Preparation method of titanium-based composite anode for heavy metal wastewater treatment

A composite anode and wastewater treatment technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of expensive precious metals, high electrode preparation costs, weakened coating adhesion, etc., to achieve long service life, excellent performance, and reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

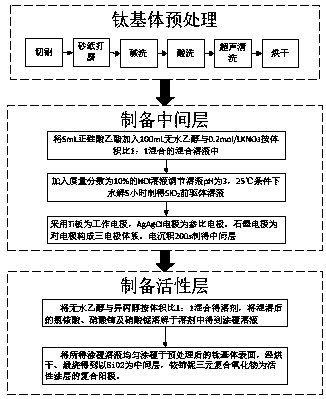

[0030] First, cut the titanium plate with a thickness of 1mm into 5cm*5cm, and then polish it with 200-grit sandpaper until it presents a silvery white metallic luster. Mix 20% sodium hydroxide solution and acetone solution at a volume ratio of 1:1, ultrasonically disperse for 10 minutes, place the polished titanium substrate in it, degrease at 60°C for 1 hour, and then put The titanium plate was placed in a 10% oxalic acid solution, etched at 90°C for 2 hours, ultrasonically cleaned with deionized water for 10 minutes, and dried in an oven for use.

[0031] Add 5mL tetraethyl orthosilicate to 100mL absolute ethanol and KNO mixed at a volume ratio of 1:1 3 In the mixed solution, add HCl solution with a mass fraction of 10% to adjust the pH of the solution to 3, and hydrolyze it for 5 hours at 25°C to obtain SiO 2 precursor solution.

[0032] The Ti plate was used as the working electrode, the Ag / AgCl electrode was used as the reference electrode, and the graphite electrode w...

Embodiment approach 2

[0038] First, cut the titanium plate with a thickness of 1mm into 5cm*5cm, and then polish it with 200-grit sandpaper until it presents a silvery white metallic luster. Mix 20% sodium hydroxide solution and acetone solution at a volume ratio of 1:1, and disperse them evenly by ultrasonication for 10 minutes. Place the polished titanium substrate in it, degrease at 60°C for 1 hour, and then put The titanium plate was placed in a 10% oxalic acid solution, etched at 90°C for 2 hours, ultrasonically cleaned with deionized water for 10 minutes, and dried in an oven for use.

[0039] Add 5mL tetraethyl orthosilicate to 100mL absolute ethanol and KNO mixed at a volume ratio of 1:1 3 In the mixed solution, add HCl solution with a mass fraction of 10% to adjust the pH of the solution to 3, and hydrolyze it for 5 hours at 25°C to obtain SiO 2 precursor solution.

[0040] The Ti plate was used as the working electrode, the Ag / AgCl electrode was used as the reference electrode, and the ...

Embodiment approach 3

[0046] First, cut the titanium plate with a thickness of 1mm into 5cm*5cm, and then polish it with 200-grit sandpaper until it presents a silvery white metallic luster. Mix 20% sodium hydroxide solution and acetone solution at a volume ratio of 1:1, ultrasonically disperse for 10 minutes, place the polished titanium substrate in it, degrease at 60°C for 1 hour, and then put The titanium plate was placed in a 10% oxalic acid solution, etched at 90°C for 2 hours, ultrasonically cleaned with deionized water for 10 minutes, and dried in an oven for use.

[0047] Add 5mL tetraethyl orthosilicate to 100mL absolute ethanol and KNO mixed at a volume ratio of 1:1 3 In the mixed solution, add HCl solution with a mass fraction of 10% to adjust the pH of the solution to 3, and hydrolyze it for 5 hours at 25°C to obtain SiO 2 precursor solution.

[0048] The Ti plate was used as the working electrode, the Ag / AgCl electrode was used as the reference electrode, and the graphite electrode w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com