NiS/NiO heterojunction-loaded nitrogen-doped carbon nano composite material and preparation method and application thereof

A nanocomposite material and nitrogen-doped carbon technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low output, time-consuming and cumbersome preparation process, etc., and achieve low cost , The process is simple and easy, and the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

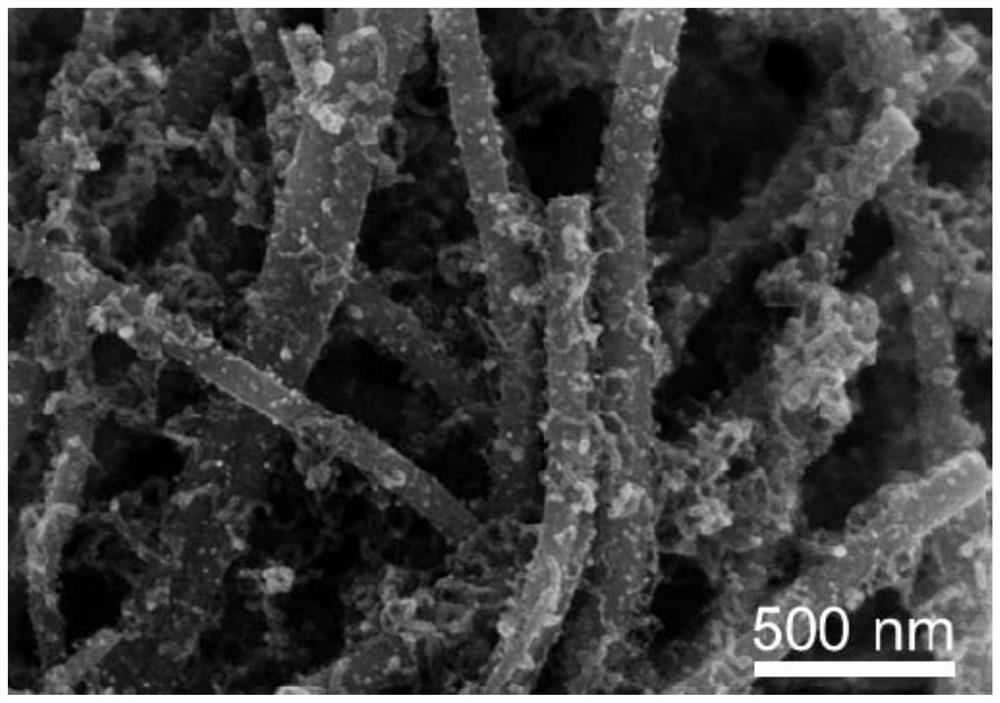

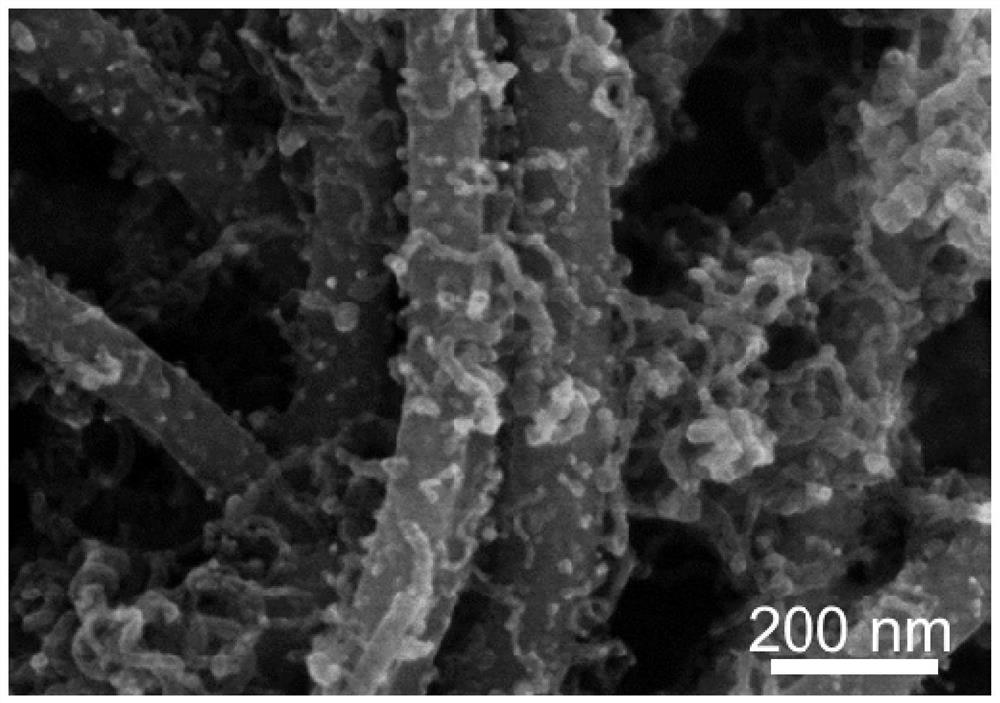

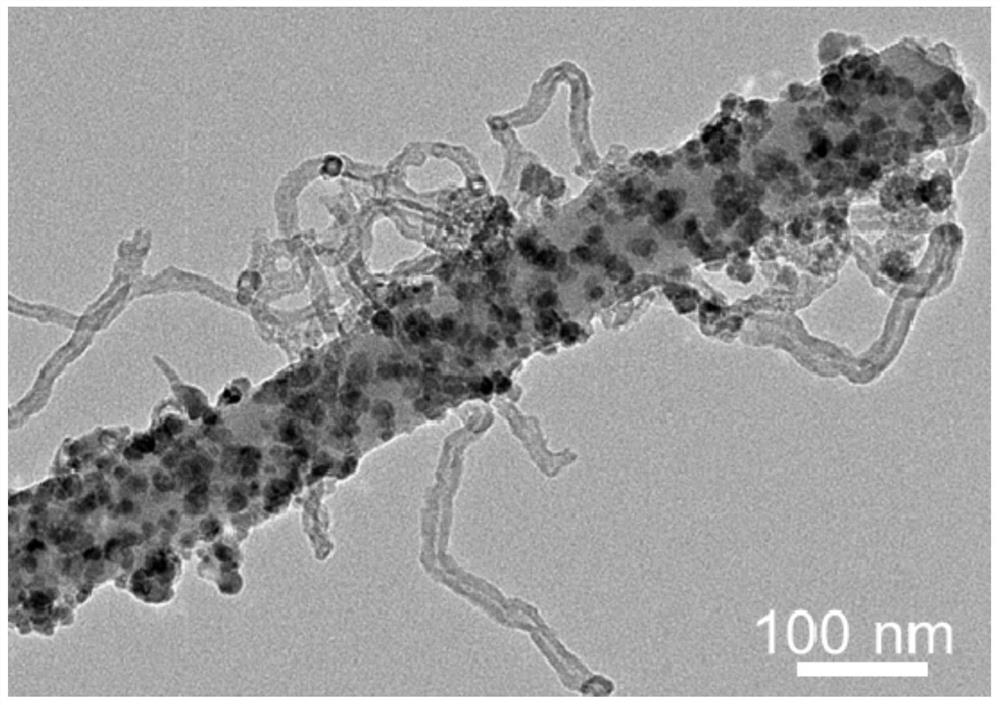

[0047] A kind of nitrogen-doped carbon nanofiber, the preparation method of carbon nanotube loaded NiS / NiO heterojunction material, comprises the following steps:

[0048] 1)Ni 2+ The preparation of / PVP mixed sol: take by weighing 1.0g PVP and 6mL DMF and 6mL C 2 h 5 OH solution mixed, adding 1.5mmol of Ni(NO 3 ) 2 ·6H 2 O solid metal nitrate; after mechanical stirring at room temperature for 12h, make it evenly mixed, you can get light green Ni 2+ / PVP sol;

[0049] 2) Preparation of nitrogen-doped carbon nanocomposites loaded NiS / NiO heterojunction composites by electrospinning: the light green Ni obtained in step 1) 2+ / PVP sol, processed by electrospinning technology, the obtained solid carbon fiber film material is pre-oxidized in the air at 250°C for 3h, and then in N 2 Under the atmosphere, the temperature was raised to 600°C at a rate of 5°C / min for heat treatment, and kept at this temperature for 3 hours, then cooled to room temperature, and then subjected to ...

Embodiment 2

[0052] A kind of nitrogen-doped carbon nanofiber, the preparation method of carbon nanotube loaded NiS / NiO heterojunction material, comprises the following steps:

