Efficient total water splitting electrocatalyst IPBAP/Ni2P@MoOx/NF and preparation method thereof

A catalyst and hydropower technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem that the oxygen evolution performance of molybdenum-based catalysts is not excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

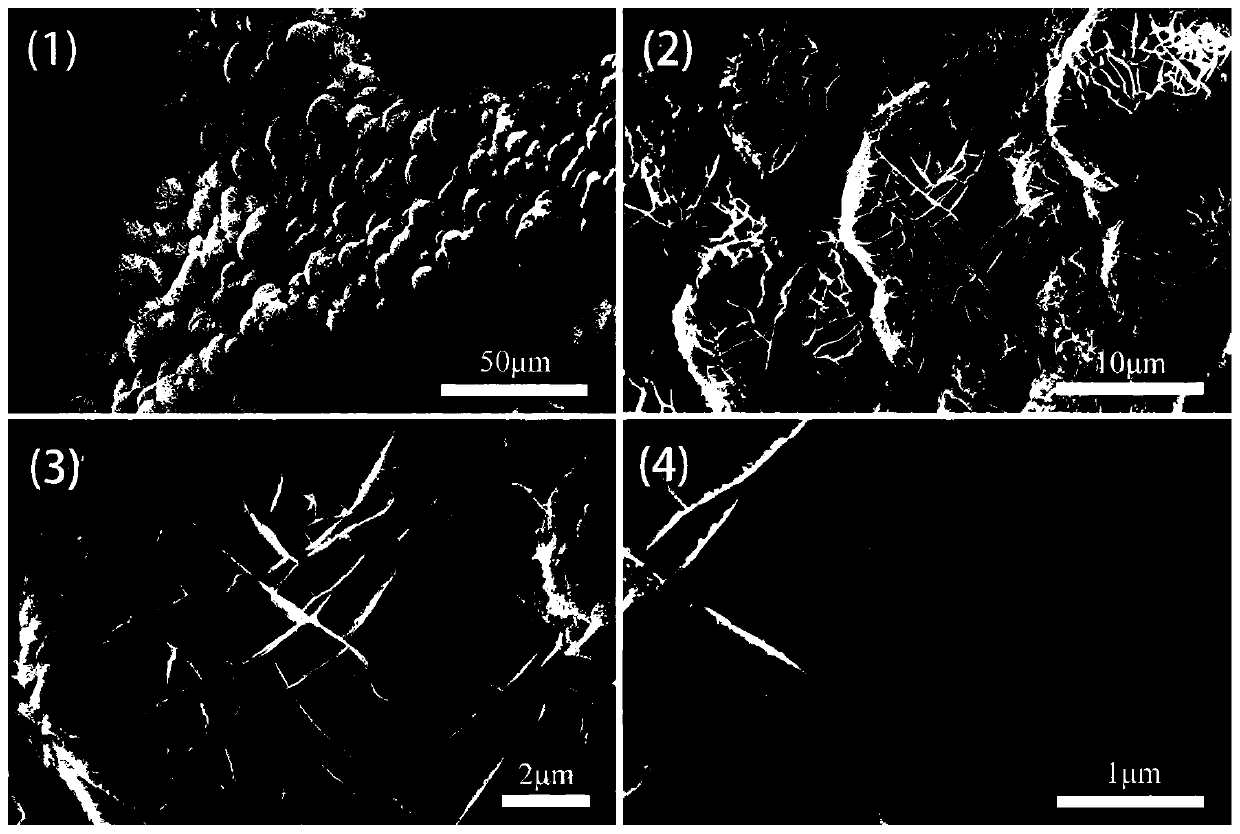

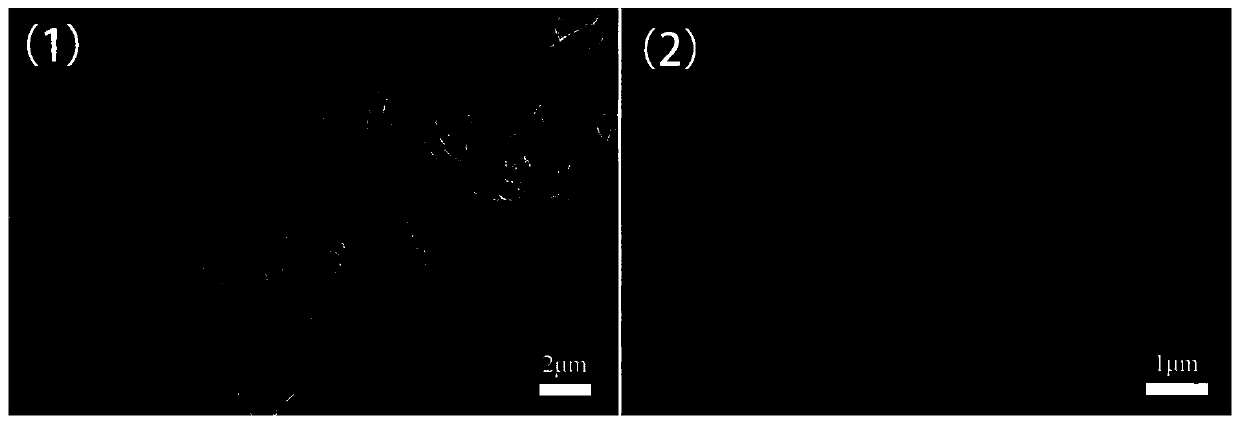

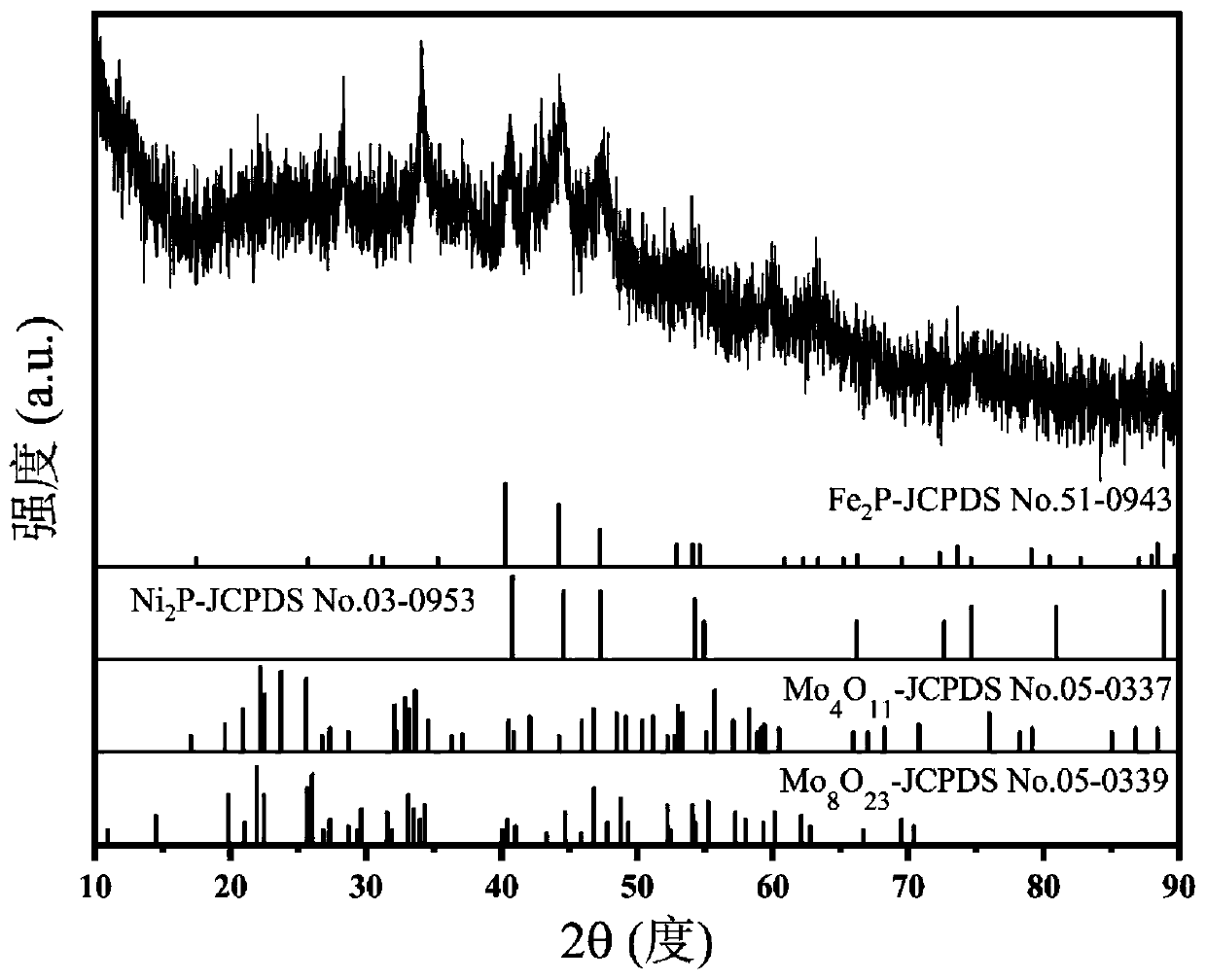

[0035] The complete hydrolysis electrocatalyst IPBAP / Ni described in this embodiment 2 The preparation method of P@MoOx / NF comprises the following steps:

[0036] (1) Cut commercial nickel foam into a size of 10mm*20mm, ultrasonically treat each in 3M dilute hydrochloric acid, absolute ethanol, and deionized water for 15 minutes, then vacuum dry at 60°C for 12 hours, and set aside;

[0037] (2) Weigh 0.1 mmol of ammonium molybdate tetrahydrate, 0.26 mmol of nickel nitrate hexahydrate and 2 mmol of acetamide, add 60 ml of deionized water and stir for 2 hours to obtain a loading solution;

