Cobalt disulfide/carbon-nitrogen composite material for water electrolysis oxygen evolution, and synthesis method thereof

A technology of cobalt disulfide and composite materials, applied in chemical instruments and methods, electrolytic processes, electrolytic components, etc., can solve problems such as performance needs to be improved, and achieve the effects of excellent hydrophilicity, uniform appearance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

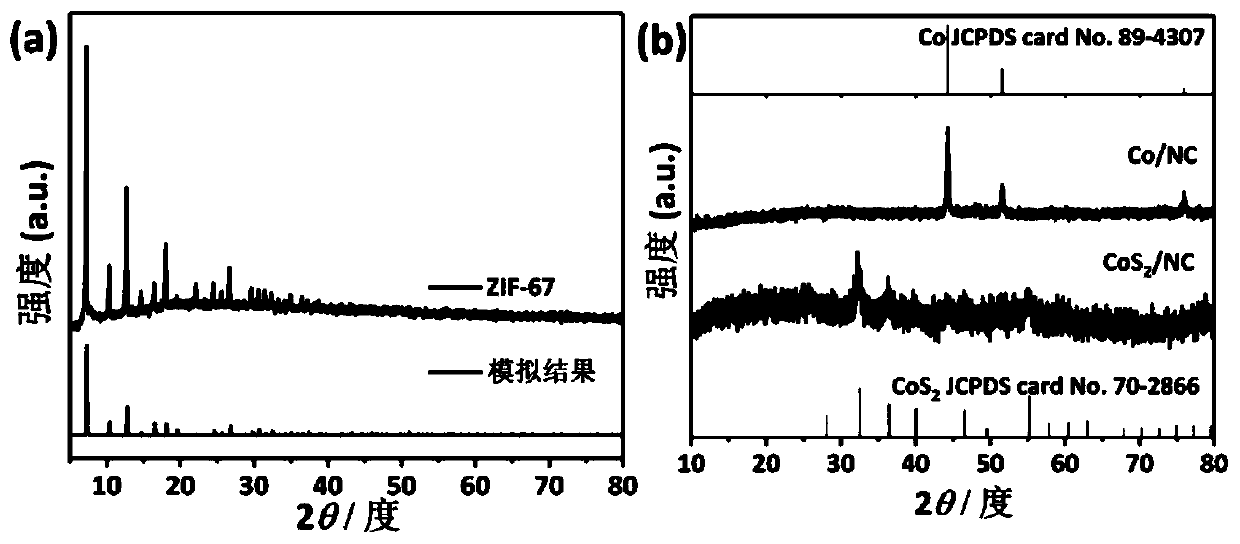

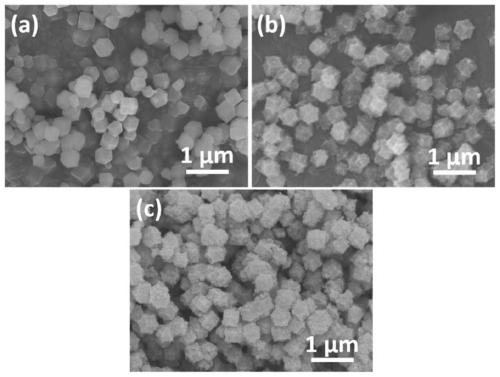

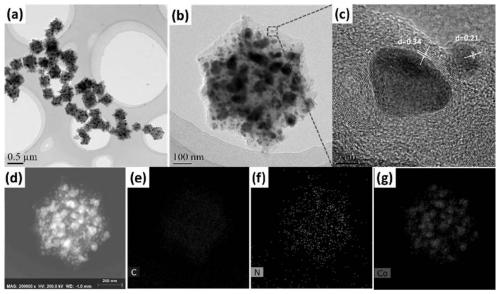

[0033] (1) Weigh 1.746g Co(NO 3 ) 2 ·6H 2O in a mixed solvent of 40ml ethanol and 40mL methanol, stirred with a magnetic stirrer for 10min, and then sonicated for 10min. Similarly, weigh 1.97g of 2-methylimidazole in a mixed solvent of 40ml of ethanol and 40ml of methanol, stir with a magnetic stirrer for 10min, and then sonicate for 10min. Pour the above organic solution into the salt solution quickly while stirring, and continue to stir for 10 minutes, then let stand at room temperature for 24 hours, wash the obtained purple precipitate with ethanol and methanol alternately, centrifuge, and dry at 60°C for 12 hours to obtain a metal organic framework Compound ZIF-67. figure 1 (a) The XRD pattern of the prepared ZIF-67 is given, and its characteristic peaks correspond to the fitted peaks one by one, figure 2 The electron microscope image in (a) shows that ZIF-67 is a dodecahedral structure with uniform size and smooth appearance. Figure 5 The Raman peaks of ZIF in the ...

Embodiment 2

[0039] (1) Weigh 1.746g Co(NO 3 ) 2 ·6H 2 O in a mixed solvent of 40ml ethanol and 40ml methanol, stirred with a magnetic stirrer for 10min, then sonicated for 10min. Similarly, weigh 1.97g of 2-methylimidazole in a mixed solvent of 40ml of ethanol and 40ml of methanol, stir with a magnetic stirrer for 10min, and then sonicate for 10min. Pour the above-mentioned organic solution into the saline solution rapidly while stirring, and keep stirring for 5 minutes, then let stand at room temperature for 18 hours, wash the obtained purple precipitate with ethanol and methanol alternately, centrifuge, and dry at 60°C for 12 hours to obtain a metal organic framework ZIF-67.

[0040] (2) Put the ZIF-67 in step (1) in a magnetic boat and anneal at 300°C for 2h in a nitrogen atmosphere in a tube furnace, then anneal at 1000°C for 3.5h, and the sample taken out after cooling is a porous dodecahedron Cobalt / carbon nitrogen composite.

[0041] (3) Add the cobalt / carbon-nitrogen composit...

Embodiment 3

[0044] (1) Weigh 1.746g Co(NO 3 ) 2 ·6H 2 O in a mixed solvent of 40ml ethanol and 40ml methanol, stirred with a magnetic stirrer for 10min, then sonicated for 10min. Similarly, weigh 1.97g of 2-methylimidazole in a mixed solvent of 50ml of ethanol and 40ml of methanol, stir with a magnetic stirrer for 10min, and then sonicate for 10min. Pour the above-mentioned organic solution into the salt solution rapidly while stirring, and continue to stir for 20 minutes, then let stand at room temperature for 24 hours, wash the obtained purple precipitate with ethanol and methanol alternately, centrifuge, and dry at 60°C for 12 hours to obtain a metal organic framework ZIF-67.

[0045] (2) Put ZIF-67 in step (1) in a magnetic boat and anneal at 300°C for 2 hours in a nitrogen atmosphere in a tube furnace, then anneal at 800°C for 4 hours, and the sample taken out after cooling is porous dodecahedral cobalt / carbon-nitrogen composite materials.

[0046] (3) Put the cobalt / carbon-ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com