Big and small impeller vane impeller with non-homogeneously distributed blades along circumference and compressor machine

A non-uniform distribution, vane impeller technology, applied in mechanical equipment, non-variable pumps, machines/engines, etc., can solve problems such as shortening the service life of compressors, accidents, cracks in stator blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

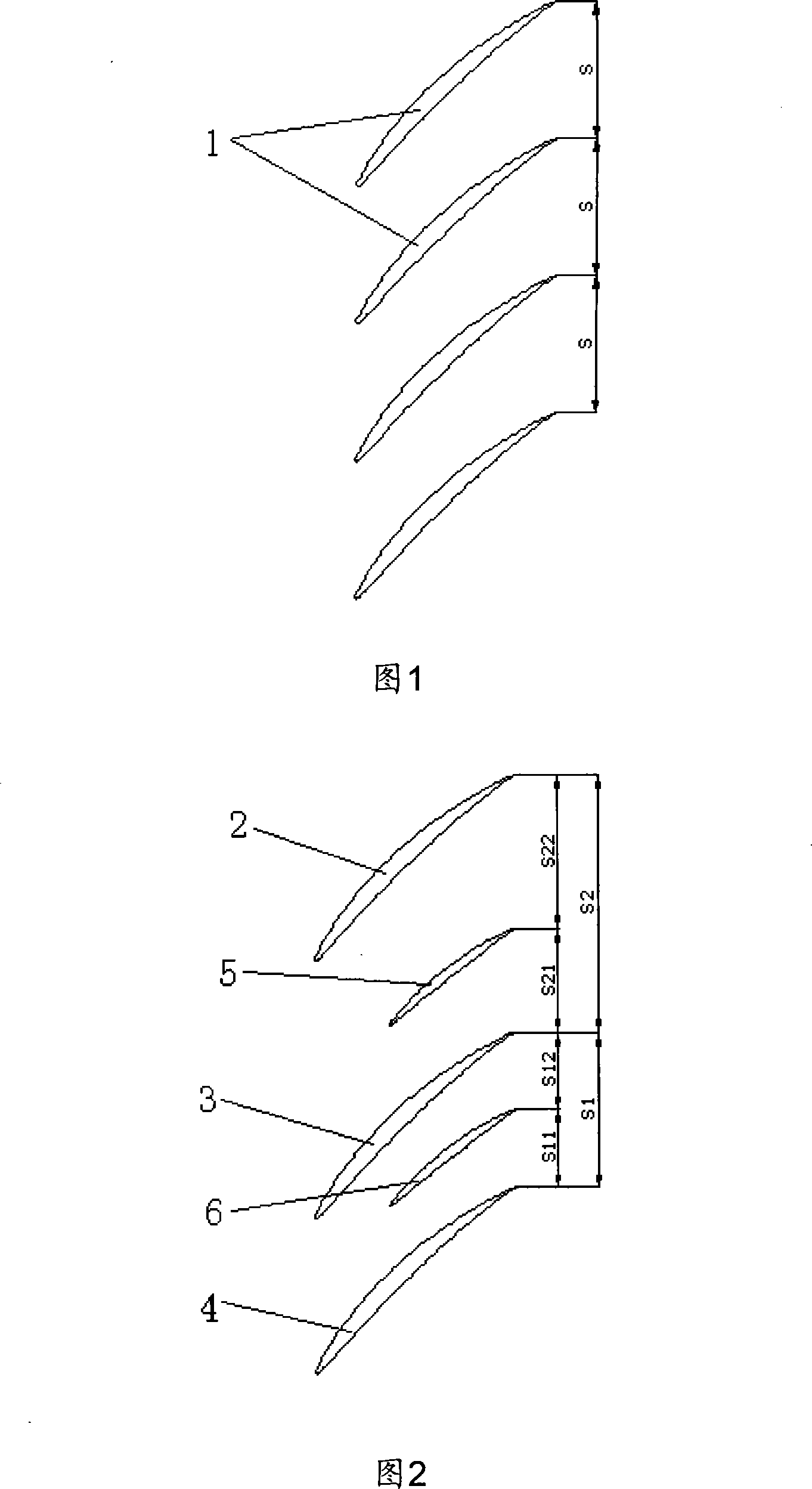

[0019] The large and small blade impeller with blades non-uniformly distributed along the circumferential direction of the present invention, its preferred specific embodiment is shown in Figure 2, including a plurality of large blades 2, 3, 4, and the gaps between the multiple large blades 2, 3, 4 are along the circumferential direction. Evenly distributed.

[0020] Among the multiple large blades 2, 3, 4, the distance in the circumferential direction between two adjacent large blades 2, 3 is a wide distance S2; the distance between two adjacent large blades 3, 4 is a narrow distance S1 . The distribution of the large blades along the circumference of the impeller with large and small blades may be such that the wide distance S2 and the narrow distance S1 are spaced apart from each other. Other non-uniform distribution methods are also possible.

[0021] The variation between the wide distance S2 and the narrow distance S1 may be less than or equal to 10%.

[0022] Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com