Explosion-proof engineering structure for hazardous article storage

A technology for engineering structures and dangerous goods, which is applied in the field of explosion-proof engineering structures for storage of dangerous goods, can solve problems such as lack of explosion-proof and anti-explosion capabilities, and achieve the effects of simple structure, quick installation, and high cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention is described in conjunction with accompanying drawings and specific embodiments:

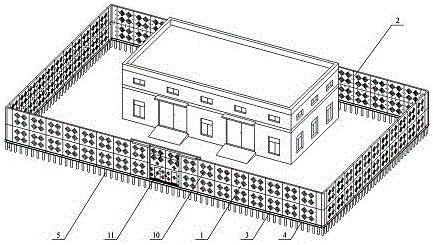

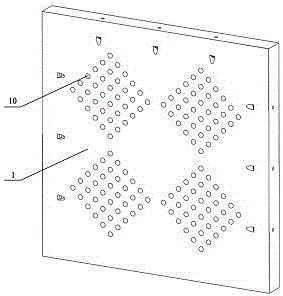

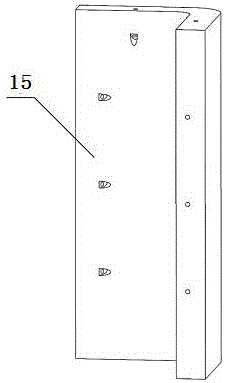

[0020] Such as figure 1 As shown, an explosion-proof engineering structure for storage of dangerous goods, the explosion-proof engineering structure has an explosion-proof wall as the main body of the explosion-proof engineering structure; the explosion-proof wall is a continuous enclosure explosion-proof structure arranged around the warehouse of dangerous goods. The damage caused by the explosion shock wave to the surrounding environment is controlled within the allowable value; the explosion-proof wall adopts a high-strength and high-performance steel fiber reinforced concrete structure, which has strong anti-explosion performance; the explosion-proof wall includes a rectangular wall and a corner wall Surface 15; the rectangular wall surface has at least two sides, the rectangular wall surface described in this embodiment has four sides, and the rectangular wall surface d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com