Foamed nickel-loaded iron-cobalt-nickel metal nano-catalyst and preparation method and application thereof

A nano-catalyst, metal nano-technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of performance degradation, poor electrode stability, etc., achieve low production cost, improve catalytic activity, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for foamed nickel-supported iron-cobalt-nickel metal nano-catalysts, comprising the following steps:

[0025] (1) Pretreatment of foamed nickel: Cut the foamed nickel into a rectangle with a size of 1 cm×4.5 cm, soak the foamed nickel in 3M HCl, acetone, absolute ethanol and deionized water in sequence for ultrasonic cleaning, each cleaning 10 min, dry and ready for use;

[0026] (2) Add 2 mmol Co(NO 3 ) 2 ·6H 2 O, 6 mmol NH 4 F, 12 mmol urea and 1 mmol Ni(NO 3 ) 2 ·6H 2 The mixture of O was dissolved in 60 mL deionized water to obtain a mixed solution and stirred for 30 min, and the first step hydrothermal solution was obtained after stirring evenly;

[0027](3) Insert the pretreated nickel foam into the PTFE mold base with slots to keep the nickel foam in a vertical state, add 100 mL of the PTFE base inserted into the foam nickel and the prepared hydrothermal solution In the autoclave, nickel foam is fixed vertically at the bottom of the a...

Embodiment 2

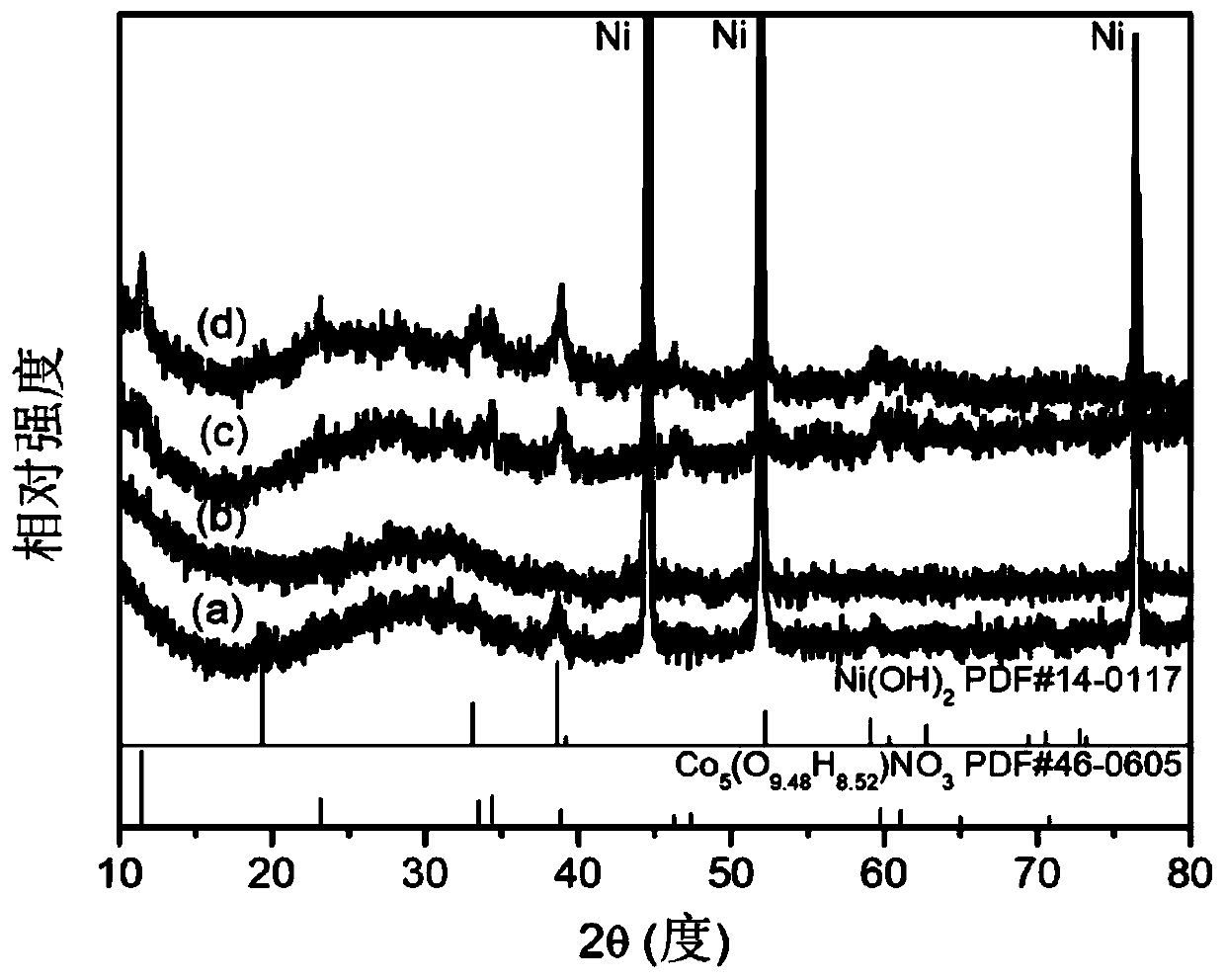

[0031] With embodiment 1, the difference is that in the step (2) Ni(NO 3 ) 2 ·6H 2 The amount of O added was 0.75 mmol, and 0.25 mmol of Fe(NO 3 ) 2 9H 2 O. The X-ray diffraction pattern of the prepared electrode can be found in figure 2 In (b) curve, the material structure of this nickel foam surface loading is mainly amorphous.

[0032] The electrode obtained in this example is at 50 mA·cm -2 The oxygen evolution overpotential at a current density of 277 mV.

