CO

A device for preventing respiratory infection of children patients in hospitals

ActiveCN109711395AReduce spreadReduce destructive effectsTelevision system detailsSpeech analysisRespiratory infectionImaging analysis

The invention relates to a device for preventing respiratory infection of children patients in hospitals. The device comprises sound analysis equipment which is arranged in a monitoring area in a hospital and is used for analyzing each component of sound in the monitoring area to determine whether a component corresponding to cough sound exists or not and sending out a first driving command if thecomponent corresponding to the cough sound exists, otherwise sending out a second driving command; and the monitoring camera is arranged near the sound analysis equipment and is used for executing real-time image acquisition on the monitoring area when the first driving command is received so as to obtain a real-time monitoring image. The device for preventing the respiratory infection of the child patient in the hospital is easy to operate and direct in monitoring. Whether a hospital site has an inelegant spitting behavior or not is accurately determined in a sound analysis and image analysis linkage mode so as to reduce diffusion of viruses and bacteria, and therefore the site environment of the hospital is effectively maintained.

Owner:李娟娟

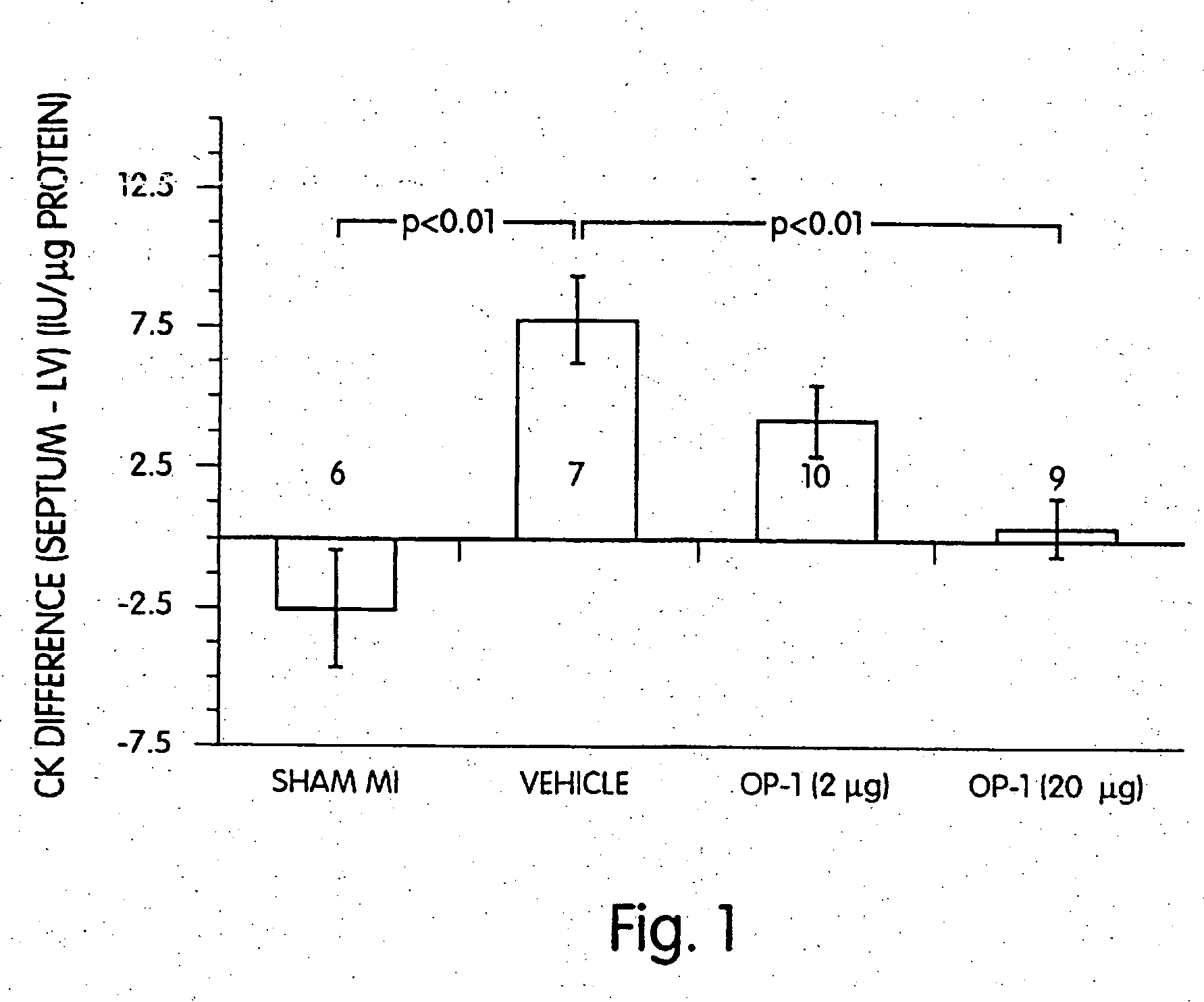

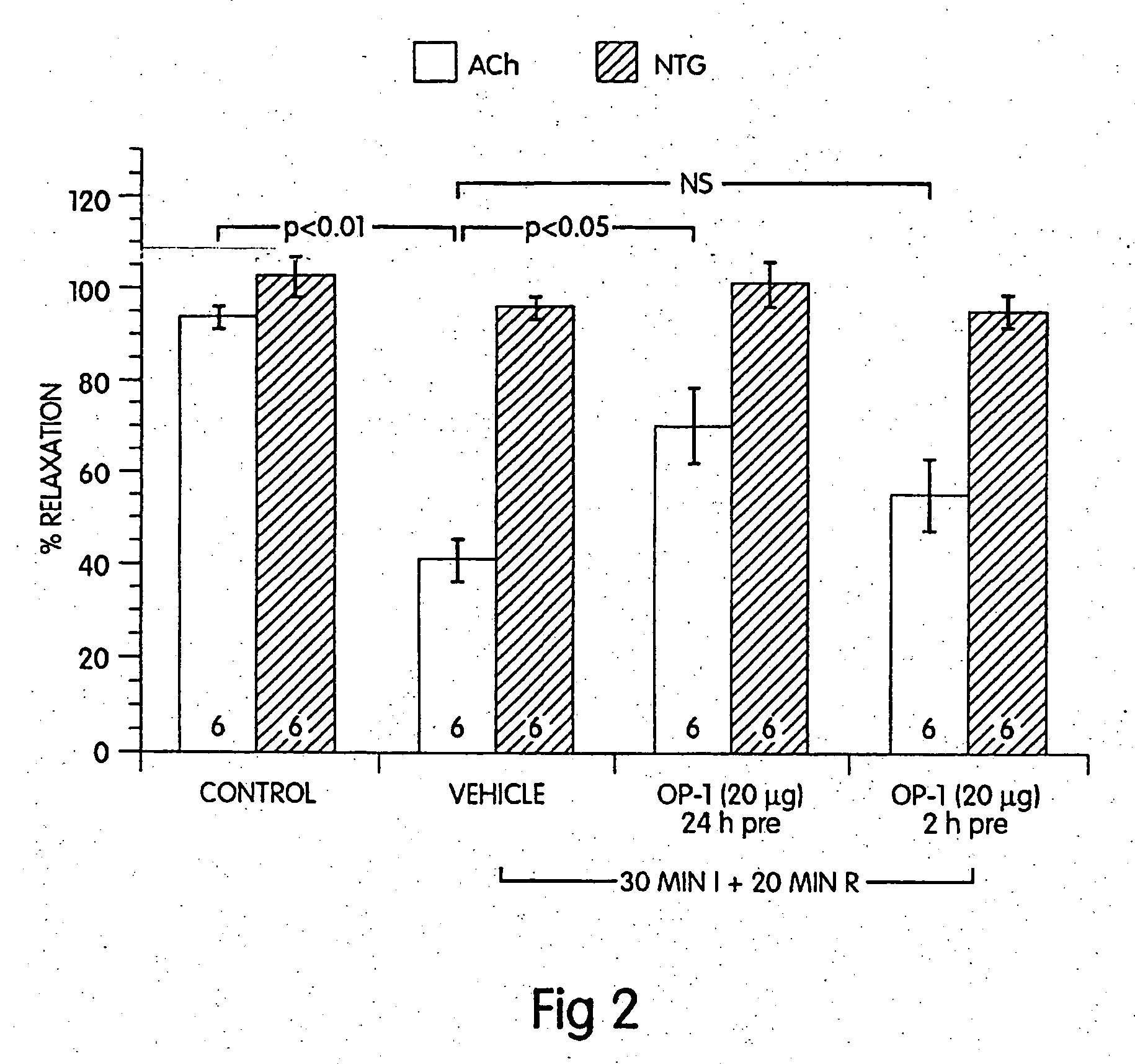

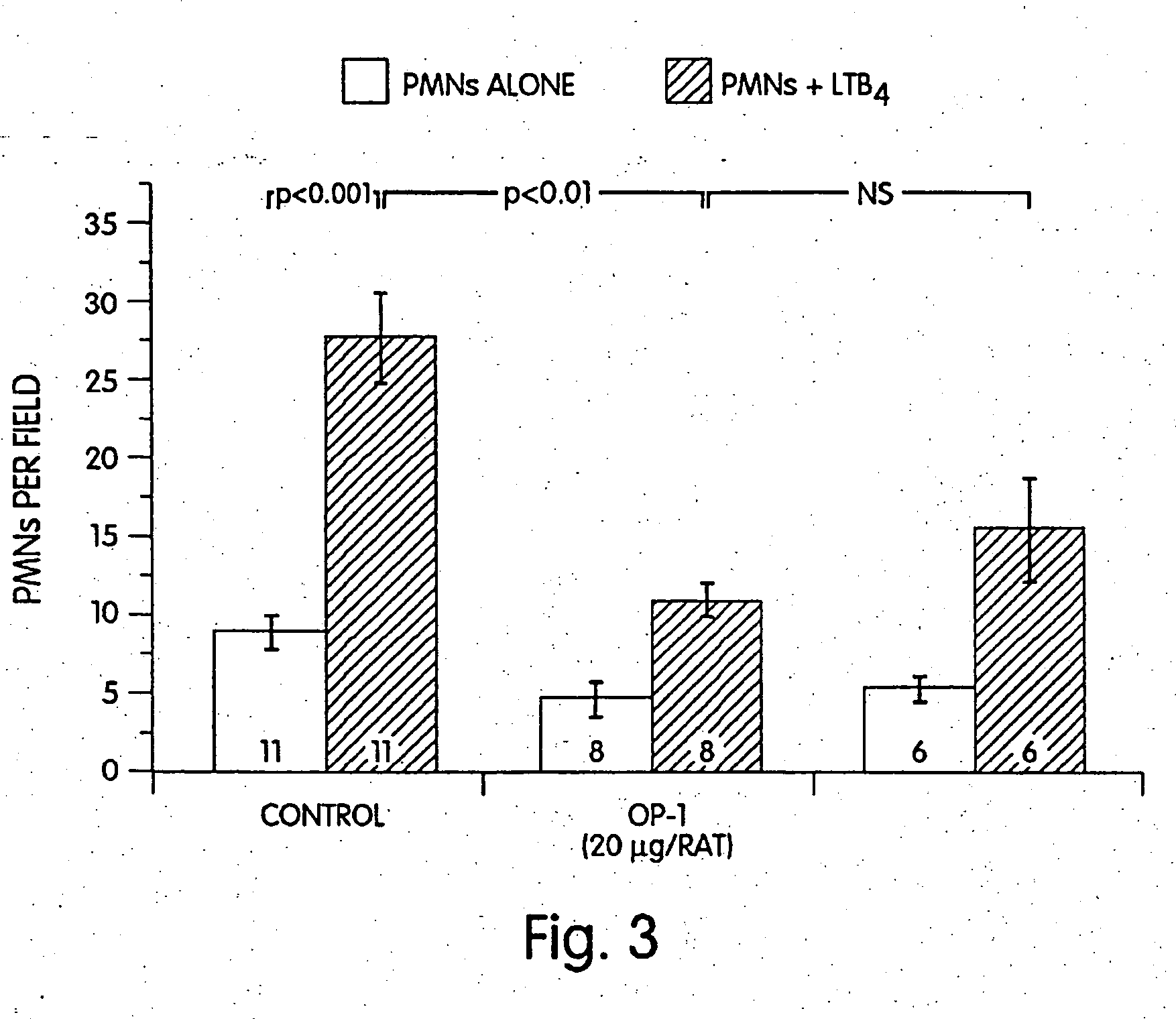

Morphogen-induced modulation of inflammatory response

InactiveUS20050096339A1Prevent blood flowInduce inflammatory responseBiocideCompound screeningMorphogenMammal

