Molybdenum carbide/foamed nickel composite material, preparation method, and application thereof in electrocatalytic oxygen evolution

A composite material, molybdenum carbide technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complicated reaction mechanism research, reduced catalytic performance, oxidation or spillage from materials, etc. , to achieve the effect of improving electrocatalytic oxygen evolution performance, improving electrocatalytic activity, protecting aggregation and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

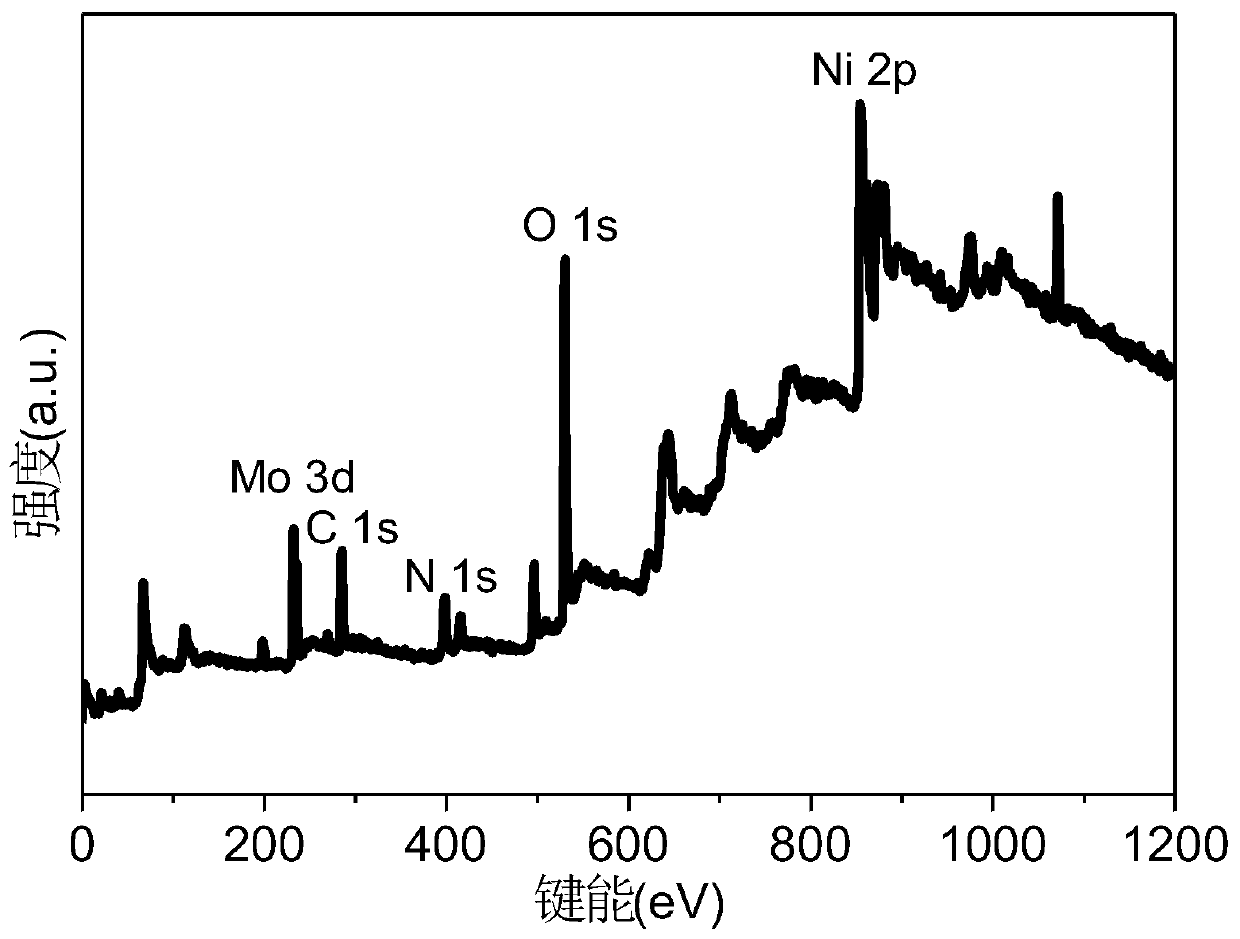

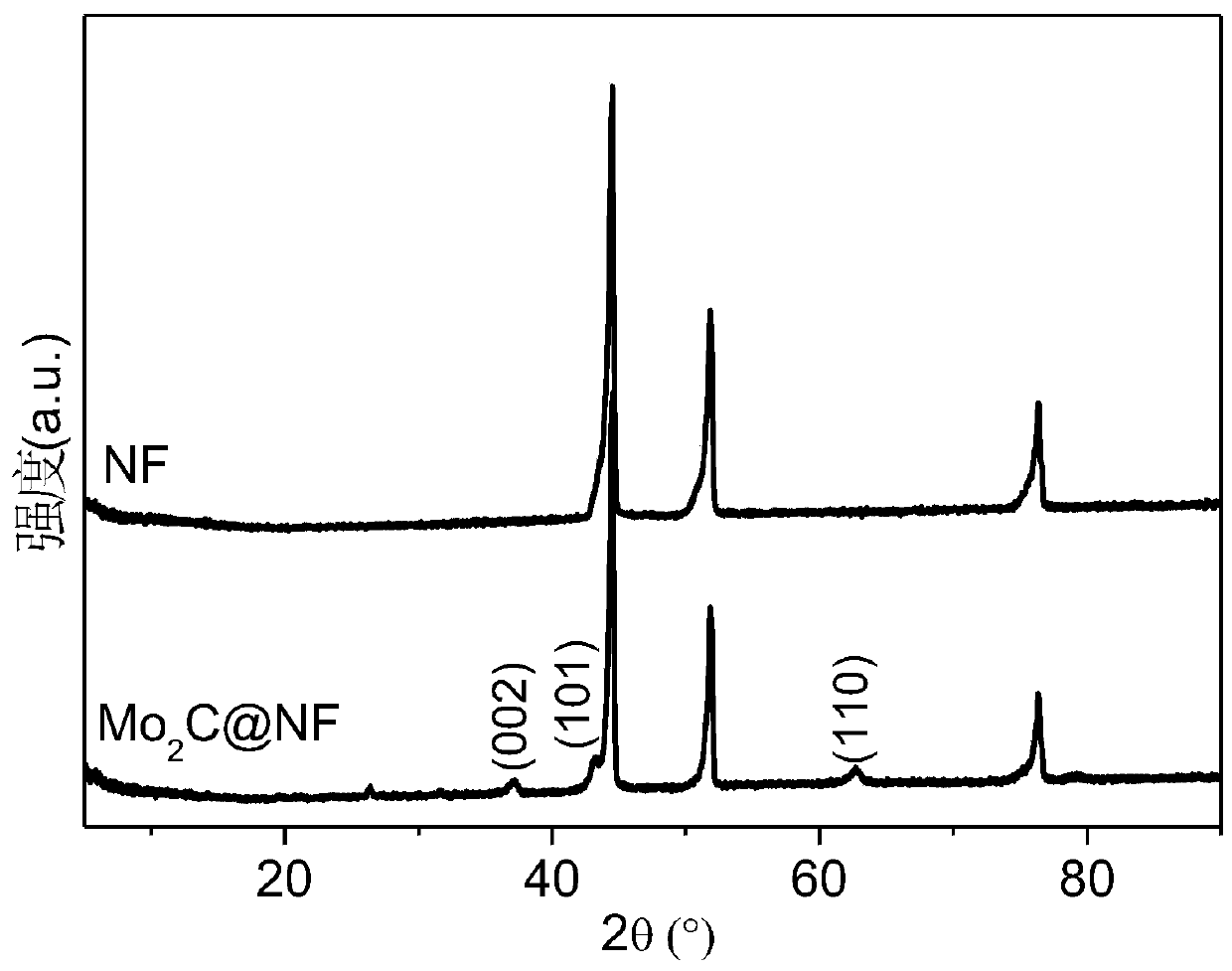

[0040] A molybdenum carbide / nickel foam composite material comprises molybdenum carbide and nickel foam, wherein the molybdenum carbide is supported on the nickel foam.

[0041] In this embodiment, the mass ratio of molybdenum carbide to nickel foam in the molybdenum carbide / nickel foam composite material is 1.5%.

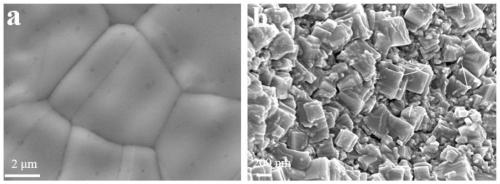

[0042] In this embodiment, the molybdenum carbide has a block structure and is a kind of cubic particles; the average particle size of the molybdenum carbide is 0.5 μm.

[0043] A preparation method of the molybdenum carbide / nickel foam composite material in the above-mentioned embodiment of the present invention comprises the following steps:

[0044] Take 0.18g area as 2×2cm 2 The foamed nickel was soaked in acetone and 1.0M hydrochloric acid solution successively, ultrasonicated for 0.5h each, washed, and dried; the pretreated foamed nickel was immersed in 40mL of ammonium molybdate / trisodium citrate aqueous solution (the aqueous solution contained 0.2mmol amm...

Embodiment 2

[0058] A molybdenum carbide / nickel foam composite material is basically the same as that of Example 1, except that the mass ratio of molybdenum carbide to nickel foam in the molybdenum carbide / nickel foam composite material of Example 2 is 1.2%.

