Foam nickel@cobalt molybdenum phosphide/nickel iron double hydroxide electrode, preparation method and application thereof

A double hydroxide and phosphide technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of high reaction temperature and long reaction time, and achieve high safety factor, reduce preparation cost, and environment-friendly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

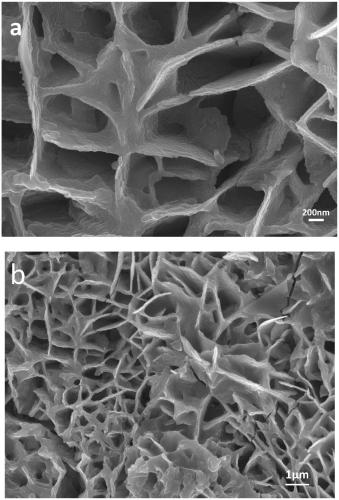

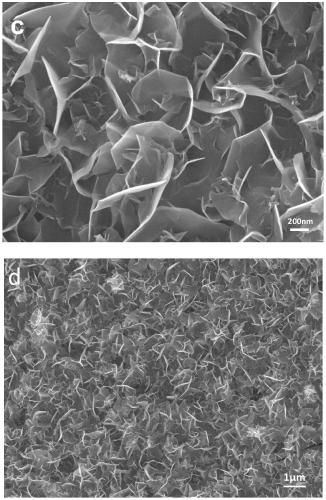

[0047] The preparation method of nickel foam@cobalt molybdenum phosphide (Co / Mo=1.5:1) electrode, the steps are as follows:

[0048] (1) Hydrothermal reaction: weigh 0.253g CoSO 4 ·7H 2 O and 0.741g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 15 ml of deionized water to prepare a precursor solution, put into clean nickel foam, placed in a reaction kettle, reacted at 100 °C for 10 hours, cooled, cleaned and vacuum dried at 40 °C for 6 hours.

[0049] (2) Phosphating treatment: the nickel foam loaded with cobalt-molybdenum composite obtained in step (1) and 0.3g Na 3 PO 4 Put two burning boats respectively, and place them in a tube furnace. Under the protection of argon, the temperature was raised to 300°C at 5°C / min, kept for 1 hour and cooled to obtain foamed nickel@cobalt molybdenum phosphide (Co / Mo =1.5:1) electrode.

[0050] Catalytic performance test: hydrogen evolution reaction and oxygen evolution reaction: install the foamed nickel@cobalt molybdenum phosphide (...

Embodiment 2

[0052] The preparation method of nickel foam@cobalt molybdenum phosphide (Co / Mo=2.3:1) electrode, the steps are as follows:

[0053] (1) Hydrothermal reaction: Weigh 0.3056g Co(NO 3 ) 2 ·6H 2 O and 0.109 g Na 2 MoO 4 2H 2 O was dissolved in 15 ml of deionized water to prepare a precursor solution, put into clean nickel foam, placed in a reaction kettle, reacted at 180 °C for 6 hours, cooled, cleaned and vacuum dried at 70 °C for 12 hours.

[0054] (2) Phosphating treatment: the nickel foam loaded with cobalt-molybdenum composite obtained in step (1) and 1.0g NaH 2 PO 2 Put two burning boats respectively, and put them in a tube furnace. Under nitrogen protection, raise the temperature to 500°C at 5°C / min, keep it warm for 3 hours and cool down to get nickel foam@cobalt molybdenum phosphide (Co / Mo= 2.3: 1) Electrodes.

[0055] Catalytic performance test: hydrogen evolution reaction and oxygen evolution reaction: install the foamed nickel@cobalt molybdenum phosphide (Co / M...

Embodiment 3

[0057] The preparation method of nickel foam@cobalt molybdenum phosphide (Co / Mo=4:1) electrode, the steps are as follows:

[0058] (1) Hydrothermal reaction: Weigh 0.349g Co(NO 3 ) 2 ·6H 2 O and 0.073g Na 2 MoO 4 2H 2 O was dissolved in 15 ml of deionized water to prepare a precursor solution, put into clean nickel foam, placed in a reaction kettle, reacted at 150 °C for 6 hours, cooled, cleaned and vacuum dried at 60 °C for 6 hours.

[0059] (2) Phosphating treatment: the nickel foam loaded with cobalt-molybdenum composite obtained in step (1) and 0.6g NaH 2 PO 2 Put two burning boats respectively, and place them in a tube furnace. Under the protection of nitrogen, raise the temperature to 450°C at 5°C / min, keep it warm for 2 hours and cool down to obtain foamed nickel@cobalt molybdenum phosphide (Co / Mo= 4:1) electrode.

[0060] Catalytic performance test: hydrogen evolution reaction and oxygen evolution reaction: install the foamed nickel@cobalt molybdenum phosphide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com