The present invention is directed to methods and compositions for alleviating tissue destructive effects associated with the inflammatory response to tissue injury in a mammal. The methods and compositions include administering a therapeutically effective concentration of a morphogen or morphogen-stimulating agent sufficient to alleviate immune cell-mediated tissue destruction.

Owner:STRYKER CORP

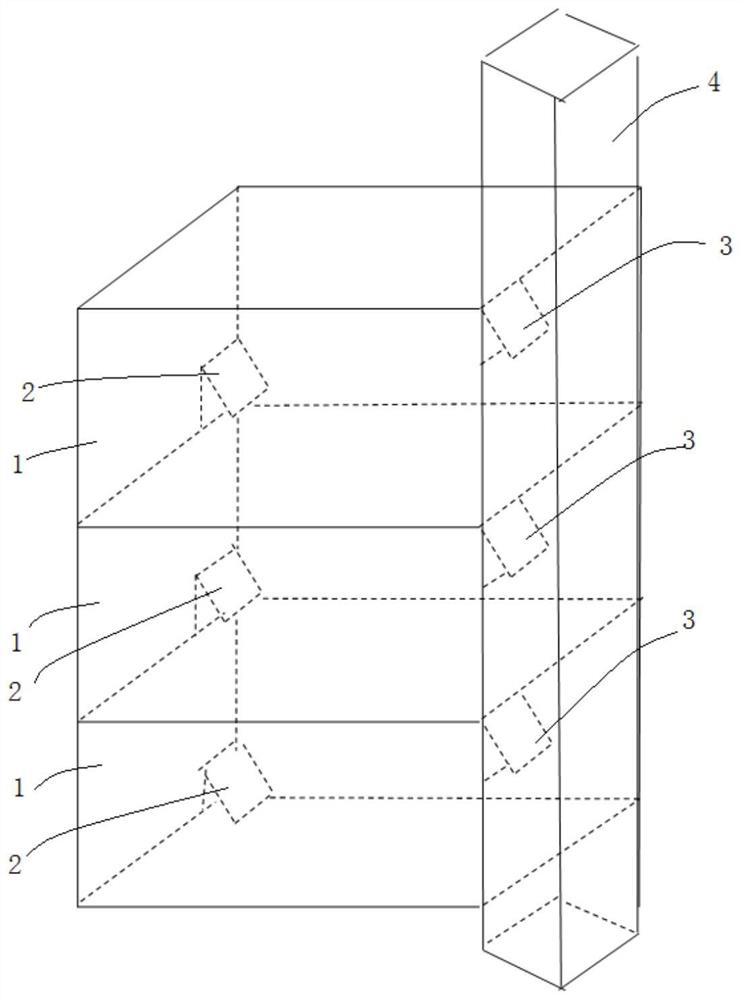

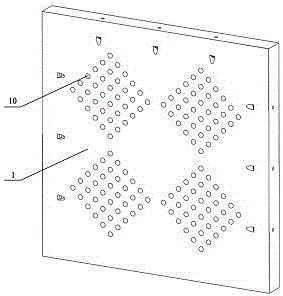

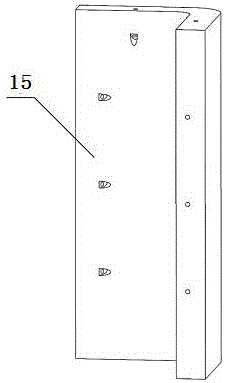

Explosion-proof engineering structure for hazardous article storage

InactiveCN106245968AReduce the destructive effectSimple structureProtective buildings/sheltersBulk storage containerDamage effectsEngineering

