Energy-saving production process of tetrapropylammonium hydroxide and tetrapropylammonium hydroxide aqueous solution prepared by energy-saving production process

A technology of tetrapropylammonium hydroxide and production process, applied in electrolytic organic production, electrodes, electrolysis process and other directions, can solve problems such as affecting anode reaction activity, prolonging electrolysis time, increasing electrolysis voltage, etc., achieving good catalytic effect, improving Oxygen evolution capacity, the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

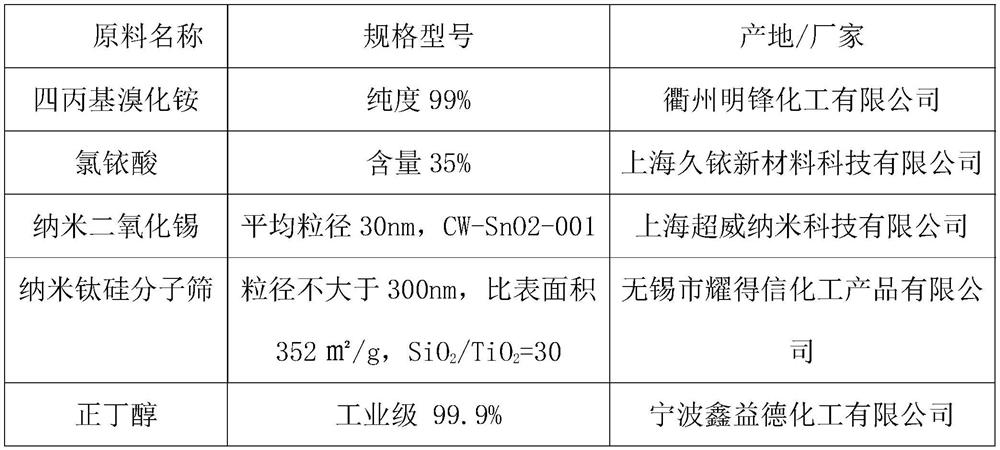

preparation example 1

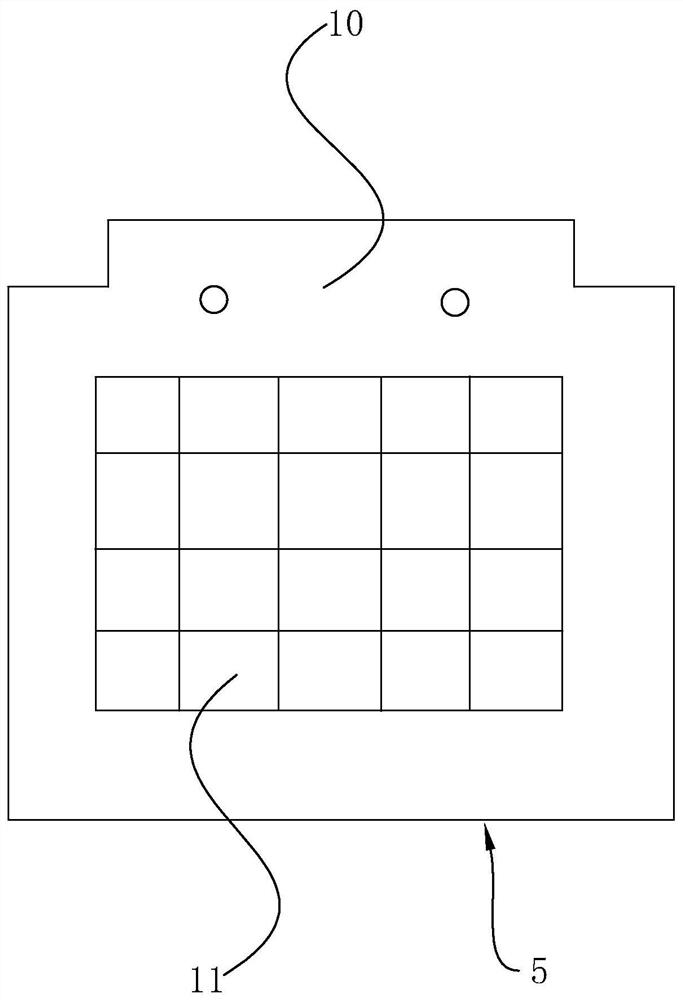

[0041] The titanium substrate includes a conductive frame 10 and a titanium mesh substrate 11 fixed in the conductive frame 10. The size of the titanium mesh substrate 11 is 20*15cm, the aperture of the titanium mesh substrate 11 is 6mm, and the thickness is 4mm. Get 20g of chloroiridic acid, add 175g of n-butanol, mix evenly, then add 45g of nano-tin dioxide and 1g of nano-titanium silicon molecular sieve, mix evenly, and make a slurry; apply the slurry evenly to the surface of the titanium mesh substrate, and control the coating. The amount of coating is such that the coating amount of iridium oxide on the surface of the titanium mesh substrate is 15g / ㎡, dried at 100°C for 60 minutes, and then baked at 450°C for 120 minutes. A catalytic coating is formed on the surface of the titanium mesh substrate 11, and several anode plates are prepared.