[0053] 1)Ni 2+ The preparation of / PVP mixed sol: take by weighing 0.8g PVP and 6mL DMF and 6mL C 2 h 5 OH solution mixed, adding 1.5mmol of Ni(NO 3 ) 2 ·6H 2 O solid metal nitrate; after mechanical stirring at room temperature for 12h, make it evenly mixed, you can get light green Ni 2+ / PVP sol;

[0054] 2) Preparation of nitrogen-doped carbon nanocomposites loaded NiS / NiO heterojunction composites by electrospinning: the light green Ni obtained in step 1) 2+ / PVP sol, processed by electrospinning technology, the obtained solid carbon fiber film material is pre-oxidized in the air at 250°C for 3h, and then in N 2 Under the atmosphere, the temperature was raised to 600°C at a rate of 5°C / min for heat treatment, and kept at this temperature for 3 hours, then cooled to room temperature, and then subjected to ...

Embodiment 3

[0056] A kind of nitrogen-doped carbon nanofiber, the preparation method of carbon nanotube loaded NiS / NiO heterojunction material, comprises the following steps:

[0057] 1)Ni 2+ The preparation of / PVP mixed sol: take by weighing 0.7g PVP and 6mL DMF and 6mL C 2 h 5 OH solution mixed, adding 1.5mmol of Ni(NO 3 ) 2 ·6H 2 O solid metal nitrate; after mechanical stirring at room temperature for 12h, make it evenly mixed, you can get light green Ni 2+ / PVP sol;

[0058] 2) Preparation of nitrogen-doped carbon nanocomposites loaded NiS / NiO heterojunction composites by electrospinning: the light green Ni obtained in step 1) 2+ / PVP sol, processed by electrospinning technology, the obtained solid carbon fiber film material is pre-oxidized in the air at 250°C for 3h, and then in N 2 Under the atmosphere, the temperature was raised to 600°C at a rate of 5°C / min for heat treatment, and kept at this temperature for 3 hours, then cooled to room temperature, and then subjected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com