The invention belongs to the technical field of disaster prevention and protection engineering of civil engineering, and provides an explosion-proof engineering structure for hazardous article storage. The explosion-proof engineering structure for hazardous article storage is provided with an explosion-proof wall, and the explosion-proof wall is of a continuous enclosing explosion-proof structure arranged on four sides of a hazardous article storehouse; the explosion-proof wall comprises at least two rectangular wall surfaces and corner wall surfaces; each rectangular wall surface is formed by splicing at least one layer of multiple rectangular wall bodies (1); the two adjacent rectangular wall bodies are connected into a whole by a corner wall surface (15); each rectangular wall body (1) is provided with multiple groups of round pressure relief holes (10); the bottom of the explosion-proof wall is installed on a groove-shaped substrate; and the explosion-proof wall is also provided with a safety door (11) through which vehicles and persons enter and exit and a management door (12). The explosion-proof engineering structure reduces the killing and damage effects of accidental explosion of ammunition depots, explosive hazardous article warehouses, oil depot and the like on outside personnel and buildings.

Owner:HUNAN MINGXIANG TECH DEV

Auger delivery tapered rotary-drum computer monitoring feeding type walnut packaging machine with outer pulp peeling function

PendingCN106275653AReduce destructive effectsEliminate vibration and shockPackagingSine waveComputer monitoring

The invention discloses an auger delivery tapered rotary-drum computer monitoring feeding type walnut packaging machine with an outer pulp peeling function. A V-shaped pulp peeling chamber is formed between two tapered rotary drums which are arranged side by side and rotate in the same direction, a camera is arranged at a discharge outlet of a double-roller differential grinding machine to provide feeding signals for a computer, and the computer guarantees optimal and uniform feeding by controlling the rotating speed of a vibration motor; when walnuts fall into the V-shaped chamber between the two tapered rotary drums, walnuts rotate in a gradual and linear accelerating mode under gravity and the friction force of the two tapered rotary drums and move towards the large end of each tapered rotary drum, linear velocity becomes higher and higher, so that walnuts can rotate in a centrifugal mode at a completely squeeze-free and friction damage-free state, and then pulp peeling packaging can be achieved through combination of centrifugal force and brushing of a soft brush. According to the creative idea, centrifugal brushing is conducted on walnuts to remove pulp by means of the tapered rotary drums with fiber hair implanted inside, and pulp can be peeled off completely without damage caused; a sine wave damper is good for damping, buffering and vibration energy elimination, and the service life of a device can be prolonged.