preparation example 2

[0043] The difference between Preparation Example 2 and Preparation Example 1 is that no titanium silicon molecular sieve is added in Preparation Example 2, and the other homogeneous Preparation Example 1 remains the same.

Embodiment 1

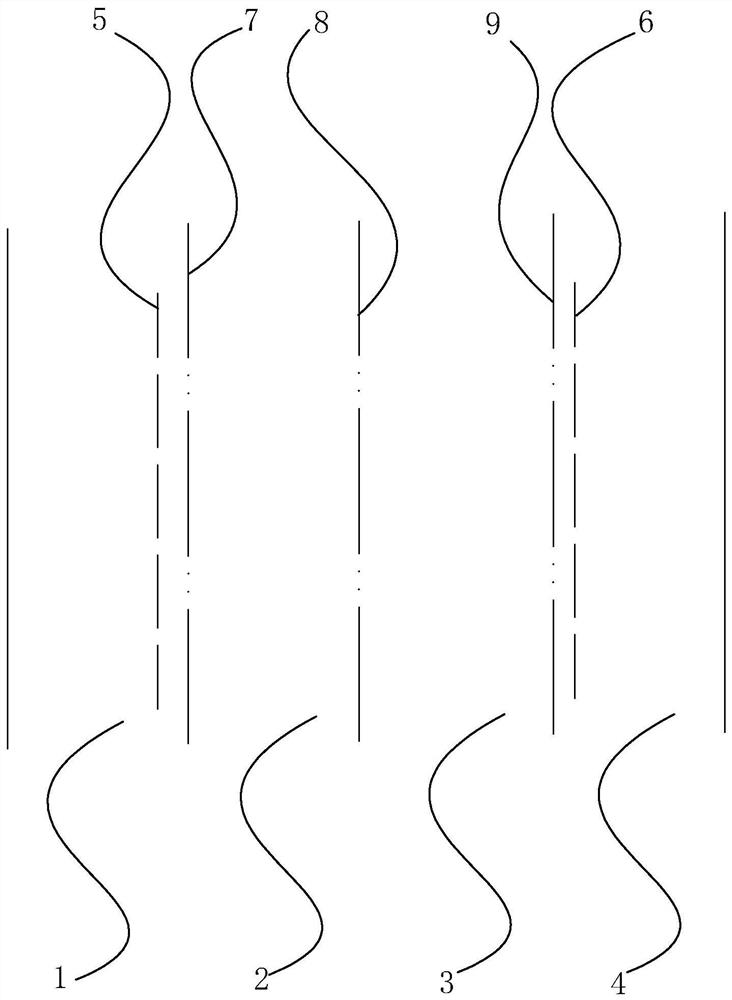

[0045] Embodiment 1: Tetrapropyl ammonium hydroxide production process, use electrolyzer to carry out electrolysis, electrolyzer comprises anode chamber 1, transition chamber 2, raw material chamber 3 and cathode chamber 4 adjacent successively at the same height; In anode chamber 1 The anode plate 5 prepared by Preparation Example 1 is installed, and the cathode plate 6 is installed in the cathode chamber 4 (the size and shape of the cathode plate 6 are consistent with the anode plate 5, and nickel electrodes are used), and the anode plate 5 and the cathode plate 6 are connected by a power supply; the anode chamber 1 communicates with the transition chamber 2 through the first cationic membrane 7, communicates between the transition chamber 2 and the raw material chamber 3 through the anion membrane 8, and communicates between the raw material chamber 3 and the cathode chamber 4 through the second cationic membrane 9; the production process includes The following steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com