[0059] A kind of preparation method of molybdenum carbide / nickel foam composite material in the above-mentioned present embodiment is basically the same as embodiment 1, the difference is only: in the preparation method of embodiment 2, the aqueous solution of ammonium molybdate / trisodium citrate used Contains 0.1mmol ammonium molybdate and 0.1mmol trisodium citrate.

[0060] The molybdenum carbide / nickel foam composite material prepared above was used as the working electrode for electrocatalytic oxygen evolution, and the other conditions were the same as in Example 1.

[0061] The electrocatalytic performance test results showed that Mo 2 The electrocatalytic oxygen evolution of C@NF can reach a current density of 10mA cm when the...

Embodiment 3

[0063] A molybdenum carbide / nickel foam composite material is basically the same as that of Example 1, except that the mass ratio of molybdenum carbide to nickel foam in the molybdenum carbide / nickel foam composite material of Example 3 is 1.8%.

[0064] A kind of preparation method of molybdenum carbide / nickel foam composite material in the above-mentioned present embodiment is basically the same as embodiment 1, the difference is only: in the preparation method of embodiment 3, the aqueous solution of ammonium molybdate / trisodium citrate used Contains 0.3mmol ammonium molybdate and 0.1mmol trisodium citrate.

[0065] The molybdenum carbide / nickel foam composite material prepared above was used as the working electrode for electrocatalytic oxygen evolution, and the other conditions were the same as in Example 1.

[0066] The electrocatalytic performance test results showed that Mo 2 The electrocatalytic oxygen evolution of C@NF can reach a current density of 10mA cm when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| polarization resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com