Embodiment 3

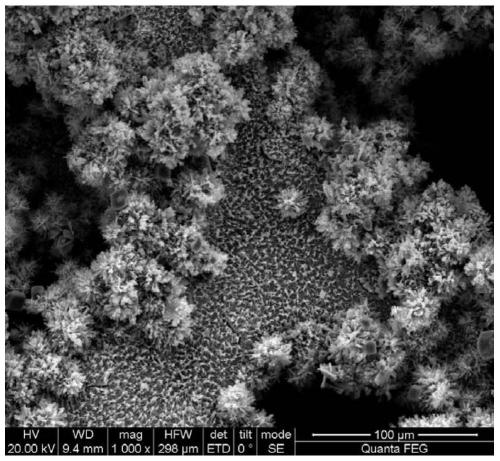

[0034] With embodiment 1, the difference is that in the step (2) Ni(NO 3 ) 2 ·6H 2 The amount of O added was 0.5 mmol, and 0.5 mmol of Fe(NO 3 ) 2 9H 2 O. Scanning electron microscope (SEM) pictures of the fabricated electrodes can be found in figure 1 , it can be seen from the figure that the material presents a beam-like structure, which is conducive to the electron transfer of the oxygen evolution reaction and the removal of the product oxygen, which is conducive to the oxygen evolution reaction. The X-ray diffraction pattern of the prepared electrode can be found in figure 2 In (c) curve, the material structure supported on the surface of this nickel foam is mainly amorphous and low crystallinity Co 5 (O 9.48 h 8.52 )NO 3 .

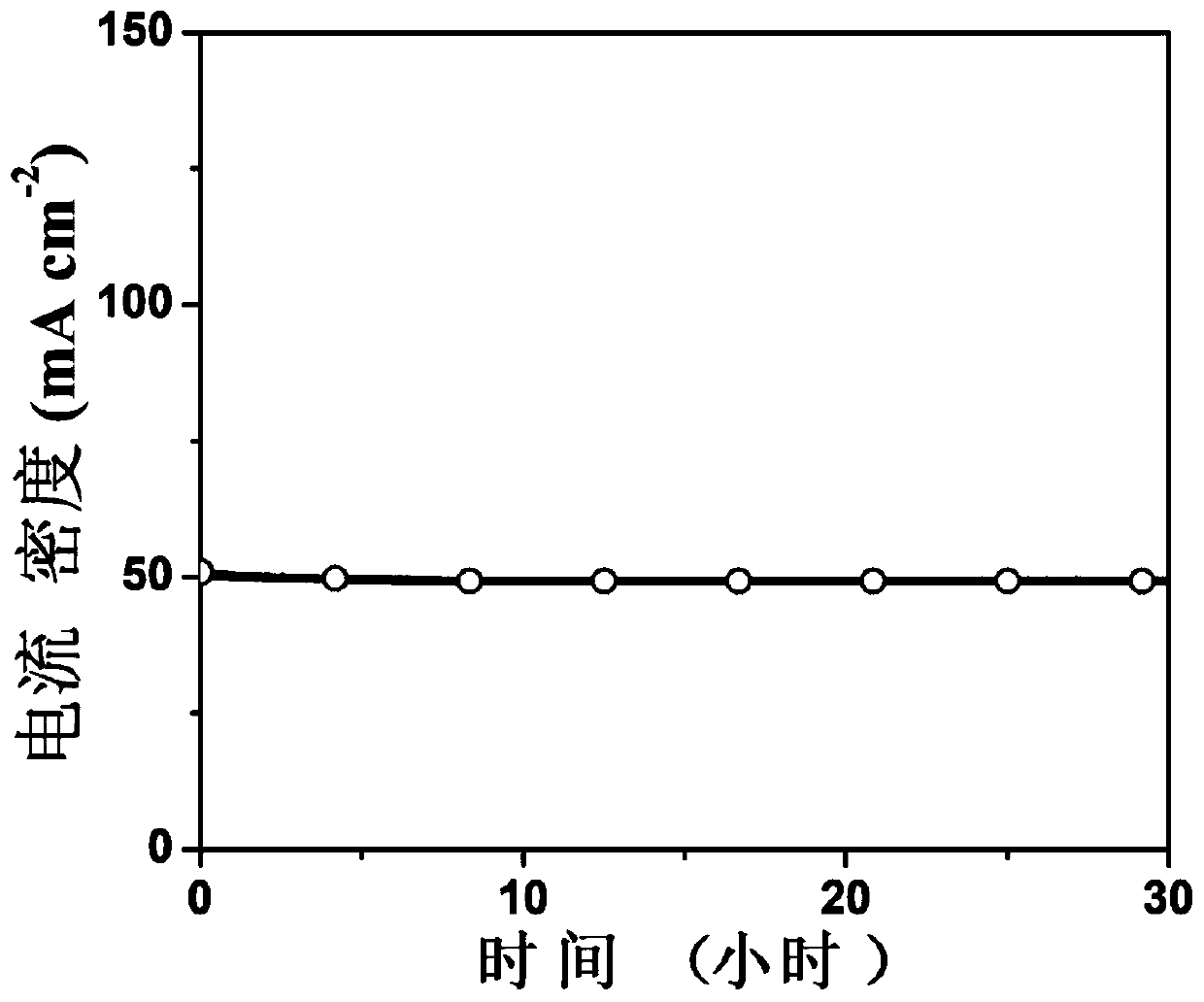

[0035] The electrode obtained in this example is at 50 mA·cm -2 The oxygen evolution overpotential at a high current density is 228 mV, and at a high current density of 100 mA cm -2 The lower overpotential is still very low at 250 mV. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com