[0038] (3) Transfer the obtained load solution to the reactor, and add the previously treated nickel foam, seal it and put it in an oven at 180°C for 24 hours; when the reactor cools down to room temperature, take out the nickel foam and wash Rinse 3 times, put into 60℃ oven to dry for 12h;

[0039] (4) Soak the dried nickel foam in 0.01M potassium ferricyanide for 24 hours, rinse it with d...

Embodiment 2

[0052] The complete hydrolysis electrocatalyst IPBAP / Ni described in this embodiment 2 The preparation method of P@MoOx / NF comprises the following steps:

[0053] (1) Cut commercial nickel foam into a size of 10mm*20mm, ultrasonically treat each in 3M dilute hydrochloric acid, absolute ethanol, and deionized water for 15 minutes, then vacuum dry at 60°C for 12 hours, and set aside;

[0054] (2) In addition, weigh 0.1 mmol of ammonium molybdate tetrahydrate, 0.35 mmol of nickel nitrate hexahydrate and 2 mmol of acetamide, add 60 ml of deionized water and stir for 2 hours to obtain a loading solution;

[0055] (3) Transfer the obtained load solution to the reaction kettle, add the previously treated foamed nickel and seal it, and put it in an oven at 180°C for 24 hours of reaction; when the reaction kettle is cooled to room temperature, take out the foamed nickel and rinse it with deionized water 3 times, put it in an oven at 60°C for 12 hours;

[0056] (4) Soak the dried nick...

Embodiment 3

[0059] The complete hydrolysis electrocatalyst IPBAP / Ni described in this embodiment 2 The preparation method of P@MoOx / NF comprises the following steps:

[0060] (1) Cut commercial nickel foam into a size of 10mm*20mm, ultrasonically treat each in 3M dilute hydrochloric acid, absolute ethanol, and deionized water for 15 minutes, then vacuum dry at 60°C for 12 hours, and set aside;

[0061] (2) Weigh 0.1 mmol of ammonium molybdate tetrahydrate, 0.175 mmol of nickel nitrate hexahydrate and 2 mmol of acetamide, add 60 ml of deionized water and stir for 2 hours to obtain a loading solution;

[0062] (3) Transfer the obtained load solution to the reaction kettle, add the previously treated foamed nickel and seal it, and put it in an oven at 180°C for 24 hours of reaction; when the reaction kettle is cooled to room temperature, take out the foamed nickel and rinse it with deionized water 3 times, put it in an oven at 60°C for 12 hours;

[0063] (4) Soak the dried nickel foam in 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com