Owner:JISHOU UNIVERSITY

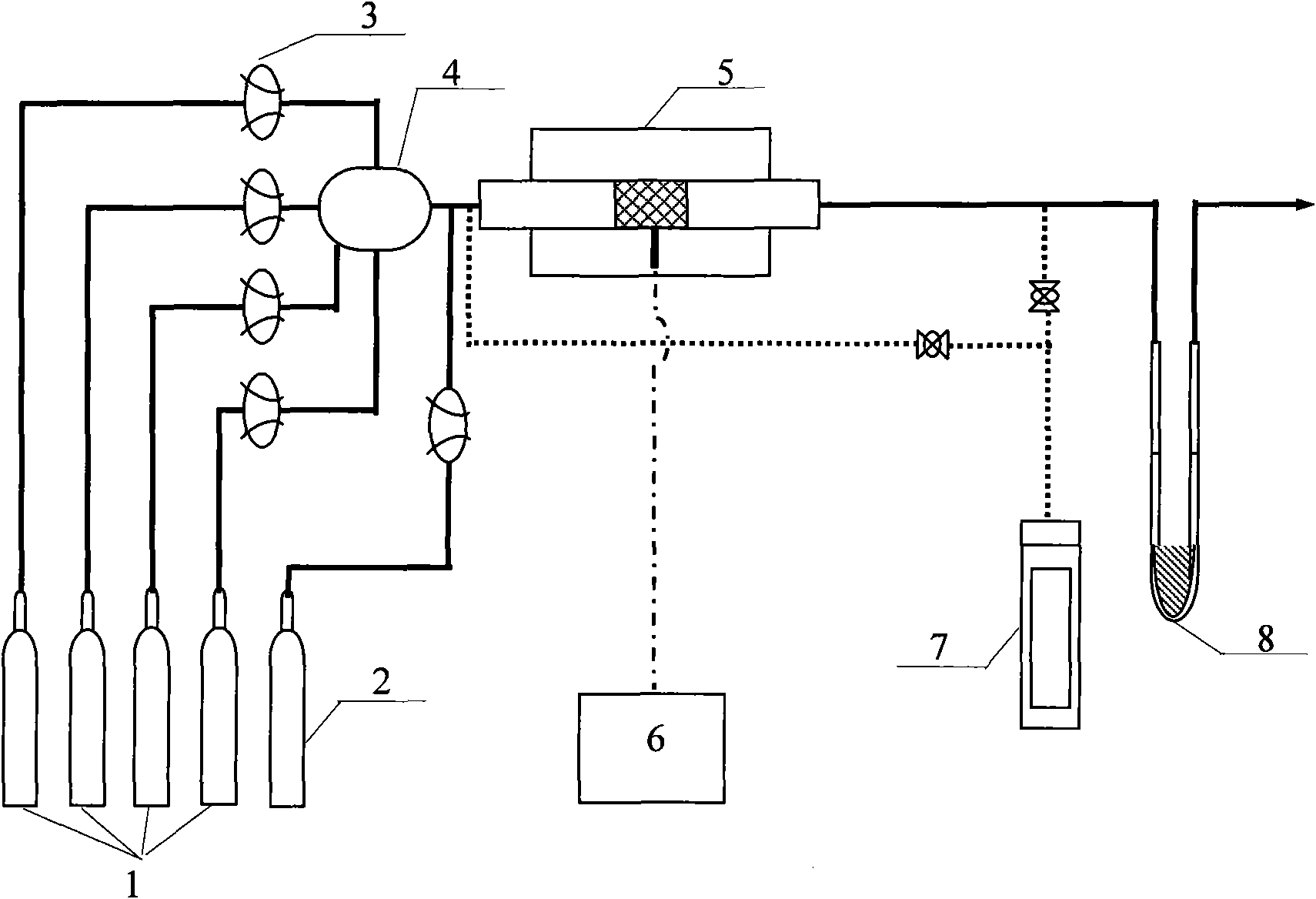

Method and device for detecting fume denitration catalyst activity

ActiveCN102103047BAdjust densityRealize dynamic simulationPreparing sample for investigationAir quality improvementNumerical controlEngineering

The invention discloses a method and device for detecting fume denitration catalyst activity, belonging to the technical field of air pollution control of environmental engineering. In the method, a numerical control flowmeter is adopted to precisely adjust the main components of stimulated fume which enters a square-shaped stainless-steel reactor provided with the catalyst to be detected after passing through an efficient rotational flow mixer; an opened square three-segment furnace in a cavity structure is adopted to heat at constant temperature; an embedded temperature measuring device is adopted to measure the changes of the fume temperature in real time; and a reductant gas state NH3 is introduced, and the concentration changes of nitric oxide (NO) of the fume before and after the reductant gas state NH3 passes through the reactor are detected by a fume analyzer to obtain the activity of the catalyst. The device provided by the invention has a simple system, and is accurate in parameter adjustment, reliable in operation and high in experimental efficiency; and by the device, the activities of the catalyst can be dynamically stimulated and detected under different operation conditions, and the gap of the detecting technique of the domestic fume denitration catalyst is filled in.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

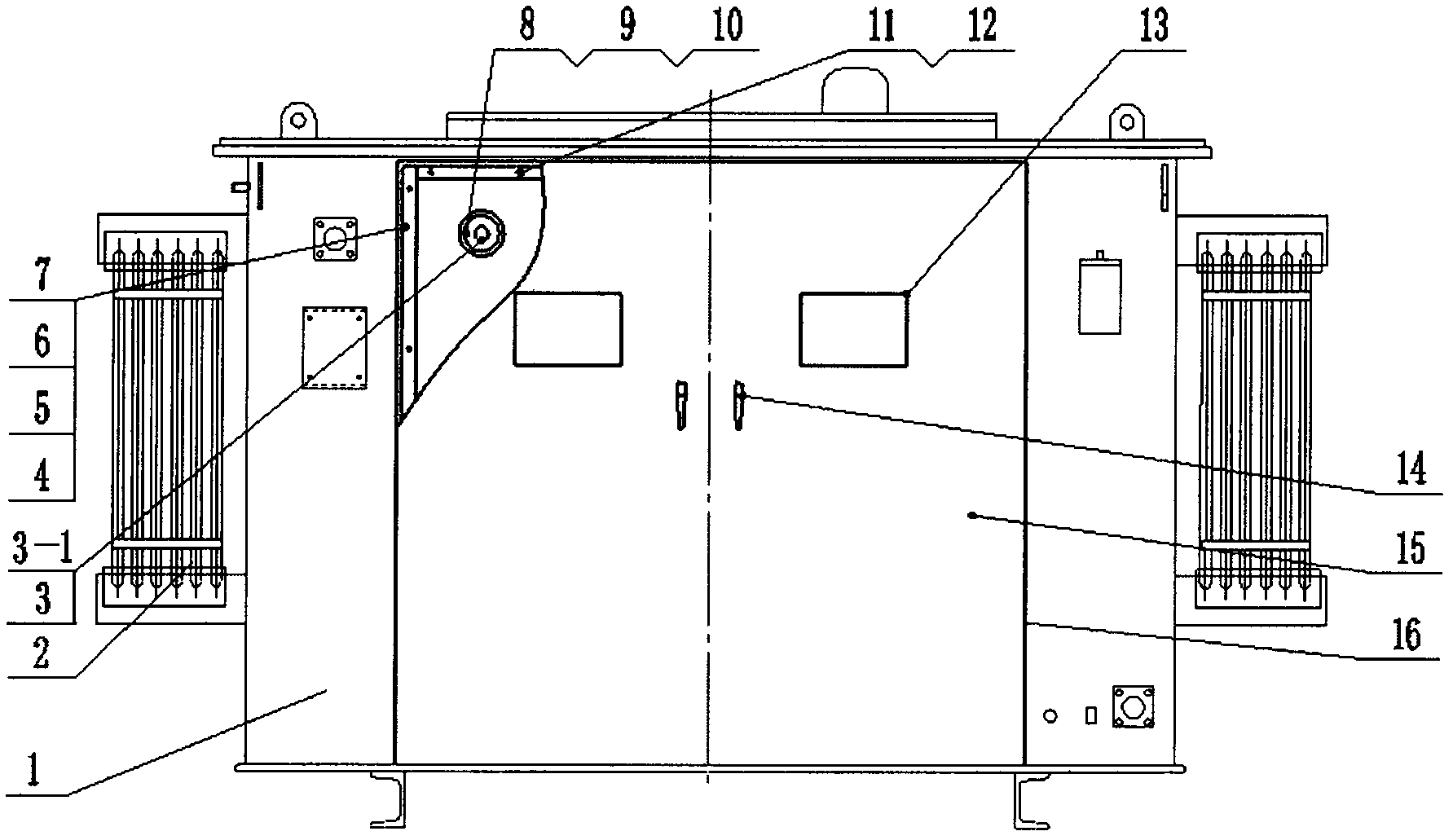

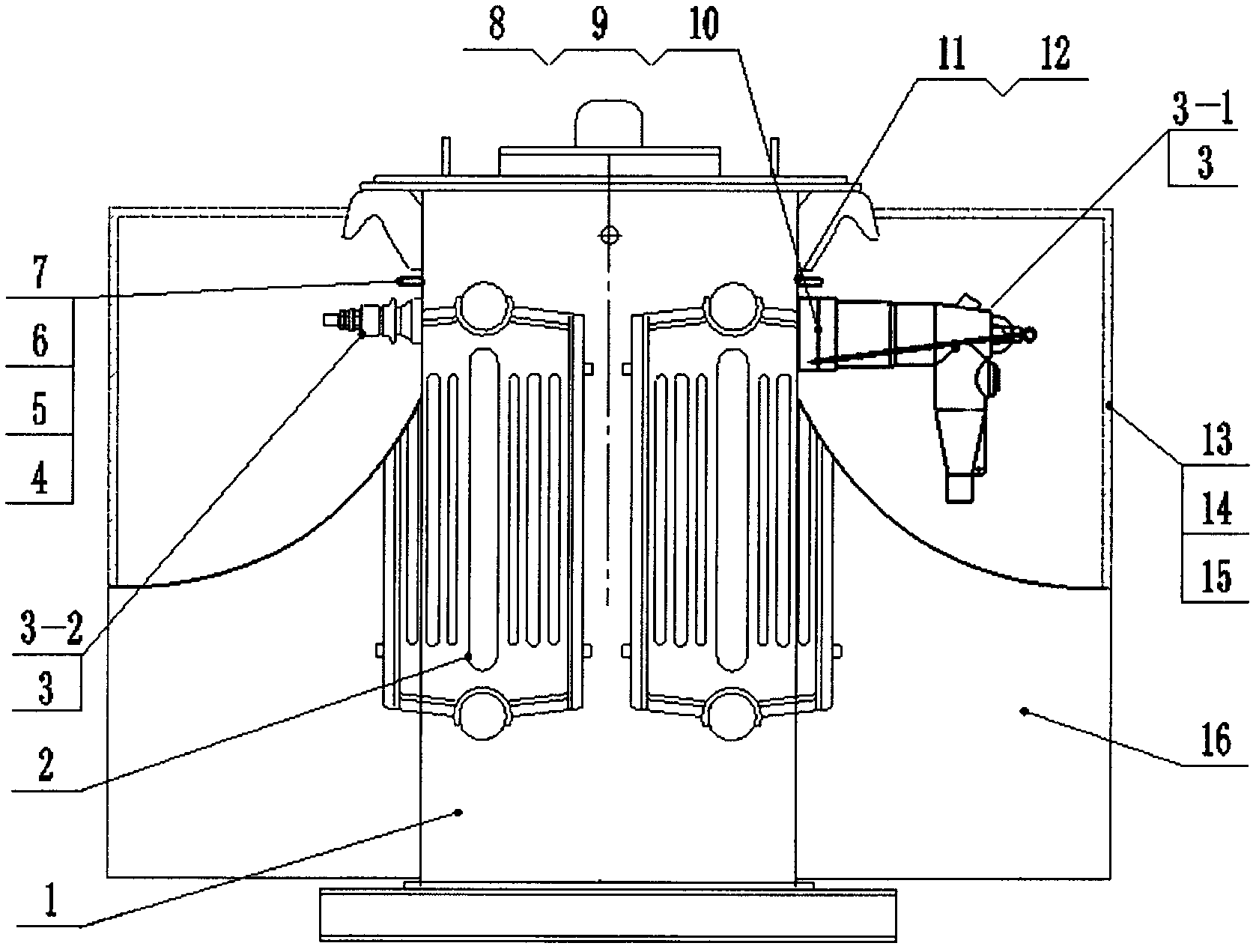

High-low voltage outgoing line terminal side transverse arrangement type oil-immersed transformer

ActiveCN102364632BMeet the requirements of nuclear phaseNuclear request to stopTransformers/inductances coils/windings/connectionsInterference resistanceLow voltage

The invention provides a high-low voltage outgoing line terminal side transverse arrangement type oil-immersed transformer. The oil-immersed transformer comprises a rectangular box body, internal working parts, a radiating fin and porcelain sleeve type high-low voltage outgoing line terminals, and is characterized in that: the porcelain sleeve type high-low voltage outgoing line terminals are transversely arranged on different side surfaces of the box body respectively, and the peripheries of the porcelain sleeve type high-low voltage outgoing line terminals are additionally provided with protective cover components consisting of rigid protective covers, rubber gaskets and fixed mounting bolts respectively; and because the rigid protective covers have certain mechanical strength, the rigid protective covers can effectively prevent outside impact or collision objects from touching the porcelain sleeve type high-low voltage outgoing line terminals, and stop the creepage distance betweensleeves from becoming shorter due to dust stratification or snowdrift on porcelain sleeve mounting surfaces, and then a reliable service life of the transformer is ensured. Compared with a conventional common oil-immersed transformer, the oil-immersed transformer provided by the invention obviously has the advantages of more reasonable structure, strong external interference resistance, reliable and safe working and the like, and has very strong practicability.

Owner:BEIJING BONA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com